Motor rotor and its mfg. method, motor, brushless motor, compressor, refrigerator and air conditioner

A technology for electric motors and induction motors, which is applied in the manufacture of motor generators, asynchronous induction motors, synchronous motors for single-phase current, etc. Small, reduced magnetoresistance, reduced pressure loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

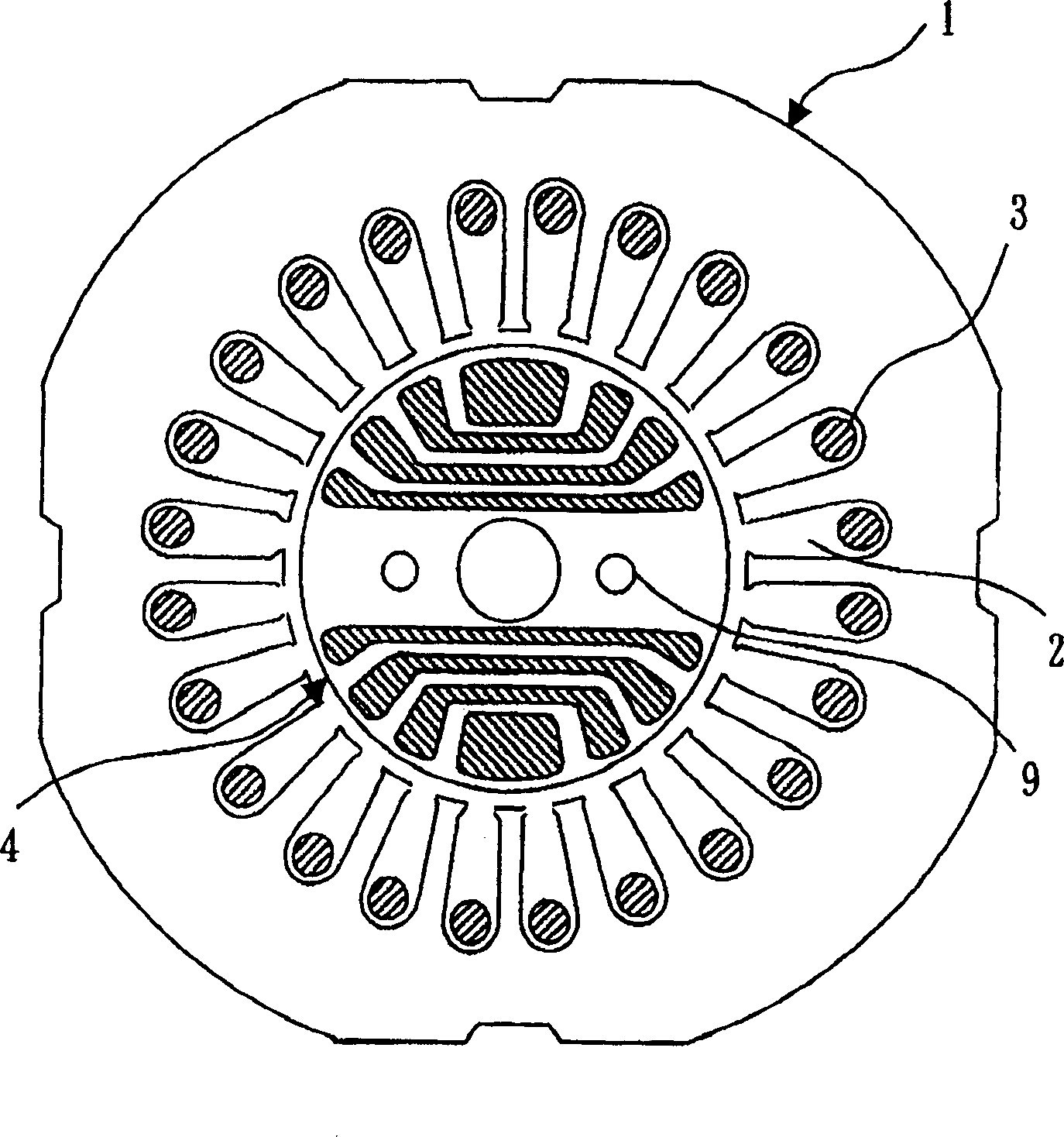

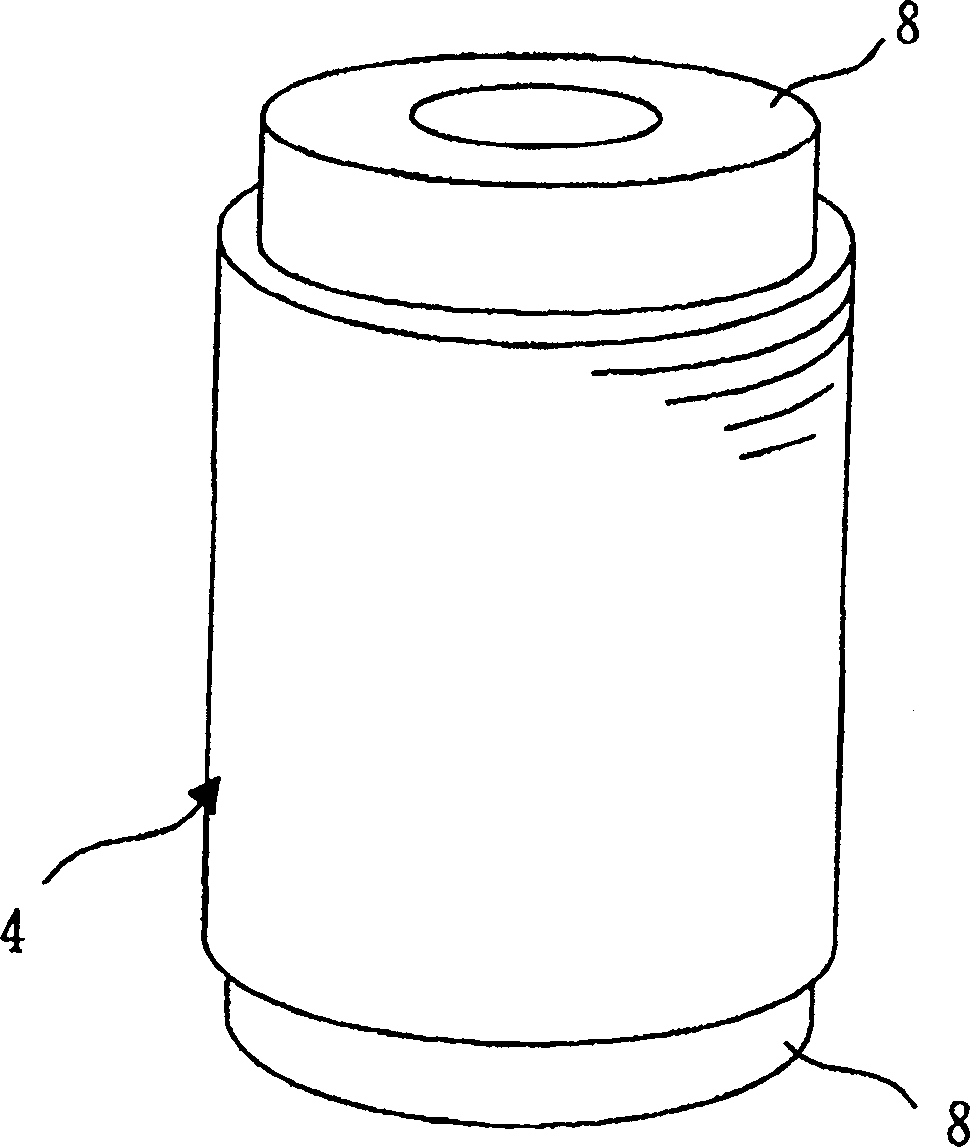

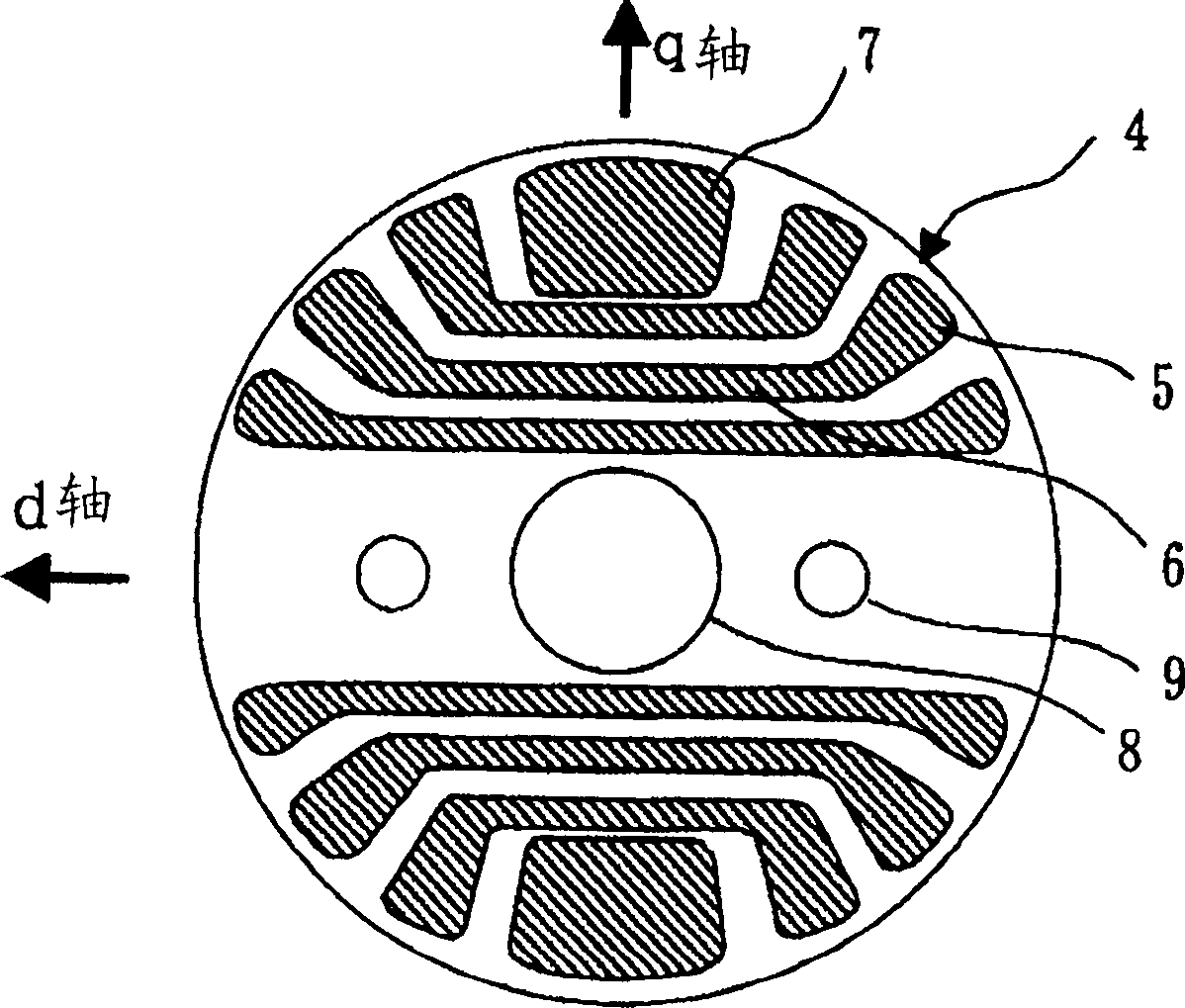

[0069] Figure 1 to Figure 4 is a diagram showing Embodiment 1, figure 1 It is a cross-sectional view of the stator and rotor of a synchronous induction motor, figure 2 is a perspective view of the rotor of a synchronous induction motor, image 3 is a cross-sectional view of the rotor of a synchronous induction motor, Figure 4 It is a cross-sectional view of a rotor of a synchronous induction motor in which a non-filled portion is provided in a slit.

[0070] exist Figure 1 ~ Figure 3 Among them, 1 is a stator of a synchronous induction motor, and coils 3 provided in a plurality of slots 2 on the inner diameter side of the stator 1 are wound so as to give a rotating