Production method of composite ceramic core for single crystal hollow blade of complex structure

A hollow blade, complex structure technology, applied in the field of superalloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

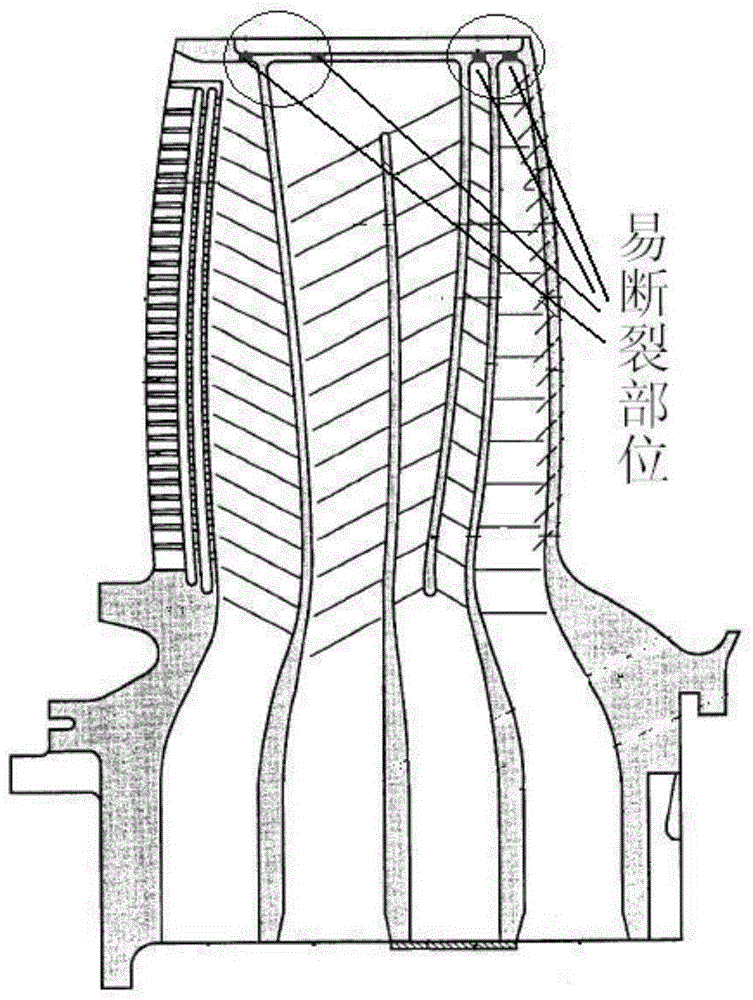

Problems solved by technology

Method used

Image

Examples

Embodiment 1

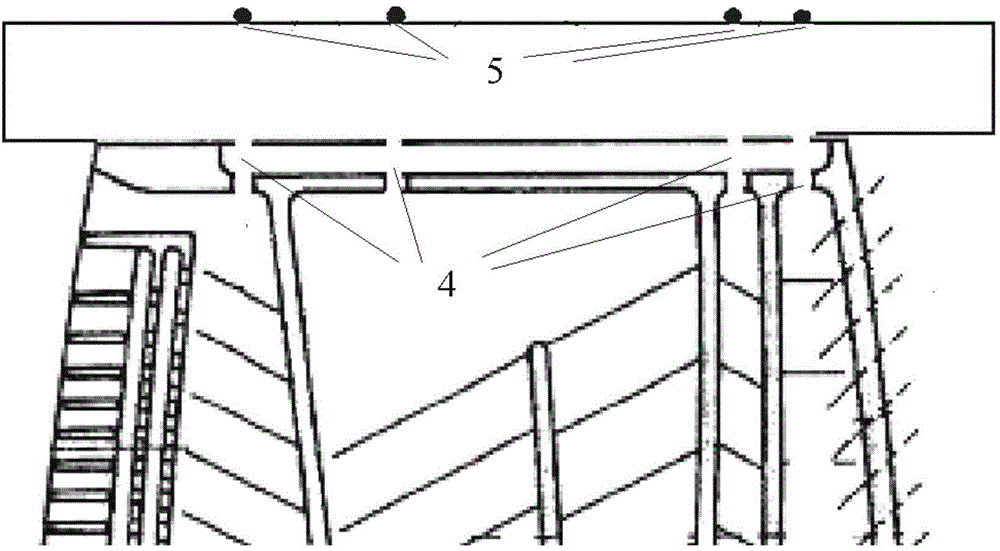

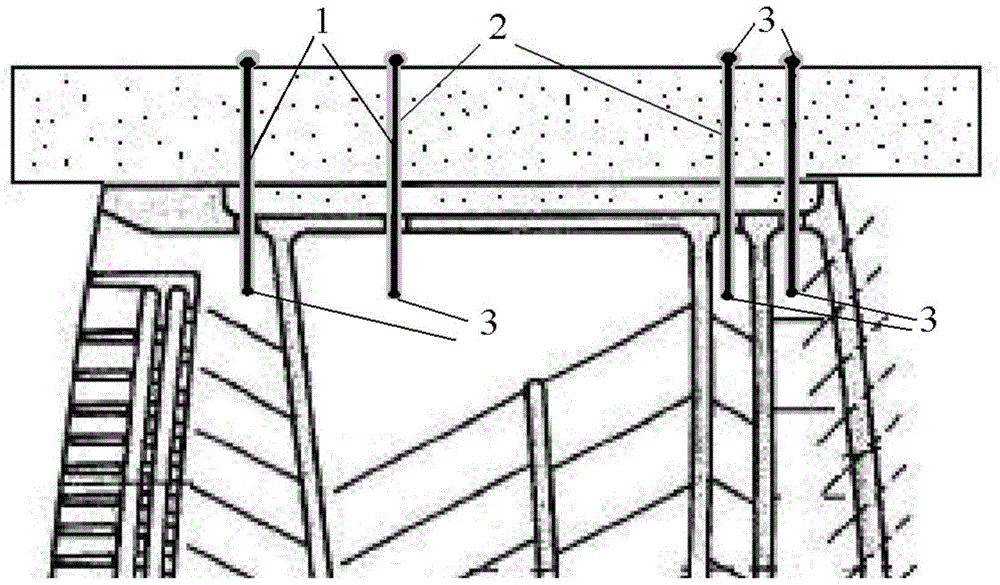

[0021] Preparation of locally strengthened composite ceramic core:

[0022] The molybdenum wire with a diameter of 0.08 mm is cut into a molybdenum wire segment with a length of 5 mm, and the two ends of the molybdenum wire segment are arc-welded to make the two ends of the molybdenum wire into a spherical shape with a diameter of 0.2 mm to form a molybdenum wire fixing mechanism. Then adopt CVD to deposit silicon dioxide on the surface of the molybdenum wire section, the thickness of the silicon dioxide thin layer is 10 microns; then the molybdenum wire section is placed in the fixed groove in the ceramic core mold to fix (see figure 2 ), the ceramic core blank was prepared by injection molding, the ceramic slurry was a silica-based material, the molding pressure was 0.8MPa, the injection time was 20 seconds, and the pressure holding time was 20 seconds; the sintering process of the composite core was: The dewaxing stage of the ceramic core is sintered with low temperature a...

Embodiment 2

[0026] The high-purity molybdenum wire with a diameter of 0.1 mm is cut into molybdenum wire segments with a length of 10 mm. The two ends of the molybdenum wire segment are welded by argon arc to make the two ends of the molybdenum wire into a spherical shape with a diameter of 0.25 mm to form a fixing