Inner cone ring of heavy truck gear box synchronizer and manufacturing process thereof

A manufacturing process and gearbox technology, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problem of affecting the function and service life of synchronizer gearboxes, difficult mass production of inner cone ring products, inner The complex shape of the cone ring and other problems can achieve the effect of reducing machining allowance, low manufacturing cost and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Formula 1: The raw material composition and weight percentage of the inner cone ring of the synchronizer of the heavy-duty truck gearbox are: 1.6% of copper powder to improve the strength of the material, 0.6% of graphite powder, 0.3% of the easy cutting agent to improve the cutting performance, and to improve the mold release 0.7% of lubricant for lubricating performance, 0.1% of binder for improving the mixing uniformity of iron powder, copper powder and graphite powder, and the balance is 96.7% of iron powder.

[0053] The manufacturing process steps of the inner cone ring using formula 1 are as follows:

[0054] (1) Mixing: Put various raw materials into the mixer according to the formula ratio, and mix for 50 minutes.

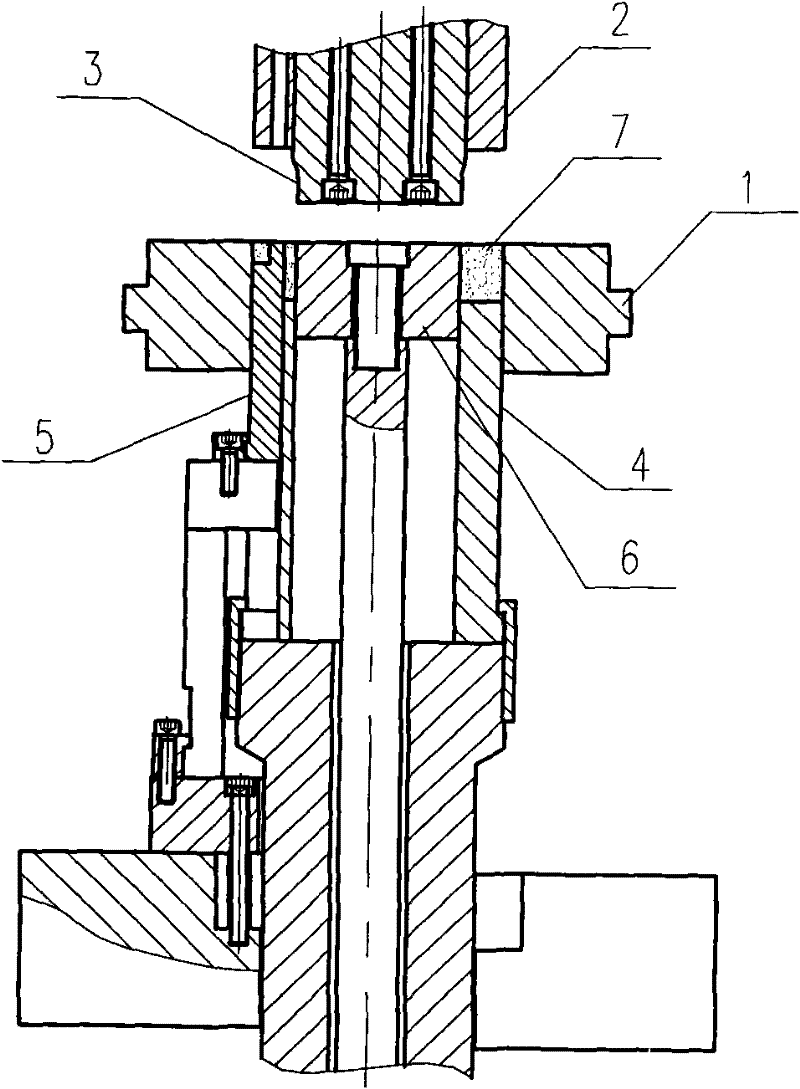

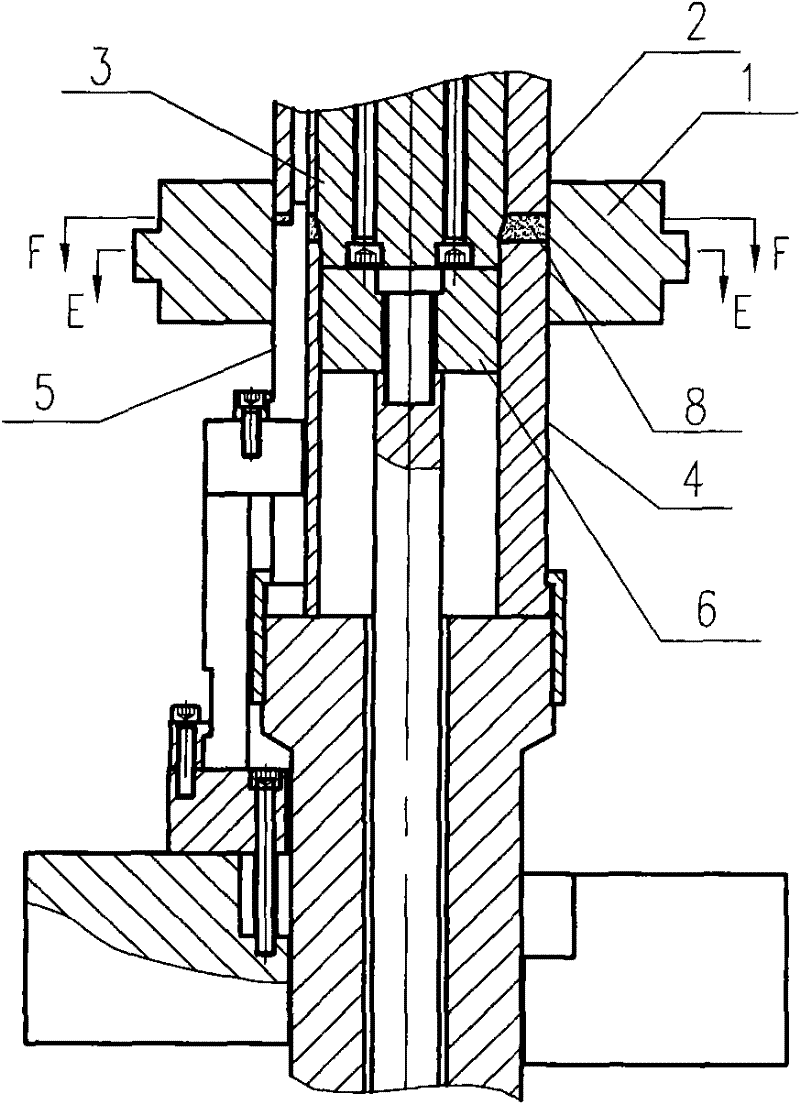

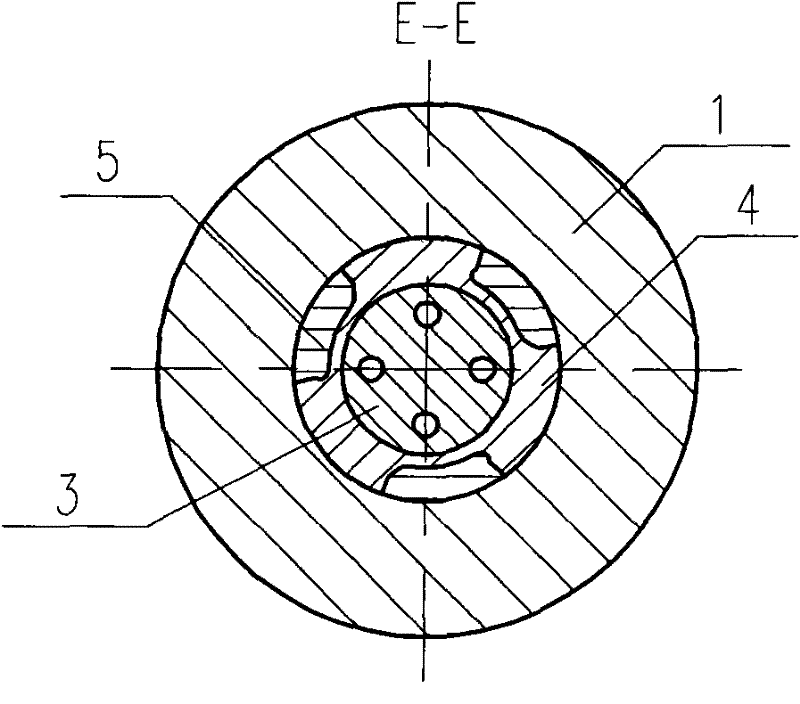

[0055] (2) Forming: The mixture in step (1) is cold-pressed with an inner cone ring pressing die and a press to form a powder metallurgy body blank of the inner cone ring, with a pressure of 6T / cm 2 ; When forming, the marks for placing the copper ...

Embodiment 2

