Motor of washing machine

A technology for washing machines and motors, which is applied in the field of motors, can solve problems such as difficulties in motor production, difficulty in manufacturing, and complex structure of outer rotor type magnetic induction motors, and achieve the effect of simple structure and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

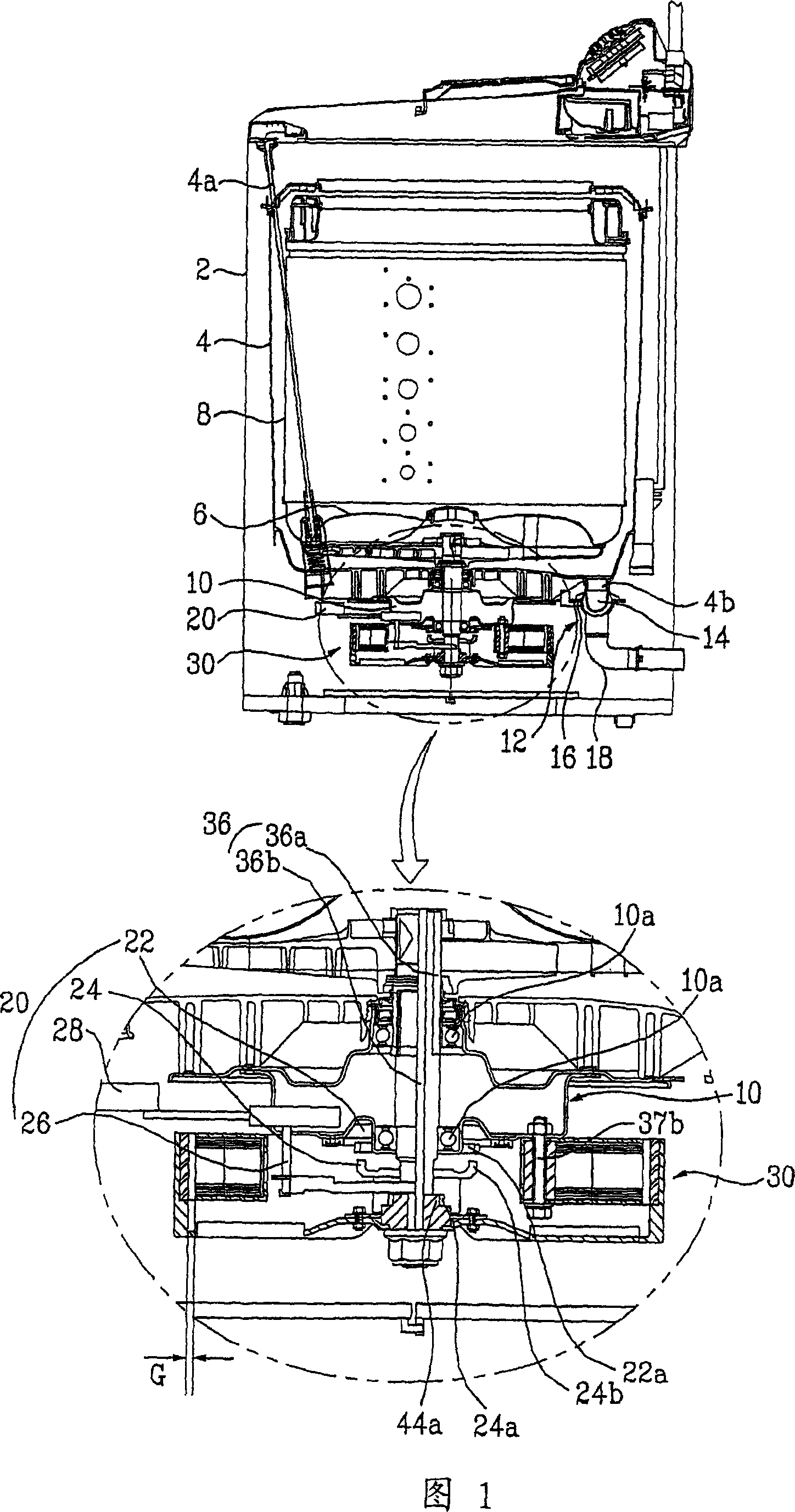

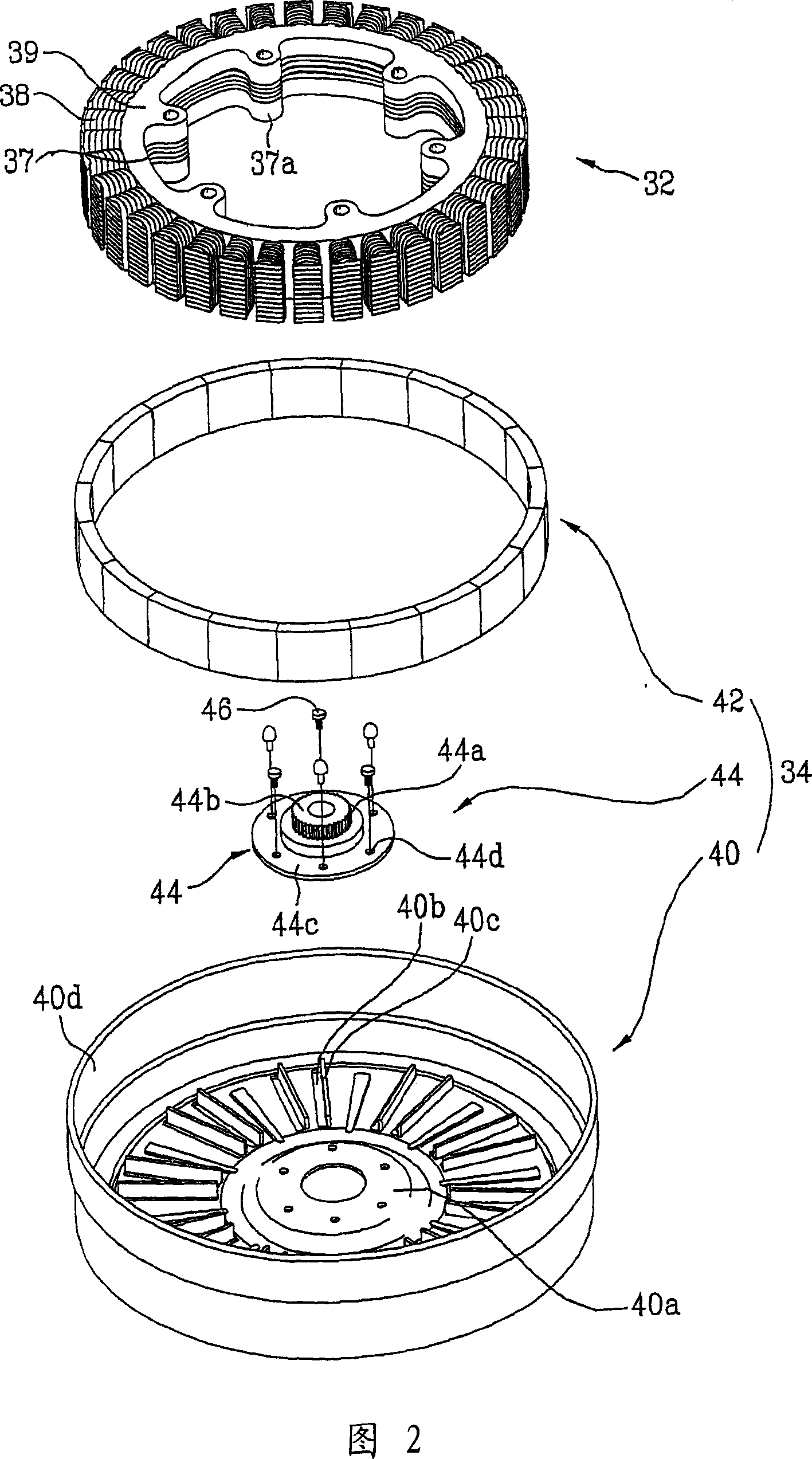

[0069] Embodiments of the present invention will be described below with reference to the drawings.

