Patents

Literature

51results about How to "Guaranteed derusting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

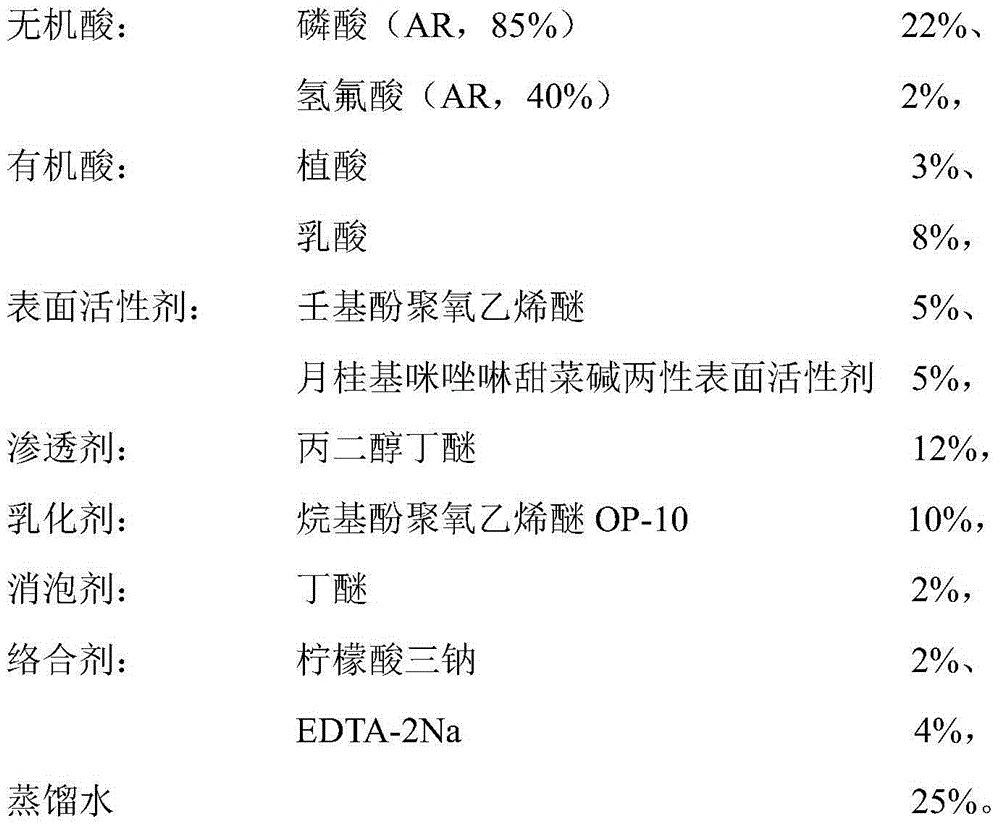

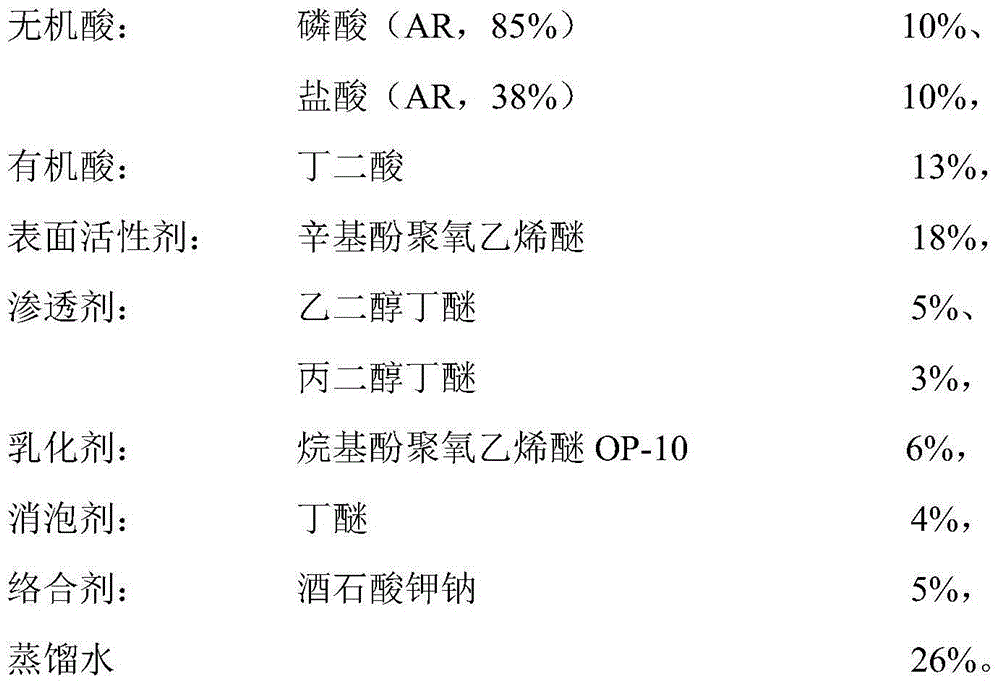

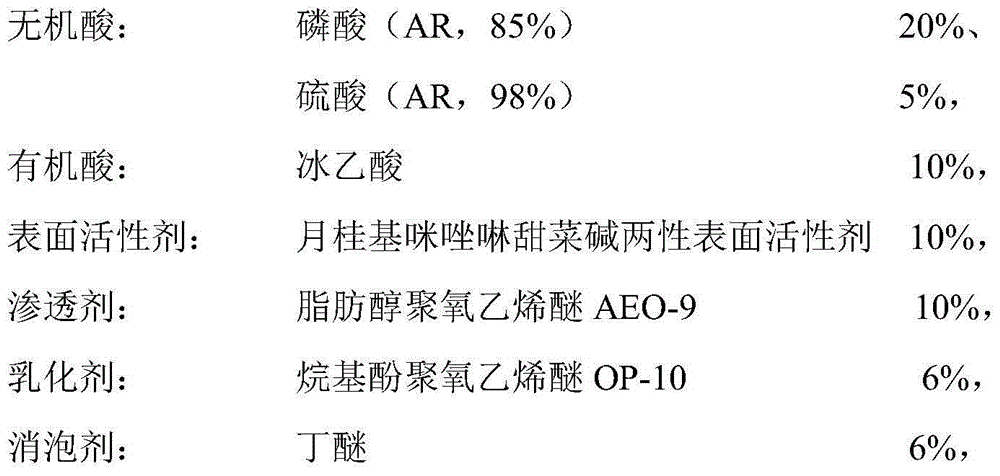

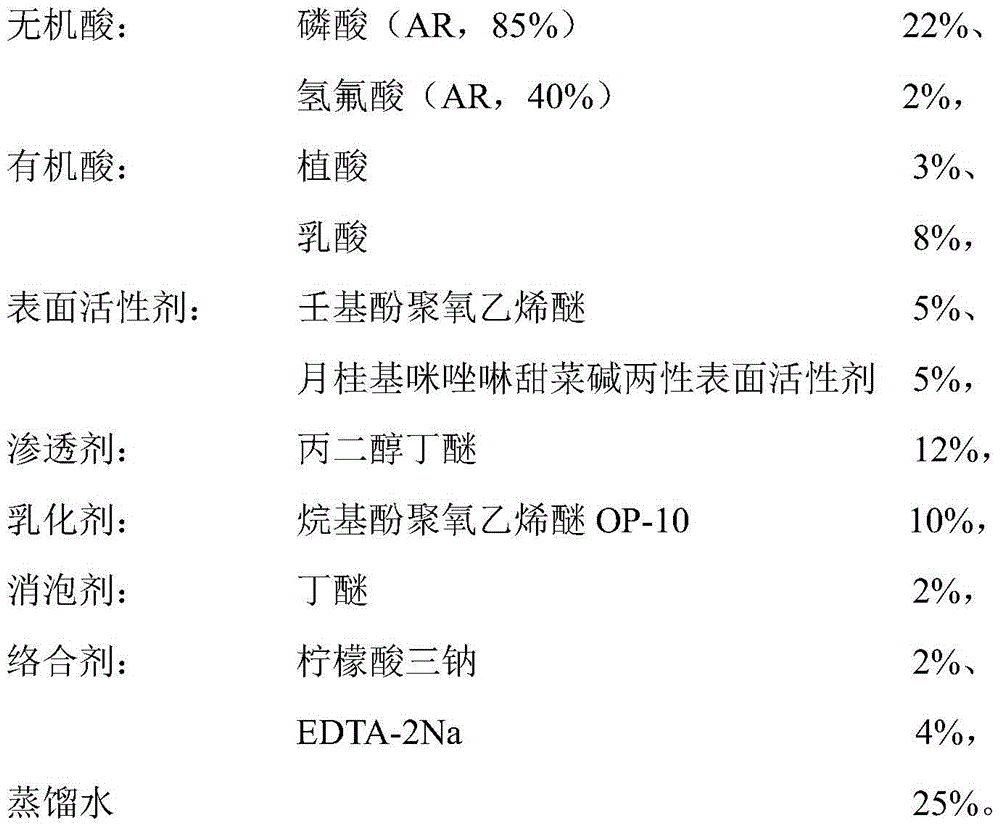

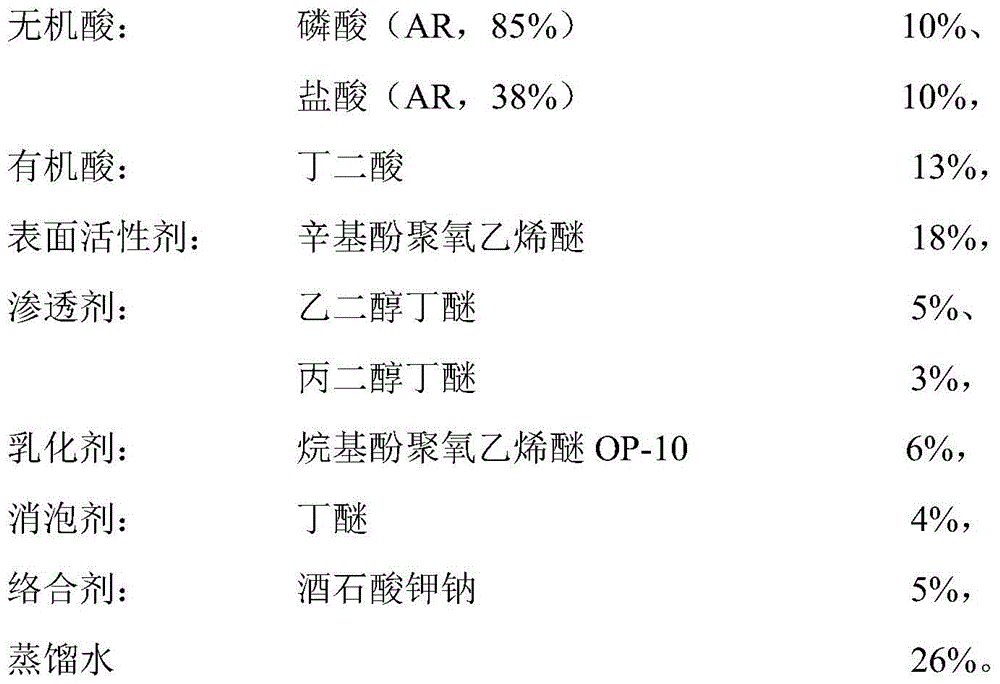

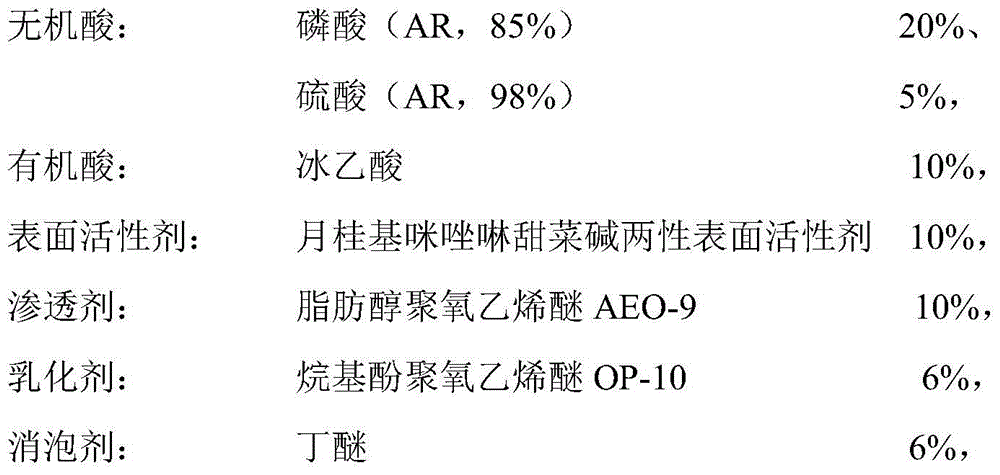

Environment-friendly aluminum cleaning agent and preparation method thereof

The invention discloses an environment-friendly aluminum cleaning agent and a preparation method thereof. The cleaning agent is composed of the following components in percentage by weight: 20% to 25% of inorganic acid, 10% to 20% of organic acid, 10% to 18% of surfactant, 8% to 15% of osmotic agent, 6% to 18% of emulsifier, 2% to 8% of antifoaming agent, 5% to 8% of complexing agent, and 25% to 30% of water. In the provided cleaning agent, the using amount of hydrochloric acid, sulfuric acid, and nitric acid is reduced, the aluminum parts are washed by medium-strong acids and organic acids, and the cleaning agent has a very good oil stain and rust removing ability. The cleaning agent is acidic, the pH value of the cleaning agent is 2.1 to 5.6, and the cleaning agent can well remove the oxide scale on the aluminum surface. Because the acidity of the organic acids is weak, the over-corrosion on work tools and acid volatilization, which can harm the workers' health, are effectively avoided, and the cleaning effect is not influenced at the same time. Moreover the adopted organic acids are easy to decompose, and thus the cleaning agent is environment-friendly.

Owner:PINGGAO GRP +1

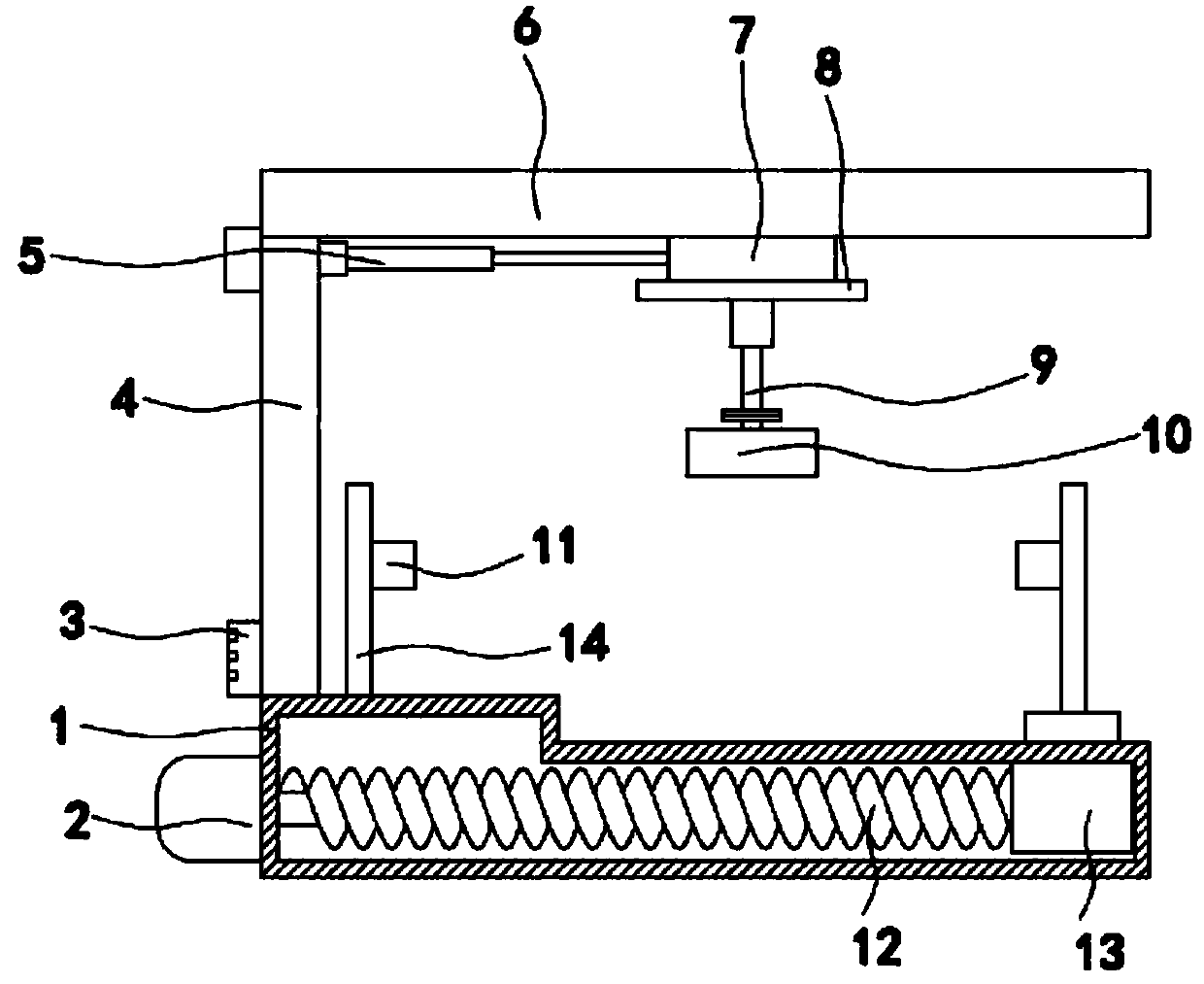

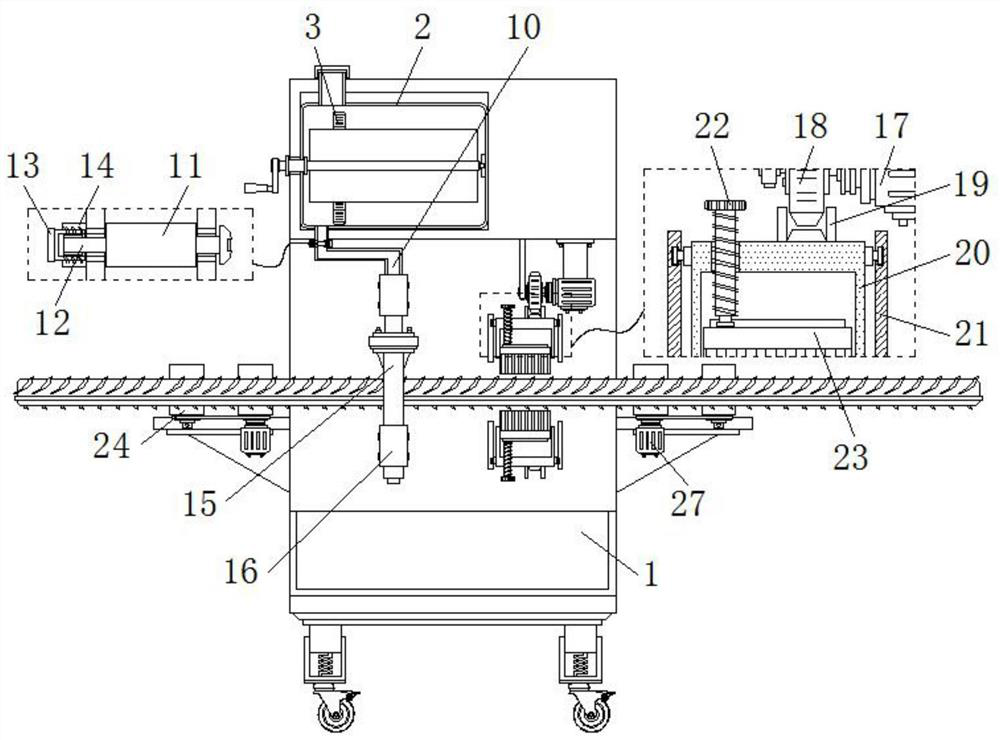

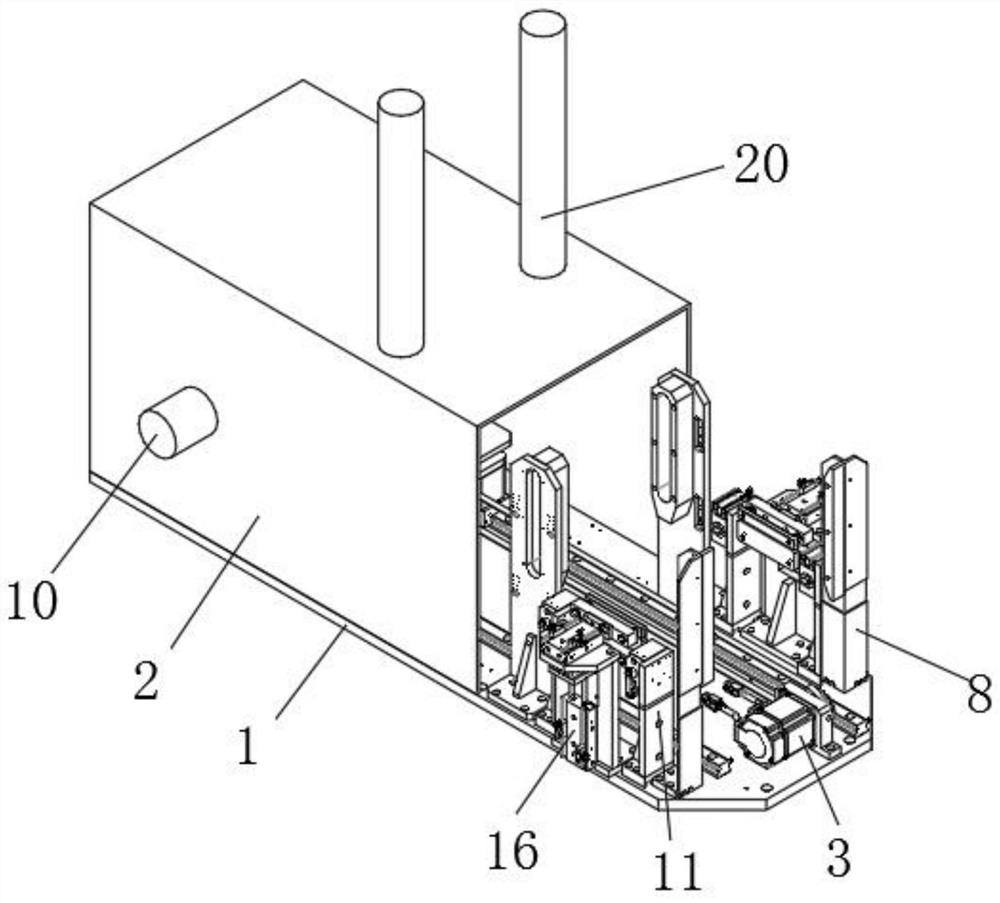

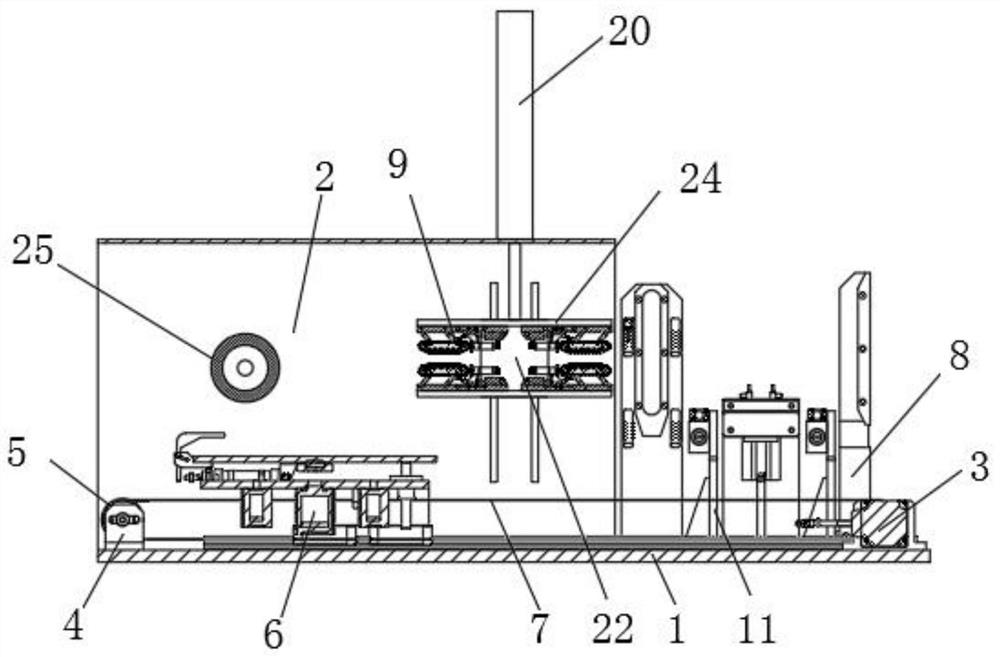

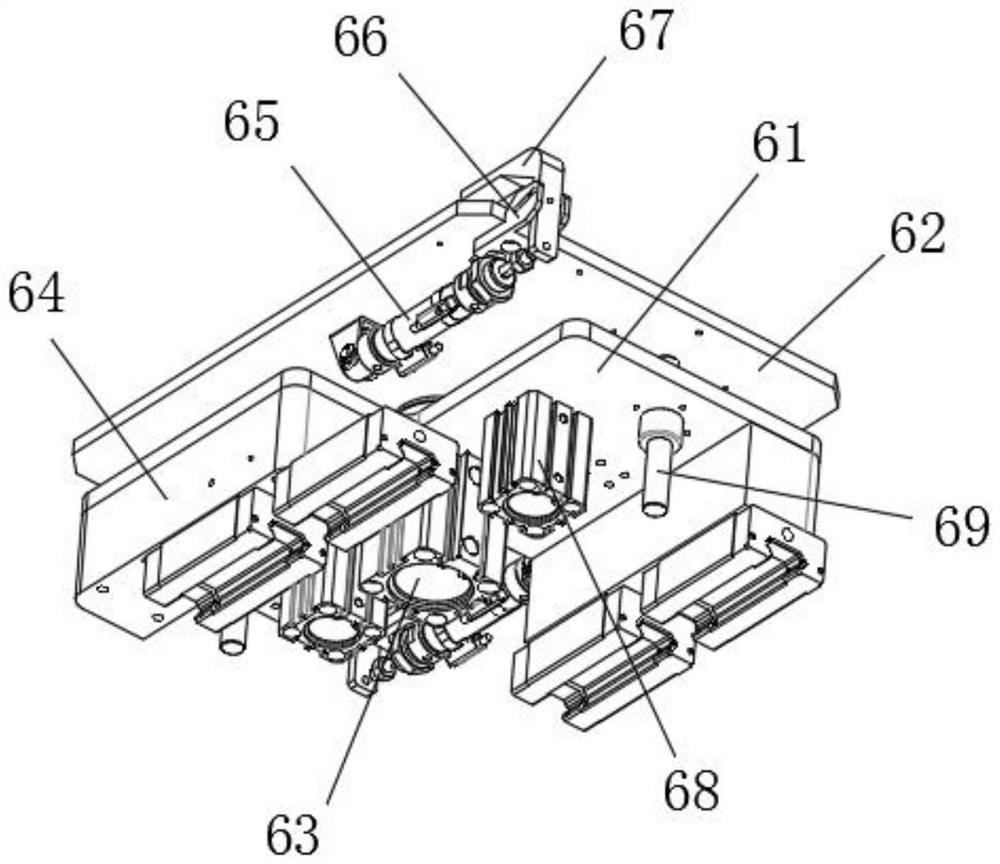

Rapid and efficient rust removal device and method

ActiveCN111230682AEasy to removeImprove rust removal efficiencyAbrasive feedersGrinding machinesIron powderRebar

The invention discloses a rapid and efficient rust removal device and method. The device comprises a base, a left side plate is welded to the upper portion of the left side of the base, a transversely-arranged sliding rail is connected to the top of the left side plate, a sliding block is movably connected to the lower portion of the sliding rail, the left side end of the sliding block is connected with the movable end of an electric extendable rod, and the fixed end of the electric extendable rod is connected with the left side plate; and an air cylinder is installed on the bottom face of thesliding block through an installation plate, the movable end of the air cylinder is connected with a rust removal assembly through a flange, supporting plates are symmetrically arranged above the base, and fixing assemblies are installed on the side faces of the supporting plates. According to the device, the rust removal efficiency of a steel pipe and a steel bar is improved through multiple motion states of the rust removal assembly, iron powder can be effectively removed and collected, the collected iron powder can be circularly sprayed to the surface of the steel pipe and the surface of the steel bar, the rust removal effect can be further enhanced in cooperation with rotation of a rust removal wheel, and it can be guaranteed that the surrounding environment is friendly all the time in the working state.

