Patents

Literature

335results about "Manufacturing cage rotors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing squirrel cage rotor

InactiveUS20050134137A1Eliminate its organic contentReduced rotor lossesSynchronous motorsFoundry mouldsElectrical conductorAdhesive

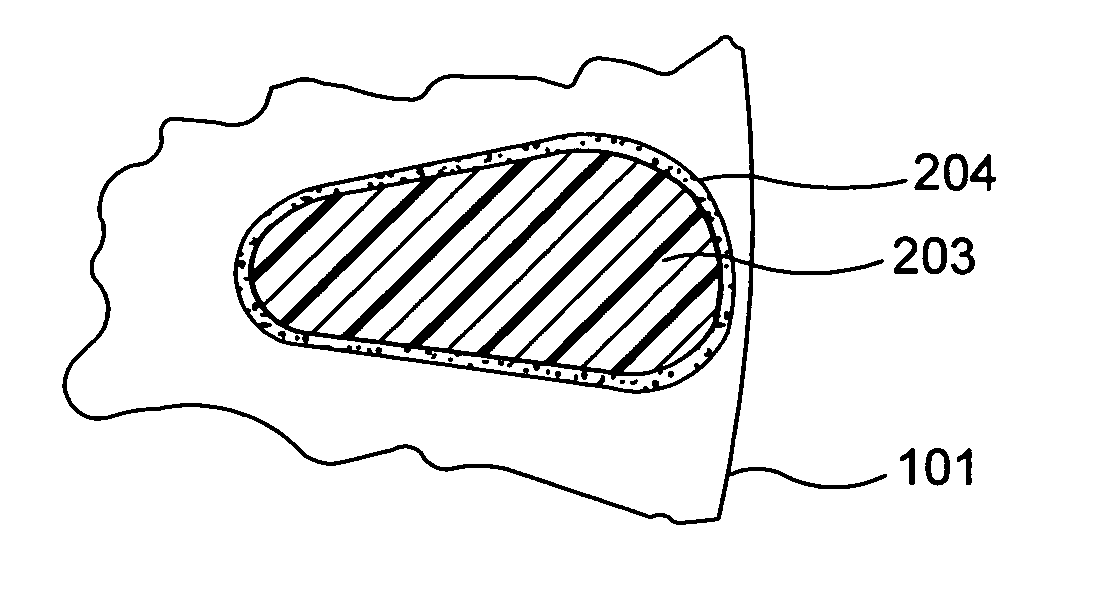

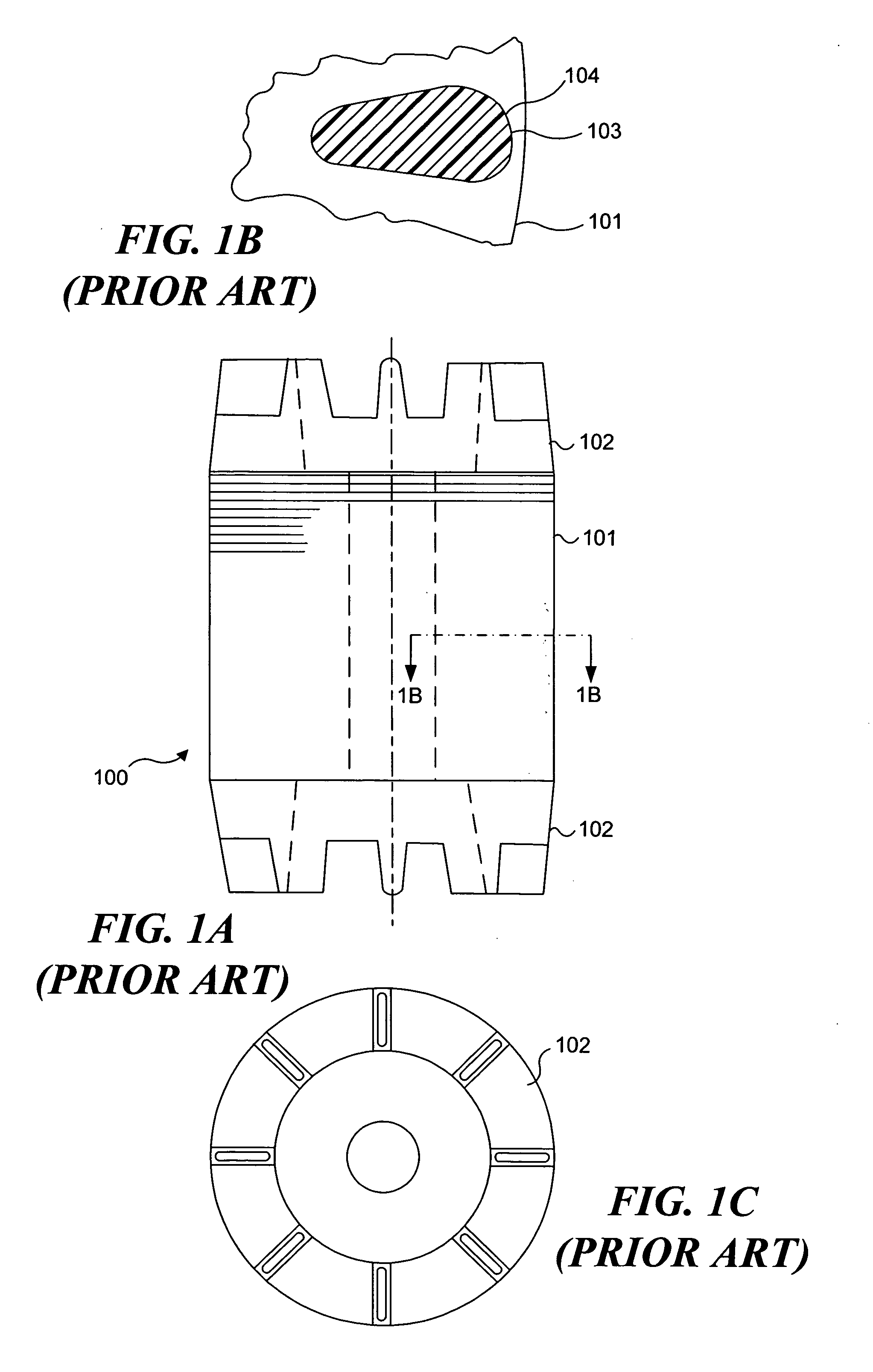

Ceramic adhesive is applied inside the slots of an electric machine squirrel cage rotor prior to casting or insertion of rotor conductors. This heat-resistant insulation provides superior electrical insulation that is also mechanically rugged, thus enabling casting of squirrel cage rotors by die or cost-effective consumable pattern casting. The consumable pattern cast copper rotors are electrically well insulated, thus minimizing rotor losses. The ceramic insulation in cast rotors enables longer conductors to be cast by thermally insulating the molten metal from the cooler laminations. The ceramic insulation in fabricated rotors withstands the high temperatures of end ring attachment. This method is applicable to both conventional induction machine rotors and brushless doubly-fed induction machine rotors and provides the degree of electrical isolation of the bars from the laminations needed to avoid excessive parasitic torques in doubly-fed machines, while ensuring adequate thermal conductivity to dissipate conductive bar heat to the laminations.

Owner:SWEO EDWIN A

Methods of manufacturing induction rotors with conductor bars having high conductivity and rotors made thereby

Squirrel cage rotors of aluminum based material end rings joined with high conductive and durable material (such as copper) conductor bars for use in electric motors and methods of making them are described. The methods include forming conductor bars by casting or other metal forming methods in the slots of laminate steel stack, or positioning the preformed or premade solid conductor bars in the longitudinal slots of the stacked laminated steel, with bar ends extending out of the laminated steel stack ends, optionally coating the extended part of the conductors (bars) with a latent exoergic coating containing Al and one or more conductor bar chemical elements, positioning the laminated steel stack having conductors (bars) in a casting mold that forms the cavity of both end rings of the rotor, filling the end ring cavities with aluminum melt, and allowing the end rings to solidify under pressure. Alternatively, the conductor bars and end rings can be made separately and mechanically joined together.

Owner:GM GLOBAL TECH OPERATIONS LLC

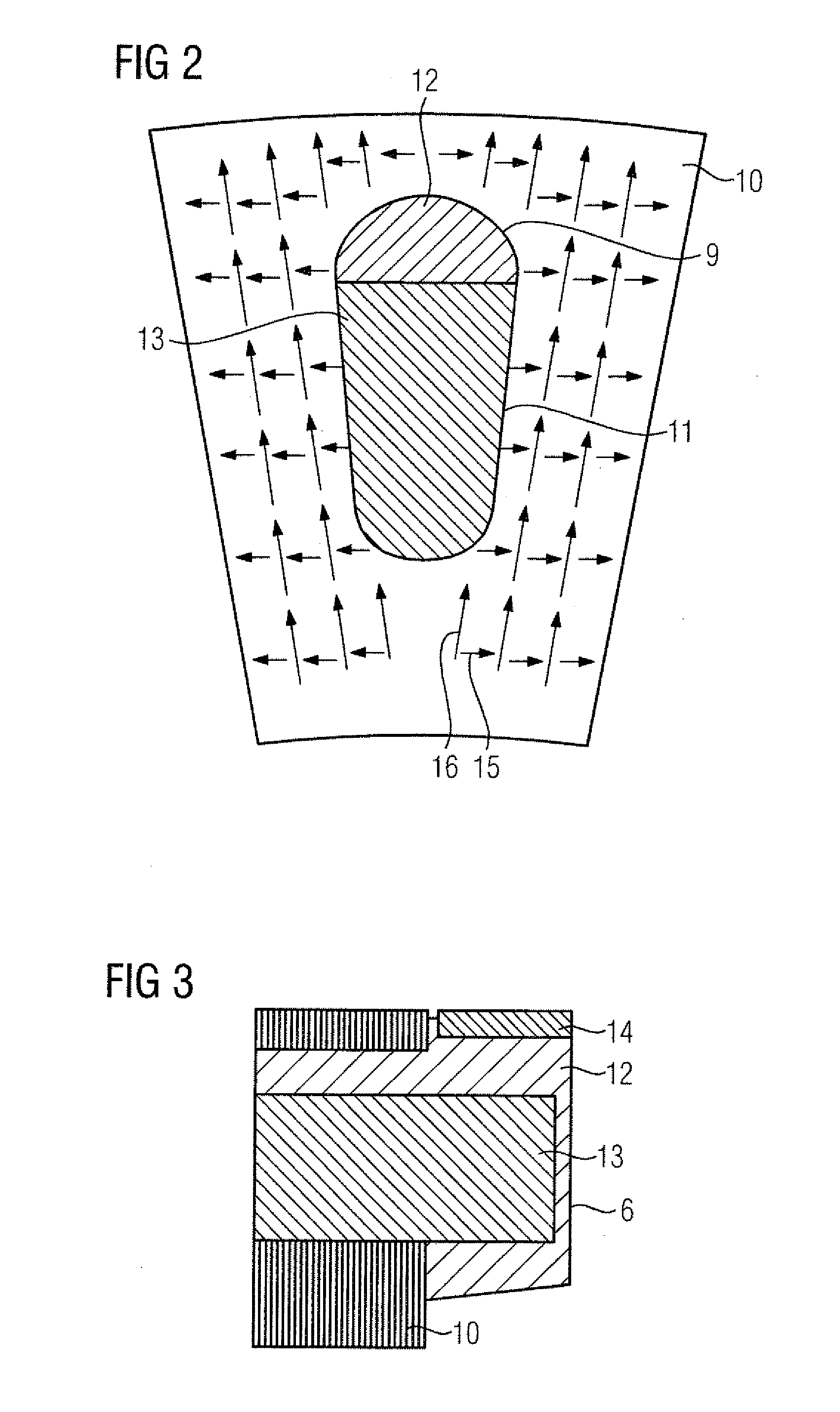

Rotor, Reluctance Machine and Production Method for a Rotor

ActiveUS20150372577A1High strengthGuaranteed uptimeMagnetic circuit rotating partsSynchronous motorsEngineeringMagnetic flux

A rotor for a reluctance machine is provided. The rotor includes a cylindrical soft-magnetic element having cutouts for forming magnetic flux barriers. Some or all of the flux barriers are divided by one or more webs, with the profile of the individual webs forming a closed line which divides the rotor in the radial direction into an inner and an outer region. The cut-outs may be partially or fully filled with a a paramagnetic or diamagnetic filler material.

Owner:KSB AG

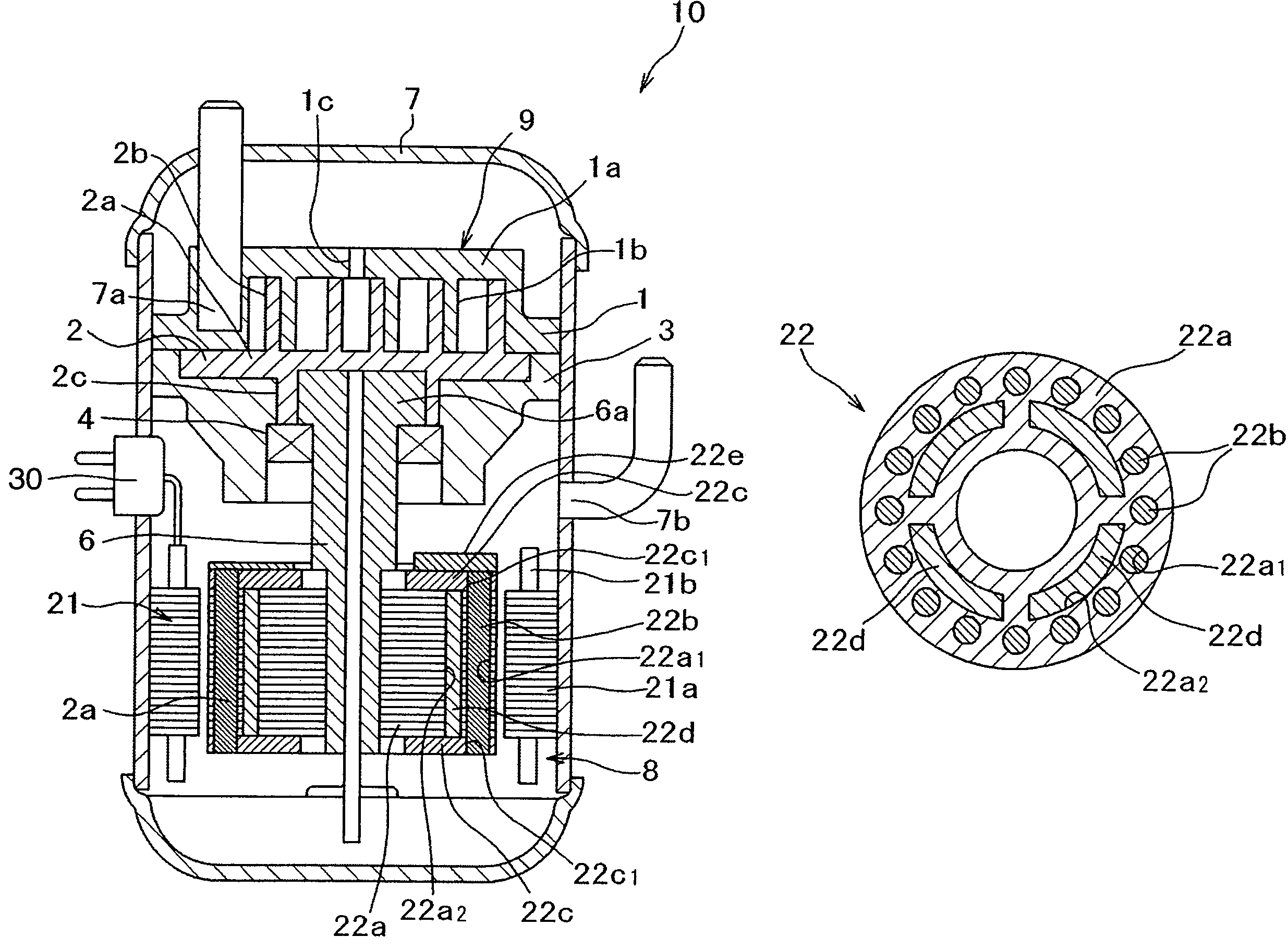

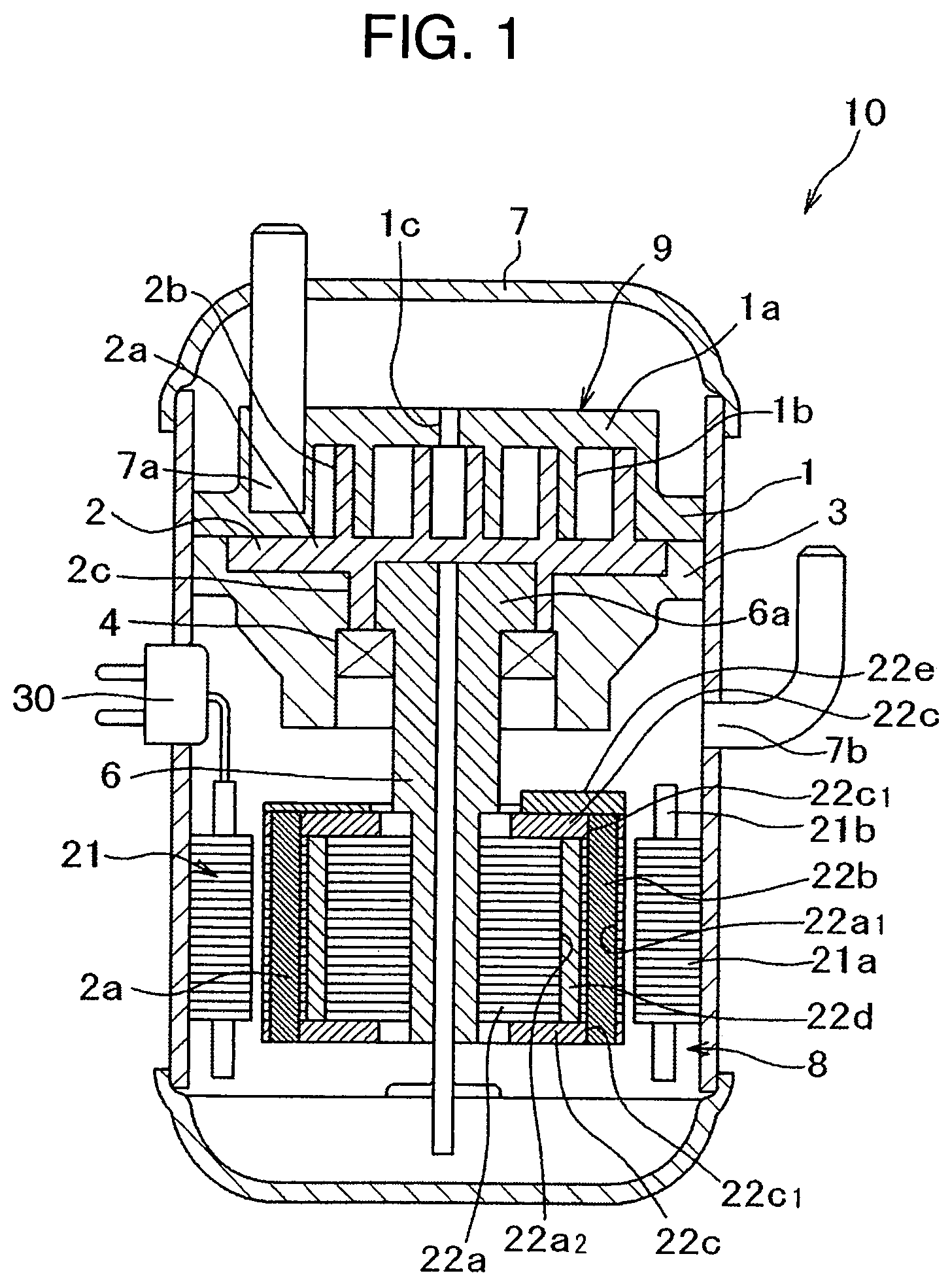

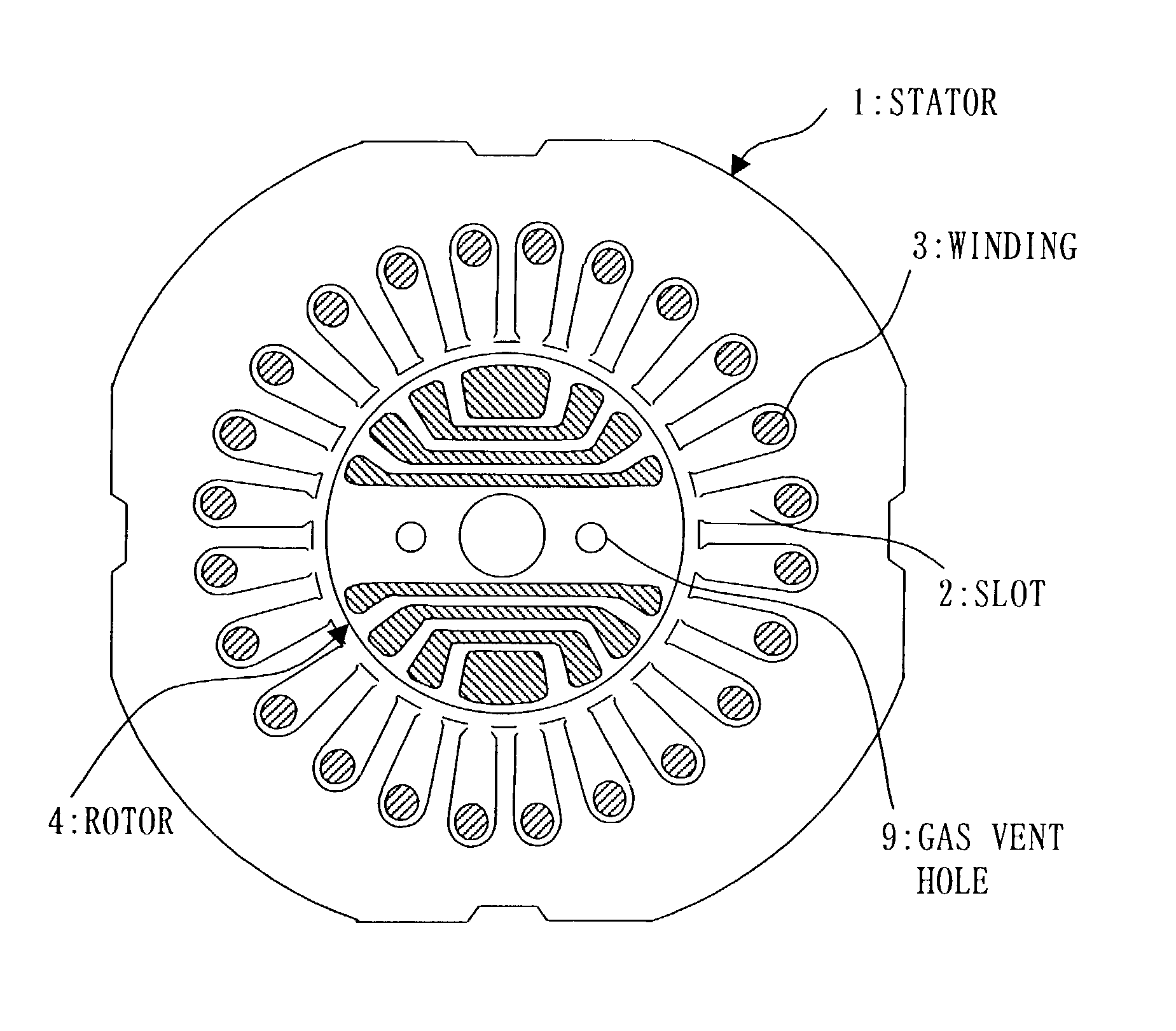

Self-start synchronous motor, method for manufacturing the same and compressor

InactiveUS20060267441A1Inhibit deteriorationImprove efficiencySynchronous motorsStatorsElectrical conductorSynchronous motor

Owner:HITACHI APPLIANCES INC

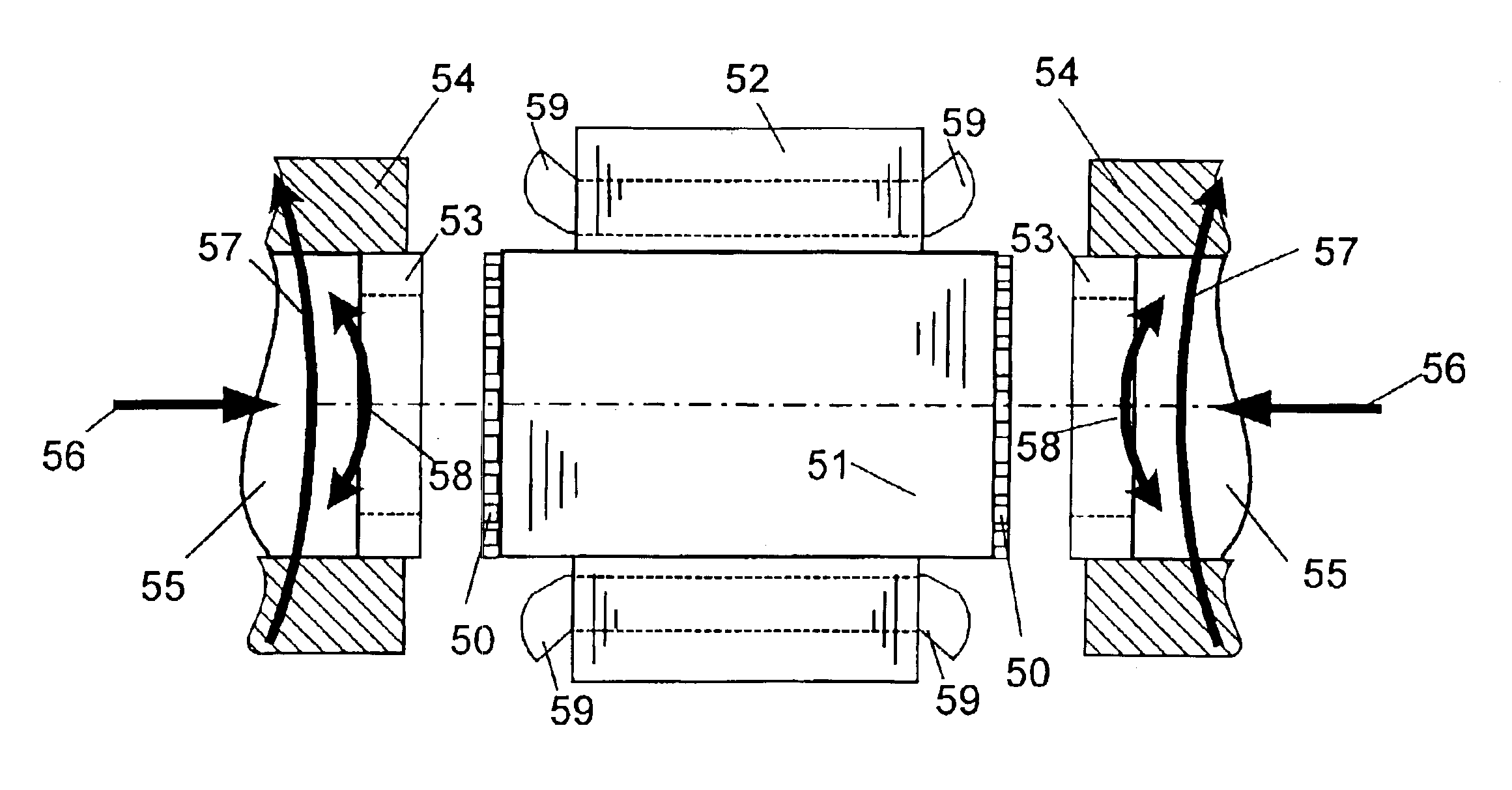

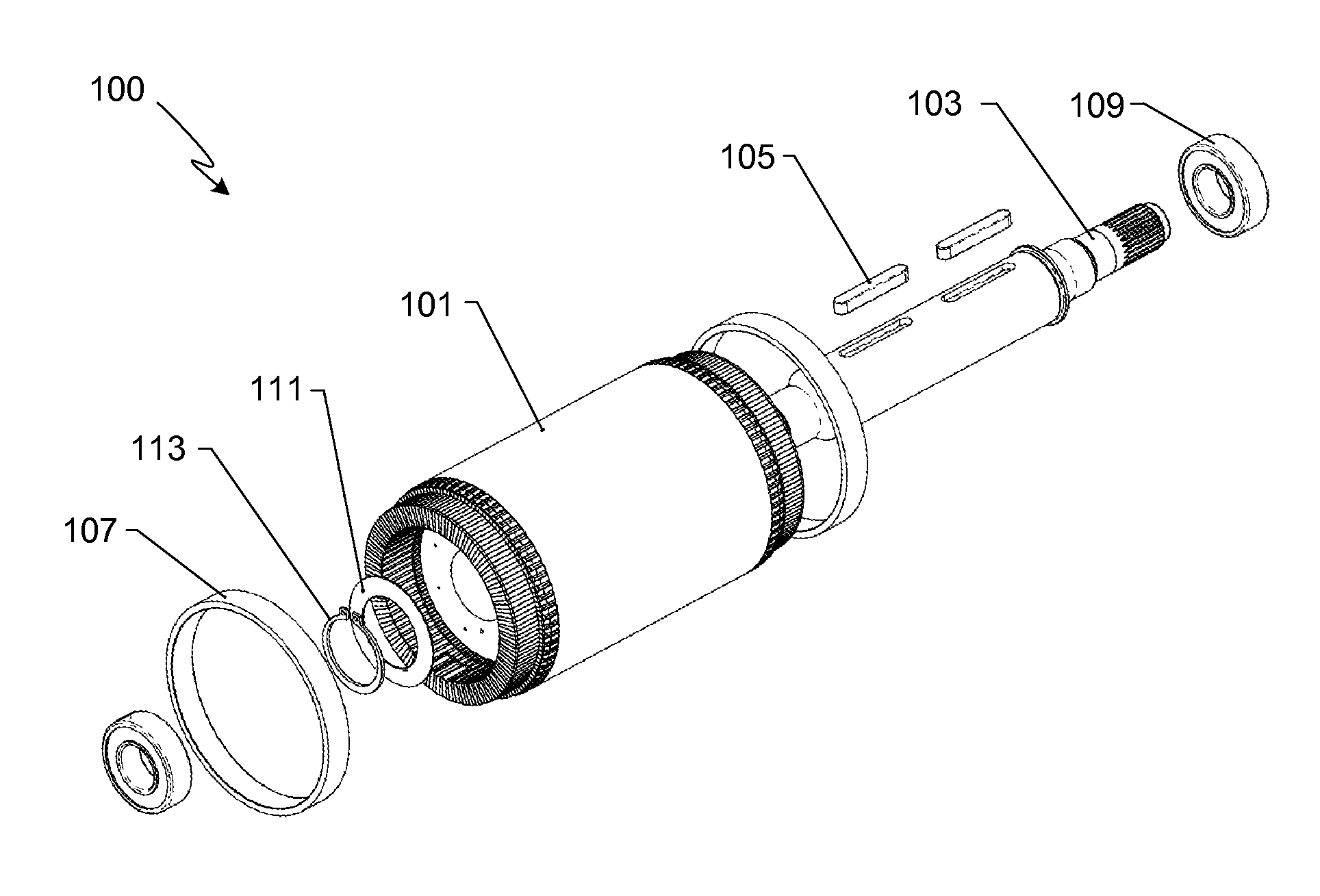

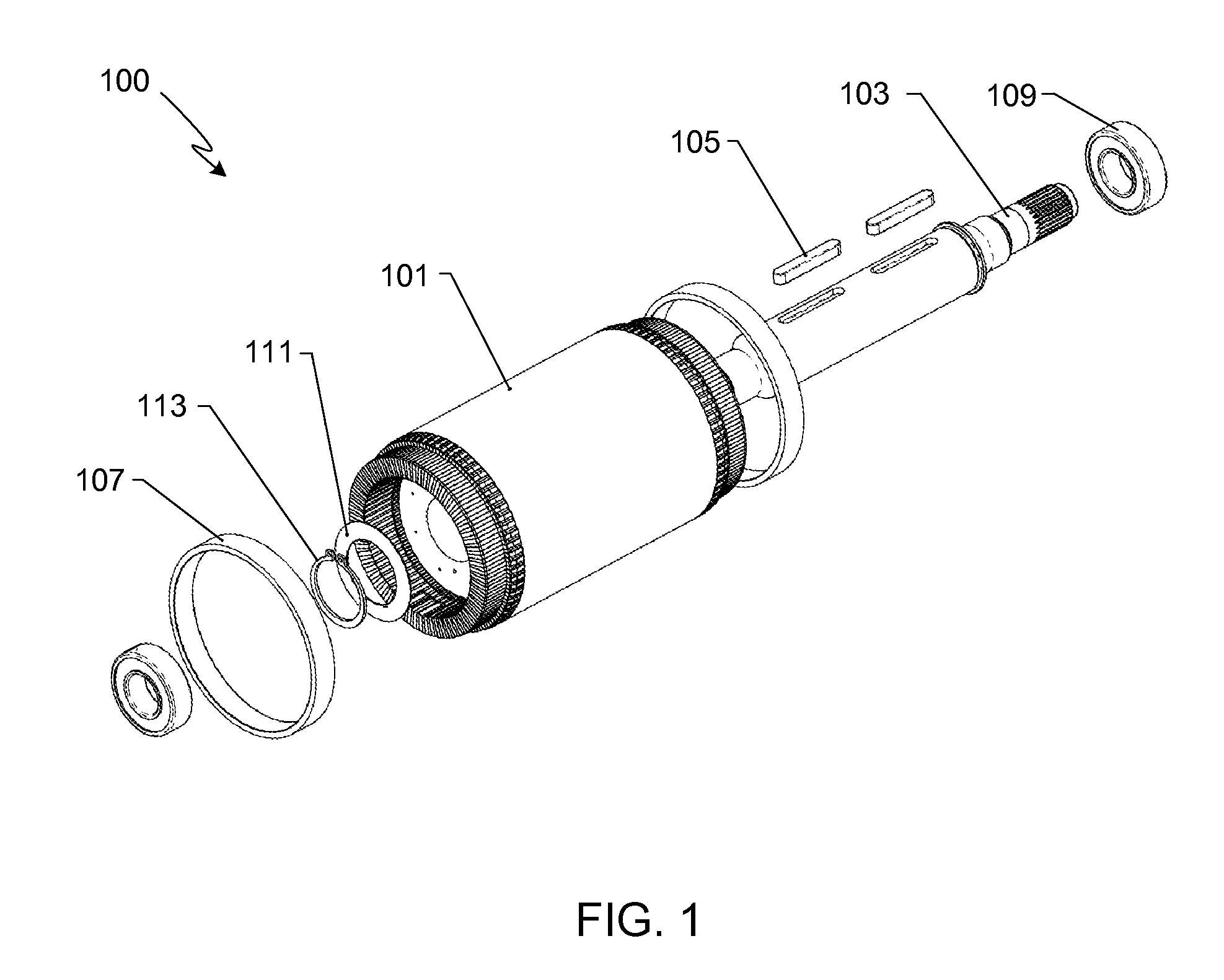

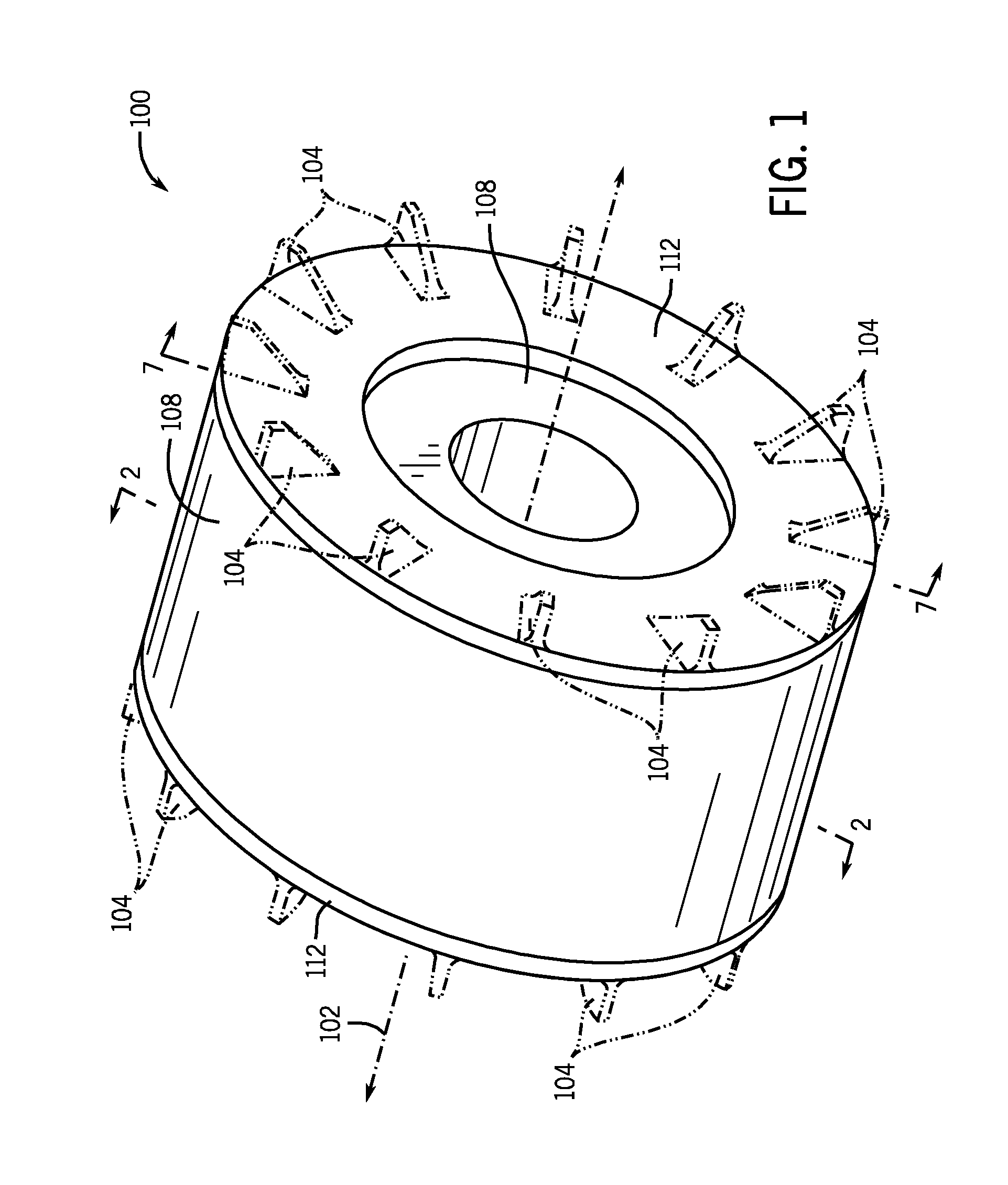

Rotor Design for an Electric Motor

ActiveUS20110062819A1Improve electricityImprove mechanical characteristicsMagnetic circuit rotating partsAsynchronous induction motorsEngineeringRotor design

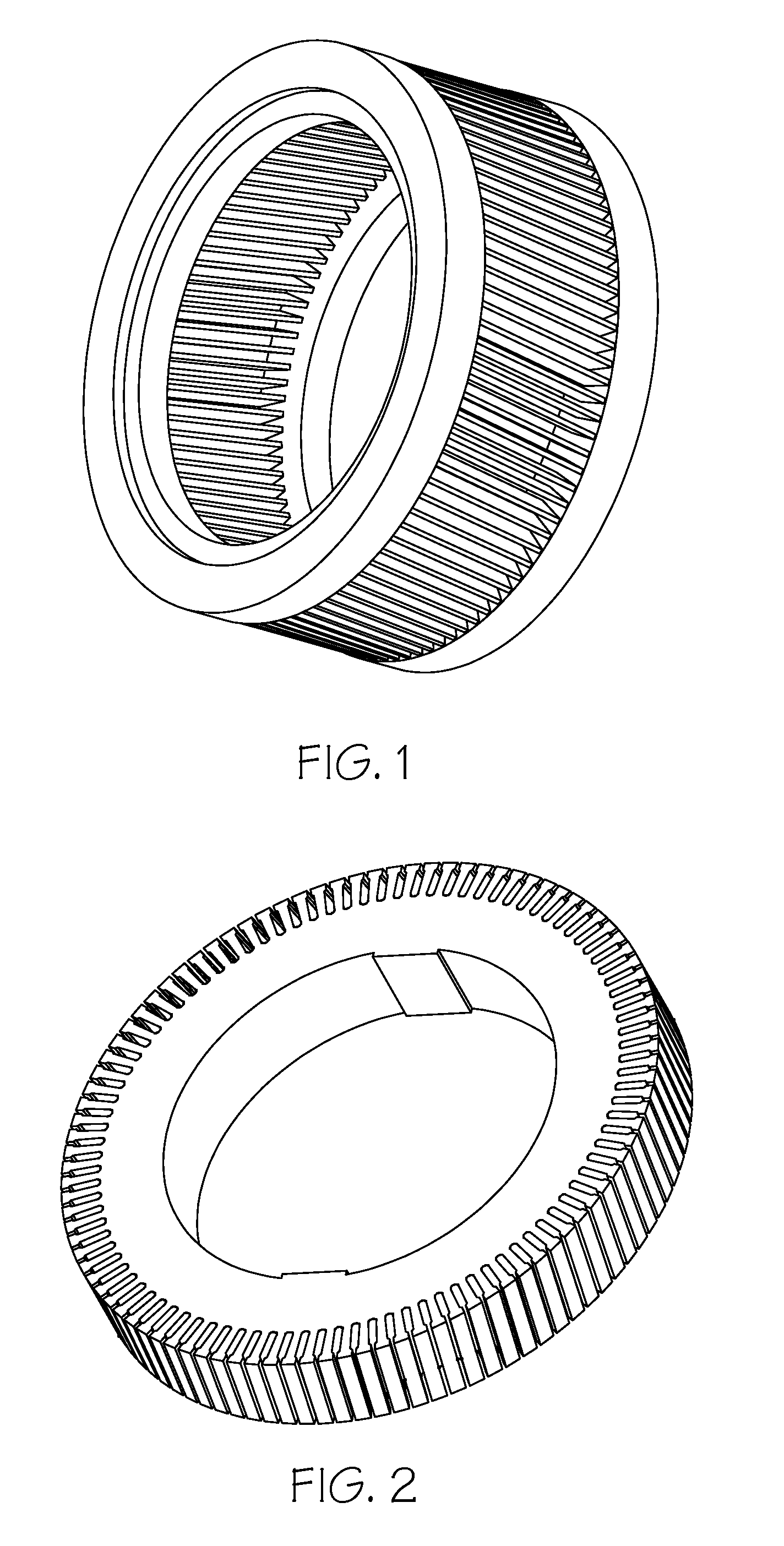

A rotor assembly and a method for fabricating the same are provided in which a solid rotor ring is formed at either end of a stack of laminated discs, the solid rotor rings yielding improved electrical and mechanical characteristics in a low weight assembly. The solid rotor rings are fabricated by brazing slugs between the end portions of the rotor bars, the braze joints contacting a large percentage (at least 90%) of the rotor bar end portions.