magnetic field for rotating the rotor 4 . The rotor 4 is arranged inside the stator 1, and the slot part 5 for generating the induction torque and the slit part 6 for generating the reluctance torque are integrally provided on the rotor 4, and inside the slot part 5 and the slit part 6 The aluminum 7 that c...

Embodiment approach 2

[0082] 5 is a diagram showing Embodiment 2, and is a cross-sectional view of a rotor of a synchronous induction motor. As shown in the figure, the non-filled portion 10 is provided on the slit portion 6 closest to the center of the rotor 4 .

[0083] With this structure, since the amount of aluminum of the end ring 8 that functions as the rotor of the induction motor is not reduced, the secondary side resistance of the rotor can be reduced, and the torque of the induction motor as a region where the slip ratio is small can be increased. After the motor starts, it can stably enter synchronous operation.

[0084] In addition, when a synchronous induction motor is used in a hermetic compressor, since the peripheral speed generated by the rotation of the non-filling portion 10 functioning as a vent hole is small when the non-filling portion 10 is located on the rotor center side, it is possible to reduce the speed of passing through the non-filling portion 10. The pressure loss o...

Embodiment approach 3

[0087] Figure 6 It is a diagram showing Embodiment 3, and is a cross-sectional view of a rotor of a synchronous induction motor. As shown in the figure, two elliptical vent holes 9 are provided in the radial direction of the d-axis, and the elliptical holes are arranged as long holes along the radial direction of the d-axis.

[0088] With this structure, the increase in the reluctance in the d-axis direction of the portion imparting the reluctance torque due to the provision of the vent hole 9 can be greatly suppressed, and the decrease in the stator coil inductance Ld viewed from the d-axis side can be greatly suppressed, so , Obtain a synchronous induction motor with increased reluctance torque and high efficiency. In addition, since torque can be generated using a more compact and narrow rotor, it can be miniaturized and cost reduced.

[0089] In the above-mentioned embodiment, the case where the elliptical air hole 9 is provided has been described, but it is not limited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com