Owner:迁安市仁泰金属制品有限公司

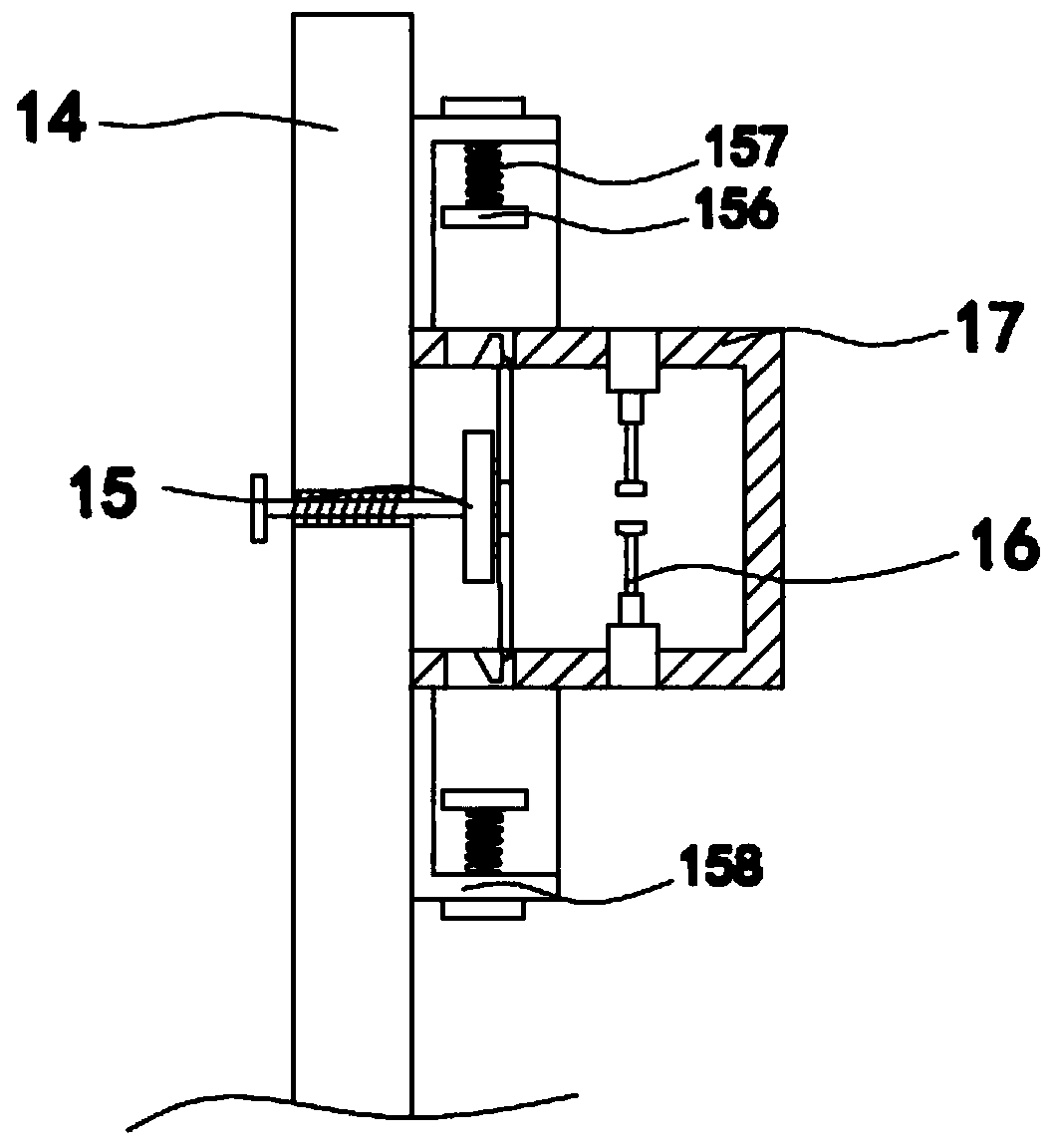

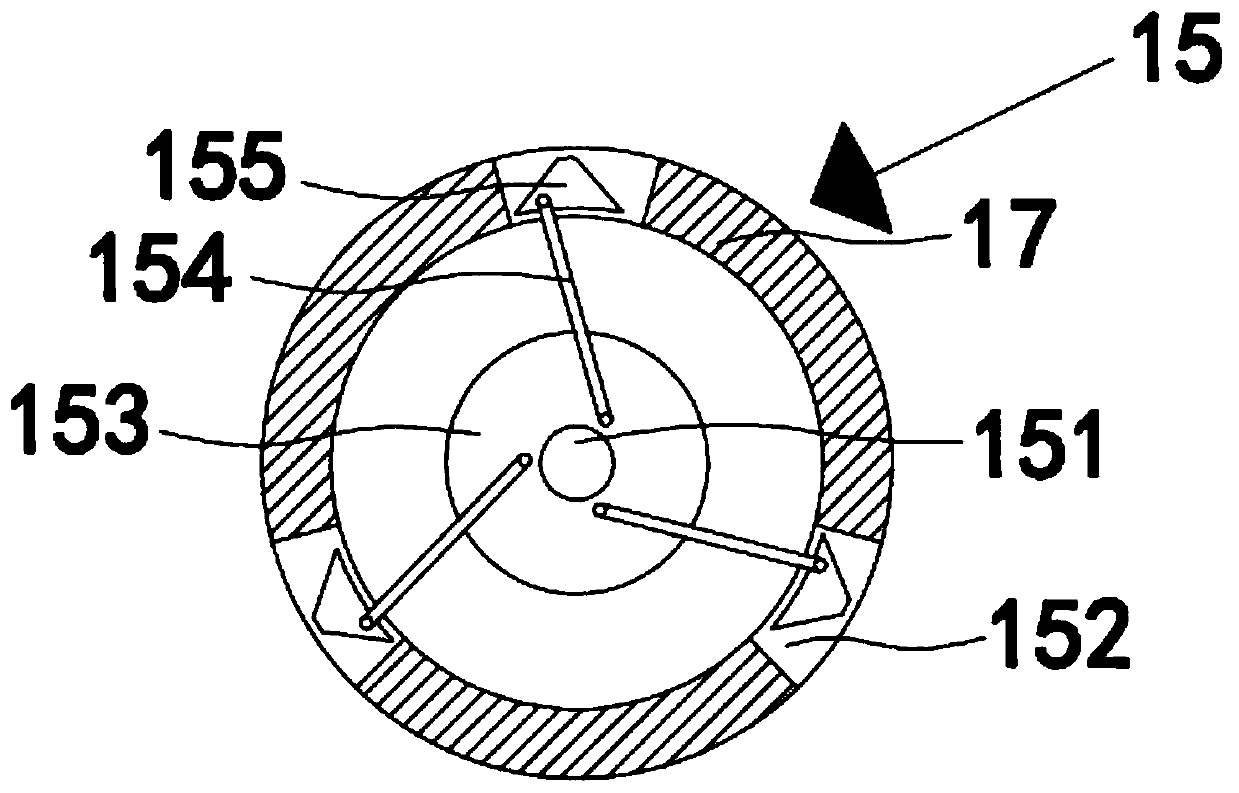

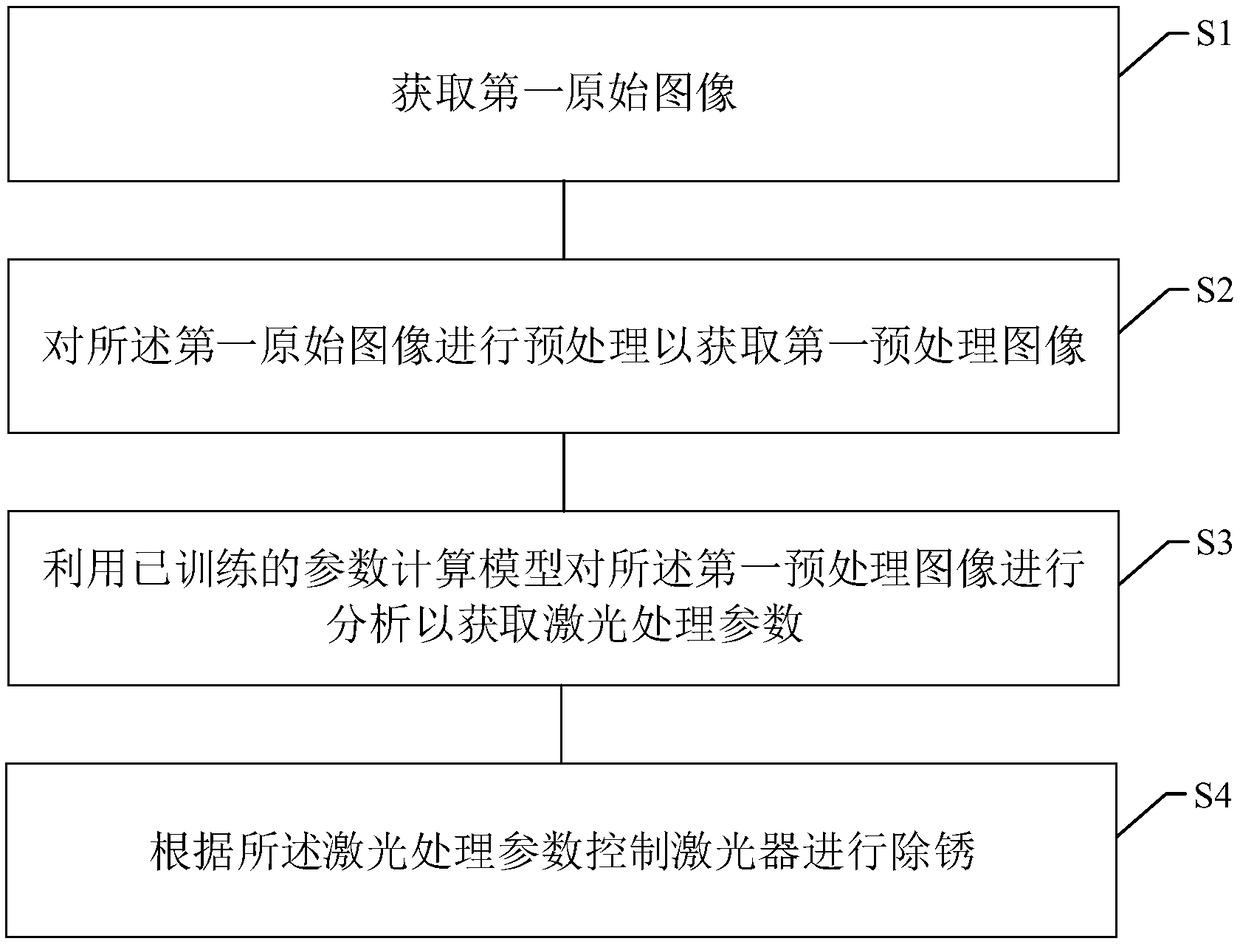

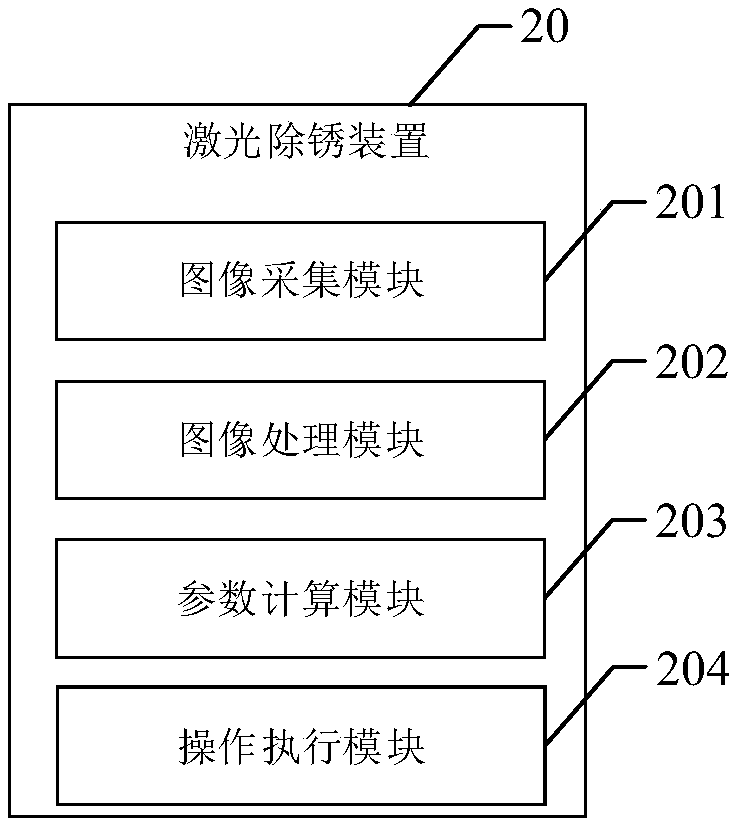

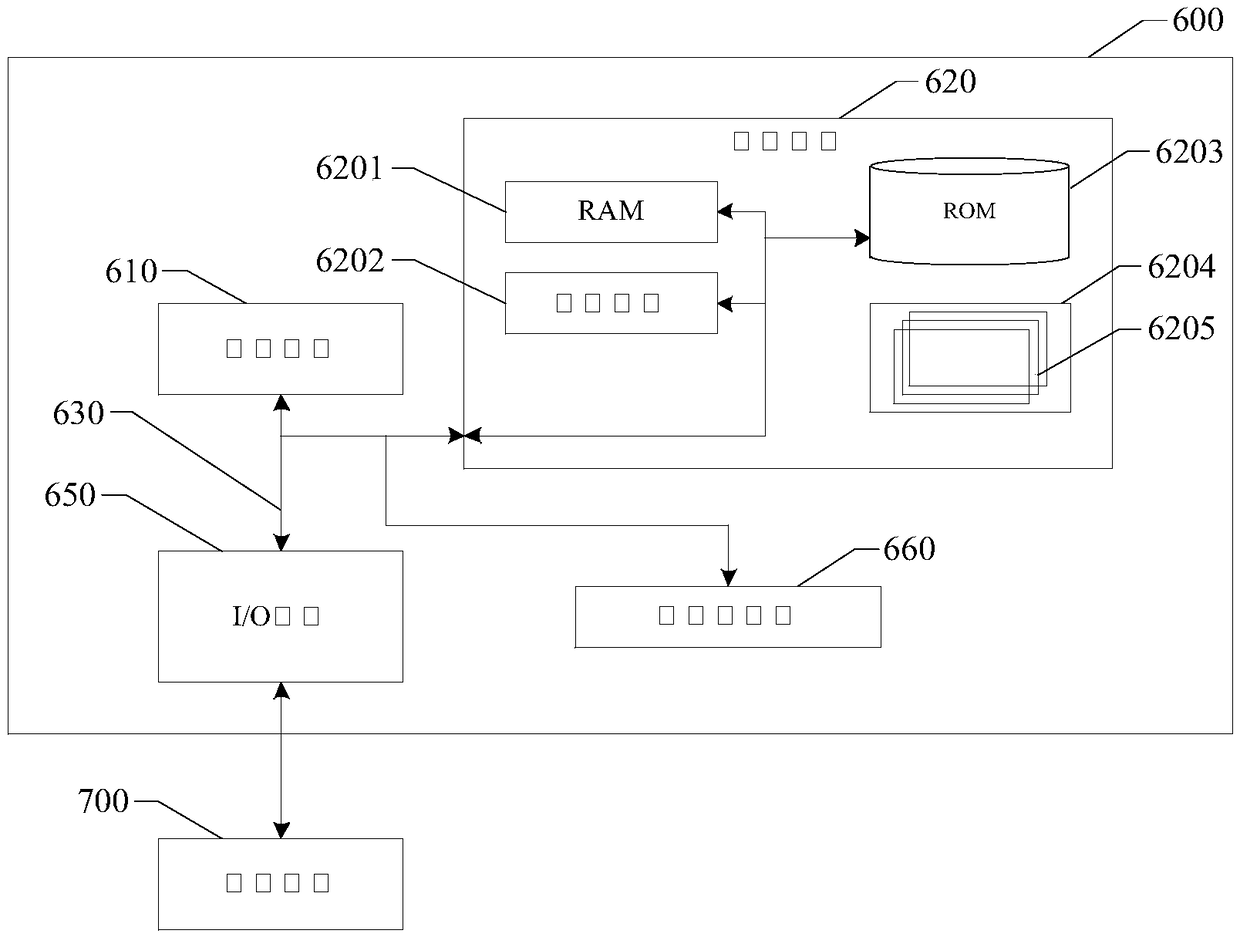

Laser derusting method and device based on machine learning

InactiveCN109447141AGuaranteed derusting effectCharacter and pattern recognitionClosed circuit television systemsLaser processingComputer vision

The present disclosure relates to the technical field of derusting, in particular to a laser derusting method based on machine learning, a laser derusting device based on the machine learning, a storage medium and an electronic terminal. The method includes acquiring a first original image; preprocessing the first original image to obtain a first preprocessed image; analyzing the first preprocessed image by using the trained parameter calculation model to obtain laser processing parameters; controlling a laser to remove rust according to that laser processing parameters. The present disclosureis capable of calculating the laser processing parameters corresponding to rust regions in each image by using a pre-trained machine learning model, so that the laser can be controlled to perform rust removal according to the laser control parameters, and the rust removal effect is effectivly guaranteed.

