Argon arc welding machine

A technology of argon arc welding machine and chassis, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of technical solution limitation, welding wire oxidation and corrosion, affecting welding quality, etc., and achieves good friction effect, increased strength, The effect of enhancing the rust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

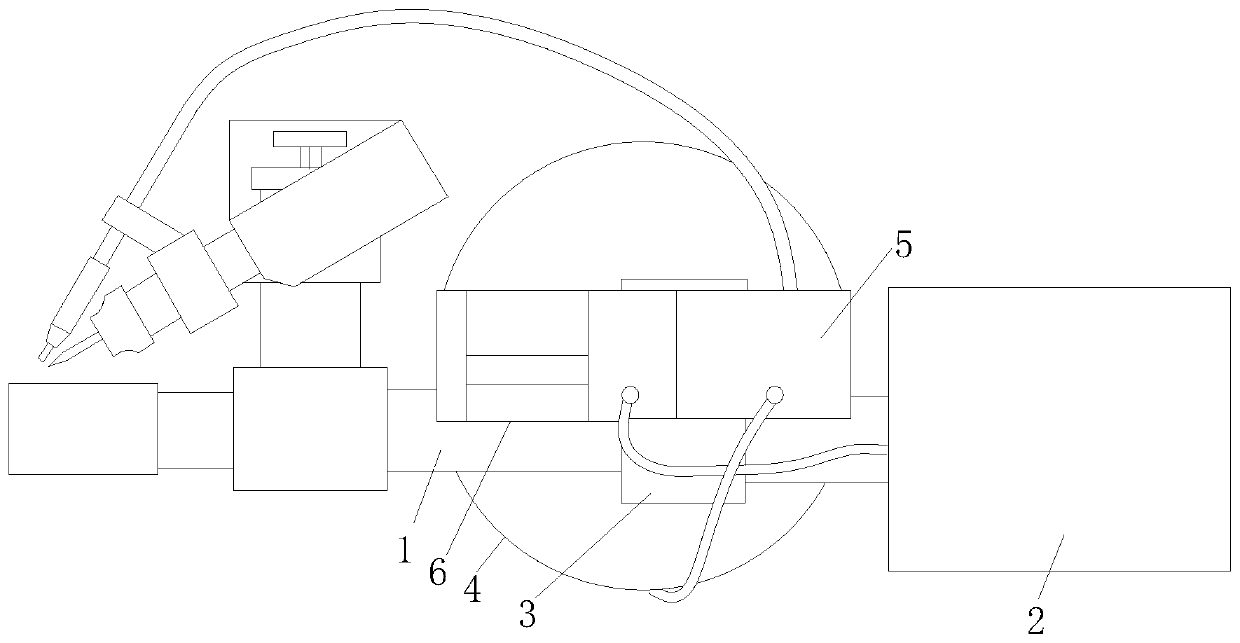

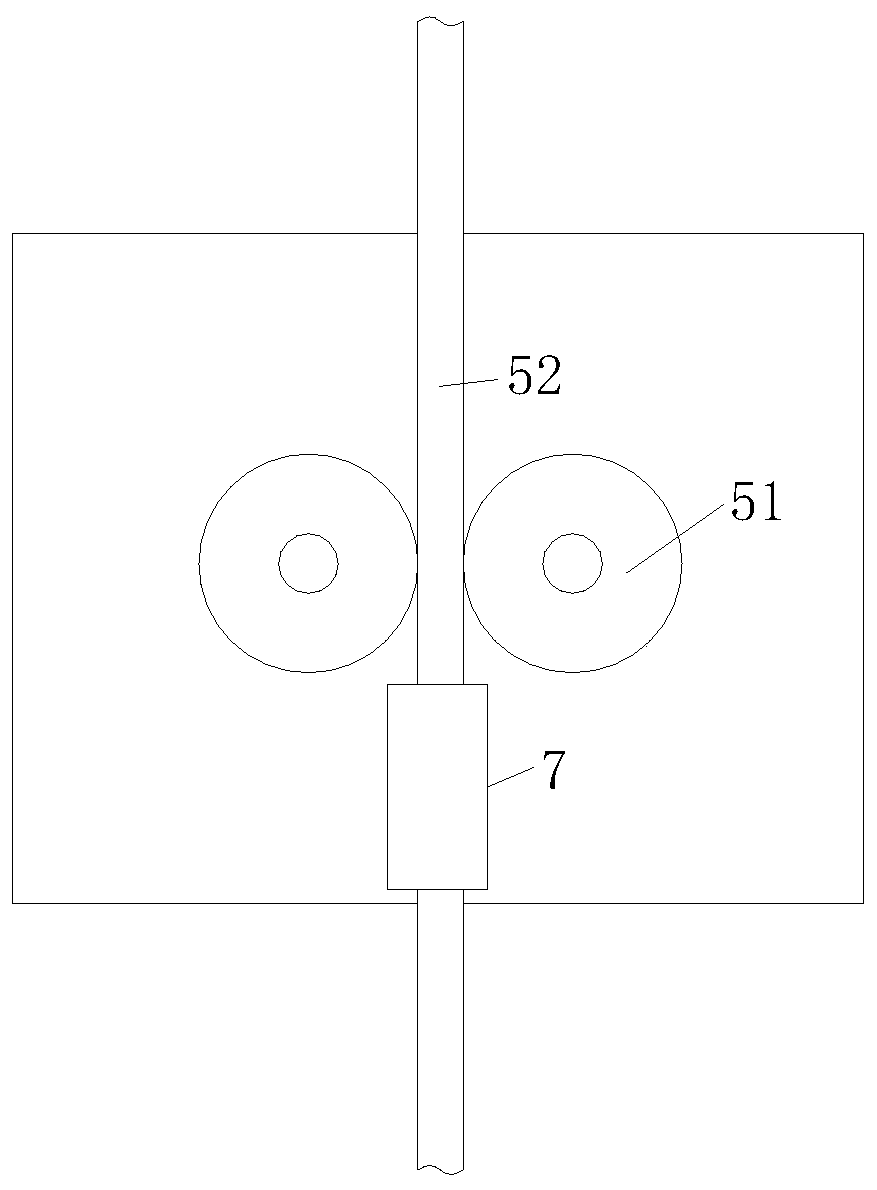

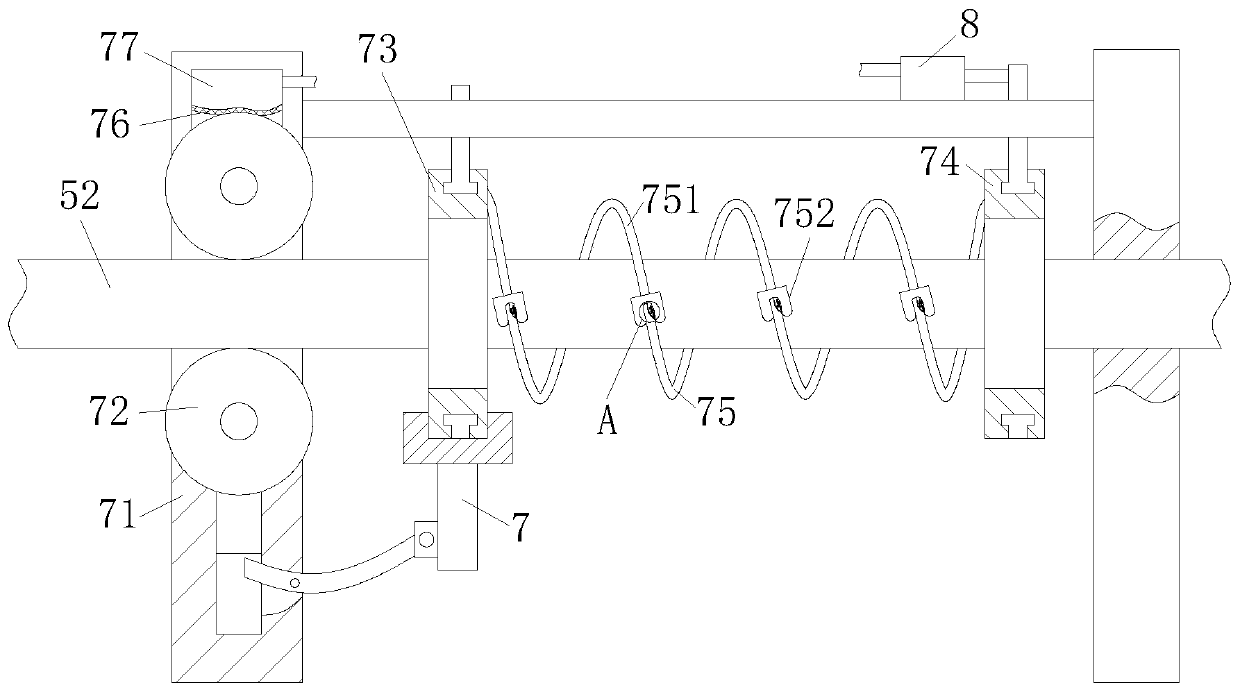

[0024] Such as Figure 1 to Figure 6As shown, an argon arc welding machine according to the present invention includes a rotating shaft 1, a cabinet 2, a counterweight 3, a wire feeding disc 4, a wire pressing body 5 and a wire feeding motor 6; There is a positioning head; the other end of the rotating shaft 1 is rotatably inserted in the cabinet 2; the counterweight 3 is sleeved on the rotating shaft 1; 4 is used to wind the welding wire 52; the wire pressing body 5 includes two wire guide wheels 51; the wire guide wheels 51 are all arranged on the counterweight 3; the right end of the welding wire 52 is wound on the wire feeding reel 4, and the other end is passed Through the gap between the two wire guide wheels 51; the wire feeding motor 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com