Automobile rear girder assembly and automobile rear lower automobile body structure

A technology for automobiles and assemblies, which is applied in the field of car body structures at the rear of automobiles. It can solve problems such as small bearing capacity, low torsional rigidity, and influence on oil injection, and achieve the effects of improving stamping formability, increasing strength and rigidity, and avoiding easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

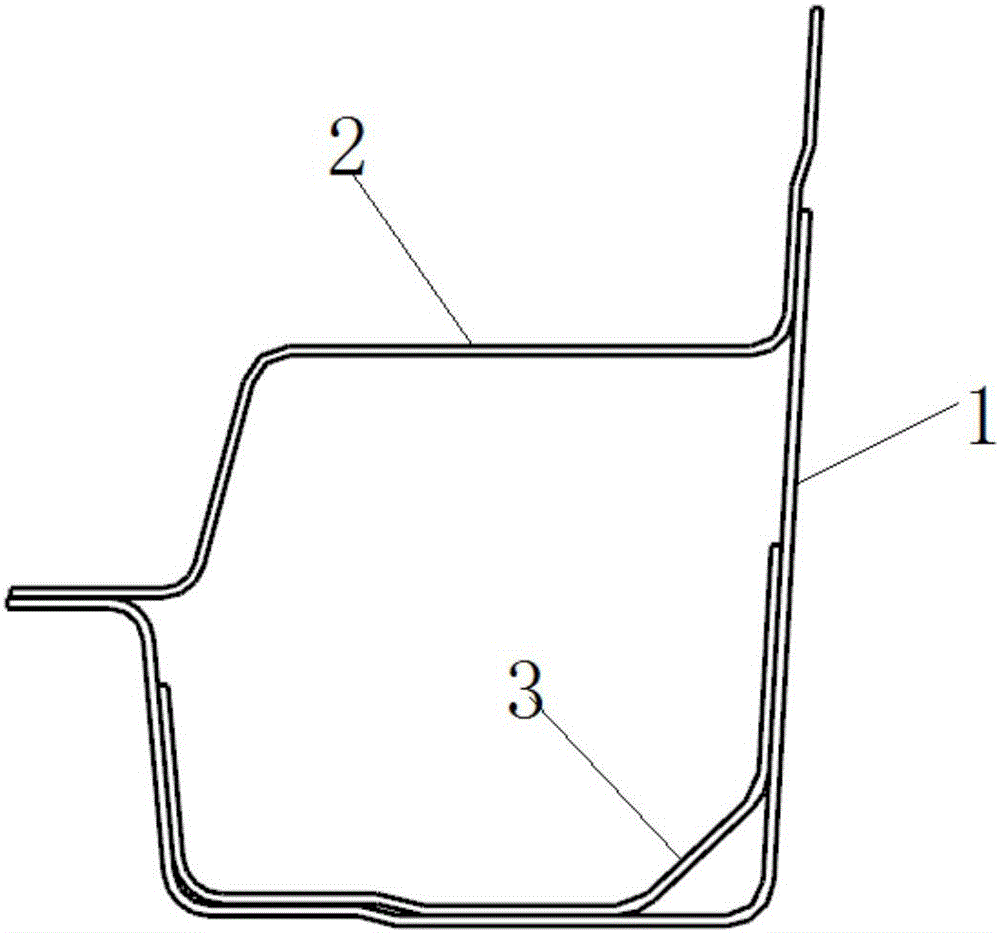

[0035] like figure 1 and figure 2 As shown, the automobile rear frame assembly of the present invention includes a fixedly connected rear frame 1 and a rear frame inner plate 2, the rear frame inner plate 2 is welded on the top of the rear frame 1, and the cross sections of both are semi-enclosed structures, The rear frame 1 and the rear frame inner panel 2 form a large closed hollow cavity as a whole, which improves the load-carrying capacity of the vehicle and can withstand a greater force when it is collided, and when the rear frame 1 is close to the rear frame A rear frame reinforcement plate 3 is added to one side of the plate 2 to increase the rigidity of the overall automobile rear frame assembly.

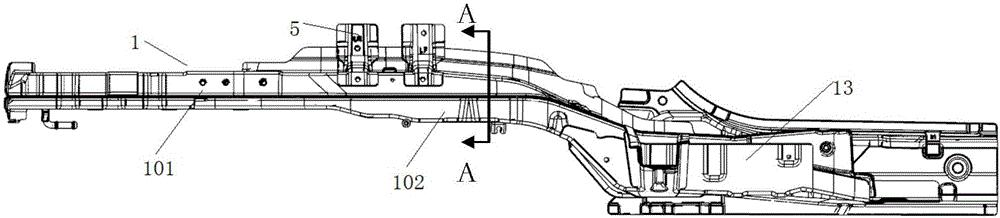

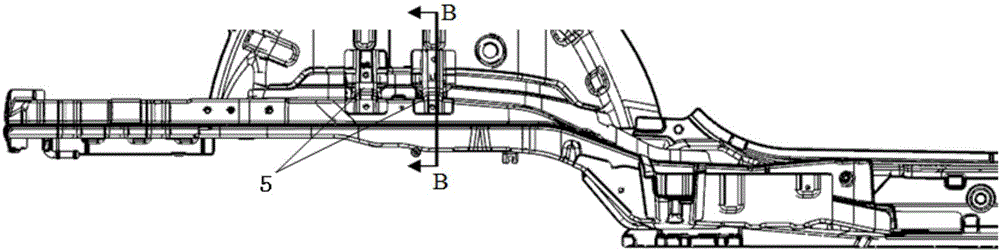

[0036] The rear frame 1 of this example is arranged on the rear end of the front frame 13, including the rear frame front portion 102 ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com