Permanent-magnet pulse contactor

A technology of contactors and permanent magnets, applied in the direction of non-polar relays, etc., can solve the problems of power consumption, slow opening speed, contactor failure, etc., to reduce production costs and use costs, increase use capacity, and not easily damage the contactor head effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

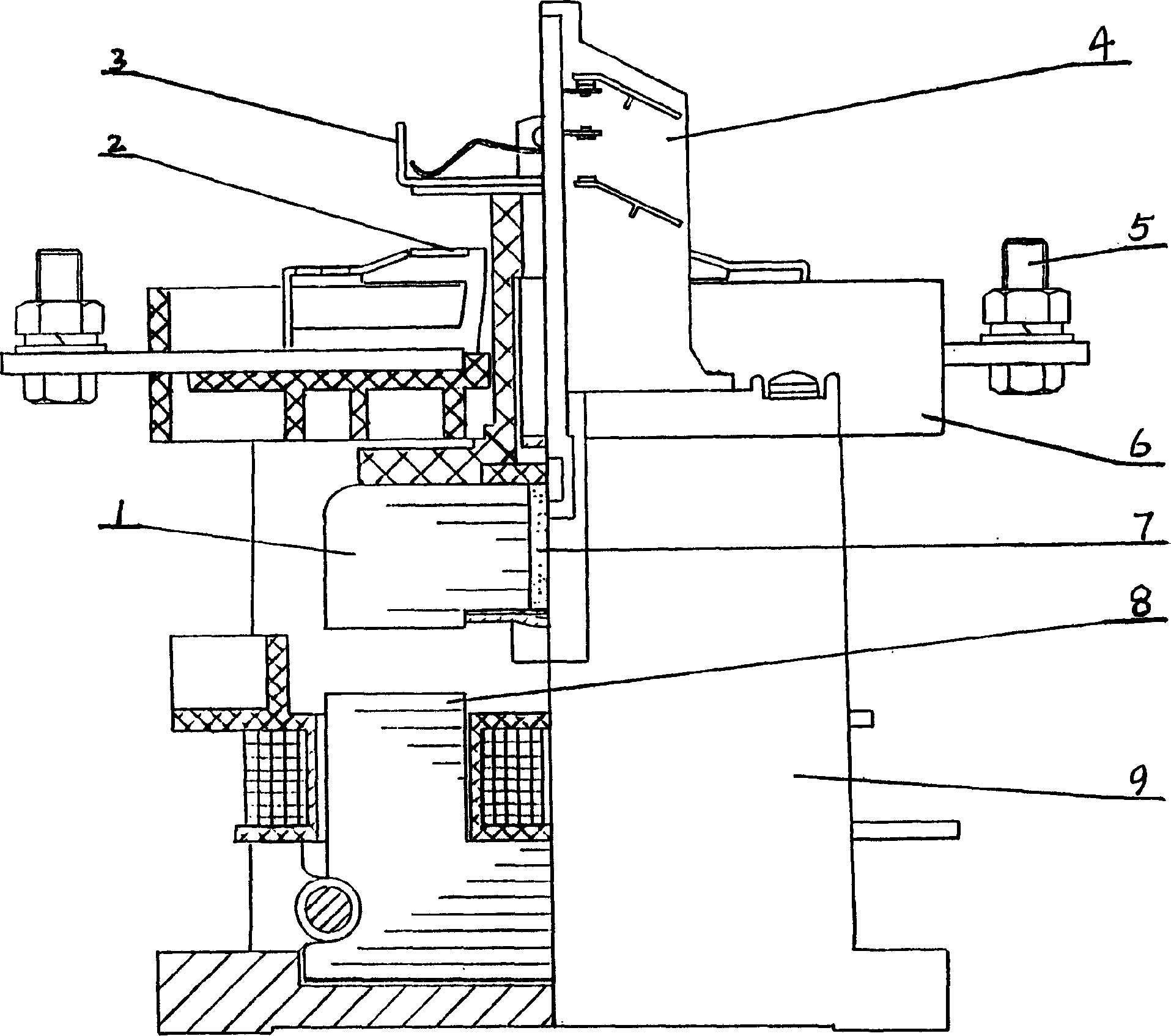

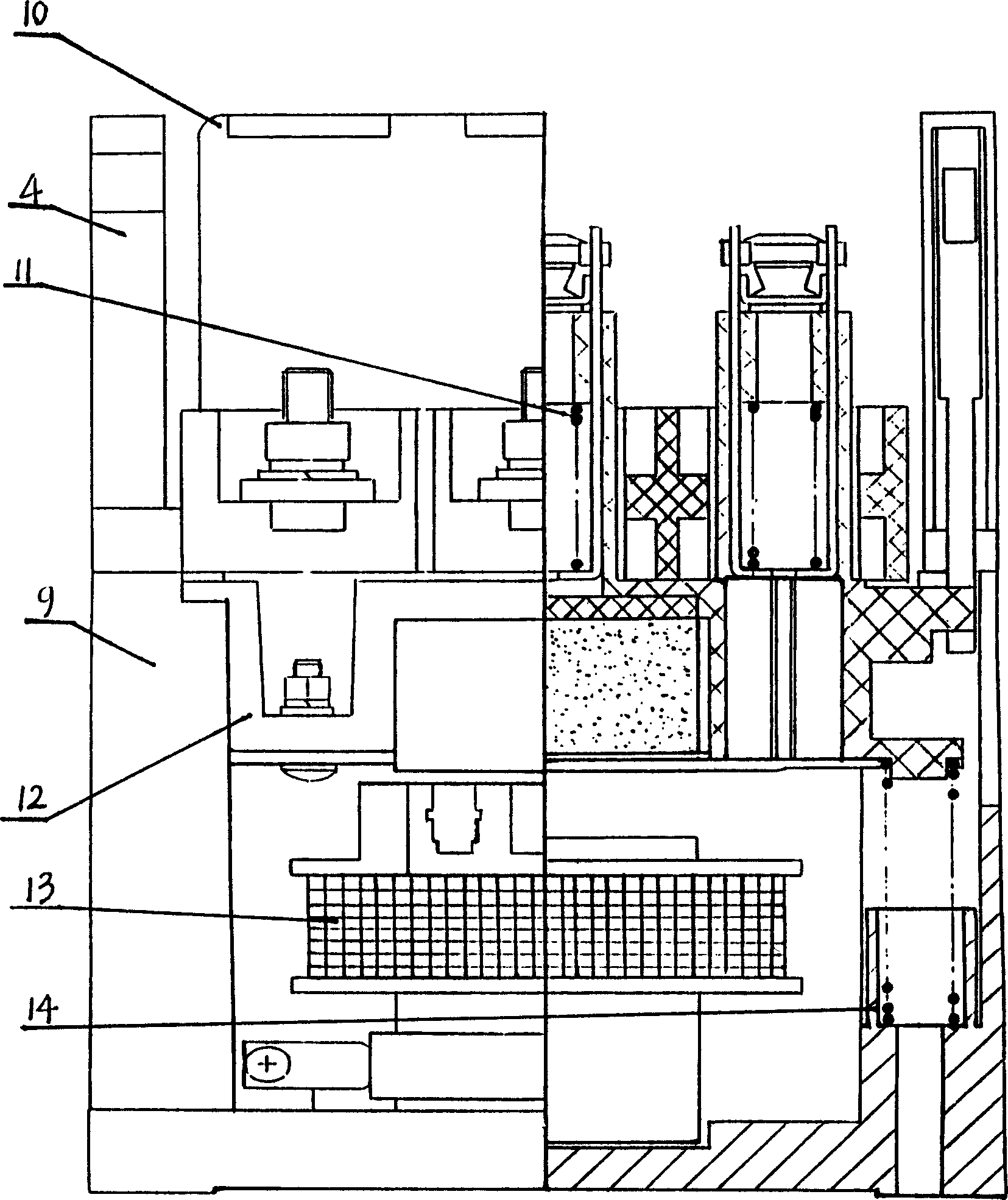

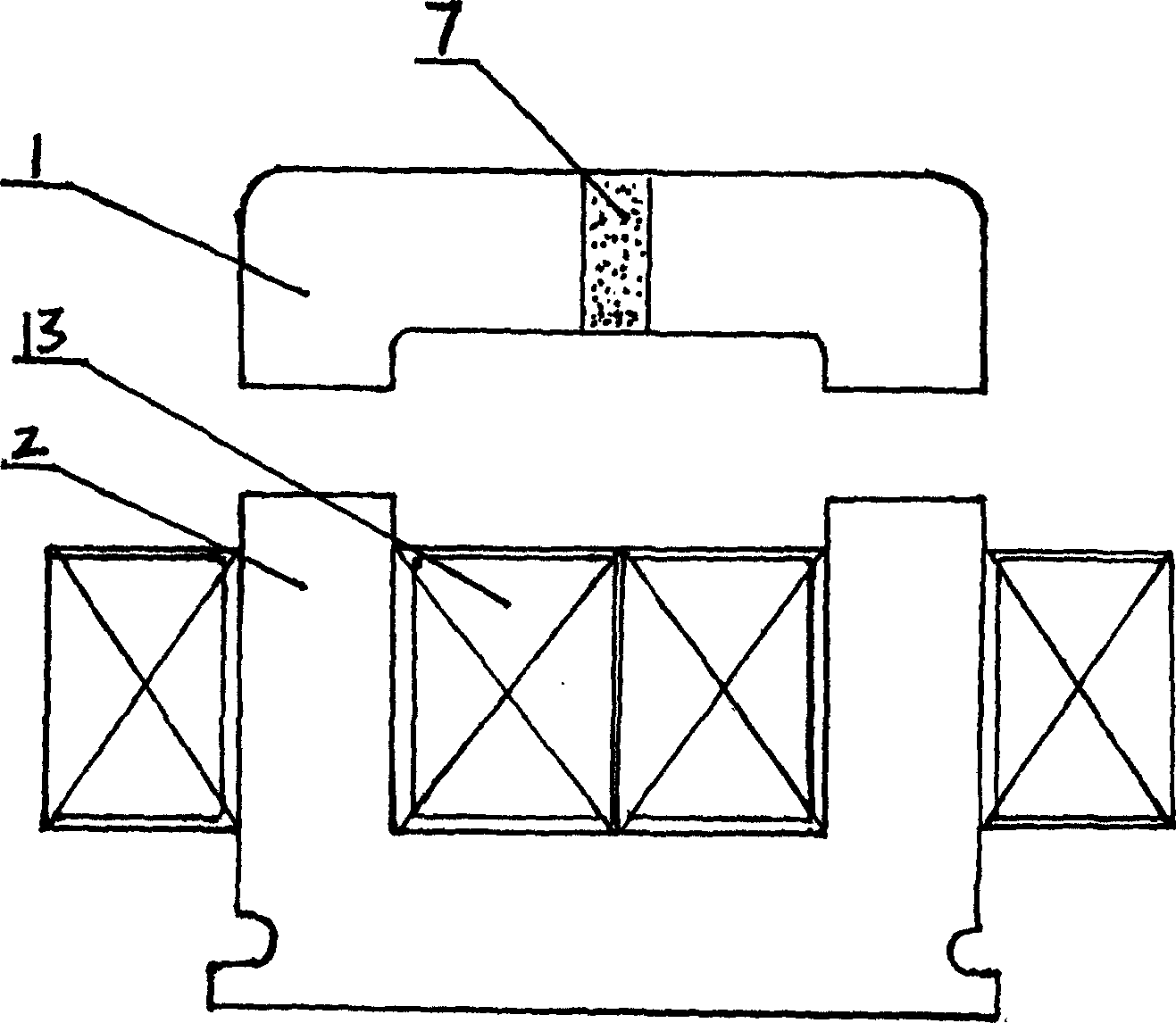

[0014] As shown in the figure, the static iron core 8 is fixedly connected to the bottom of the housing 9 and cooperates with the electromagnetic coil 13 , and the upper part of the static iron core 8 is provided with a corresponding moving iron core 1 . The permanent magnetic steel 7 is arranged on the moving iron core 1, and is fixedly connected with the moving bracket 12. Due to the structure of the permanent magnetic steel 7, the contactor does not need to maintain the current after it is turned on, and the static iron core 8 can adopt a non-split phase iron core without split phase and short-circuit ring, which still makes the moving iron core 1 stable and does not vibrate when it is pulled in. , which simplifies the core structure and reduces the product cost. Main springs 14 are arranged on both sides below the movable support 12, and a contact fixing plate 6 is arranged above. Wiring fixing screws 5 are arranged on both sides of the contact fixing plate 6, and are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com