Patents

Literature

41results about How to "Thorough and effective cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

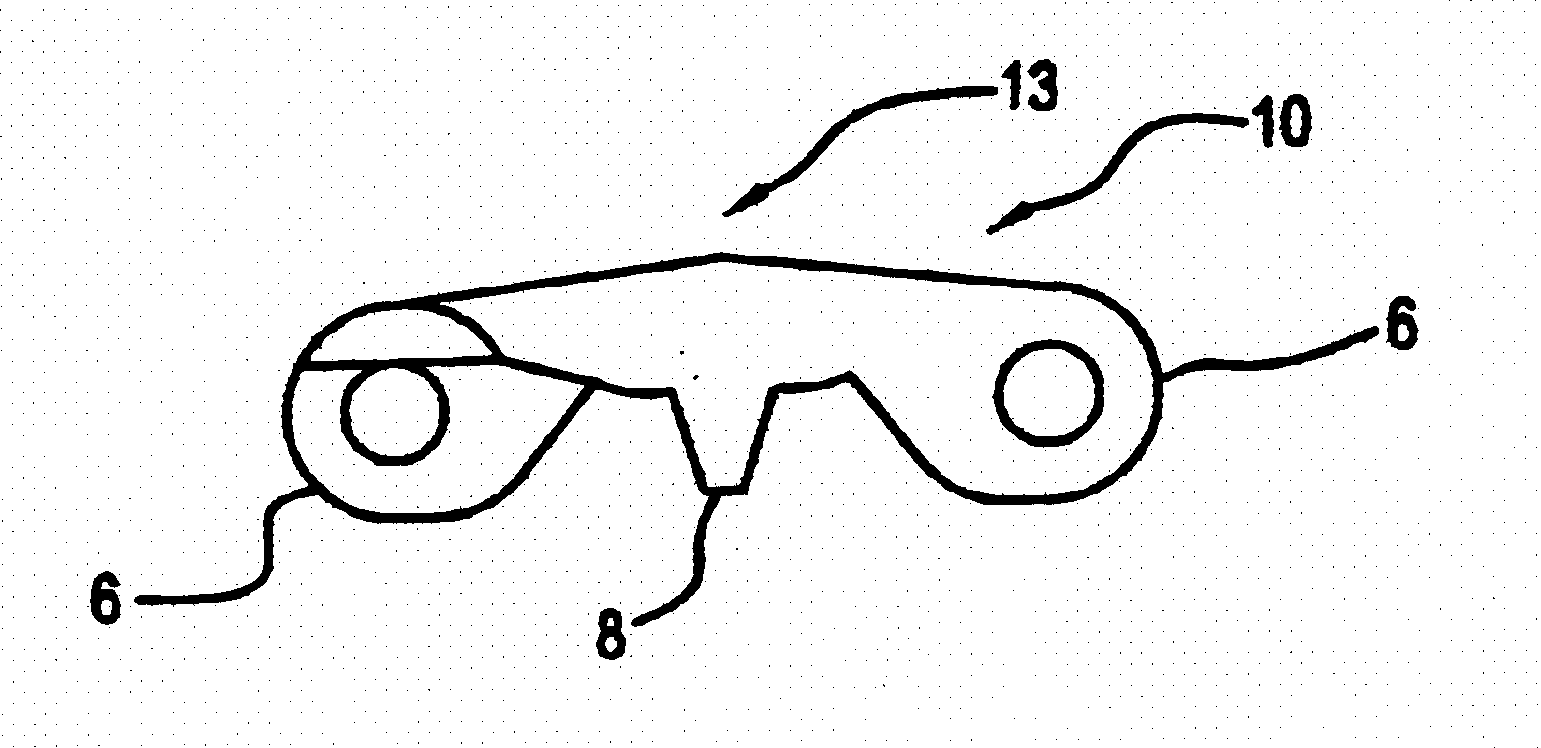

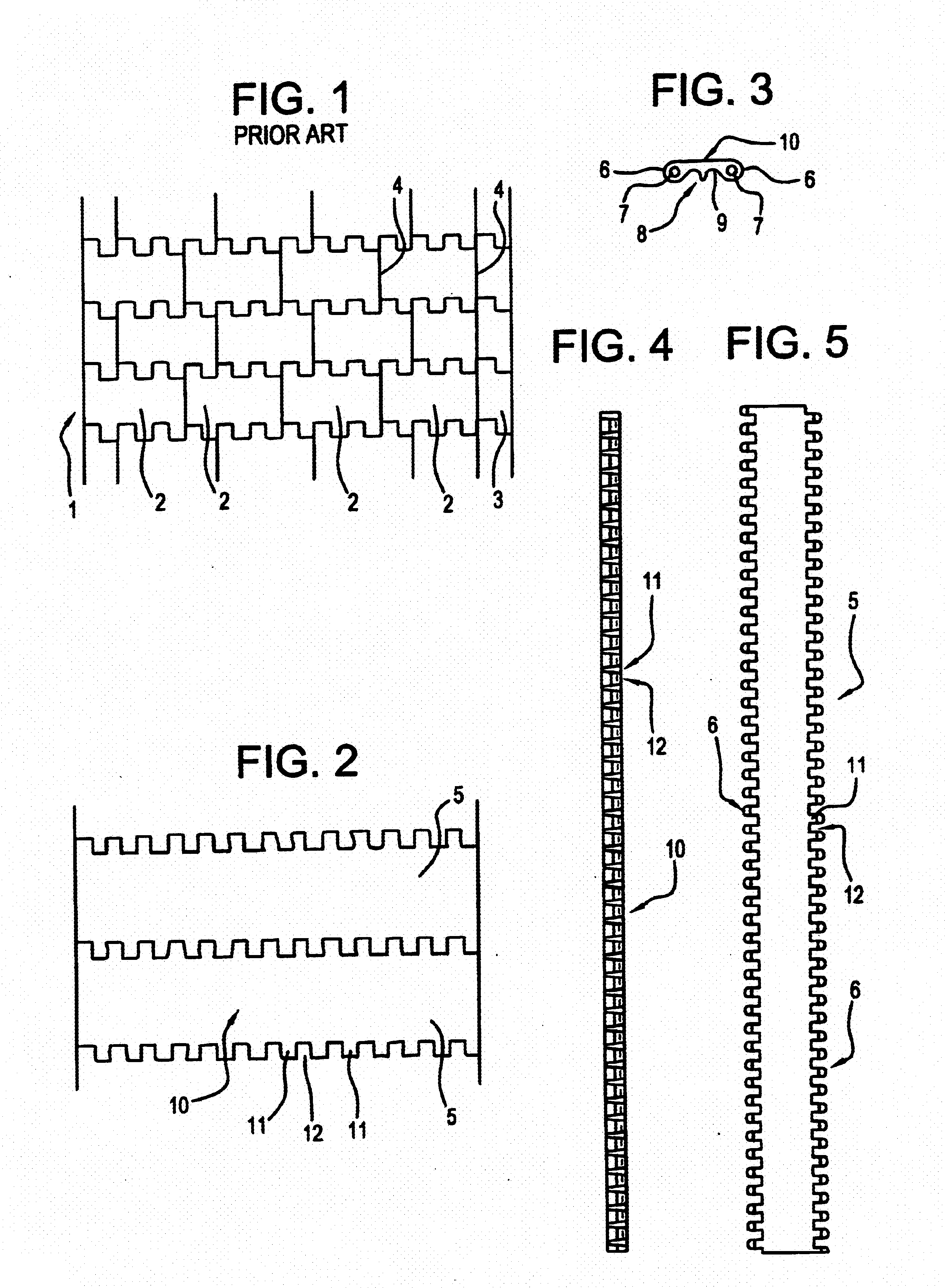

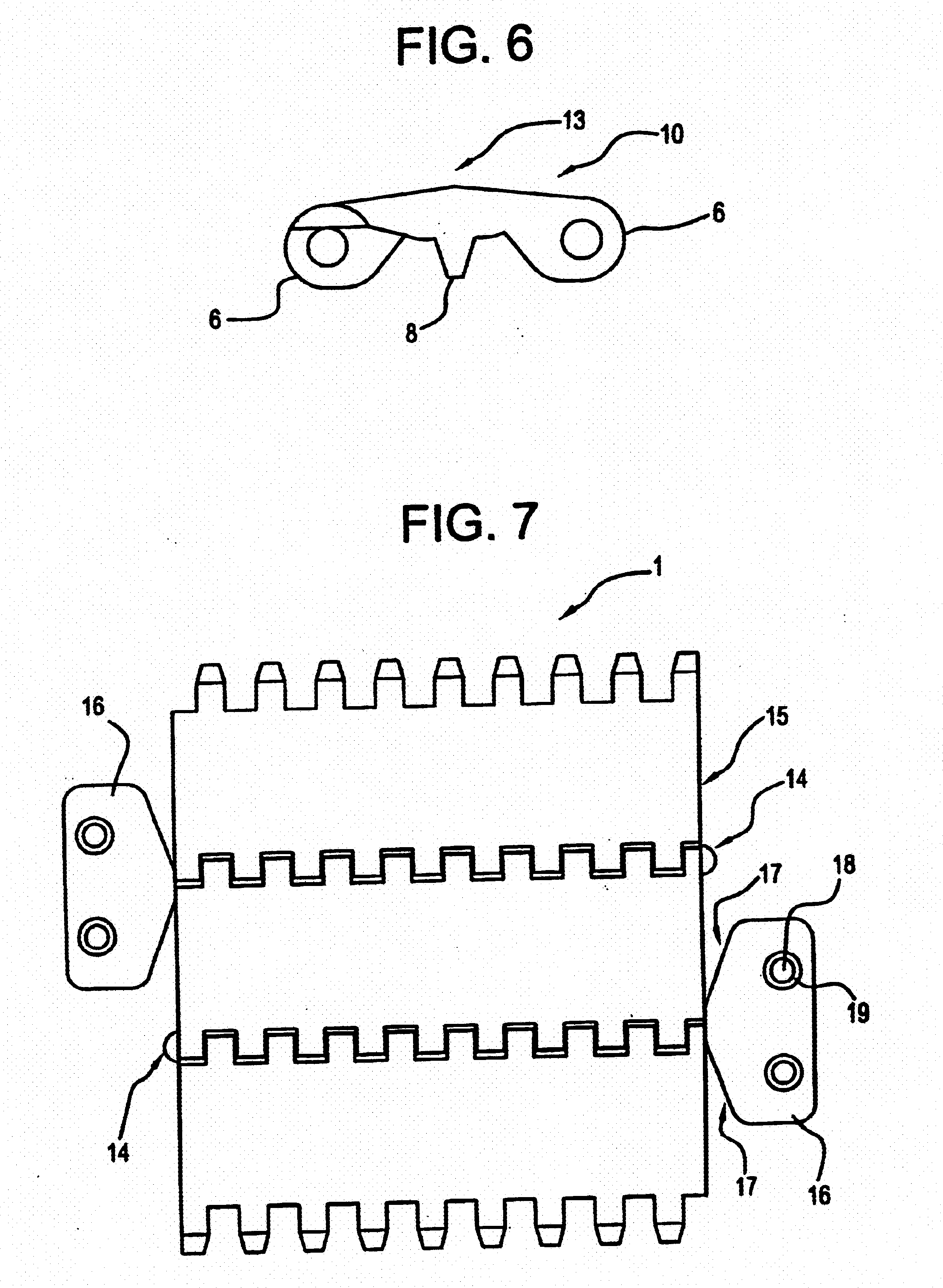

Wide chain link conveyor structure

ActiveUS6758329B1Thorough and effective cleaningImprove cleaning processConveyorsPackagingHinge angleEngineering

The invention provided a conveyor belt, which is special in that the belt in a direction perpendicular to the traveling direction of the belt is made from one single chain link, and that the transport top surface comprises a wide main portion and