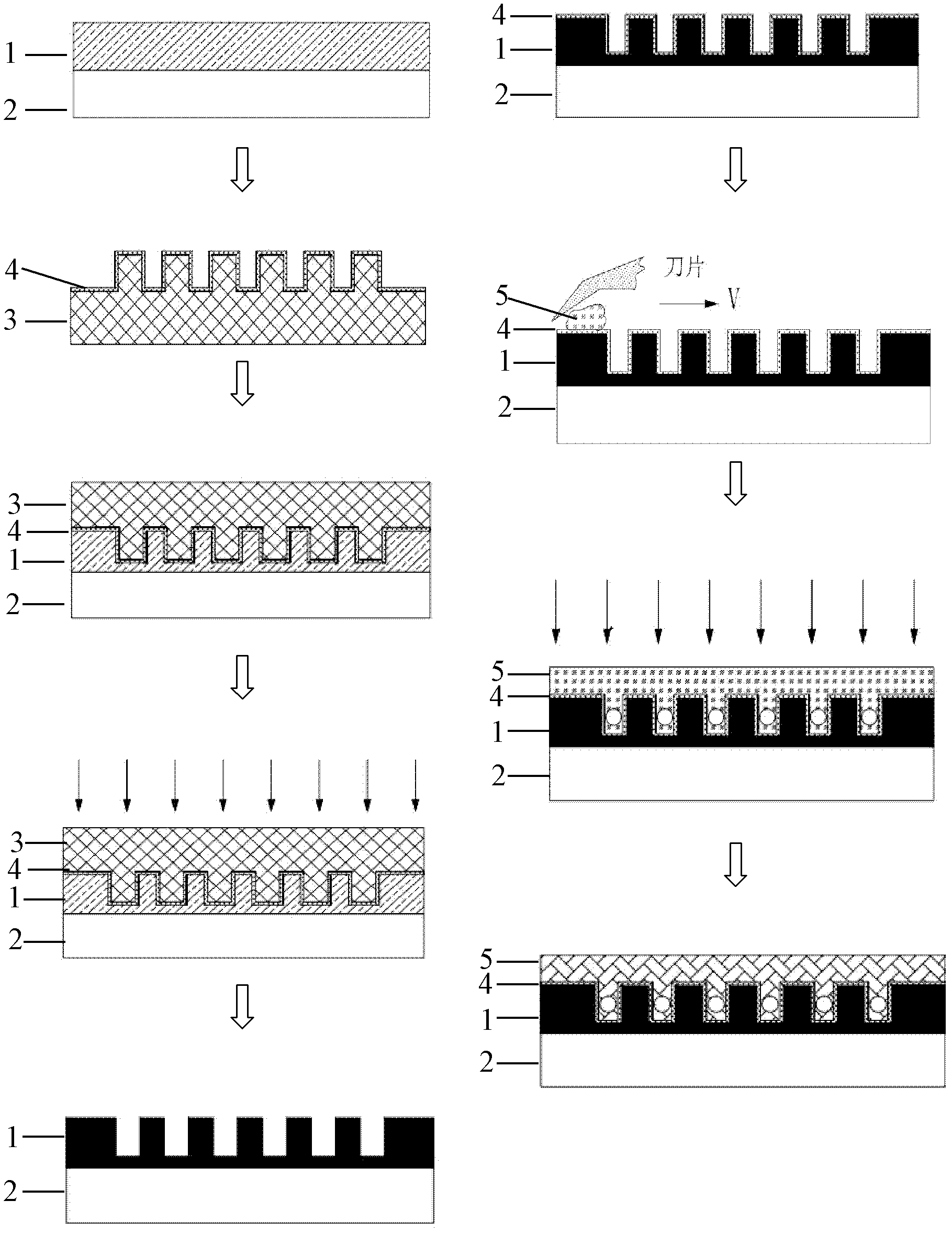

Method for preparing micro-nano-channels based on liquid-gas equilibrium polymer nano-channels self-building mechanism

A technology of nano-channels and polymers, which is applied in the direction of nano-technology, opto-mechanical equipment, and photolithography on patterned surfaces. easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this example, the micro-nanofluidic system is prepared by self-construction of polymer nanochannels based on liquid-gas equilibrium, and the operation is as follows:

[0028] 1. Take the glass sheet as the substrate, wash it with water and acetone, put it in an oven, and bake it at 130°C for 20 minutes to remove water vapor and residual acetone; then perform oxygen plasma treatment to increase the surface energy and the adhesion of the photoresist Force, the vacuum degree of oxygen plasma treatment on the substrate is 25Pa, the power is 60W, and the bombardment time is 90 seconds. A layer of SU-82002 photoresist with a thickness of 2 μm was spin-coated on the pretreated substrate, and baked on a hot stage at 90° C. for 20 minutes to remove the solvent in the adhesive layer.

[0029] 2. Put the glass grating template in concentrated H 2 SO 4 Soak in a mixed solution of hydrogen peroxide and hydrogen peroxide (volume ratio 2:1) for two hours, then clean it with deion...

Embodiment 2

[0036] The operation process of this example is the same as that of Example 1. In step 5, SU-82025 is replaced by SU-82002, and other parameters remain unchanged, and a nanochannel with a diameter of about 60 nm can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com