Torque coupler

A technology of coupler and spring shock absorber, applied in the direction of coupling, elastic coupling, spring/shock absorber, etc., can solve problems such as reducing the service life of the connection, achieve compact design, reduce bending load, improve The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

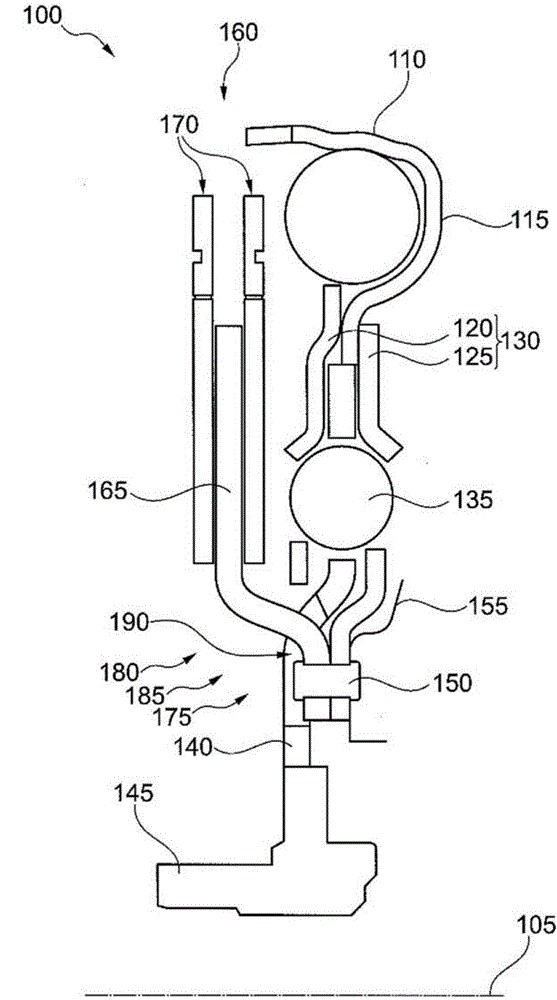

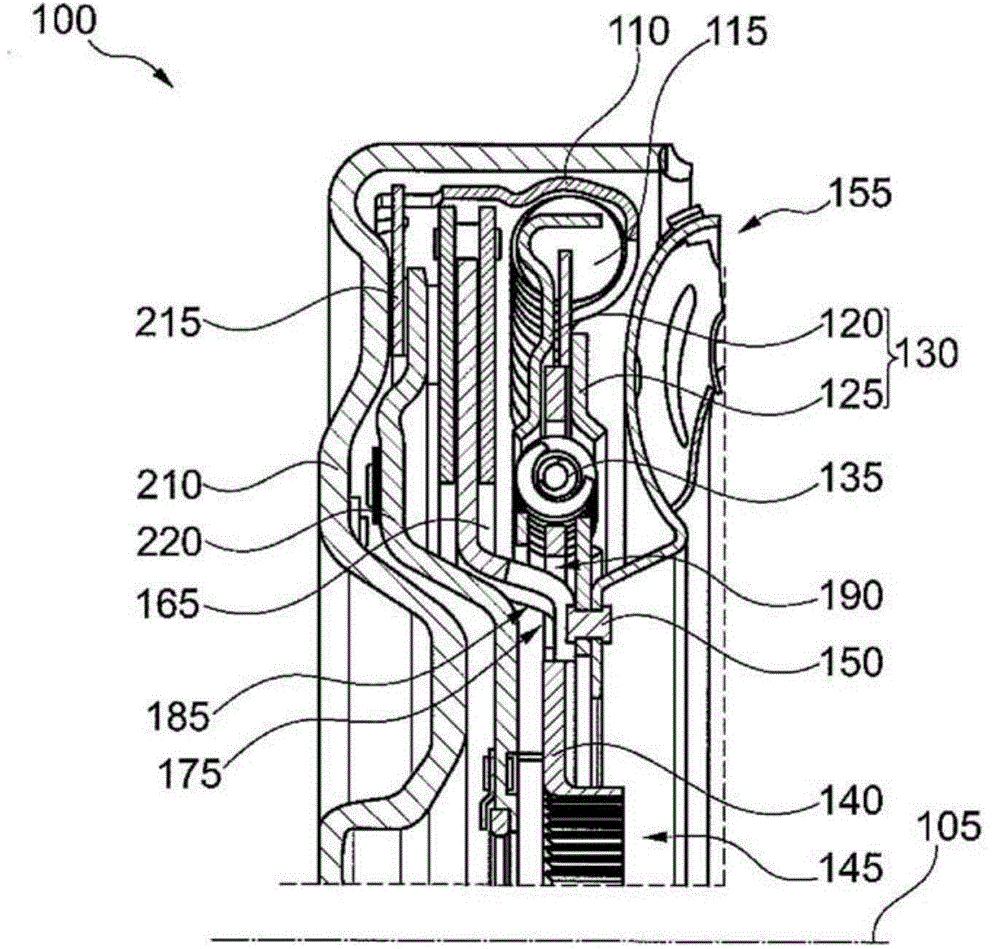

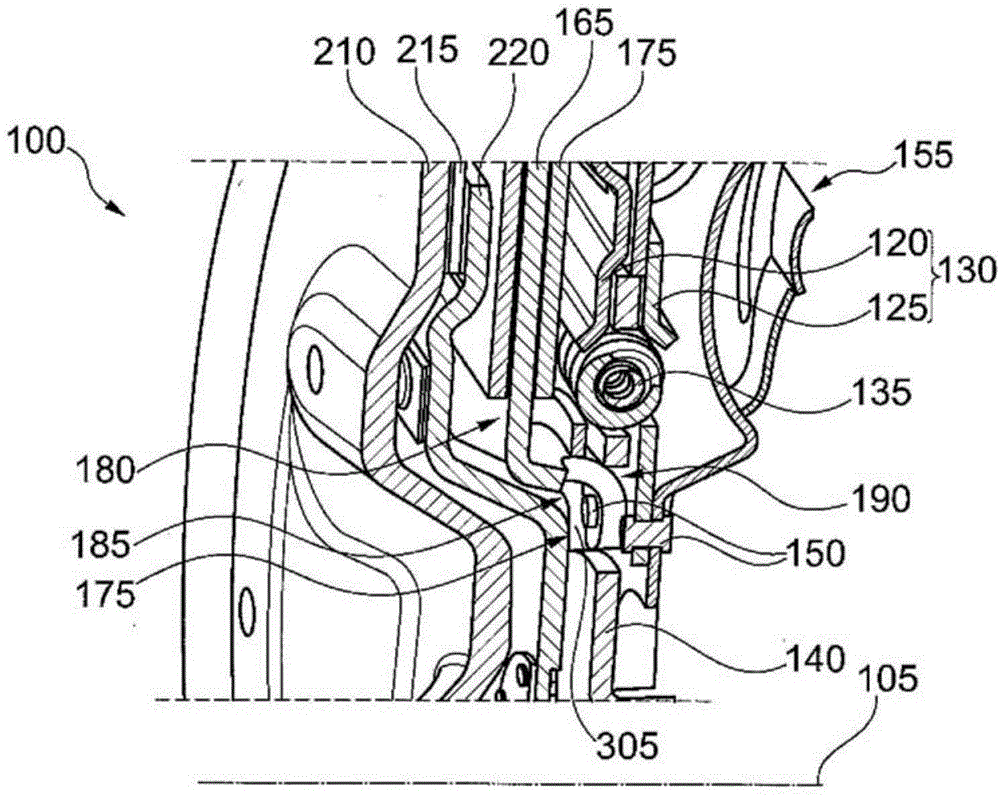

[0020] figure 1 A cross-sectional view of the torque coupler 100 is shown. The illustration only shows the upper half of the longitudinal section through the axis of rotation 105, the elements of the torque coupler 100 being arranged in a rotatable manner about the axis of rotation.

[0021] The torque coupler 100 shown includes a holding element 110 for connection with the input side of the torque introduced not shown, a first elastic element 115, a first disc element 120 (on the left here), and a first disc element (on the right here). 的) The second disc element 120, wherein the intermediate disc 130 includes disc elements 115 and 120; in addition, the torque coupler includes a second elastic element 135, an output flange 140, a hub 145, a connecting element 150, figure 1 The turbine 155 and the centrifugal force pendulum 160 are only briefly outlined in, and the centrifugal force pendulum includes a pendulum flange 165 and a pendulum mass 170.

[0022] Not all the components of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com