the top part of the eye projections which are flush with the main portion, such that the belt surface is substantially without apertures and / or openings and further that the hinge-like assembly arrangement is fully accessible only from the underside of the belt.By this inventive chain link is achieved that the narrow gaps between each assembled chain link in the prior art is not present such that from a hygienic point of view it becomes much easier to clean the entire conveyor belt satisfactory in that for each chain link, which usually constitutes 40-60 mm of the total length of the conveyor belt, which altogether, especially for deboning lines, might be 300-400 meter long, no gaps are present. This in turn gives the added security that the multitude of gaps, sometimes more than 30,000 gaps, does not have to be cleaned. This gives rise to a substantial increase in the confidence that a satisfactory cleaning process complying with the high hygienic standards in the meat producing business can be achieved.

Owner:AMMERAAL BELTECH MODULAR

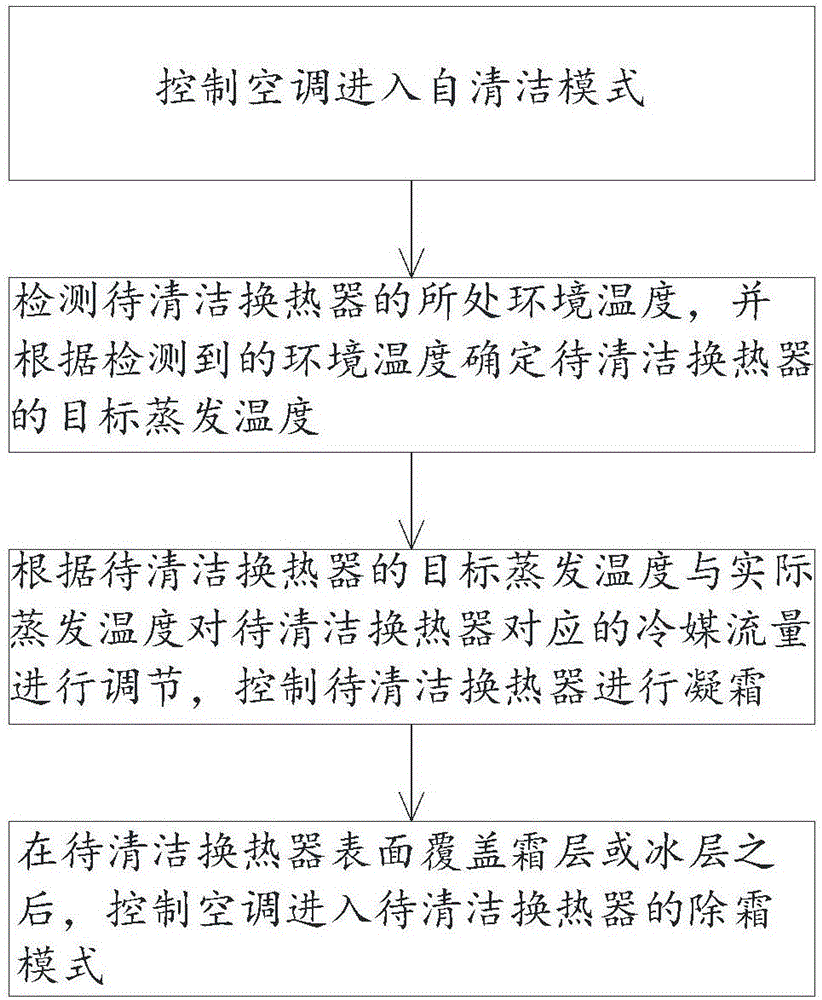

Air-conditioning heat exchanger self-cleaning method

InactiveCN106642540AImprove heat transfer efficiencyAvoid breedingMechanical apparatusSpace heating and ventilation safety systemsFrostEngineering