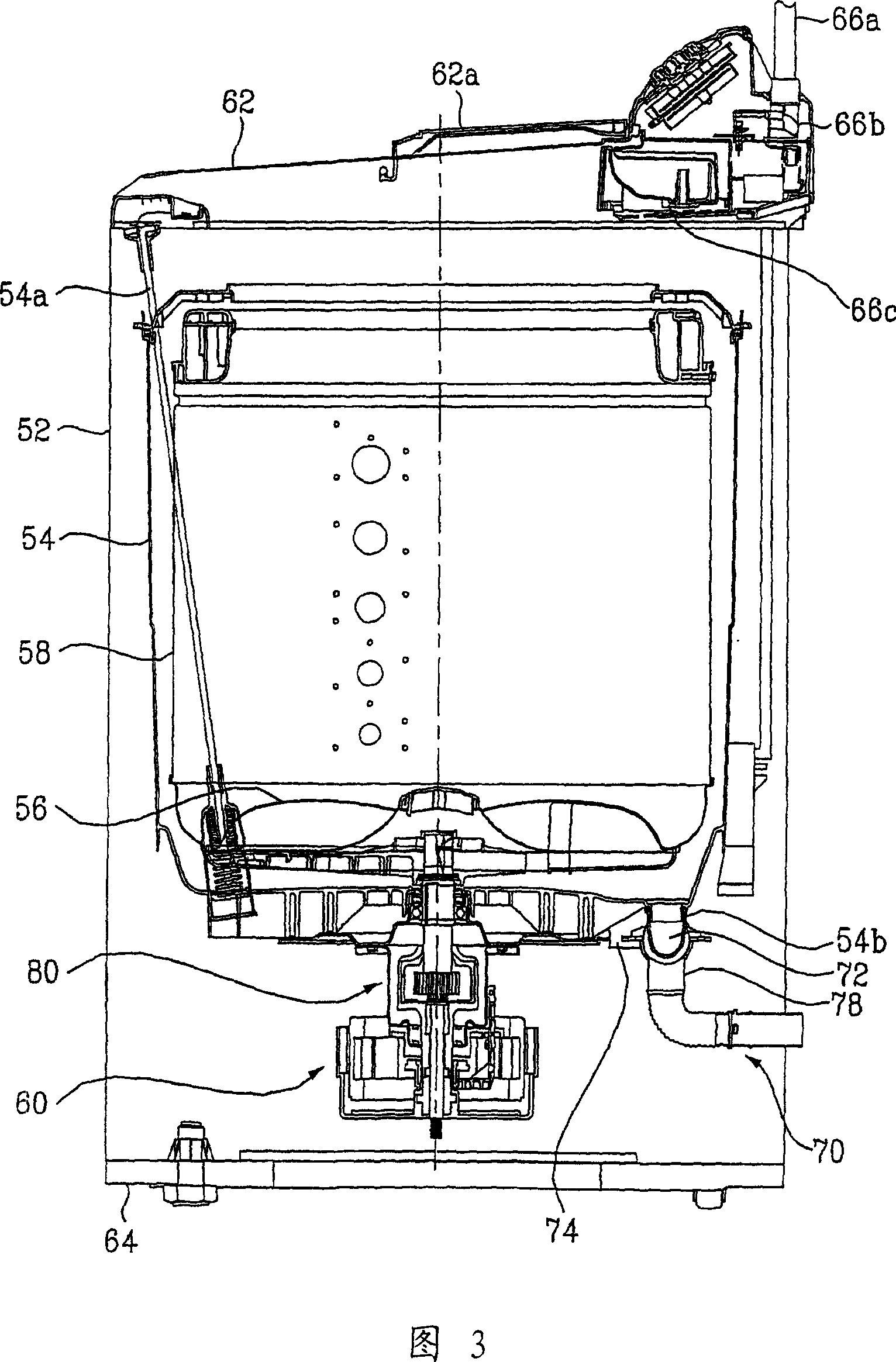

[0070] Fig. 3 shows a sectional view of a washing machine having a motor applied in accordance with a preferred embodiment of the present invention, Fig. 4 shows a perspective view showing key parts of Fig. 3 , and Fig. 5 shows a section showing key parts of Fig. 3 , And FIG. 6 shows a cross section along the line A-A in FIG. 4 .

[0071] Referring to Figures 3 to 6, the washing machine includes a cabinet 52 forming its exterior; an outer tub 54 suspended within the cabinet 52 by means of a support member 54a, which has a space for holding washing water inside; an inner tub 58 rotatably mounted in the outer tub 54, whose bottom A commutator 56 is installed, and water holes are arranged on the side wall; a motor 60 located below the outer tub 54, which provides driving force to rotate the commutator 56 and the inner tub 58; and a power transmission between the motor 60 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com