Rapid and efficient rust removal device and method

A fast and efficient technology, applied in the field of machinery, can solve the problems of low rust removal efficiency, affecting the use of steel bars, incomplete rust removal, etc., to improve the rust removal efficiency and effect, reduce the probability of corrosion pits, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

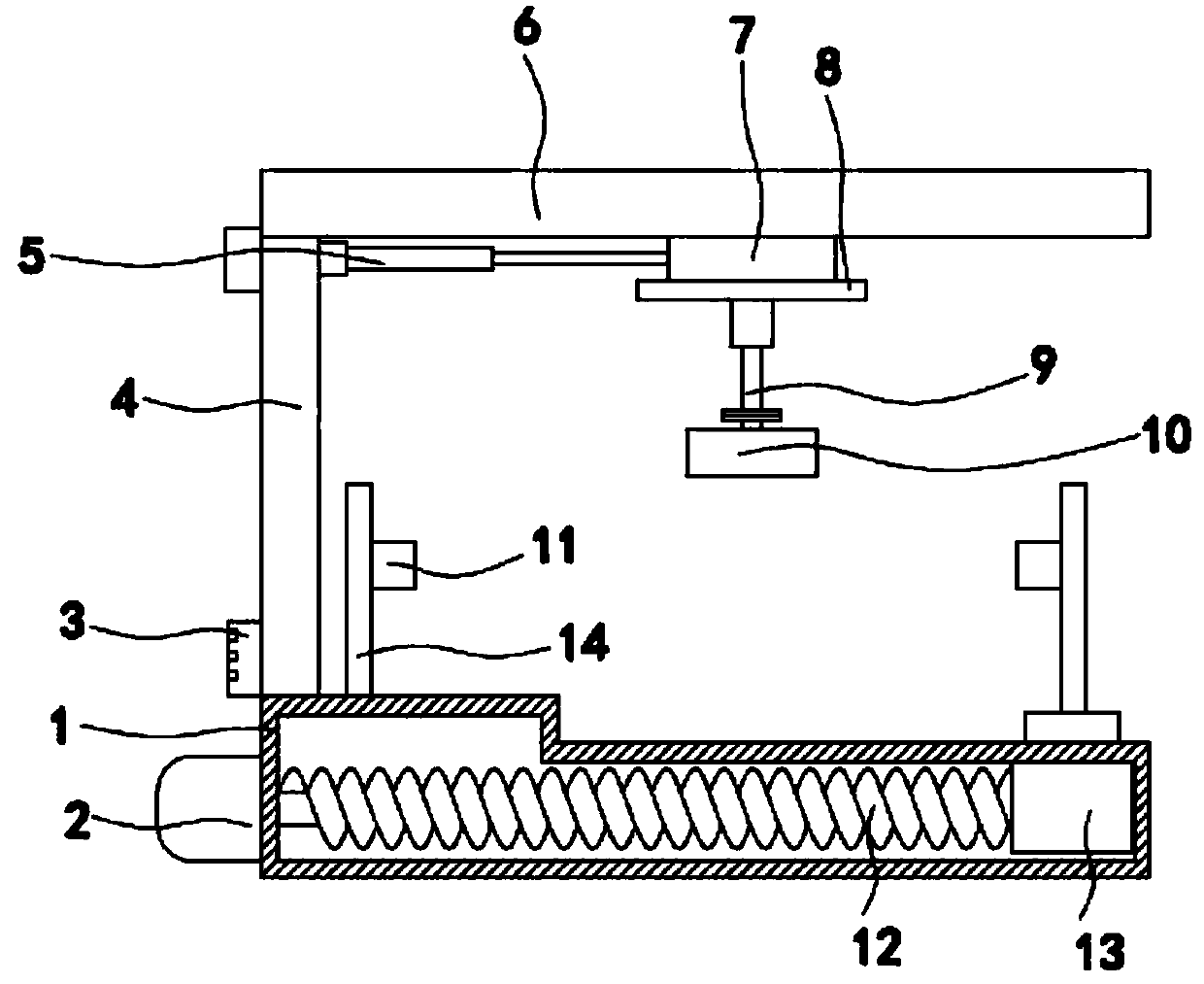

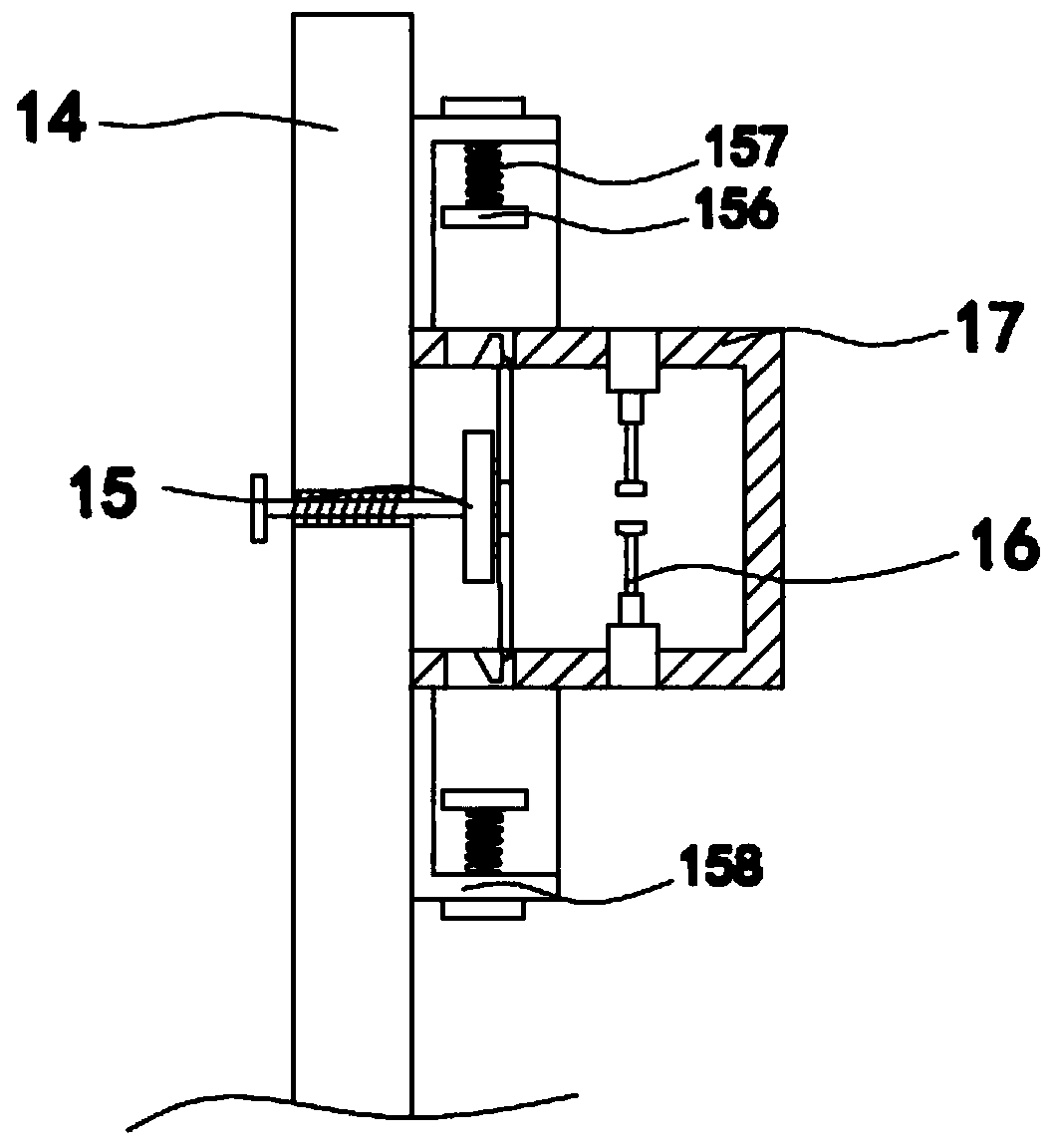

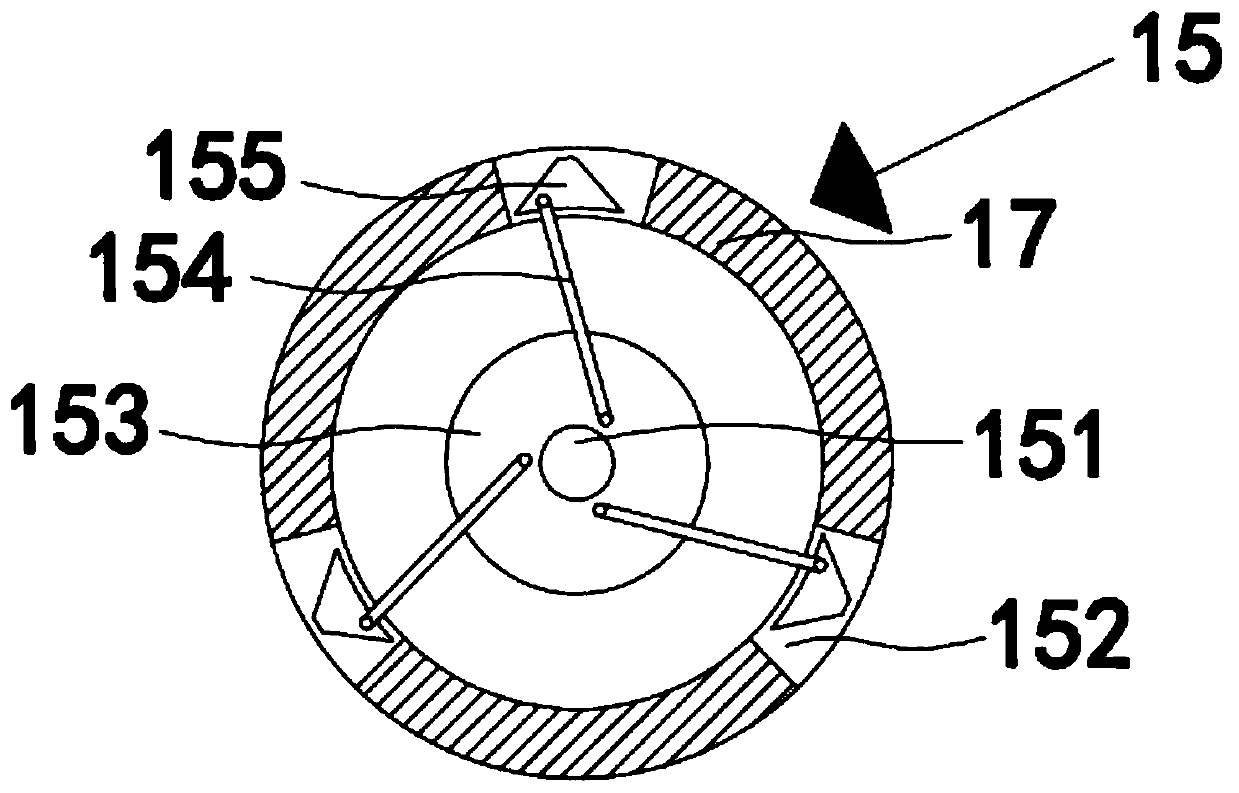

[0033] see Figure 1-9 As shown, a fast and efficient derusting device includes a base 1, a left side plate 4 is welded on the upper left side of the base 1, a horizontally arranged slide rail 6 is connected to the top of the left side plate 4, and a slider is movably connected under the slide rail 6 7. The left end of the slider 7 is connected to the movable end of the electric telescopic rod 5, and the fixed end of the electric telescopic rod 5 is connected to the left side plate 4. The bottom surface of the slider 7 is installed with a cylinder 9 through the mounting plate 8, and the movable end of the cylinder 9 passes through the The flange is connected with the