[0062] Formula 2: The raw material composition and weight percentage of the inner cone ring are: 0.5% copper powder to improve material strength performance, 0.75% graphite powder, 0.4% easy cutting agent to improve cutting performance, and lubricant to improve mold release lubrication performance 0.8%, 0.15% of binder for improving the mixing uniformity of iron powder, copper powder and graphite powder, and the balance is 97.4% of iron powder.

[0063] The manufacturing process steps of the inner cone ring using formula 2 are as follows:

[0064] (1) Mixing: Put various raw materials into the mixer according to the formula ratio, and mix for 70 minutes.

[0065] (2) Forming: The mixture in step (1) is cold-pressed with an inner cone ring pressing die and a press to form a powder metallurgy body blank of the inner cone ring, with a pressure of 6.5T / cm 2 ; When forming, the marks for placing the copper infiltrating block are formed at the positions of the three small holes tha...

Embodiment 3

[0072] Formula 3: The raw material composition and weight percentage of the inner cone ring are: 2.5% copper powder to improve material strength performance, 0.9% graphite powder, 0.45% easy cutting agent to improve cutting performance, and lubricant to improve mold release lubrication performance 0.85%, 0.2% of the binder to improve the mixing uniformity of iron powder, copper powder and graphite powder, and the balance is 95.1% of iron powder.

[0073] The manufacturing process steps of the inner cone ring using formula 3 are as follows:

[0074] (1) Mixing: Put various raw materials into the mixer according to the formula ratio, and mix for 45 minutes.

[0075] (2) Forming: The mixture in step (1) is cold-pressed with an inner cone ring pressing die and a press to form a powder metallurgy body blank of the inner cone ring, with a pressure of 5.8T / cm 2 ; When forming, the marks for placing the copper infiltrating block are formed at the positions of the three small holes th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com