Owner:济宁聚鑫众泽电气科技有限公司

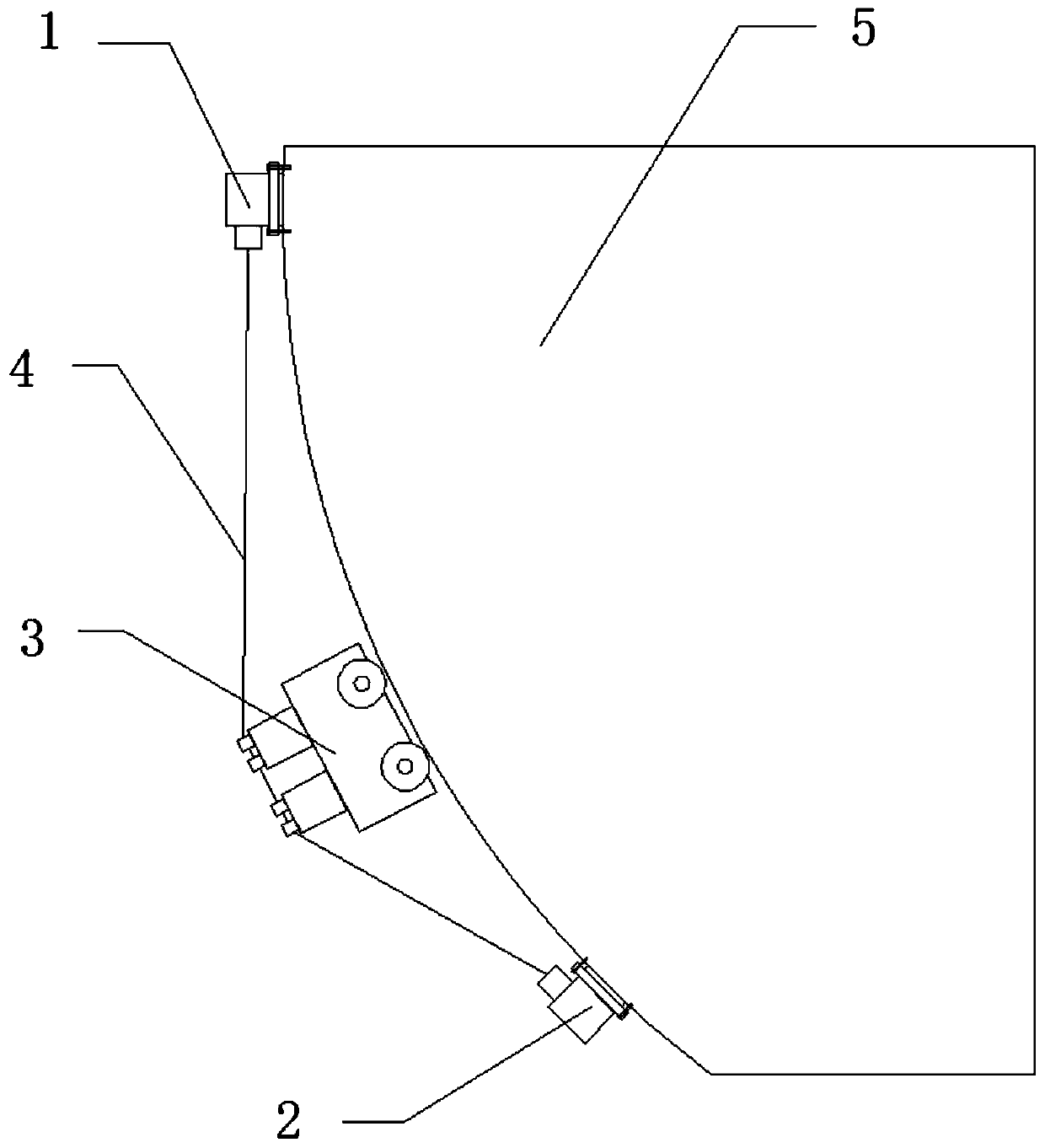

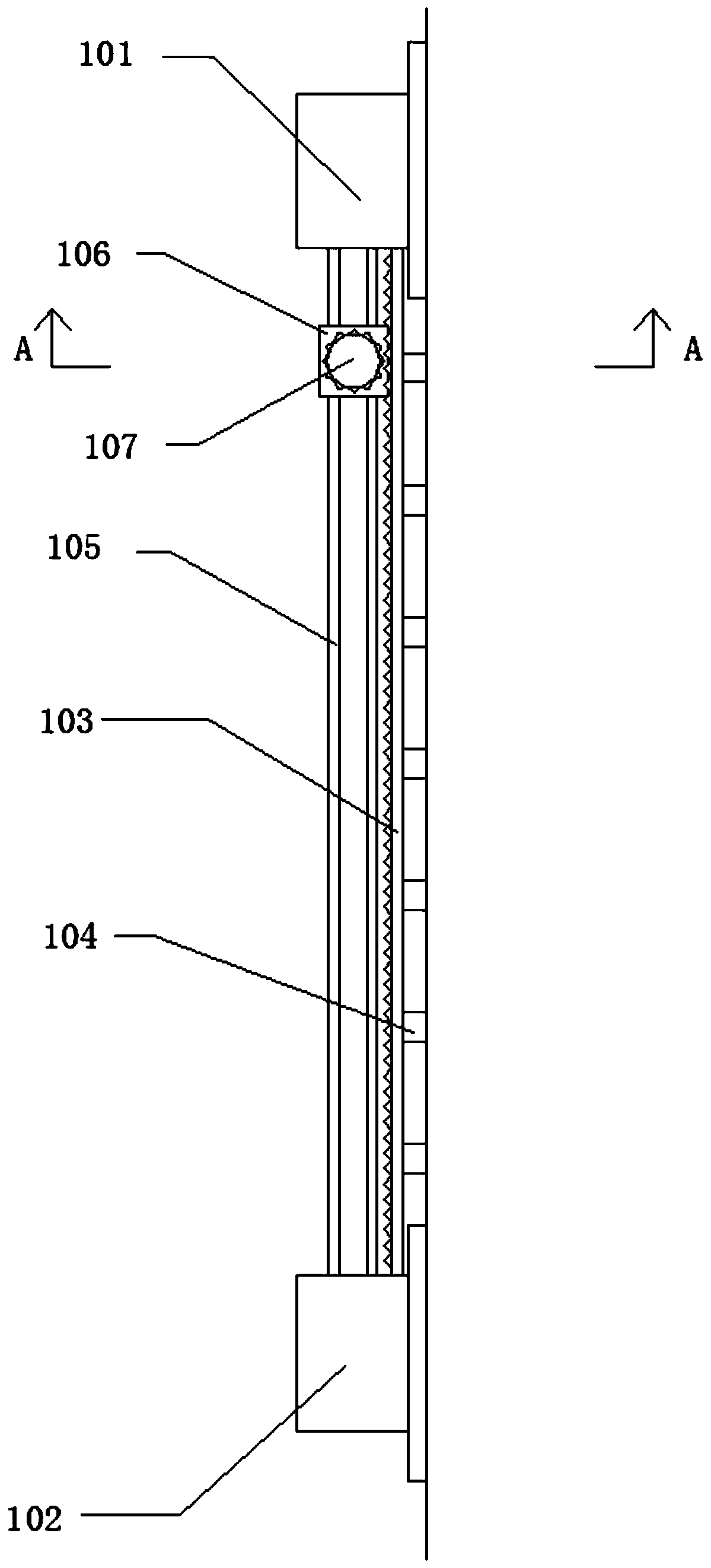

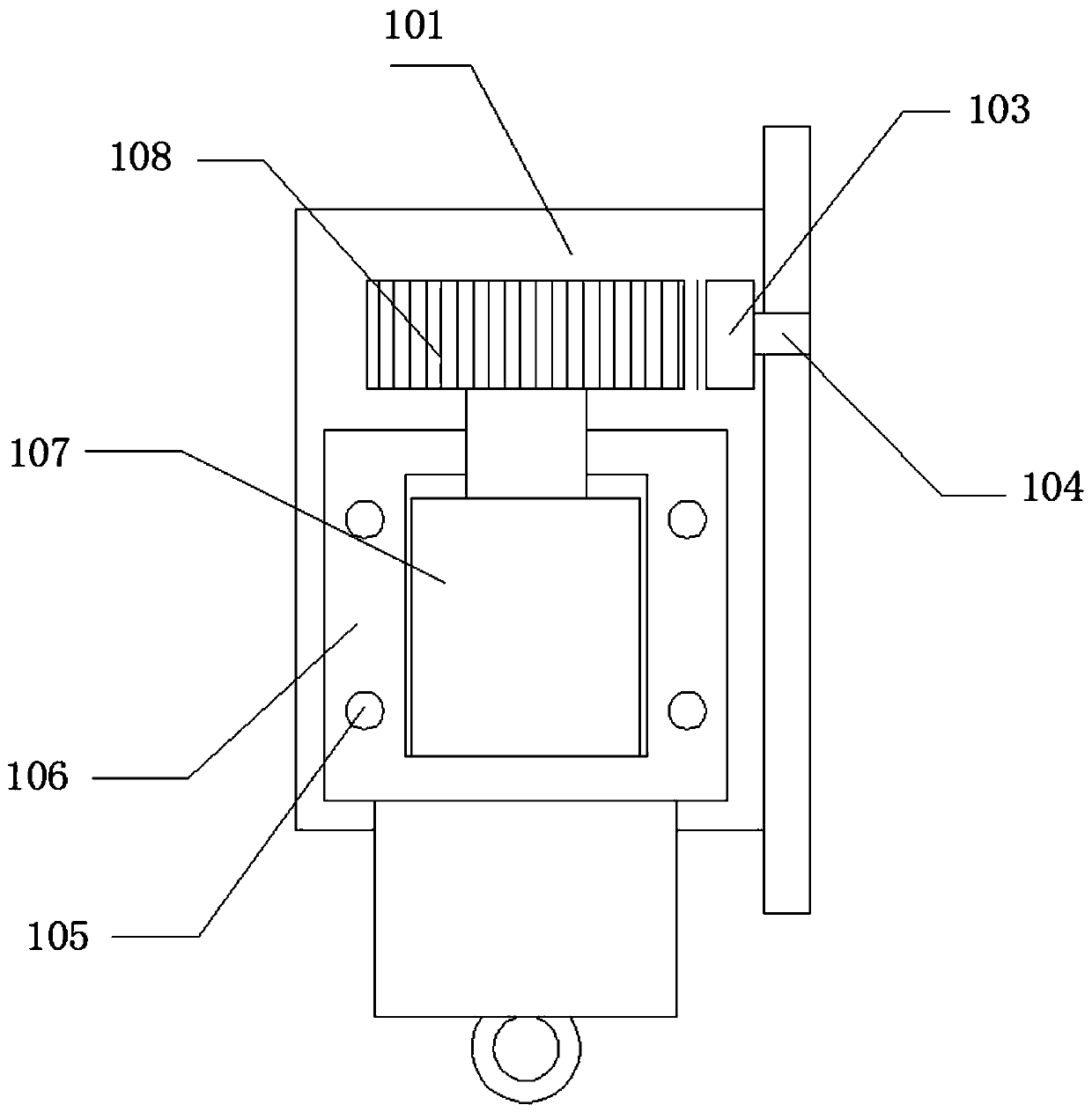

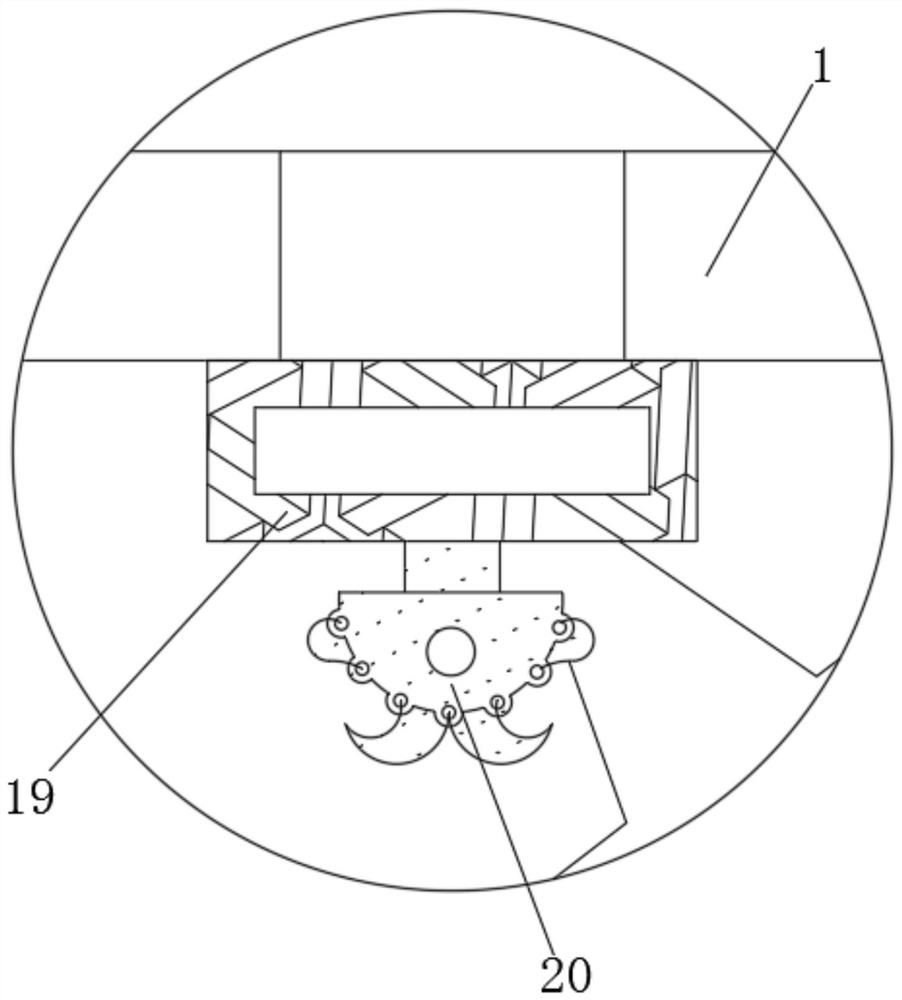

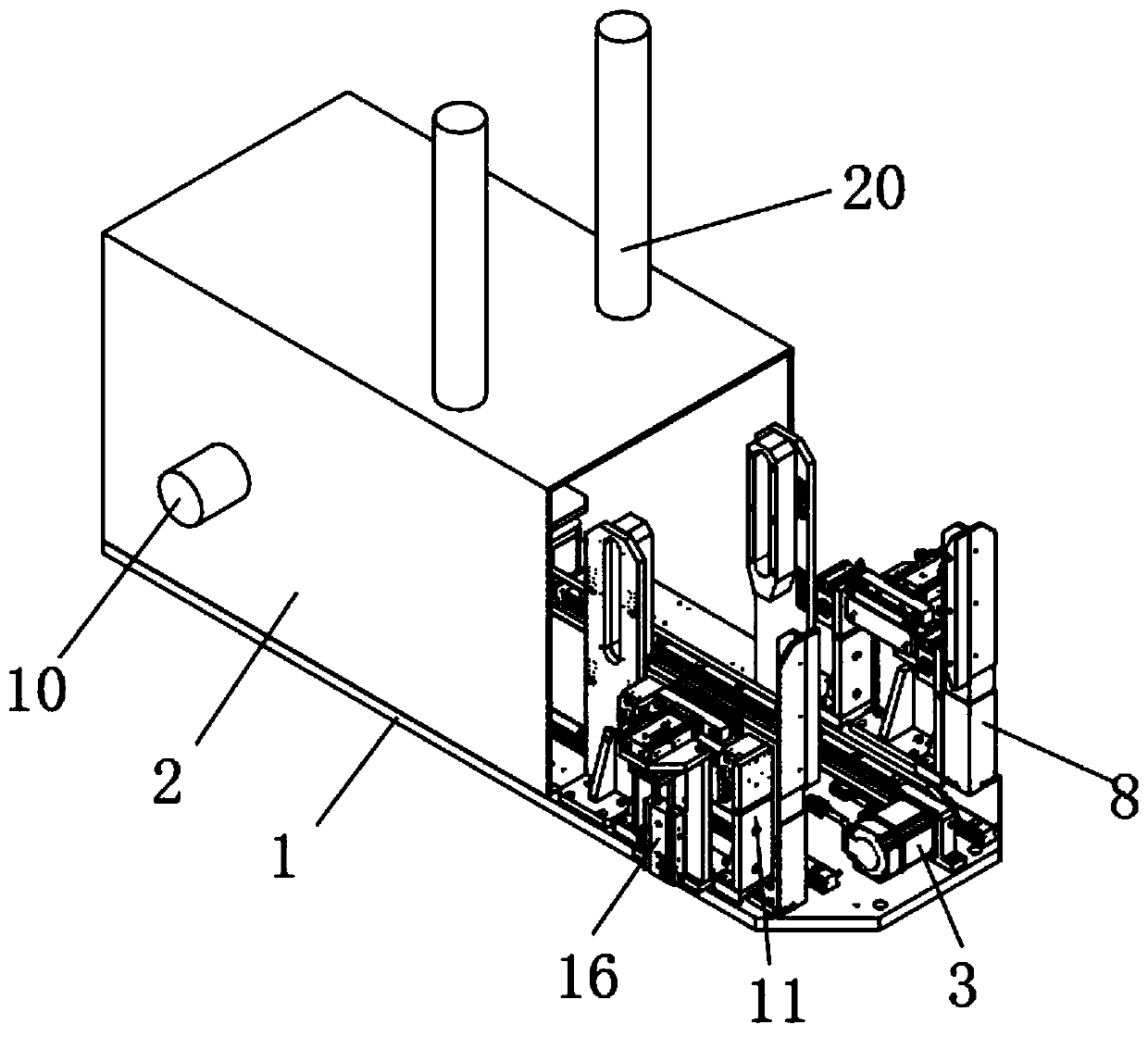

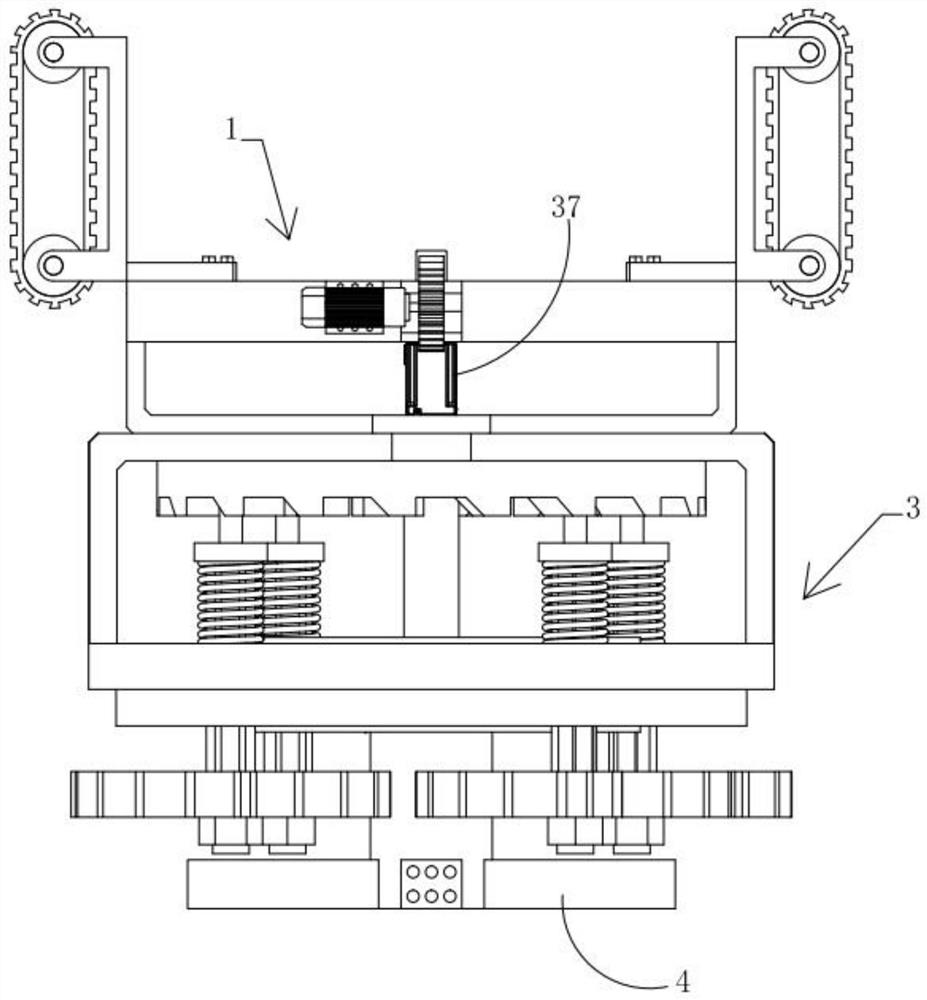

Automatic rust removal device for ships

ActiveCN110550164AEnsure personal safetyImprove rust removal efficiencyVessel cleaningHullsEngineeringRust

The invention puts forward an automatic rust removal device for ships. The device comprises an upper guiding mechanism, a lower guiding mechanism and a rust removal mechanism, wherein the upper guiding mechanism and the lower guiding mechanism are independently fixed on the upper end and the lower end of a ship; a steel wire rope is arranged between the upper guiding mechanism and the lower guiding mechanism and penetrates through the rust removal mechanism to press the rust removal mechanism on the ship; the rust removal mechanism can move along the steel wire rope and carries out a rust removal operation on the ship; the upper guiding mechanism and the lower guiding mechanism independently comprise a first fixed terminal and a second fixed terminal; the first fixed terminal and the second fixed terminal are detachably fixed on the ship; a long toothed plate is tensioned and fixed between the first fixed terminal and the second fixed terminal; one side, which is near the ship, of thetoothed plate is provided with a plurality of supporting terminals, and the supporting terminals are pressed on the ship; and a movable traction component is arranged between the first fixed terminaland the second fixed terminal. By use of the device, rust removal efficiency is improved, a rust removal effect is guaranteed, and meanwhile, the personal safety of operation personnel is guaranteed.

Owner:ZHEJIANG OCEAN UNIV

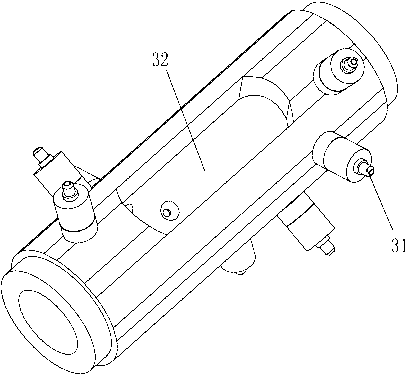

Steel surface rust removing device

InactiveCN102873644AAchieve recyclingGuaranteed derusting effectBlast gunsAbrasive machine appurtenancesWater dischargeSand blasting

The invention discloses a steel surface rust removing device which comprises a sand-blasting drum, a cleaning head and a drying part, wherein the cleaning head is arranged on one end of the sand-blasting drum, and the drying part is arranged on one side of the cleaning head; the cleaning head is connected with a water tank through a pipeline, and a filter device is arranged between an inlet and an outlet of the water tank; the filter device comprises a magnetic filter, a backwashing filter, a high-precision filter and a cooler, a water pump is connected with an inlet of the magnetic filter through the pipeline, a drain outlet of the magnetic filter is connected with a drain tank through a drain pipe, and a water outlet of the magnetic filter is connected with an inlet of the backwashing filter through the pipeline; a drain port of the backwashing filter is connected with the drain tank through the drain pipe, and the water outlet of the backwashing filter is connected with an inlet of the high-precision filter through a water discharge pipe; and an outlet of the high-precision filter is connected with an inlet of the cooler, and an outlet of the cooler is connected with the water tank through the pipeline. With the steel surface rust removing device, water can be recycled, water in the water tank can keep clean all the time, and thus, a sand blasting rust removing effect is ensured.

Owner:浙江金汇钢业股份有限公司

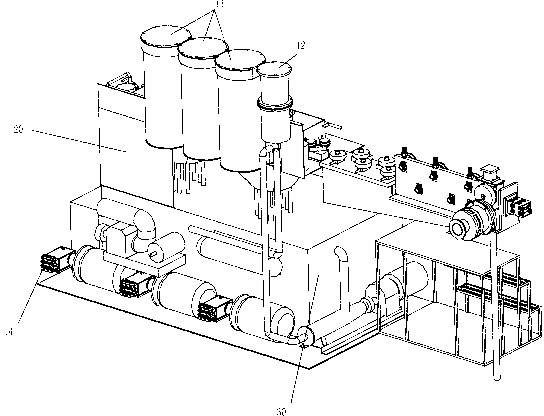

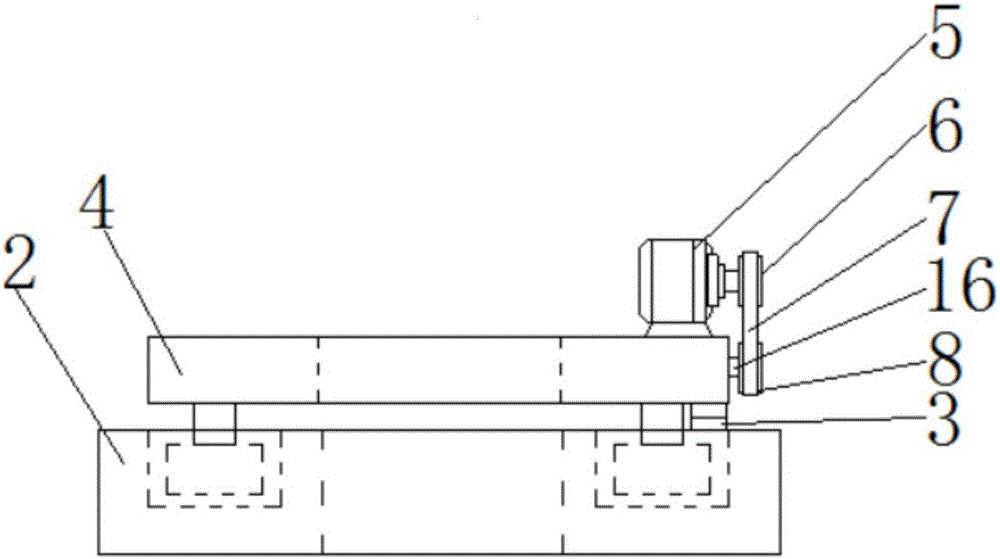

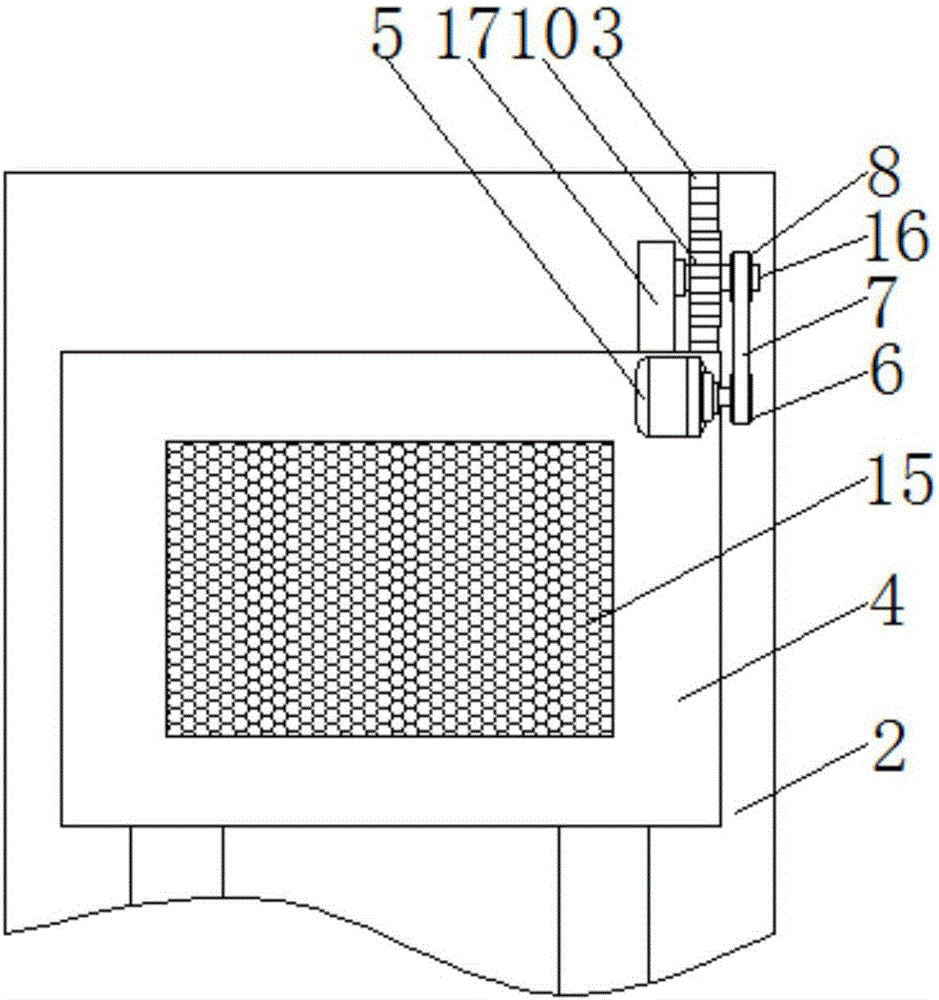

Wire rod rust removal equipment

InactiveCN108044475APrevent rustGuaranteed derusting effectGrinding carriagesLiquid surface applicatorsWire rodDrive shaft

The invention relates to wire rod rust removal equipment. The equipment comprises an upper base, a lower base and a box body, and is characterized in that a track A is arranged on the upper surface ofthe lower base; and rolling wheels A are inlaid on the track A; a telescopic device A is arranged on the rolling wheels A; a motor A is riveted on the telescopic device A, and the motor A is connected with a grinding ball body A through a transmission shaft A; a track B is arranged on the lower surface of the upper base; and rolling wheels B are inlaid below the track B; a telescopic device B isarranged below the rolling wheels B; and a motor B is riveted below the telescopic device B, and the motor B is connected with a grinding ball body B through a transmission shaft B. Compared with theprior art, the pair of grinding ball bodies which are reasonably distributed on the periphery of a wire rod are utilized by the wire rod mechanical rust removal equipment, automatic rust removal can be realized, and the rust removal working efficiency can be improved on the premise of ensuring the rust removal effect. On the other hand, oil applying work is combined, so that the rust-removed wirerod is prevented from rusting once again.

Owner:成都沃夫铌科技有限公司

Correcting and derusting device for steel bars of prefabricated members

InactiveCN112454122APrevent insufficient rust removalThorough rust removalGrinding drivesGrinding machinesRebarMechanical engineering

The invention relates to the technical field of prefabricated members, and discloses a correcting and derusting device for steel bars of prefabricated members. The device comprises an outer shell, wherein conveying wheels are movably connected into the outer shell, supporting shells are movably connected into each conveying wheel, electrorheological fluid is arranged in each supporting shell, a push rod is movably connected to the outer portion of each supporting shell, connecting springs are movably connected to the outer portion of each push rod, a copper rod is fixedly connected into each push rod, and a first magnet is fixedly connected into each supporting shell. Under the interaction of all the structures of the device, the steel bars can be corrected through clamping assemblies after entering the device, the surfaces of the steel bars are derusted through friction blocks, meanwhile a steel bar rust remover is sprayed to the surfaces of the steel bars, so that the surfaces of thesteel bars are derusted more thoroughly, the effects of automatically correcting and derusting the steel bars are achieved, the derusting effect on the surfaces of the steel bars is guaranteed, and the property safety of people can be guaranteed.

Owner:侯勇

Surface rust removing device and method of rolled steel

InactiveCN103341827AKeep water cleanGuaranteed derusting effectAbrasive machine appurtenancesAbrasive blasting machinesSand blastingWater quality

The invention discloses a surface rust removing device of rolled steel. The surface rust removing device comprises a guiding part, a primary sand blasting part, a secondary sand blasting part and a filtering device, wherein the primary sand blasting part and the secondary sand blasting part are arranged in a sand box; the guiding part is arranged at the inlet of the sand box, and one side of the sand box is provided with the filtering device; the primary sand blasting part comprises a primary sand blasting cylinder, an inlet end of the primary sand blasting cylinder is connected with a first cleaning head, and an outlet end of the primary sand blasting cylinder is connected with a second cleaning head; the first cleaning head is connected with a guiding wheel, multiple sand sucking pipes are arranged below the primary sand blasting cylinder, and the multiple sand sucking pipes are connected with an air cylinder. The surface rust removing device provided by the invention has the advantages that water in a cleaning water box is clean, the sand blasting rust removing effect is guaranteed, the surface rust removing device does not need to wipe and dry after rust removing, and the use is convenient. The invention also discloses a surface rust removing method of the rolled steel.

Owner:浙江金汇钢业股份有限公司

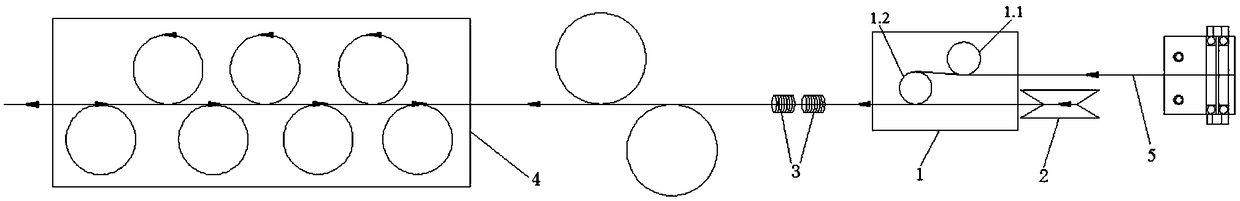

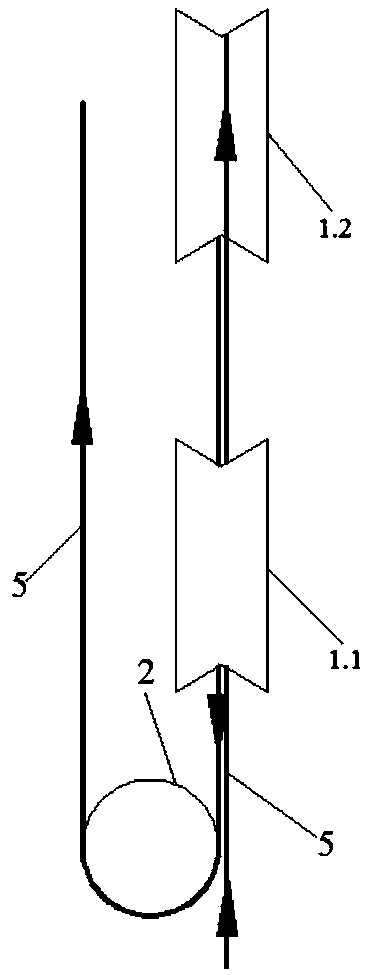

Acid-free pretreatment process for steel wires

PendingCN109382744AImprove rust removal effectOptimal adjustmentGrinding machinesGrinding feedersWire brushPre treatment

The invention relates to a steel wire batched physical rust removal device, and belongs to the technical field of steel wire surface treatment. The device comprises a vertical shelling wheel, a transverse shelling, a spiral steel wire brush and a rust removal machine; the vertical shelling wheel comprises a first rolling wheel and a second rolling wheel which are arranged vertically, the first rolling wheel is located on the upper portion of the second rolling wheel, and the highest point location of a wheel groove of the second rolling wheel is located between the highest point location and the lowest point location of the first rolling wheel; the transverse shelling wheel is horizontally arranged on the right side of the second rolling wheel, the spiral steel wire brush and the rust removal machine are sequentially arranged on the left side of the vertical shelling wheel, a steel wire passes through the wheel groove at the lowest point of the wheel groove of the second rolling wheeland then continues to drive forwards by surrounding the transverse shelling wheel; the spiral steel brush is composed of a spiral rod and a rust removal wire, and one end of the rust removal wire is fixedly arranged on the inner surface of the spiral rod. The steel wire batched rust removal device and process can achieve the pickling effect, and chemical pickling rust removal can be completely replaced.

Owner:山东创大钢丝制品有限公司

Metal surface rust removal device

InactiveCN107520539AAvoid harmReduce the amount of manual laborLaser beam welding apparatusReciprocating motionEngineering

The invention discloses a metal surface derusting device, which comprises a casing, one side of the inner wall of the casing is fixedly connected with a support plate, one side of the support plate penetrates the left side of the casing and extends to the outside of the casing, the support plate The top is slidingly connected with a movable frame; the inner wall of the top surface of the shell is fixed with a moving device that can move back and forth left and right, the bottom of the moving device is fixedly connected with a telescopic rod, and the bottom end of the telescopic rod is fixedly connected with a moving board, and the bottom of the moving board is fixed A laser descaler is attached. This method of rust removal does not require manual use of a grinder to remove rust, avoiding damage to the metal surface caused by grinding and rust removal, and ensuring the effect of rust removal on the metal surface to be derusted, and the reciprocating motion of the laser rust remover can also achieve uniform and stable rust removal the goal of.

