Rotary type double-nozzle switching device for 3D printing

A 3D printing and switching device technology, applied in additive processing and other directions, can solve problems such as material, color error, affecting printing accuracy, workpiece deformation, etc., to reduce motor load, improve printing accuracy, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

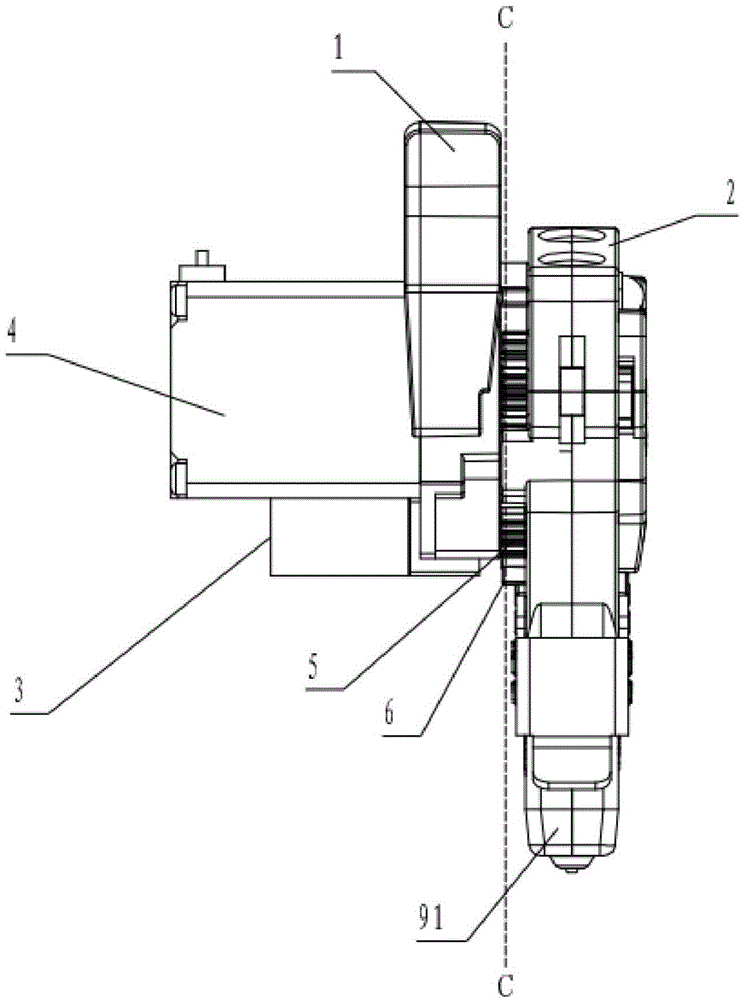

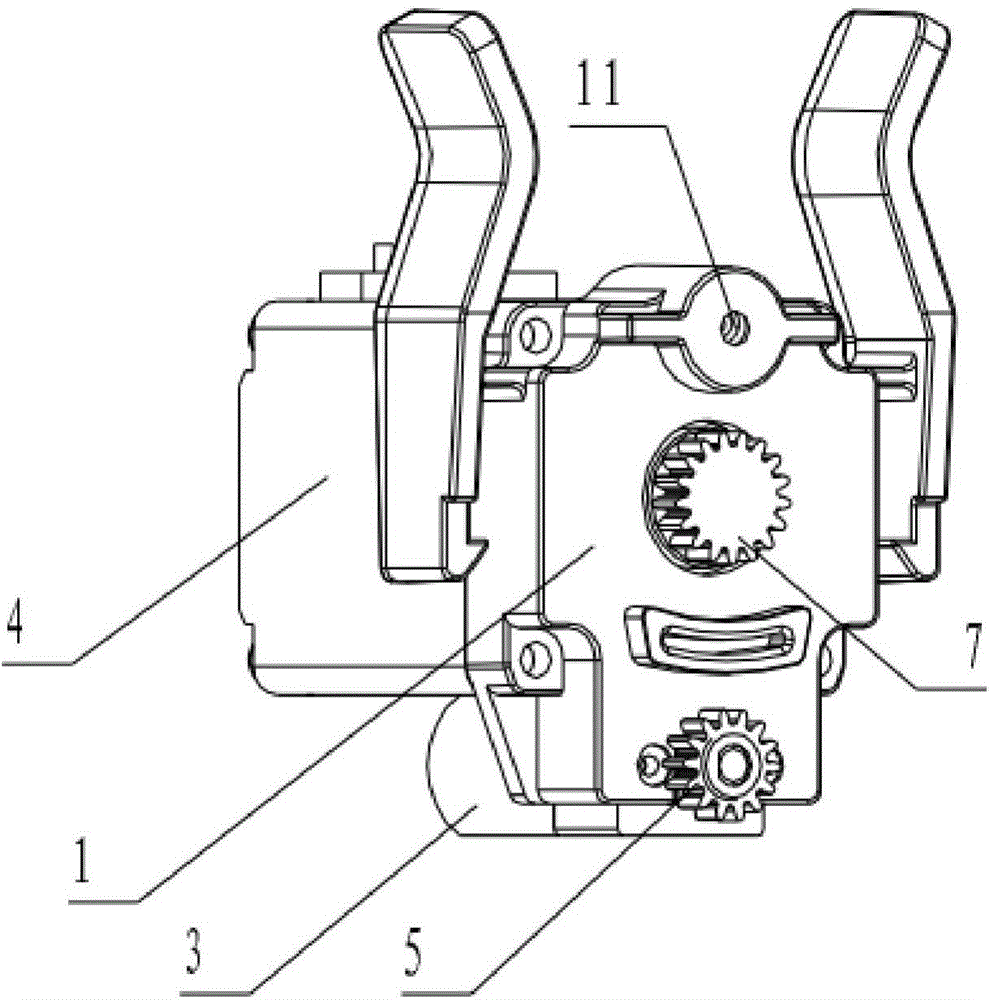

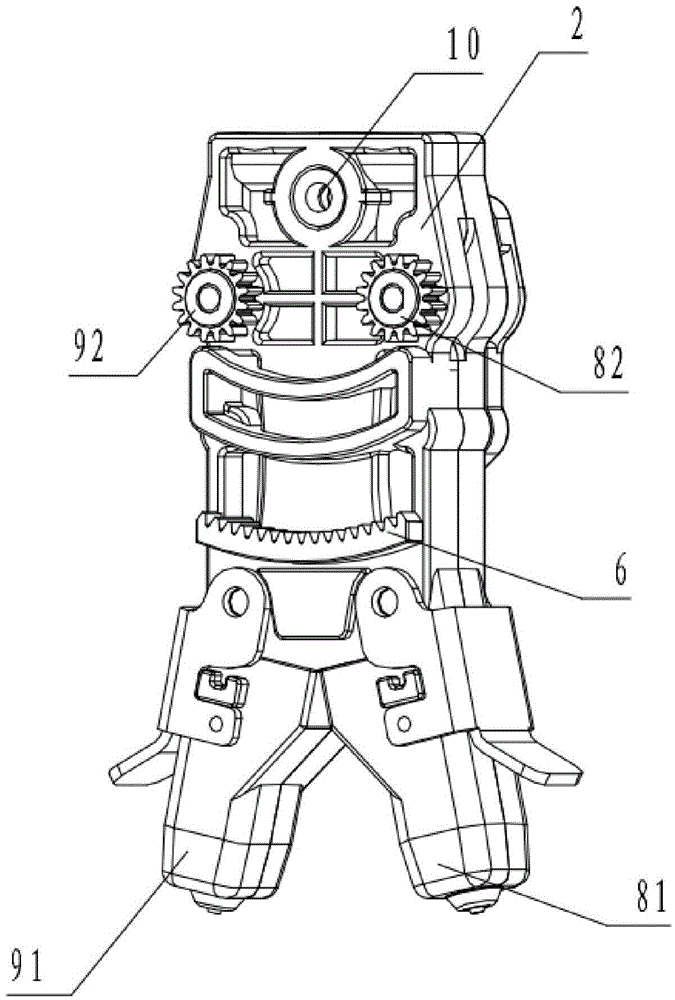

[0034] Example 1: Such as figure 1 , figure 2 , image 3 , Figure 5 , Figure 6 As shown, the rotary double nozzle switching device for 3D printing provided in Example 1 includes a first bracket 1, a second bracket 2, a steering motor 3, a steering gear 5, an arc rack 6, a wire feeding motor 4, and a wire feeding motor. driving wheel 7;

[0035] Such as figure 1 and figure 2 As shown, the steering motor 3 and the wire feeding motor 4 are fixedly arranged on the first bracket 1 . Such as image 3 As shown, the second bracket 2 is provided with a first nozzle installation groove and a second nozzle installation groove, and first and second wire feeding gears corresponding to the first and second nozzle installation grooves respectively (not shown in the figure output), and the first and second driven wheels coaxially connected with the first and second wire feeding gears respectively.

[0036] combine Figure 5 and Figure 6As shown, the second bracket 2 is rota...

Embodiment 2

[0044] Example 2: The structure is basically the same as that of Embodiment 1, and the similarities are no longer repeated, but the difference is:

[0045] The rotatable setting of the second bracket 2 on the first bracket 1 is realized in the following manner: the first bracket 1 is also fixedly provided with a rotation central axis; the curved rack 6 on the second bracket There is a perforation at the center of the circle, and a bearing in which the outer ring is in interference fit with the inner wall of the perforation; the inner ring of the bearing is in interference fit with the rotating central shaft.

[0046] The center of the arc formed by the first driven wheel 82 , the second driven wheel 92 and the center of the wire feeding driving wheel 7 (ie the arc center) coincides with the center of circle (ie the arc center) of the arc-shaped rack 6 .

[0047] Taking the preferred embodiment 1 as an example, using the 3D printing rotary double nozzle switching device provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com