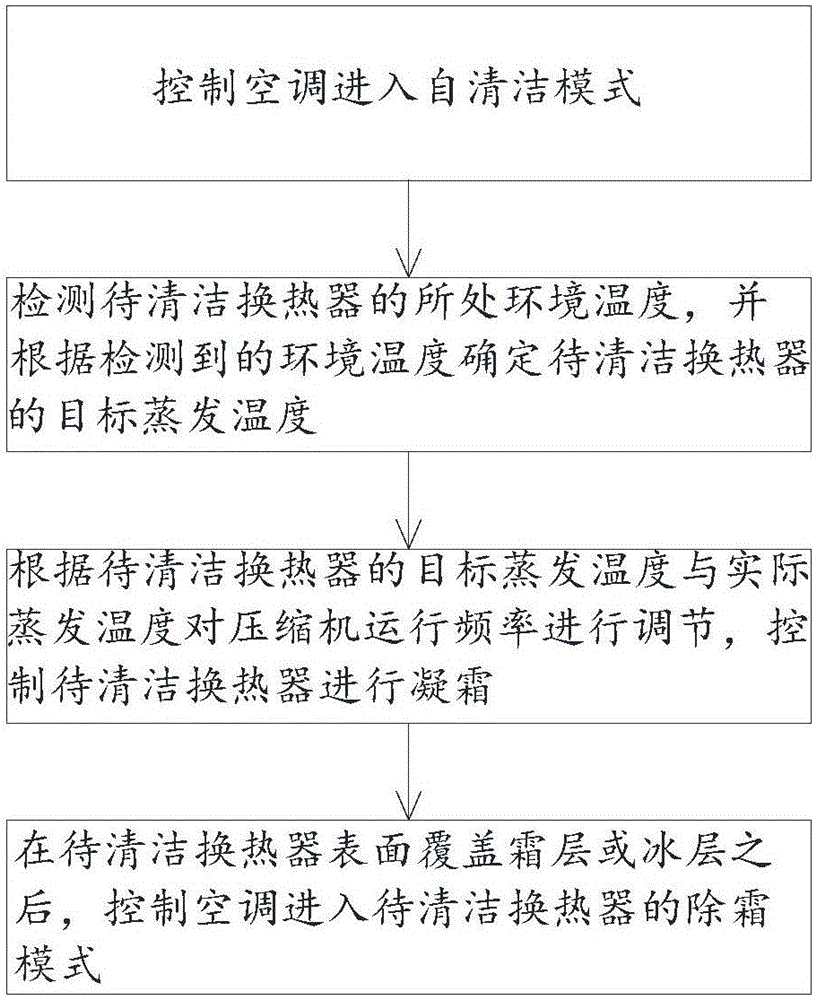

The invention discloses an air-conditioning heat exchanger self-cleaning method. The air-conditioning heat exchanger self-cleaning method includes controlling an air-conditioning to enter a self-cleaning mode; detecting a temperature of an environment in which a heat exchanger to be cleaned is located, and determining a target vaporization temperature of the heat exchanger to be cleaned according to the detected environment temperature; regulating a coolant flow rate of the heat exchanger to be cleaned according to the target vaporization temperature and an actual vaporization temperature of the heat exchanger to be cleaned, and controlling the heat exchanger to be cleaned for frosting; covering the surface of the heat exchanger to be cleaned with a frost layer or an ice layer, and controlling the air-conditioning to enter a defrosting mode of the heat exchanger to be cleaned. The air-conditioning heat exchanger self-cleaning method is capable of achieving self-cleaning of the air-conditioning heat exchanger conveniently, and is good in self-cleaning effect and high in cleaning efficiency.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Self-cleaning method of air conditioner heat exchanger

InactiveCN106765873AImprove heat transfer efficiencyAvoid breedingSpace heating and ventilation safety systemsLighting and heating apparatusFrostEngineering