Owner:TESLA INC

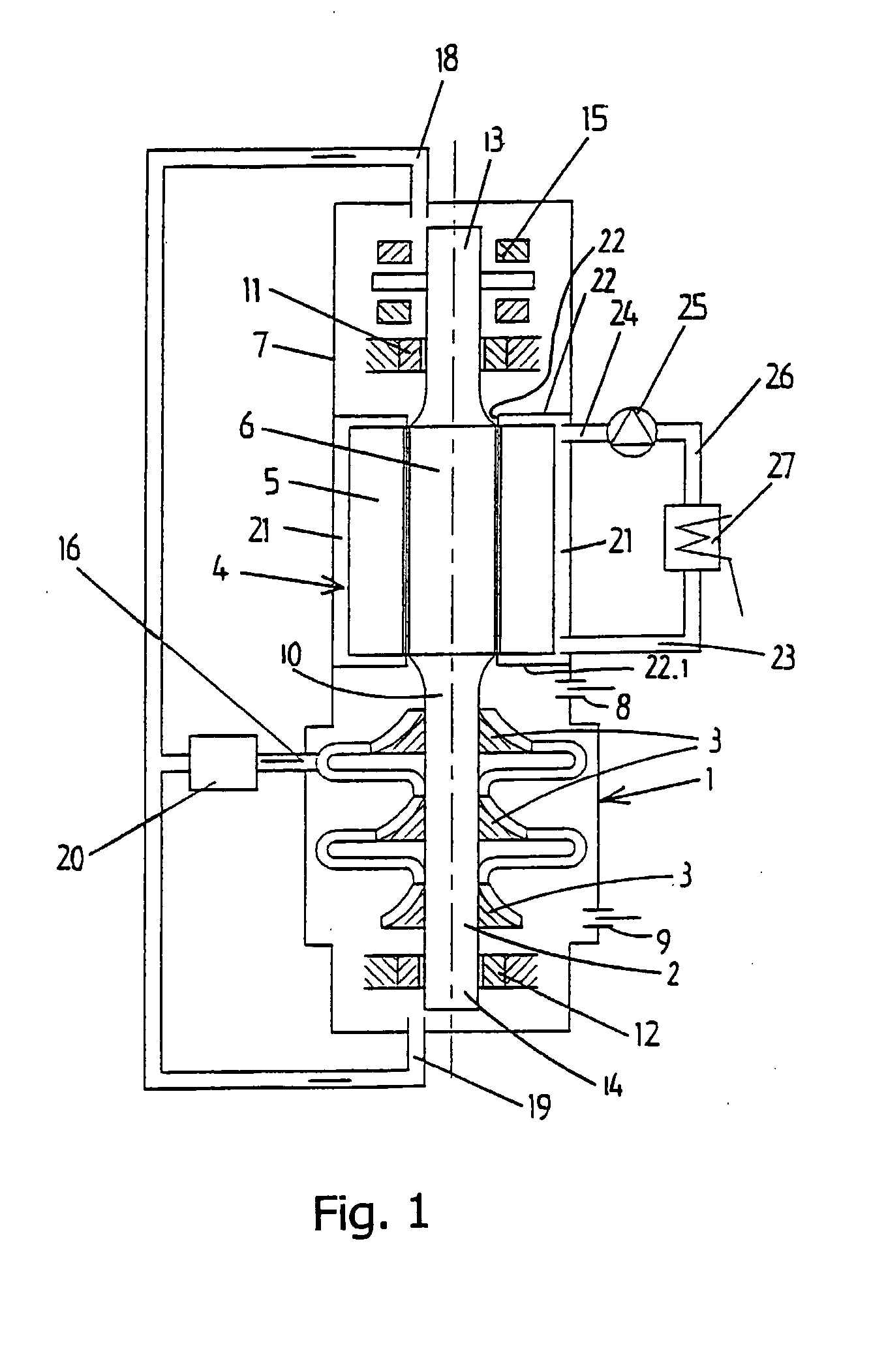

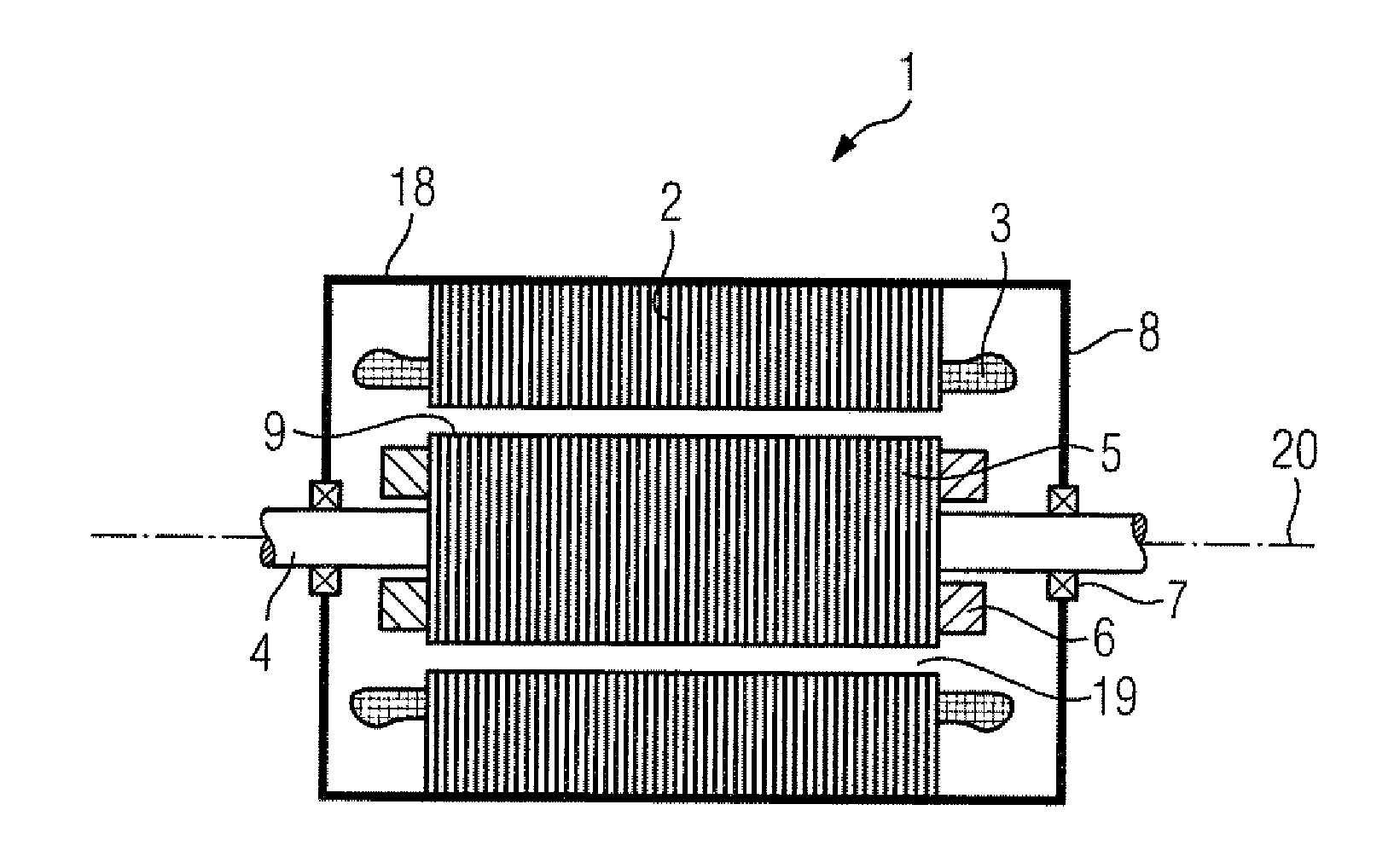

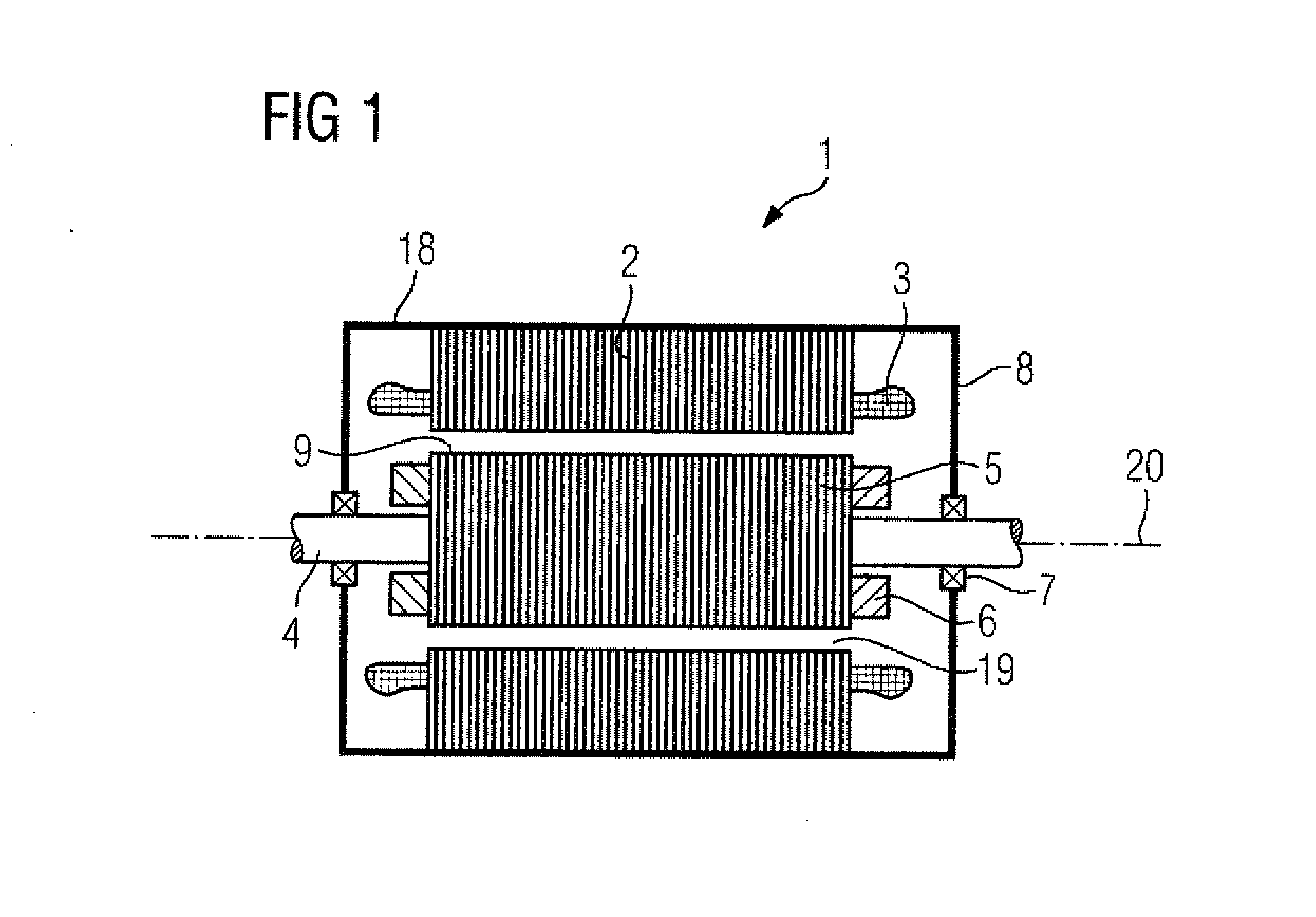

Rotor for Electric Motor, Compressor Unit Provided with Rotor, Method for Producing a Rotor for an Electric Motor

ActiveUS20070290569A1High strengthImprove the rotation effectWindingsMagnetic circuit rotating partsEngineeringConductive materials

A rotor for an electric motor according to the invention comprises a substantially cylindrical core, conductive rods and two short-circuit rings. The cylindrical core is formed from a core material and provided with a plurality of longitudinal grooves which extend substantially in the direction of the cylinder axis. The conductive rods are formed from an electrically conductive material and are provided in the longitudinal grooves of the cylindrical core. The two short-circuit rings conductively connect the axial ends of the conductive rods to one another. A diffusion layer extends between the conductive rods and the cylindrical core. The diffusion layer comprises a diffusion material.

Owner:SIEMENS AG

Electrofriction method of manufacturing squirrel cage rotors

InactiveUS6877210B2Smooth connectionReduce area of smallWindingsMagnetic circuitEngineeringConductive materials

A method of making a squirrel cage rotor of copper material for use in AC or DC motors, includes forming a core with longitudinal slots, inserting bars of conductive material in the slots, with ends extending out of opposite ends of the core, and joining the end rings to the bars, wherein the conductive material of either the end rings or the bars is copper. Various methods of joining the end rings to the bars are disclosed including electrofriction welding, current pulse welding and brazing, transient liquid phase joining and casting. Pressure is also applied to the end rings to improve contact and reduce areas of small or uneven contact between the bar ends and the end rings. Rotors made with such methods are also disclosed.

Owner:UT BATTELLE LLC

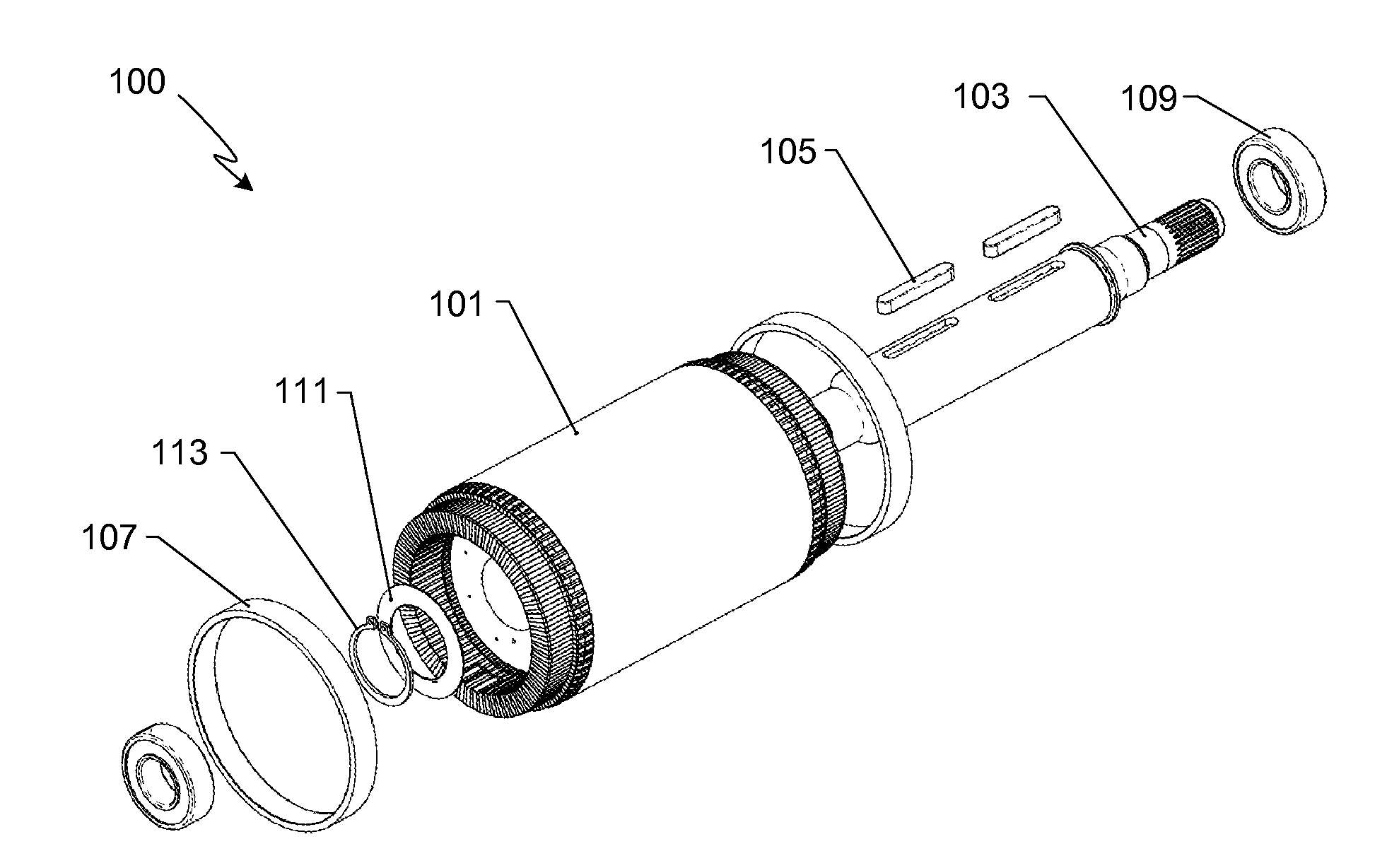

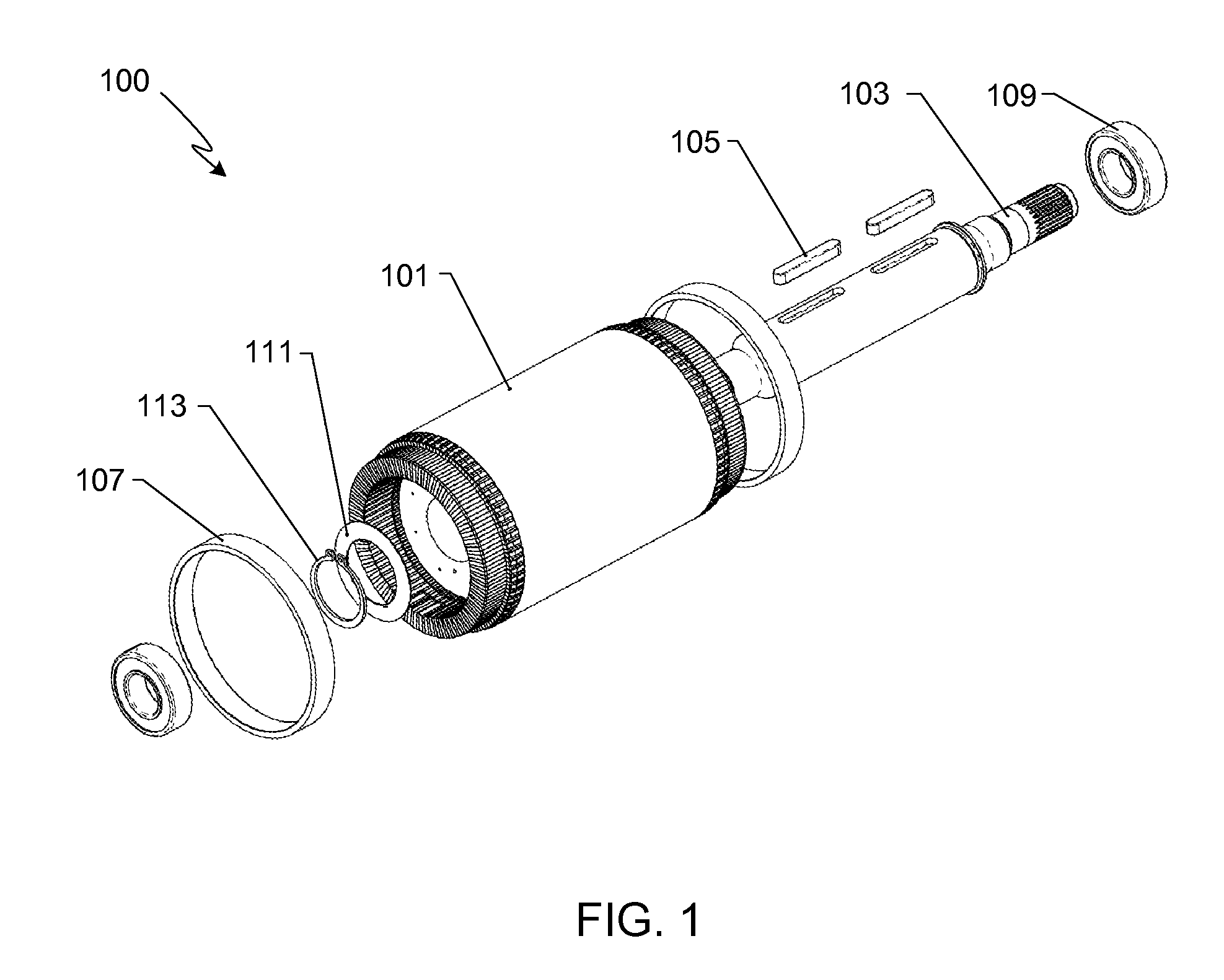

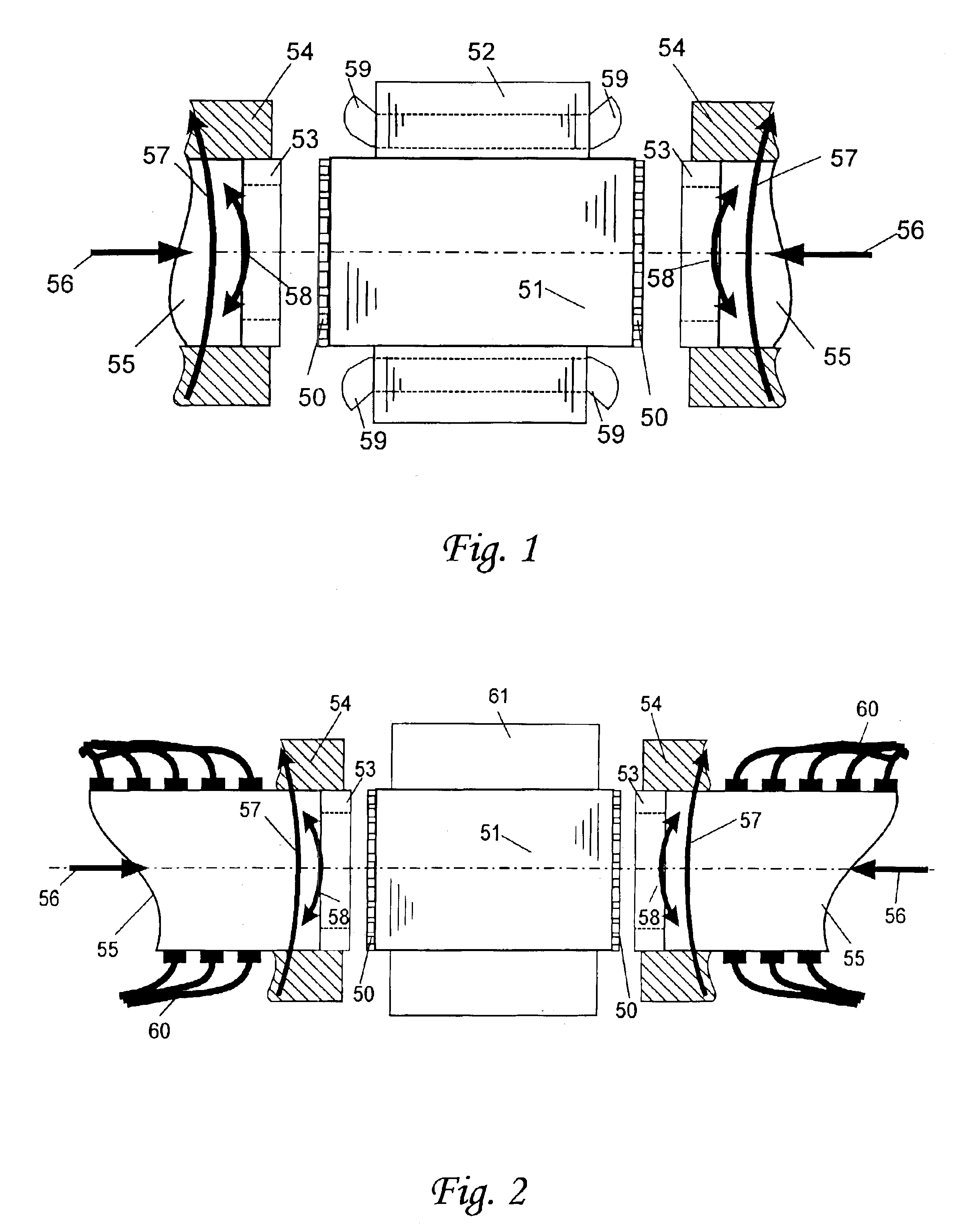

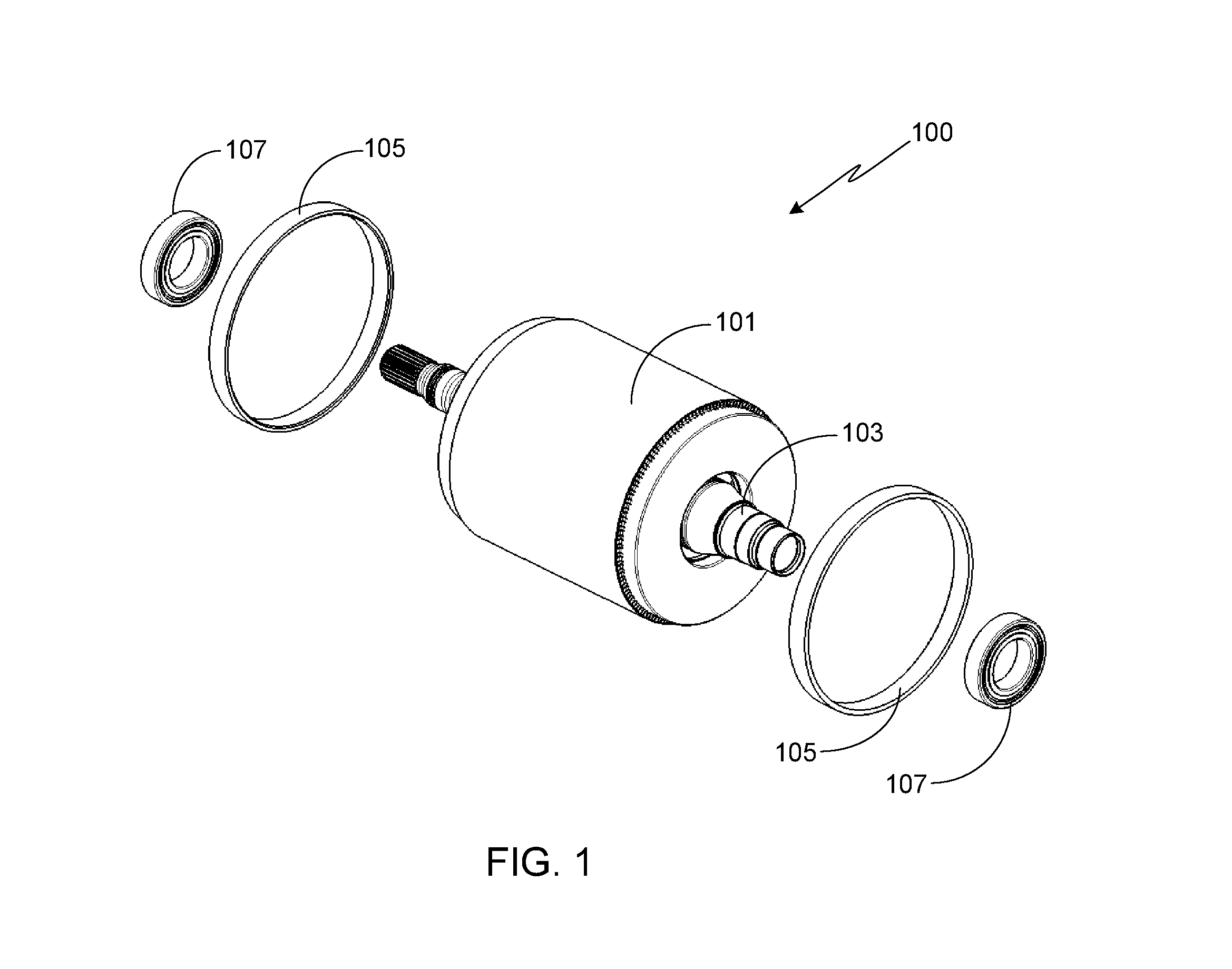

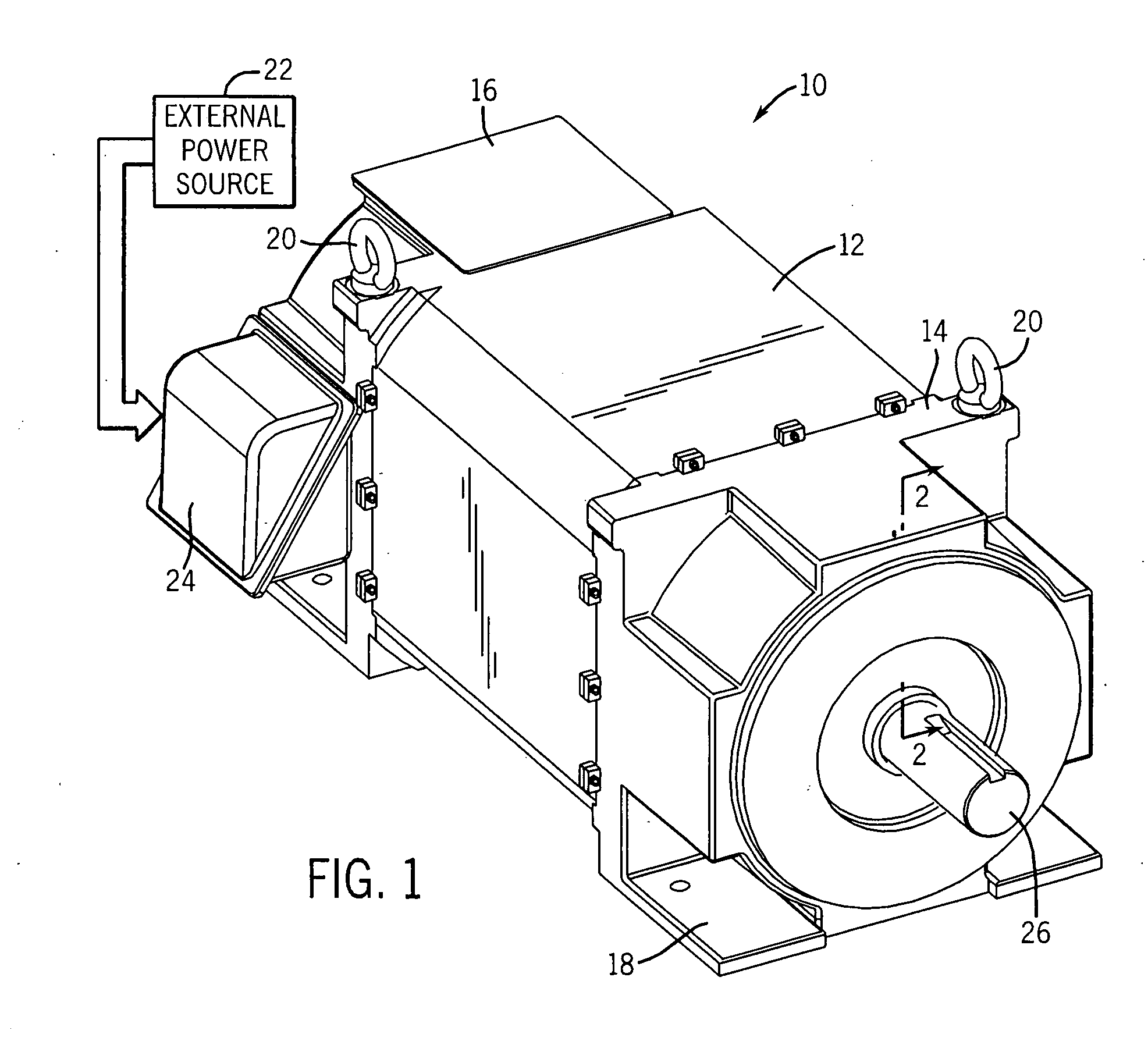

Rotor Assembly with Electron Beam Welded End Caps

A rotor assembly and a method for fabricating the same are provided in which a pair of end caps, positioned at either end of the stack of laminated discs, are fusion welded to the rotor bars using an electron beam welder, thereby yielding improved electrical and mechanical characteristics in a low weight assembly.

Owner:TESLA INC

Aluminum based composite squirrel cage for induction rotor and methods of making

InactiveUS20110163627A1Synchronous motorsAsynchronous induction motorsCarbon nanotubeAluminum composites

A method of making a rotor is provided. The method includes mixing aluminum and carbon nanotubes; forming the mixture into an aluminum-carbon nanotube composite conductor bar; providing a laminated steel stack having a plurality of longitudinal slots; placing a plurality of the conductor bars in the longitudinal slots, first and second ends of the plurality of conductor bars extending out of the logitudinal slots; placing the laminated steel stack with the plurality of conductor bars in a casting mold having cavities for a pair of end rings wherein the first and second ends of the plurality of conductor bars extend into the cavities; and filling the cavities with aluminum, aluminum alloys, an aluminum composite, or combinations thereof. Rotors made from aluminum-carbon nanotube composite are also described.

Owner:GM GLOBAL TECH OPERATIONS LLC

Rotor of induction motor and method for manufacturing the same

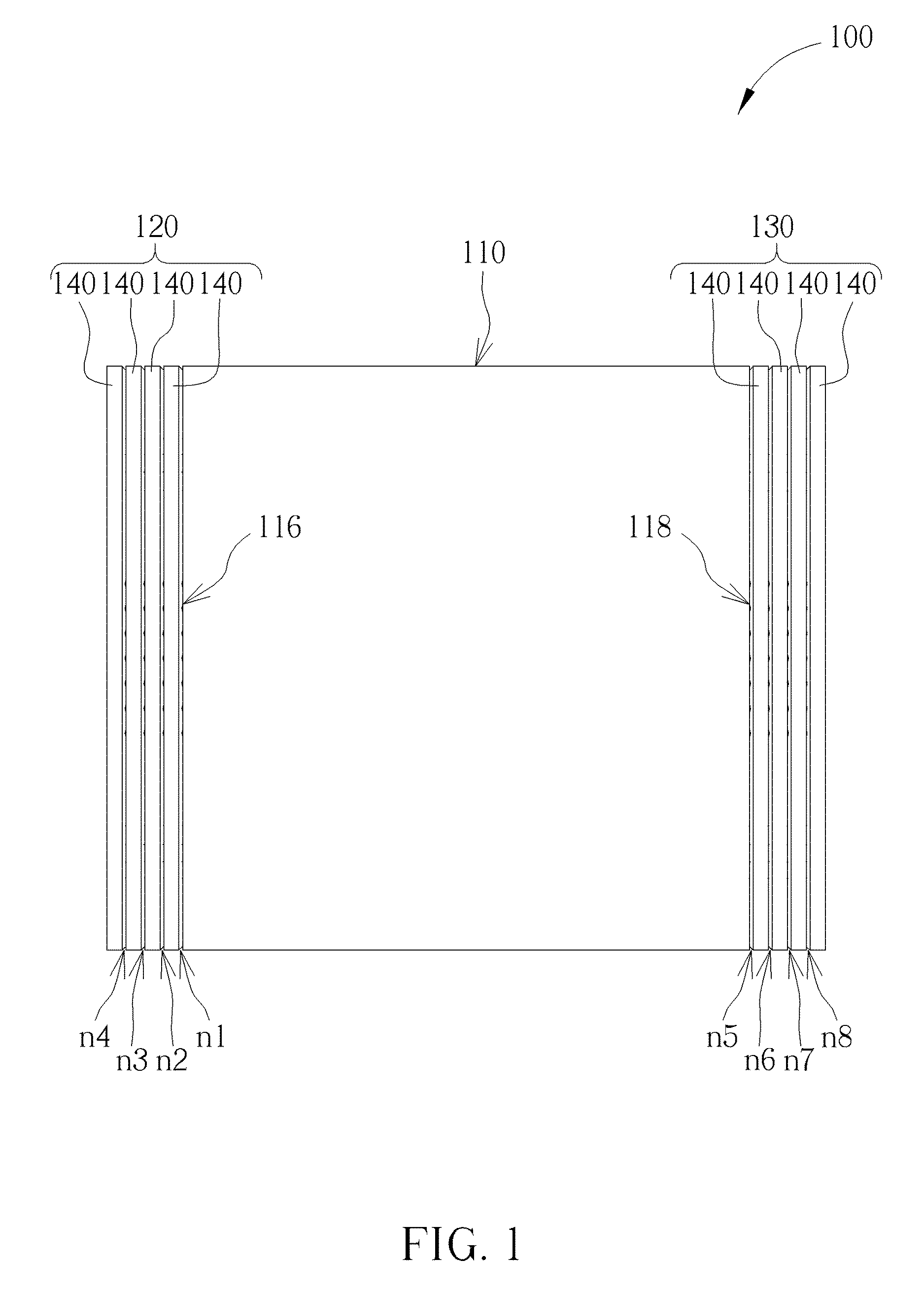

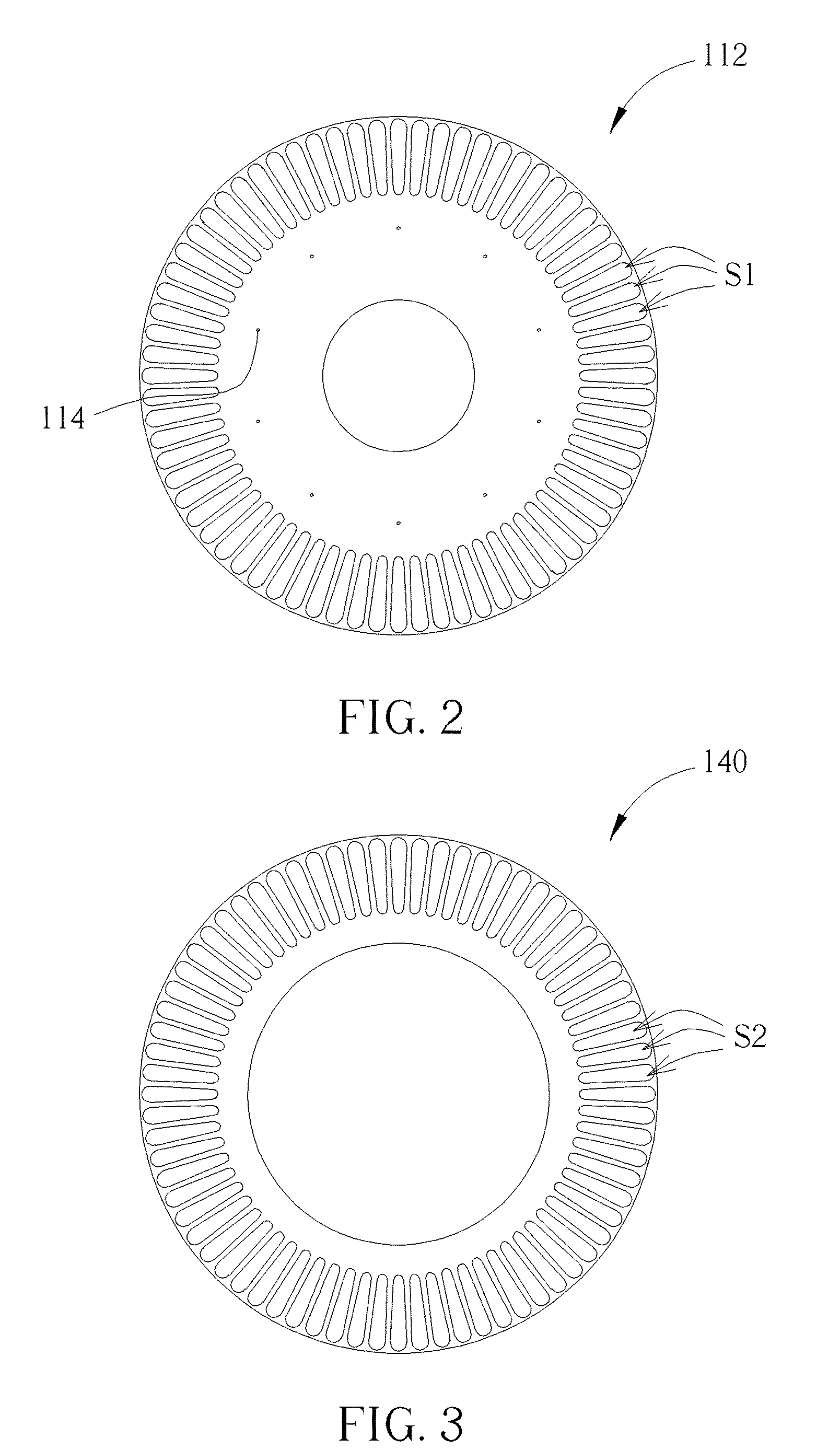

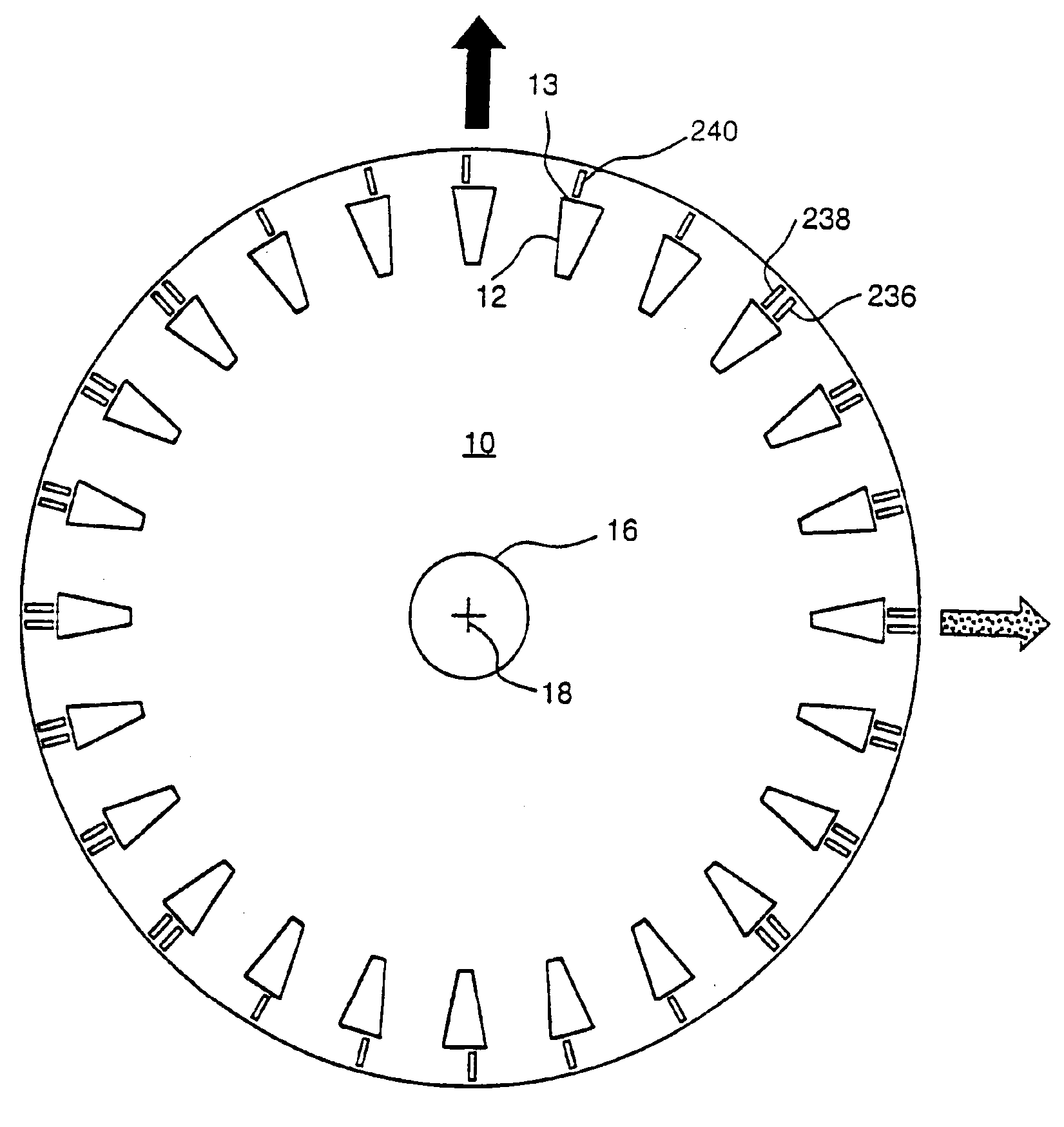

A rotor of an induction motor includes a core assembly including a plurality of core discs formed with a plurality of slots; a plurality of conductive bars passing through the slots, each of the conductive bars having a first end and a second end respectively extended out of a first end surface and a second end surface of the core assembly; a first end ring assembly including a plurality of first conductive rings stacked on each other and penetrated by the first ends of the conductive bars; and a second end ring assembly including a plurality of second conductive rings stacked on each other and penetrated by the second ends of the conductive bars; wherein the first conductive rings and the second conductive rings are respectively welded to the first ends and the second ends of the conductive bars by electron beam welding or laser welding.