Owner:GANZHOU YANSHUNFEI TECH CO LTD

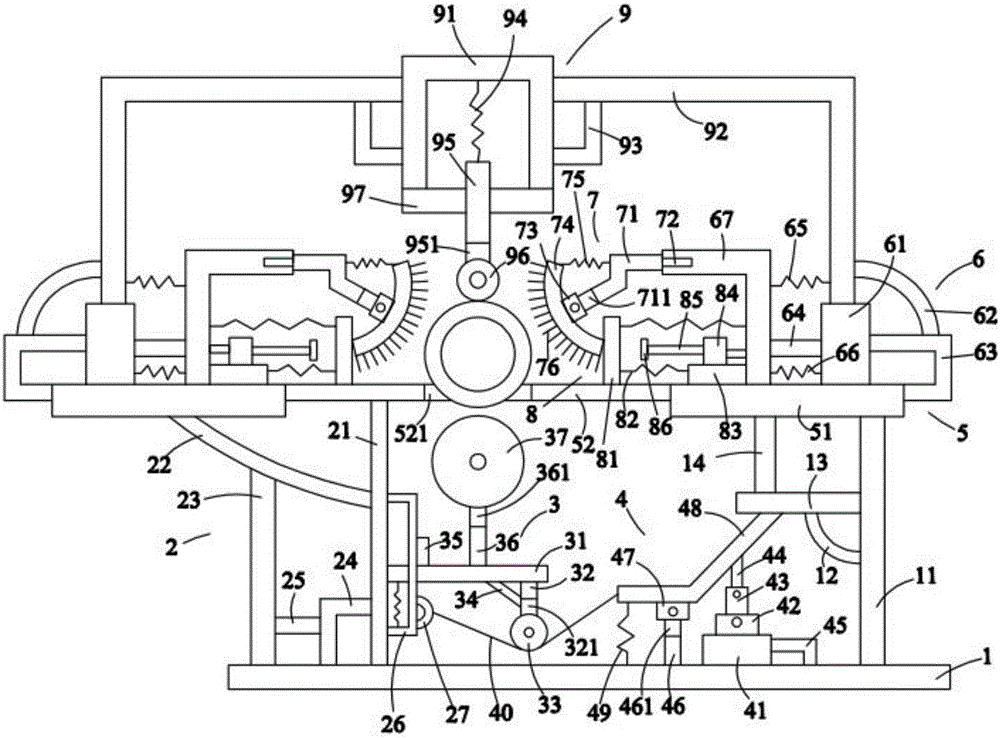

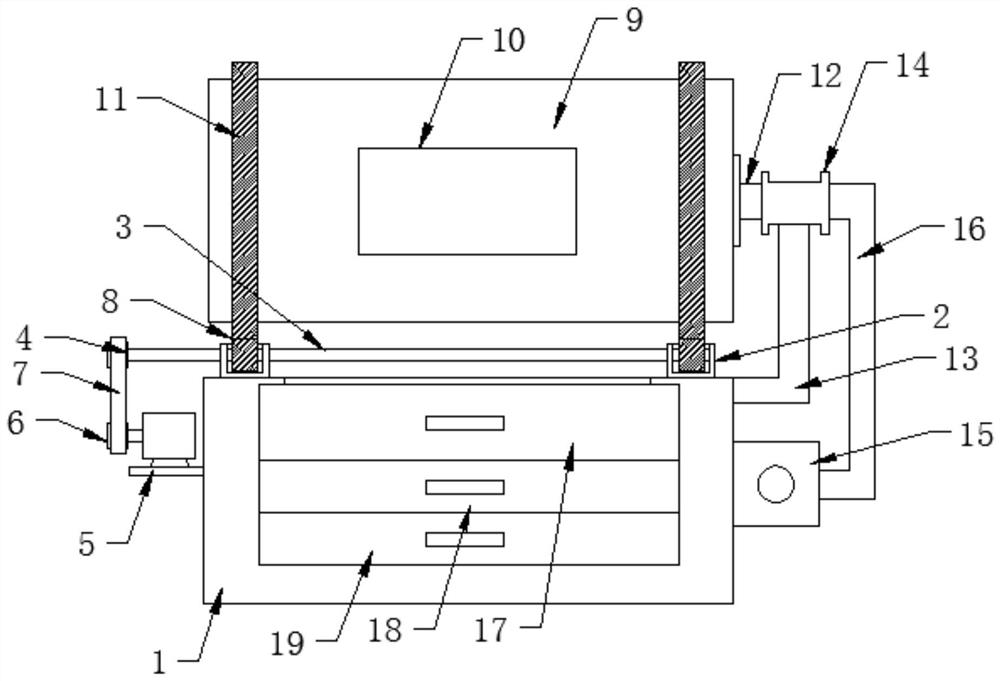

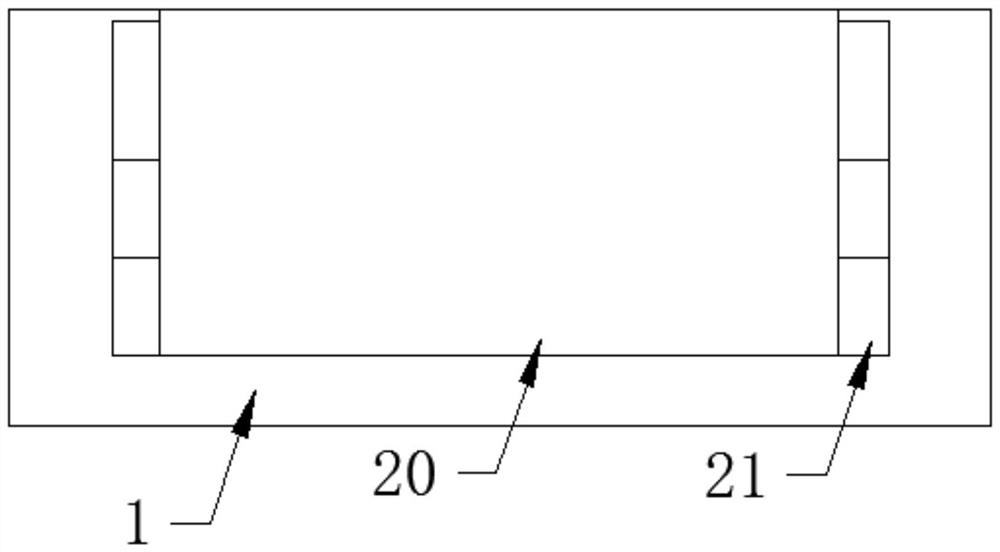

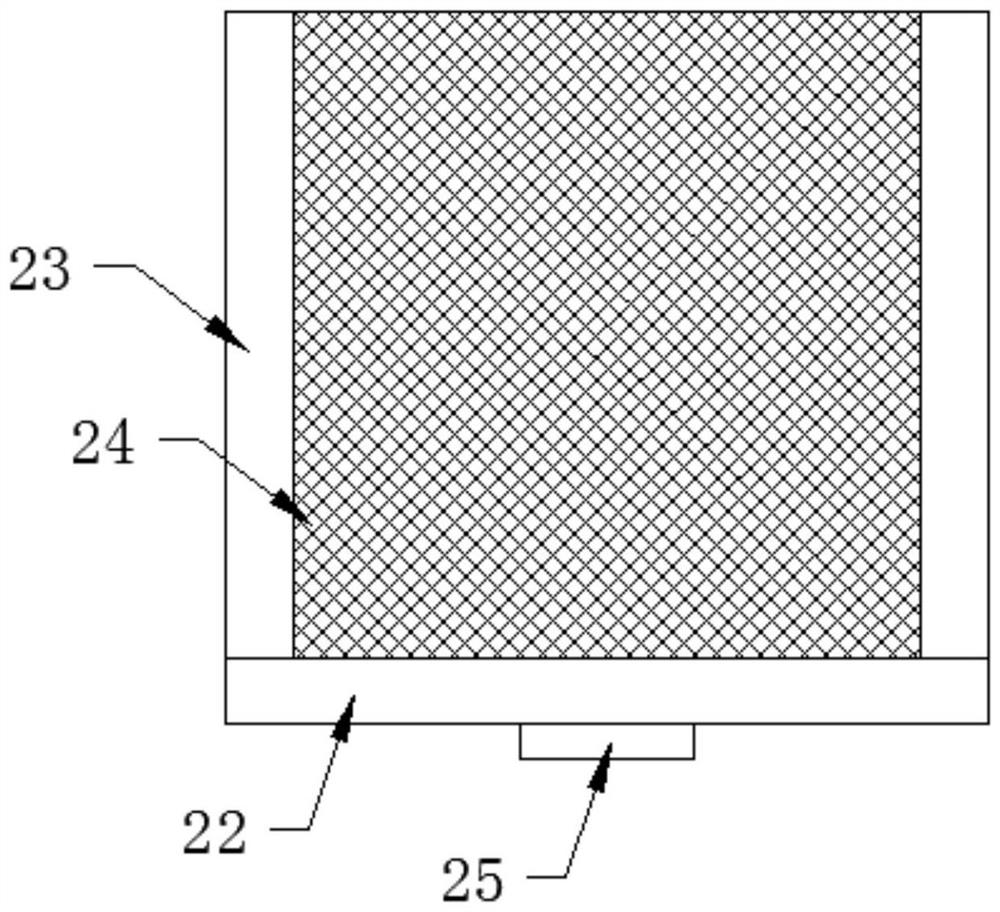

Building material steel pipe rust-removal equipment provided with elastic device

The invention discloses building material steel pipe rust-removal equipment provided with an elastic device. The building material steel pipe rust-removal equipment comprises a bottom plate, a bracket device, a drive device, a lever device, a supporting plate device, an electric cylinder device, a rust-removal device, a pushing device and the elastic device, wherein a first supporting rod, a first bending rod, a first limiting rod and a first vertical rod are arranged on the bottom plate; the bracket device comprises a second supporting rod, a second bending rod, a third supporting rod, a first bracket, a first cross rod, a first locating frame, a first fixed ring and a first spring; the drive device comprises a first cross plate, a second vertical rod, a first roller wheel, a first fixed rod, a first slide block, a fourth supporting rod and a drive wheel; and the lever device comprises a first electric cylinder, a first pushing rod, a second pushing rod, a first connecting block, a second bracket, a fifth supporting rod, a first fixed block, a lever, a second spring and a pulling wire; and the supporting plate device comprises a first supporting plate and a second supporting plate. The building material steel pipe rust-removal equipment can be used for effectively brushing a building material steel pipe to remove iron rust on the surface of the building material steel pipe.

Owner:HEBEI SIWEI CHEM IND

Rapid dirt and rust removing mechanism for outer walls of steel pipes

PendingCN112757131AGood sandingNeutral goodGrinding carriagesGrinding machinesMining engineeringPipe

The invention discloses a rapid dirt and rust removing mechanism for outer walls of steel pipes, and relates to the technical field of steel pipe machining. The problems that an existing dirt and rust removing device for steel pipes only cleans pipelines within a certain diameter range during use, parts with large diameters are prone to falling off during cleaning, meanwhile, the feeding speed adjusting difficulty is large in the pipeline cleaning process, and adjusting operation is inconvenient are solved. The rapid dirt and rust removing mechanism comprises a mounting base. The top of the mounting base is fixedly connected with a set of lifting driving piece. The left side and the right side of the top of a guide wheel bearing piece are each rotationally connected with a set of guide assembly. A rust removing cleaning device is mounted at the front part of a lifting seat. The rapid dirt and rust removing mechanism has good feeding and conveying capacity, meanwhile can be adjusted according to needs and can carry out rust removing on pipelines with different diameters, the situation that steel pipes fall off due to too large diameters of the steel pipes is effectively avoided, meanwhile, the feeding speed can be adjusted so as to guarantee the rust removing effect, cleanliness of the surfaces of the pipelines is guaranteed, and the rapid dirt and rust removing mechanism is simple to use and convenient to operate.

Owner:丁月红

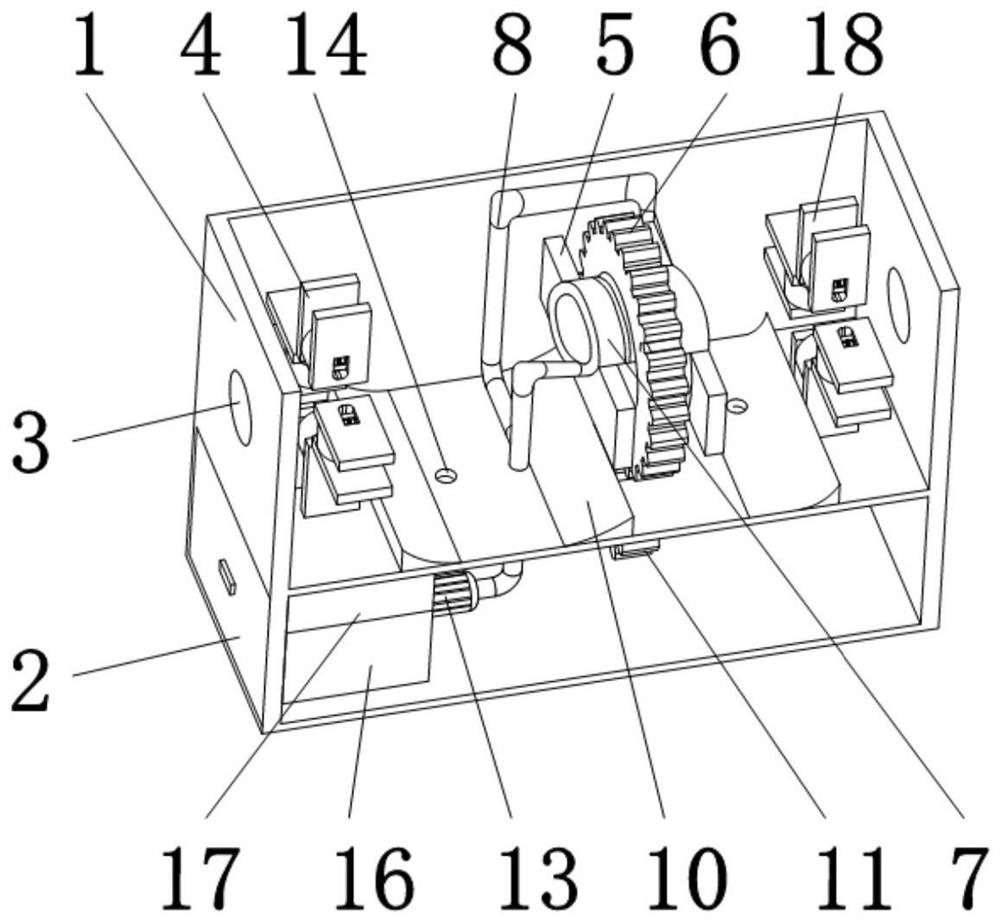

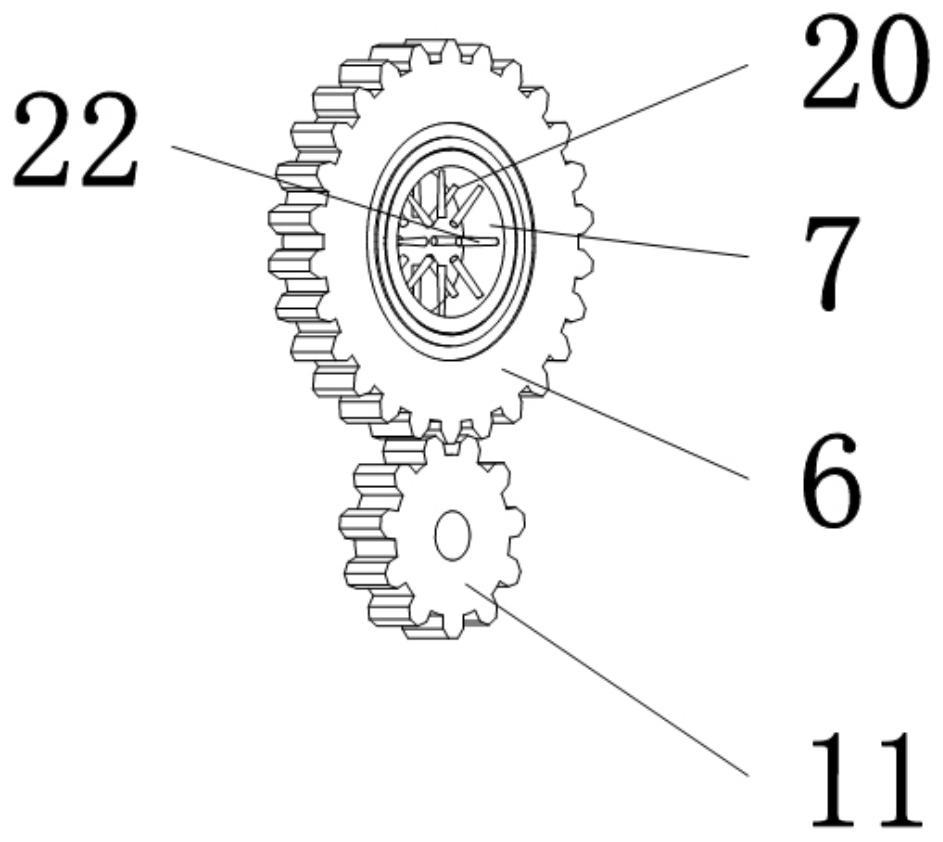

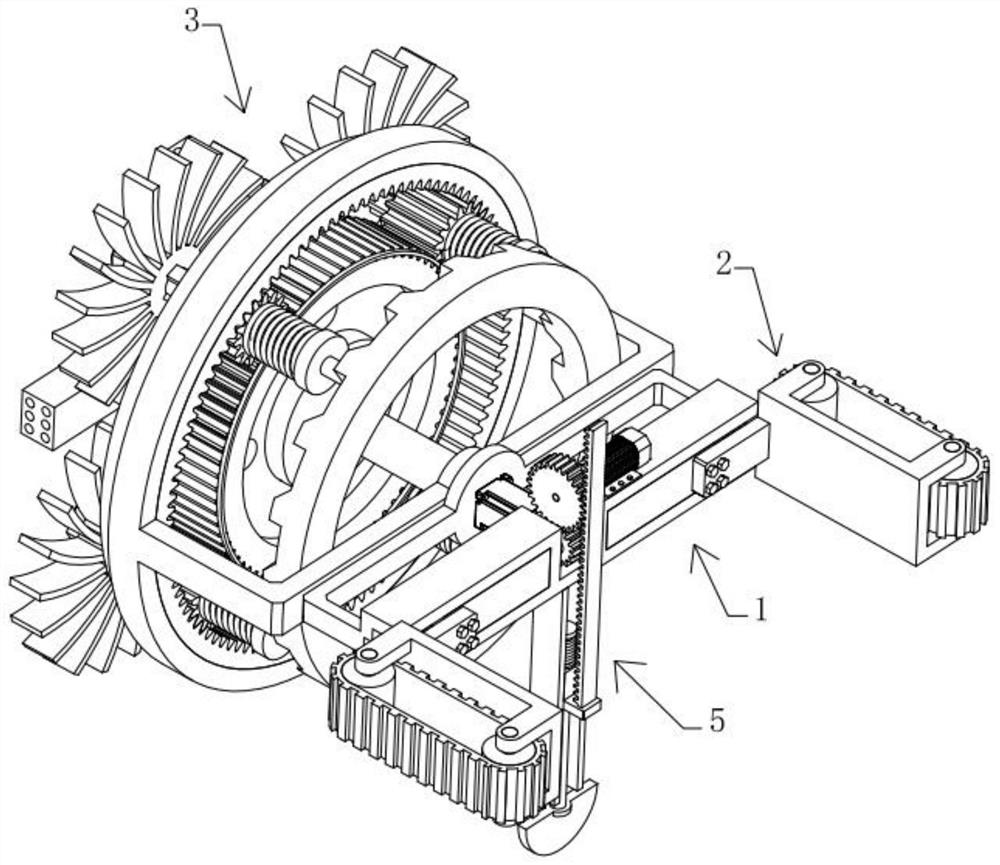

Derusting device for iron cores of drum type transformers

PendingCN111633552AWill not affect workNovel structural designEdge grinding machinesPolishing machinesElectric machineGear wheel

The invention discloses a derusting device for iron cores of drum type transformers. The derusting device comprises a base. Gear housings are fixed to the two ends of the top of the base correspondingly. Supporting gears installed in the two gear housings are connected through a connecting shaft. The gear housing on one side is connected with a driven belt wheel. One side wall of the base is provided with a driving motor. An output end of the driving motor is connected with a driving belt wheel. A drum is arranged on the upper side of the base. A material door is arranged on the outer wall ofthe drum. The two sides of the outer wall of the drum are fixedly provided with gear rings meshing with the supporting gears. One end of each gear ring is provided with a dust suction port. A dust collector is arranged on the base. A plurality of collection boxes are slidingly connected into the base. Sand removal, derusting, oxide skin removal and surface reinforcing of the iron cores of the transformers can be performed, dust generated during derusting is sucked in, derusting operation on the transformers is facilitated, the transformer iron cores, blasting shots and rust can be convenientlyseparated, artificial screening is avoided, no procedures are added, and labor cost is effectively reduced.

Owner:新沂市宏展电子科技有限公司

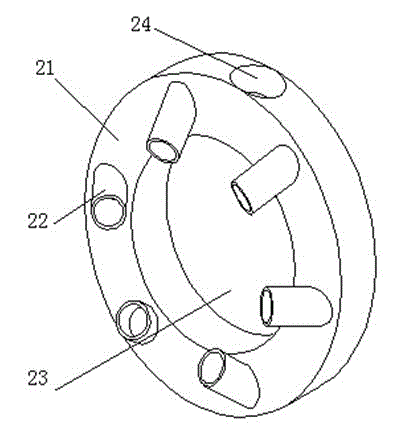

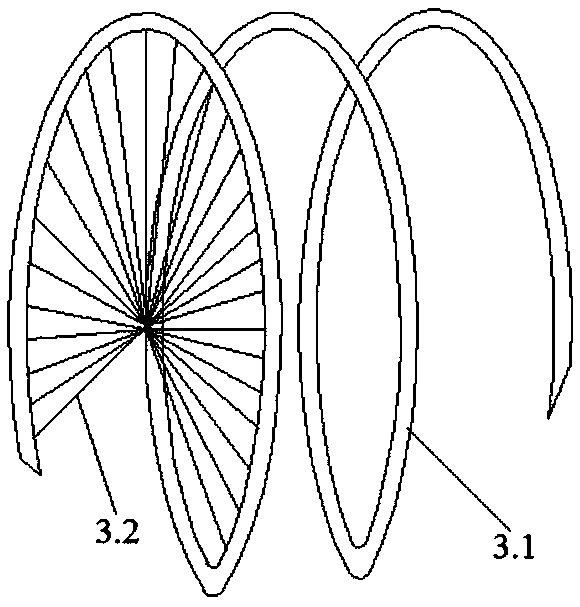

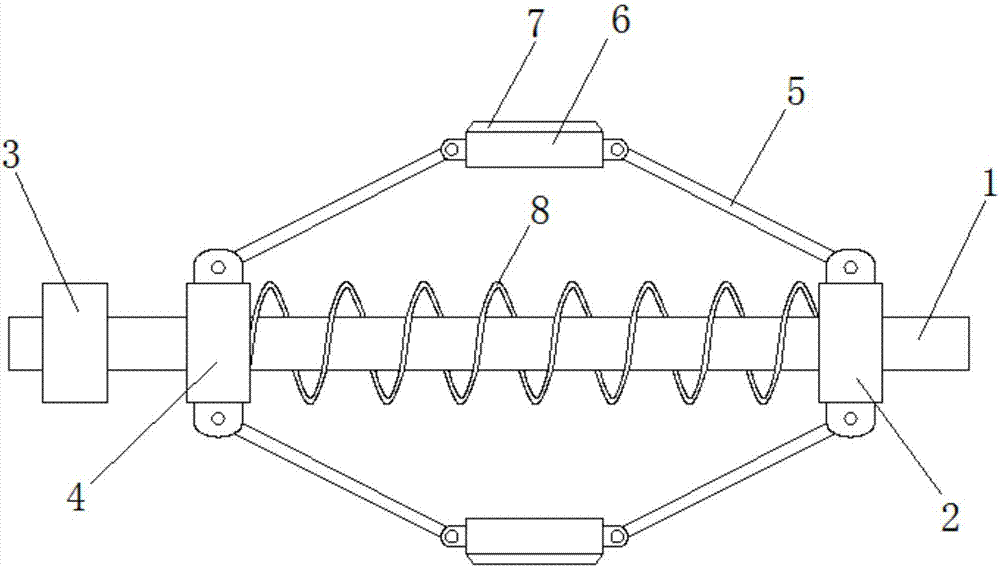

Building supporting steel tube inner part rust cleaning brush head

InactiveCN107471101AMeet the requirements of rust removalClose contactGrinding machine componentsGrinding machinesEngineeringMetal

The invention discloses a rust-removing brush head inside a building support steel pipe, comprising: a rotating shaft, a fixed ring, a top ring, a moving ring, a connecting rod, a counterweight, a metal brush piece, a spring, and the output of the rotating shaft and a power motor The shaft is affixed, the fixed ring is affixed to the rear of the front end of the rotating shaft, the top ring is affixed to the top of the front end of the rotating shaft, the moving ring is slidably connected to the rotating shaft, and the moving ring is located between the fixed ring and the top ring. In between, the two ends of the counterweight are respectively connected to one end of the connecting rod through a pin shaft, wherein the other end of the front connecting rod is connected with the moving ring through a pin shaft, and the other end of the rear connecting rod is connected through a pin shaft It is connected with the fixed ring, the metal brush is fixed on the outside of the counterweight, the spring is sleeved on the rotating shaft, and the two ends of the spring are respectively connected with the fixed ring and the moving ring. The invention has the advantages of simple structure, meeting the technical requirements of internal rust removal, and good use effect.

Portable building steel bar rust removal device with conveying and rotating structure

InactiveCN113601362AWell mixedEase of Controlling EmissionsGrinding carriagesGrinding drivesElectric machineryRebar

The invention discloses a portable building steel bar rust removal device with a conveying and rotating structure. The portable building steel bar rust removal device comprises a rust removal box, a mixing and proportioning box and a first driving motor, wherein the rust removal box is arranged on the ground through universal wheels mounted at the bottom; a measuring mechanism is arranged in the mixing and proportioning box, and a conveying water pipe is mounted on the left side of the lower portion of the mixing and proportioning box; a discharging mechanism is arranged in the conveying water pipe, and a pesticide spraying mechanism is connected to the lower side of the conveying water pipe; and a rust removal mechanism is arranged on the left side of the first driving motor. According to the portable building steel bar rust removal device with the conveying and rotating structure, all-directional spraying operation can be conducted on steel bars, the rust removal efficiency is improved, medicines can be conveniently proportioned and mixed, rust removal is achieved through continuous rotation of three sets of rust removal steel wire brushes, rust removal dead corners can be avoided, the rust removal effect is guaranteed, and the rust removal mechanism can be adjusted according to the steel bars of different sizes.

Owner:郭桃会

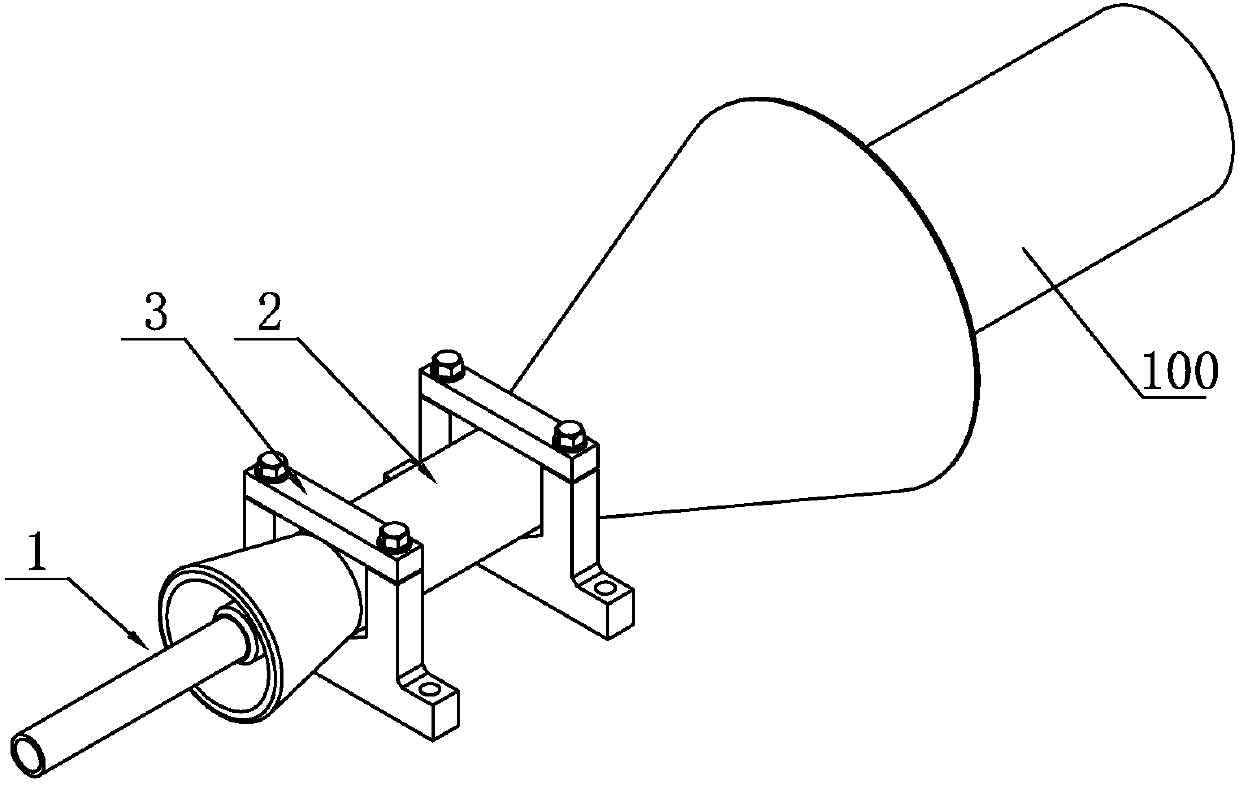

Rust removal device and method for inner wall of metal pipe

InactiveCN108857846AGuaranteed derusting effectWon't hurtEdge grinding machinesPolishing machinesMetal particleRust

The invention discloses a rust removal device and method for the inner wall of a metal pipe. The device comprises a pipe body and a rotation ring; metal particles are placed in a cavity of the pipe body, the rotation ring is located on the outer surface of the pipe body and connected with the pipe body through a thread track, multiple magnets electrically connected with the exterior are arranged in the rotation ring, and the rotation ring can rotate relative to the pipe body and can move in the length direction of the thread track in the rotation process. The device is easy to operate, the inner wall of the metal pipe can be subjected to dust removal operation, the dust removal effect is guaranteed, and the portions, without rusty layers, of the metal pipe cannot be damaged.