The invention discloses a self-cleaning method of an air conditioner heat exchanger. The self-cleaning method of the air conditioner heat exchanger comprises the steps that an air conditioner is controlled to enter a self-cleaning mode; the environmental temperature of the heat exchanger to be cleaned is detected, and the target evaporation temperature of the heat exchanger to be cleaned is determined according to the detected environmental temperature; the operation frequency of a compressor is adjusted according to the target evaporation temperature of the heat exchanger to be cleaned and the actual evaporation temperature, and the heat exchanger to be cleaned is controlled to frost; and after the surface of the heat exchanger to be cleaned is covered with a frost layer or an ice layer, the air conditioner is controlled to enter the defrosting mode of the heat exchanger to be cleaned. According to the self-cleaning method of the air conditioner heat exchanger, the air conditioner heat exchanger can be self-cleaned conveniently, the self-cleaning effect is good, and the cleaning efficiency is high.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Washing device for containers for chemical experiments of senior middle schools

ActiveCN106670197AImprove protectionImprove cleaning efficiencyHollow article cleaningEngineeringMechanical engineering

Owner:靖江德方科技服务有限公司

Environmentally-friendly glass fiber powder manufacturing and processing raw material cleaning facility

ActiveCN111136043AImprove cleanlinessAvoid secondary pollutionCleaning using toolsCleaning using liquidsManufacturing engineeringMechanical engineering

