Automobile front door ring, manufacturing method thereof and automobile

A technology for automobiles and front doors, applied in vehicle parts, transportation and packaging, superstructure, etc., can solve the problems of complex process, low strength of welding point area, fatal injury to drivers and passengers of automobile A-pillars and roof beams, etc. The effect of high safety factor, ensuring body strength and avoiding fatal injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

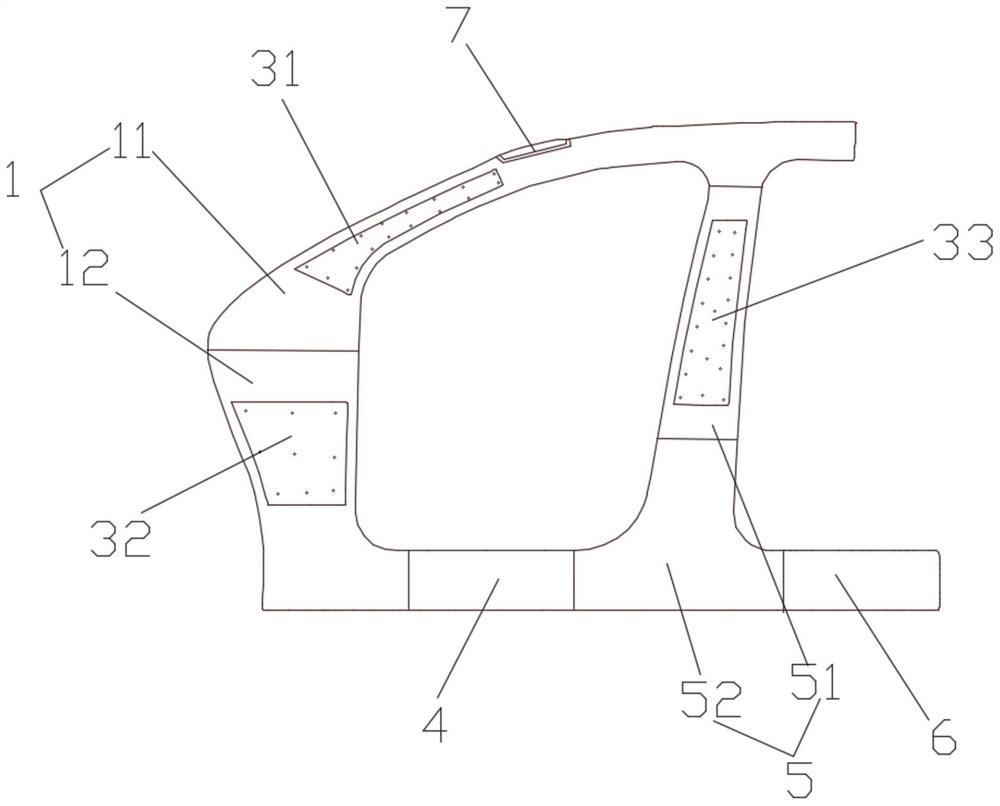

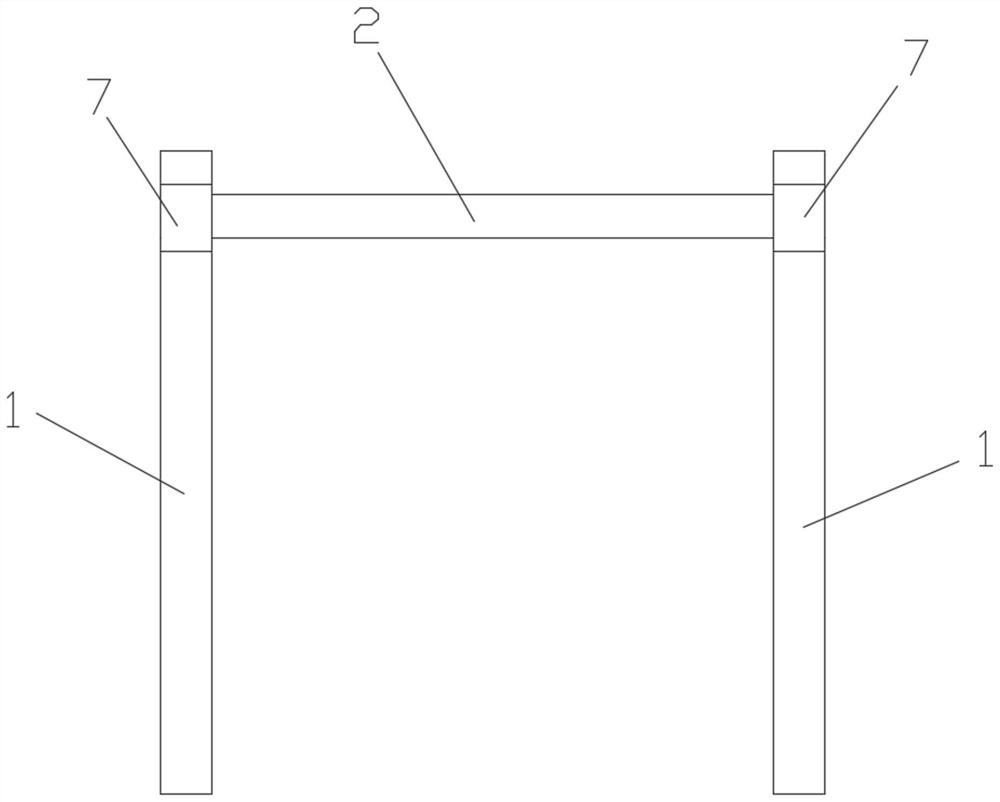

[0041] Such as figure 1 , figure 2 As shown, the embodiment of the automobile front door knocker disclosed by the present invention includes,

[0042] include,

[0043] An automobile A-pillar 1 comprising an A-pillar upper section 11 and an A-pillar lower section 12, the lower end of the A-pillar upper section 11 is fixed to the A-pillar lower section 12, and the A-pillar upper section 11 has a first soft zone 7 for welding with the roof beam 2;

[0044] The automobile B-pillar 5 comprising the upper section 51 of the B-pillar and the lower section 52 of the B-pillar, the upper end of the upper section 51 of the B-pillar is fixed to the upper section 11 of the A-pillar, and the lower end of the upper section 51 of the B-pillar is fixed to the upper end of the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com