Owner:FOSHAN GAOMING XILUO TECH CO LTD

Cleaning device for steel pipe machining

InactiveCN112872061AThorough and effective cleaningIncrease profitHollow article cleaningGrinding machinesGear wheelMachining

The invention belongs to the technical field of steel pipe machining, and discloses a cleaning device for steel pipe machining. The cleaning device comprises a shell, wherein the shell is divided into an upper layer and a lower layer, one side of the shell is provided with a feed port, the other side of the shell is provided with a discharge port, one side of the inner surface of the upper layer of the shell is provided with a first clamping device, a second clamping device is arranged on the other side of the inner surface of the shell, a plurality of fixing buckles are arranged on the inner walls of the two ends of the upper layer of the shell respectively, a sleeving ring is arranged in the middle of the two fixing buckles, a first communicating pipeline is excavated in the sleeving ring, an electric rotating table is arranged on the outer surface of the sleeving ring, one end of the electric rotating table is rotatably connected with a rotating ring, the rotating ring is rotatably connected with the sleeving ring through a bearing, and a plurality of water cavities are evenly excavated in the rotating ring in arrays. According to the device, the outer wall of a steel pipe is deoiled through a rotating roller, so that the rust on the outer wall of the steel pipe is removed through the differential rotation of the first gear and the rotating ring, the cleaning effect is good and the cleaning efficiency is high.