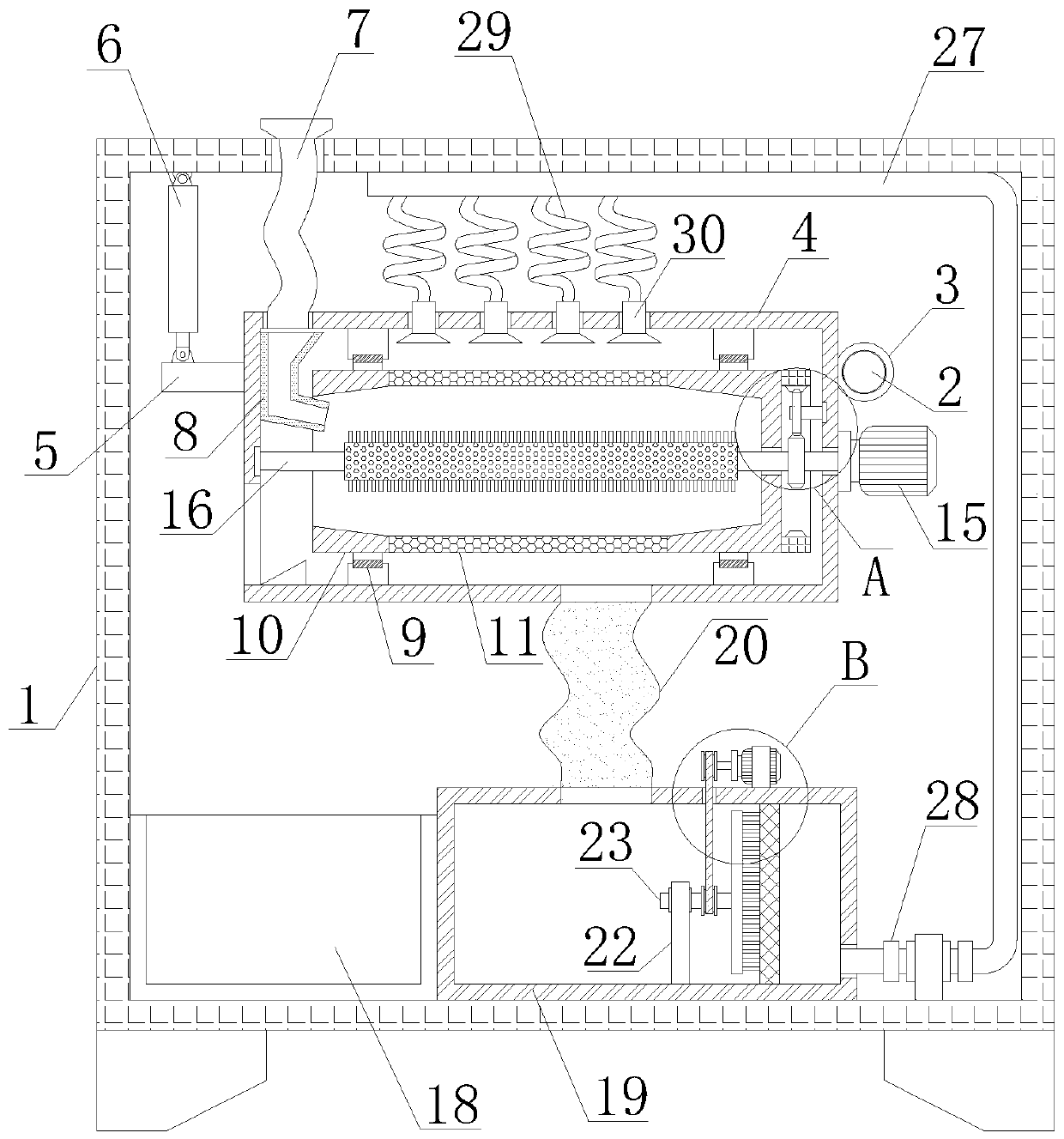

The invention relates to the technical field of glass fiber powder raw material processing, and discloses an environmentally-friendly glass fiber powder manufacturing and processing raw material cleaning facility. The environmentally-friendly glass fiber powder manufacturing and processing raw material cleaning facility comprises a box body. A feeding inlet is formed in the top of the box body. The same circular rod is fixed between the front side wall and the rear side wall of the box body, and a sleeve is movably connected with the excircle face of the circular rod in a sleeving mode. An inner box is fixedly arranged on the excircle face of the sleeve, a discharging outlet is formed in the lower end of the left side wall of the inner box, and a fixing plate is fixedly arranged at the upper end of the left side wall of the inner box. A hydraulic cylinder is movably hinged with the top of the fixing plate, and the top end of the hydraulic cylinder is movably hinged with the inner top wall of the box body. A first stretchable flexible pipe communicates between the top of the inner box and the feeding inlet of the box body, and a material guide cover is fixedly arranged at the upperend of the inner wall of the left side of the inner box. The environmentally-friendly glass fiber powder manufacturing and processing raw material cleaning facility solves the problem that due to thefacts that glass fiber raw materials are not thoroughly cleaned by an existing cleaning facility, and a large number of impurities still adhere to the raw materials after the raw materials are cleaned, the product quality is poor after the raw materials are processed.