Owner:XPT NANJING E POWERTRAIN TECH CO LTD

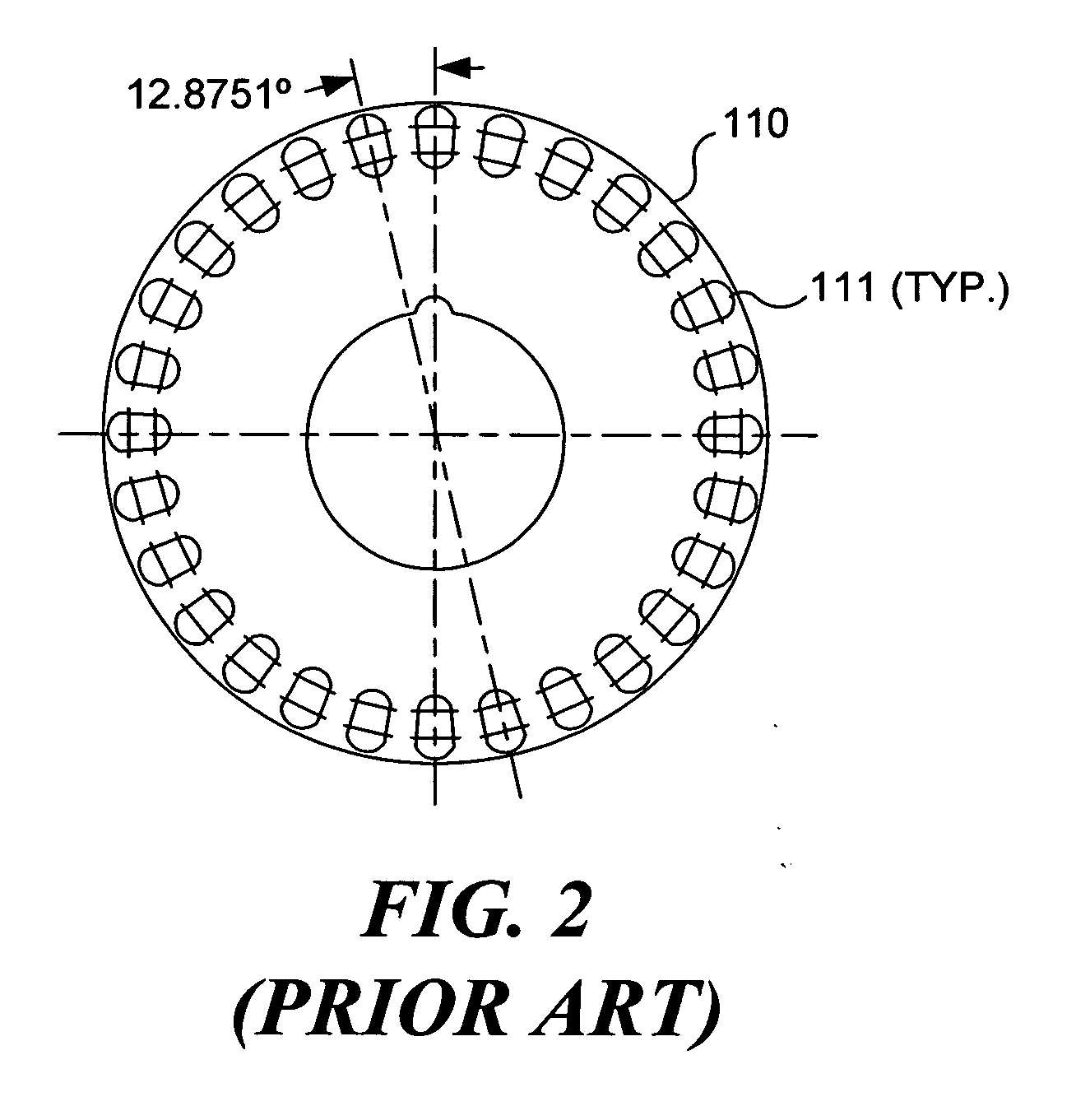

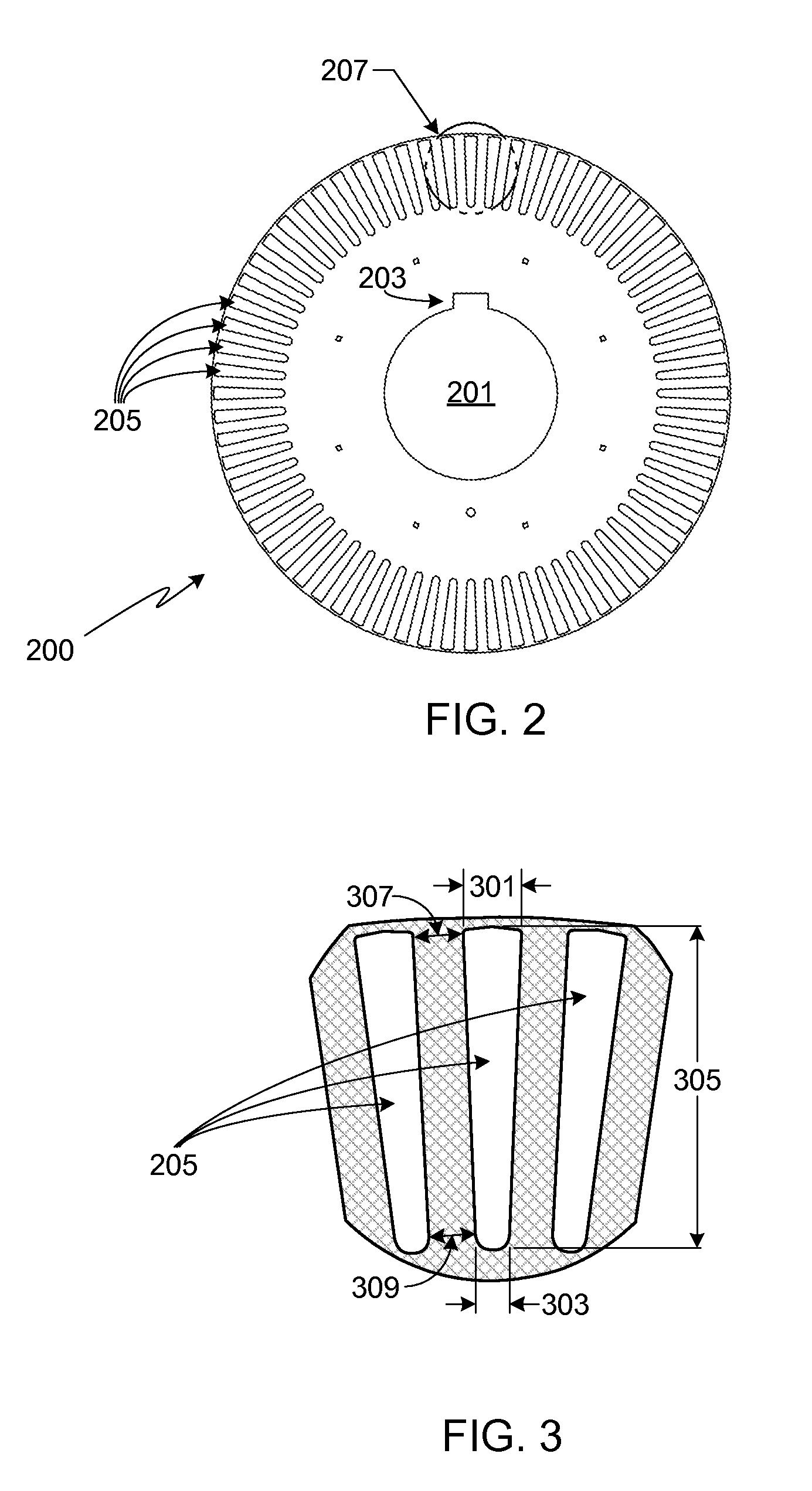

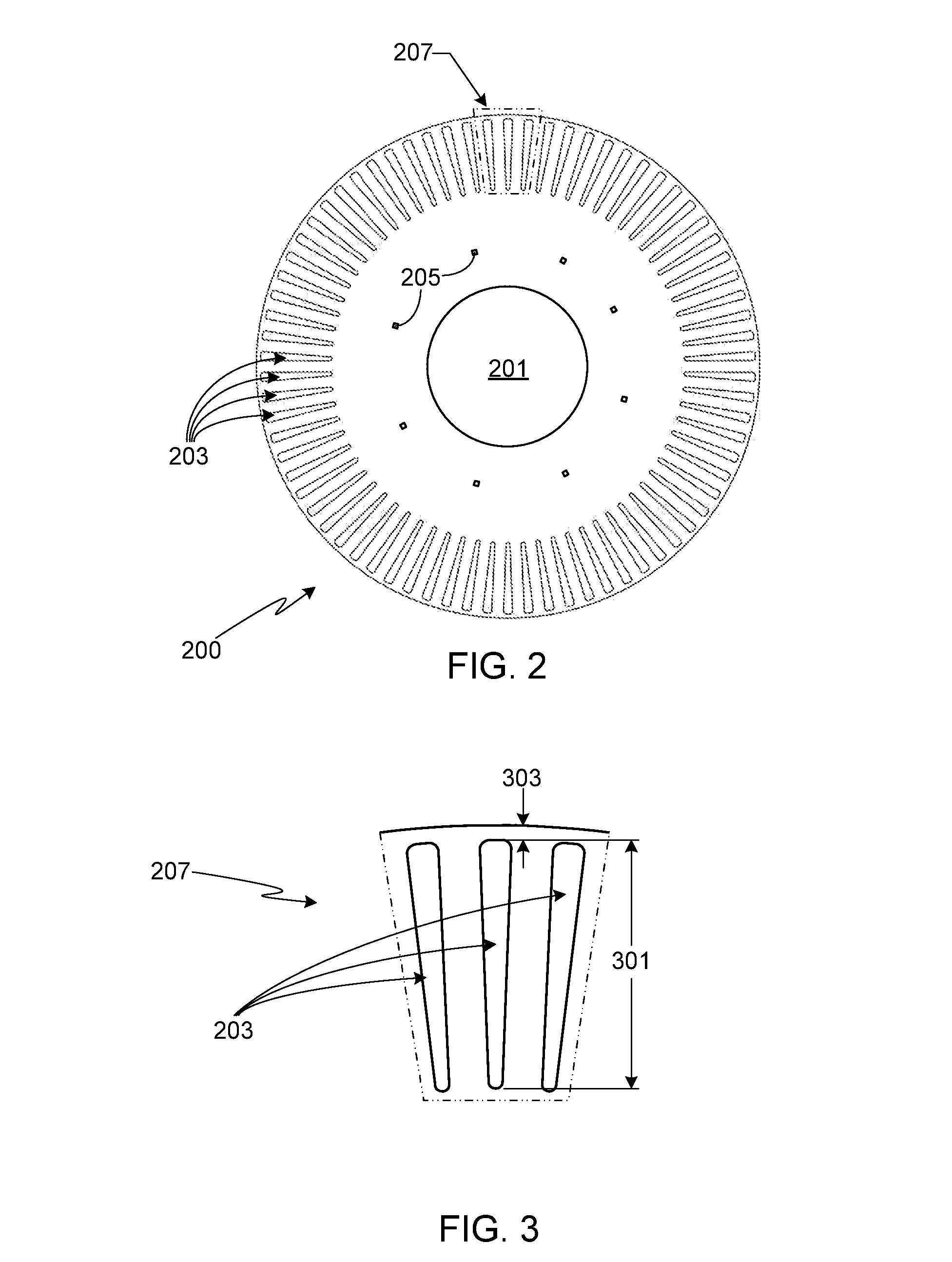

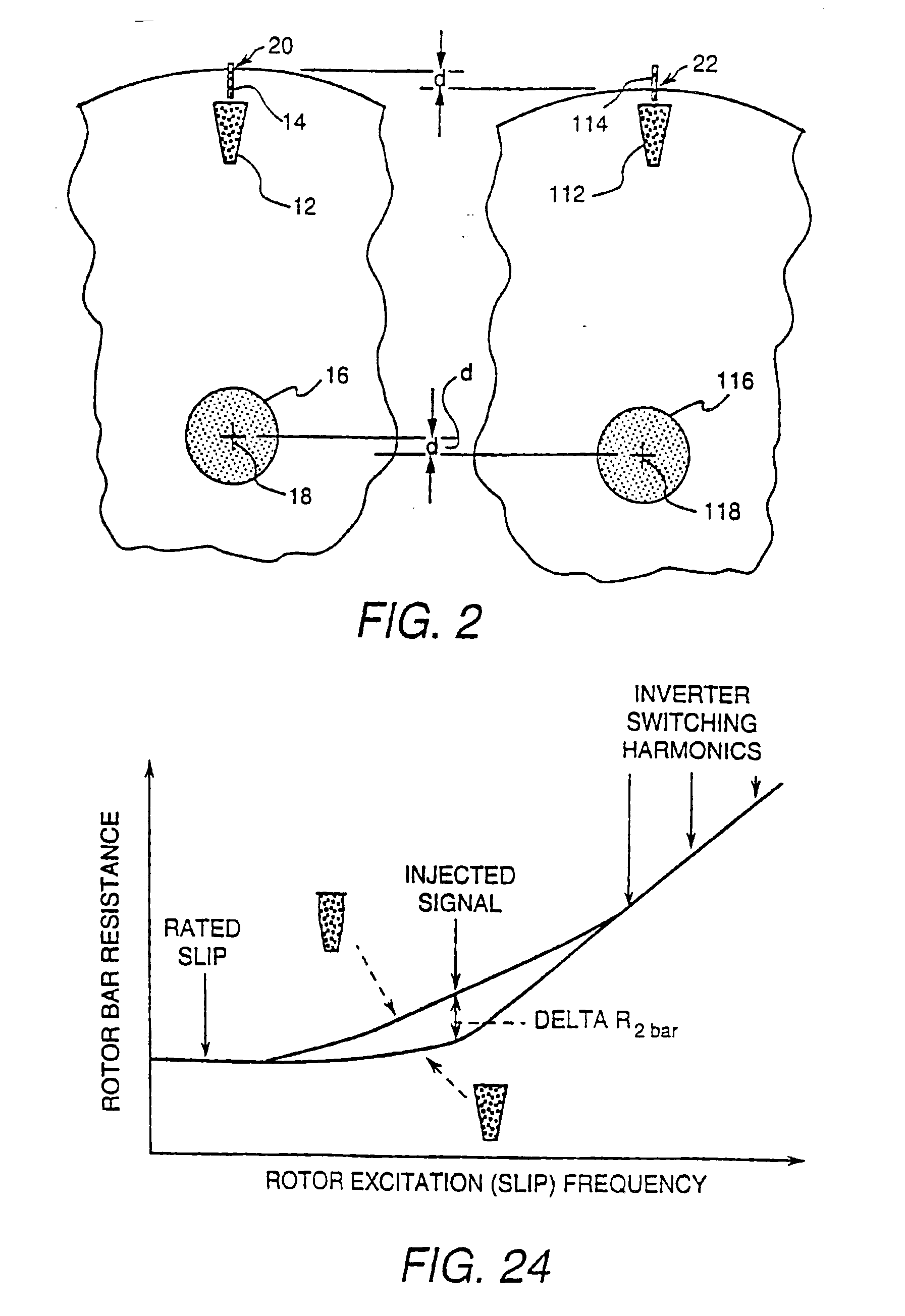

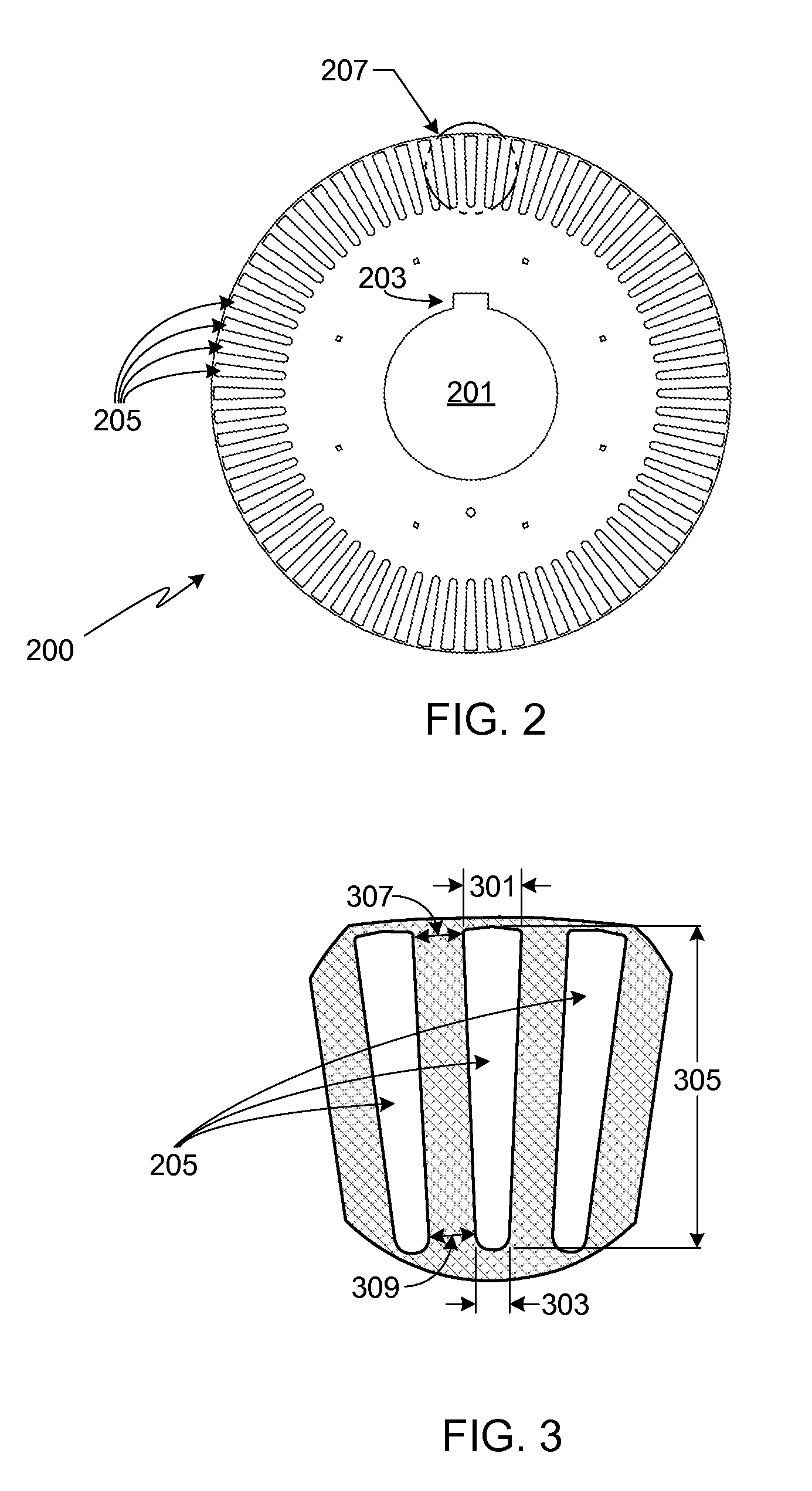

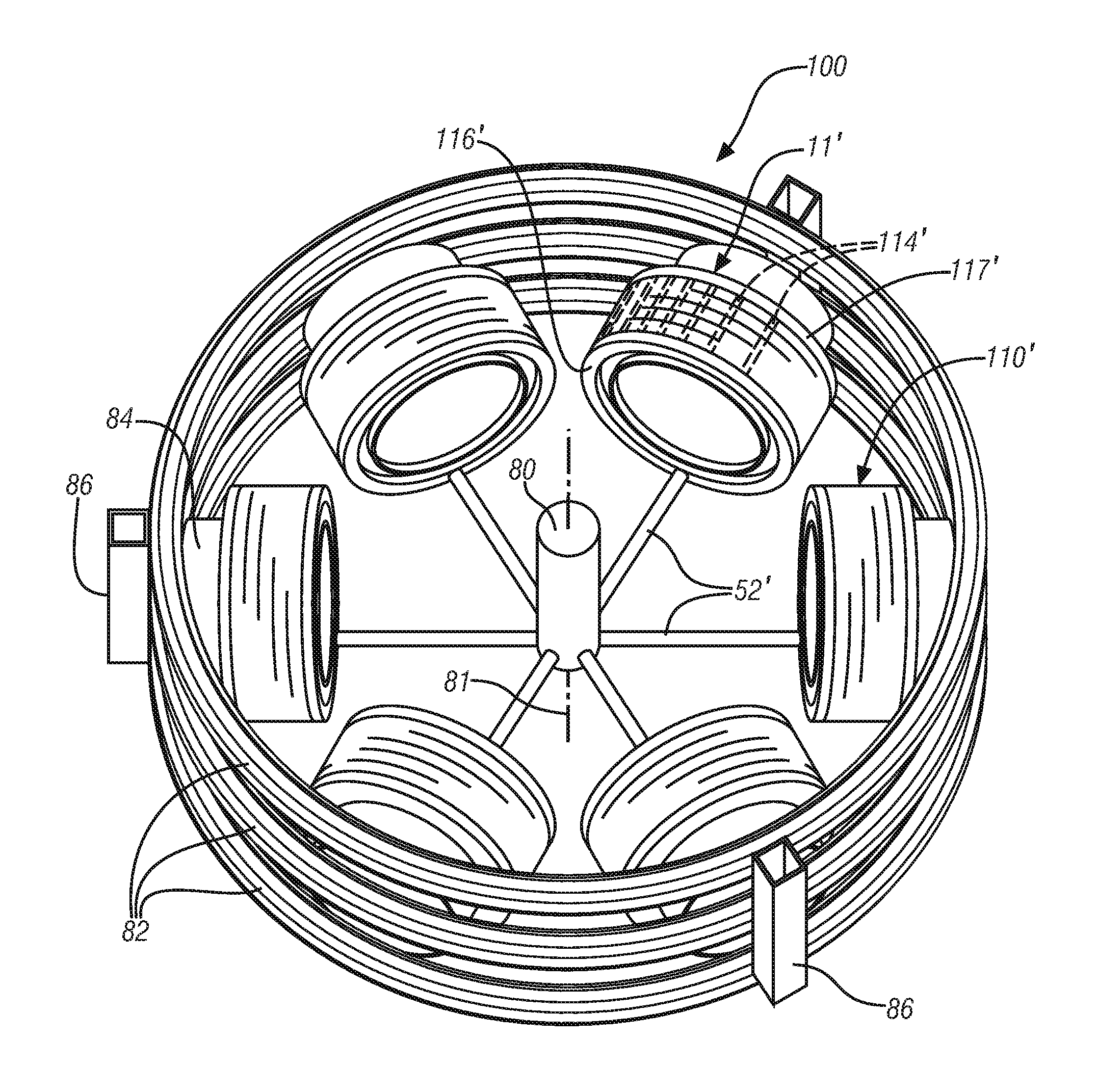

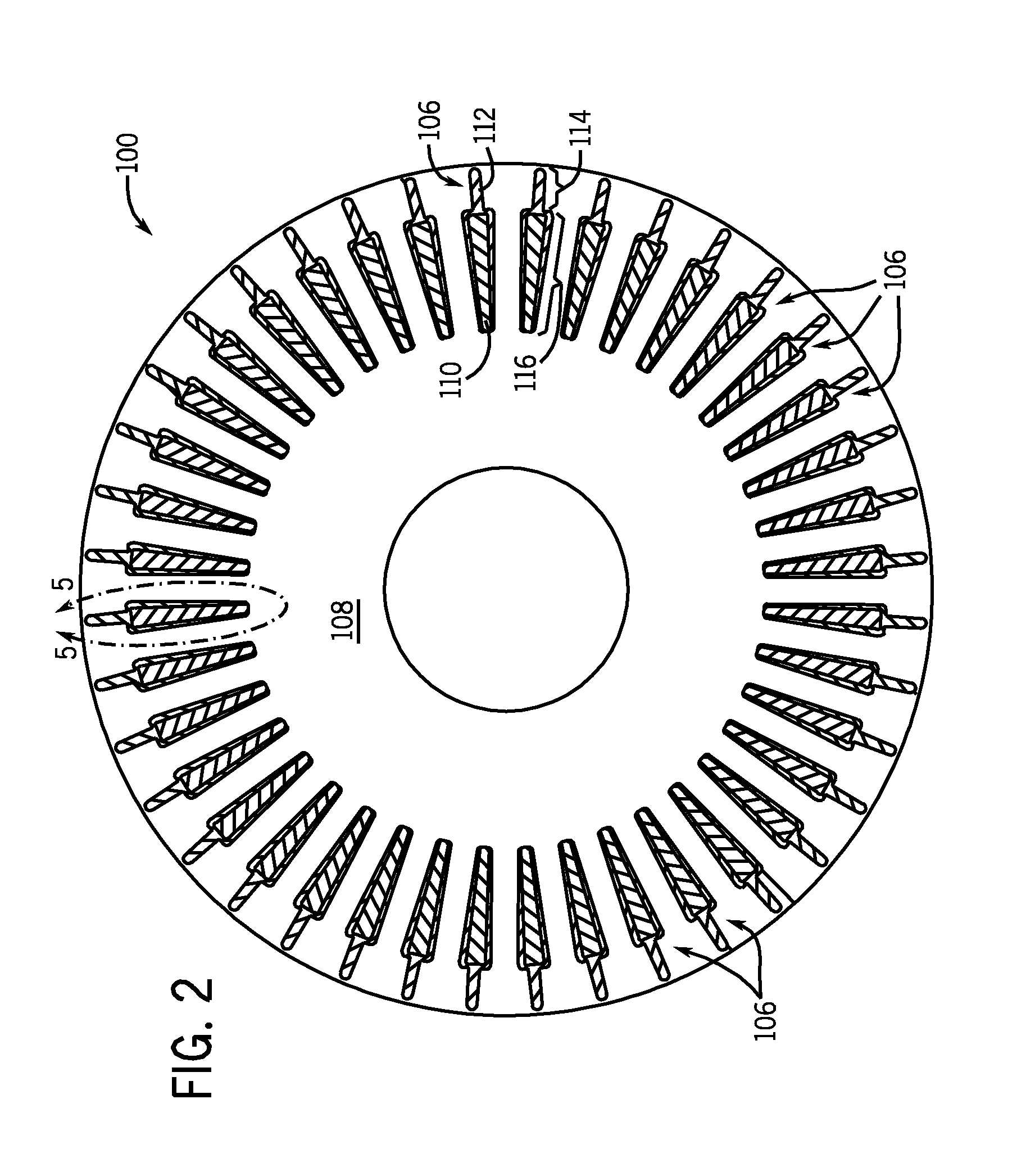

Sensorless control induction motor rotor slot shapes and fabrication methods

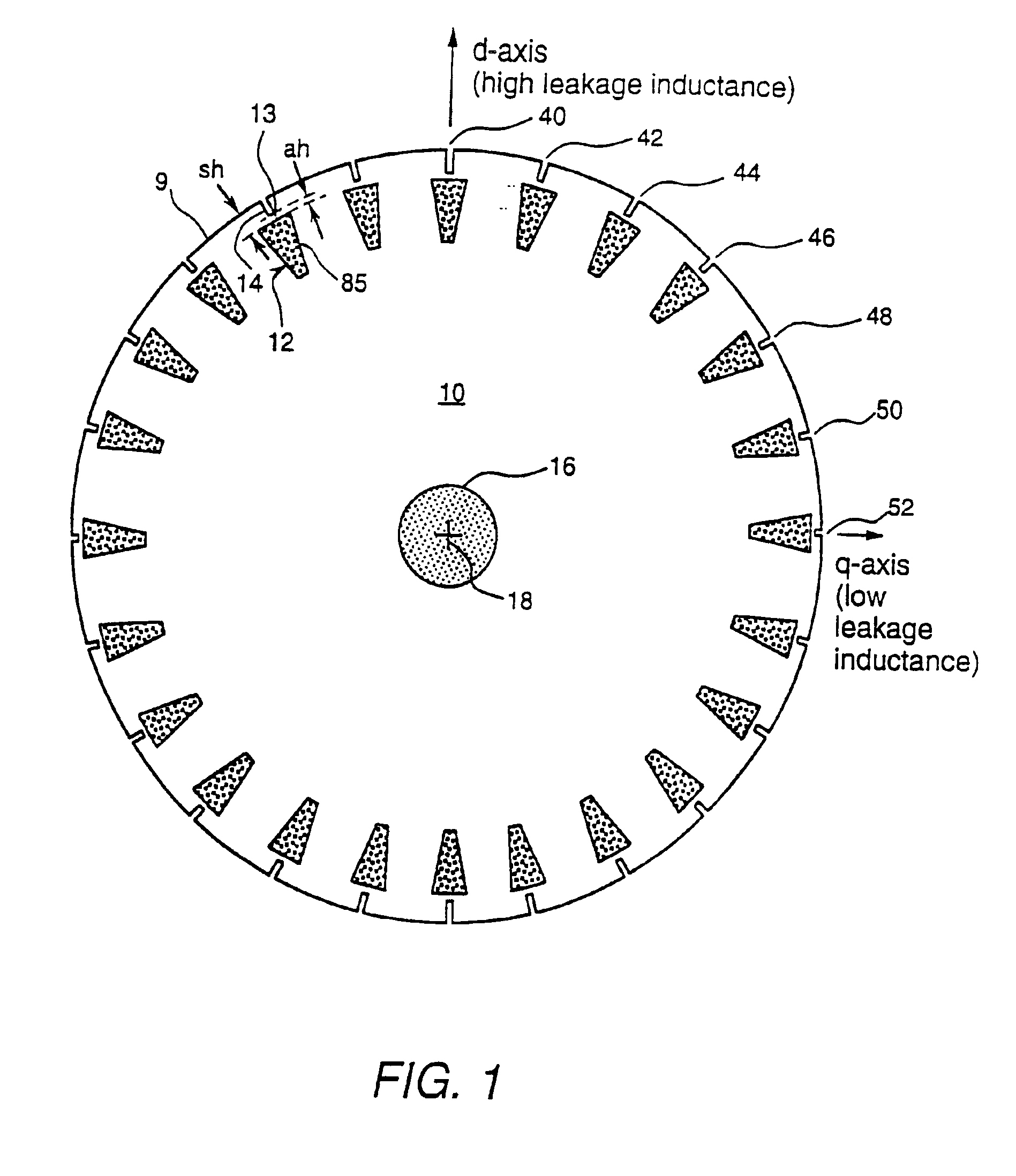

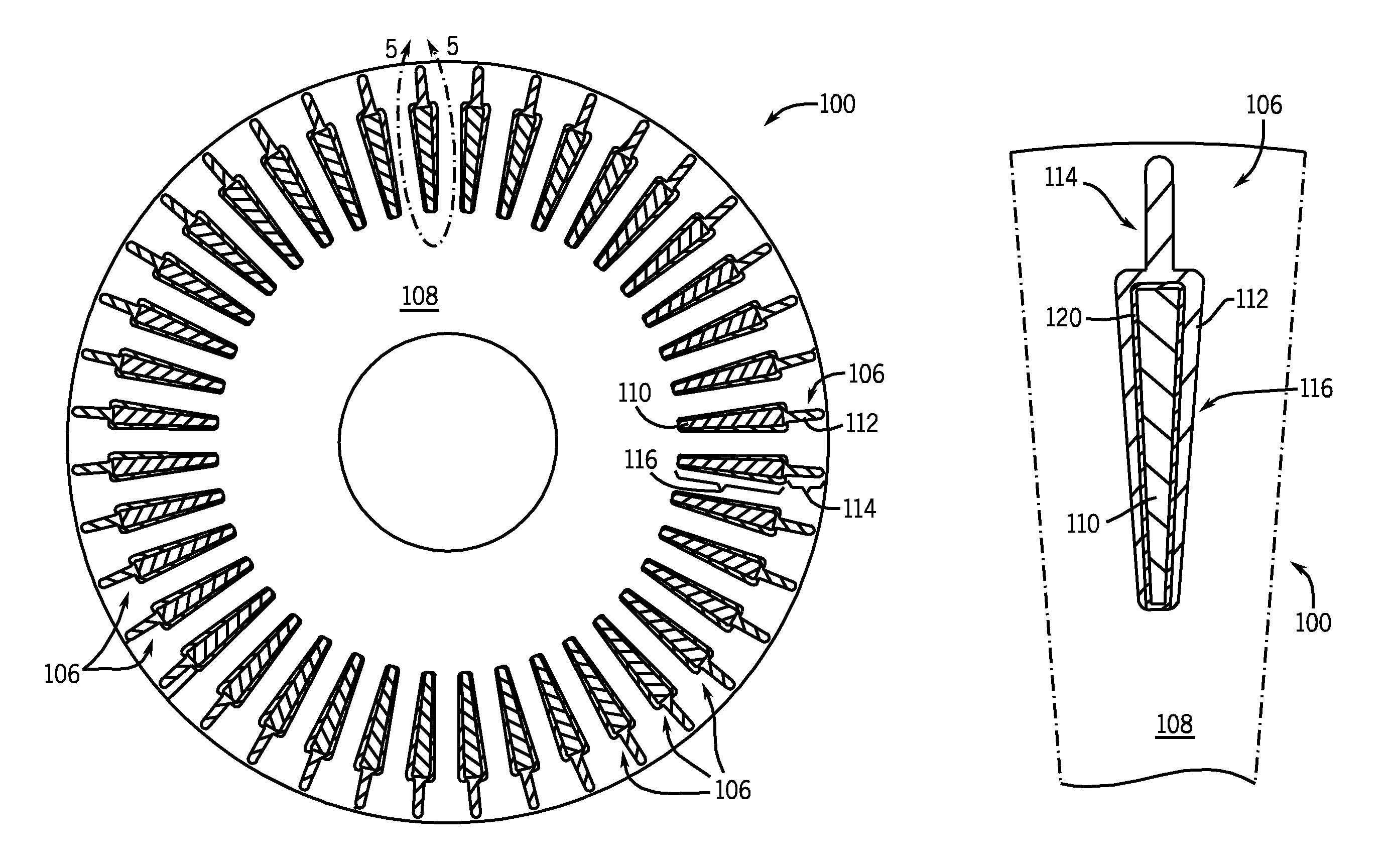

A method for fabricating an induction motor rotor lamination includes using an indexed notching die to punch a plurality of closed rotor slots at different distances from a center point of rotation by punching a first rotor slot, changing the position of a center point of the rotor lamination with respect to the notching die, and punching a second rotor slot. In another embodiment, a plurality of rotor slit patterns are punched using a variable depth indexed notching die including at least two rotor slit punching portions, one being deeper than another, by punching a first rotor slit pattern, changing the depth of closure of the notching die, and punching a second rotor slit pattern with the second rotor slit pattern having a different number of rotor slits than the first. In another embodiment, each rotor slit is open to and off center with respect to its respective rotor slot, and rotor laminations are stacked by positioning some of the rotor laminations in an orientation with is turned over and rotated with respect to others of the rotor laminations; filling the rotor slots and the rotor slits with cage material; and machining outer surfaces of the rotor laminations. In another embodiment, uniformly spaced identical rotor slots are punched and modulation is created by punching a contoured outside diameter or by inserting slot wedges of molded magnetic material.

Owner:GENERAL ELECTRIC CO

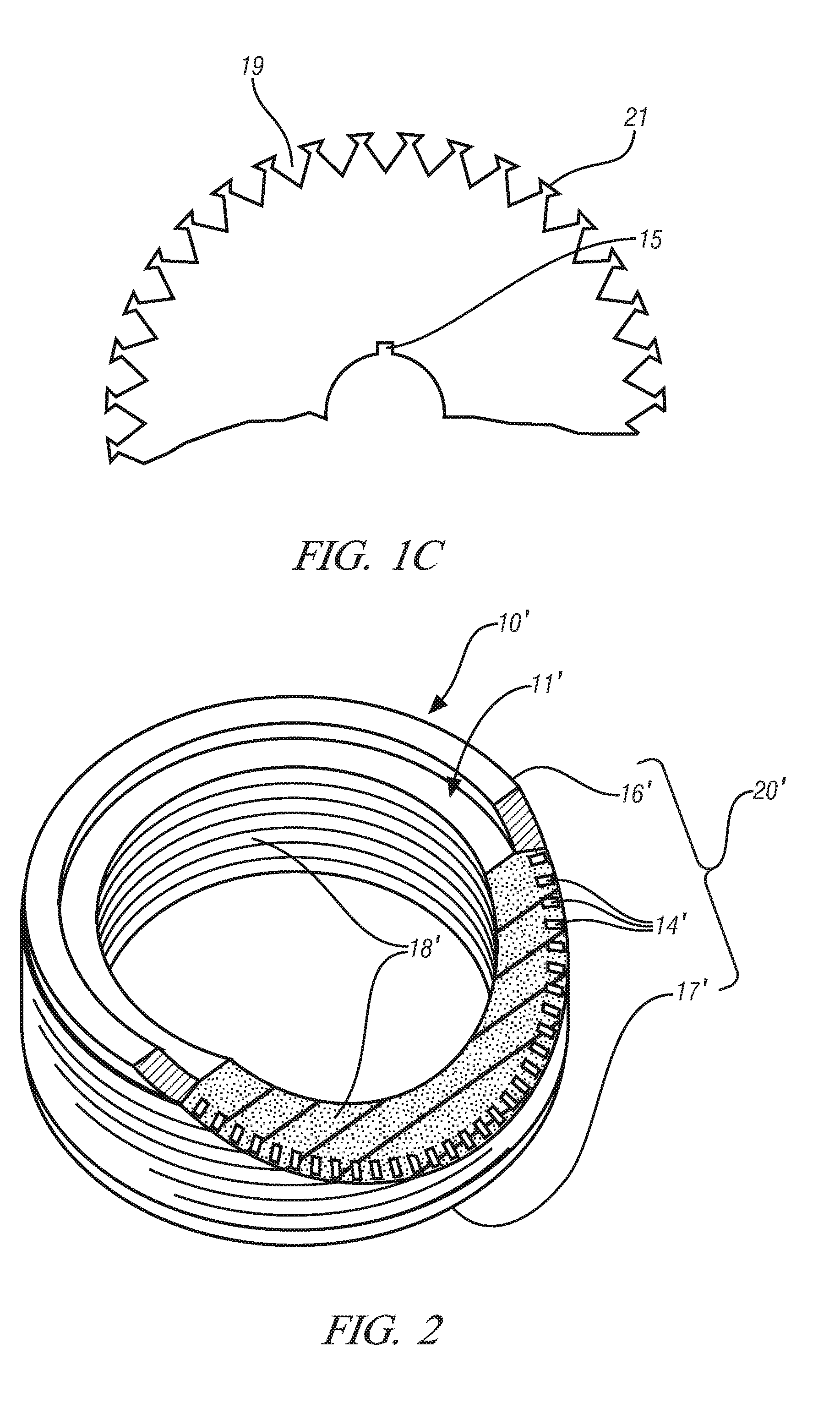

Electric machine rotor bar and method of making same

ActiveUS20110291516A1Windings insulation shape/form/constructionSynchronous motorsElectricityCoupling

A method, system, and apparatus including an electric machine having a plurality of rotor bars and a first coupling component configured to electrically couple the plurality of rotor bars together. Each rotor bar of the plurality of rotor bars includes a first metallic material having a first electrical resistivity and a second metallic material cast about the first material, where the second metallic material has a second electrical resistivity greater than the first electrical resistivity. The first metallic material has a first end and a second end opposite the first end and the first coupling component is coupled to the first end of the first metallic material.

Owner:GENERAL ELECTRIC CO

Self-start synchronous motor with permanent magnets and at least one frictional agitation joint, method for manufacturing the same and compressor comprising the same

InactiveUS7531934B2Inhibit deteriorationImprove efficiencySynchronous motorsStatorsSynchronous motorElectrical conductor

In a method of manufacturing a self-start synchronous motor for preventing deterioration of permanent magnets used in a rotor, and also for enhancing the efficiency of the self-start synchronous motor, the self-start synchronous motor comprising a stator having a stator core and windings wound around the stator core, and a rotor having an outer diameter slightly smaller than an inner diameter of the stator and arranged inside of the stator. The rotor is provided with a rotor core, a plurality of conductor bars embedded in the outer peripheral portion of the rotor core over an entire periphery thereof, end rings provided on opposite end sides of the conductor bars and constituting a squirrel cage conductor in cooperation with the conductor bars, and a plurality of permanent magnets embedded in the rotor core and arranged at a position inner than that of an inner peripheral surface of the conductor bars. Further, the conductor bars and the end rings are electrically and mechanically joined together through frictional agitation joint.