Owner:徐敏旺

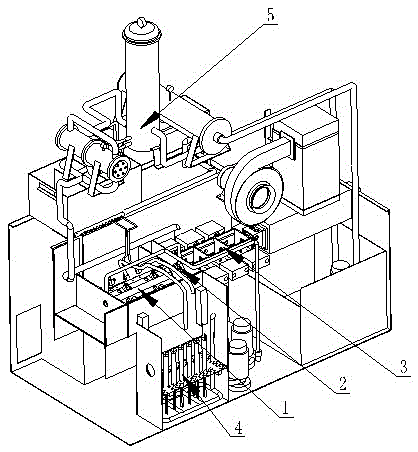

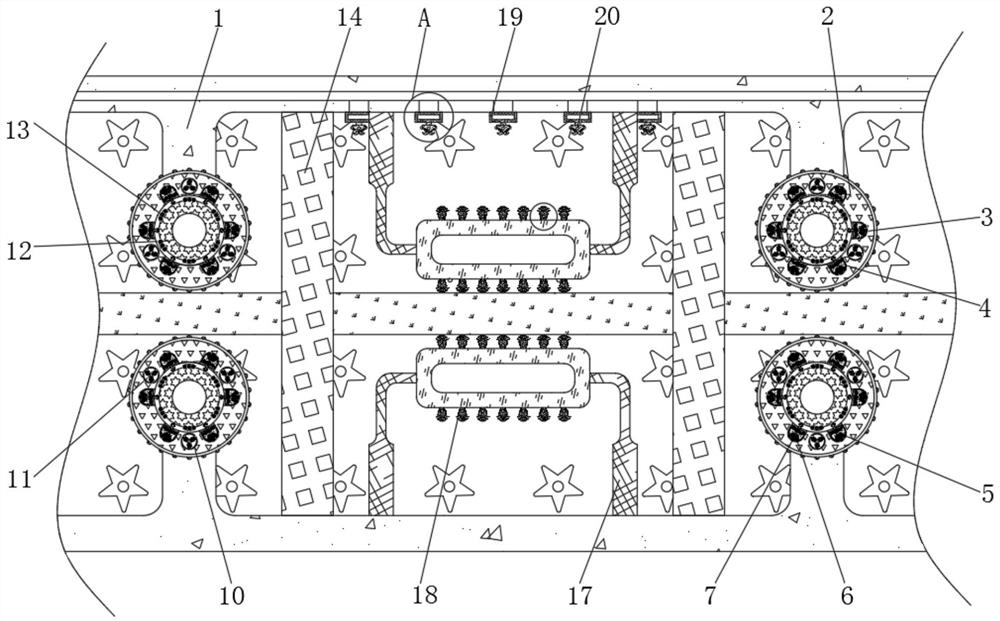

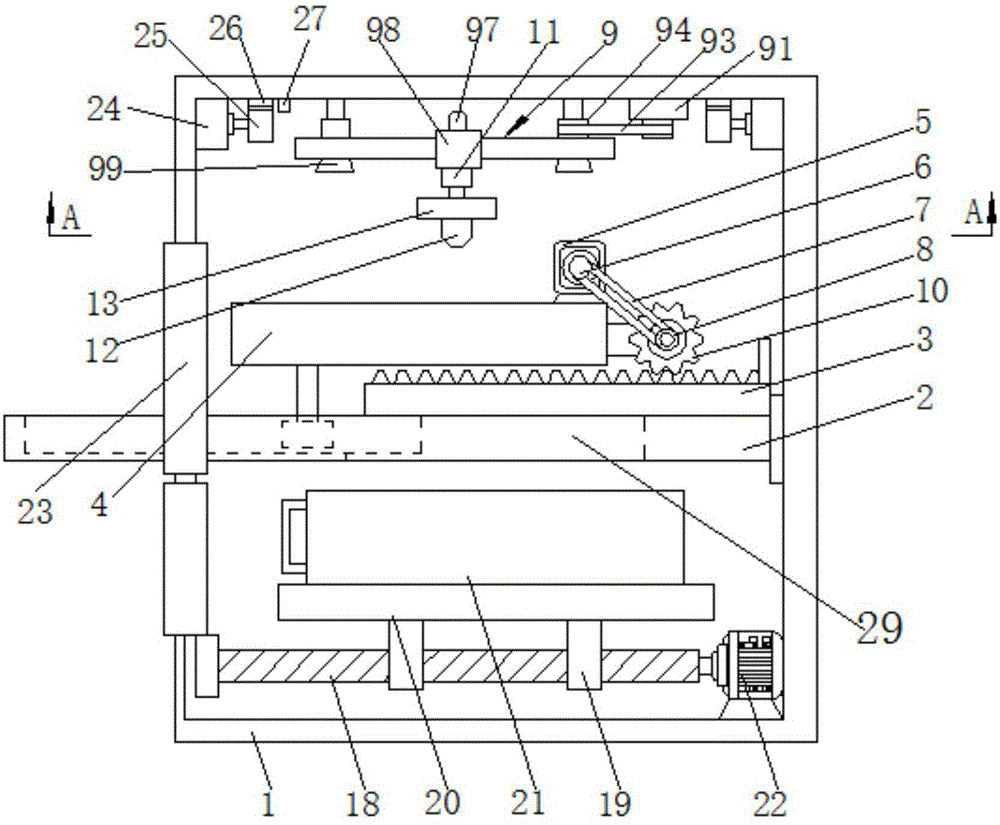

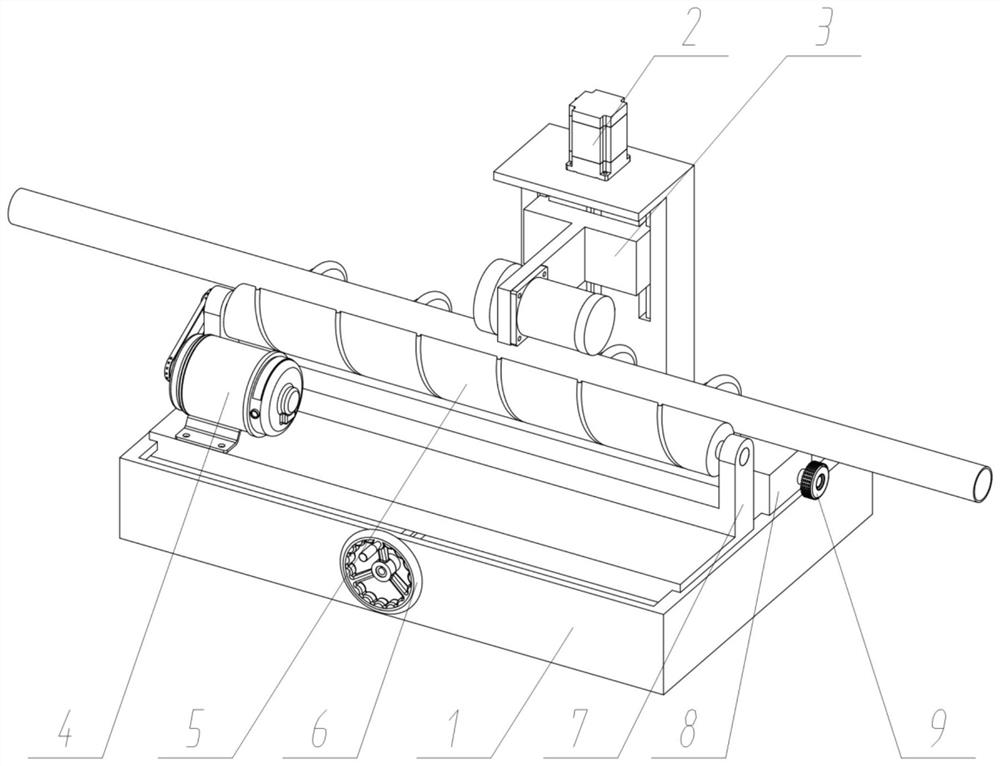

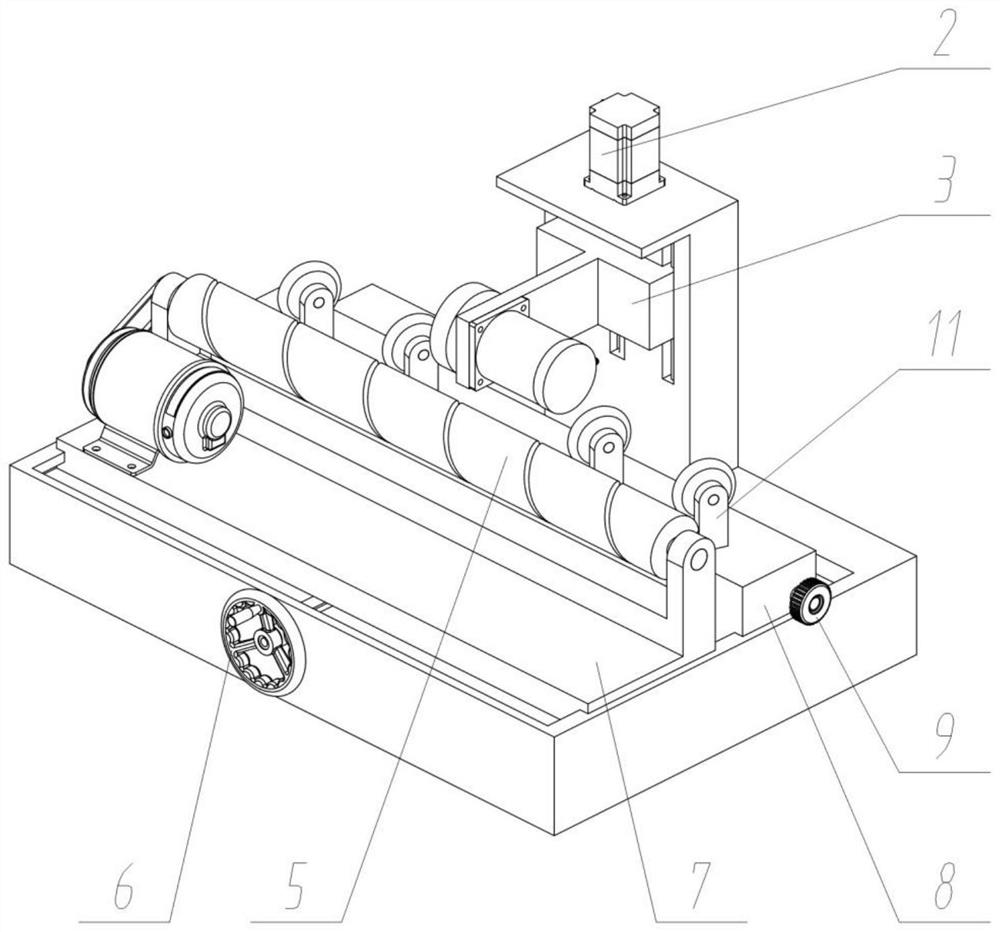

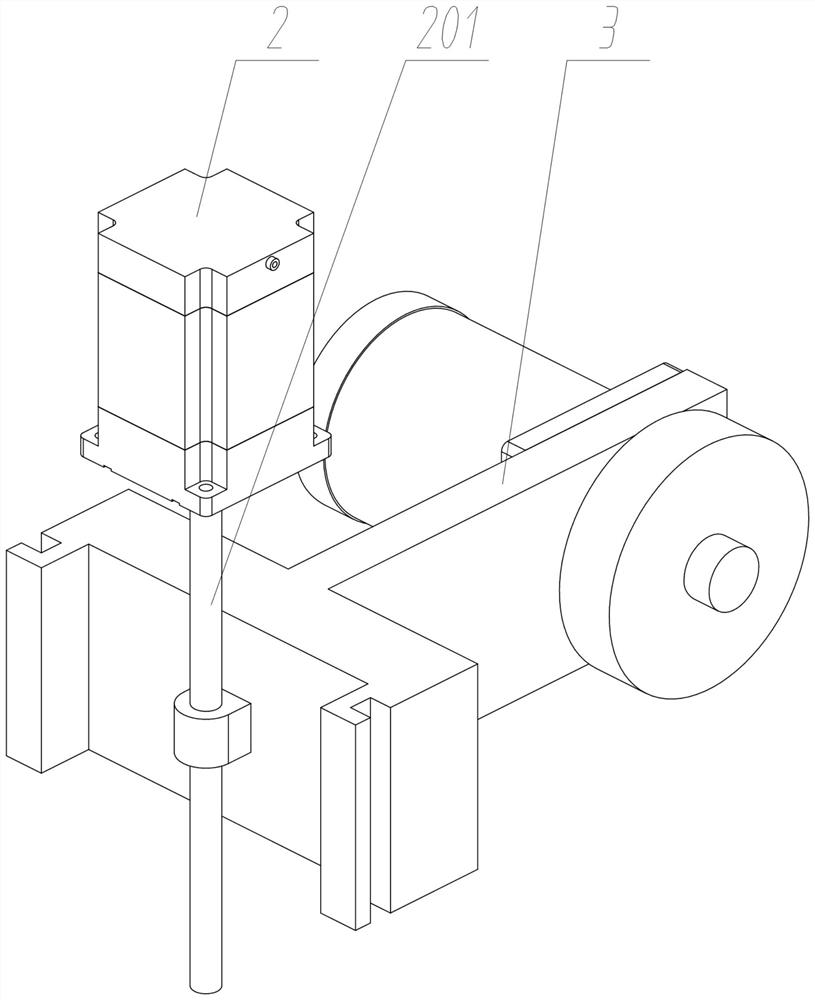

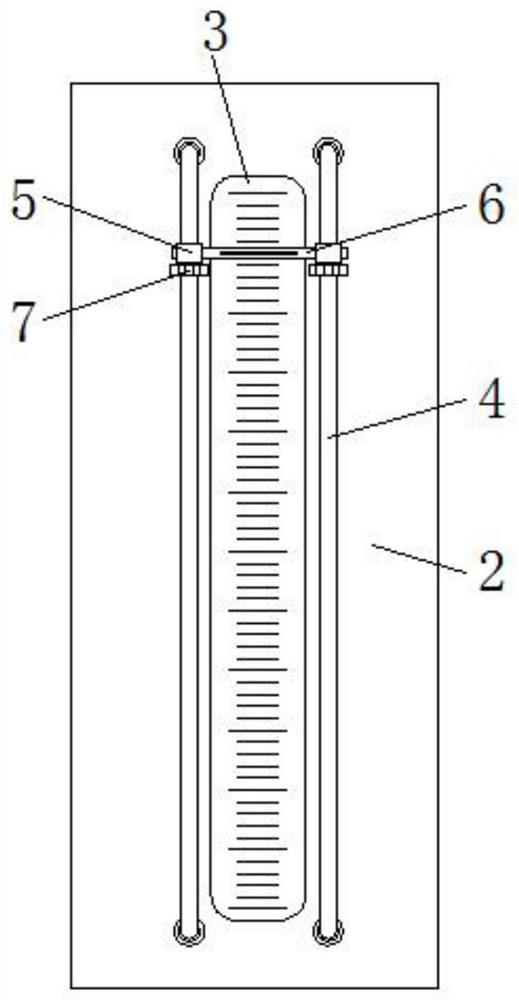

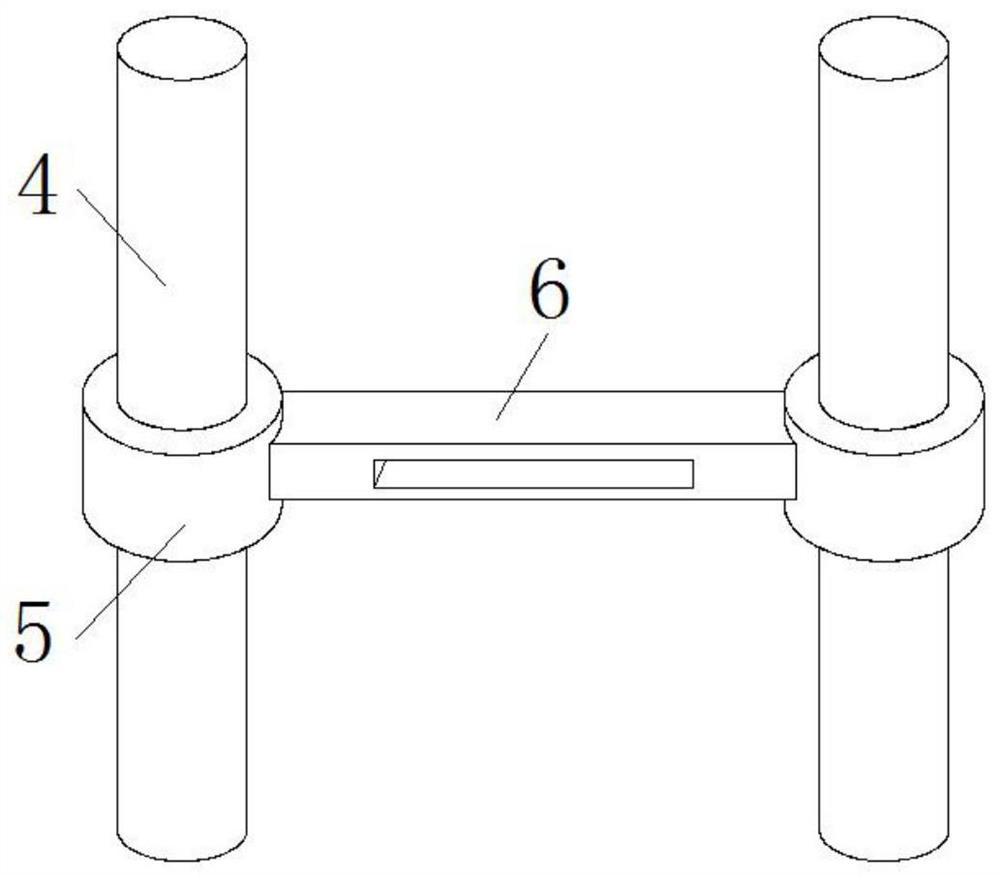

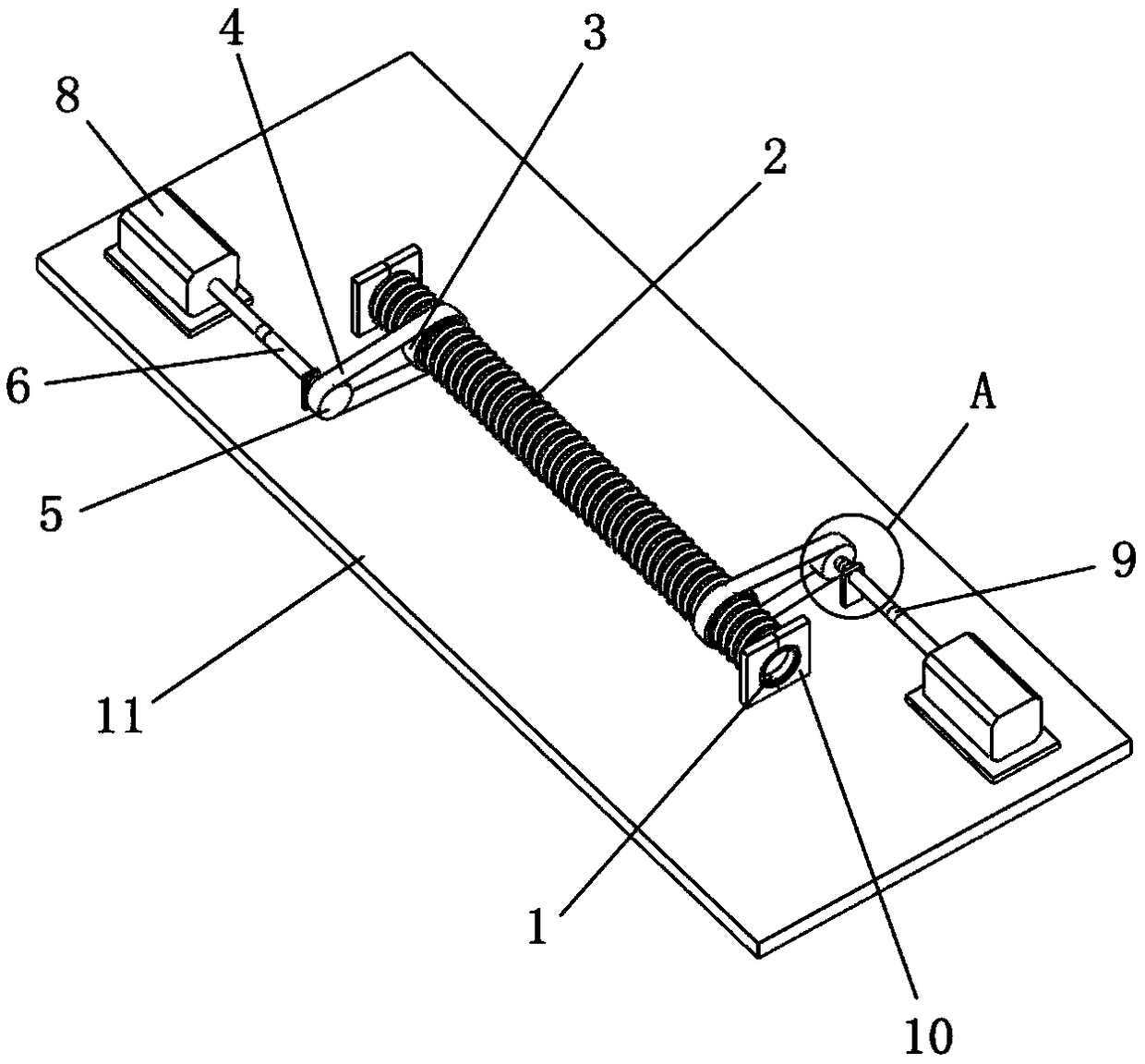

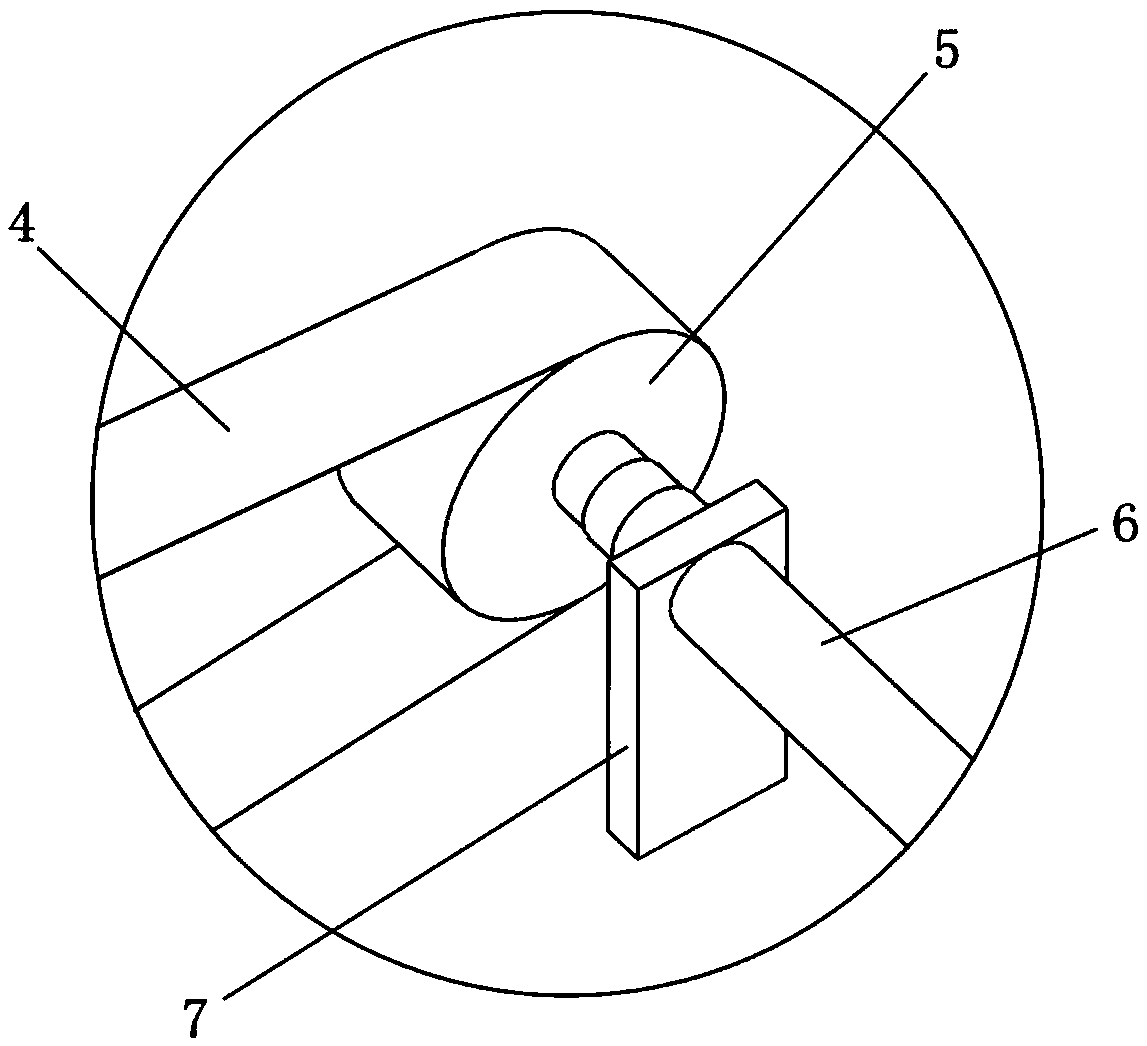

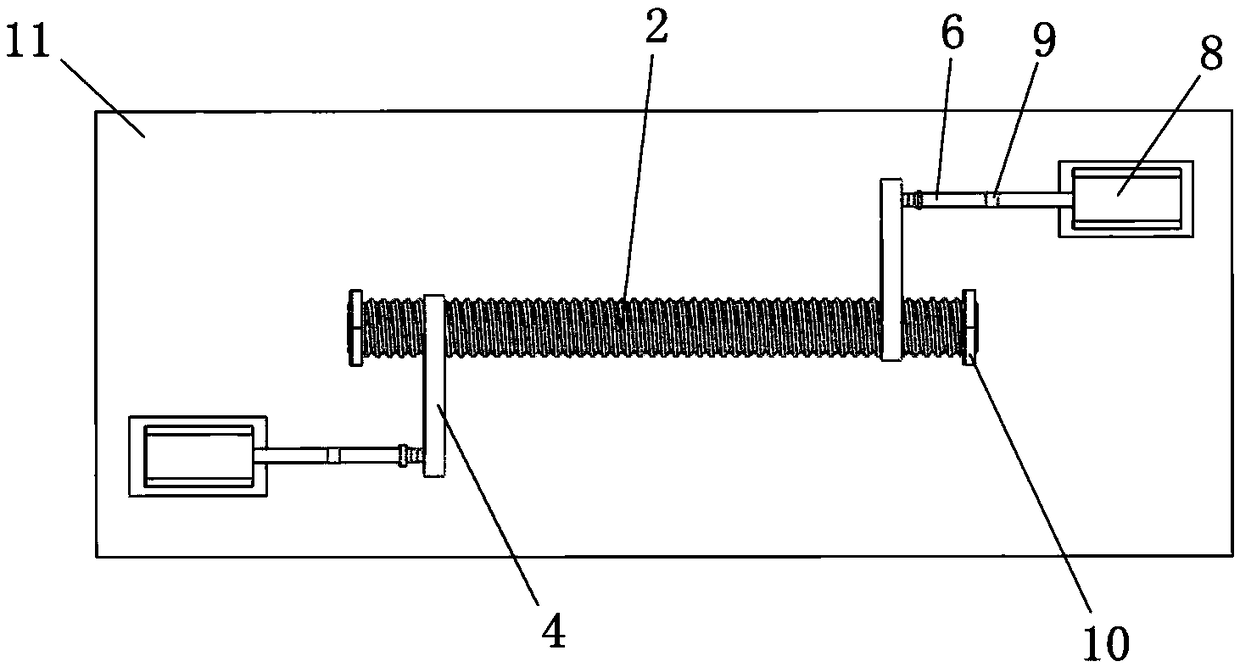

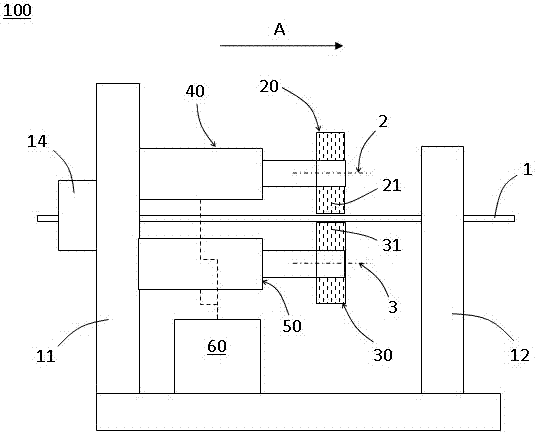

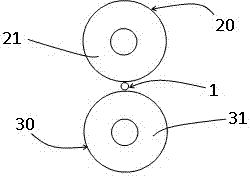

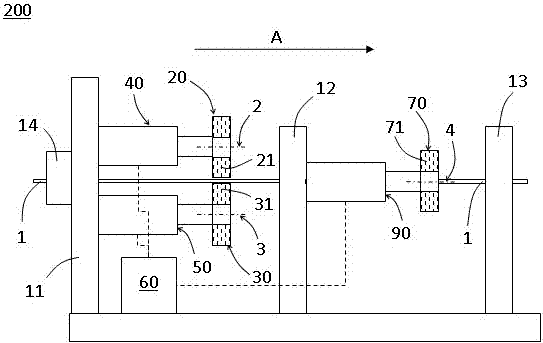

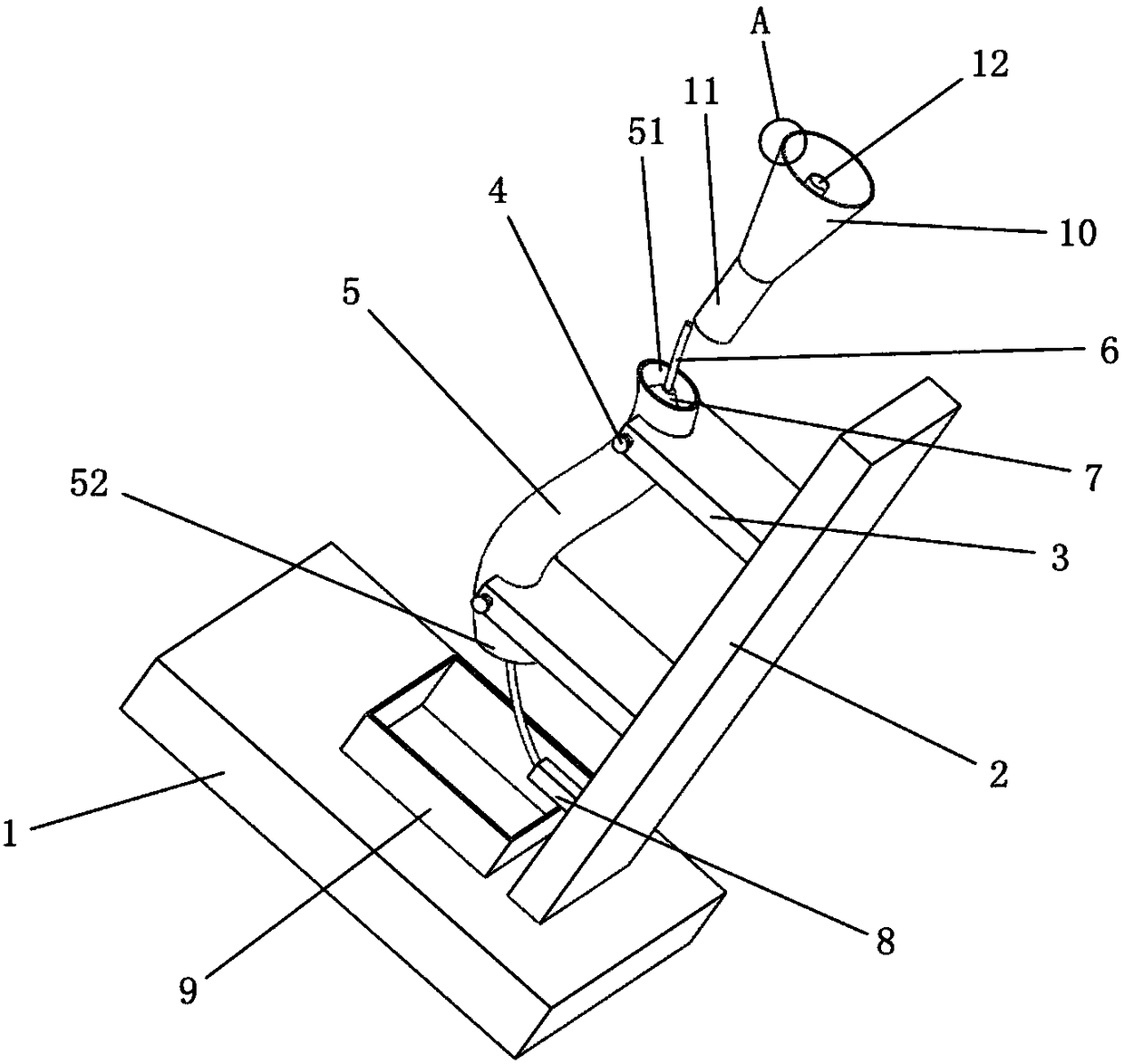

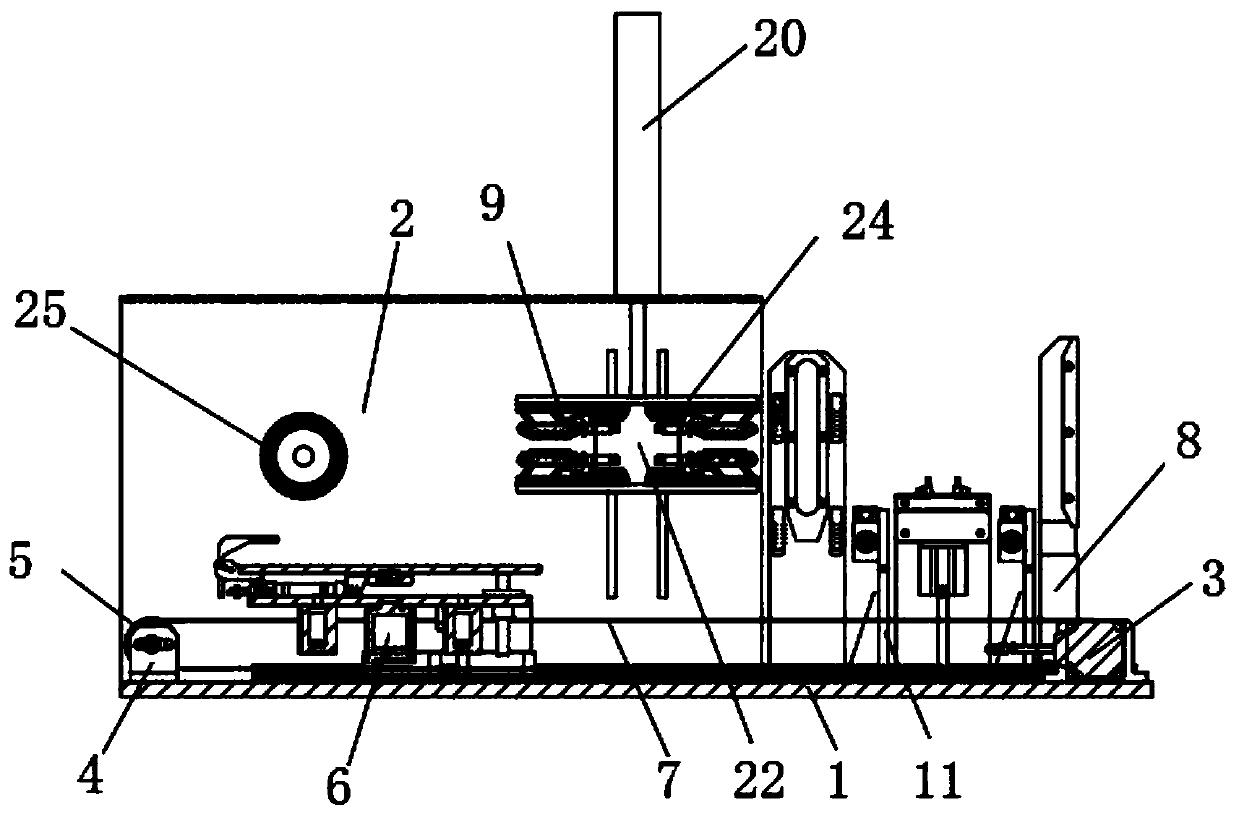

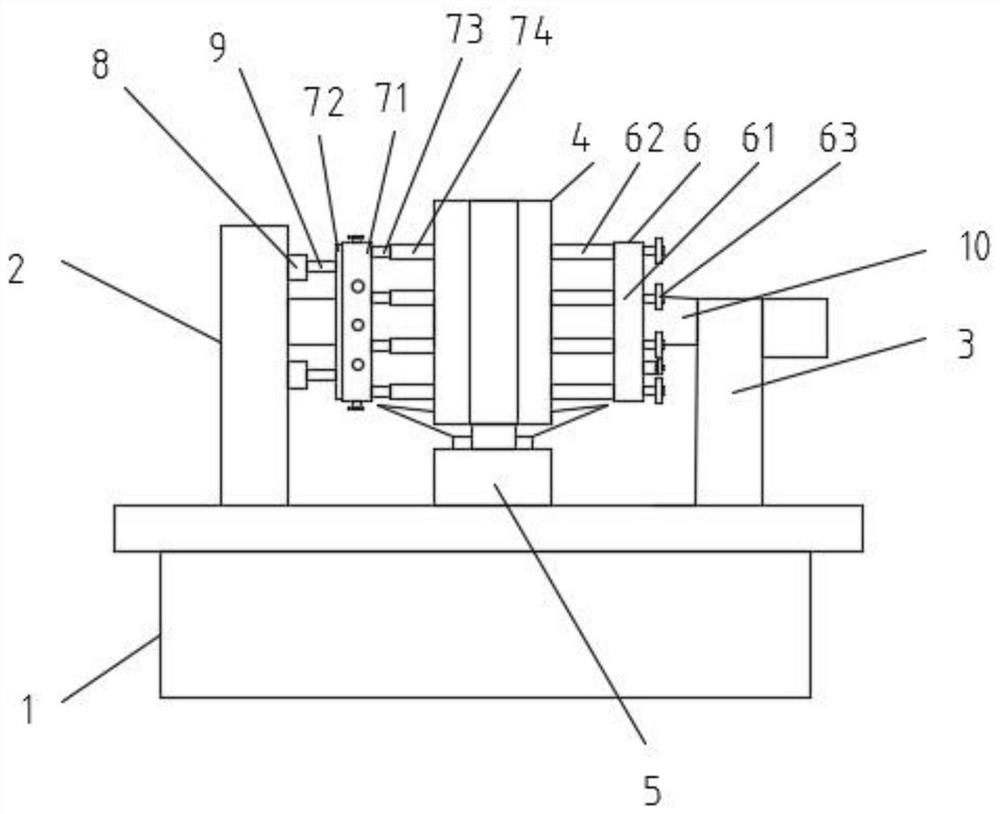

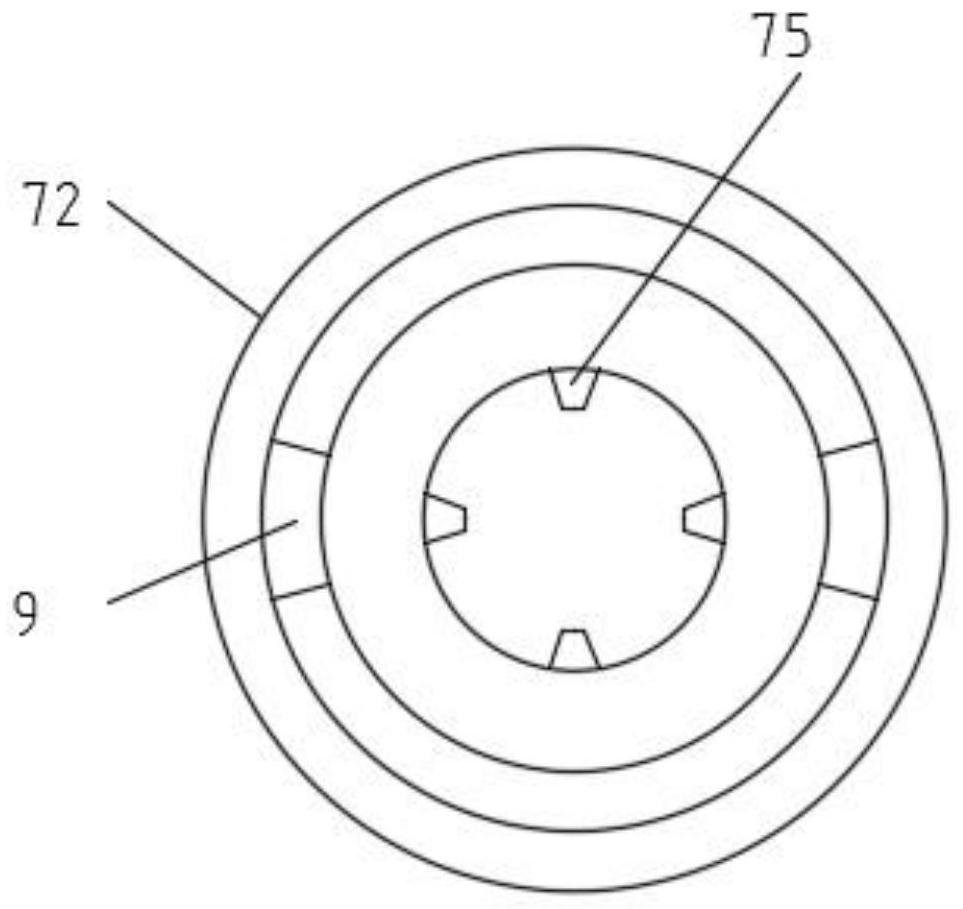

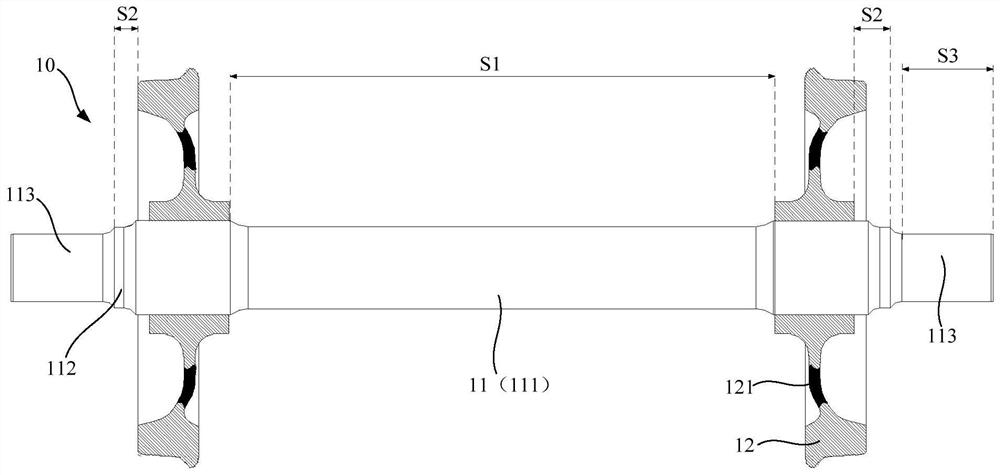

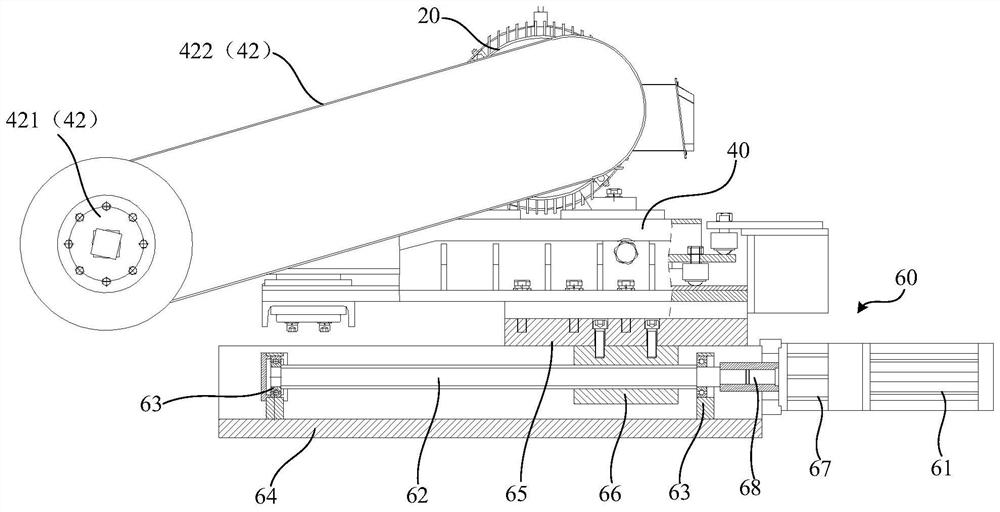

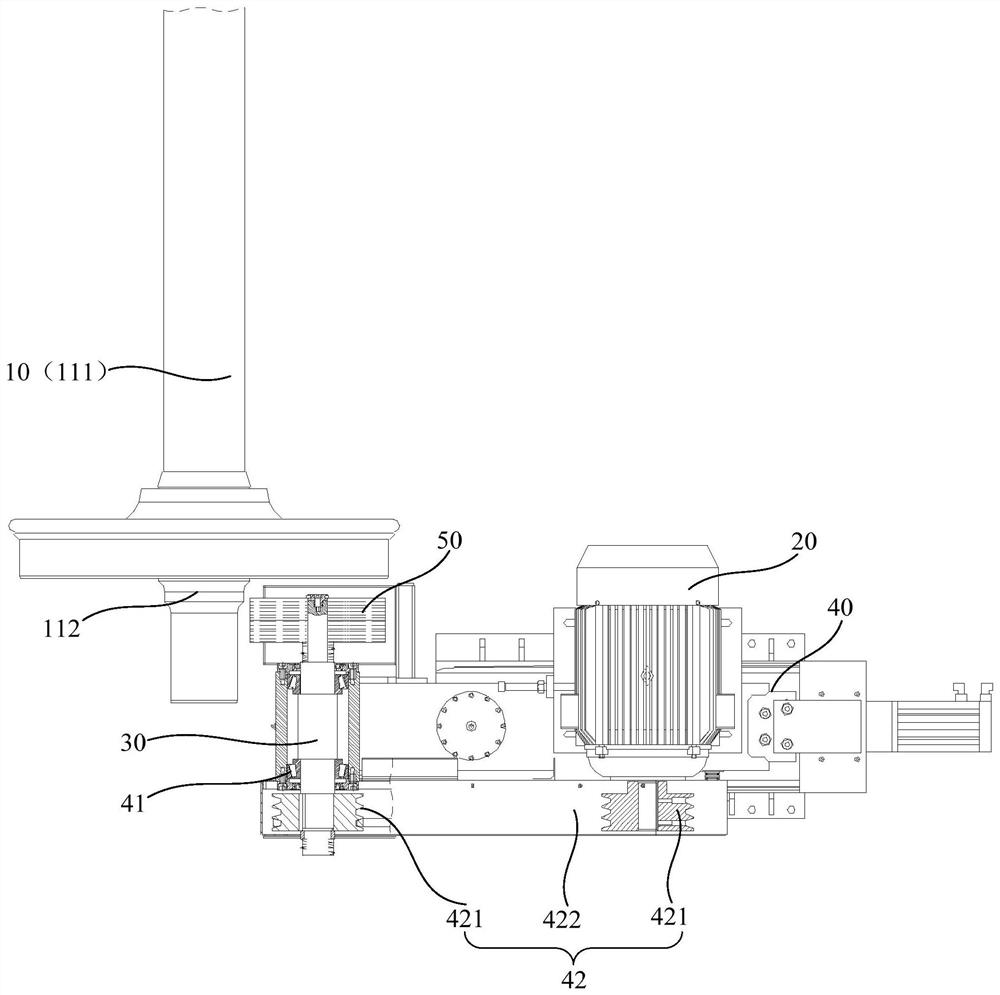

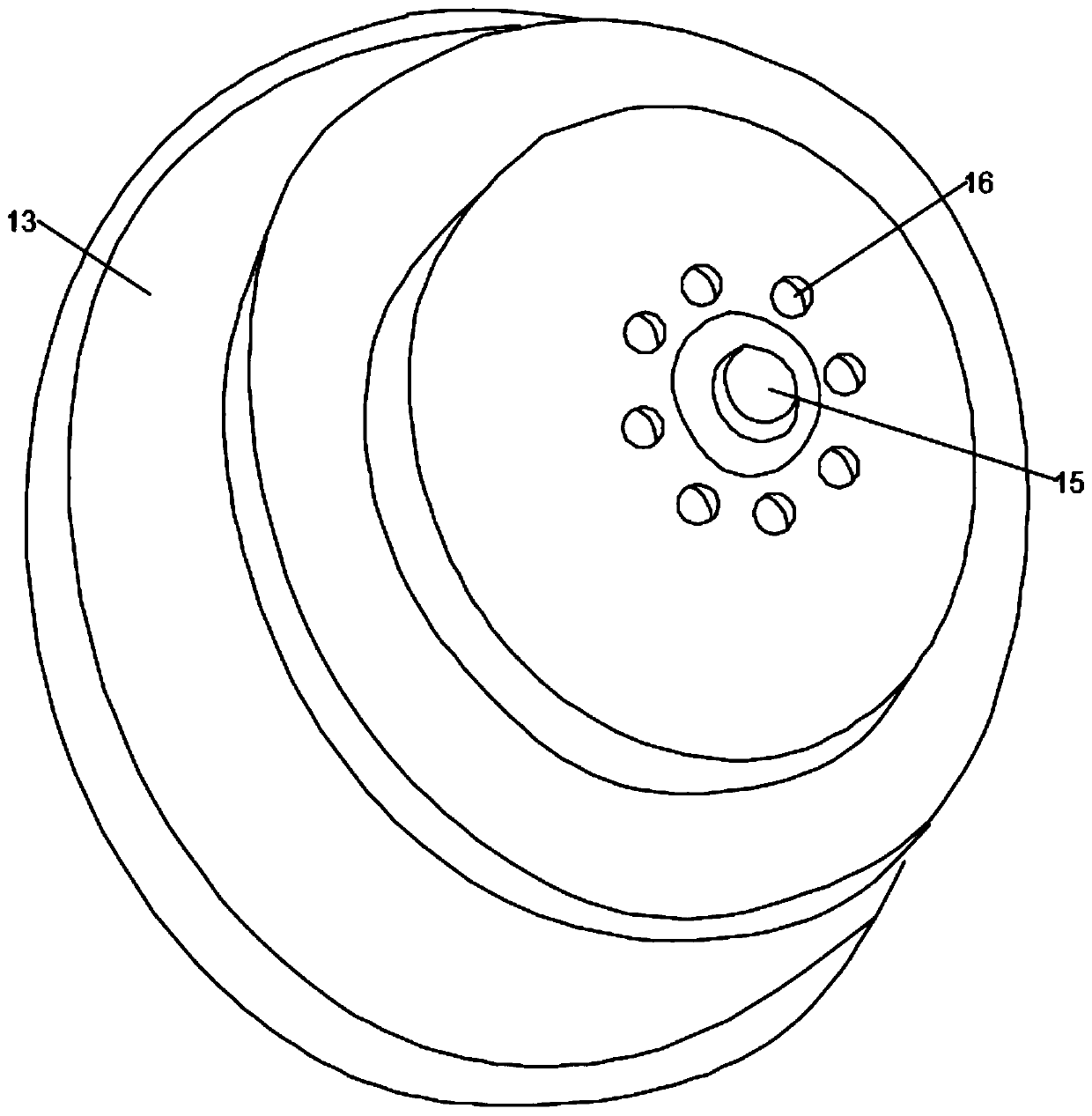

Mechanical derusting equipment for wire rods

PendingCN107097134ARust removal achievedGuaranteed derusting effectGrinding carriagesGrinding machinesWire rodEngineering

The invention provides mechanical derusting equipment for wire rods. The equipment comprises a support, a first turnplate, a second turnplate, a first transmission part, a second transmission part and a drive part. A first boss and a second boss of the support are provided with wire rod penetrating holes allowing a to-be-derusted wire rod to penetrate through in a wire rod arranging direction correspondingly. The first turnplate and the second turnpalte are provided with a first friction part rotating along the first axis and a second friction part rotating along the second axis correspondingly. The second turnplate and the first turnplate are symmetric with respect to the to-be-derusted wire rod penetrating through the wire rod penetrating holes. The to-be-derusted wire rod is located between the first friction part and the second friction part and tightly abuts against both the first friction part and the second friction part. The drive part enables the first turnplate to rotate through the first transmission part, so that the first friction part is driven to rub the to-be-derusted wire rod; and the drive part also enables the second turnplate to rotate through the second transmission part, so that the second friction part is driven to rub the to-be-derusted wire rod. By adoption of the mechanical derusting equipment, the wire rod can be automatically and mechanically derusted, and the working efficiency is improved on the premise that the derusting effect is guaranteed.

