Squirrel-cage rotor of induction motor and production method thereof wherein end ring is brazed with bar

A squirrel-cage rotor and induction motor technology, which is applied in the field of squirrel-cage rotors, can solve the problems of increased working hours, manual work procedures, and increased working hours, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

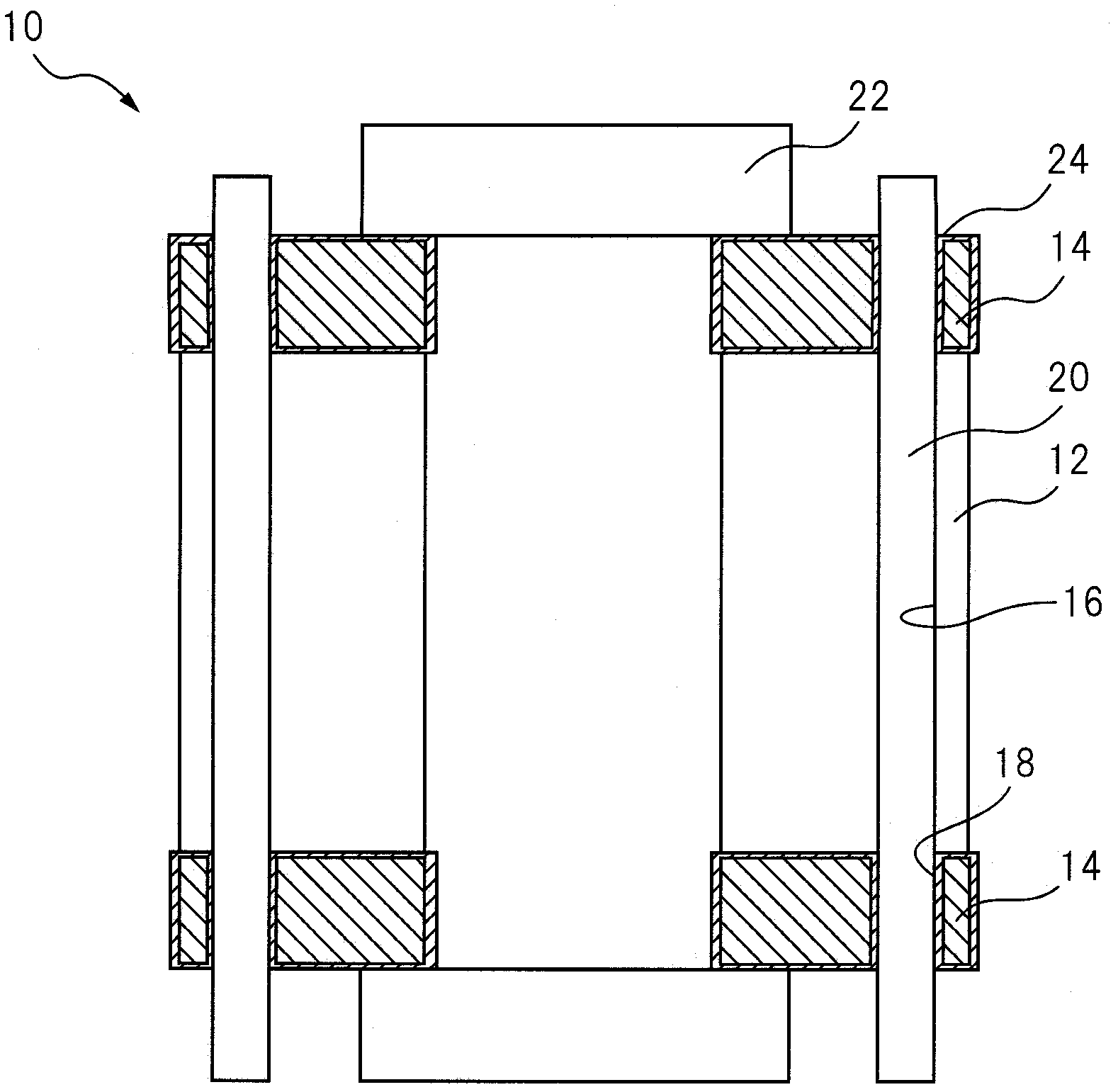

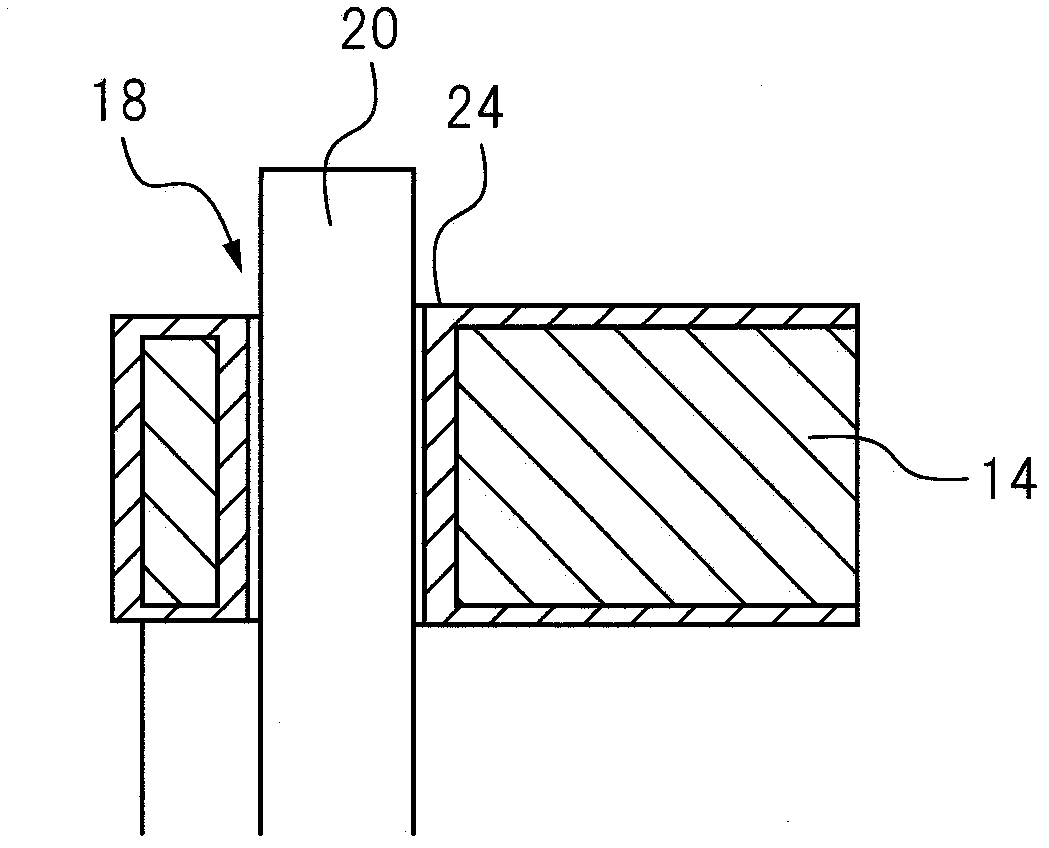