Owner:HITACHI APPLIANCES INC

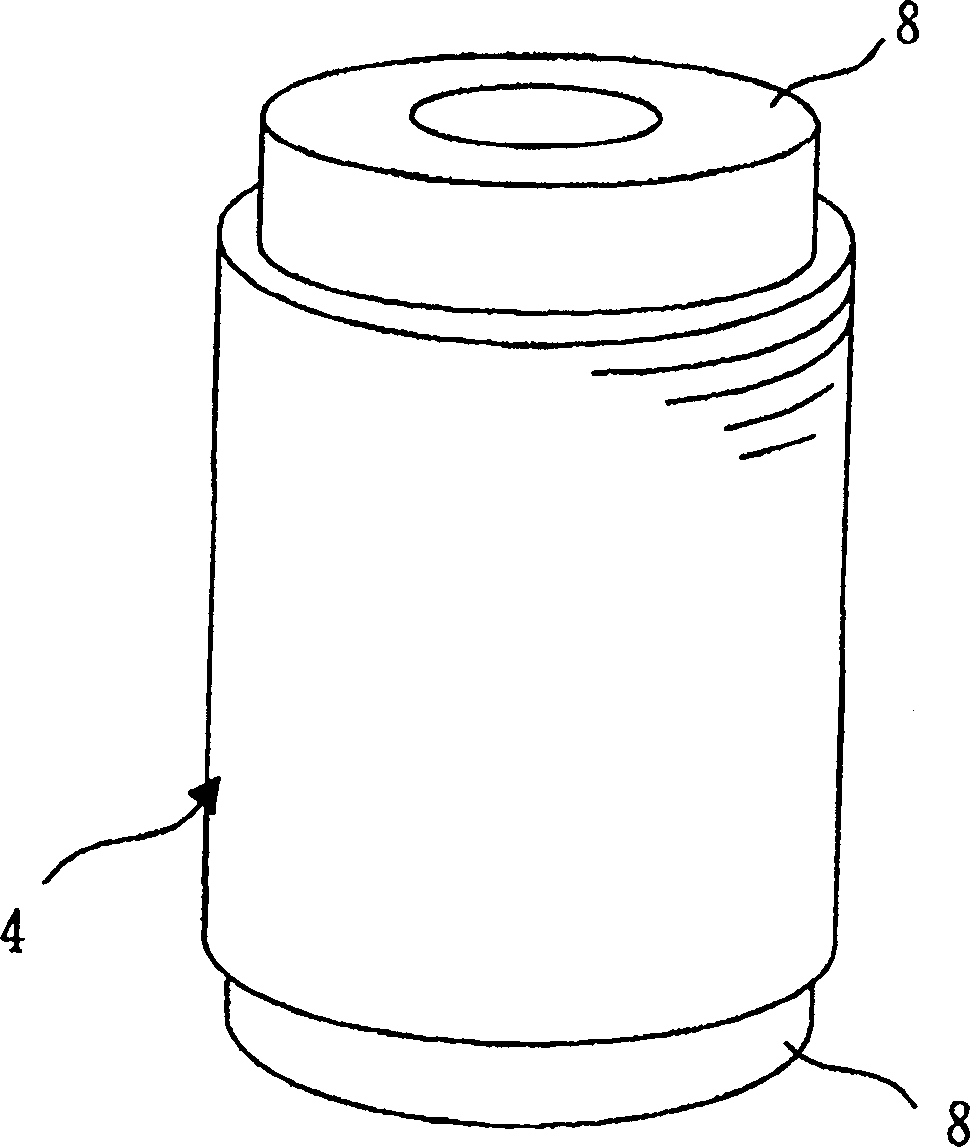

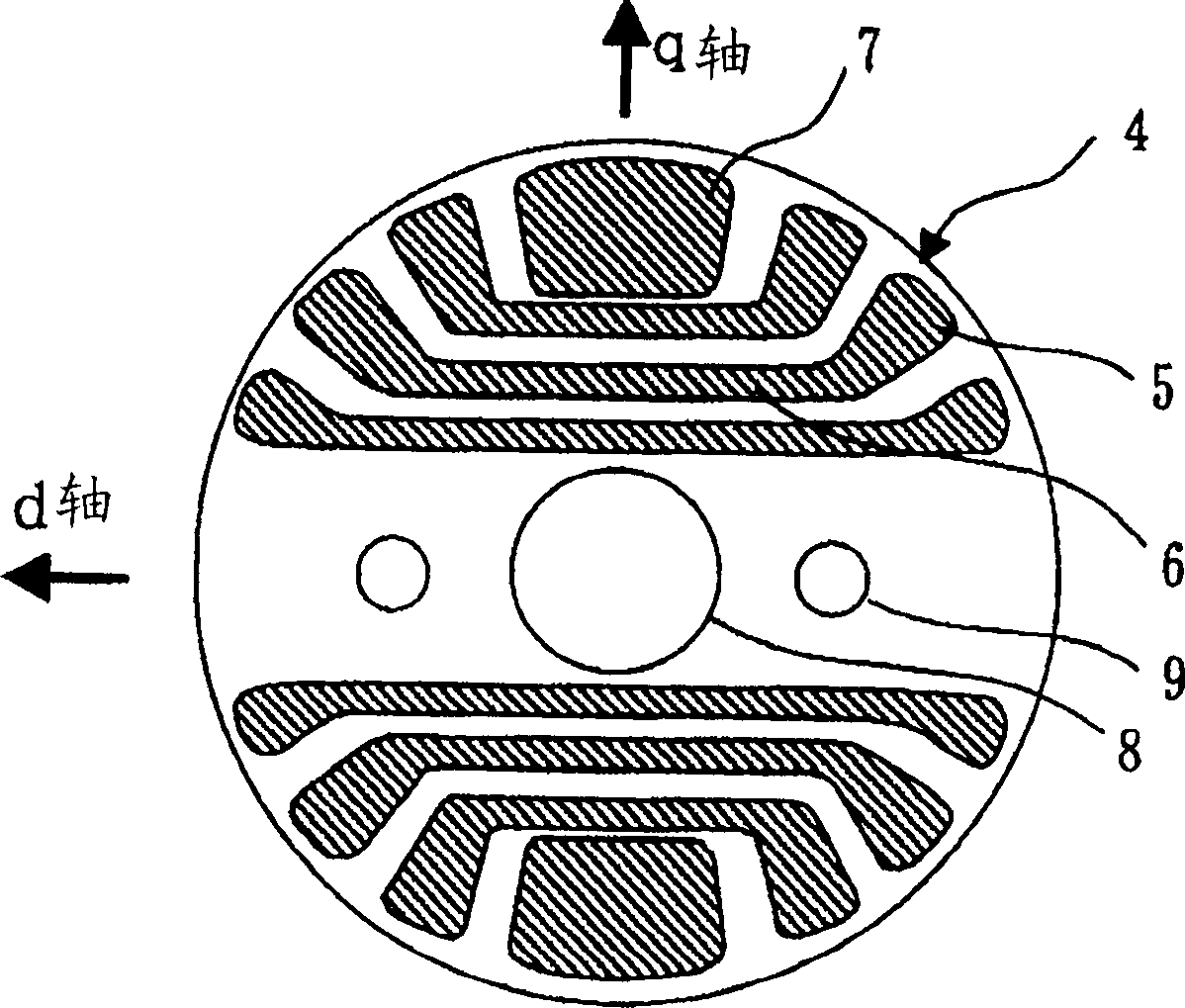

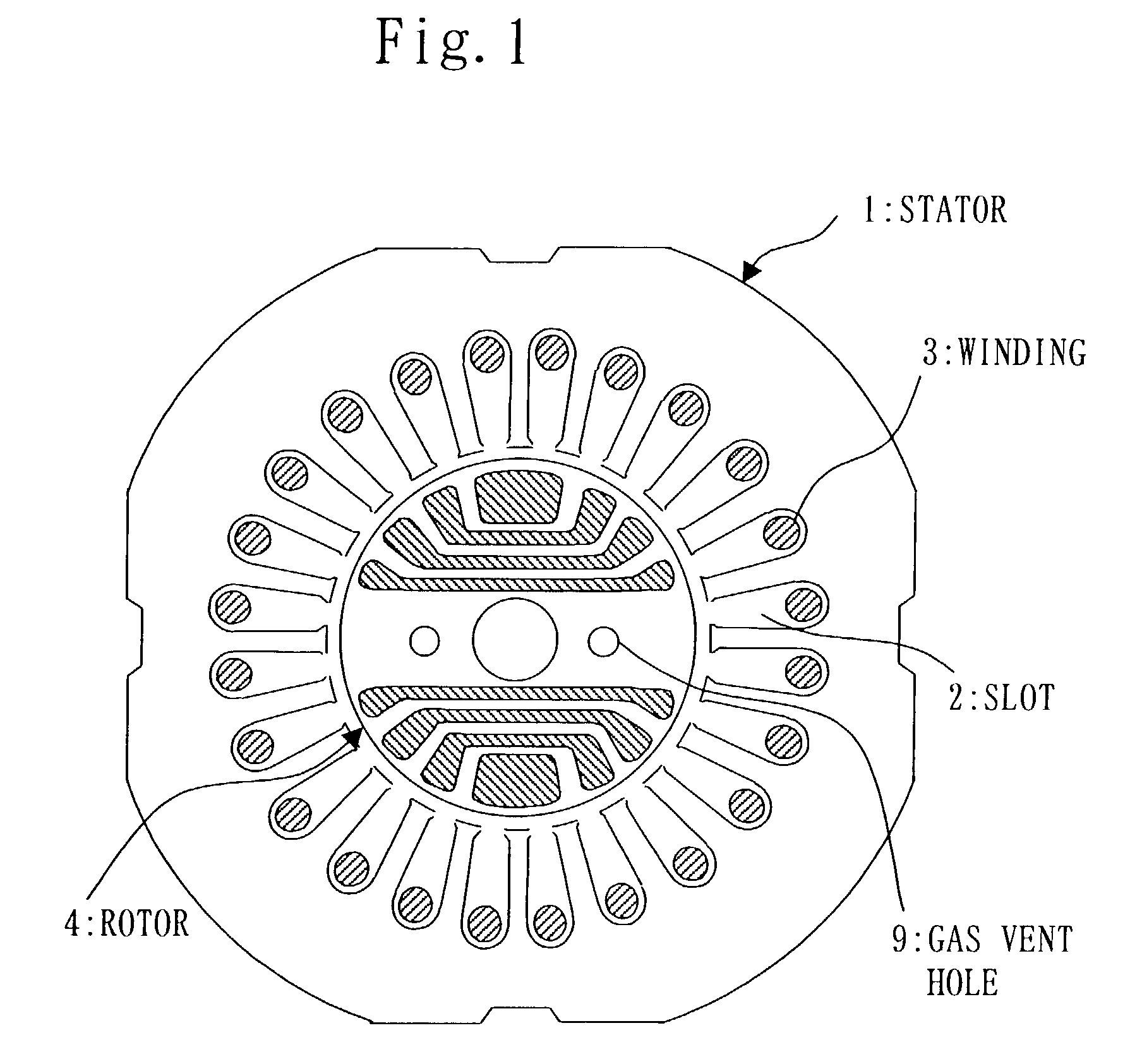

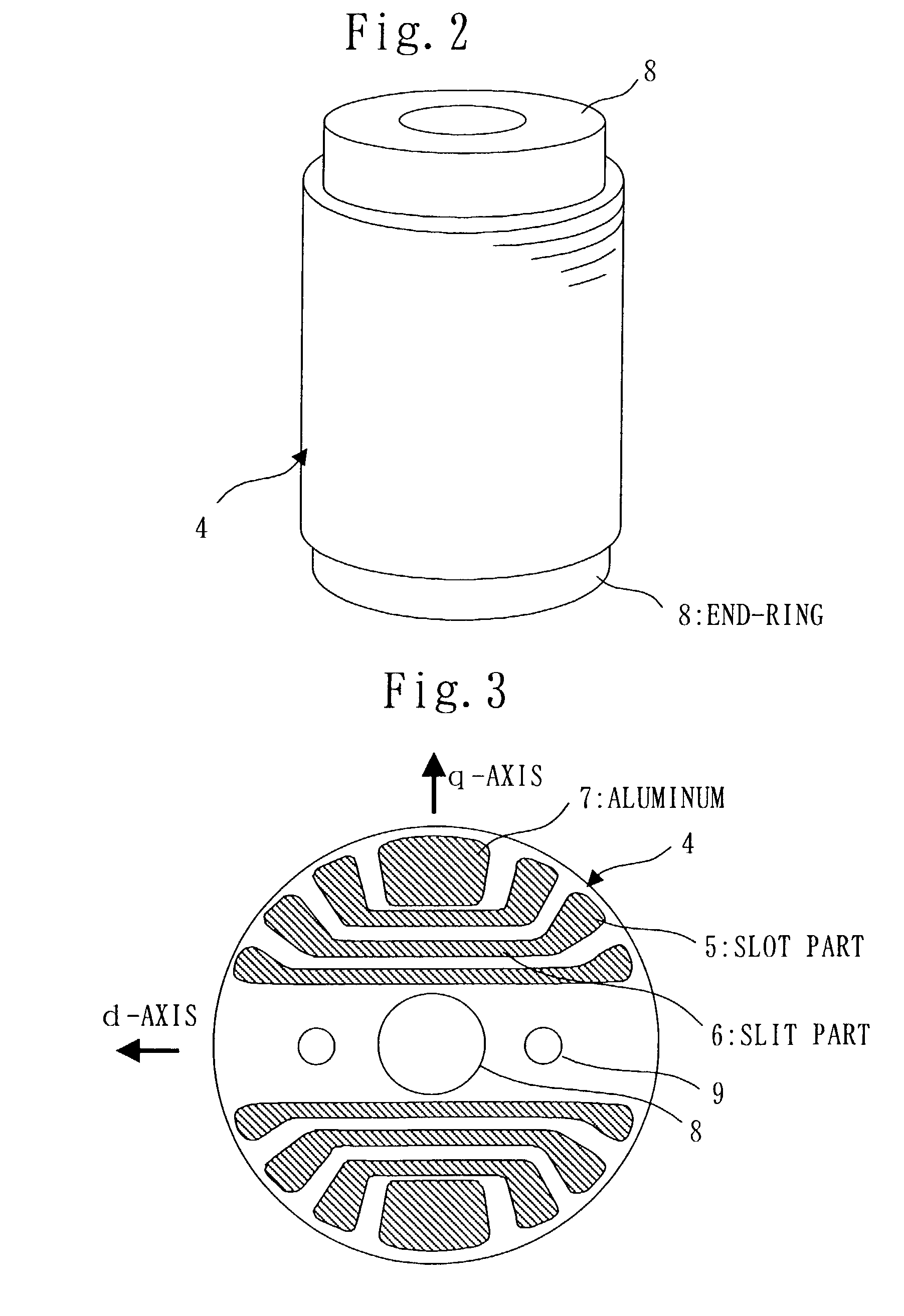

Motor rotor and its mfg. method, motor, brushless motor, compressor, refrigerator and air conditioner

InactiveCN1420606AWon't burn outReduce circulationMagnetic circuit rotating partsPositive displacement pump componentsBrushless motorsInduction motor

To provide a rotor for synchronous induction motor capable of preventing the lowering of output or efficiency due to increasing magnetic resistance even if a gas venting hole is formed for using a hermetic compressor. This rotor includes slots for generating induction torque and slits for generating reluctance torque. The slot and the slits are filled with aluminum. The filling aluminum is shorted by end ring at both ends of the rotor, and a non-filling section axially passed through the slit and not filled with aluminum is provided.