mechanism. Then PVD is used to deposit silicon dioxide on the surface of the molybdenum wire segment, and the thickness of the silicon dioxide thin layer is 20 microns; it is then fixed in a ceramic core mold, and the ceramic core blank is prepared by injection molding, and the ceramic slurry is Alumina-based materials, the molding pressure is 0.5MPa, the injection time is 30 seconds, and the pressure holding time is 30 seconds; the sintering process of the composite core is: the ceramic core is sintered at a low temperature and slowly raised during the dewaxing stage, and the heating rate is controlled at 0.8°C / min, temperature 600°C, holding time 2 hours; the final sintering ...

Embodiment 3

[0030]The high-purity molybdenum wire with a diameter of 0.16 mm is cut into molybdenum wire segments with a length of 10 mm. The two ends of the molybdenum wire segment are welded by argon arc to make the two ends of the molybdenum wire into a spherical shape with a diameter of 0.4 mm to form a fixing mechanism. Then use the sol-gel method to deposit alumina on the surface of the molybdenum wire segment, the thickness of the aluminum oxide thin layer is 100 microns; then place the molybdenum wire segment in the ceramic core mold and fix it, and prepare the ceramic core element by injection molding The blank, the ceramic slurry is silica-based, the molding pressure is 0.8MPa, the injection time is 120 seconds, and the pressure holding time is 120 seconds; the sintering process of the composite core is: the ceramic core dewaxing stage is sintered at low temperature and slowly The heating rate is controlled at 1°C / min, the temperature is 600°C, and the holding time is 2 hours; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com