derusting assembly 10 , a support plate 14 is arranged symmetrically above the base 1 , and a fixing assembly 11 is installed on the side of the support plate 14 . The device has a high degree of automation, and the steel bar or steel pipe can be derusted by inputting the corresponding program on the control panel...

Embodiment 2

[0046] In the actual operation process of a fast and efficient derusting device of the present invention: move the fixed component 11 on the right side to the far right side of the base 1, then insert the steel pipe or steel bar into the derusting component 10, and the cylinder 9 drives the derusting The component 10 moves down to a position flush with the fixed component 11, then pushes the steel pipe or steel bar to the left and inserts it into the fixed component 11 to fix it, and the steel bar or steel bar can be derusted by inputting the corresponding program on the control panel 3 , the derusting component 10 can not only slide left and right on the slide rail 6 through the electric telescopic rod 5 for derusting, but also drive the derusting wheel 101 to rotate and derust on the surface of the steel pipe or steel bar through the small motor 107. The two derusting methods are combined The use can greatly improve the rust removal efficiency and rust removal effect of steel...

Embodiment 3

[0048] Select 16 steel bars and divide them into 4 groups, 4 in each group. The diameter of the steel bar is 26mm, and the steel bar is straight without local bending. The rusted area of each steel bar is between 95% and 96%. Experiment; Experimental device adopted: derusting device of the present invention, model on the market is the derusting device of CQ-01; Experimental procedure: experiment is carried out respectively under different states to 3 groups of steel bars selected above-mentioned; State 1: the present invention The derusting device is running normally; State 2: the derusting device of the present invention is operating normally, and the suction pump is turned on, and the iron powder collected by recycling is sprayed to the surface of the steel bar; State 3: the common derusting device on the market is operating normally; the purpose of the experiment : compare the removal rates of two derusting devices;

[0049] by attaching Figure 10It can be seen that und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com