Owner:MITSUBISHI ELECTRIC CORP

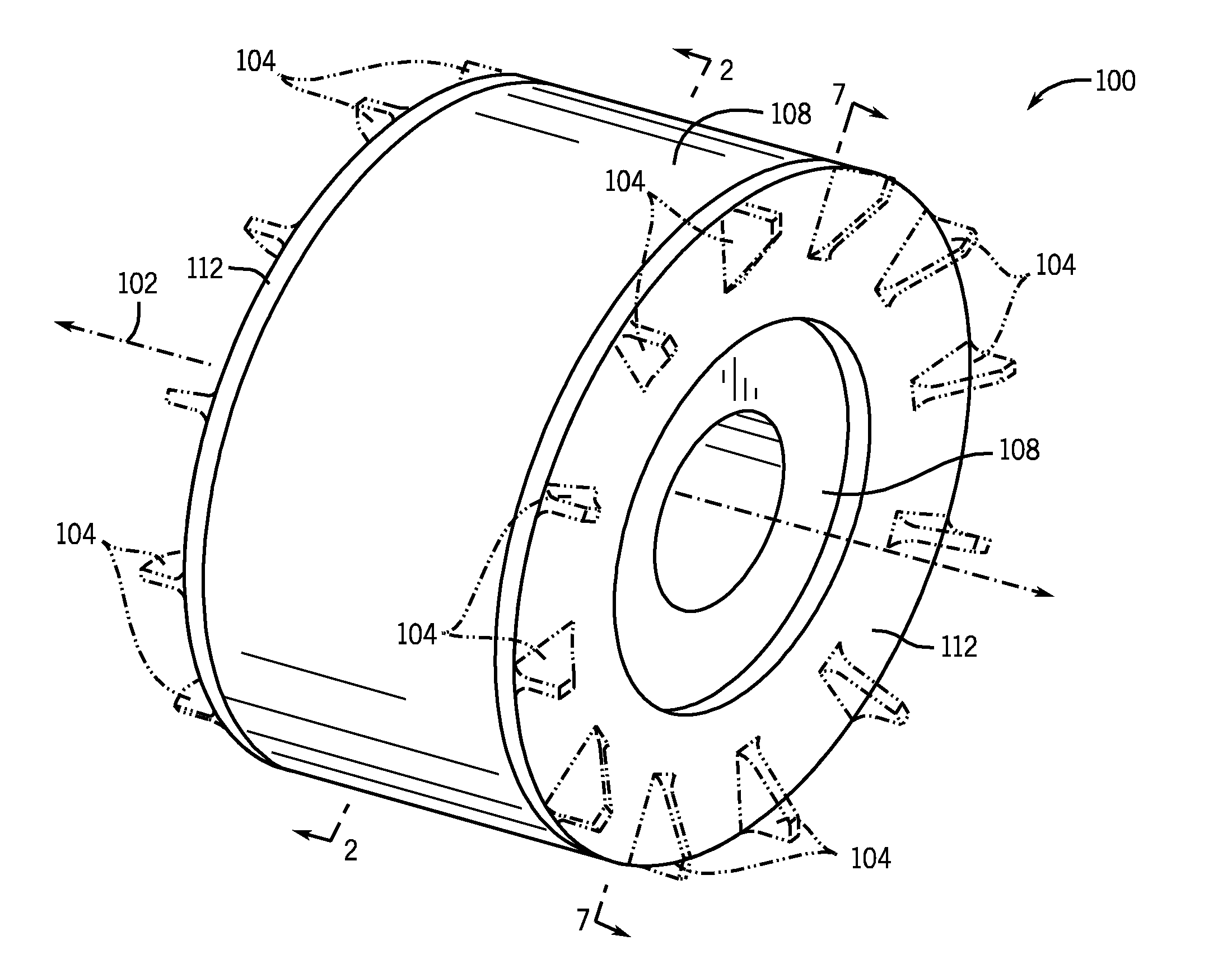

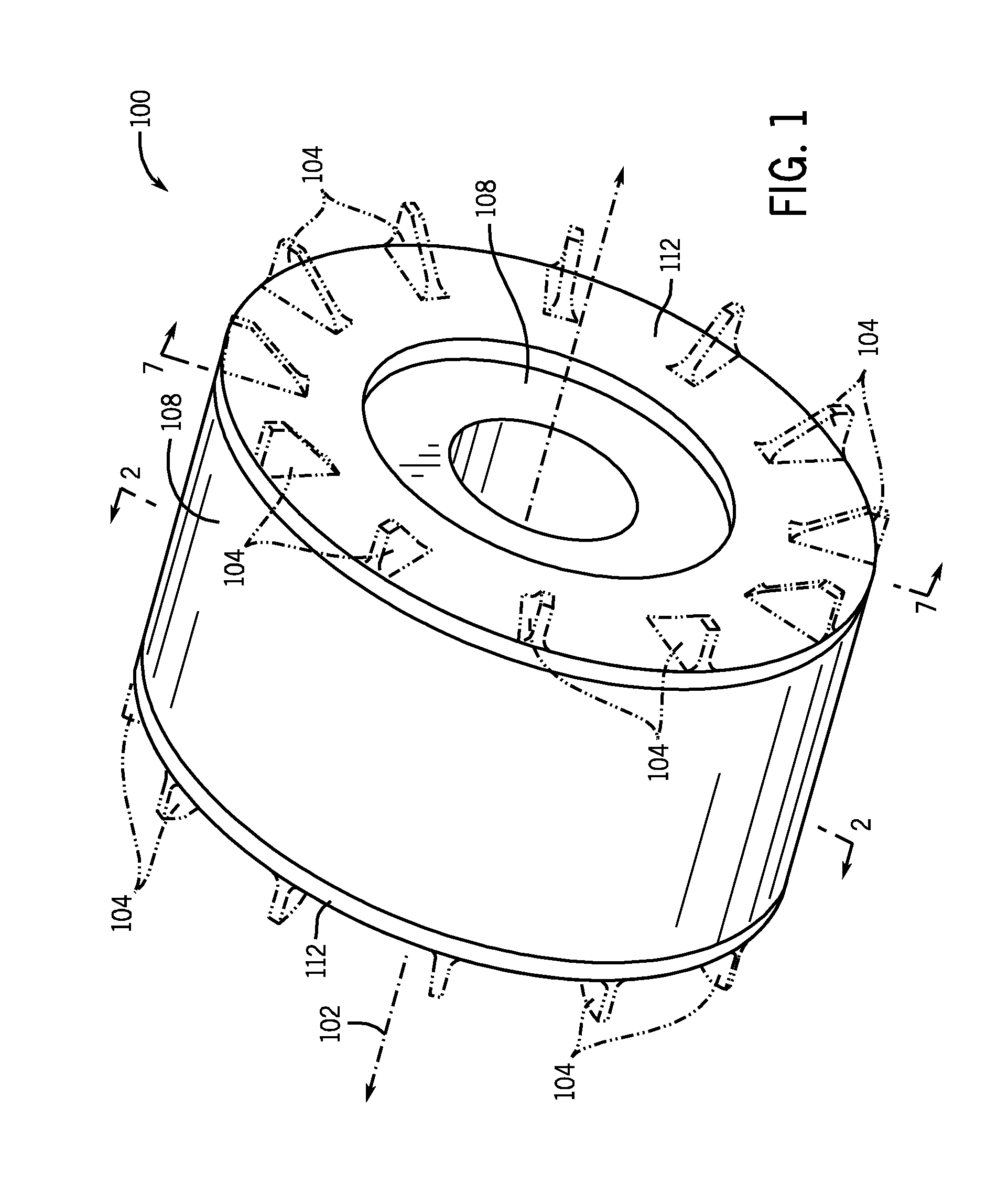

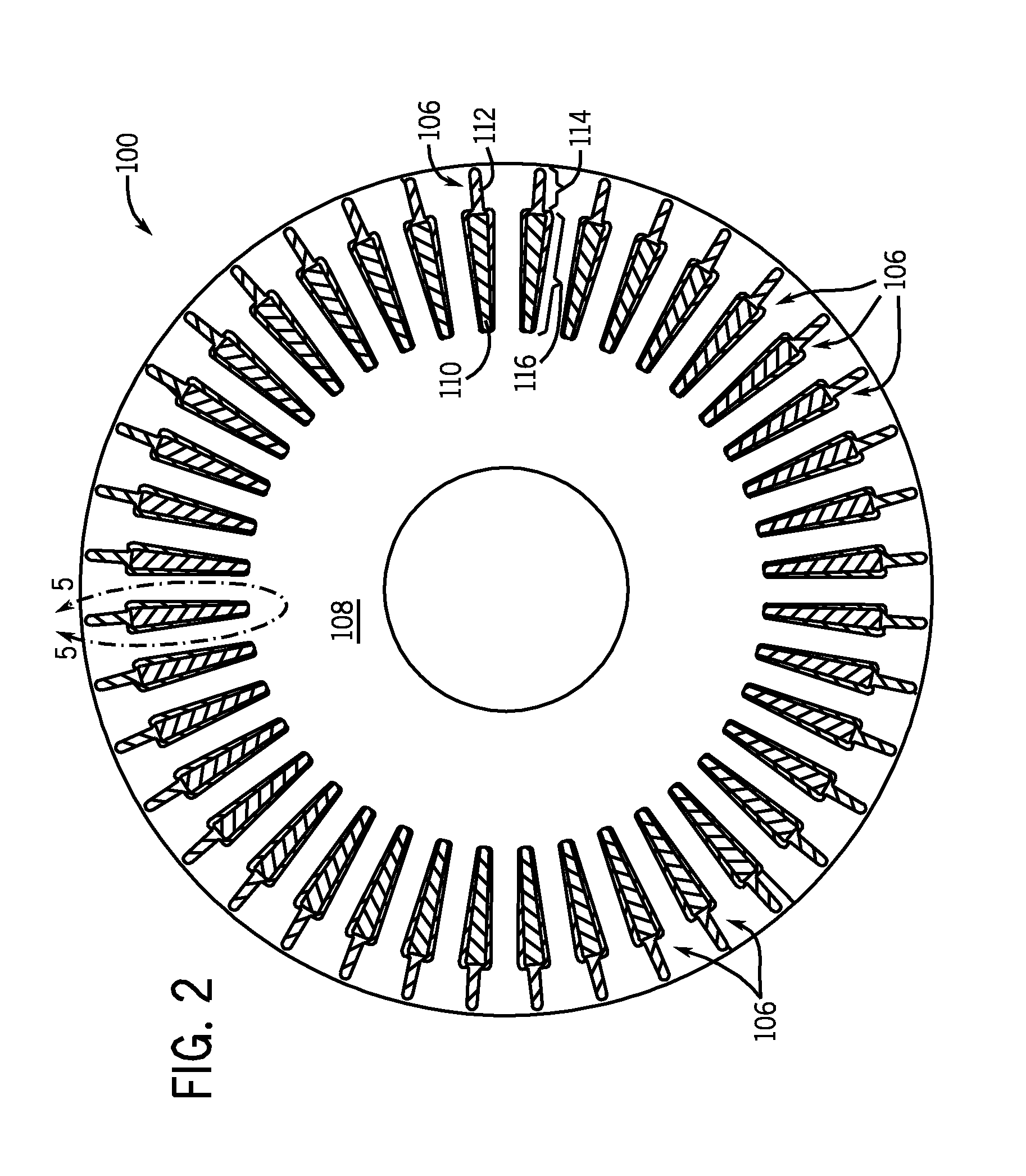

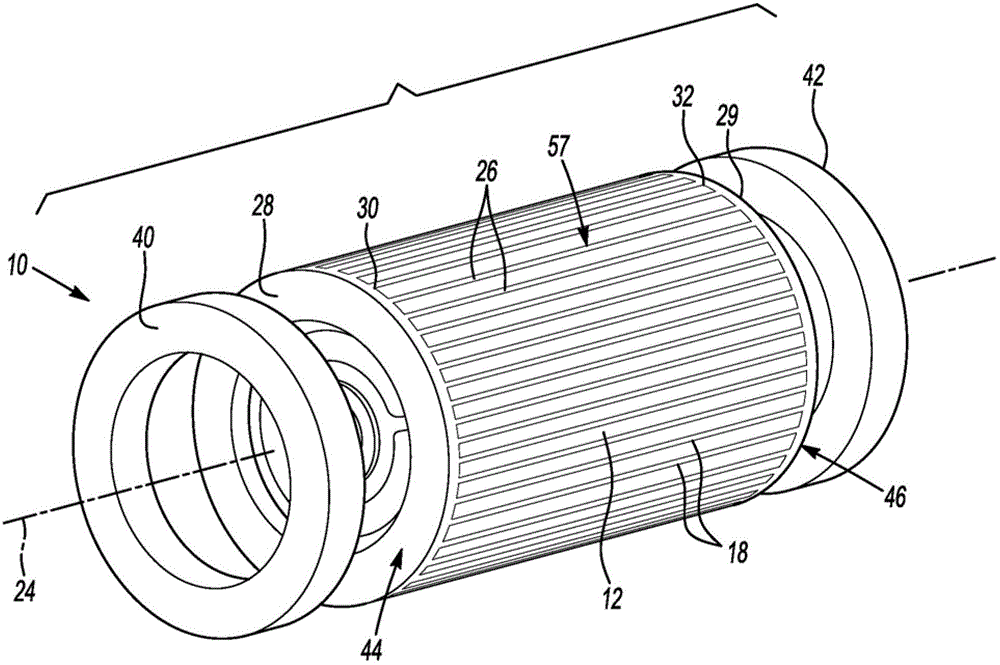

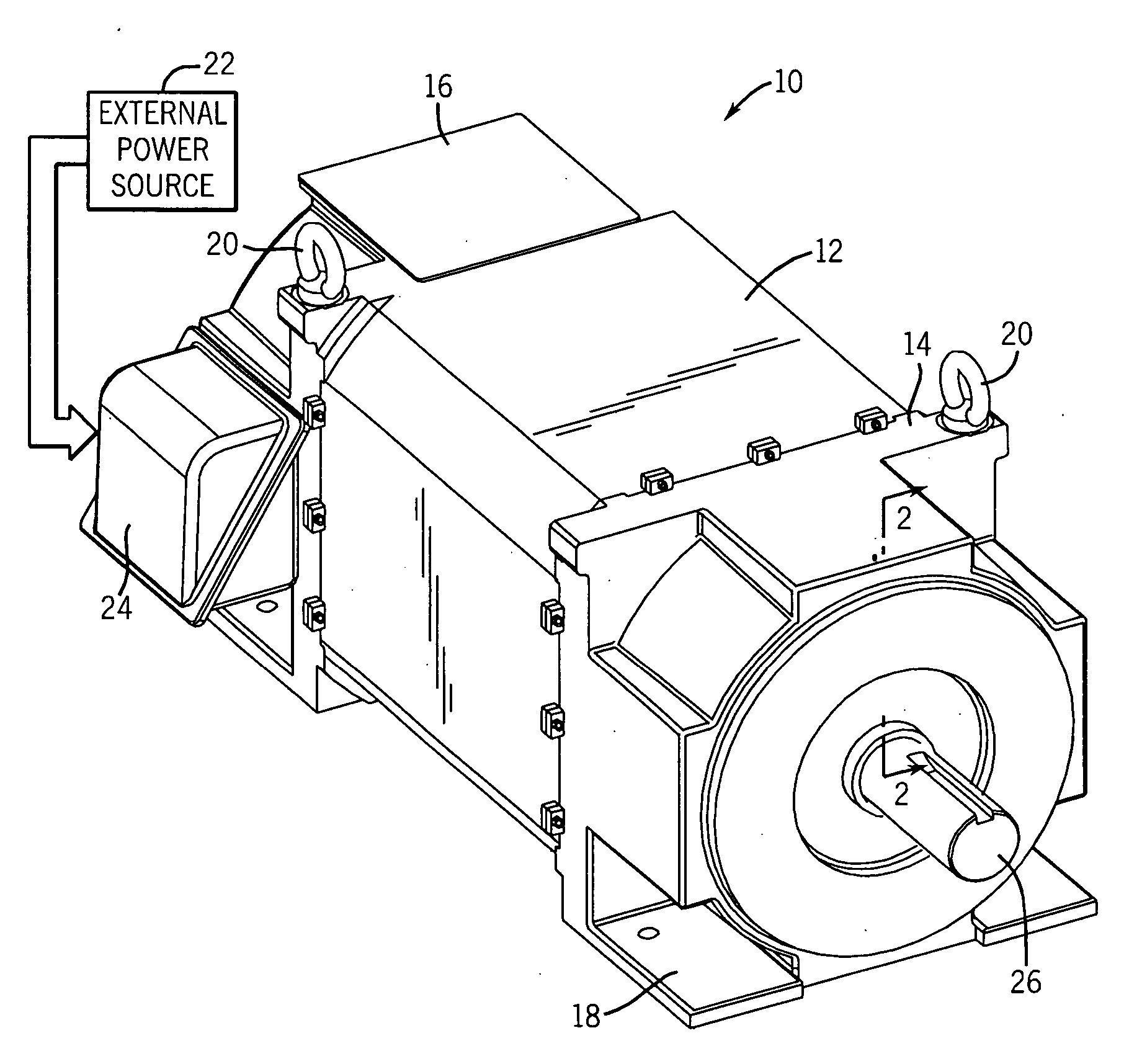

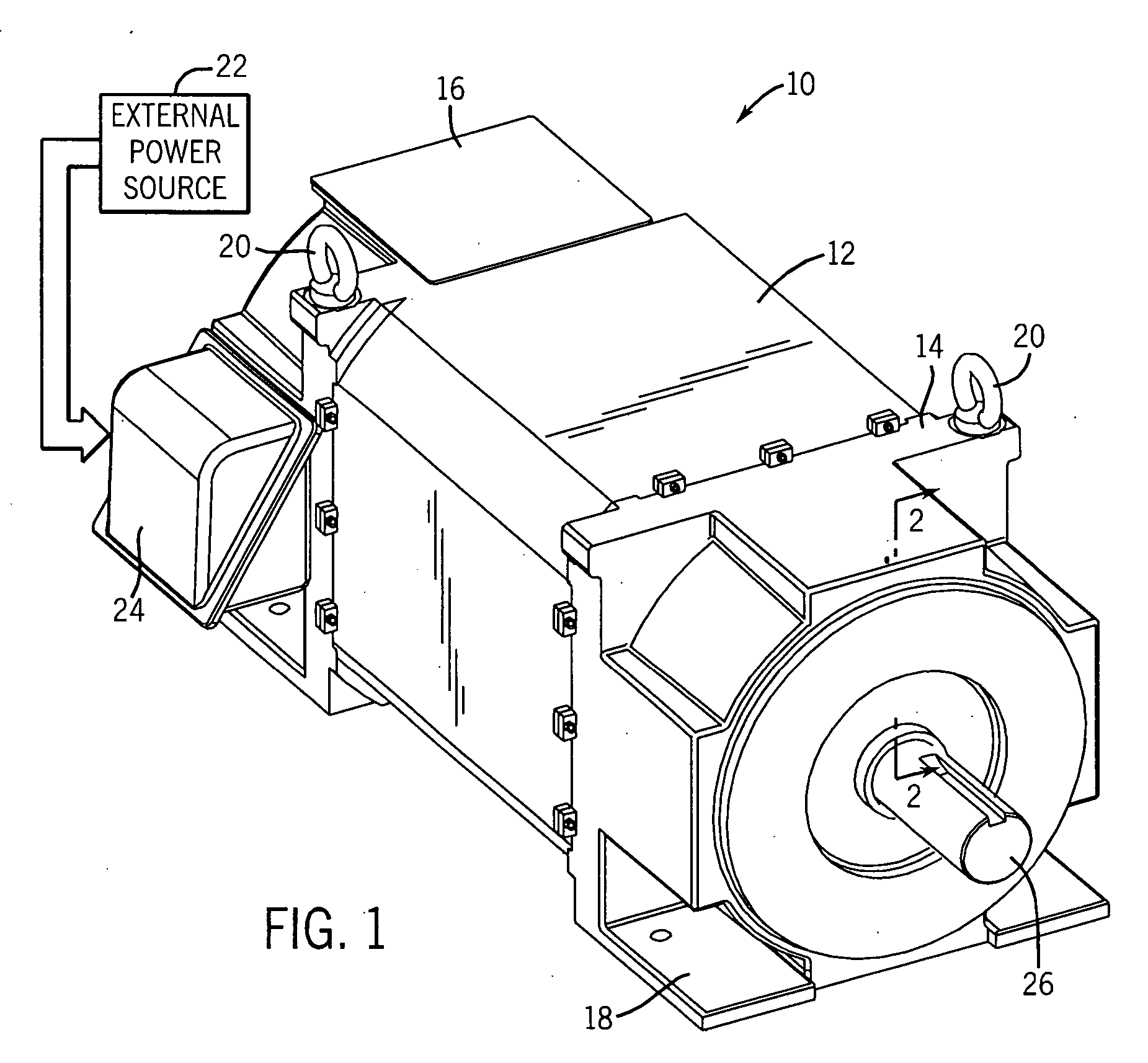

Method of fabricating a rotor assembly for an electric motor

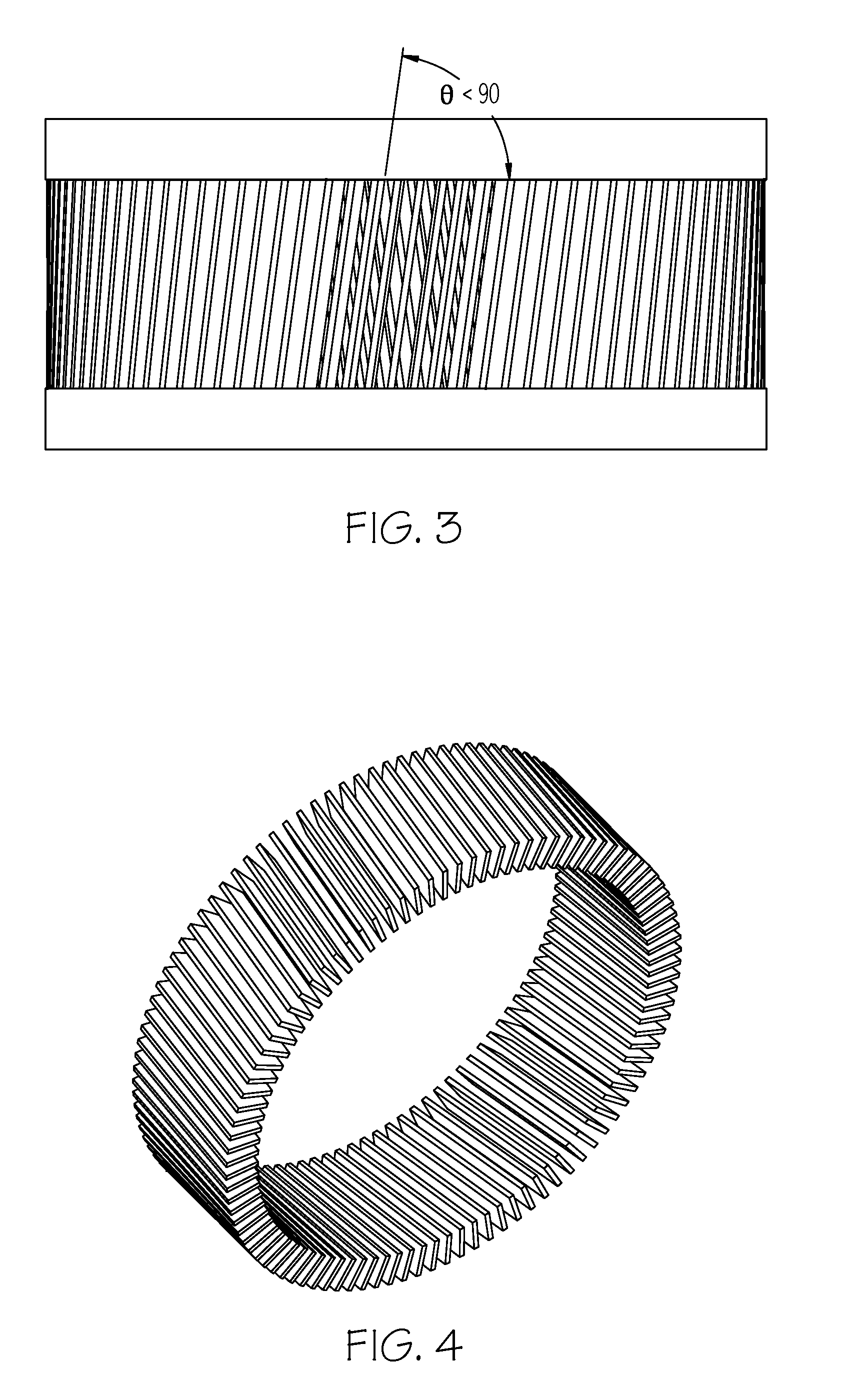

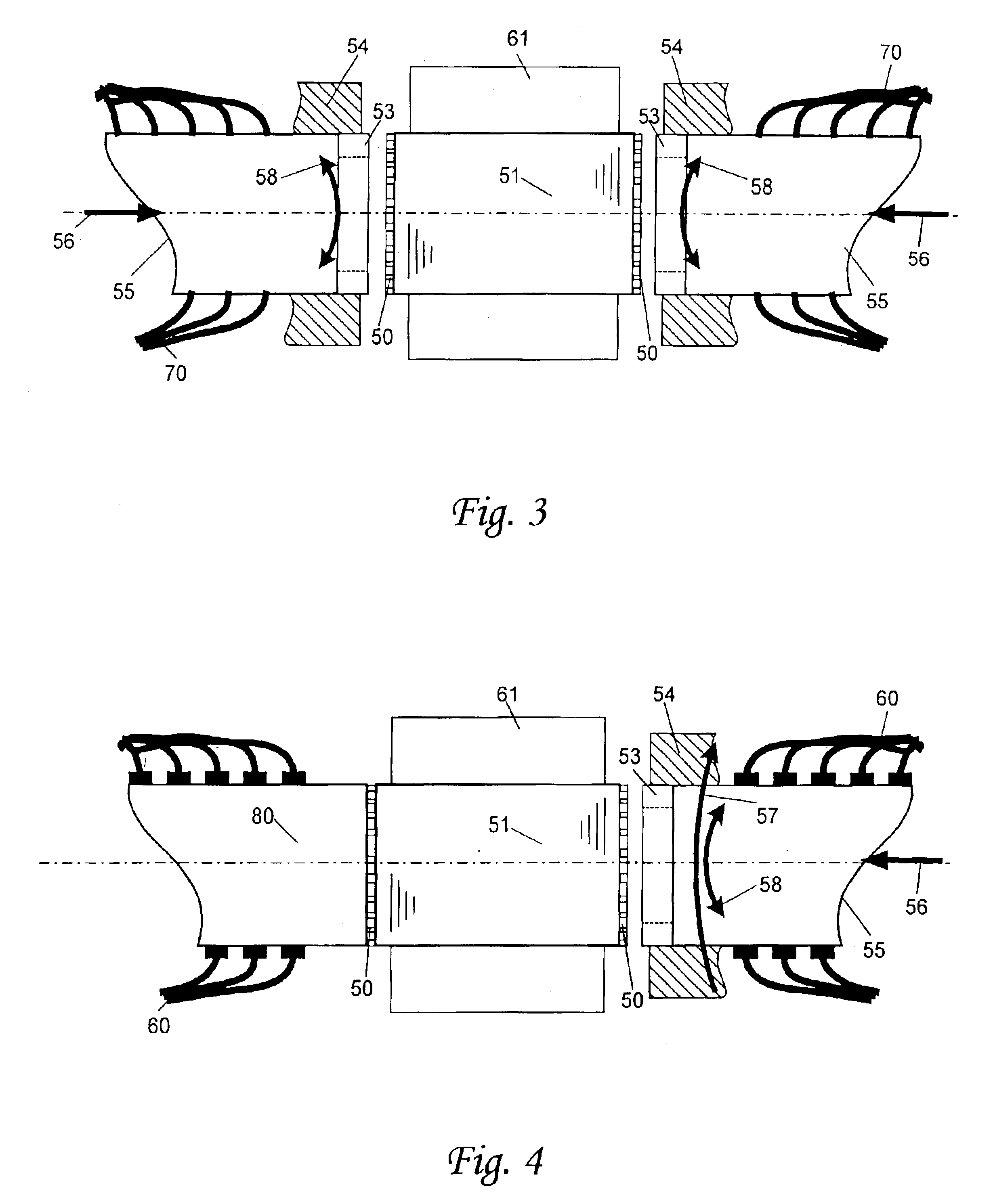

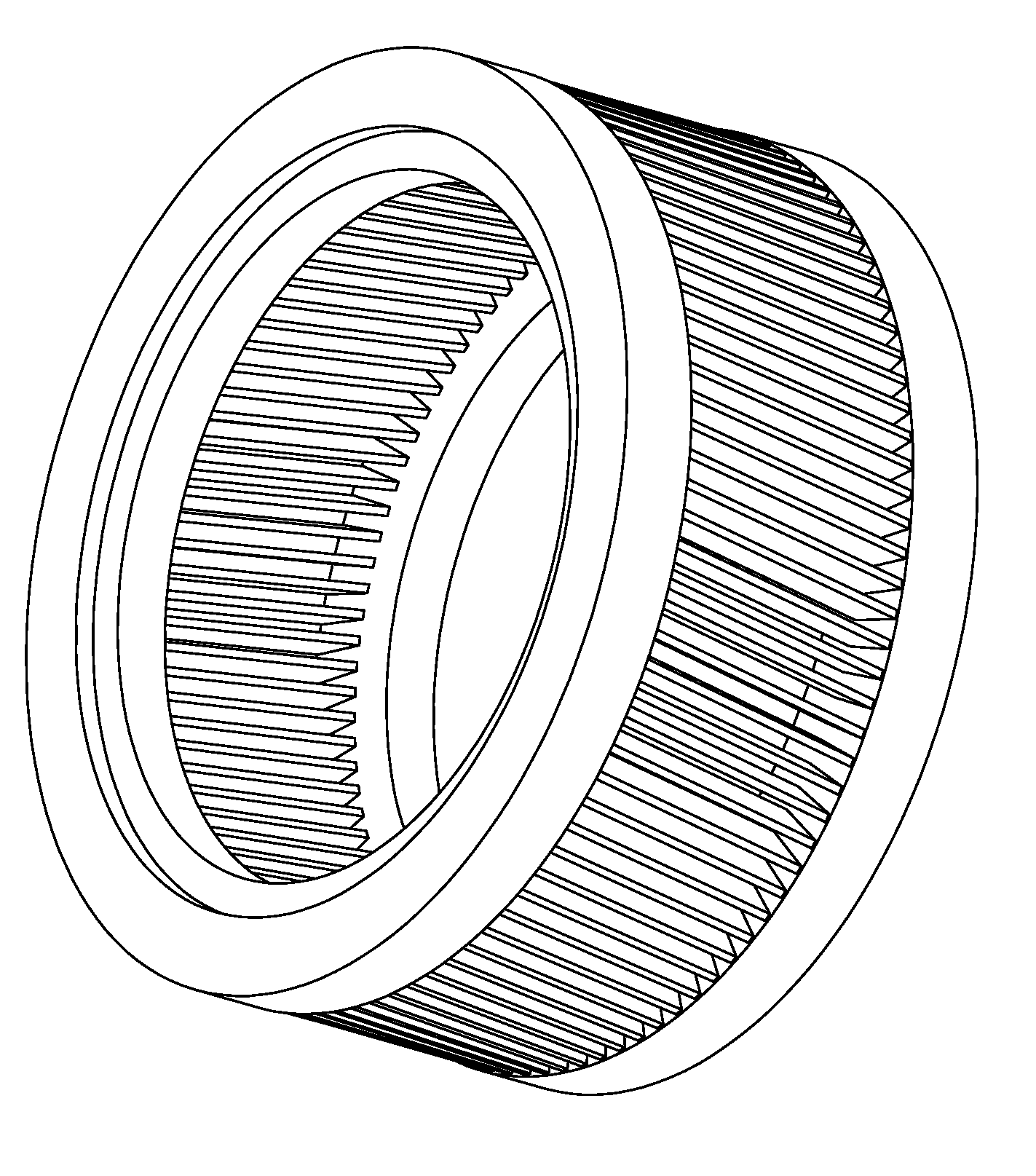

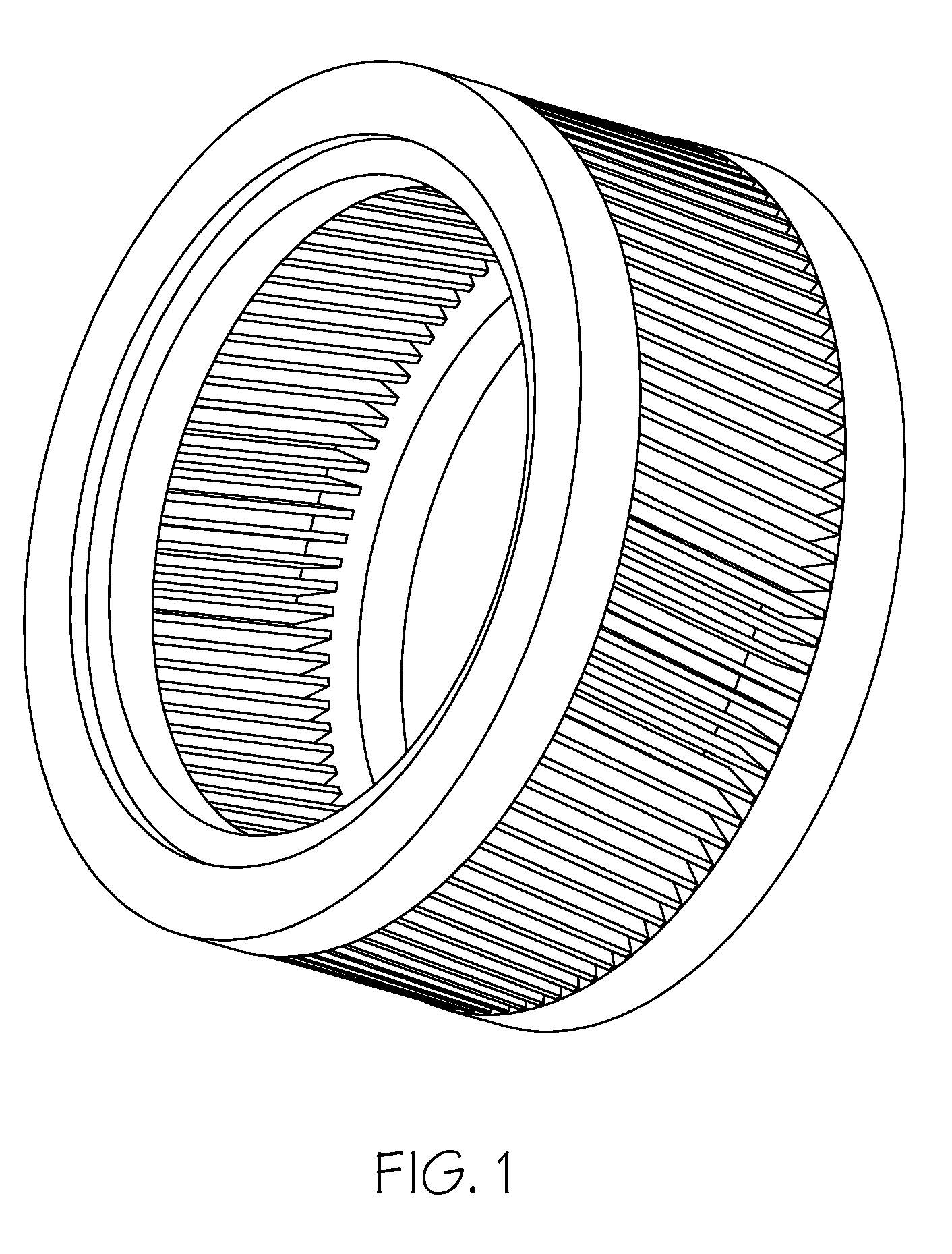

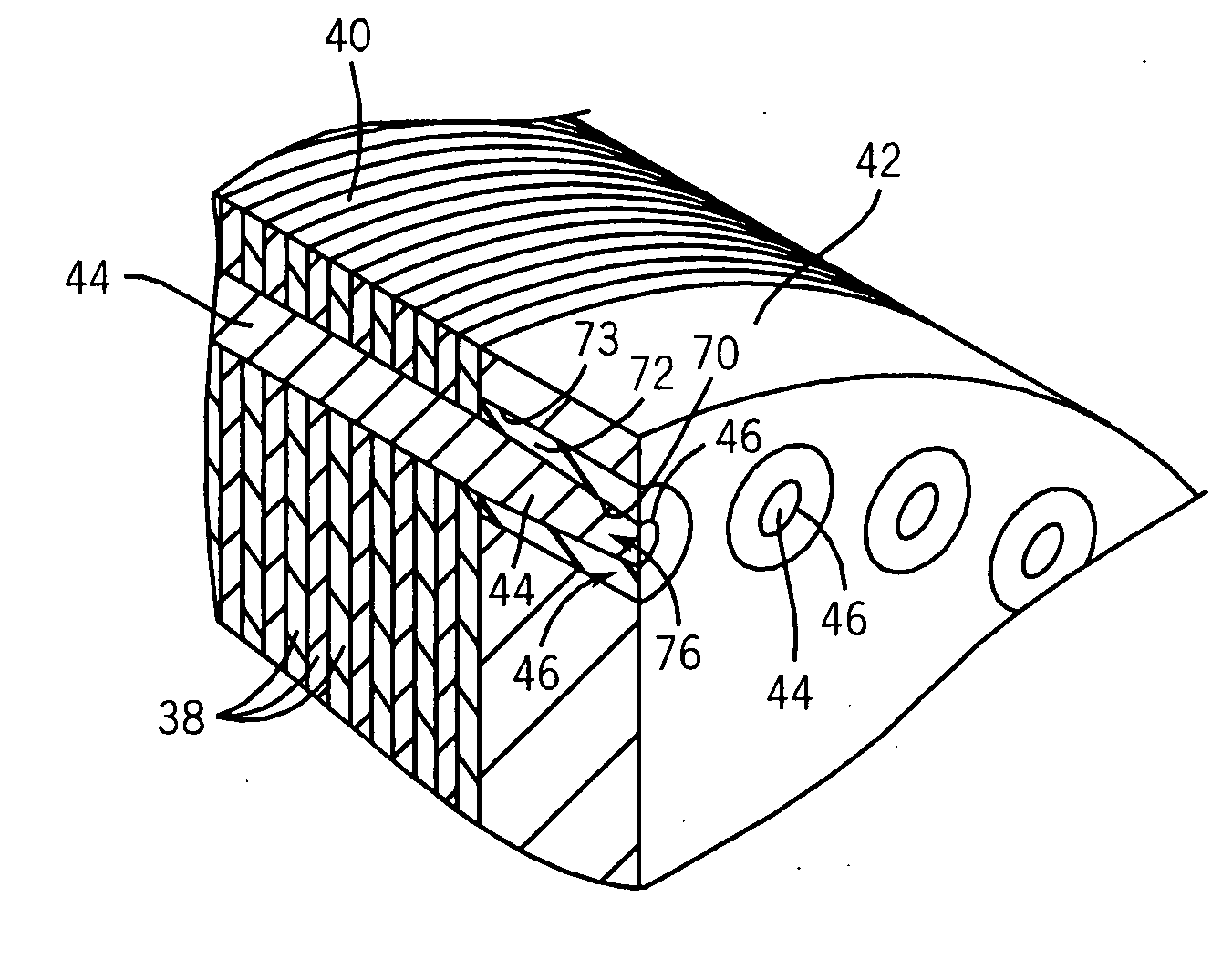

ActiveUS8365392B2Improve featuresReduce weightAsynchronous induction motorsManufacturing cage rotorsElectric motorJoint contact

A rotor assembly and a method for fabricating the same are provided in which a solid rotor ring is formed at either end of a stack of laminated discs, the solid rotor rings yielding improved electrical and mechanical characteristics in a low weight assembly. The solid rotor rings are fabricated by brazing slugs between the end portions of the rotor bars, the braze joints contacting a large percentage (at least 90 %) of the rotor bar end portions.

Owner:TESLA INC

Method for manufacturing squirrel cage rotor

InactiveUS7337526B2Reduced rotor lossesAvoid loopsSynchronous motorsFoundry mouldsElectrical conductorAdhesive

Ceramic adhesive is applied inside the slots of an electric machine squirrel cage rotor prior to casting or insertion of rotor conductors. This heat-resistant insulation provides superior electrical insulation that is also mechanically rugged, thus enabling casting of squirrel cage rotors by die or cost-effective consumable pattern casting. The consumable pattern cast copper rotors are electrically well insulated, thus minimizing rotor losses. The ceramic insulation in cast rotors enables longer conductors to be cast by thermally insulating the molten metal from the cooler laminations. The ceramic insulation in fabricated rotors withstands the high temperatures of end ring attachment. This method is applicable to both conventional induction machine rotors and brushless doubly-fed induction machine rotors and provides the degree of electrical isolation of the bars from the laminations needed to avoid excessive parasitic torques in doubly-fed machines, while ensuring adequate thermal conductivity to dissipate conductive bar heat to the laminations.

Owner:DUAL STATOR TECH INC

Rotor of a synchronous induction electric motor

InactiveUS7102259B2Increased reluctanceLow efficiencyMagnetic circuit rotating partsPositive displacement pump componentsRotational axisInduction motor

A rotor of a synchronous induction electric motor according to the present invention includes a slot for generating induction torque and a slit for generating reluctance torque. The slot and the slit are filled up with aluminum which is short-circuited by an end-ring at each of both ends of the rotor, and the slit includes a non-filling part penetrating in the direction of the rotational axis and not filled up with the aluminum.

Owner:MITSUBISHI ELECTRIC CORP

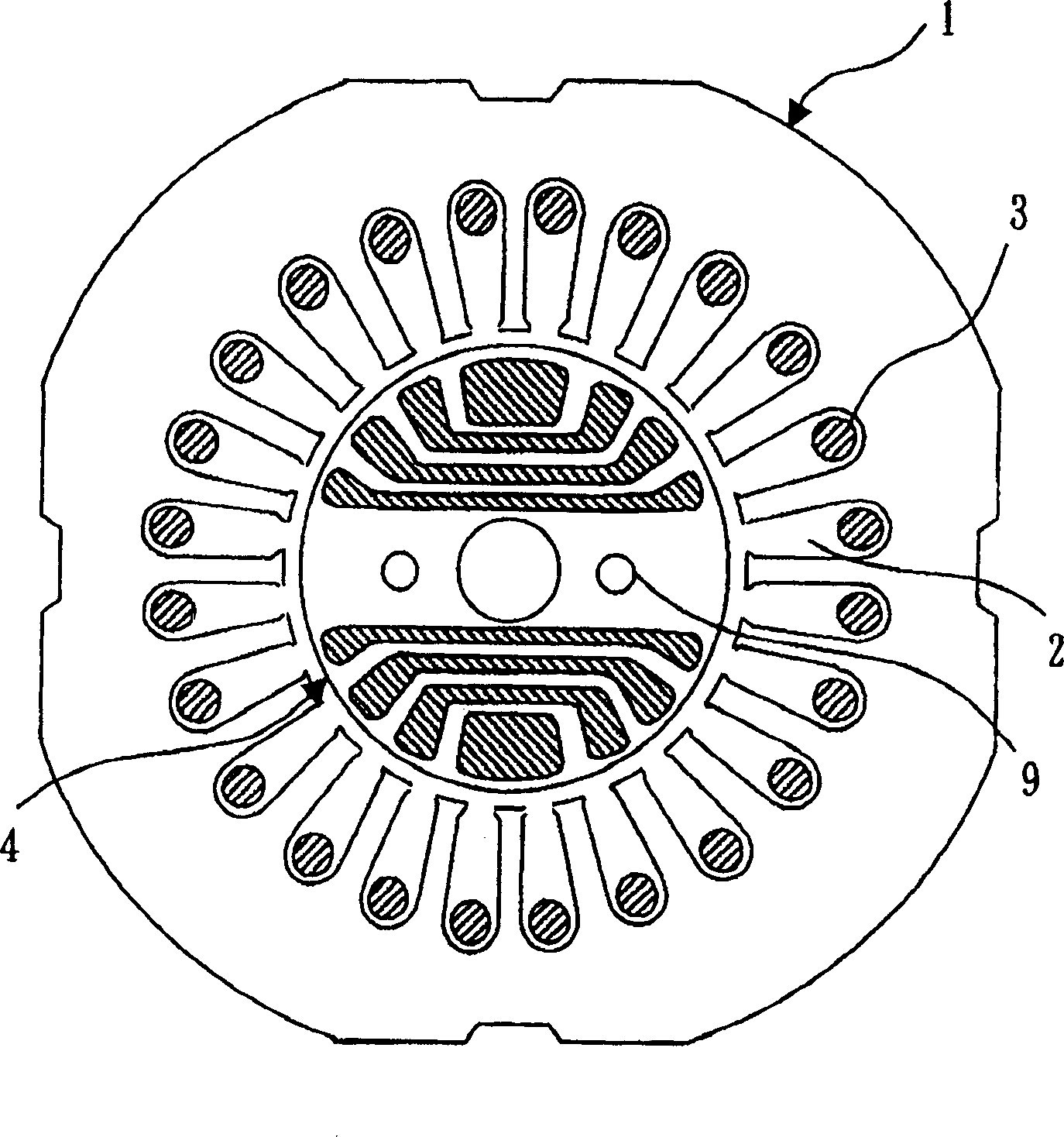

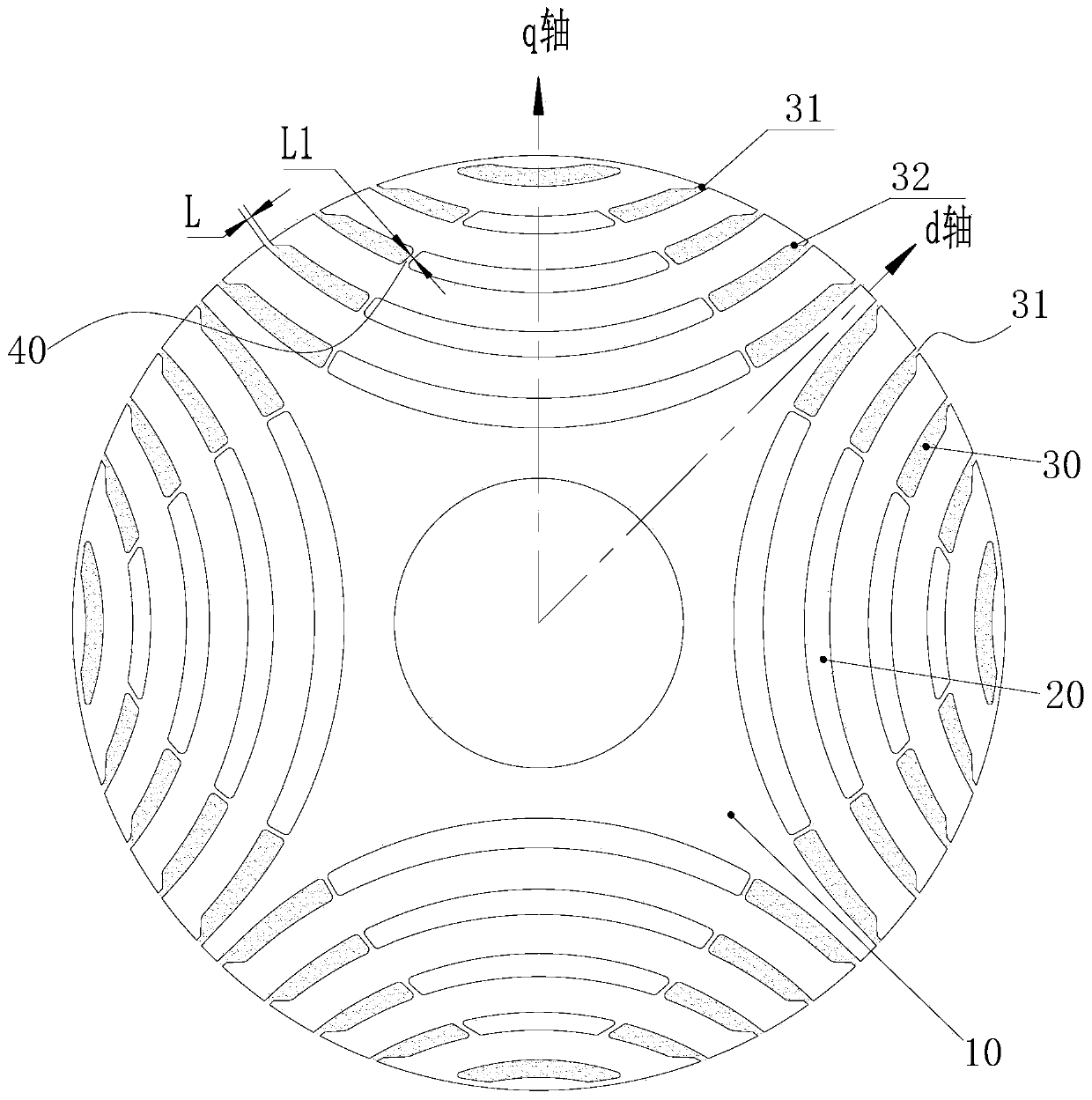

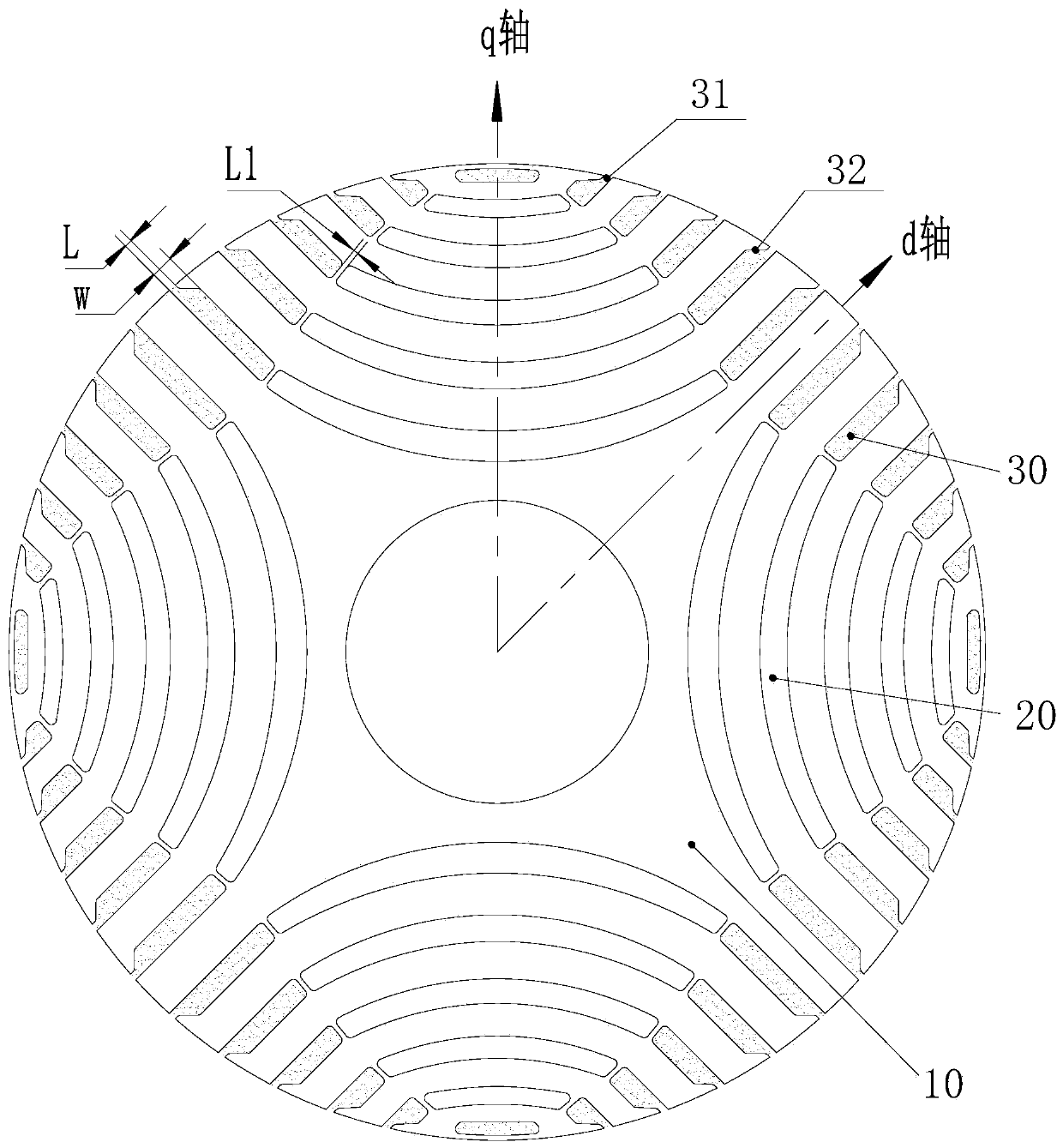

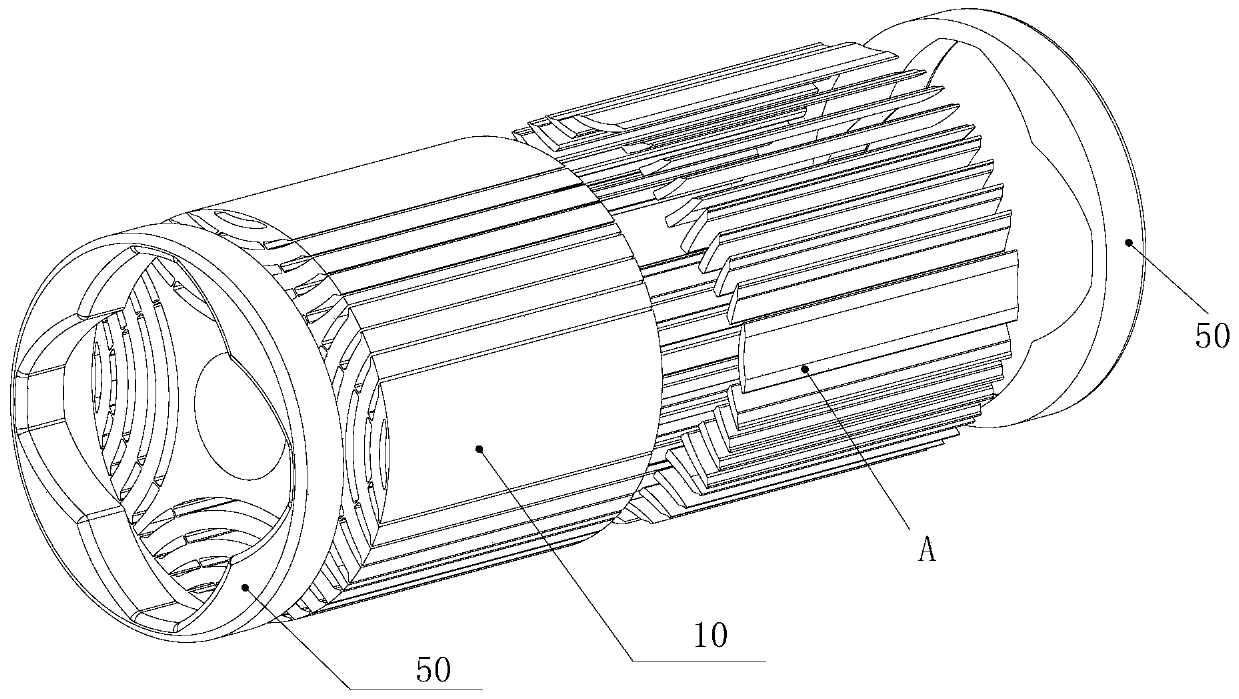

Synchronous reluctance motor rotor structure, motor and manufacturing method of rotor structure

ActiveCN110138117AReduced torque rippleReduce vibration and noiseMagnetic circuit rotating partsSynchronous motorsMagnetic barrierSynchronous reluctance motor

The invention provides a synchronous reluctance motor rotor structure, a motor and a manufacturing method of the rotor structure. The synchronous reluctance motor rotor structure comprises a rotor core which is provided with multiple slit slots, two ends of each of the slit slots are provided with two filling grooves to form a magnetic barrier layer, a first end of each of the filling grooves is adjacent to a slit slot, a second end of each of the filling grooves extends in the radial direction of the rotor core, and the outer peripheral surface of the rotor core is provided with a notch communicating with an end of the second end each of the filling grooves. By setting notches and bevels at the ends of the filling grooves, the reluctance torque of the motor can be increased, the torque ripples generated by a rotor and a stator tooth space can be weakened by each other, the purpose of reducing the torque ripple of the motor is achieved, the vibration noise of the motor is reduced, theefficiency of the motor with the rotor structure is improved, and the starting ability of the motor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

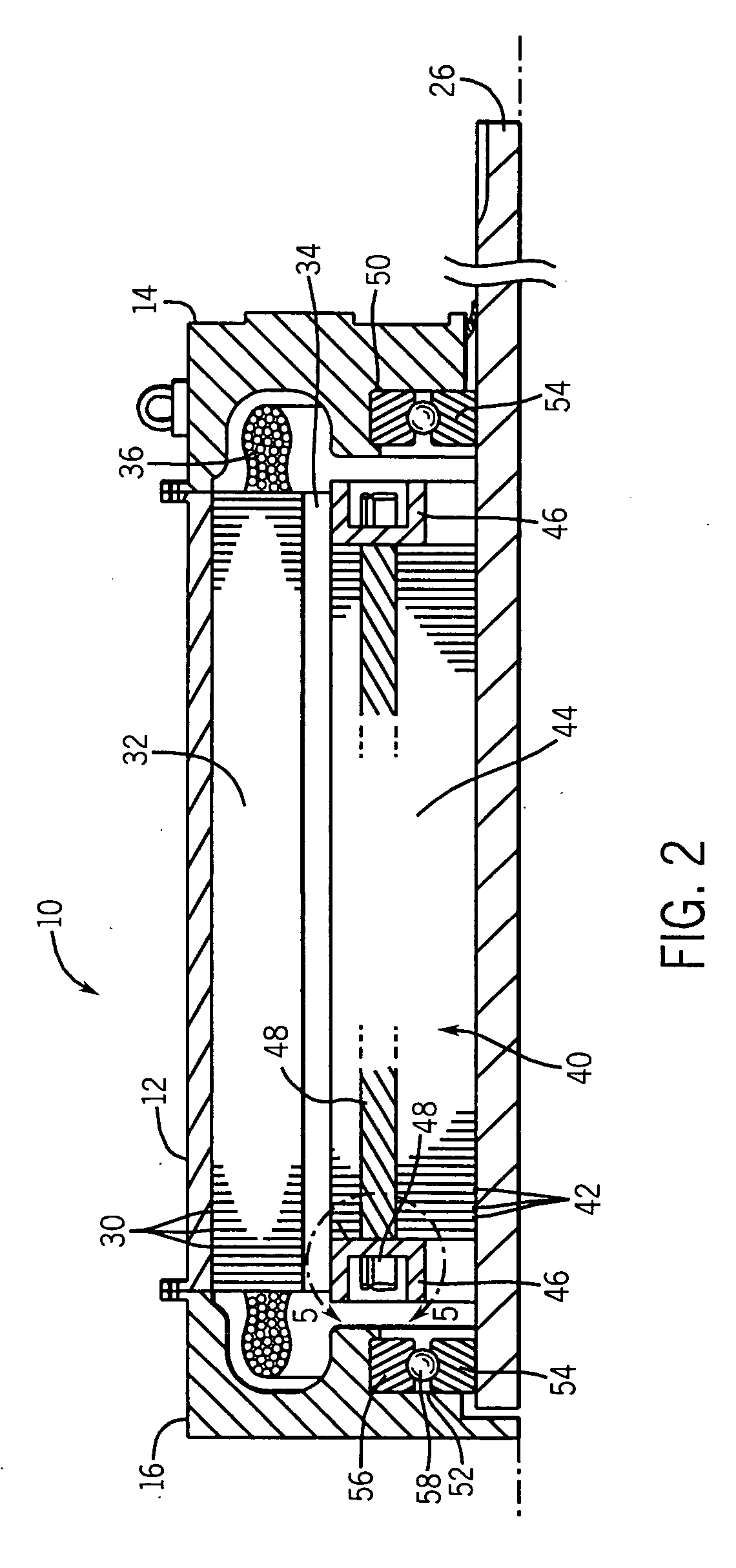

Induction rotor assembly and method of manufacturing same

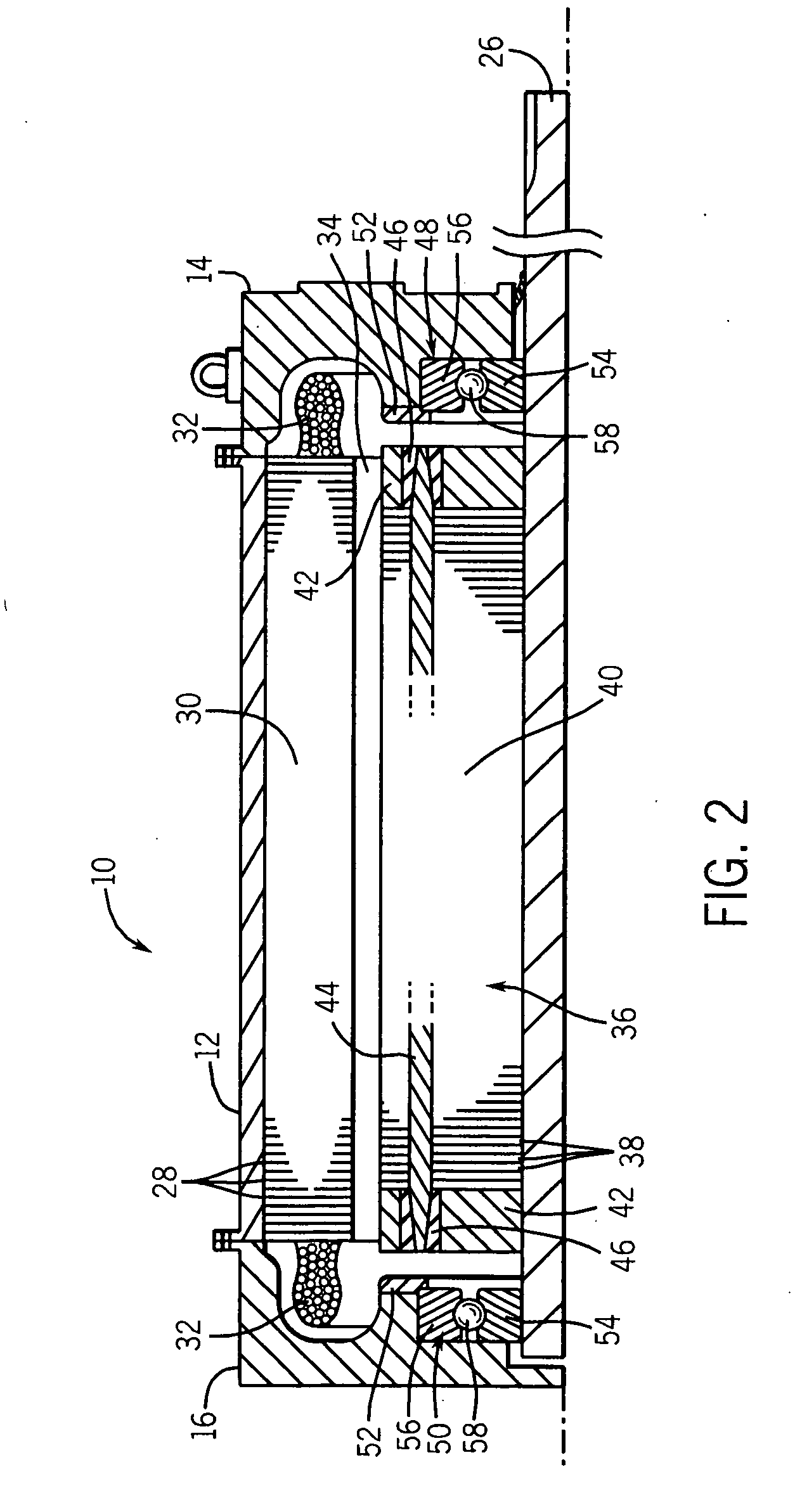

ActiveCN102801259AMagnetic circuit rotating partsAsynchronous induction motorsElectrical conductorEngineering

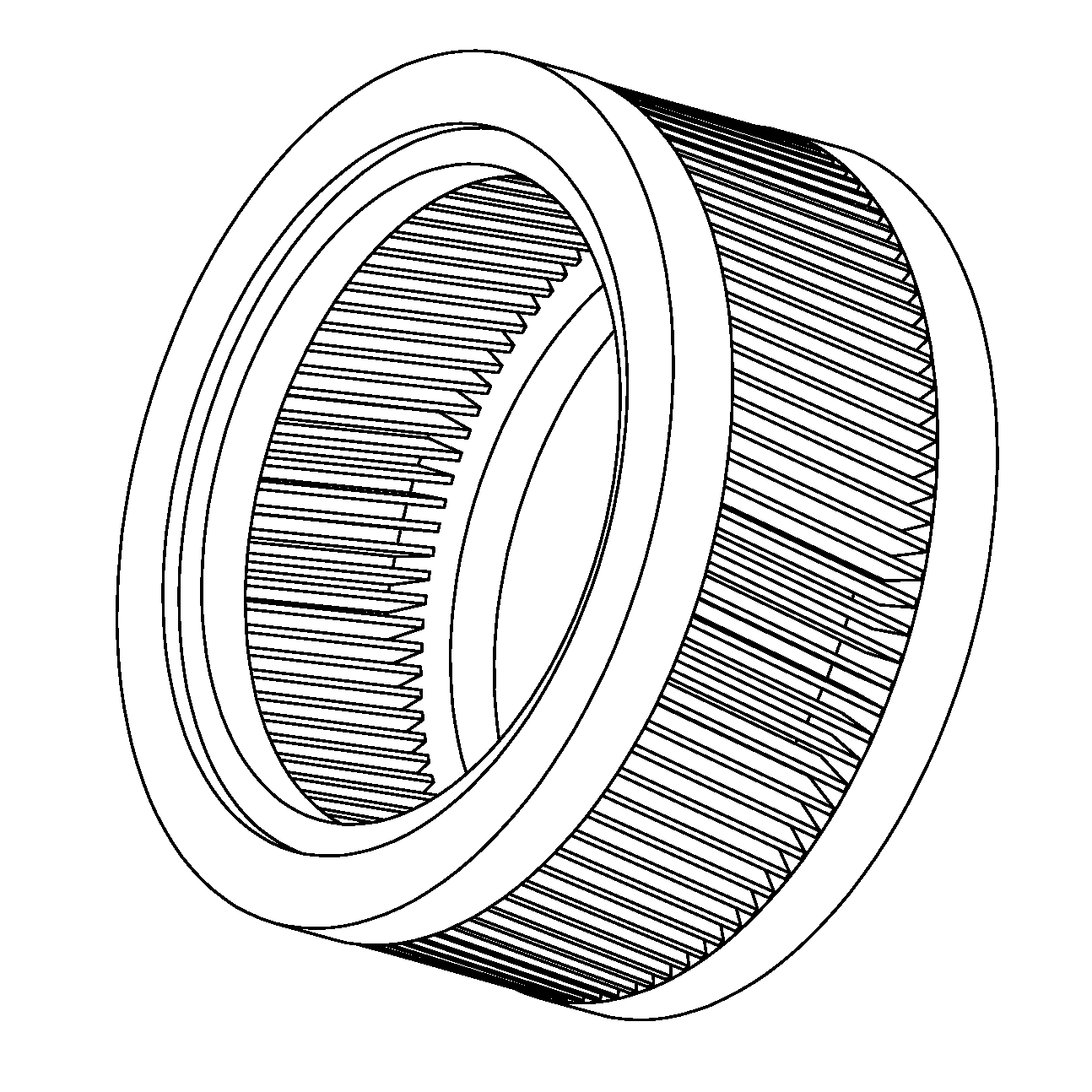

A method of manufacturing a rotor assembly includes placing a generally cylindrical rotor core in a die. The rotor core has axial grooves spaced about a perimeter of the rotor core. The grooves may be formed by stacked laminated disks. Material is cast around the annular rotor core in the die such that the cast material forms conductor bars that fill the grooves and first end ring portions at opposing ends of the rotor core connected with the conductor bars. Each of the first end ring portions has substantially a first axial width. The rotor core with cast conductor bars and cast first end ring portions is then removed from the die. A respective second end ring portion is welded to each of the cast first end ring portions to form end ring assemblies. Each second end ring portion has a second axial width greater than the first axial width.