Owner:天长市天意玻璃制品有限公司

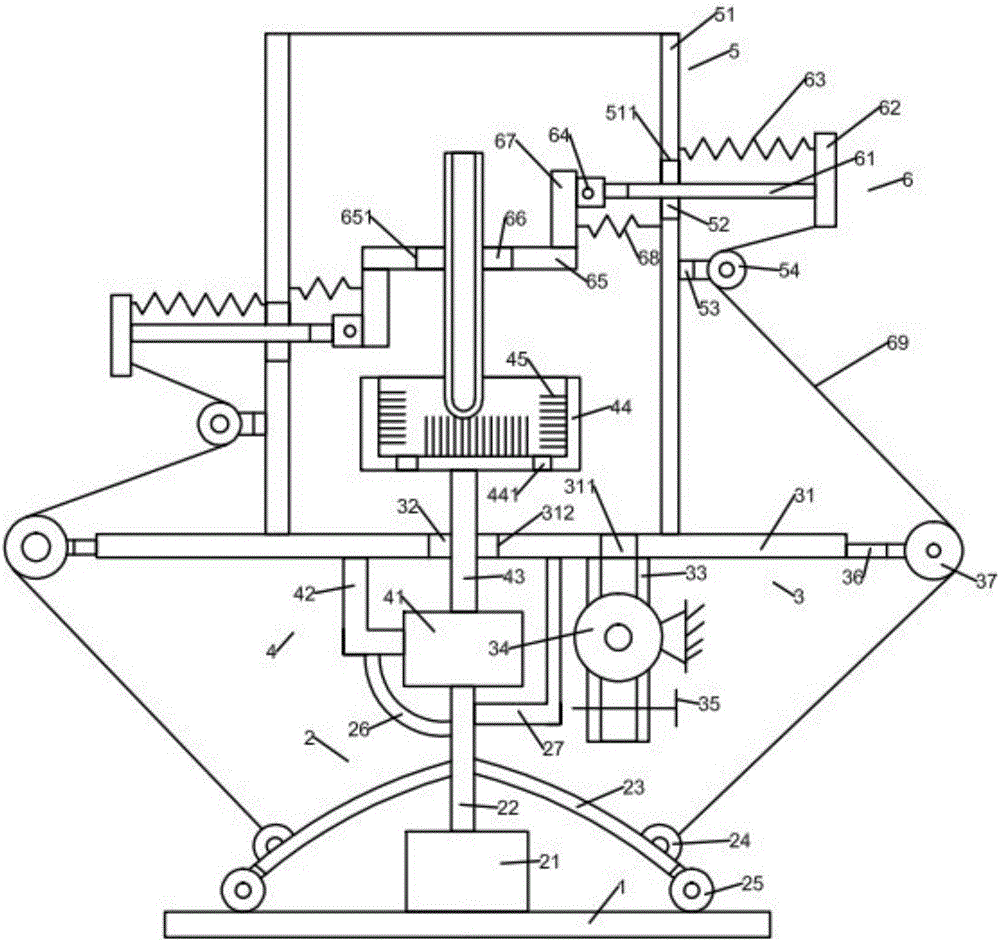

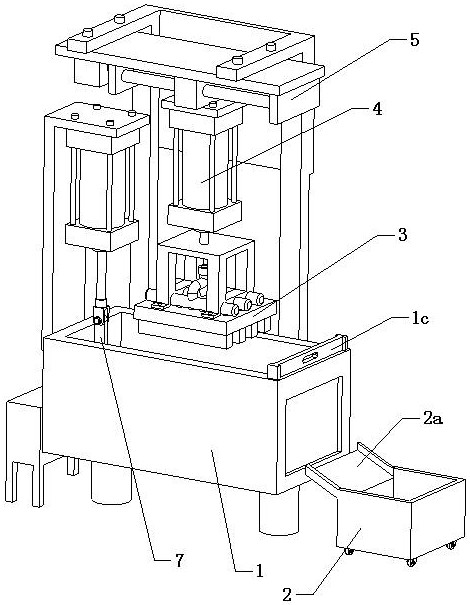

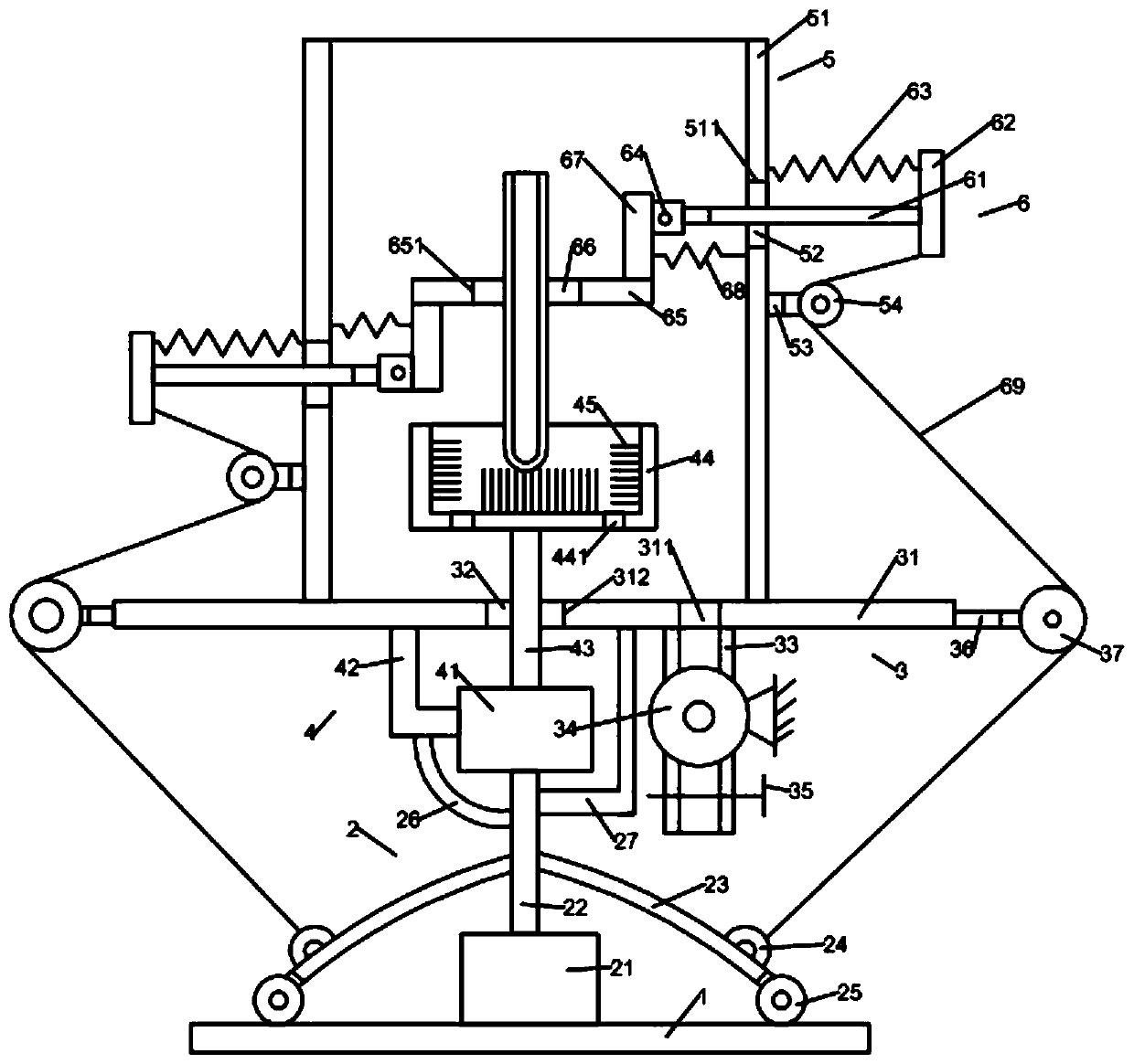

Efficient and environment-friendly test tube dirt automatic removal device for chemical engineering