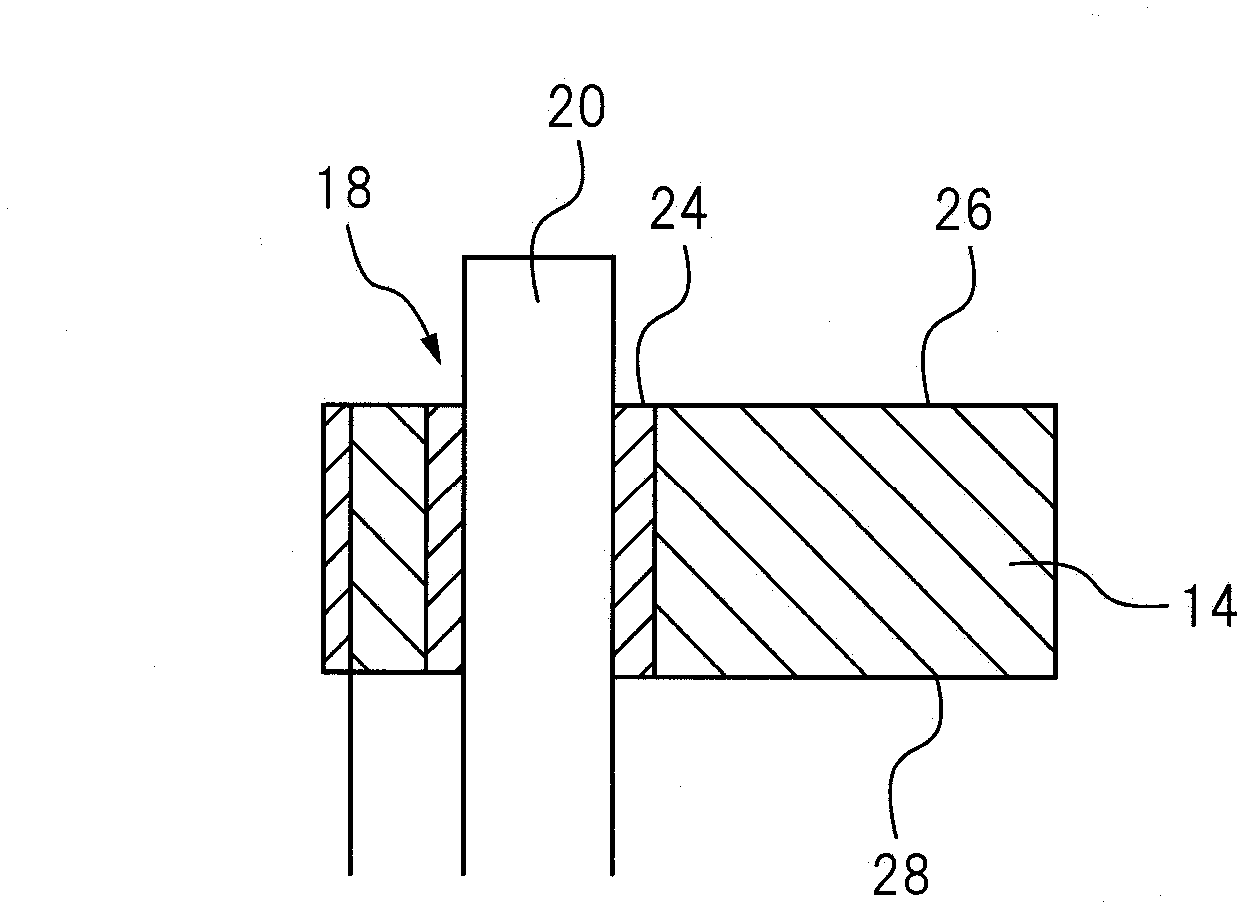

[0020] figure 1 It is a schematic structural diagram showing the squirrel-cage rotor 10 of the induction motor of the present invention, and shows a cross-sectional view of the rotor in the direction of the rotation axis. The squirrel-cage rotor 10 includes a rotor iron core 12 made of silicon steel sheets, and end rings 14 made of pure copper or a copper alloy disposed at both ends of the rotor iron core 12 in the rotational axis direction, and formed so as to be inserted into the rotor iron. One or more conductor bars (rotor bars) 20 made of pure copper or copper alloy formed in the through holes 16 in the core 12 and the through grooves 18 in the end ring 14, and a jig 22 for fixing the above components.

[0021] The shape of the through groove 18 formed in the end ring 14 is substantially complementary to the outer shape of the conductor bar 20. In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com