Owner:GM GLOBAL TECH OPERATIONS LLC

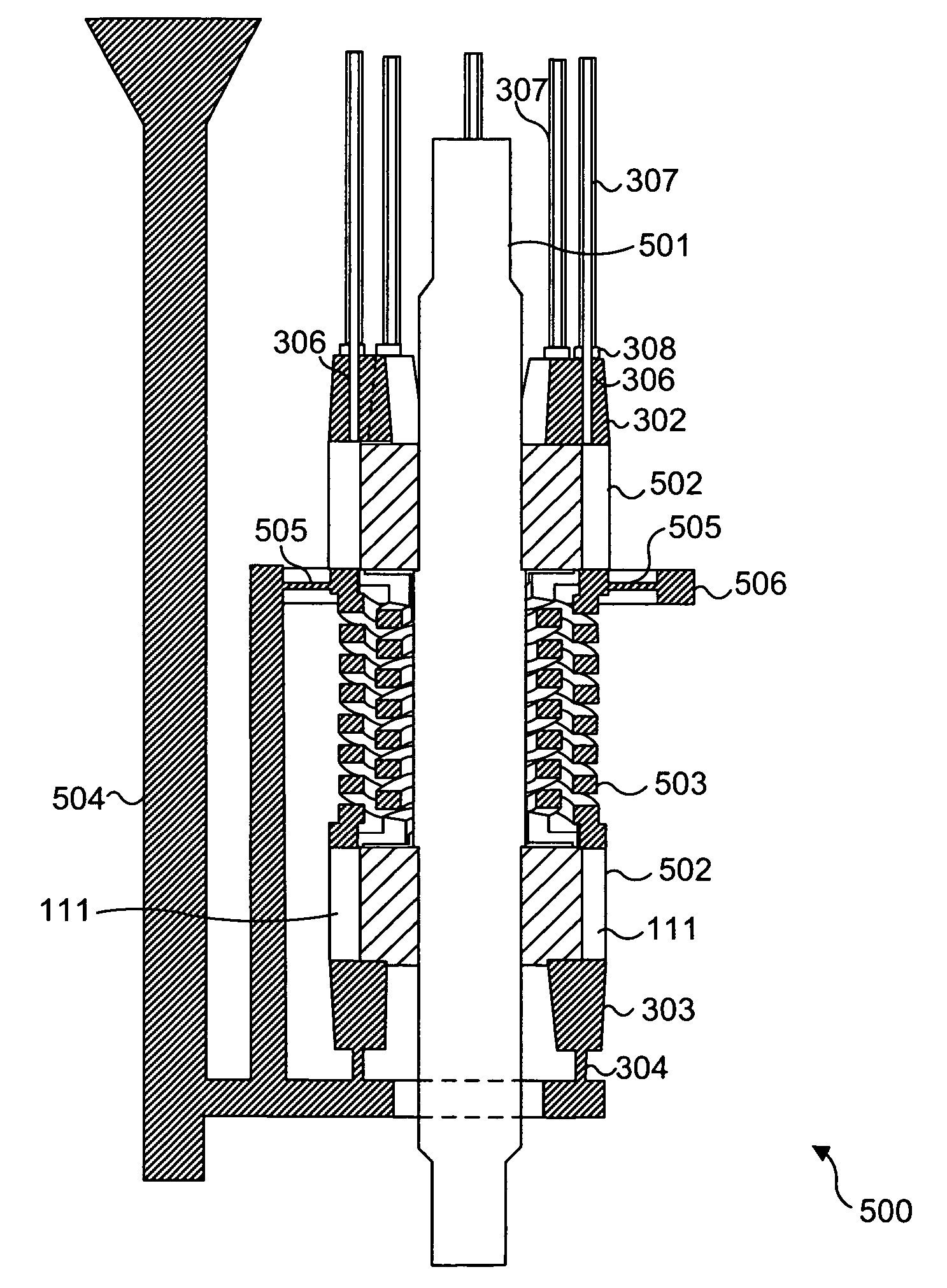

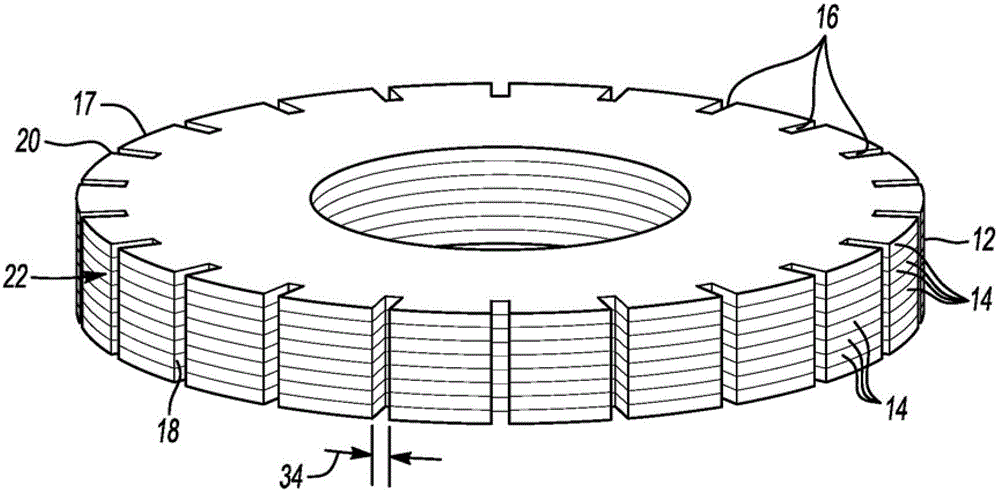

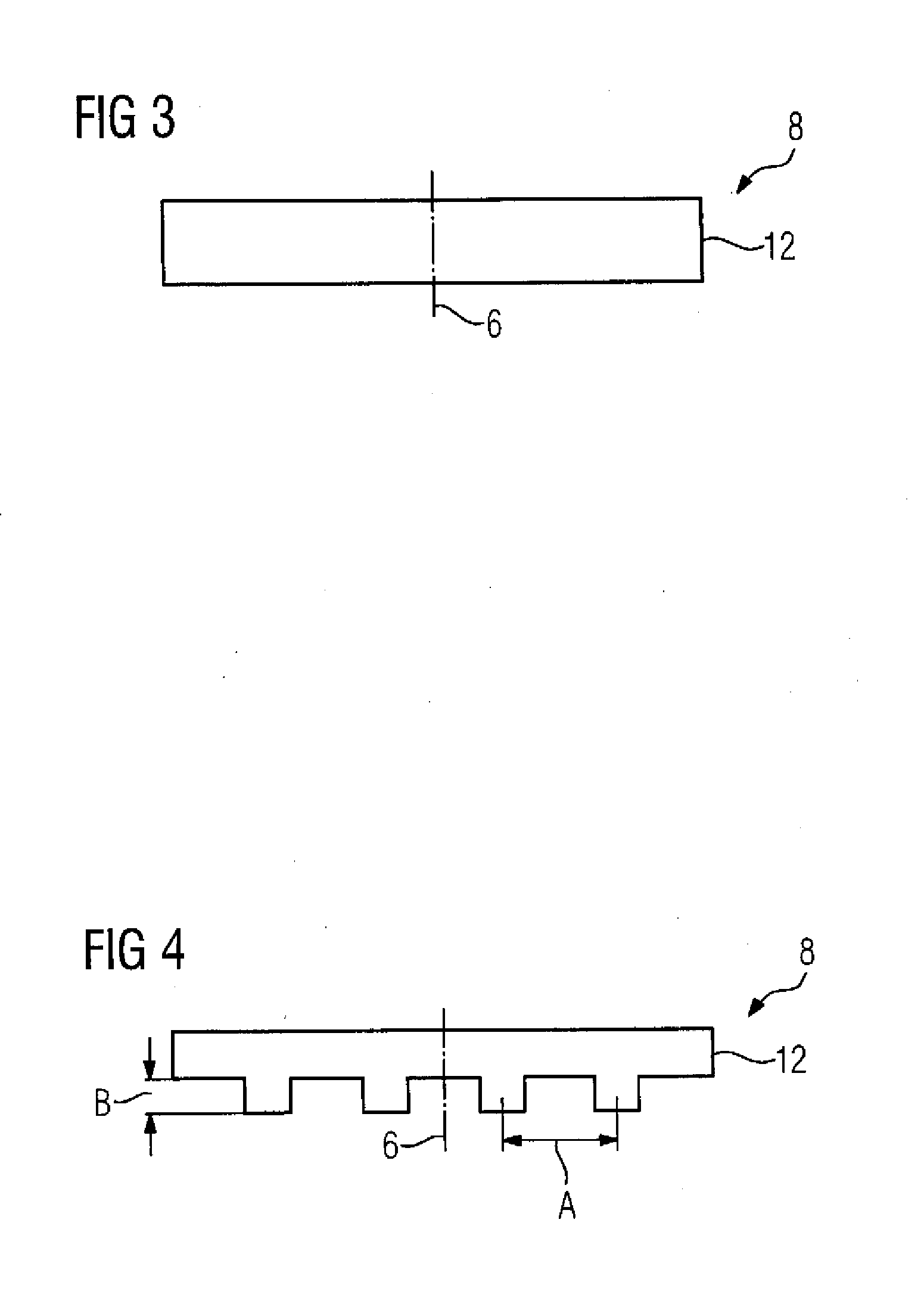

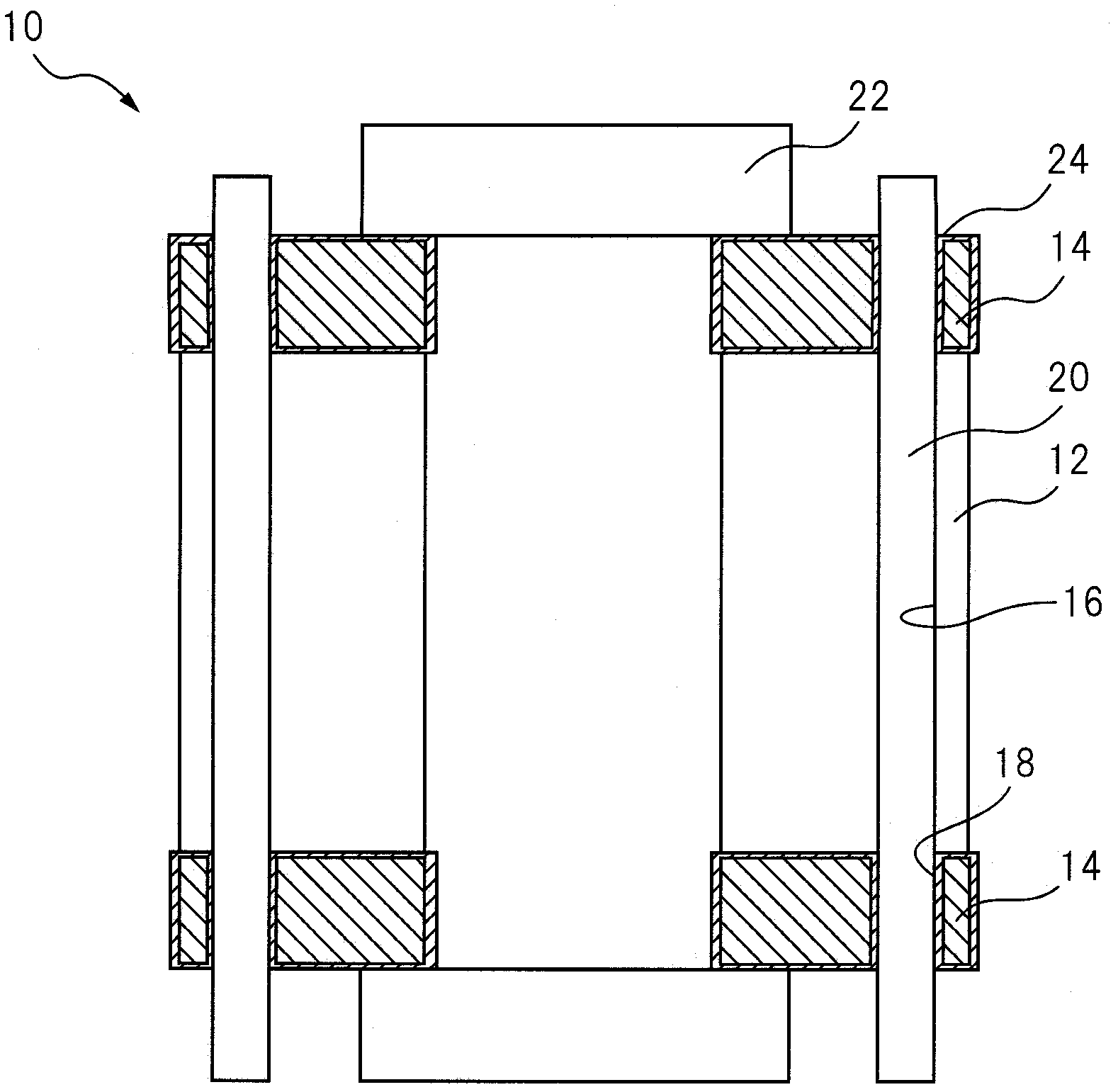

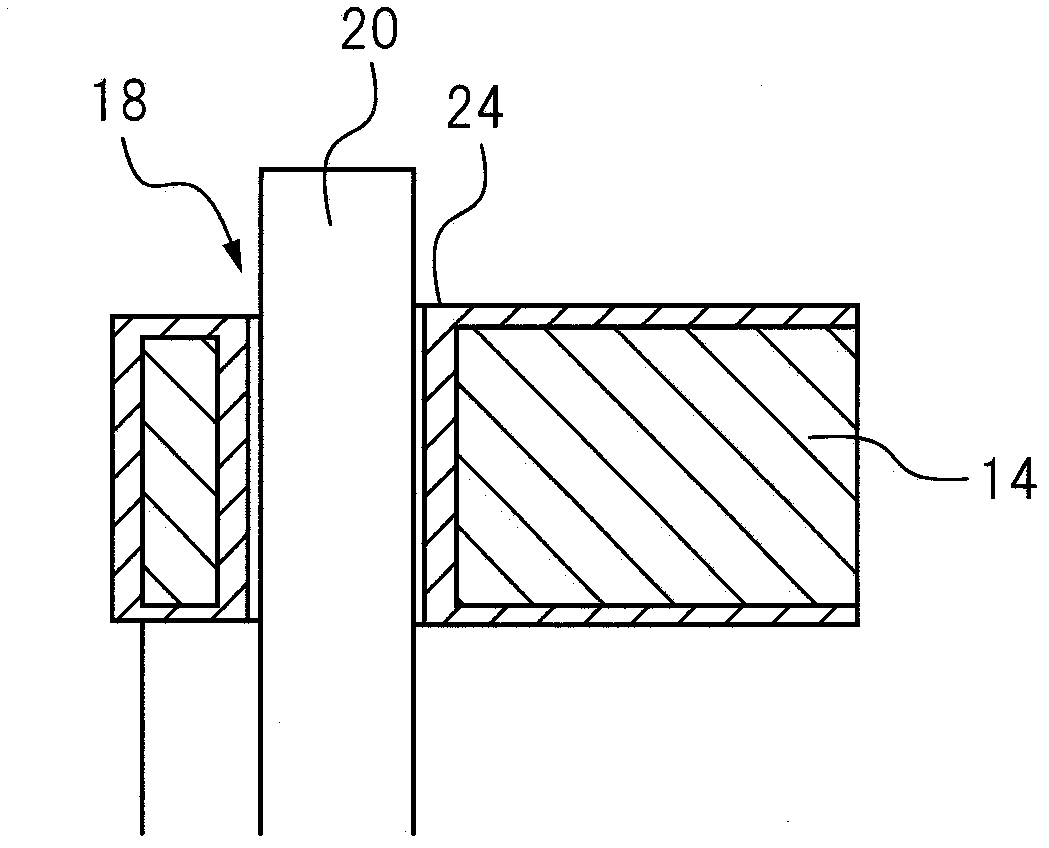

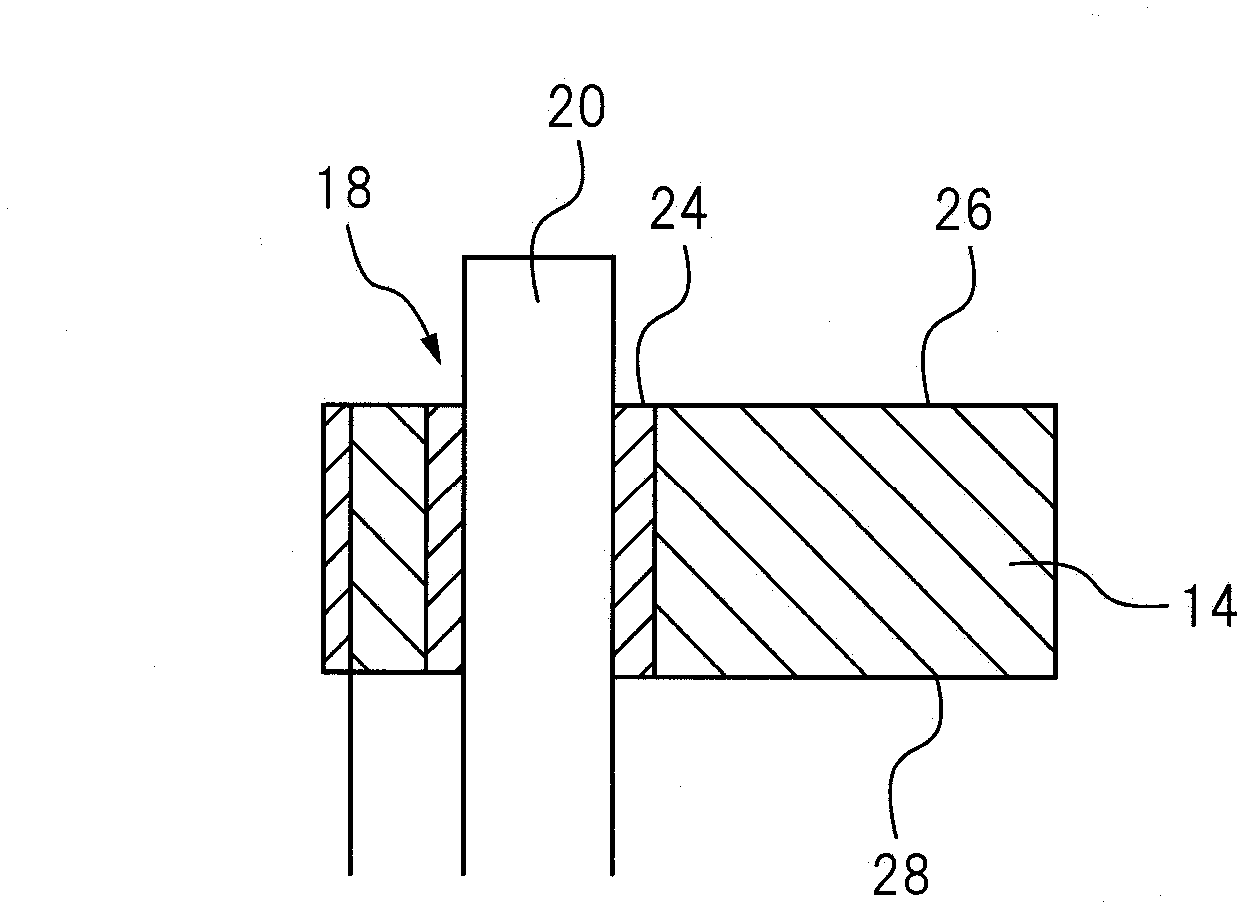

Fabricated rotor assembly fixture and method

InactiveUS20070062026A1Improving rotor performanceEasy constructionMagnetic circuit rotating partsSynchronous motorsMechanical engineeringPiston

In accordance with one embodiment, the present technique provides an apparatus for assembling a rotor. The exemplary apparatus includes a base that has a central aperture and a seating surface for receiving the rotor. An arbor then extends through the central aperture, the arbor having a longitudinal axis that is substantially orthogonal to the seating surface, and including threaded ends opposite with respect to one another. The exemplary apparatus also includes at least one member of a family of fixtures coupleable to the arbor, the family including a pressure fixture that has first and second piston assemblies disposed at diametrically opposite locations to one another, the family also including a support fixture coupleable the arbor and having members extending axially therefrom, the members being configured to support securing members of the rotor. Advantageously, the exemplary apparatus provides for a mechanism through which a securing member may be symmetrically installed with respect to the rotor core, thus improving rotor performance and construction.

Owner:RELIANCE ELECTRIC TECH

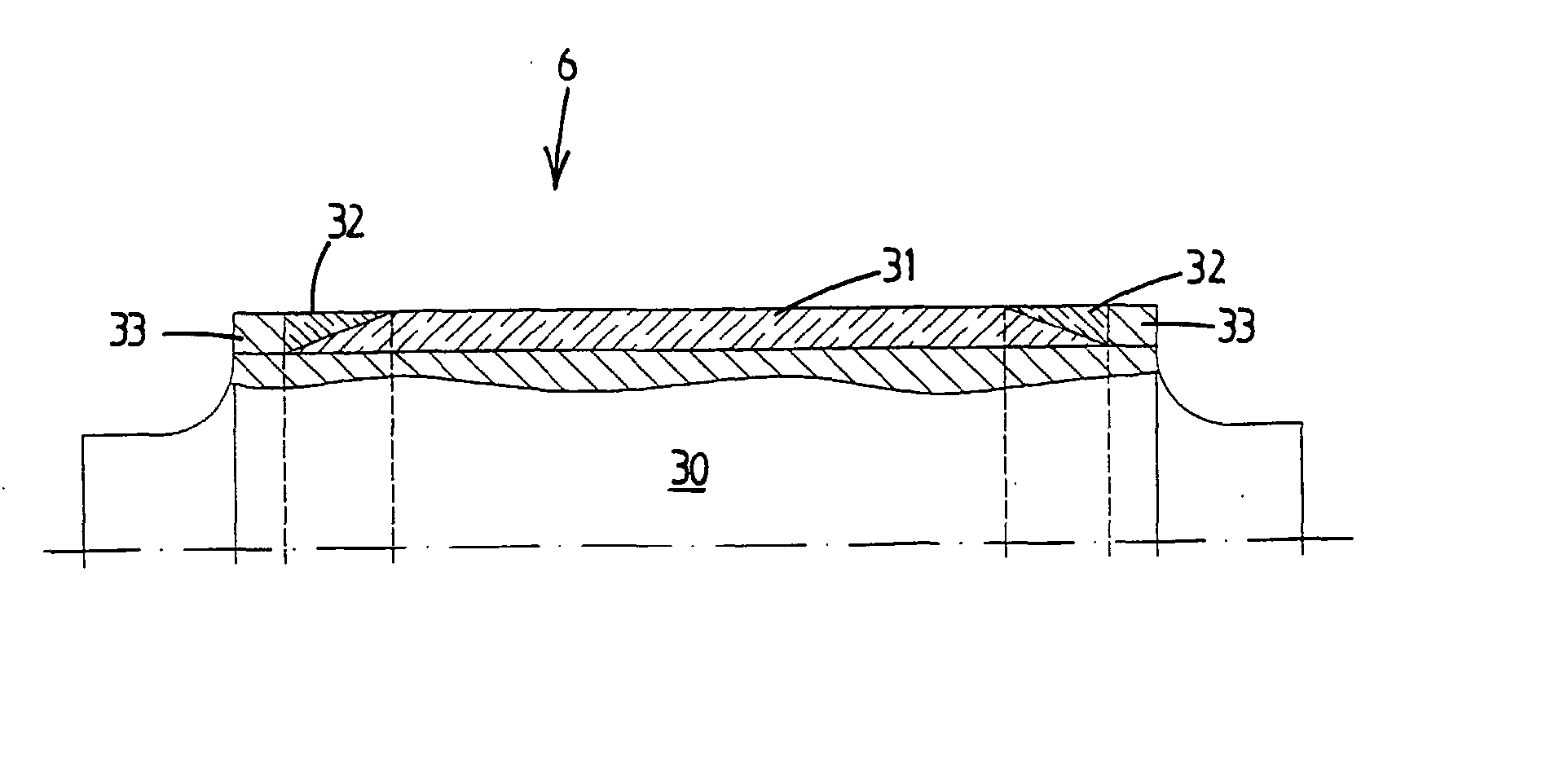

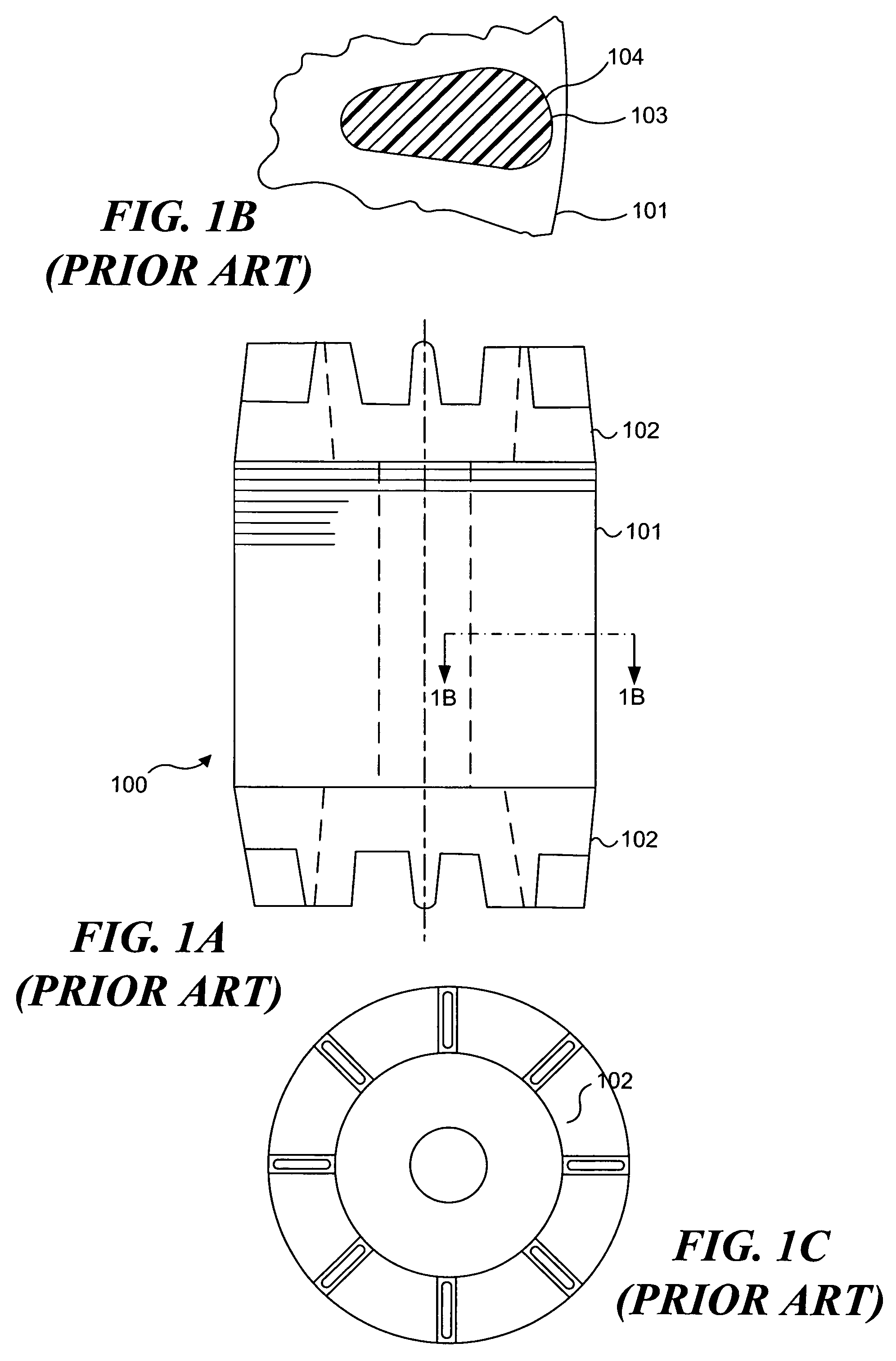

Process for the injection of an electric motor rotor

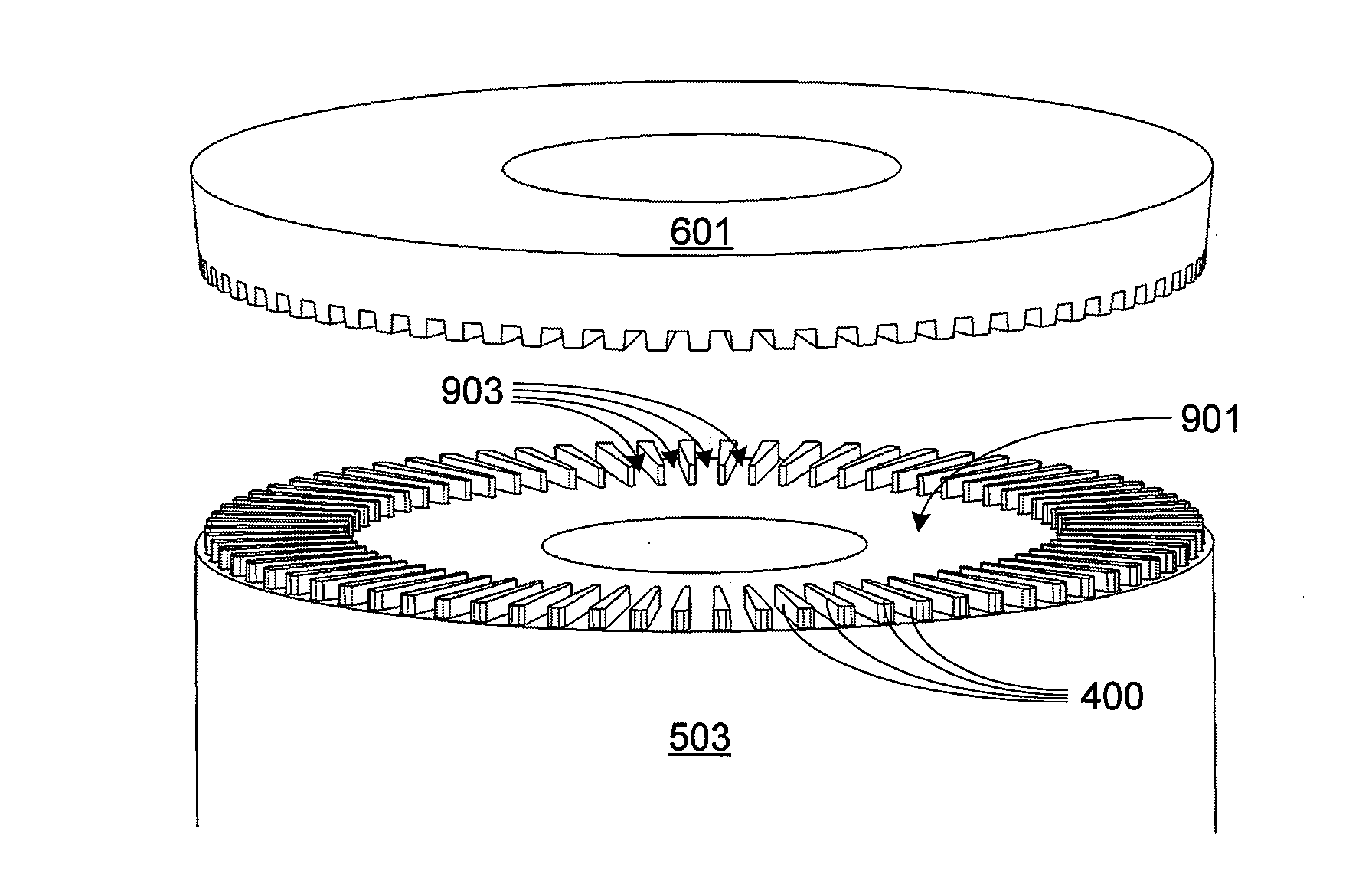

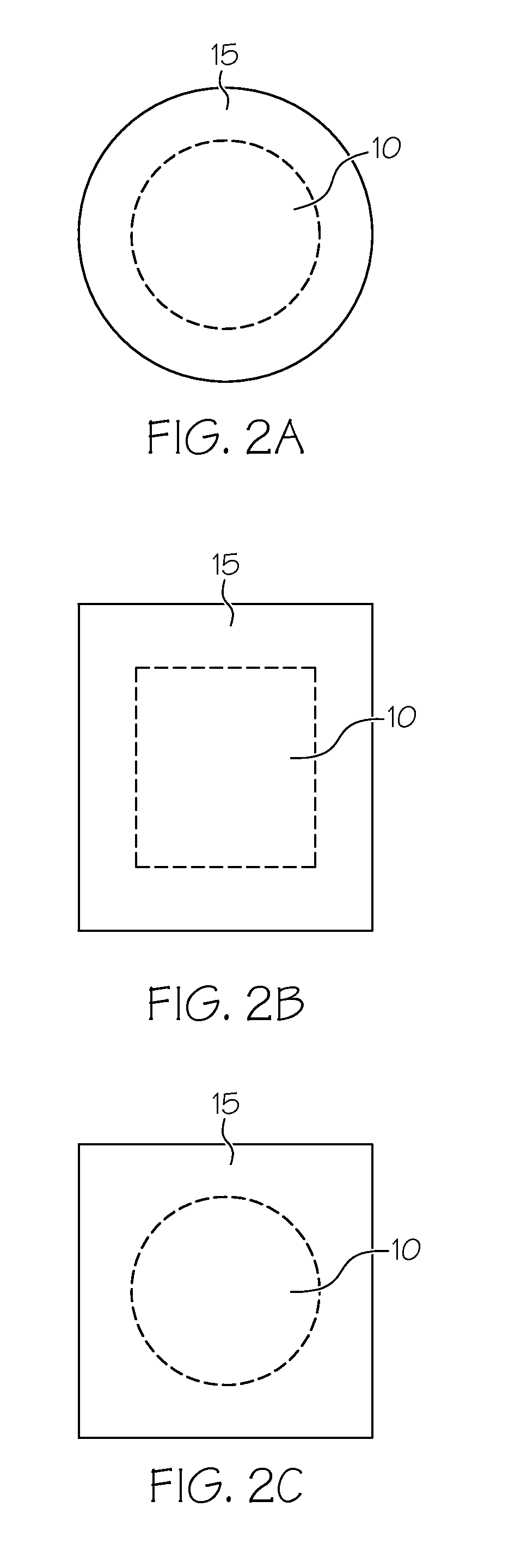

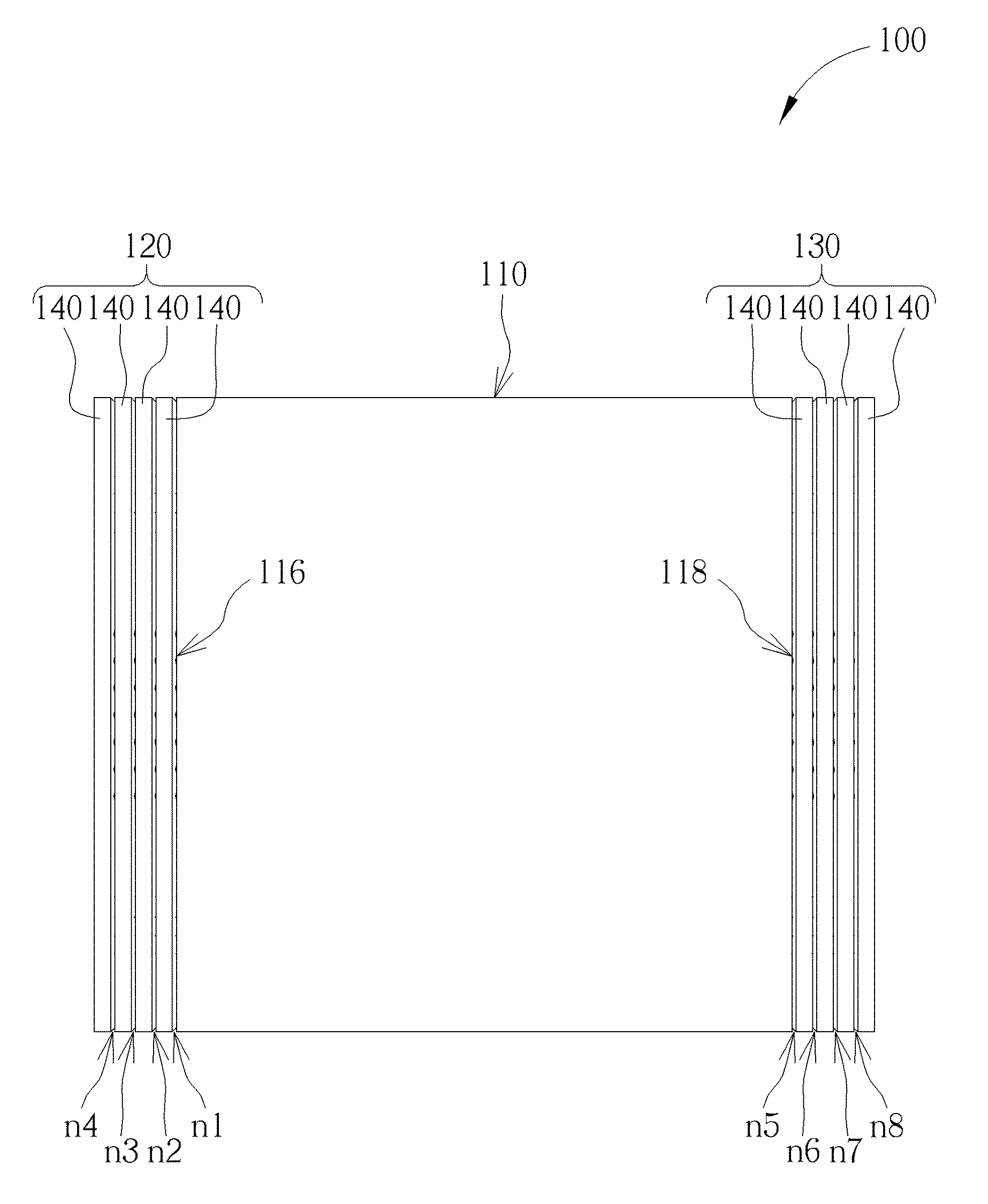

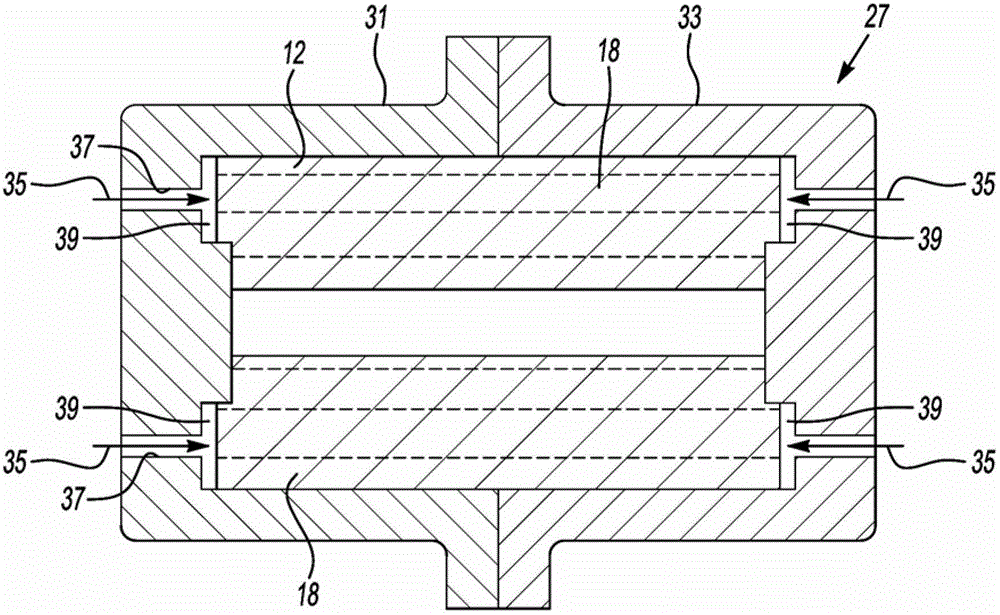

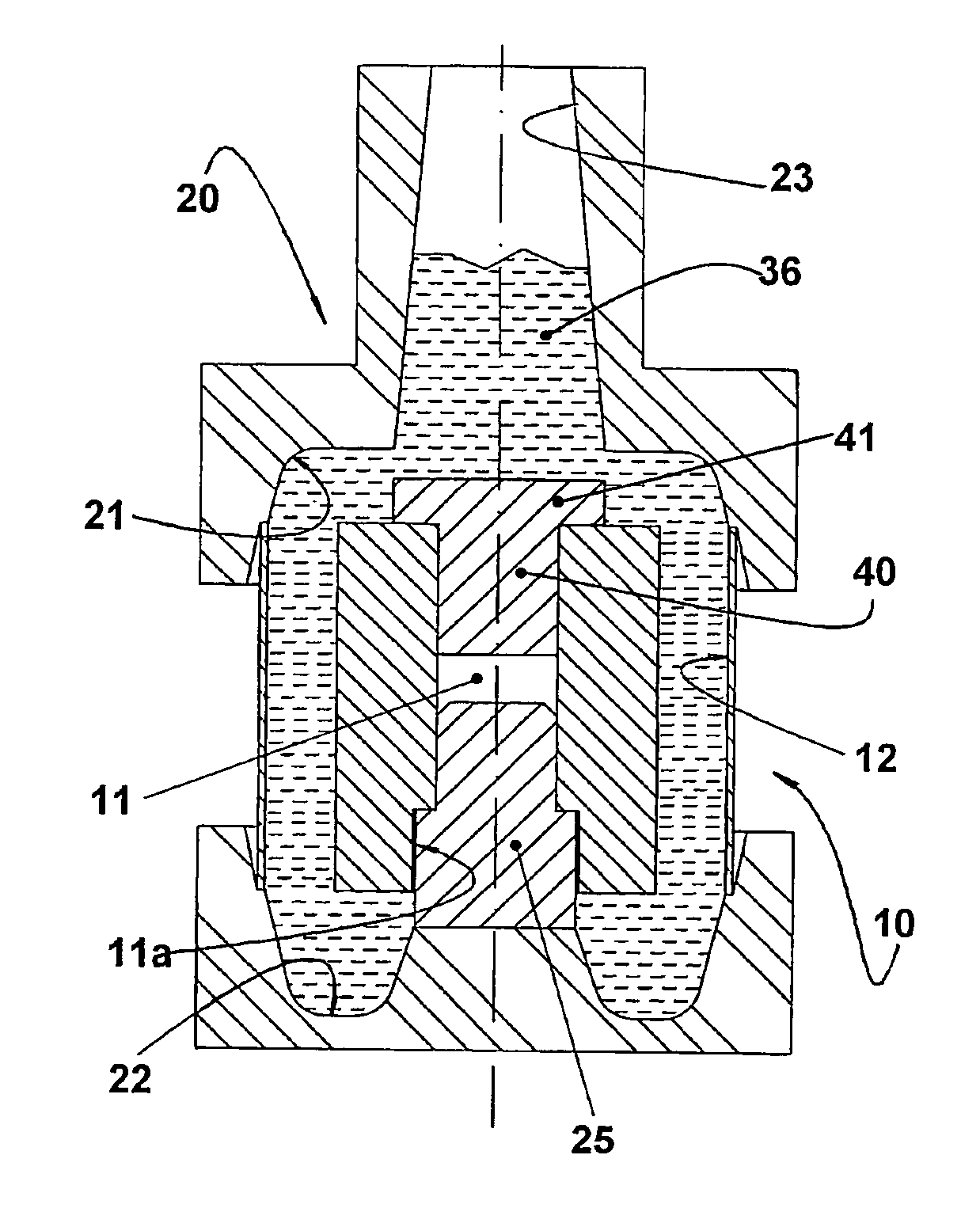

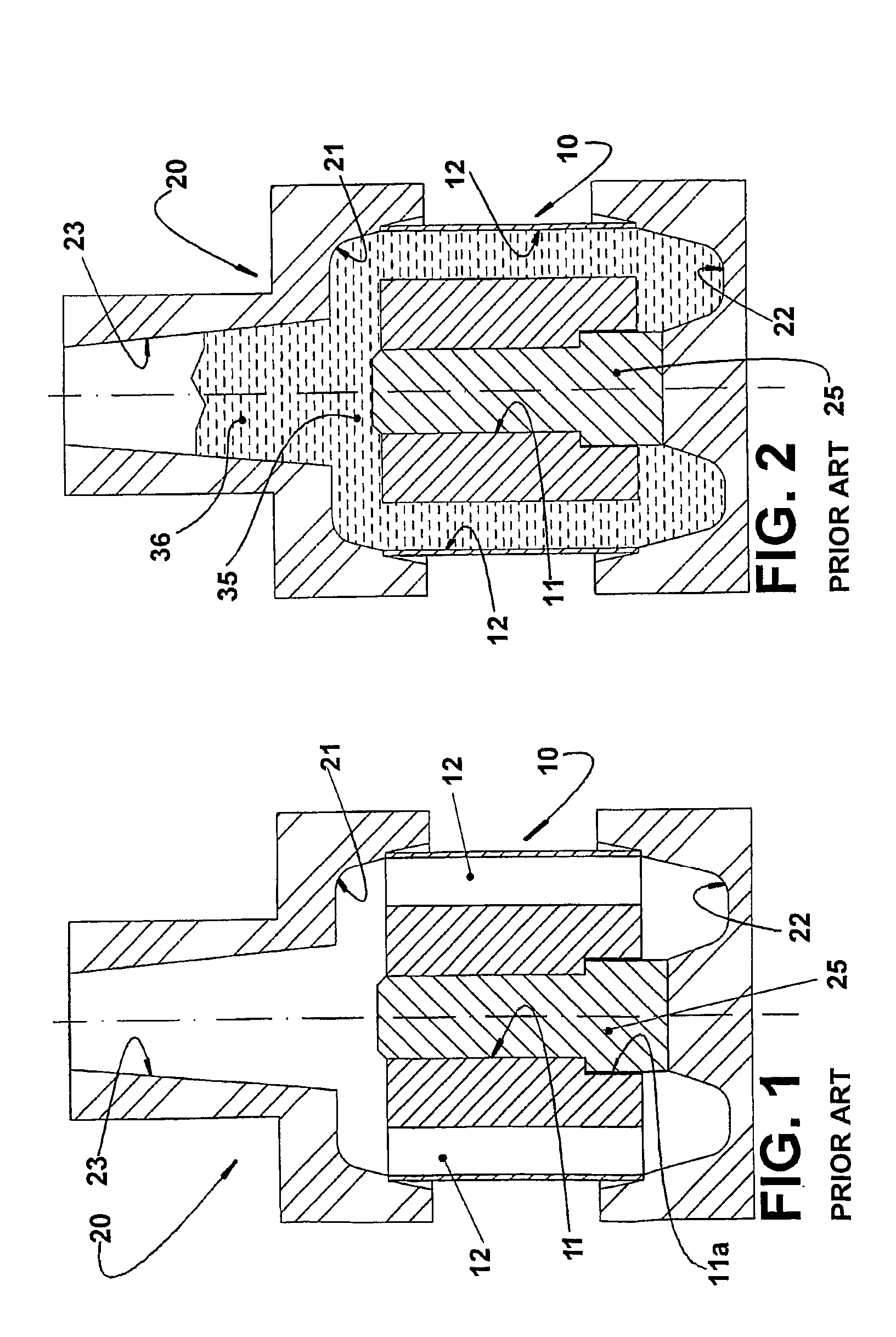

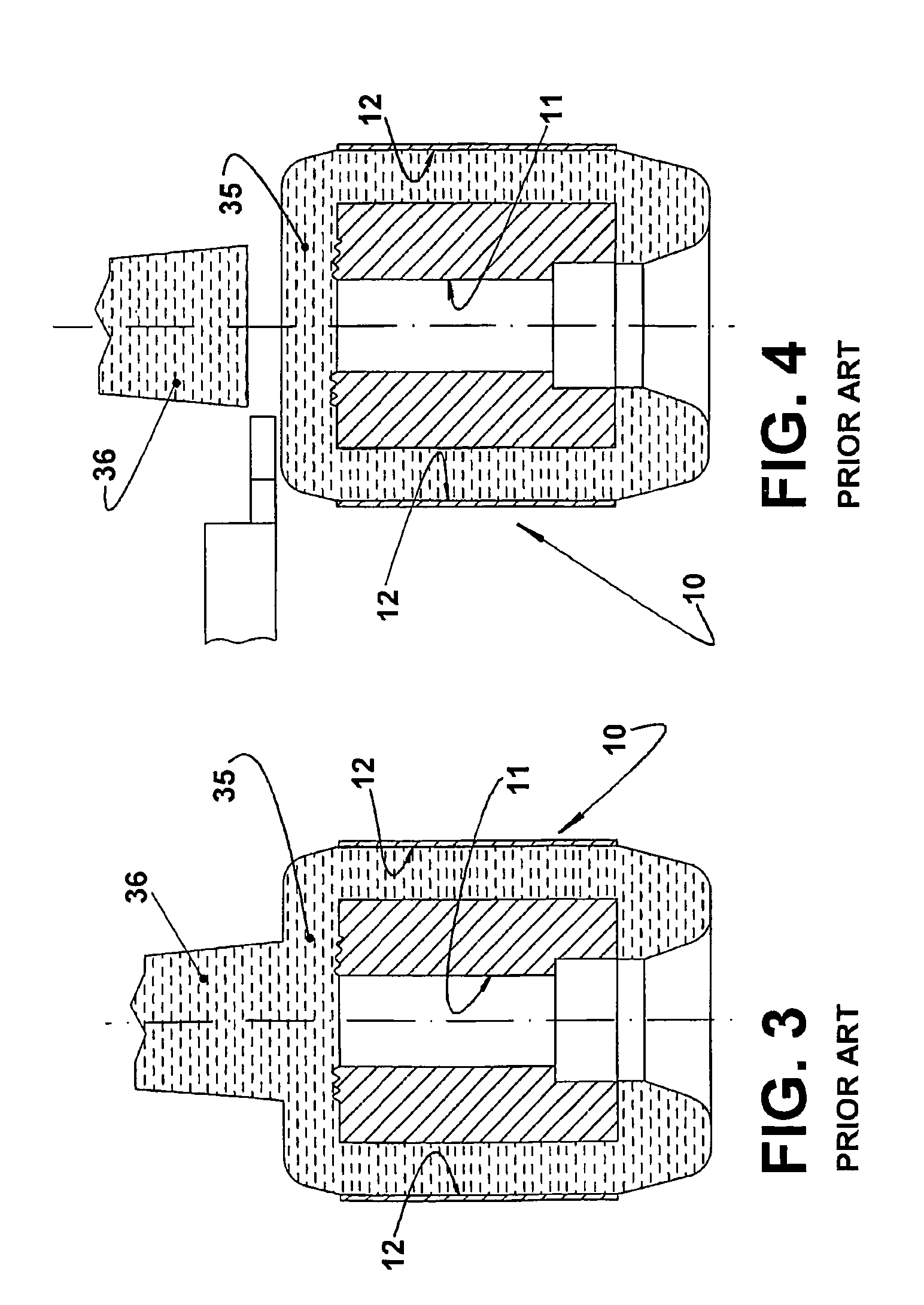

InactiveUS6991021B2Reduce stepsReduce harmful effectsStatorsManufacturing cage rotorsInlet channelEngineering

