Method of enhancing heat radiation of large aluminium electrolytic bath shell

An aluminum electrolytic cell and electrolytic cell technology, which is applied in the field of strengthening the heat dissipation of large-scale aluminum electrolytic cell shells, can solve problems that cannot be used as solutions, achieve the effects of reducing lining damage, significant effects, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

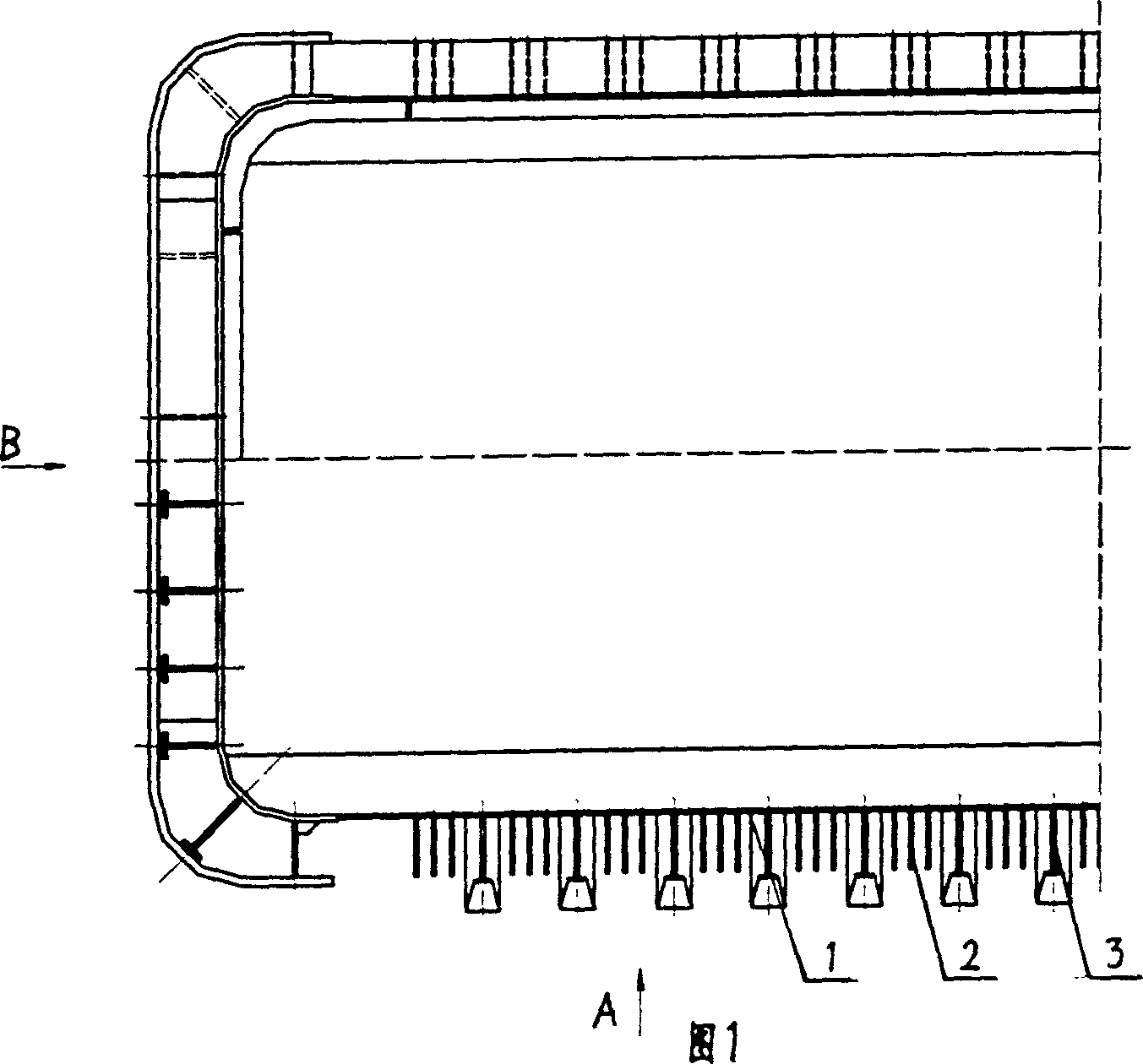

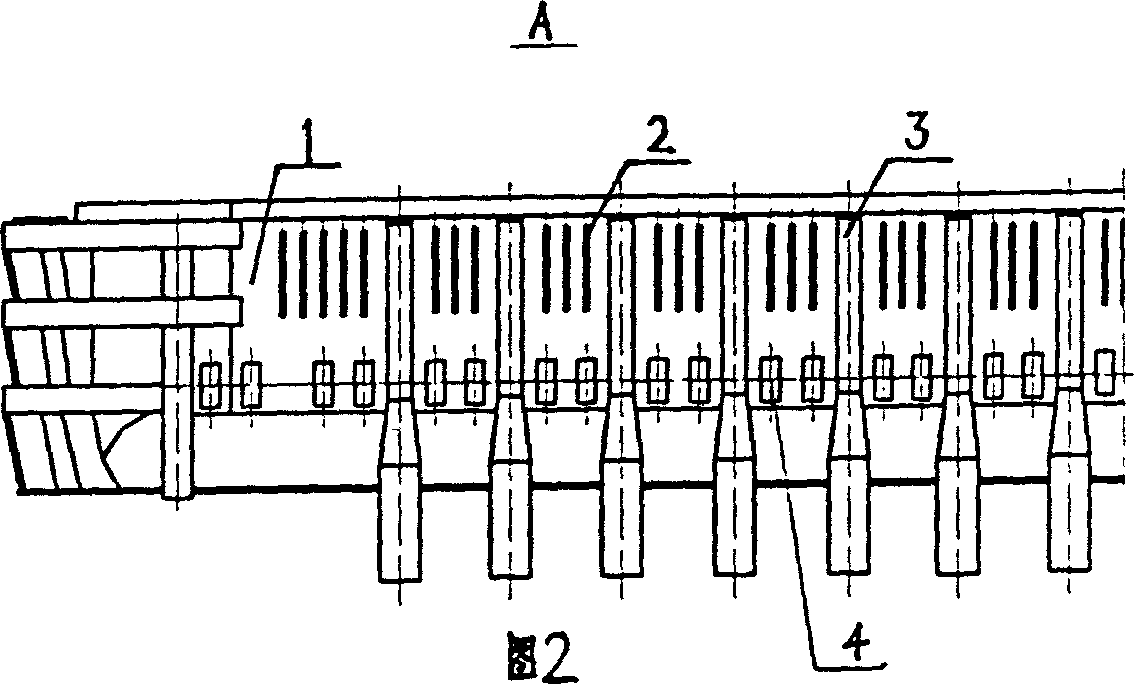

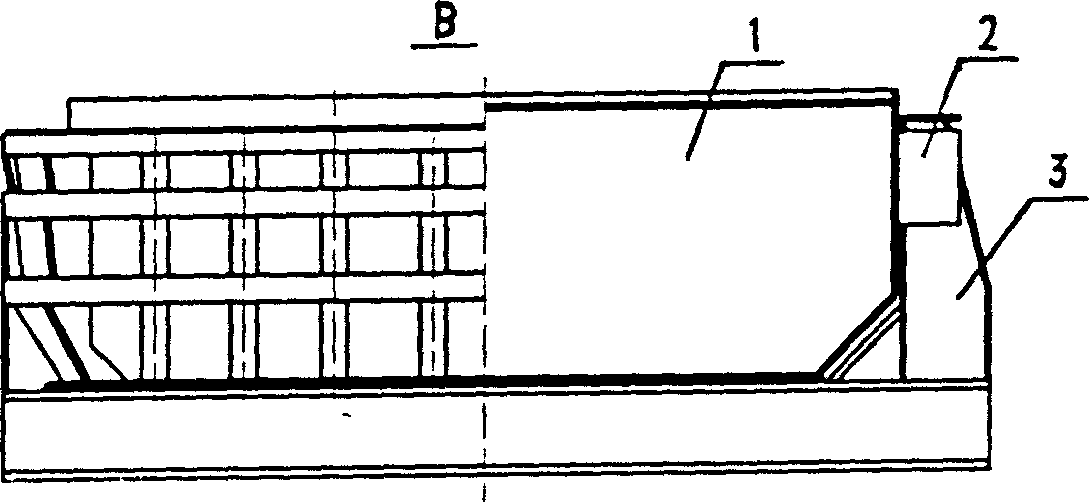

[0014] On the outer periphery of the electrolytic cell shell 1, several cooling fins 2 are welded. The left and right welding positions of the heat sink 2 should avoid the cradle 3 of the electrolytic cell. The upper and lower welding positions of the heat sink 2 should make its upper end close to the lower side of the tank edge plate, and make its lower end away from the cathode of the electrolytic cell. The upper side of the steel rod 4 is more than 50mm. According to the different sizes of the slot capacity, determine the length, width, thickness and quantity of the cooling fins. For 300KA-500KA electrolytic cells, the length of the heat sink is 400-800mm, the width is 150-400mm, the thickness is 5-25mm, and the number of welded heat sinks for each tank is 70-300. The heat sink is welded in a straight direction. The heat sink is made of ordinary carbon steel. The shape of the heat sink can be rectangular or non-rectangular, such as trapezoidal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com