Flame detector cooling device and method

A technology for flame detectors and cooling devices, which is applied to household refrigeration devices, combustion methods, and safety devices for combustion chambers. Reduce operating costs, simple and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

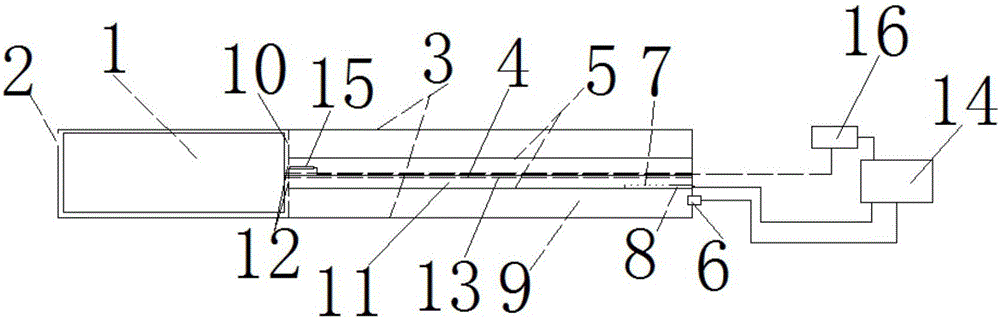

[0027] see figure 1 As shown, a flame detector cooling device is composed of flame detector probe 1, flame detector probe cooling air outlet 2, outer cooling pipe 3, optical fiber 4, inner cooling pipe 5, outer cooling pipe cooling air inlet 6, inner and outer Cooling pipe ventilation hole slot vent 7, ventilation hole slot 8, outer cooling pipe cooling air duct 9, outer cooling pipe cooling air outlet 10, inner cooling pipe cooling air duct 11, ventilation hole 12, heat insulation layer 13, The air volume adjustment device 14, the temperature measuring element 15 and the regulator 16 are composed. The flame detector probe 1 is set in the outer cooling pipe 3; Connection; the optical fiber 4 is arranged in the inner cooling pipe 5, one end of the optical fiber 4 is connected to the signal output interface of the flame detector probe 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com