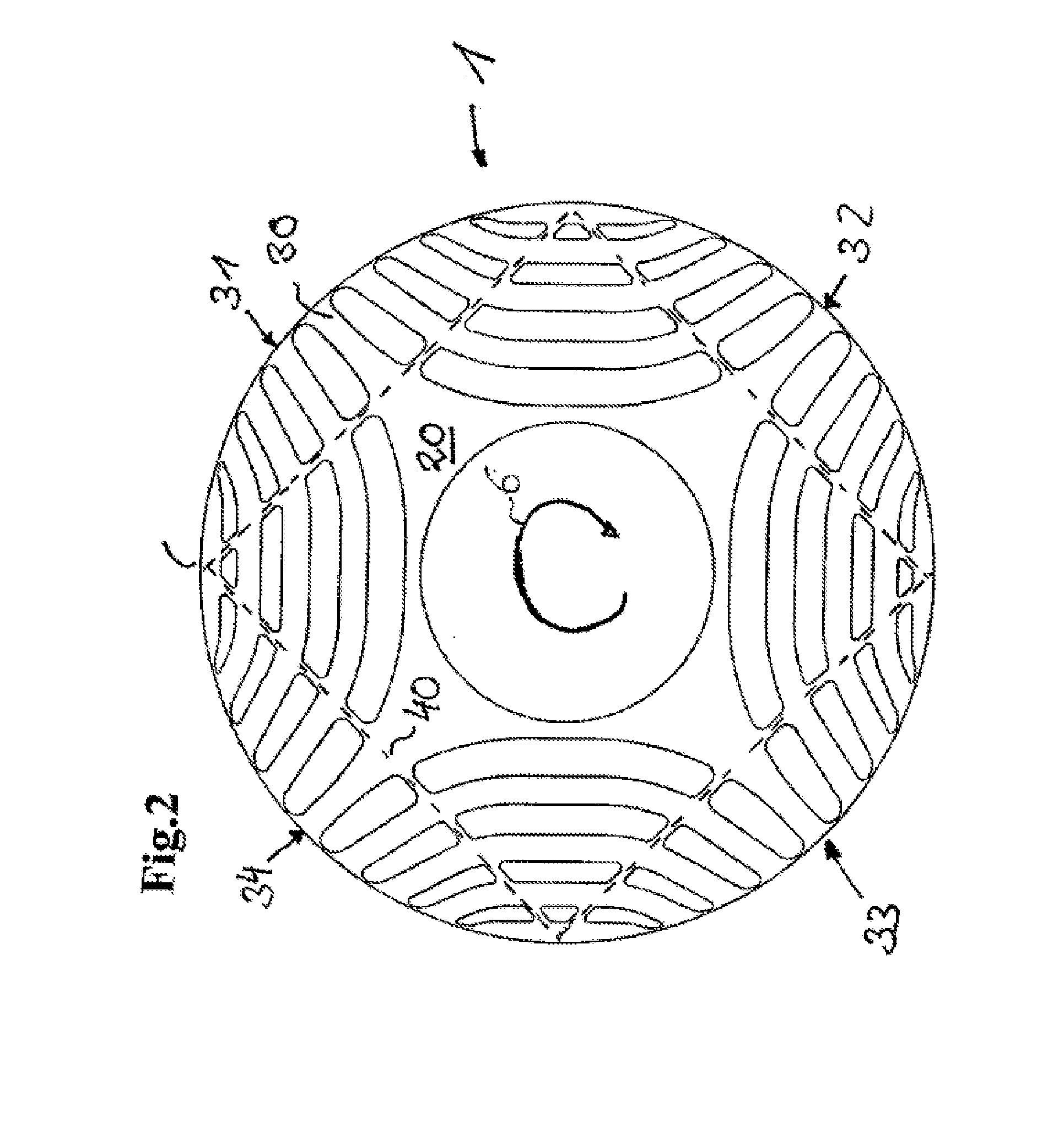

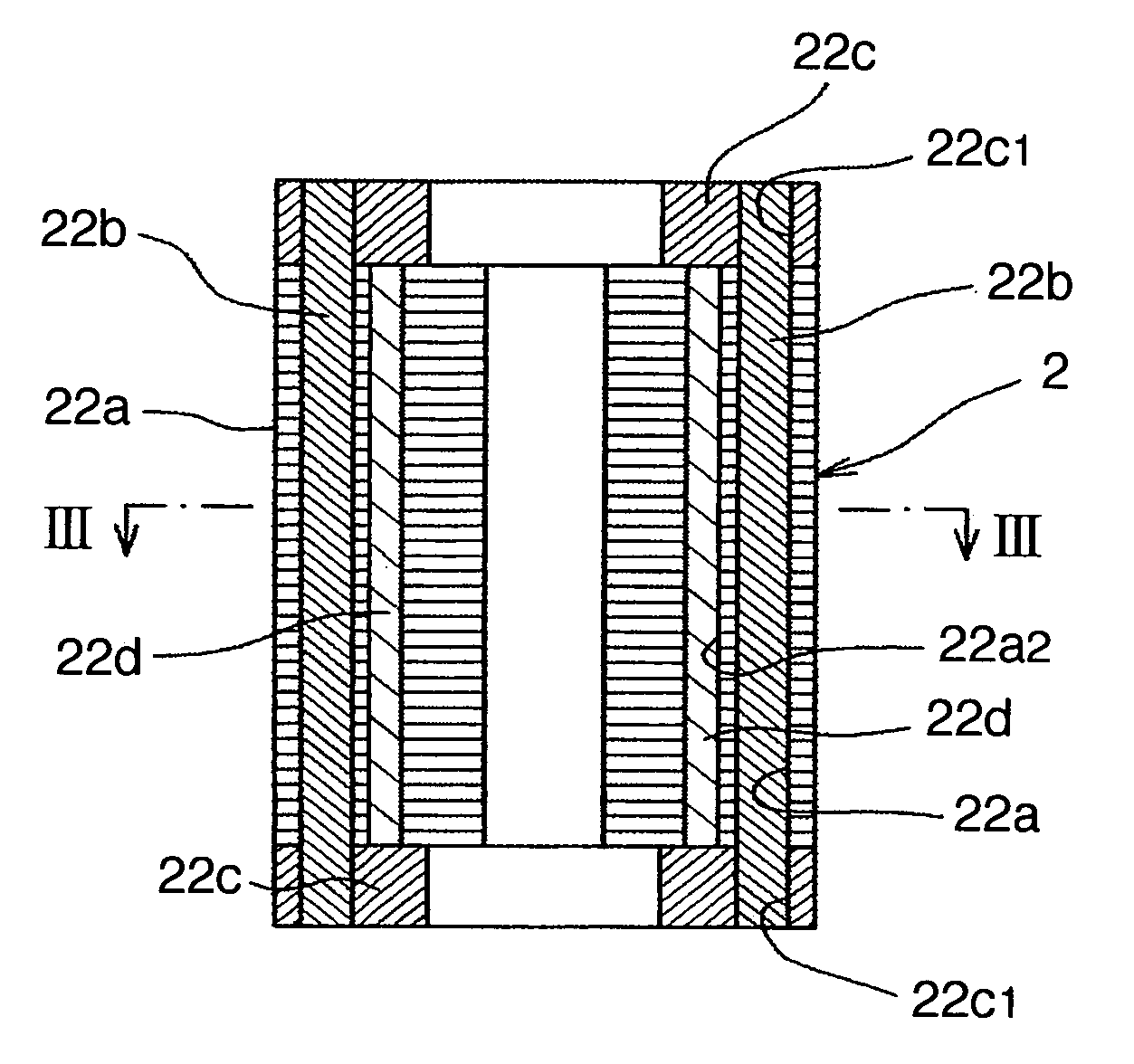

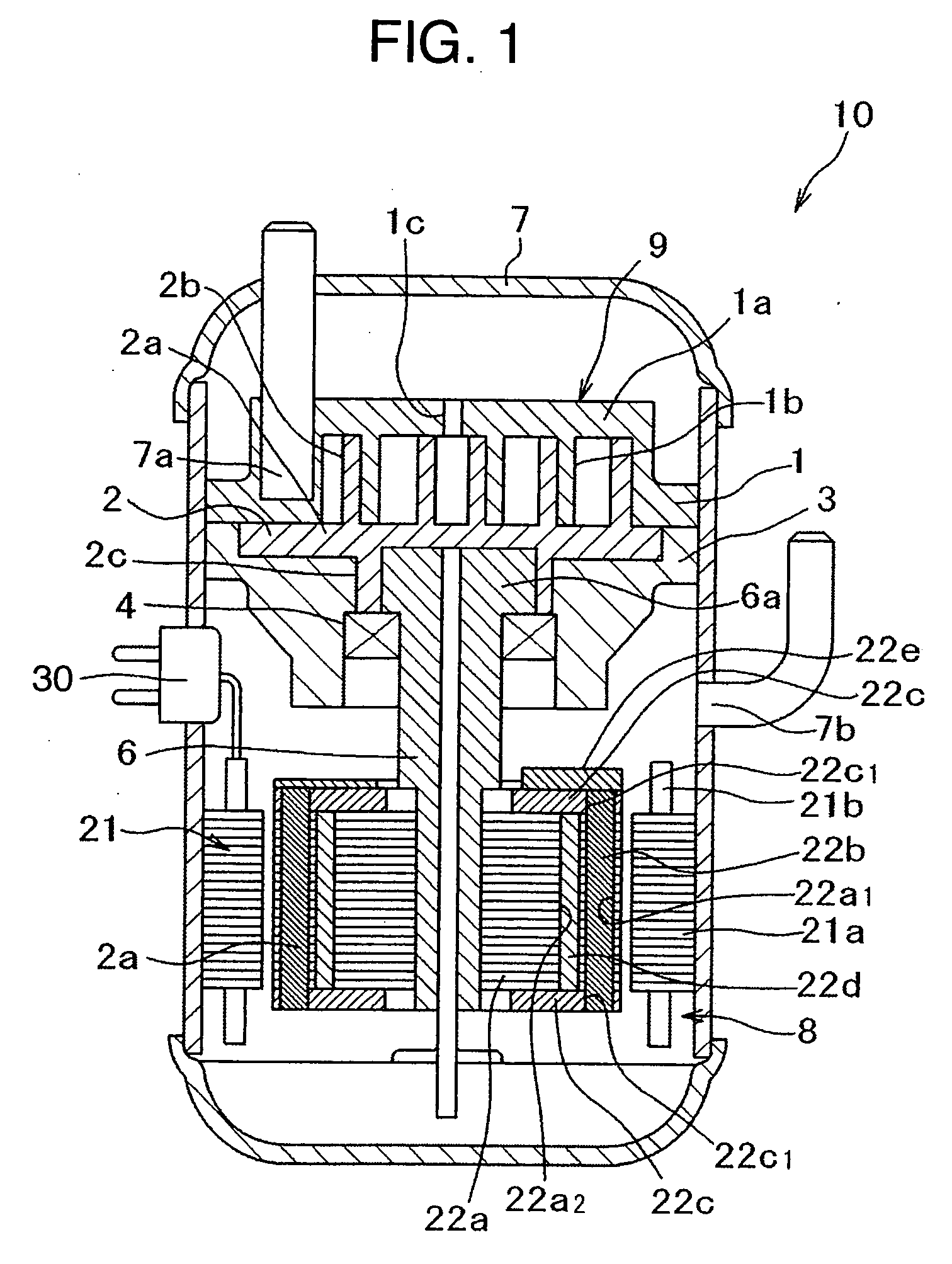

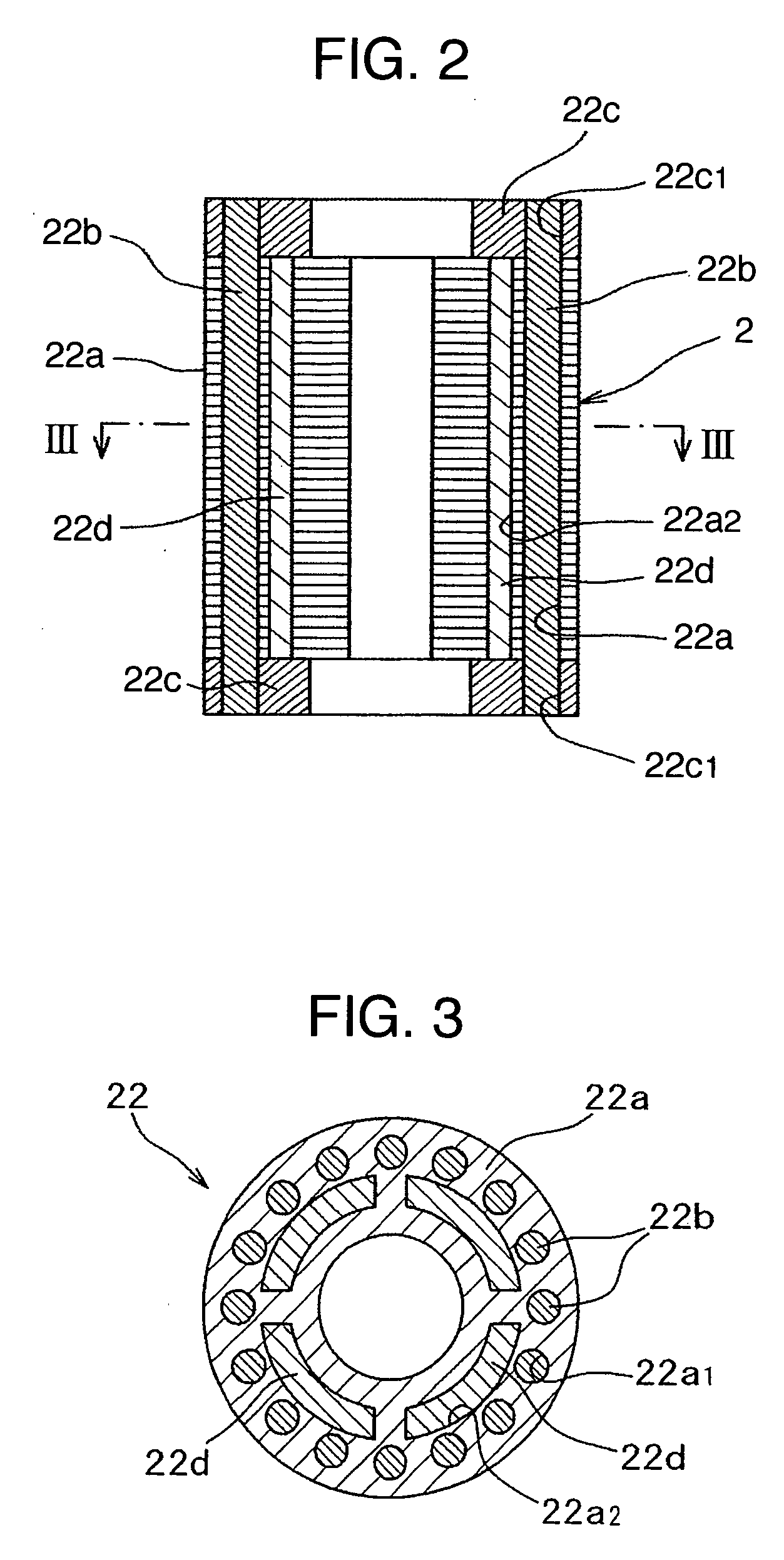

A process for the injection of an electric motor rotor, said rotor comprising: a lamination stack (10) having a central axial bore (11) and a plurality of axial channels (12); and a cage (30) of aluminum, which is formed by an upper end ring (31) and a lower end ring (32), which are interconnected by a plurality of bars (33) molten in the axial channels (12). The process comprises the steps of: mounting, at the upper end portion of the central axial bore (11), a stamping pin (40), which has a widened head (41) seated against the upper end lamination of the lamination stack (10); heating the lamination stack, as well as an upper cavity (21) and a lower cavity (22) of a mold (20); positioning the lamination stack (10) inside the mold (20); rotating the mold (20) and pouring the aluminum into the inside thereof through the inlet channel (23); removing, from the mold (20), the rotor (R) with the cage (30) already formed and comprising an upper plate (35) that covers the stamping pin (40); and axially extracting the stamping pin (40) in order to break, centrally, the upper plate (35), transforming it in the upper ring (31) of the cage (30).

Owner:EMBRACO IND DE COMPRESSORES E SOLUCOES EM REFRIGERACAO LTDA

Rotor of an asynchronous machine with retaining element

ActiveUS20130113331A1Increase pressureIncrease shear stressSynchronous motorsAsynchronous induction motorsElectric machineDie casting

A squirrel-cage rotor of an asynchronous machine, in particular a die-cast rotor, includes a rotatable shaft, a laminated core being rotation-locked on the shaft and having grooves and opposing end faces. A squirrel-cage winding has rotor rods disposed in the grooves and a cage ring disposed on each of the end faces and electrically connecting the rotor rods. A pair of retaining elements is disposed on the shaft, wherein each retaining element extends in a radial direction in form of a disk or a spoke and has in an axial direction a wall and / or an axially extending finger. The wall overlaps on a radial periphery in the axial direction both the cage ring and a predefined axial section of the rotor rods that terminate in the cage ring, without increasing an external diameter of the laminated core.

Owner:SIEMENS AG

Investment casting of induction motor rotors

ActiveUS20110198964A1Improve productivityQuality improvementSynchronous motorsFoundry mouldsWaxInduction motor

A procedure for casting a shorted structure around a plurality of induction motor rotors is described. The method comprises forming a wax representation of the shorted structure around a lamination stack; mounting a plurality of such lamination stacks in a mounting fixture and attaching a suitable gating and runner system; forming an investment by coating the structure with refractory followed by melting out the wax; casting molten metal into the investment while it is rotating and aligning the mold to allow the centrifugal force generated to promote mold filling; and, continuing to rotate the investment until solidification is substantially complete.

Owner:GM GLOBAL TECH OPERATIONS LLC

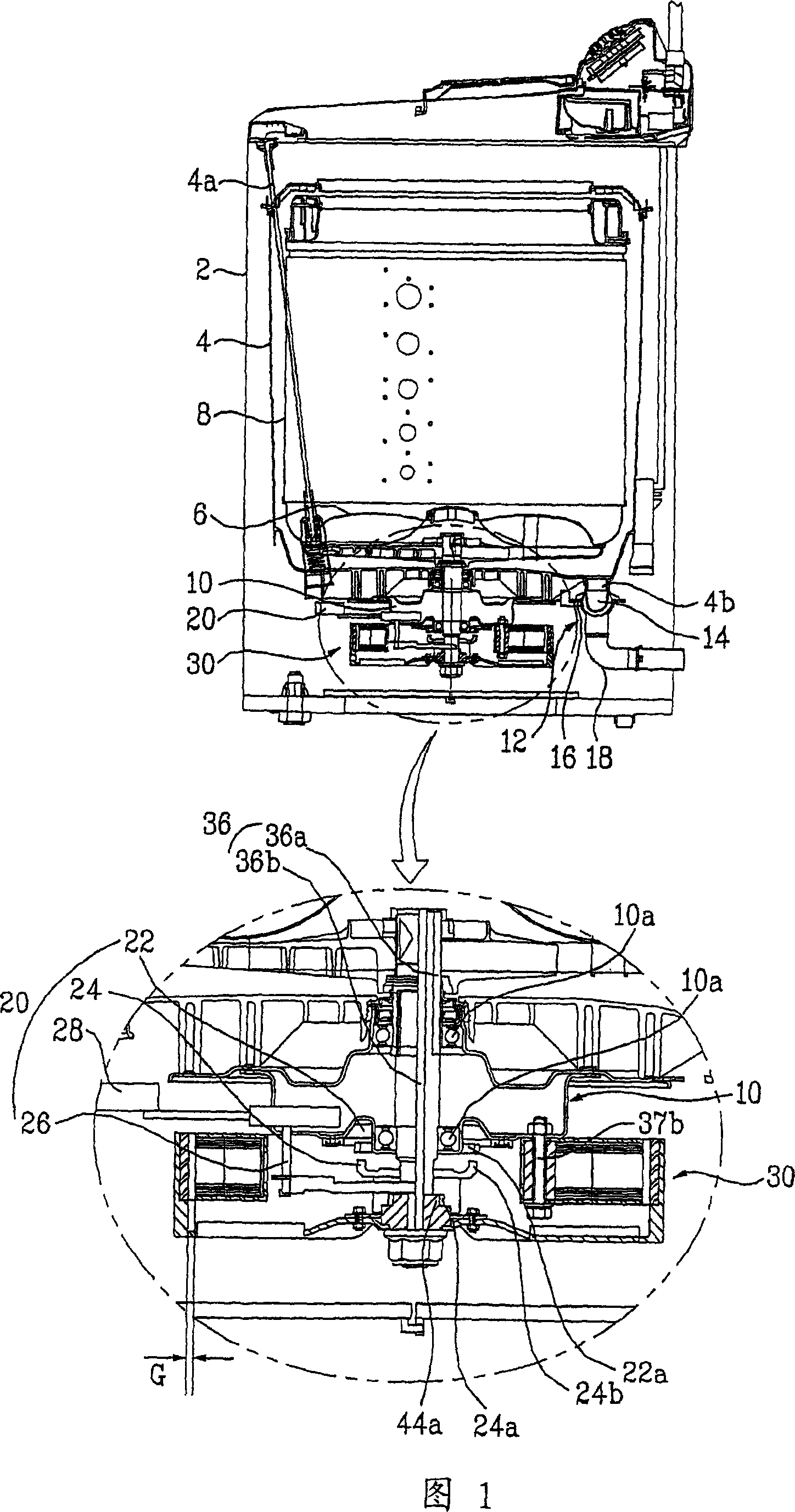

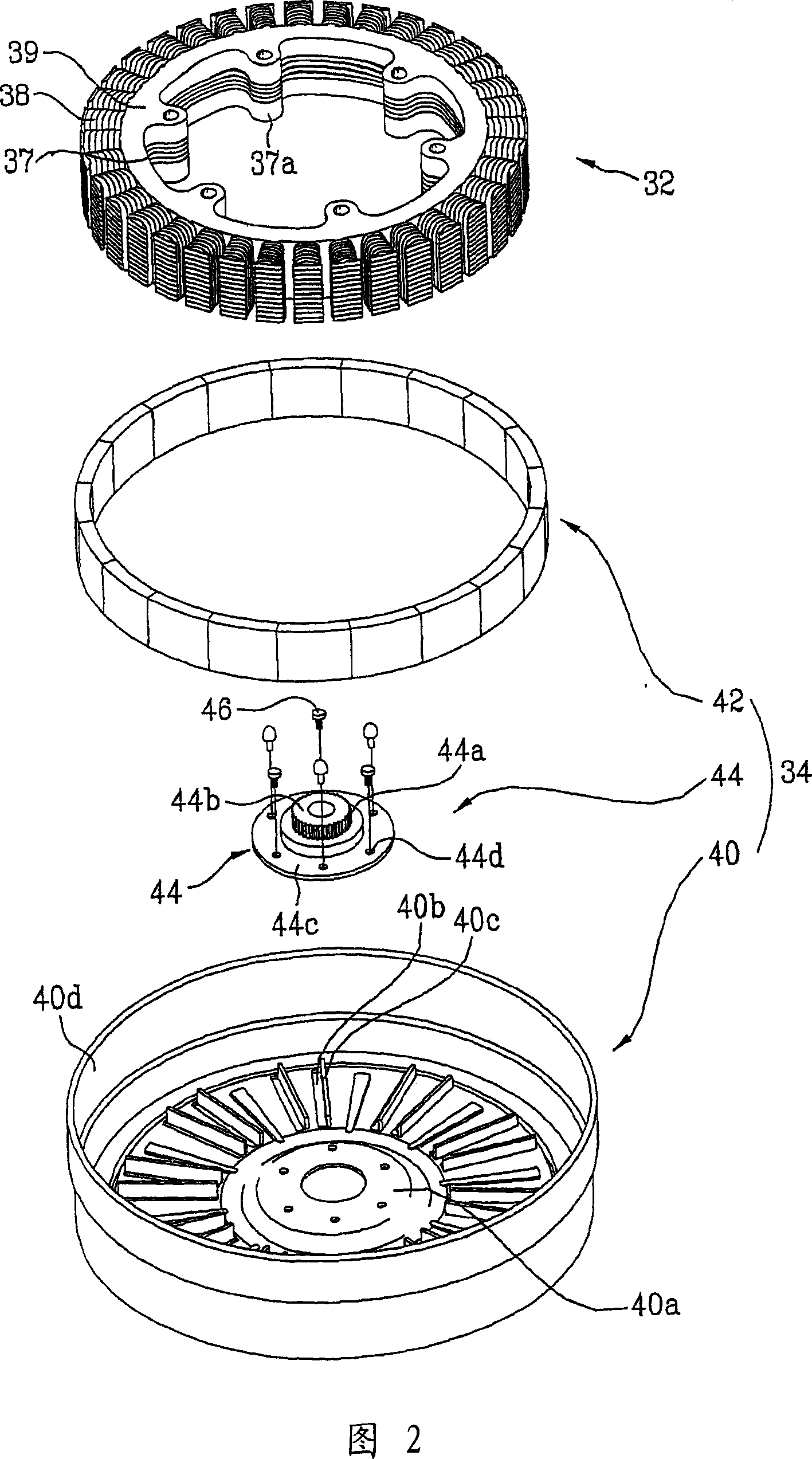

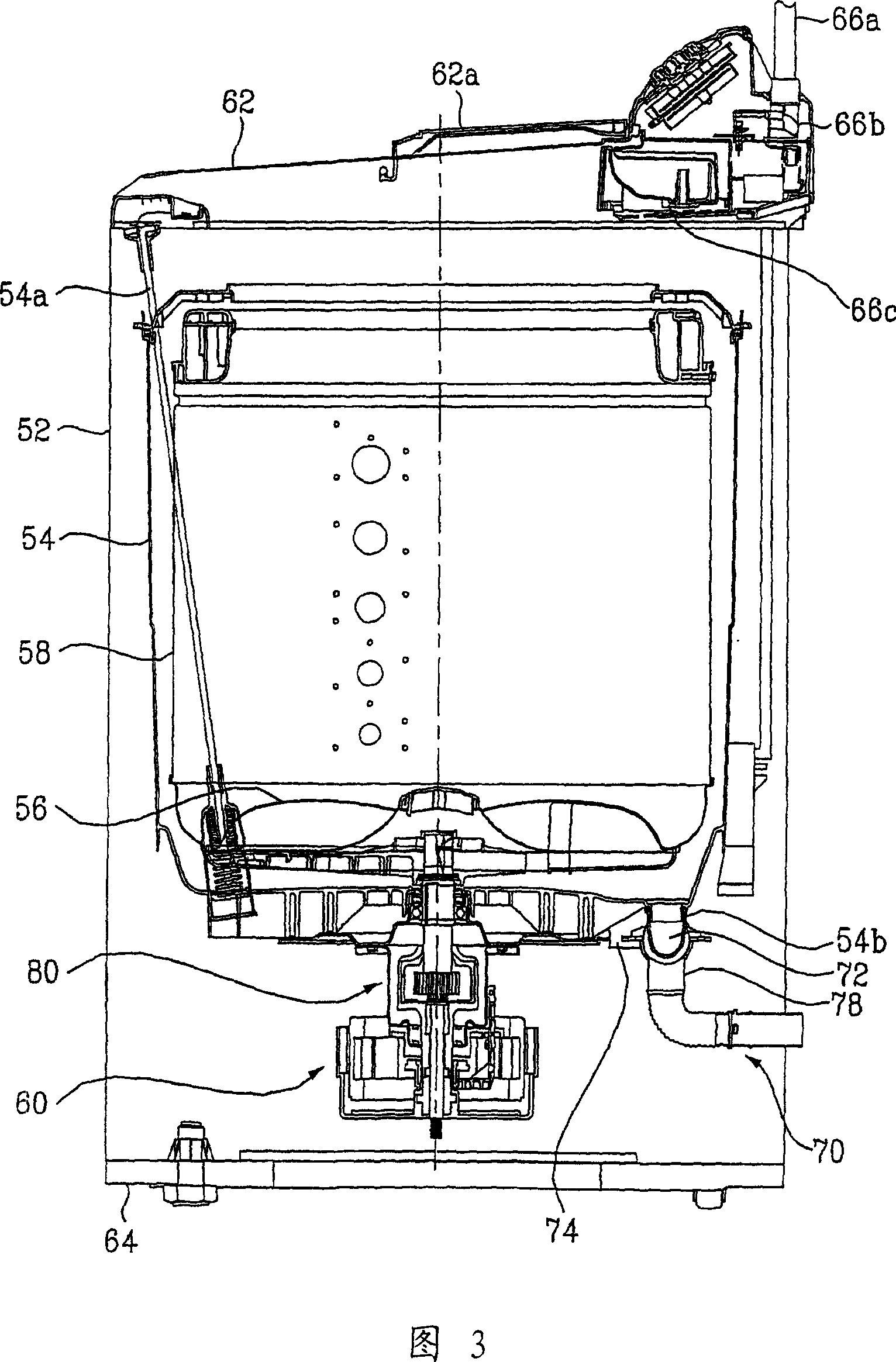

Motor of washing machine

ActiveCN1954110ASimple structureEasy to manufactureMagnetic circuit rotating partsOther washing machinesMechanical engineeringEngineering

Owner:LG ELECTRONICS INC

Coating compositions for electronic components and other metal surfaces, and methods for making and using the compositions

InactiveUS6995484B1Eliminate solderingImprove motor performanceHot-dipping/immersion processesNanotechTransformerEngineering

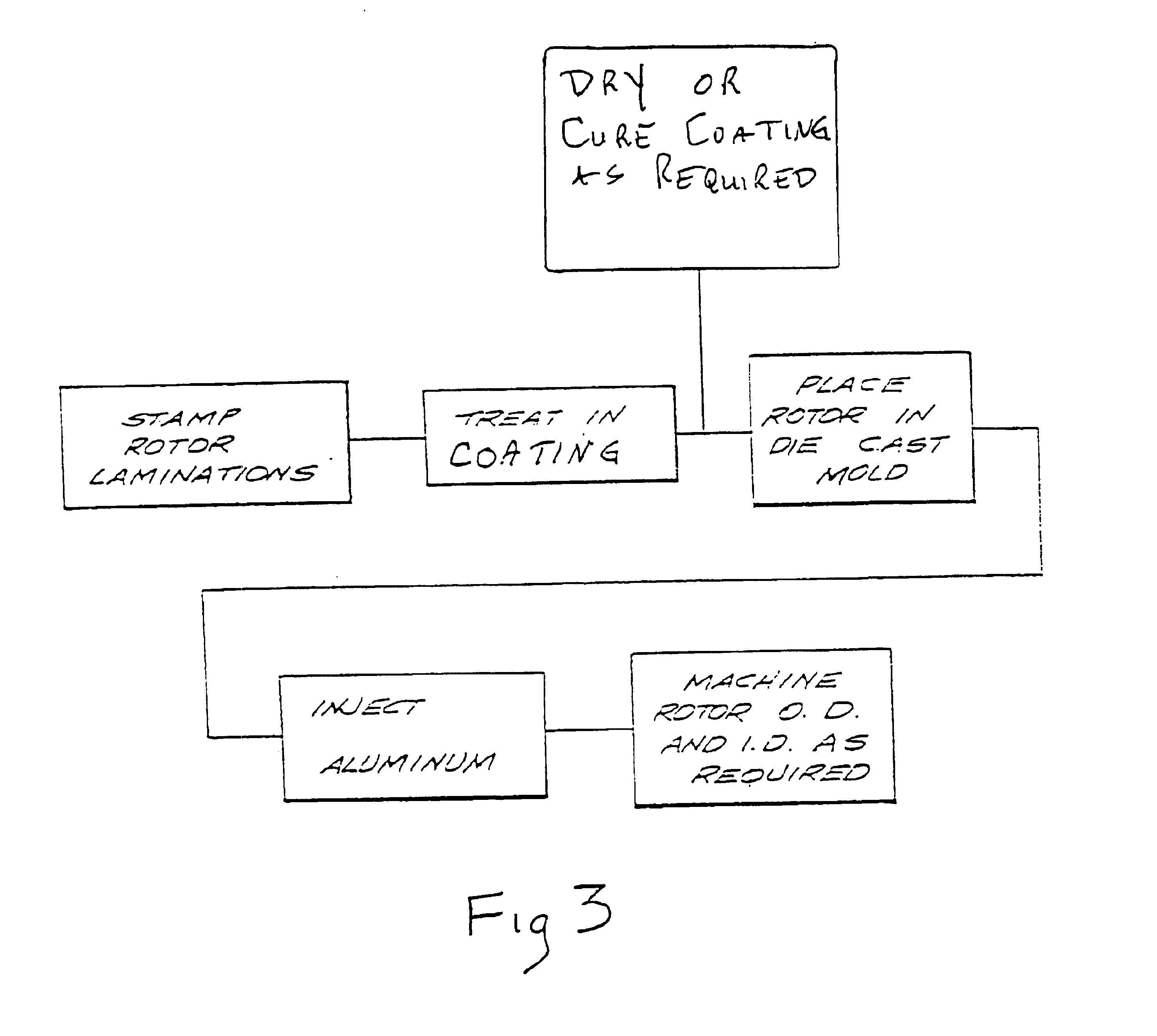

A method is disclosed for providing inorganic and / or organic coating compositions onto rotor cores to eliminate soldering during aluminum injection. These coatings can also be applied upon electric motor rotors and / or stators laminates as well as other electronic components such as transformers. The disclosed method provides at least one film or layer of a coating composition within channels or bar slots defined by the rotor of the electric motor core / rotor (depending upon the design of the motor the slots can be defined within the rotor or open ended along the longitudinal axis of the rotor). The coating composition is also typically applied upon all exposed surfaces of the rotor, e.g., within the channels and exterior surfaces of the rotor. The coated rotor is then contacted with a molten metal. The coating composition functions to isolate the laminates (e.g., steel) of the rotor from a molten metal (e.g., aluminum and its alloys), which surrounds the rotor and fills the channels thereby embedding the rotor, and prevents the metal from forming an undesirable conductive path typically termed soldering among the individual laminates.

Owner:ELISHA HLDG LLC

Electric machine rotor bar and method of making same

ActiveUS8274190B2Windings insulation shape/form/constructionSynchronous motorsCouplingElectric machine

A method, system, and apparatus including an electric machine having a plurality of rotor bars and a first coupling component configured to electrically couple the plurality of rotor bars together. Each rotor bar of the plurality of rotor bars includes a first metallic material having a first electrical resistivity and a second metallic material cast about the first material, where the second metallic material has a second electrical resistivity greater than the first electrical resistivity. The first metallic material has a first end and a second end opposite the first end and the first coupling component is coupled to the first end of the first metallic material.

Owner:GENERAL ELECTRIC CO

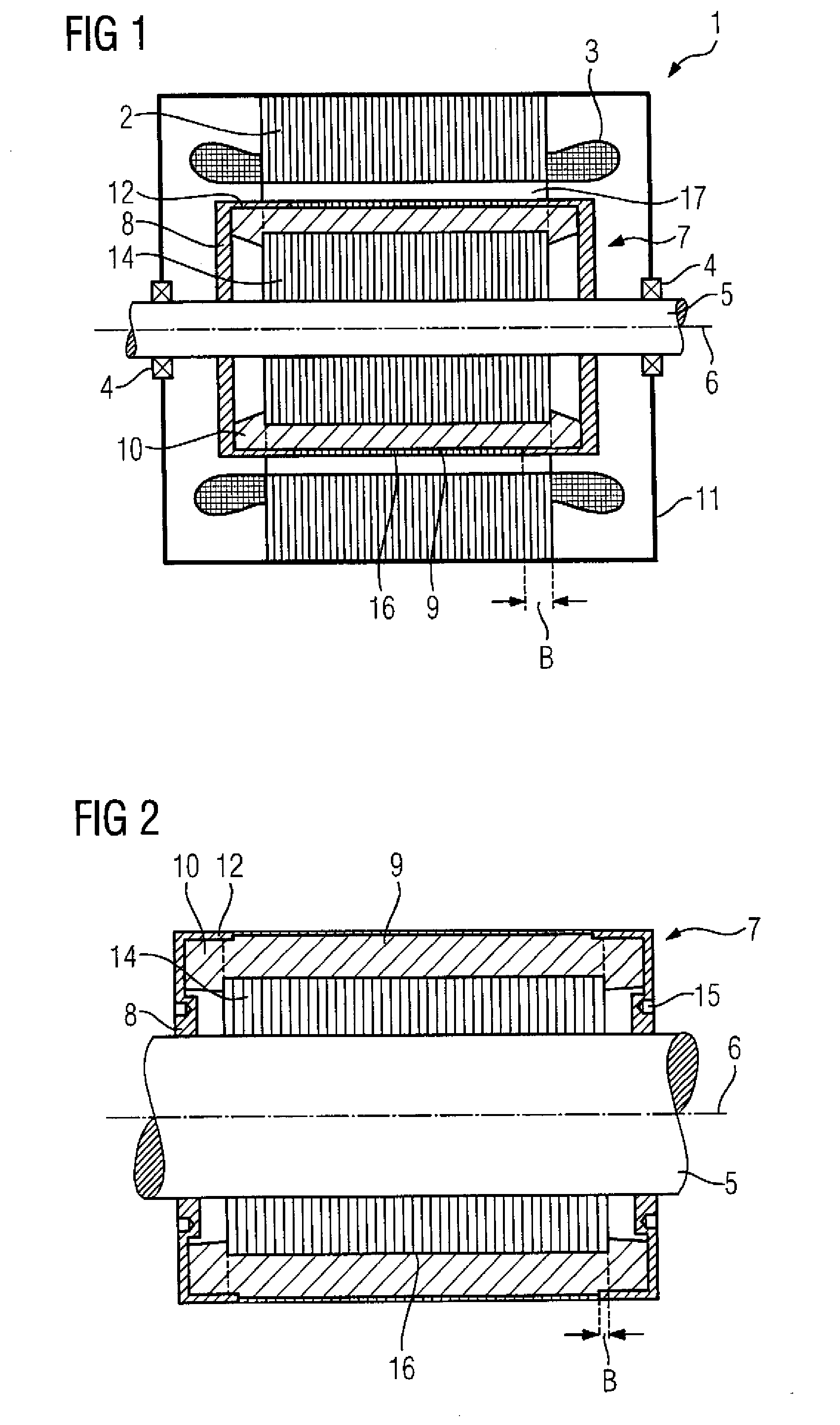

Cage rotor of an asynchronous machine

ActiveUS20150349616A1High material strengthSuitable for useSynchronous motorsAsynchronous induction motorsElectrical conductorEngineering

A cage rotor of a rotary asynchronous machine includes an axially laminated core having substantially axially extending grooves, at least one electrical conductor disposed in the grooves and composed of at least of two partial conductors constructed from materials having different electrical conductivities and different mechanical strengths, wherein the partial conductor made of the higher-strength material is disposed radially farther outwardly at least in sections of the groove, as viewed along the axial extent of the respective, and a short-circuit ring arranged on a respective end face side of the laminated core and electrically-conductively interconnecting the electrical conductors that are disposed in the respective grooves and protrude axially from the laminated core.

