Induction rotor assembly and method of manufacturing same

A component and rotor technology, applied in the field of manufacturing induction rotor components, can solve problems such as porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

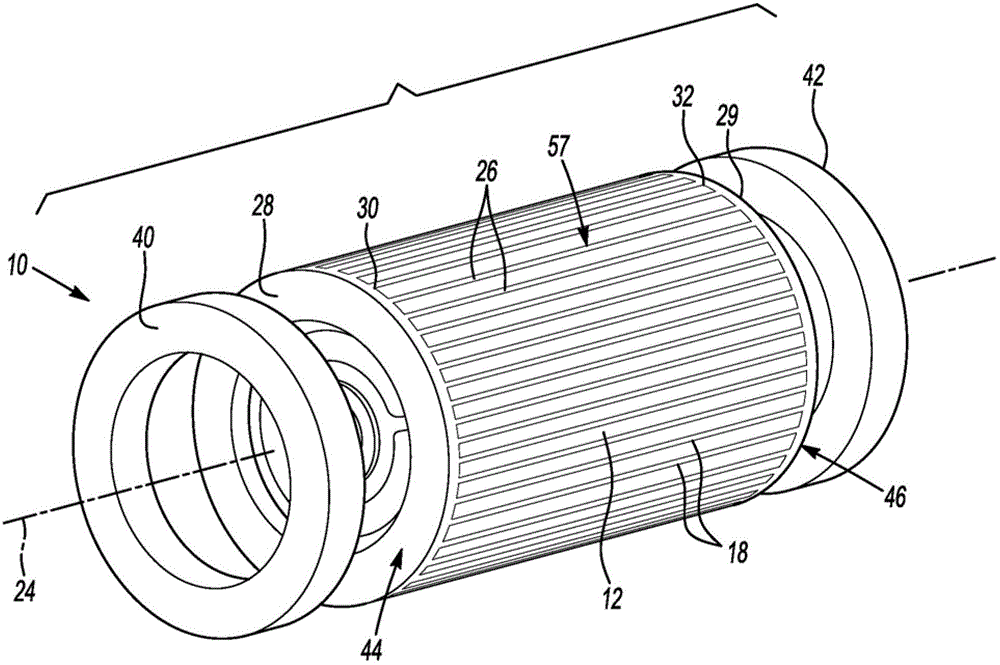

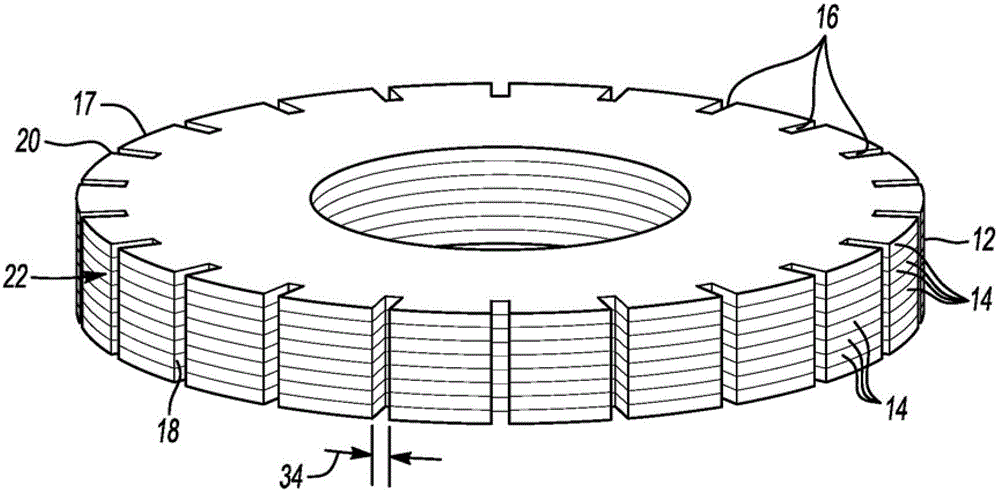

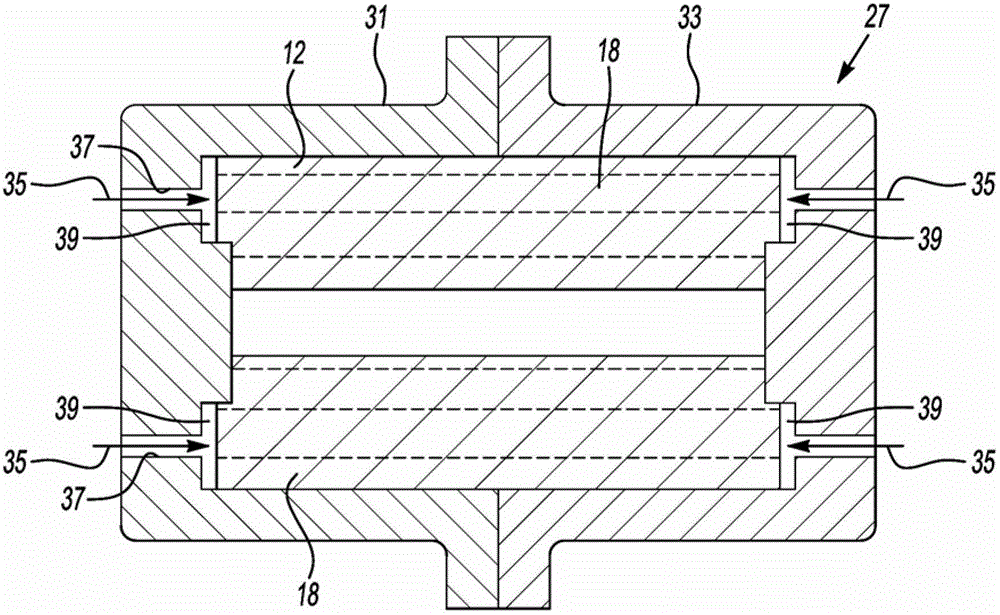

[0013] Referring to the drawings, wherein like reference numerals represent like parts throughout the several views, figure 1 The induction rotor assembly 10 is shown in an exploded view. The rotor assembly 10 includes a generally cylindrical rotor core 12 . The rotor core 12 is a lamination stack of identical sheets 14 of high magnetic steel, also referred to herein as a disc, as figure 2 , wherein some of the sheets 14 of the rotor core 12 are shown stacked to at least partially form as figure 1 The rotor core 12 is shown. Each plate 14 has grooves 16 spaced around its periphery 17 . When the plates 14 are stacked together, the grooves 16 of each plate 14 align with the grooves 16 in the adjacent plate 14 to define a perimeter 20 spaced around the outer surface 22 of the rotor core 12 and parallel to the central axis. The axial groove 18, the central axis is also the rotation axis 24 of the rotor assembly 10, such as figure 1 shown. A person skilled in the art underst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com