Fan failure braking device of aero-engine

A technology of braking device and fan, applied in gas turbine devices, machines/engines, jet propulsion devices, etc., can solve problems such as affecting the fuel economy of the engine and increasing the weight of the engine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

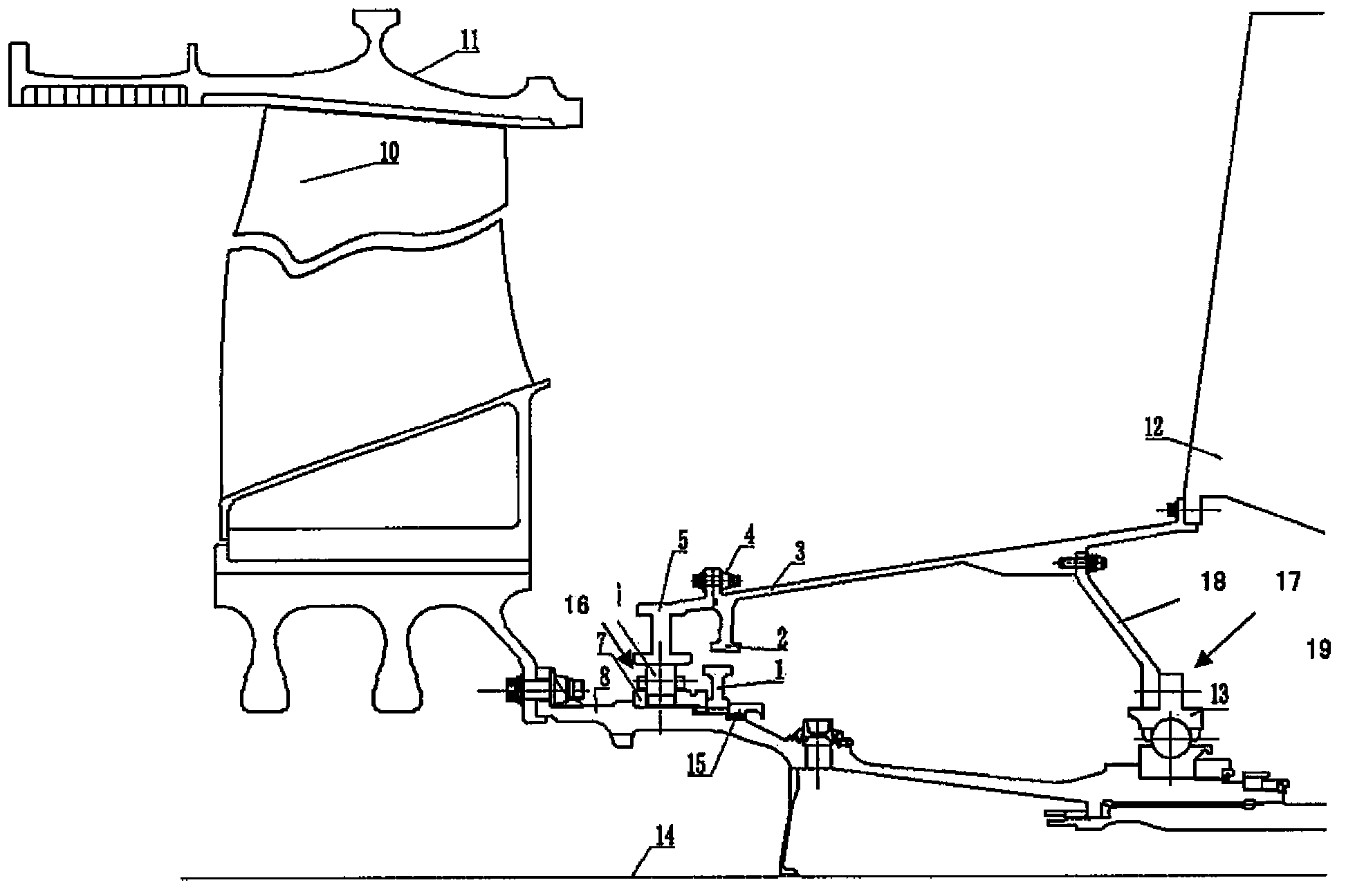

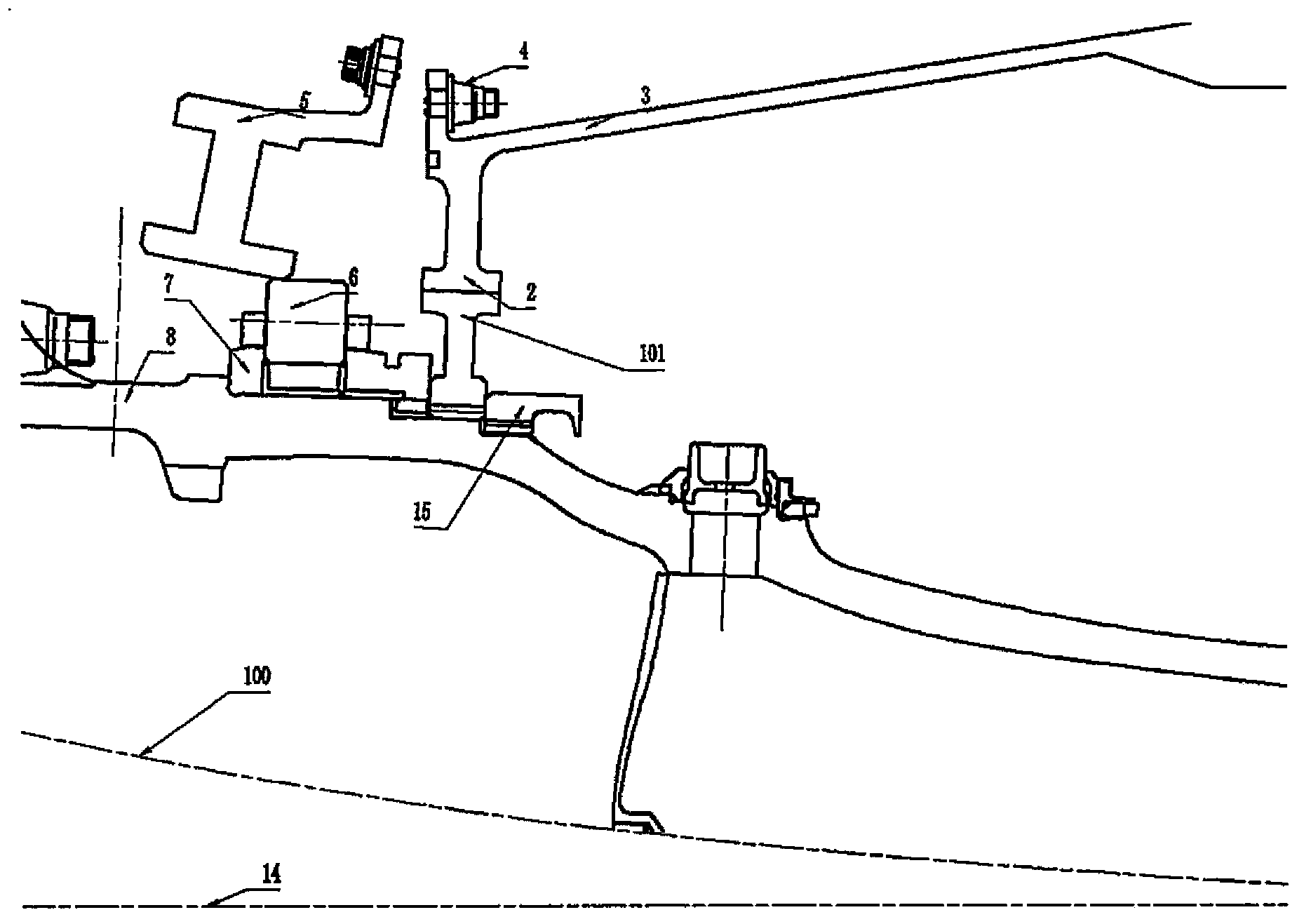

[0030] Such as figure 1 As shown, it shows a schematic structural diagram of the fan failure brake device when the engine is in normal operation. Specifically, the fan failure braking device mainly includes: a fan shaft 8 , a fan blade 10 , a bearing support 3 and a first bearing assembly 16 . Therein, the fan shaft 8 extends along the engine axis 14 , on which the rotor brake disc 1 is arranged. Mounted on the fan shaft 8 are fan blades 10 which are upstream relative to the rotor brake disc 1 in the direction of fluid flow. The fan blade 10 is mounted on the fan blade 10 and extends radially outward and is accommodated and protected by the fan case 11 . The rear end of the bearing support 3 is fixed to the intermediate casing 12, and the front end extends inwardly with a stator brake disc 2, which surrounds the rotor brake disc 1 circumferentially and is connected with the rotor brake disc 1 Radially spaced apart, the inner sides of the stator brake disc 2 are used as fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com