Owner:葛云杰

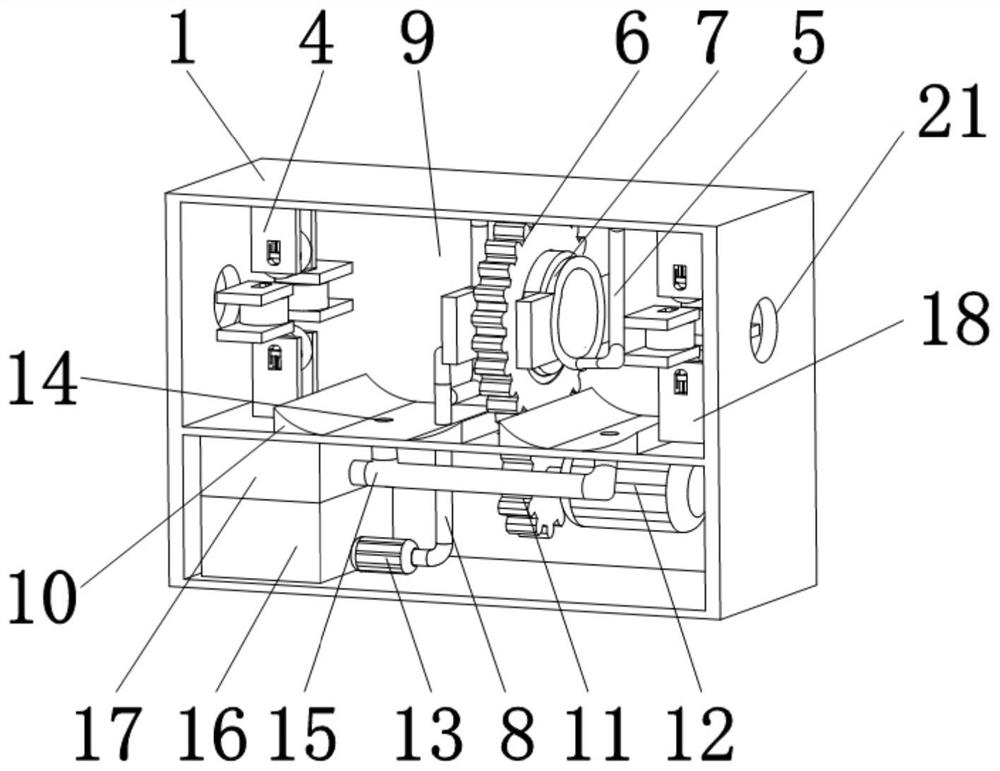

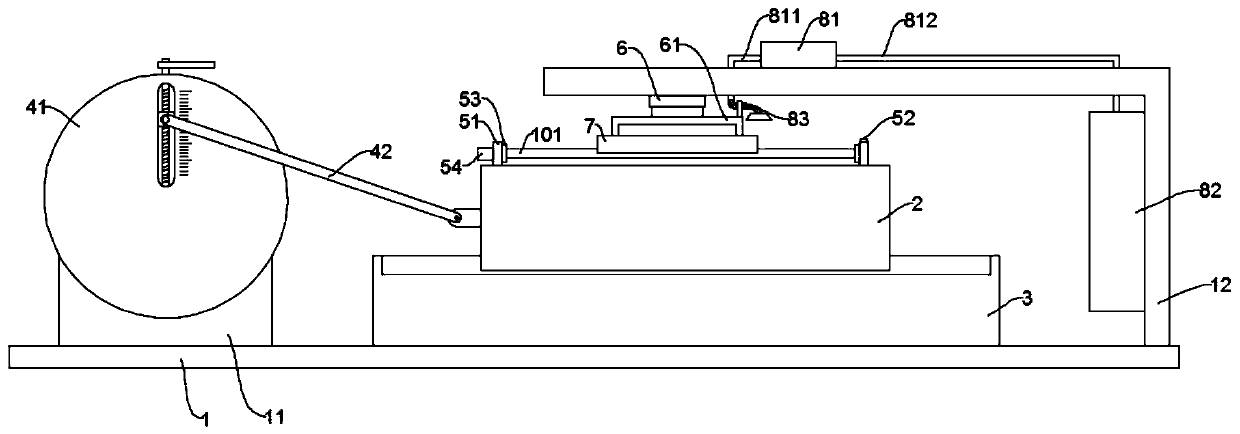

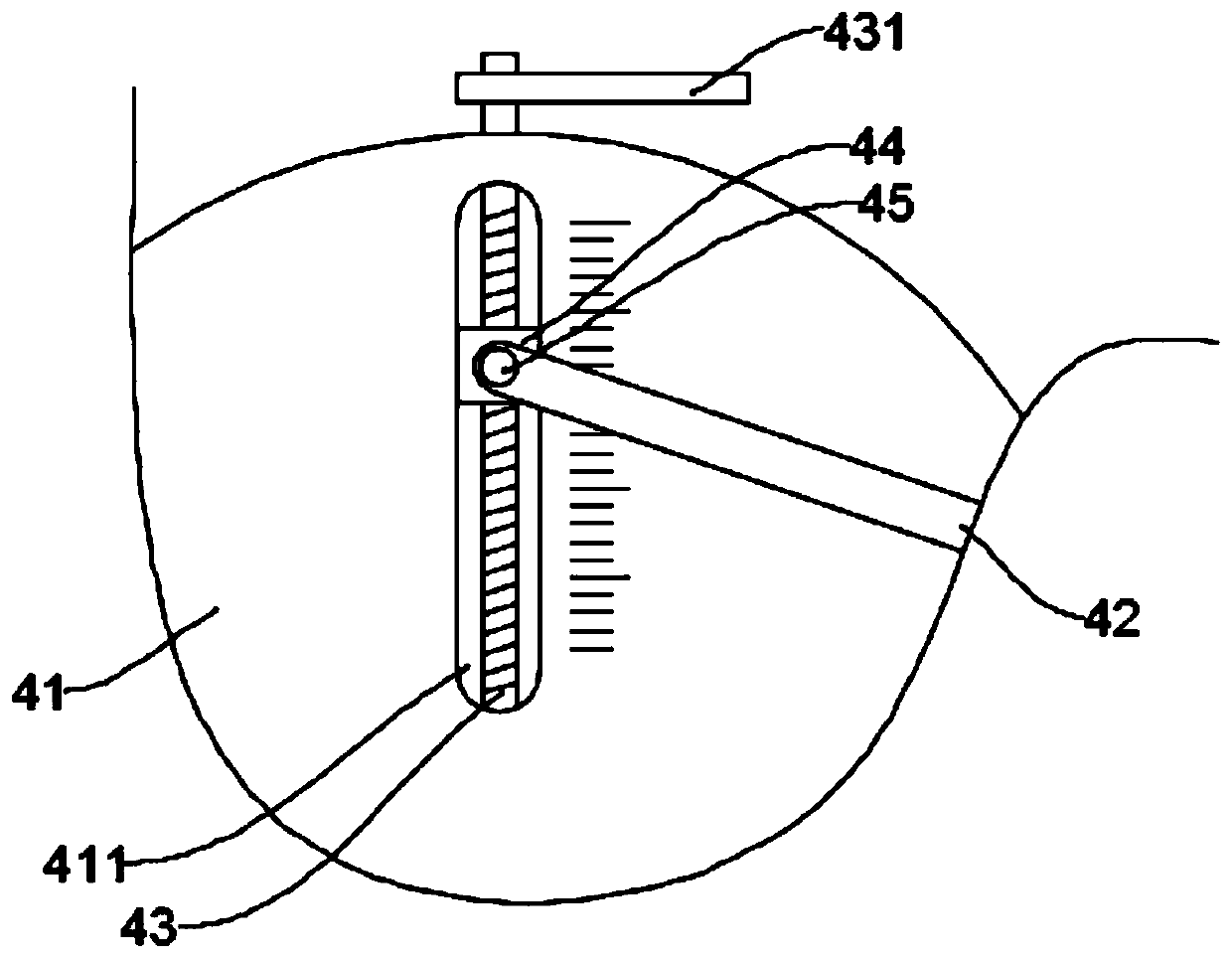

Adjustable building reinforcement rust removing device

InactiveCN110653707AImprove versatilityCooperate wellGrinding carriagesGrinding drivesScrew threadIndustrial engineering

The invention discloses an adjustable building reinforcement rust removing device, and relates to the field of building trades. The device comprises a base; a mounting frame, a support base and a support frame are fixed on the base; a driving mechanism for driving a worktable to move is mounted on the mounting frame; the driving mechanism comprises a rotating disc; the rotating disc is provided with a chute formed in the radius direction; a lead screw is rotationally connected into the chute; a slide block in threaded fit with the lead screw sleeves the outer periphery of the lead screw; the slide block is clamped in the chute; one end of the lead screw extends out of the chute, and is connected with an operation handle; a connecting column is fixed on the slide block; a connecting rod sleeves the outer periphery of the connecting column; one end of the connecting rod is rotationally connected with the connecting column; and the other end of the connecting rod is hinged to the worktable. The rotating disc is provided with the slide block capable of moving in the radius direction, and the connecting column is fixed on the slide block, so that the rotating radius of the connecting column can be adjusted to finish adjustment of the working range, and the overall device generality is improved.

Owner:时守东

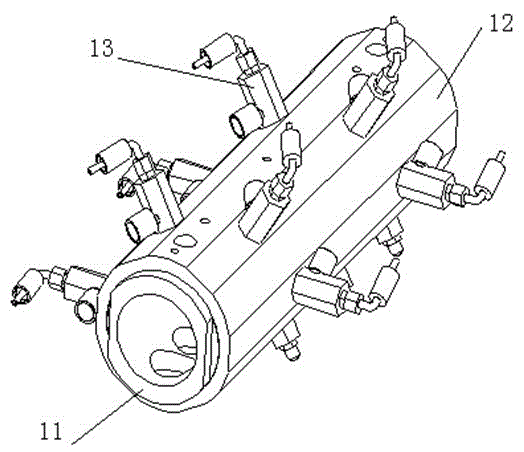

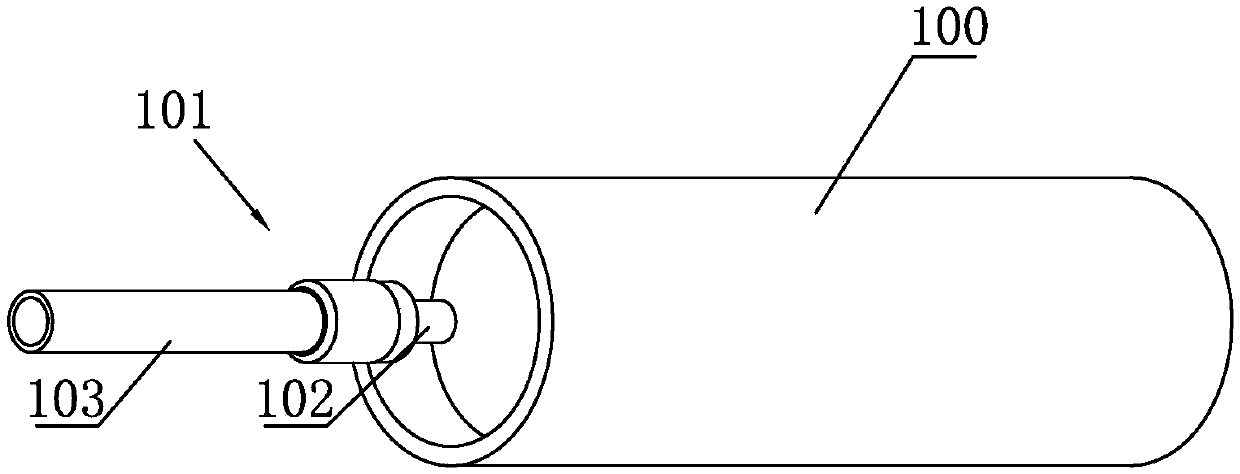

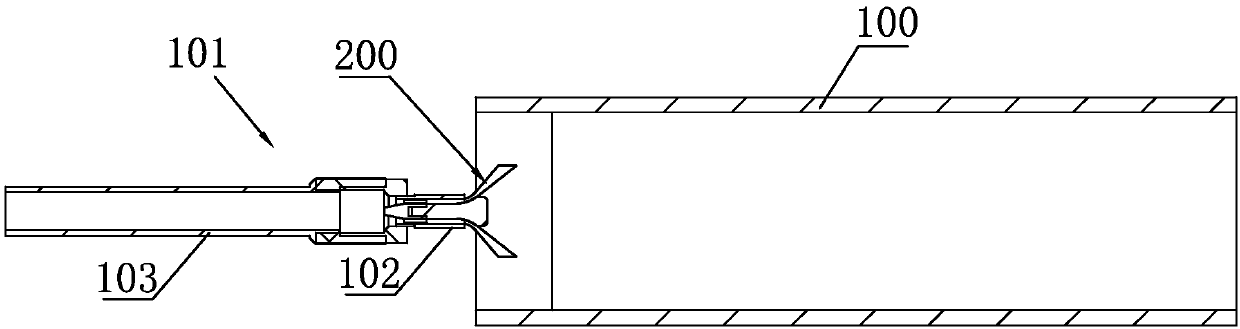

Steel pipe sand blasting rust removing device

PendingCN107717748AEasy to insertGuaranteed derusting effectAbrasive machine appurtenancesAbrasive blasting machinesSteel tubeOxide

The invention relates to a steel pipe sand blasting rust removing device. The steel pipe sand blasting rust removing device comprises a sand blasting gun and a sand blasting positioning assembly. Thesand blasting positioning assembly comprises a positioning pipe and a fixing base. The two ends of the positioning pipe are a first end portion used for covering a sand blasting gun nozzle and a second end portion used for covering the end portion of a steel pipe. The sand blasting gun nozzle of the sand blasting gun stretches into the positioning pipe from the first end portion, the second end portion is in a horn mouth shape, and the pipe diameter of the second end portion is gradually increased in the outward extending direction of the positioning pipe. Pellet sand flow sprayed out throughthe sand blasting gun nozzle impacts on the steel pipe in the positioning pipe so that an oxidization layer on the inner wall of the steel pipe can be removed, accordingly, dust generated through sandblasting can be closed in the positioning pipe, it is guaranteed that dust does not overflow, and pollution to the environment due to sand blasting is greatly reduced. Due to the fact that the sand blasting gun nozzle starts to conduct sand blasting treatment on the steel pipe in the positioning pipe, the end portion of the steel pipe can be cleaned thoroughly through sand blasting, and the rustremoving effect of the steel pipe is guaranteed.

Owner:江苏鑫德龙环保科技有限公司

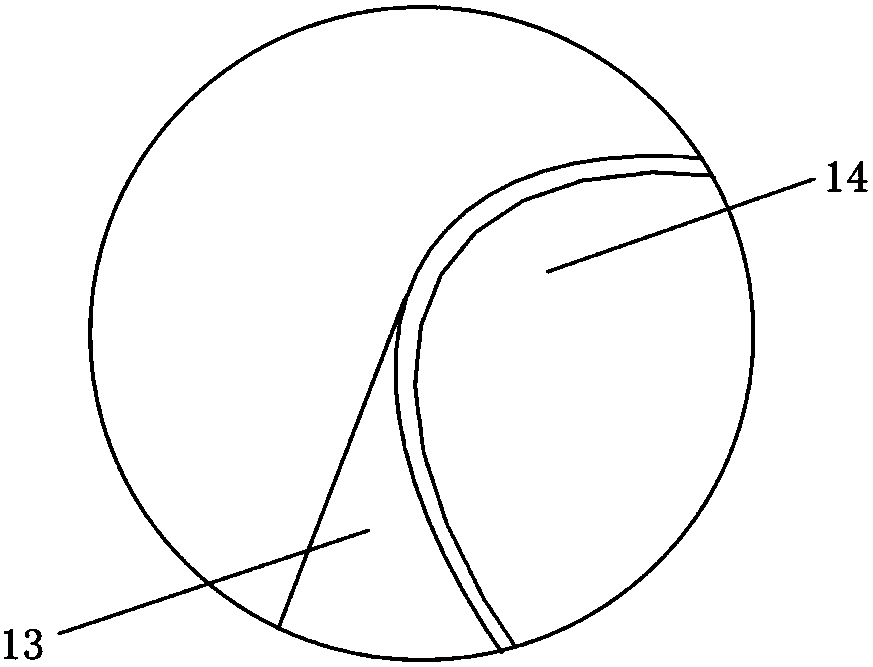

Metal bent pipe rust removal device and method thereof

InactiveCN108453631AGuaranteed derusting effectImprove rust removal effectAbrasive machine appurtenancesAbrasive blasting machinesEngineeringHigh pressure

The invention discloses a metal bent pipe rust removal device and method thereof. The metal bent pipe rust removal device comprises a bottom plate, a metal bent pipe, a guide hose pipe and a hopper, wherein the metal bent pipe is a hollow pipe; one end of the metal bent pipe is a feeding opening end; the other end of the metal bent pipe is a discharging opening end; the guide hose pipe is locatedin the metal bent pipe and is consistent with the bent shape of the metal bent pipe; a guide block capable of moving along a length direction of the guide hose pipe is arranged on the guide hose pipe;the hopper comprises a feeding hopper and a discharging hopper; the discharging hopper corresponds to the position of the feeding opening end of the metal bent pipe; a high-pressure nozzle is arranged in the feeding hopper; the tail end of the high-pressure nozzle is connected with an external air supply device. The rust removal device and the rust removal method are simple to operate, are capable of carrying out the operation of removing the rust on the inner wall of the metal bent pipe by simultaneously using two physical and chemical manners, are simple to implement and excellent in rust removal effect; the influence on the environment is reduced to the minimum.

Owner:FOSHAN JINJINGCHUANG ENVIRONMENTAL PROTECTION TECH CO LTD

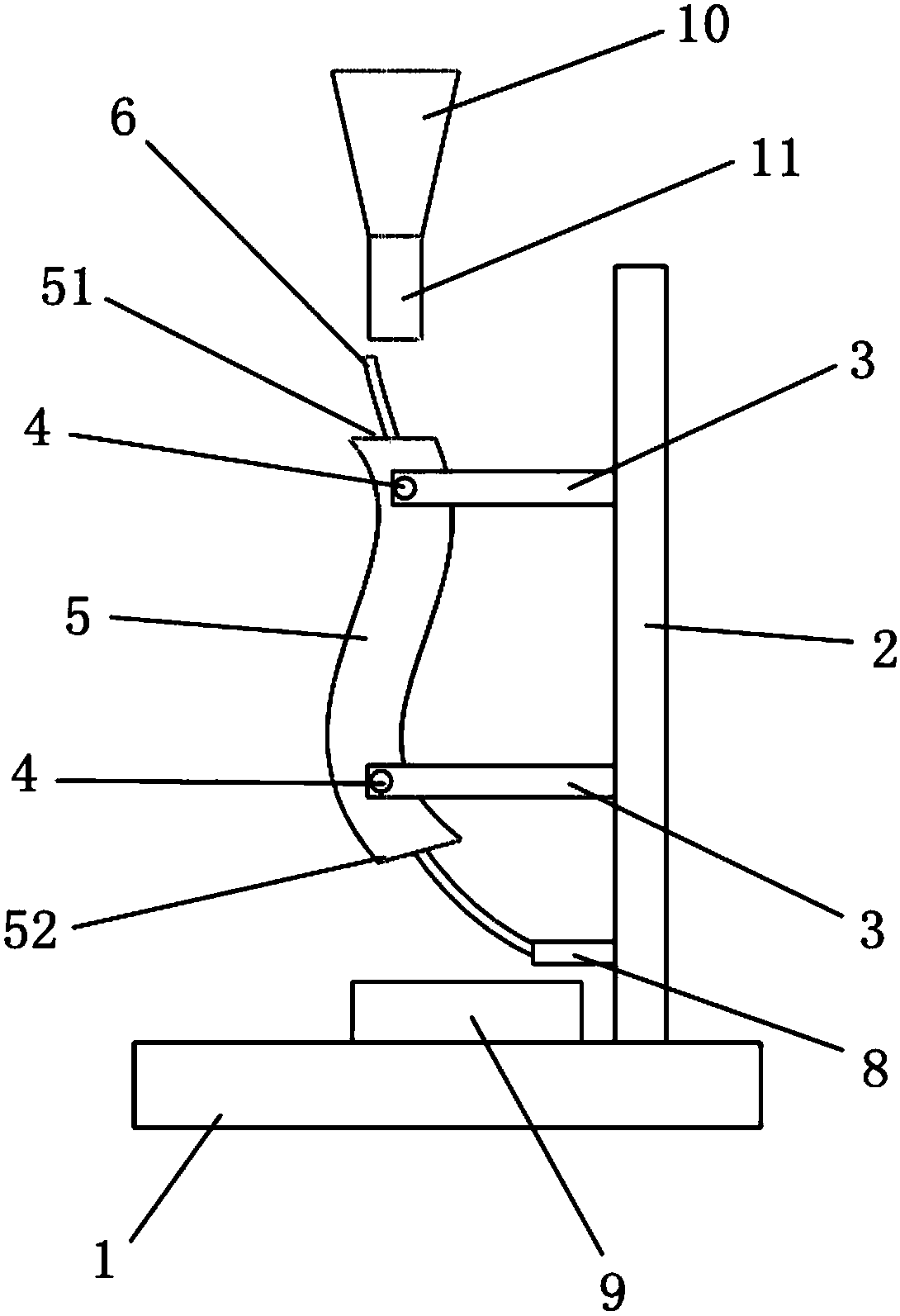

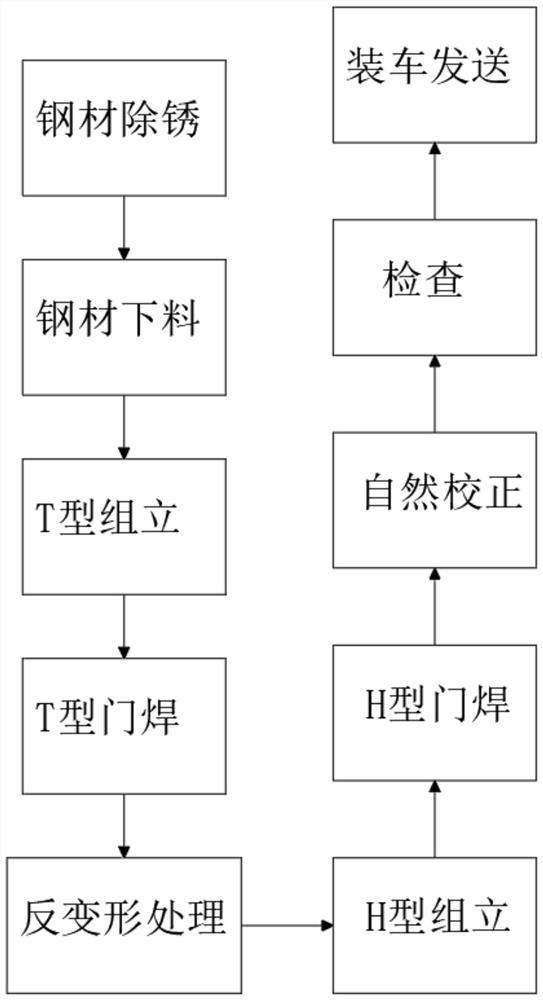

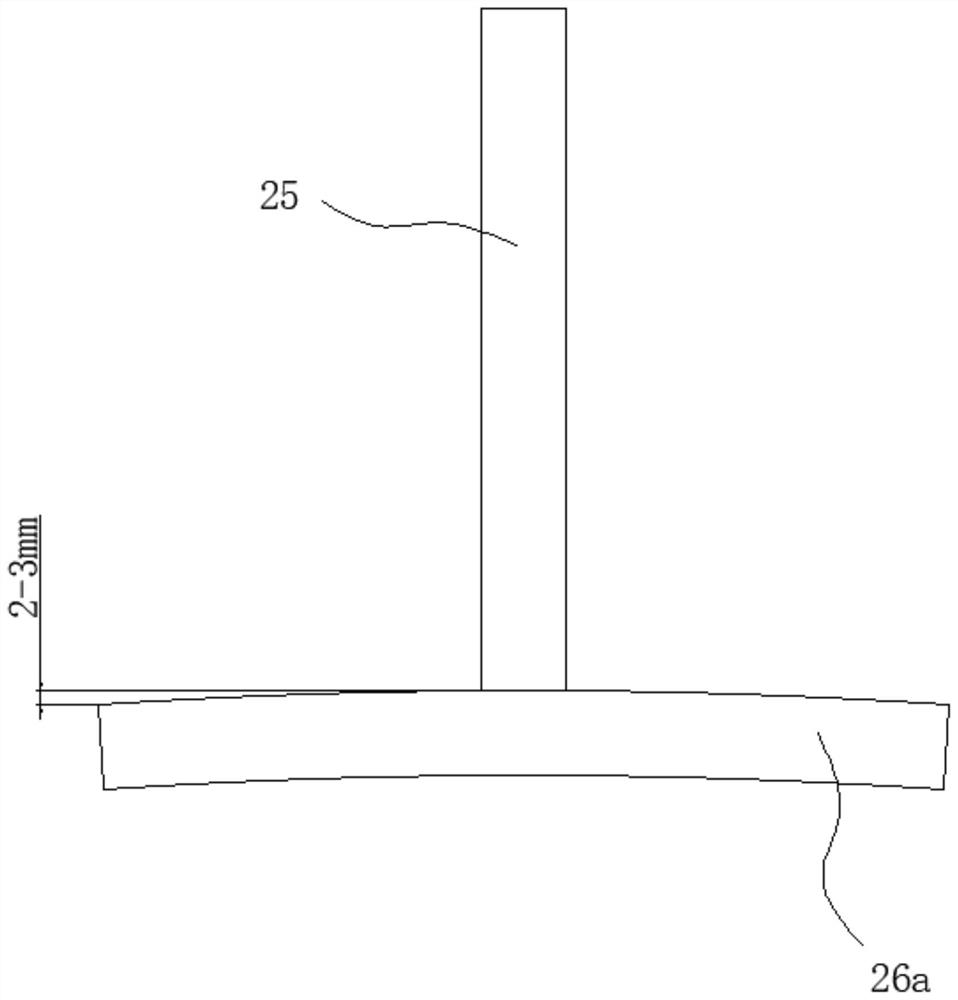

A Reverse Deformation Correction Process of Narrow Section H Steel

ActiveCN112139765BRealize the correction effectEnsure productivityGrinding drivesArc welding apparatusFlangeManufacturing engineering

The invention relates to the field of construction technology, and discloses an anti-deformation correction process for narrow-section H steel, which includes the steps of steel rust removal, steel blanking, T-shaped assembly, T-shaped gate welding, anti-deformation treatment and the like. The anti-deformation treatment is to pre-press the second flange plate with a straightening machine, so that the two ends of the flange plate two are bent in the same direction to form a certain distance from the original plate surface. The bending direction of the two ends of the flange plate is a direction away from one side of the web plate. The T-shaped member in the narrow-section H-shaped steel and the single flange plate are subjected to pre-compression and anti-deformation treatment before assembly and welding, so that the flange plate of the H-shaped steel after assembly and welding will expand due to thermal expansion and contraction at the weld. The natural correction is retracted to offset the anti-deformation, so as to achieve the correction effect on the narrow section H-beam, which not only reduces the labor intensity of people, but also improves the correction efficiency and reduces the production cost, so as to ensure the production and delivery of H-beam. .

Owner:CHANGJIANG & JINGGONG STEEL STRUCTURE GRP CO LTD

A kind of environment-friendly aluminum cleaning agent and preparation method thereof

Owner:PINGGAO GRP +1

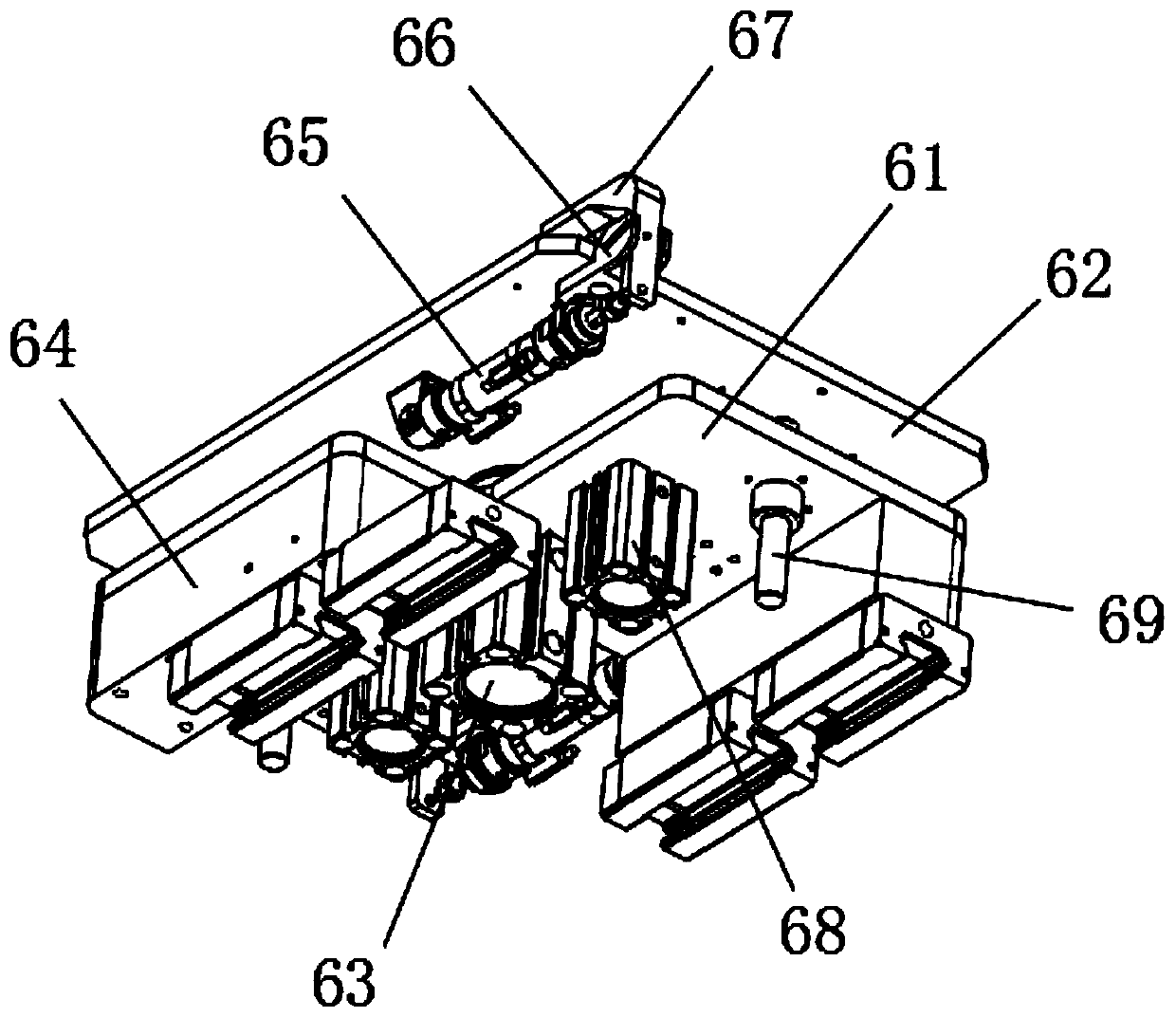

Iron product efficient rust removing device used for hardware manufacturing and use method of iron product efficient rust removing device

ActiveCN111590439ASolve technical problems with low work efficiencyFlip EffectGrinding carriagesGrinding drivesElectric machineryStructural engineering

The invention discloses an iron product efficient rust removing device used for hardware manufacturing and a use method of the iron product efficient rust removing device. The rust removing device comprises a supporting bottom plate, and a shell is fixedly installed on the upper surface of the supporting bottom plate in a welded manner. A moving bracket is movably installed on the supporting bottom plate in the horizontal direction, and an output shaft end of a rust removing motor is connected with a rust removing roller. A first lifting air cylinder is fixedly installed on the upper surface of the supporting bottom plate, and the top end of an output rod of the first lifting air cylinder is fixedly provided with a centering air cylinder. A centering plate is fixedly installed at the end portion of an output rod of the centering air cylinder. One end of a connecting rod is fixedly connected with one end of a sliding rod, one end of the sliding rod is fixedly connected with a supportingshort plate, and two opposite clamping assemblies are fixedly installed on the opposite faces of an overturning installation plate. By means of the rust removing device, manual carrying of iron product plates is not needed, the labor intensity is greatly lowered, face overturning rust removing can be conducted on the iron product plates, the work efficiency is high, design is reasonable, and therust removing effect is ensured.