Owner:SIEMENS AG

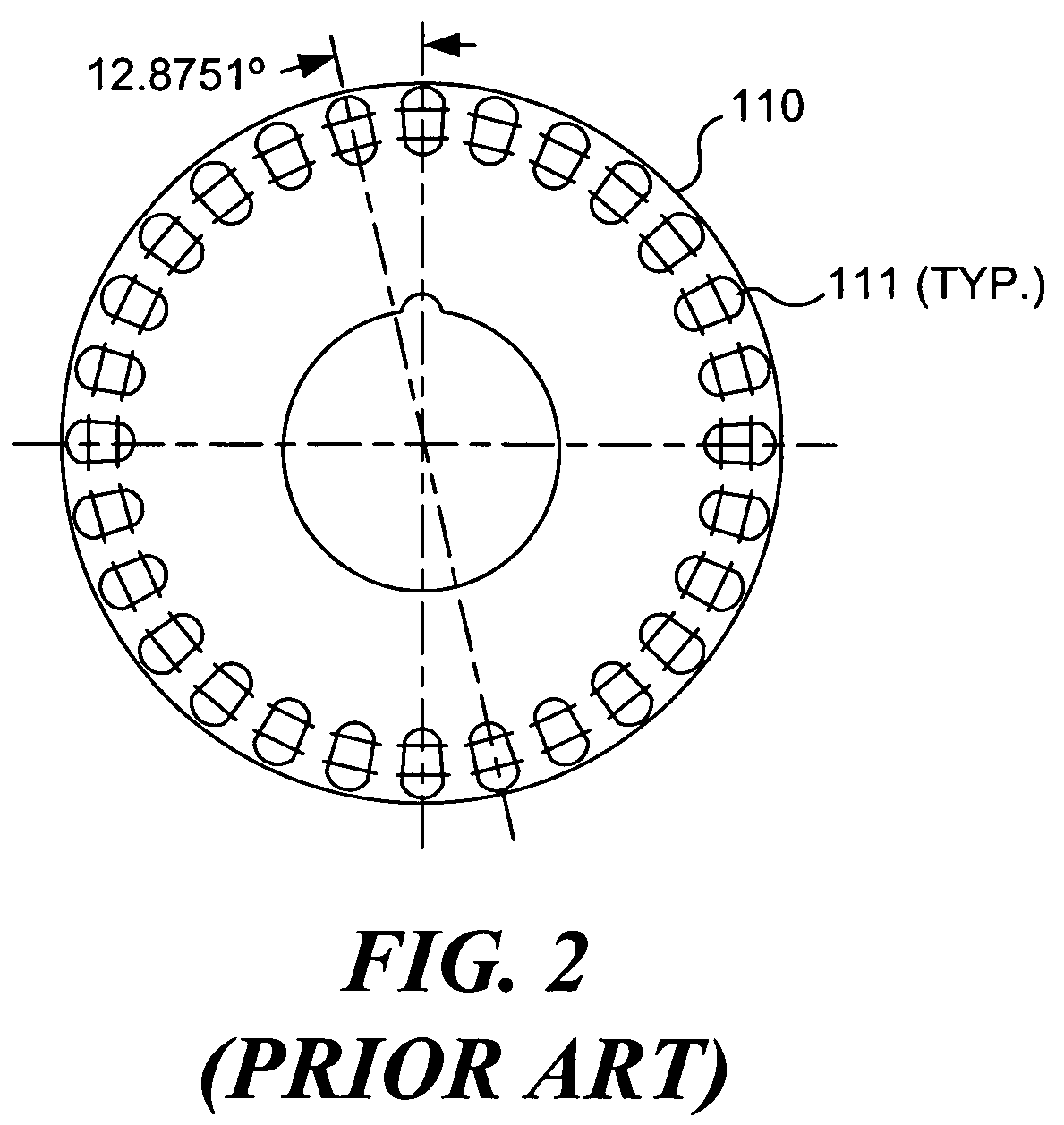

Rotor for an induction device

InactiveUS20060066157A1Facilitate electrical communicationGood mechanical integrityMagnetic circuit rotating partsMagnetic circuit stationary partsMechanical integrityEngineering

According to one embodiment, the present invention provides a rotor assembly. The exemplary rotor assembly includes a plurality of rotor laminations, which cooperate to form a rotor core, capped at each end by end members. Extending through the rotor core and the end members, a plurality of rotor channels is configured to receive electrically conductive members therethrough. Each of the electrically conductive members has external portions, which extend beyond the rotor channel, and an interior portion that is housed within the rotor channel. By flexing the external portions, a compression force that secures the laminations and the end members with respect to one another may be provided. Advantageously, the external portions may be fused to one another and / or to the end members. As one example, the external portions may be fused through the introduction of a molten metal into the end member. Advantageously, fusing of the external portions to the end members and / or one another increases the mechanical integrity of the rotor and provides for good electrical communicativeness between the conductive members, for example.

Owner:RELIANCE ELECTRIC TECH

Squirrel-cage rotor of induction motor and production method thereof wherein end ring is brazed with bar

ActiveCN102684435AReduce working hoursMagnetic circuit rotating partsAsynchronous induction motorsSilver plateElectrical conductor

The present invention relates to a squirrel-cage rotor of an induction motor and a production method thereof, wherein an end ring is brazed with a bar. An object of the present invention is to provide a squirrel-cage rotor of an induction motor and a production method thereof, wherein locating of the brazing material is not necessary in order to reduce manhours for brazing, and a bar is easily connected to an end ring. Before assembling a rotor, a silver plated layer is formed on at least one of an end ring and a conductive bar. In order to melt the silver plated layer, the rotor is heated to a temperature which is equal to or larger than the melting point of the silver plated layer. The melted layer functions as a brazing material, whereby the end ring and the conductive bar are connected.

Owner:FANUC LTD

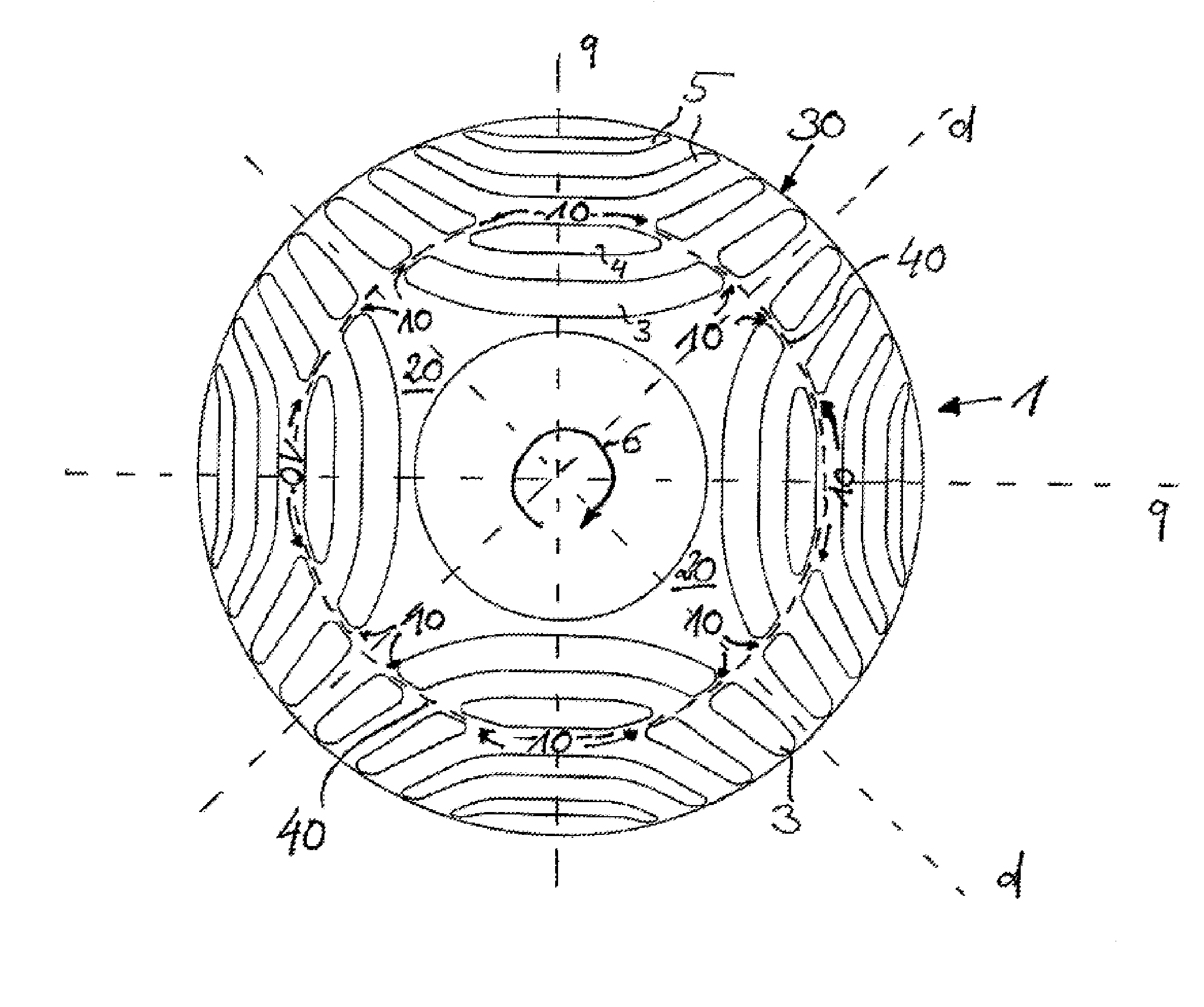

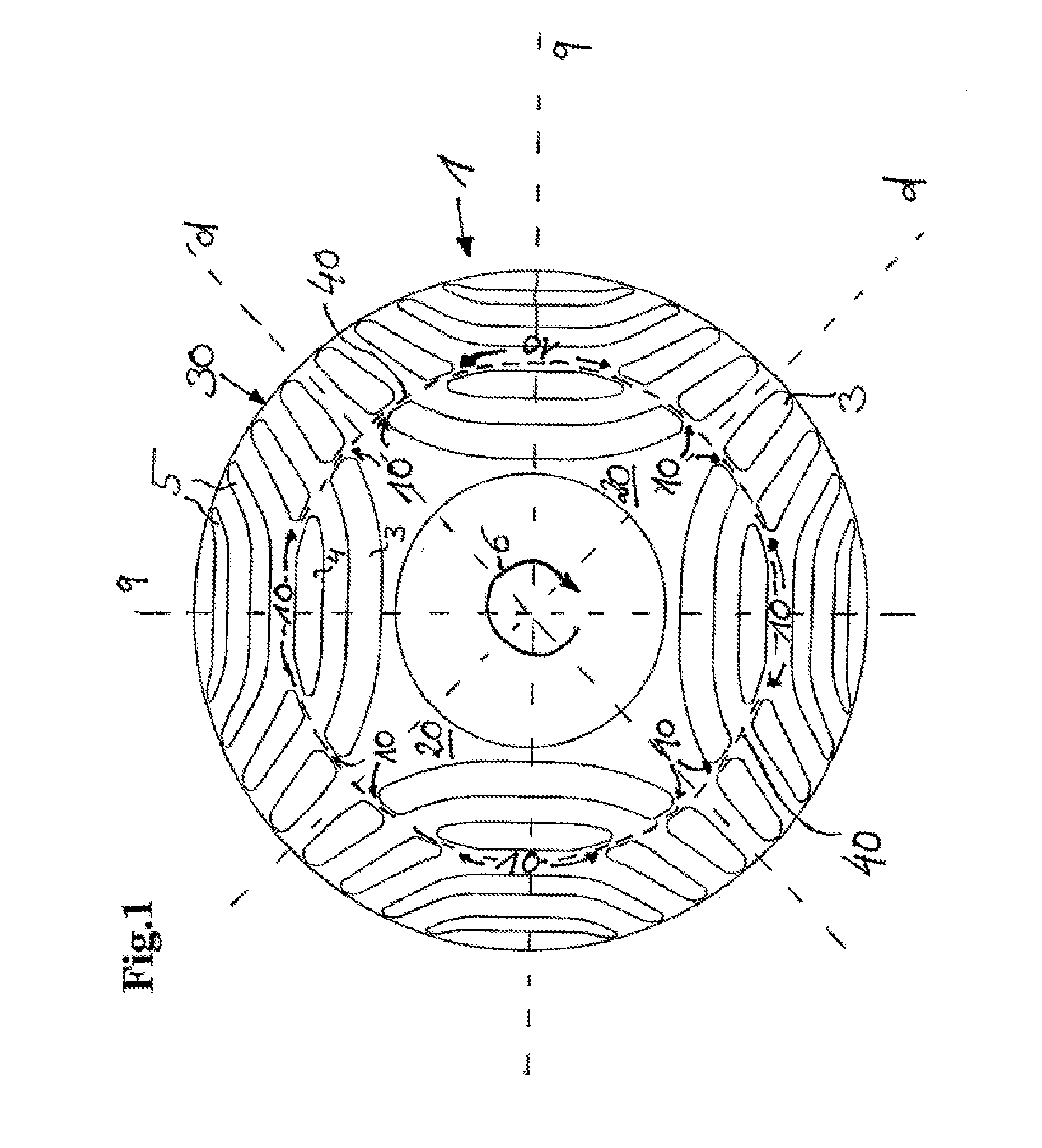

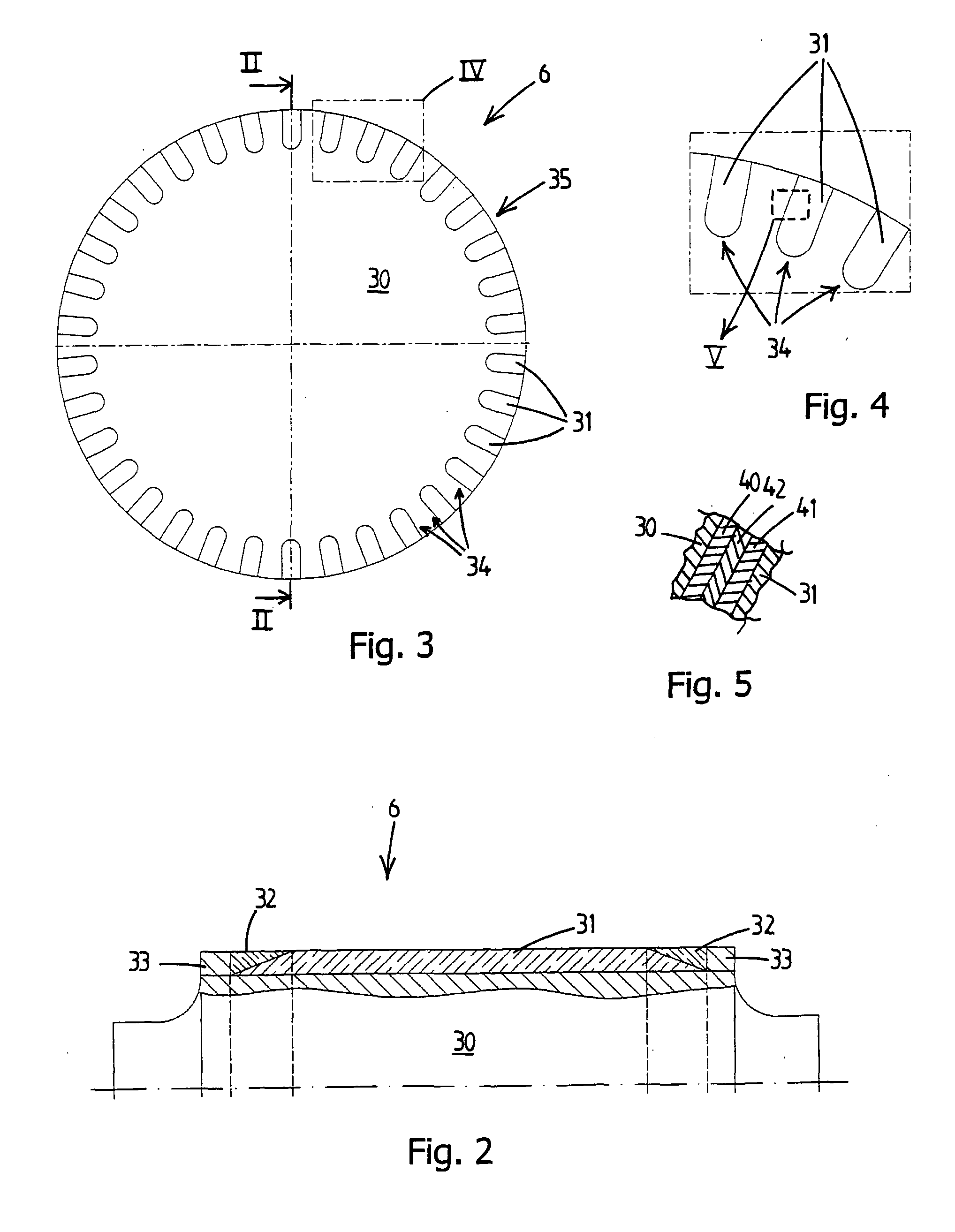

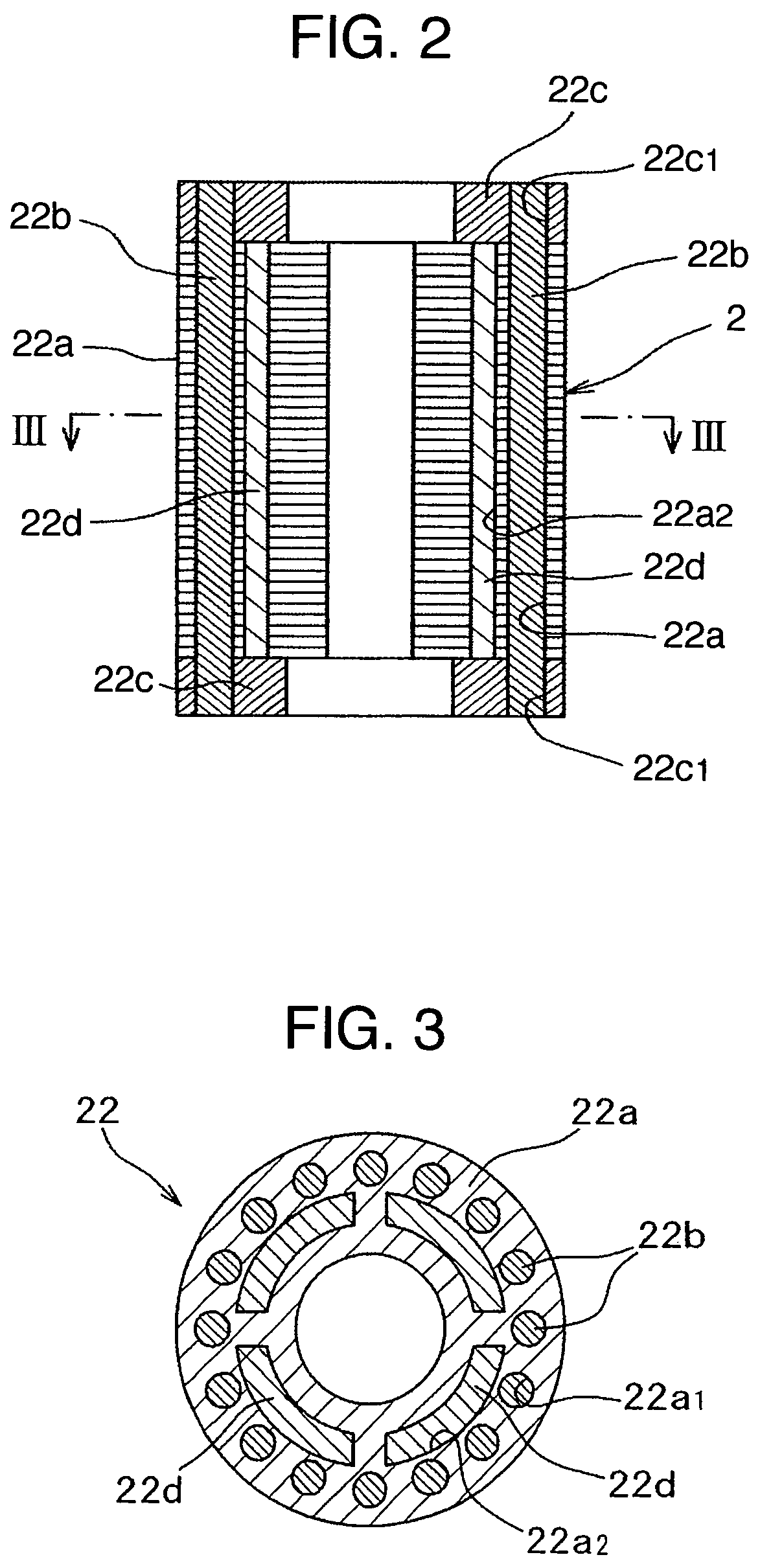

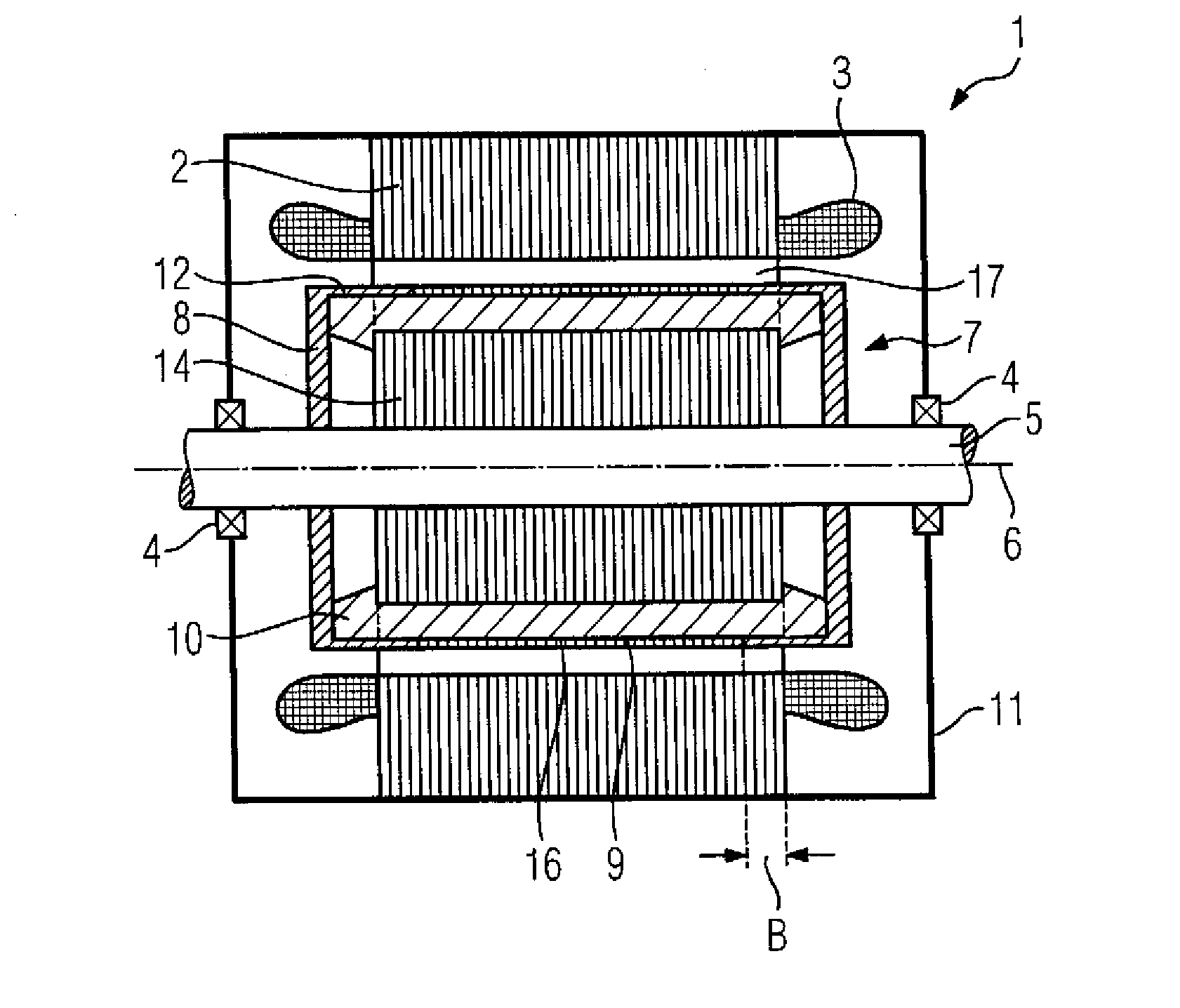

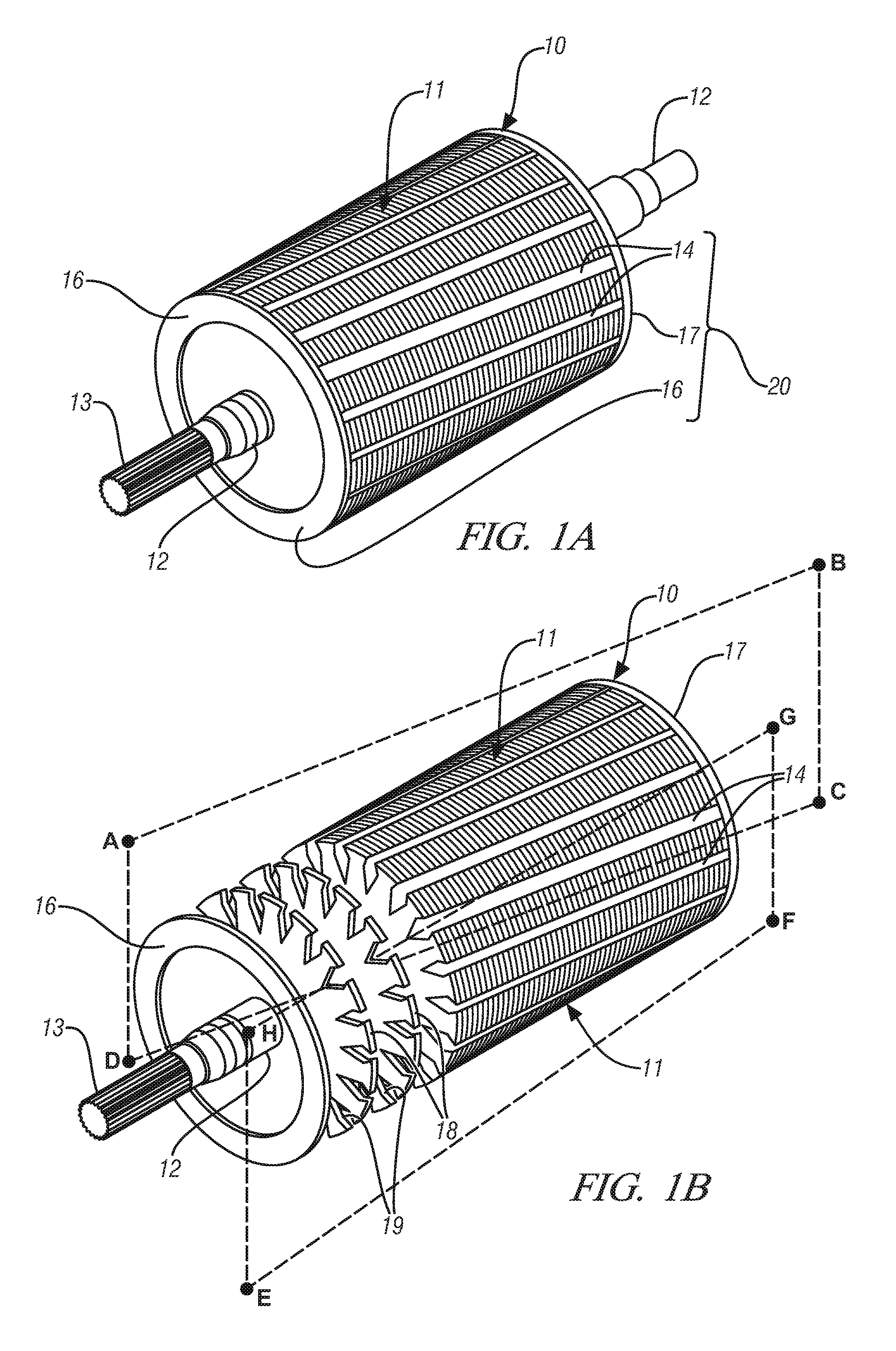

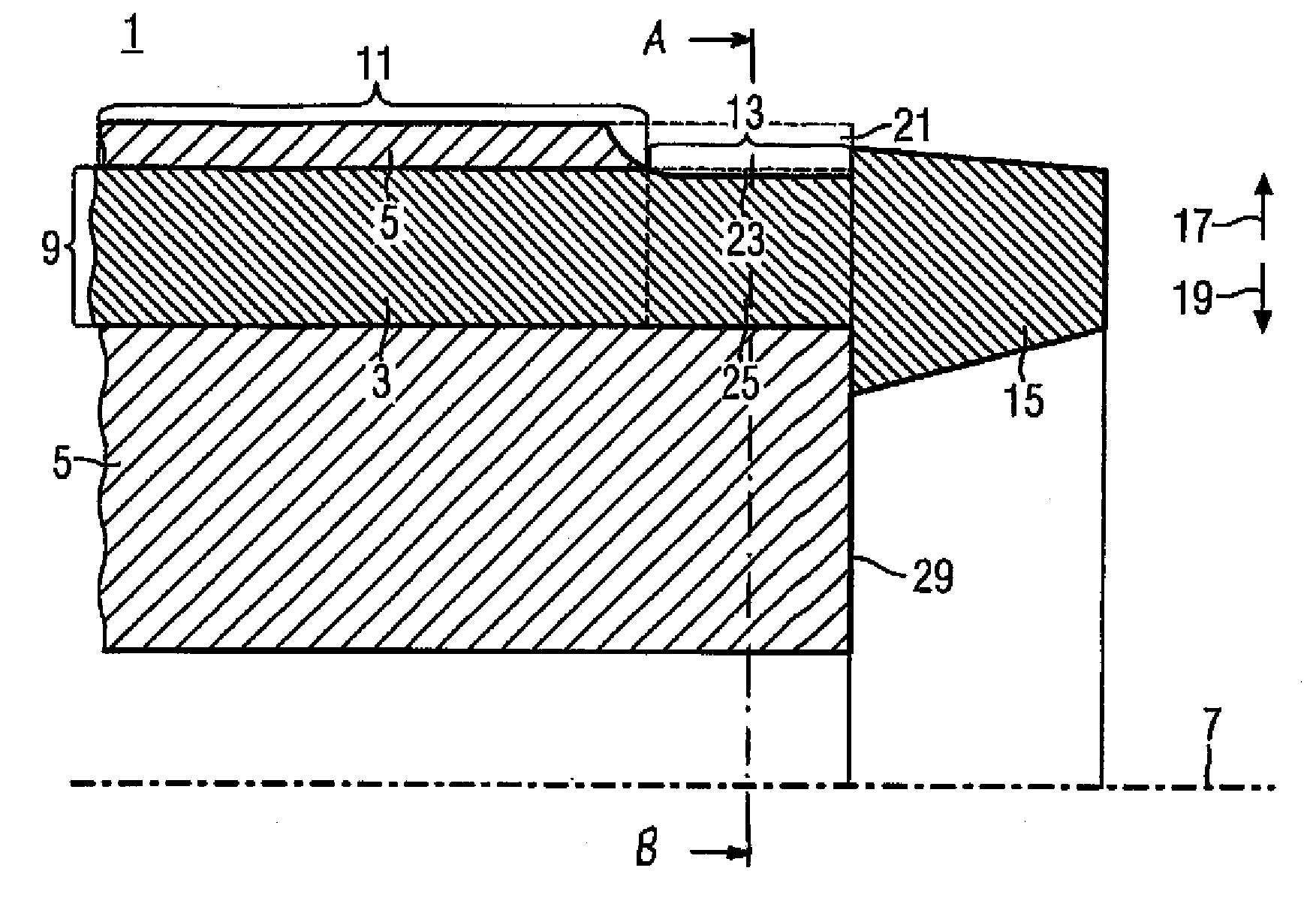

Squirrel-cage rotor

InactiveUS20070210667A1Improved squirrel-cage rotorReduce material stressSynchronous motorsStatorsElectrical conductorEngineering

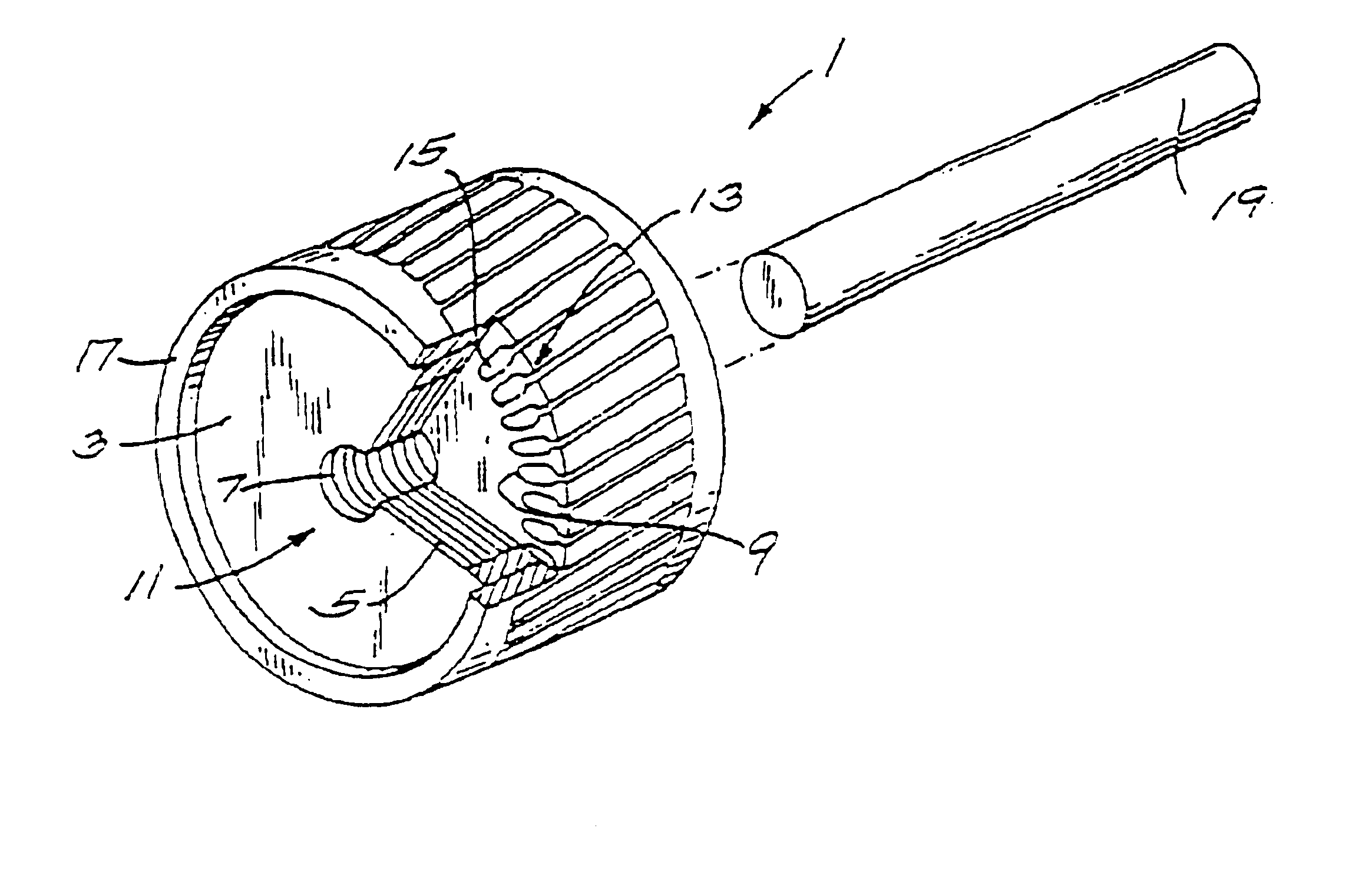

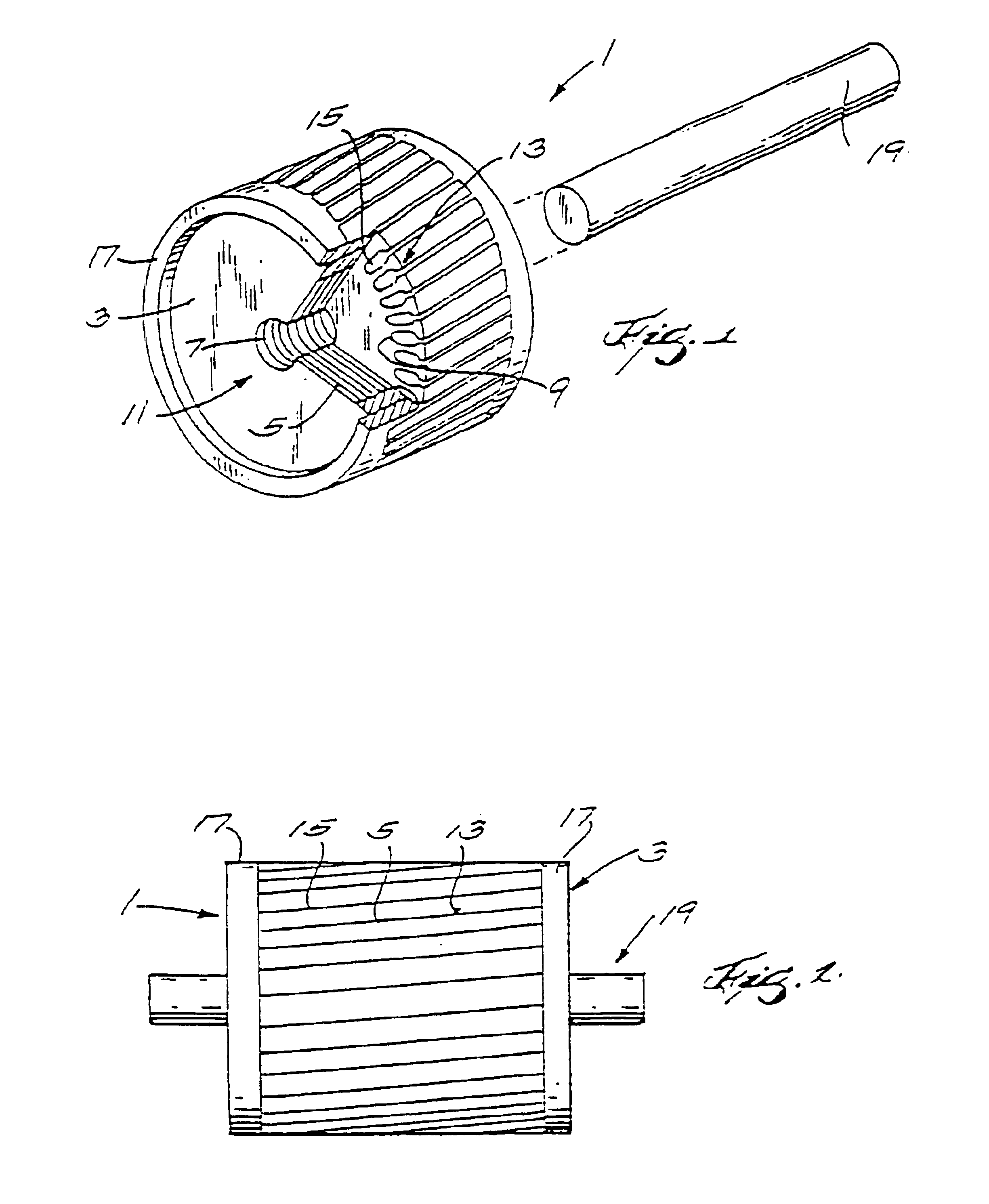

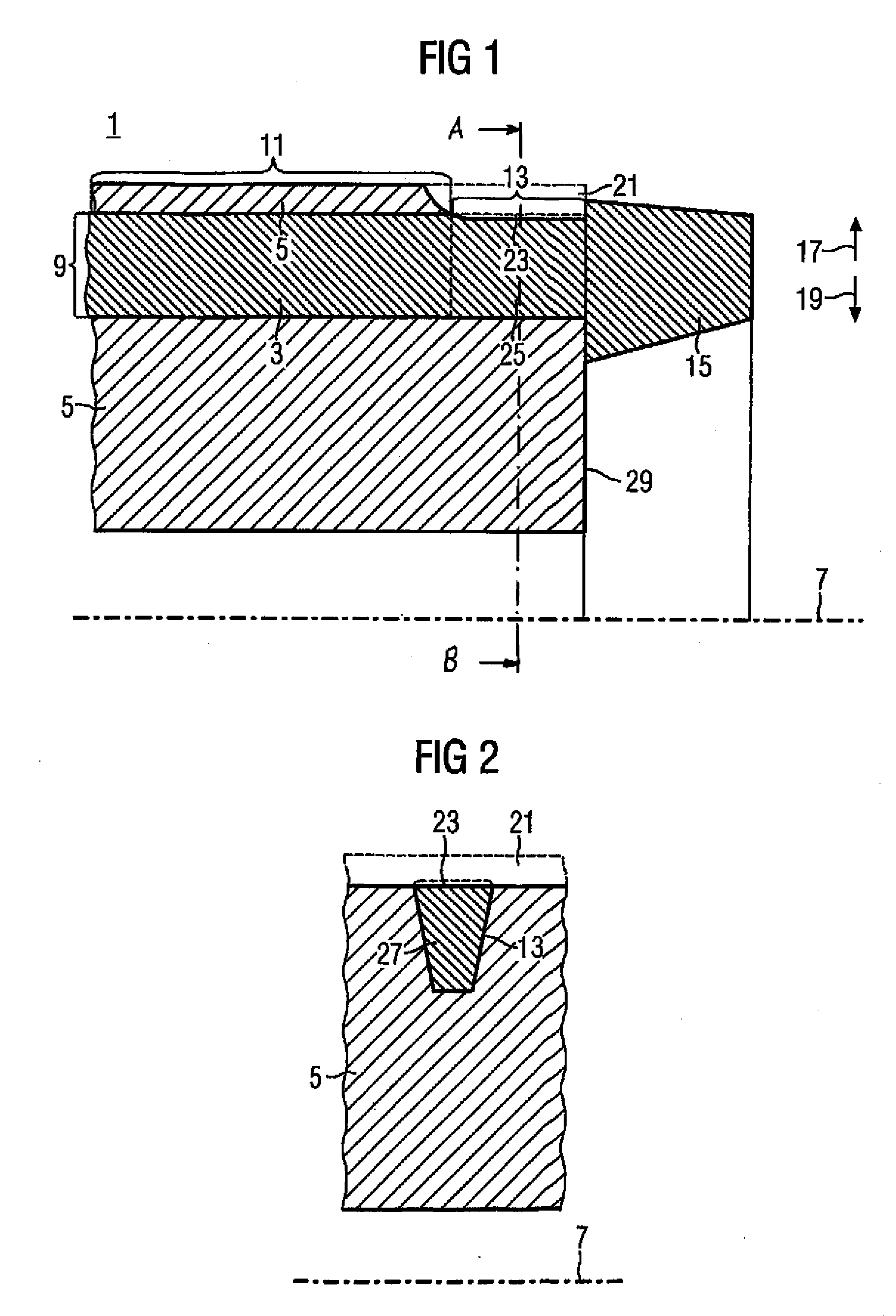

A squirrel-cage rotor (1) includes squirrel-cage rotor conductors (3) and a carrier (5) for the squirrel-cage rotor conductors (3). The carrier (5) is provided with axial slots (9) in which the squirrel-cage rotor conductors (3) are accommodated. An axial slot (9) includes at least one closed slot portion (11) and an open slot portion (13), with the open slot portion (13) located between the closed slot portion (11) and a cage ring (15). In a method for producing a squirrel-cage rotor (1) having a carrier (5) for squirrel-cage rotor conductors (3), with the carrier (5) having closed slots (9), the squirrel-cage rotor conductors (3) are cast into the slots or are inserted therein as bars, whereupon carrier material is removed in the area of the end surfaces (29) of the carrier (5) in such a way that an open slot portion (13) is formed.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com