Fastening mechanism of a fuel cell stack

A fuel cell stack and fixing mechanism technology, which is applied to fuel cell grouping, fuel cells, and fuel cell components, etc., can solve problems such as the complex structure of fuel cell stacks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

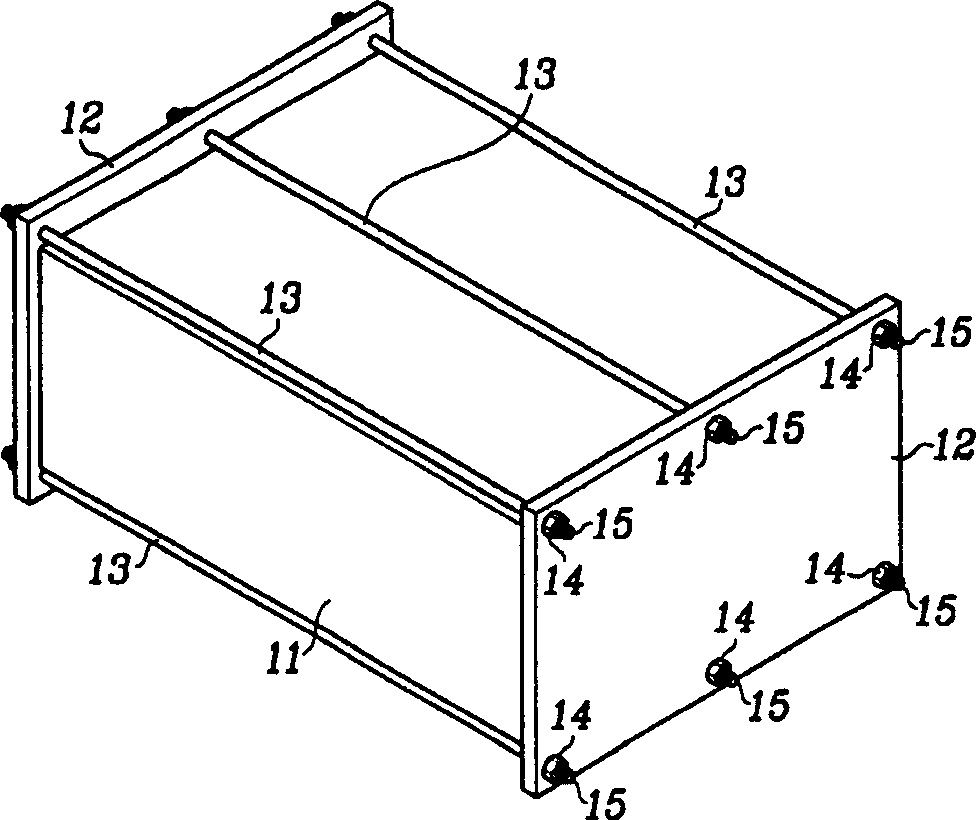

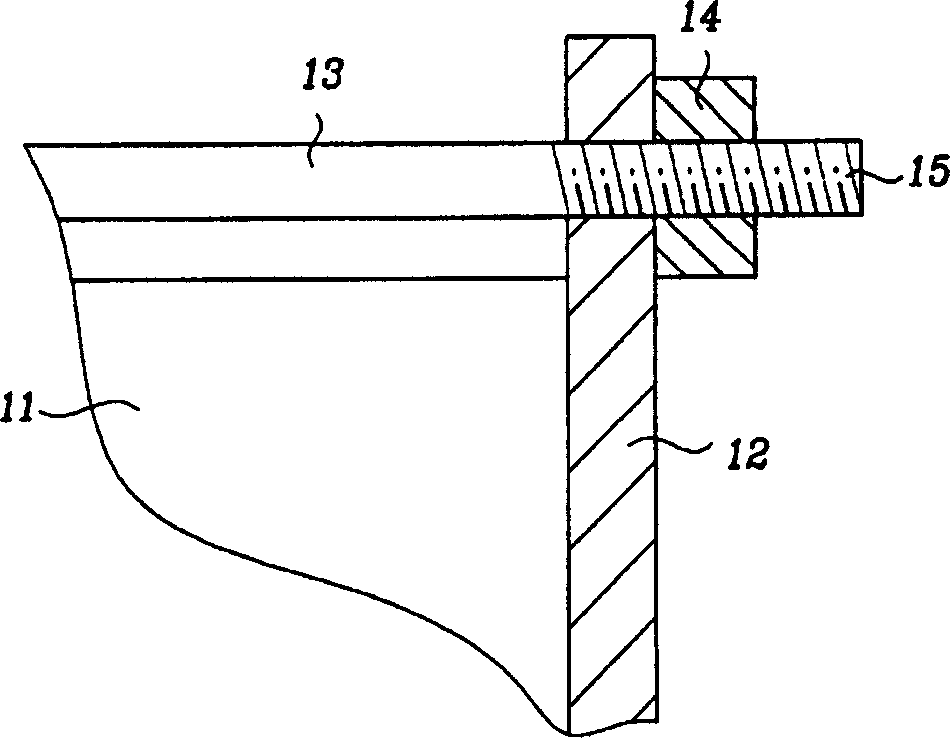

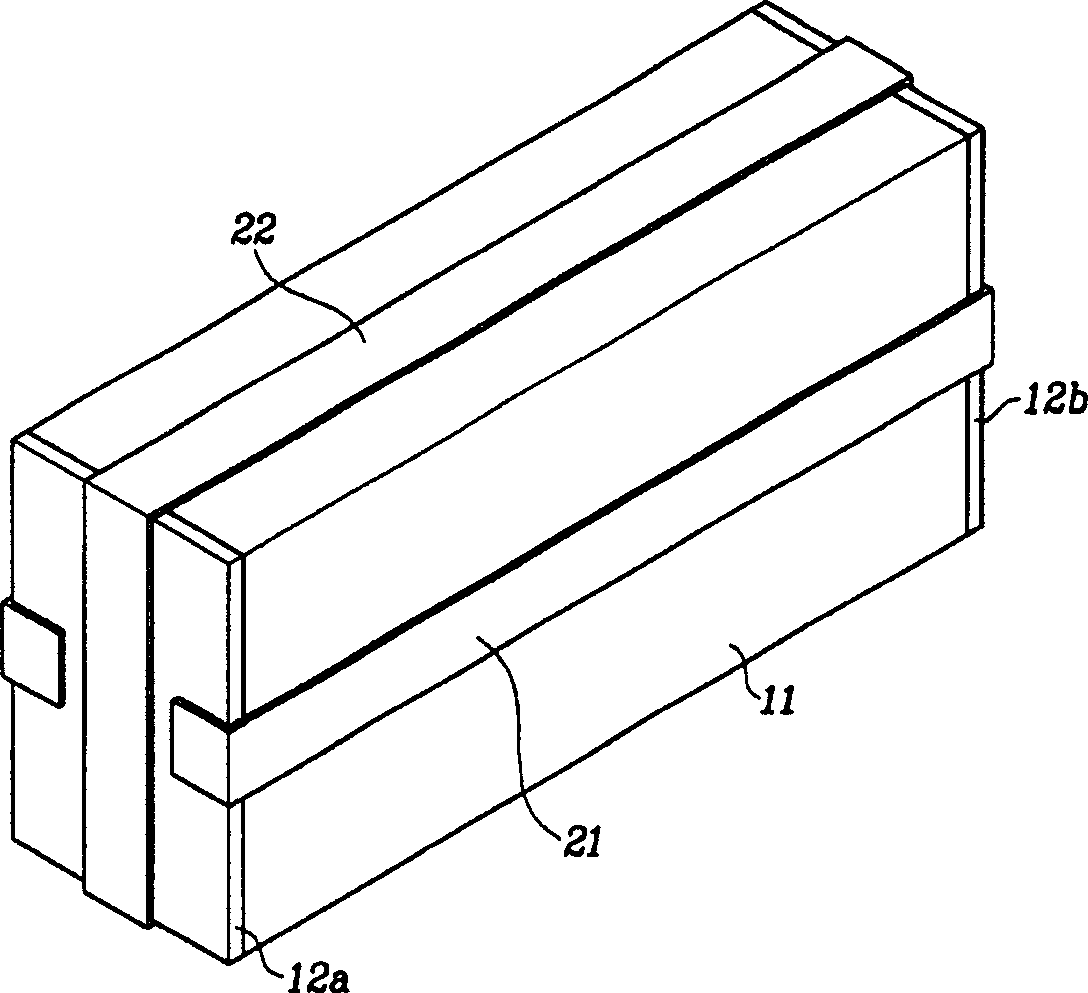

[0046] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. image 3 The fixing mechanism of the fuel cell stack according to the first embodiment of the present invention is shown.

[0047] Such as image 3 As shown, MEAs and separators are stacked alternately to form a fuel cell stack 11, and end plates 12a and 12b are installed at both ends of the fuel cell stack 11, respectively.

[0048]The fuel cell according to the embodiment of the present invention includes a first fixing band 21 and a second fixing band 22 designed in a U shape.

[0049] The first fixing band 21 extends on two sides of the fuel cell stack 11 parallel to each other, and the second fixing band extends on a side parallel to each other, which is different from the side on which the first fixing band is placed.

[0050] Open ends of the first and second fixing straps 21 and 22 elastically press the different end plates 12a and 12b, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com