Owner:安徽省阜南志峰工艺品有限公司

Detection, repair and corrosion control method of new and old pipelines

InactiveCN109373101AImprove corrosion resistanceAvoid pollutionCorrosion preventionPipe elementsEngineeringHigh pressure

The invention provides a detection, repair and corrosion control method of new and old pipelines. The method comprises the following steps that pipeline cleaning is performed, specifically, high-pressure purging is performed on the interiors of the pipelines through compressed air, and residual liquid and impurities in the pipelines are discharged; a cleaning solution and cooling liquid are addedinto a spiral airflow generator, and the pipelines are derusted through the compressed air which is generated by the spiral airflow generator and provided with the cleaning solution and the cooling liquid; waste produced during derusting is cleaned and recovered after derusting is performed; and repair coating is performed on the inner walls of the pipelines through a repair agent. The inner wallsof the pipelines are derusted by adding the cleaning solution and the cooling liquid into spiral airflow, the derusting effect is good, the derusting efficiency is high, meanwhile, the waste producedduring derusting is cleaned and recovered, environment pollution and resource wasting are effectively avoided, repair coating is performed on the inner walls of the pipelines after repair, and the corrosion resistance and rust resistance of the pipelines are improved.

Owner:北京扬帆凯程科技有限公司

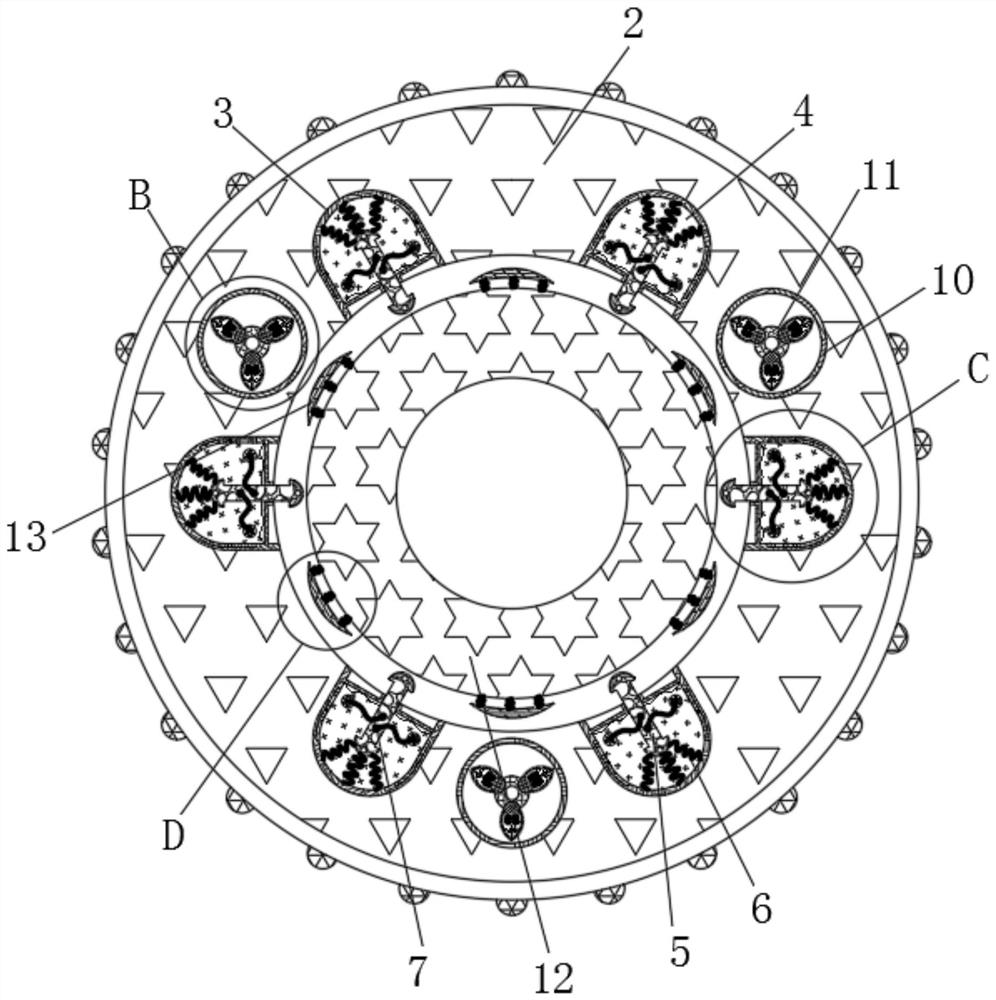

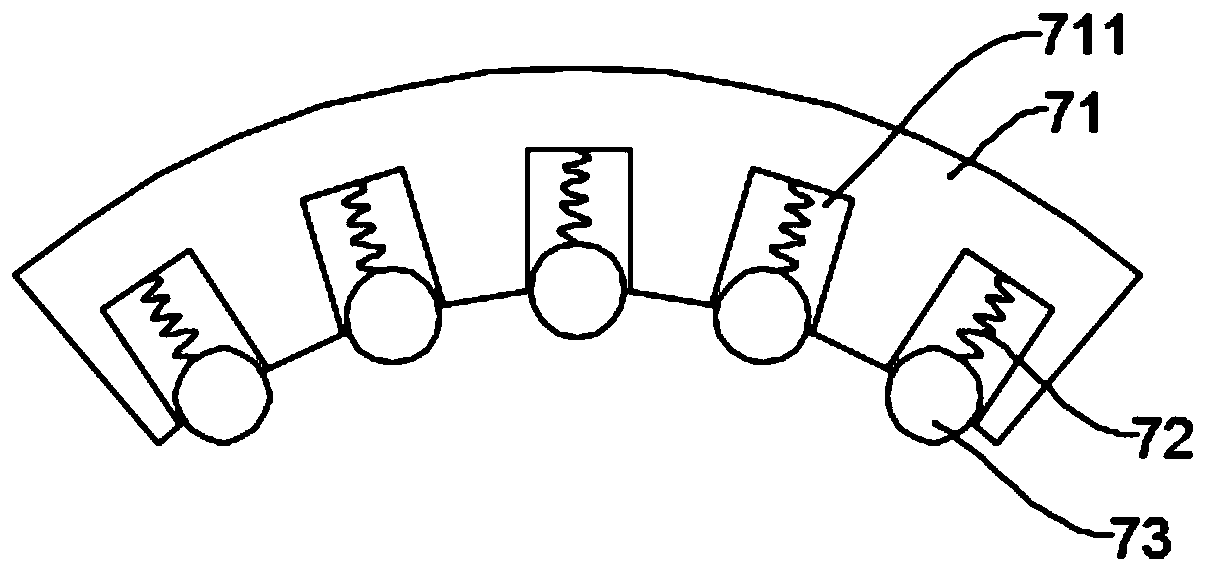

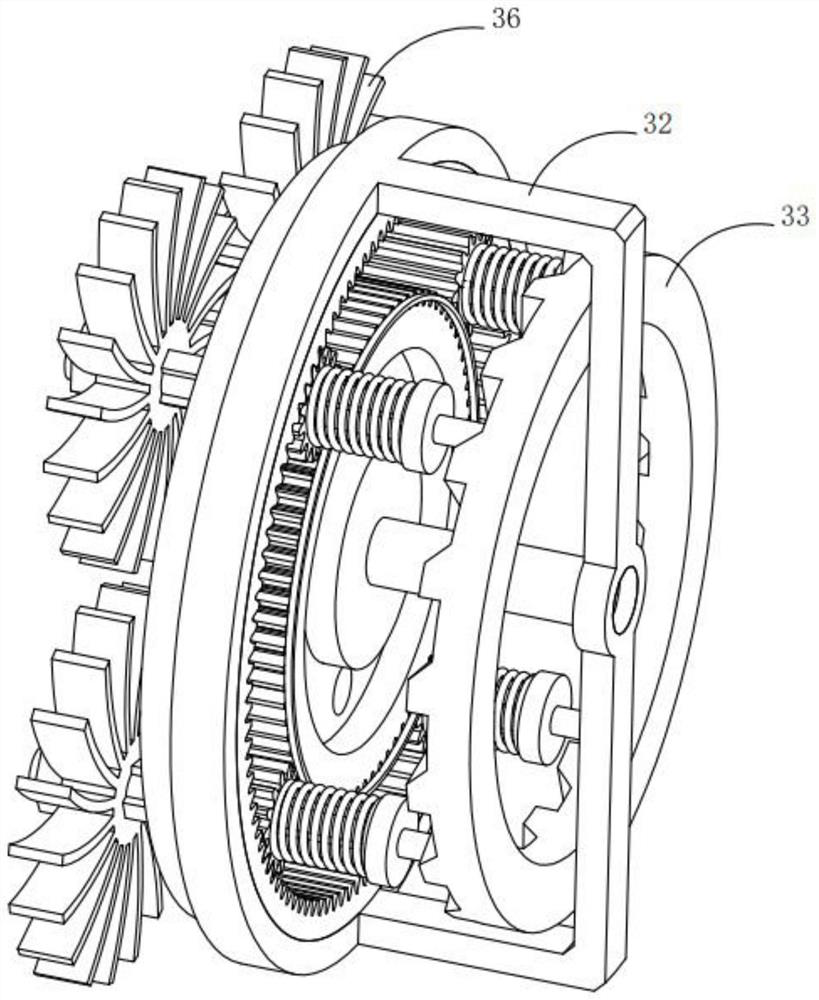

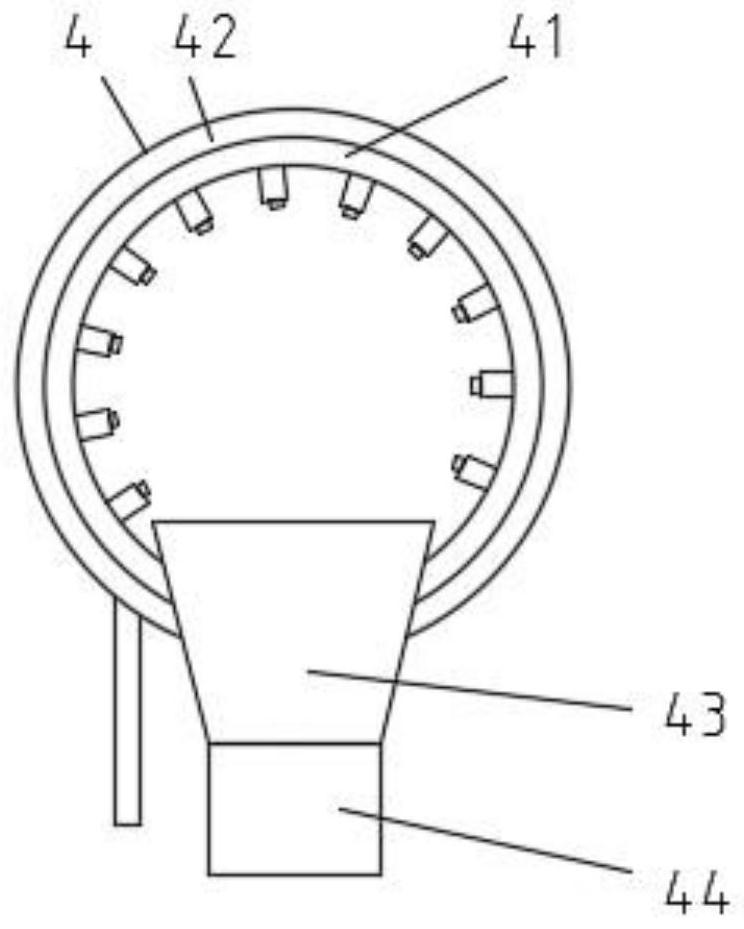

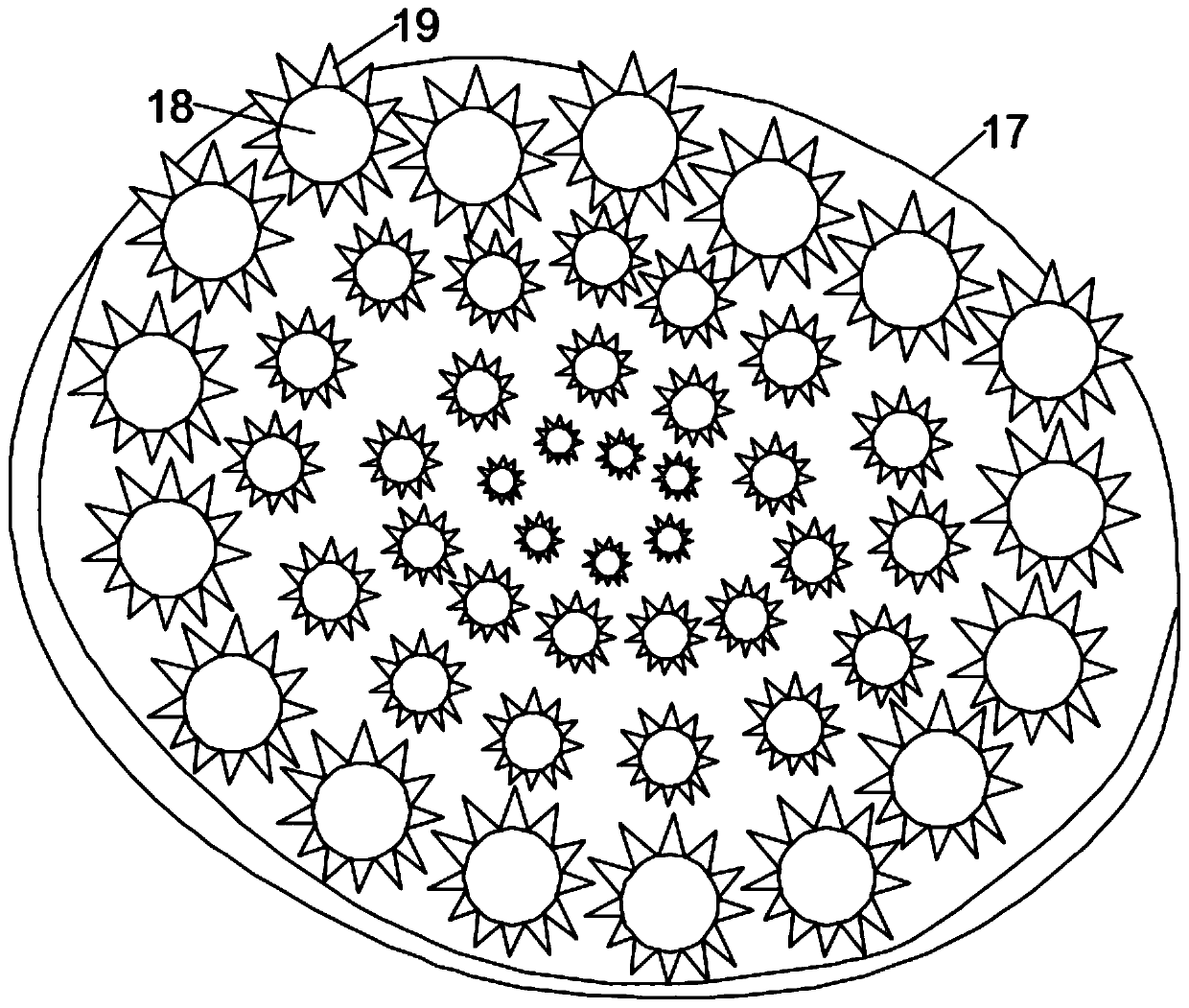

Tower drum sand blasting and rust removing device

PendingCN113478397AGuaranteed derusting effectGrinding drivesGrinding machinesElectric machineryEnvironmental geology

The invention provides a tower drum sand blasting and rust removing device. The tower drum sand blasting and rust removing device comprises a two-way driving mechanism, crawler-type advancing assemblies, a friction rust removing mechanism, a sand blasting assembly and a sand removing assembly; the two crawler-type advancing assemblies are mounted on two power execution components in the two-way driving mechanism correspondingly; the friction rust removing mechanism comprises a planetary driving mechanism, a support, a disc, an ejector rod, a spring I, a rust removing brush and a motor I; the sand blasting assembly is arranged on a sun assembly in the planetary driving mechanism; and the sand removing assembly is arranged on the two-way driving mechanism and used for scraping out rust removing sand in a tower drum. The ejector rod is driven to move synchronously through rotation and revolution of a planetary wheel in the planetary driving mechanism, the ejector rod in the revolution state moves along the disc, the rust removing brush achieves rotation, revolution and reciprocating motion along the interior of the tower drum, and then rust removing is conducted on the tower drum in cooperation with the rust removing sand sprayed out by the sand blasting mechanism; and the rust removing brush can raise the rust removing sand for the second time when moving in the tower drum, and the rust removing effect is guaranteed.

Owner:安徽达必立新能源科技有限公司

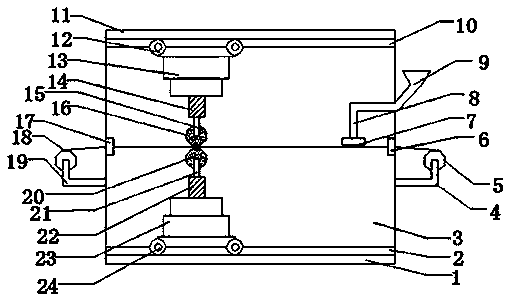

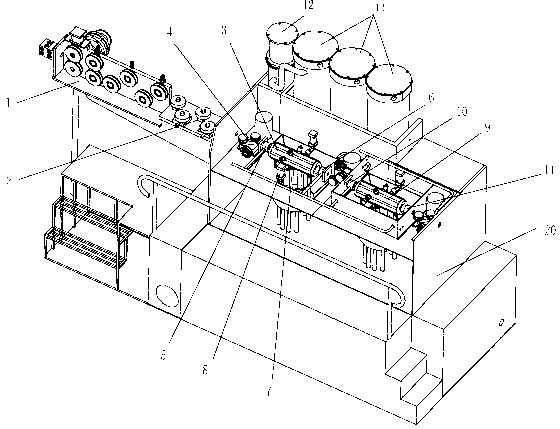

Rust removal equipment for rear cross beam in rear floor rear cross beam assembly and working method thereof

PendingCN113305742AImprove the fixed effectGuaranteed derusting effectBlast gunsAbrasive machine appurtenancesStructural engineeringMechanical engineering

The invention discloses rust removal equipment for a rear cross beam in a rear floor rear cross beam assembly and a working method thereof. The rust removal equipment comprises a collecting mechanism, a first stand column, a second stand column, a rust removal mechanism, a sand pump, a first fixing mechanism, an air cylinder, a positioning rod and a rotating shaft; a bearing plate is installed at the upper end of the collecting mechanism, and the first stand column, the second stand column, the rust removal mechanism and the sand pump are installed at the upper end of the bearing plate; the rust removal mechanism and the sand pump are both located between the first stand column and the second stand column, the second stand column is located at one side of the first stand column, the sand pump is located in front of the rust removal mechanism, the rotating shaft is rotationally installed between the first stand column and the second stand column and penetrates through the rust removal mechanism, and a rotating motor is arranged at one side of the second stand column; and the output end of the rotating motor penetrates through the second stand column to be connected with the rotating shaft, and the first fixing mechanism and a second fixing mechanism are installed on the outer surface of the rotating shaft. According to the rust removal equipment, multiple workpieces to be derusted can be derusted at the same time, and the derusting efficiency is improved.

Owner:合肥至信机械制造有限公司

Dust guard seat rust removal device and method

InactiveCN112677010AReduce pollutionImprove the efficiency of rust removal and paint removalGrinding carriagesGrinding drivesPaint stripperAutomotive engineering

The invention relates to a dust guard seat rust removal device and method. The device comprises a first servo motor, a first transmission shaft, a first support, a side brush, a first moving mechanism, a controller and a detector. The side brush is arranged on the first transmission shaft. The detector is used for detecting a working current of the first servo motor, and the controller is used for controlling the first moving mechanism to move and work according to the current detection value of the detector. When rust removal work is carried out, the first support is moved through the first moving mechanism, so that the side brush can get close to a dust guard seat to make contact with the dust guard seat, the side brush is pressed on the dust guard seat with a constant pressure, the first servo motor drives the first transmission shaft to rotate to drive the side brush to rotate, and rust removal treatment can be carried out on the dust guard seat when the side brush rotates. Therefore, on the one hand, the environmental pollution can be reduced as a paint remover is not adopted. On the other hand, the side brush is pressed on the dust guard seat at constant pressure and conducts rotary rust removal, so that the rust removal effect is good, and meanwhile the rust removal and paint removal efficiency is high.

Owner:SHENHUA RAIL & FREIGHT WAGONS TRANSPORT

A high-efficiency derusting device for iron products used in hardware production and its use method

ActiveCN111590439BReduce labor intensityQuick rust removalGrinding carriagesGrinding drivesElectric machineryStructural engineering

The invention discloses a high-efficiency derusting device for iron products used in hardware manufacturing and a method for using the derusting device. The derusting device includes a support base plate. A shell is fixedly installed on the upper surface of the support base plate through welding, and the support base plate moves along the horizontal direction. A mobile bracket is installed, the output shaft end of the derusting motor is connected with the derusting roller, and the upper surface of the support base plate is fixedly equipped with a lifting cylinder one, and the top of the output rod of the lifting cylinder one is fixedly equipped with a centering cylinder. The end of the output rod of the middle cylinder is fixedly installed with a centering plate, one end of the connecting rod is fixedly connected with one end of the slide bar, and one end of the slide bar is fixedly connected with a supporting short plate, and two Clamp assembly; the derusting device does not need to manually carry the iron product plate, which greatly reduces the labor intensity. It can turn over the iron product plate to remove rust. The work efficiency is high and the design is reasonable, which ensures the derusting effect.

Owner:安徽省阜南志峰工艺品有限公司

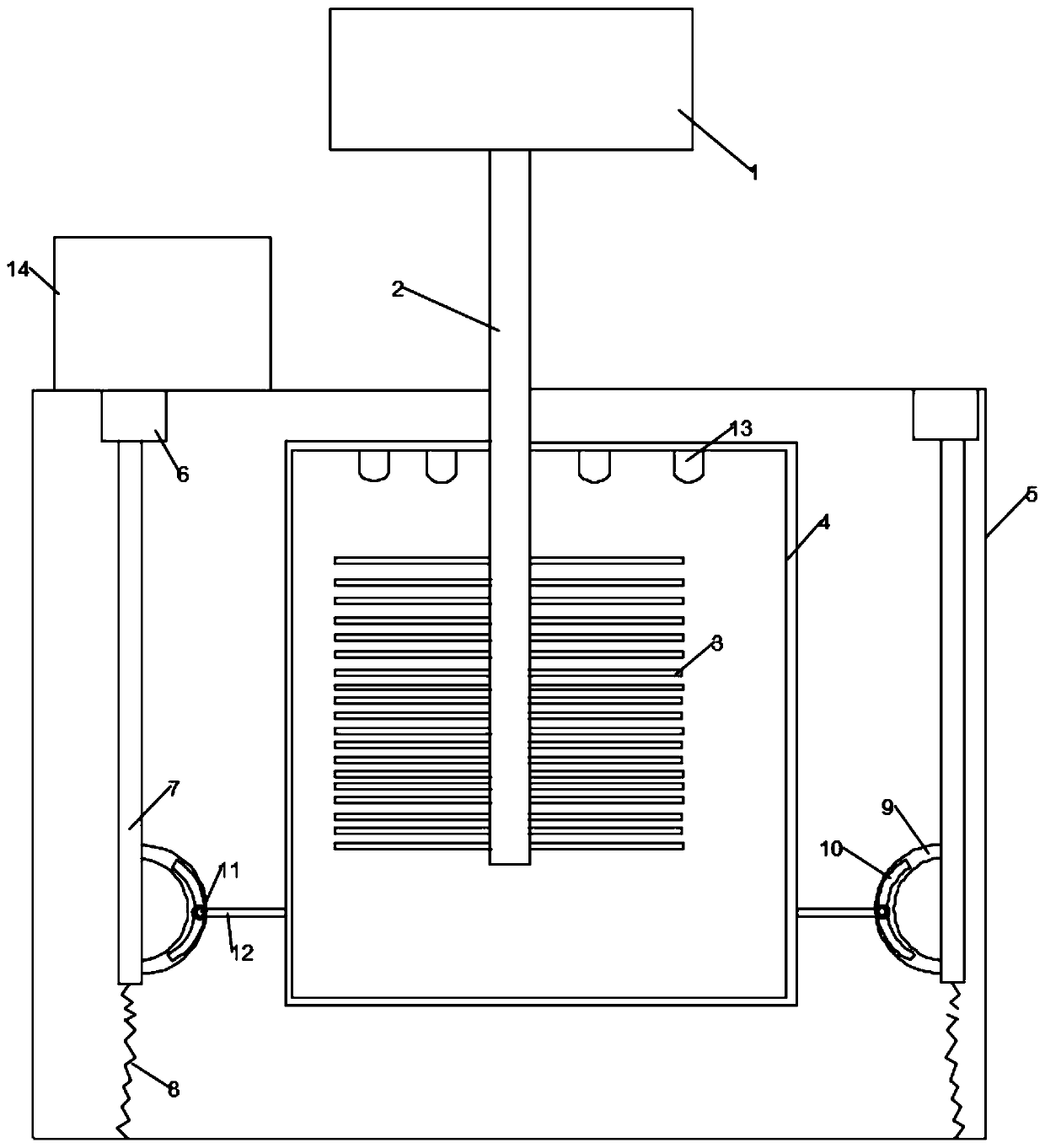

Rusted steel acid pickling device

InactiveCN111485244AEasy picklingReasonable designGrinding drivesGrinding machinesRotational axisElectric machine

The invention discloses a rusted steel acid pickling device to solve the problem that an existing acid pickling device is poor in rust removing effect. The rusted steel acid pickling device comprisesa frame, a rotating motor, a cleaning tank and a control panel. The output end of the rotating motor is connected with a rotating shaft, the lower end of the rotating shaft is inserted in the cleaningtank, and polishing parts are evenly distributed on the rotating shaft. Electric air cylinders are installed at the top end of the inner wall of the frame, and the output end of each electric air cylinder is provided with an electric push rod. The bottom end of each electric push rod is connected with the bottom of the inner wall of the frame through an elastic part, and an arc plate is installedat the side portion of each electric push rod. Each arc plate is provide with an arc groove, a sliding part is installed in each arc groove in a sliding manner, and each sliding part is connected with the outer wall of the cleaning tank through a fixing rod. When the polishing parts are used for polishing the surface of rusted steel, the cleaning tank is further driven to wobble left and right atthe same time, acid pickling liquid can conduct acid pickling on the rusted steel better, the acid pickling process is accelerated, and the work efficiency is high.

Owner:司秀玲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com