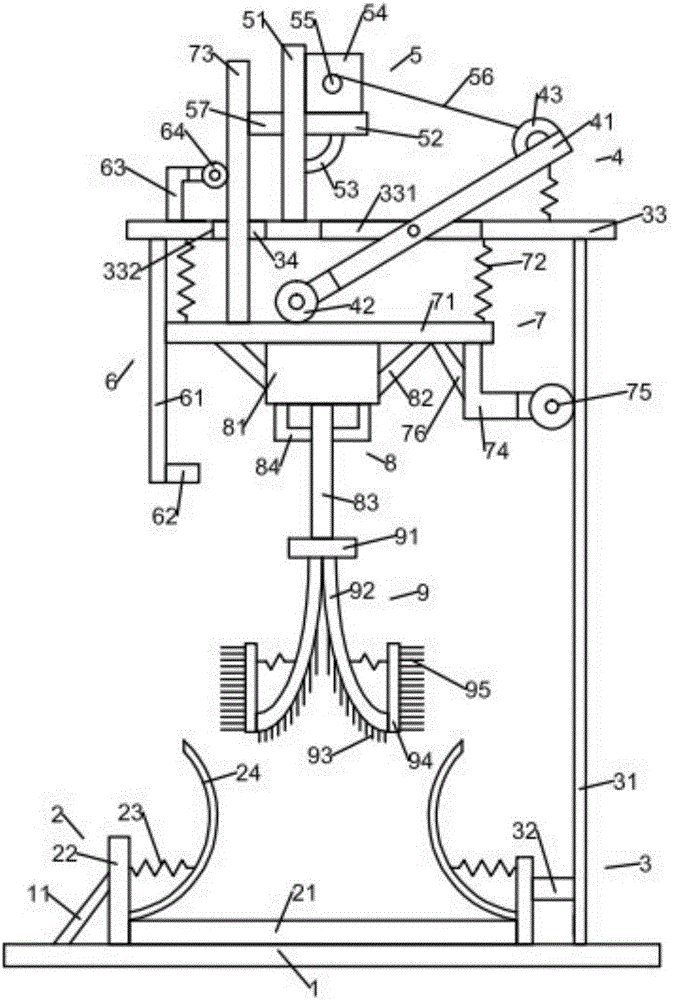

ActiveCN107175245AThorough and effective cleaningFully contactedHollow article cleaningUltimate tensile strengthReagent

Provided is an efficient and environment-friendly test tube dirt automatic removal device for chemical engineering. The device comprises a bottom board, an electric cylinder device located on the bottom board, a supporting board device located above the electric cylinder device, a cleaning device arranged on the supporting board device, a frame device located on the supporting board device, and a shaking device arranged on the frame device. The device can perform thorough and effective cleaning on test tubes, the cleaning efficiency is high, the labor intensity is low, meanwhile water and the test tubes can make sufficient contact, and the cleaning effect is remarkable; and meanwhile, the degree of automation is high, the skin is not in contact with residual reagents in the test tubes, and the security of workers is guaranteed.

Owner:ZHEJIANG GUOGUANG BIOCHEM CO LTD

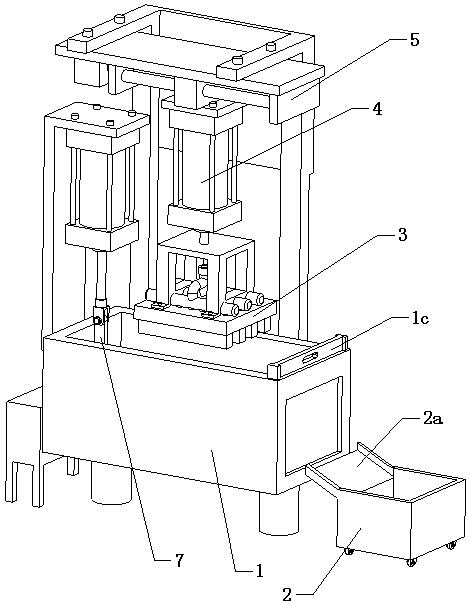

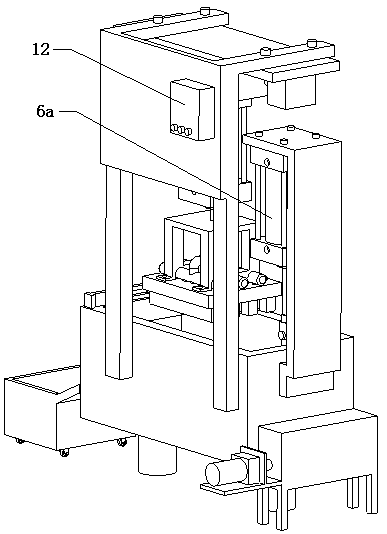

Car part cleaning device

ActiveCN109013499AReduce labor burdenThorough and effective cleaningCleaning using toolsCleaning using liquidsManufacturing technologyReciprocating motion

The invention relates to the technical field of car manufacturing, in particular to a car part cleaning device. The car part cleaning device comprises a cleaning tank, a first cleaning device, a second cleaning device, a transferring device and a collecting box. The first cleaning device comprises a spraying-brushing assembly, a first lifting assembly and a moving assembly enabling the first lifting assembly to make horizontal reciprocating movement; the transferring device comprises a second lifting assembly, a connecting rod and a transferring plate; the second cleaning device comprises a box, a brushing device and a motor; a transferring opening is formed in the side, away from the transferring device, of the cleaning tank; and a master controller is mounted on the back face of a mounting frame of the first cleaning device. According to the car part cleaning device, by arranging the first cleaning device, the second cleaning device and the transferring device, car parts are sprayedand brushed after being soaked, so that it is ensured that cleaning can be more thorough and more effective; and the transferring device can complete automatic collection of the cleaned car parts, sothat the labor burden of workers is relieved, and the production efficiency is improved.

Owner:日照新睿招商发展有限公司

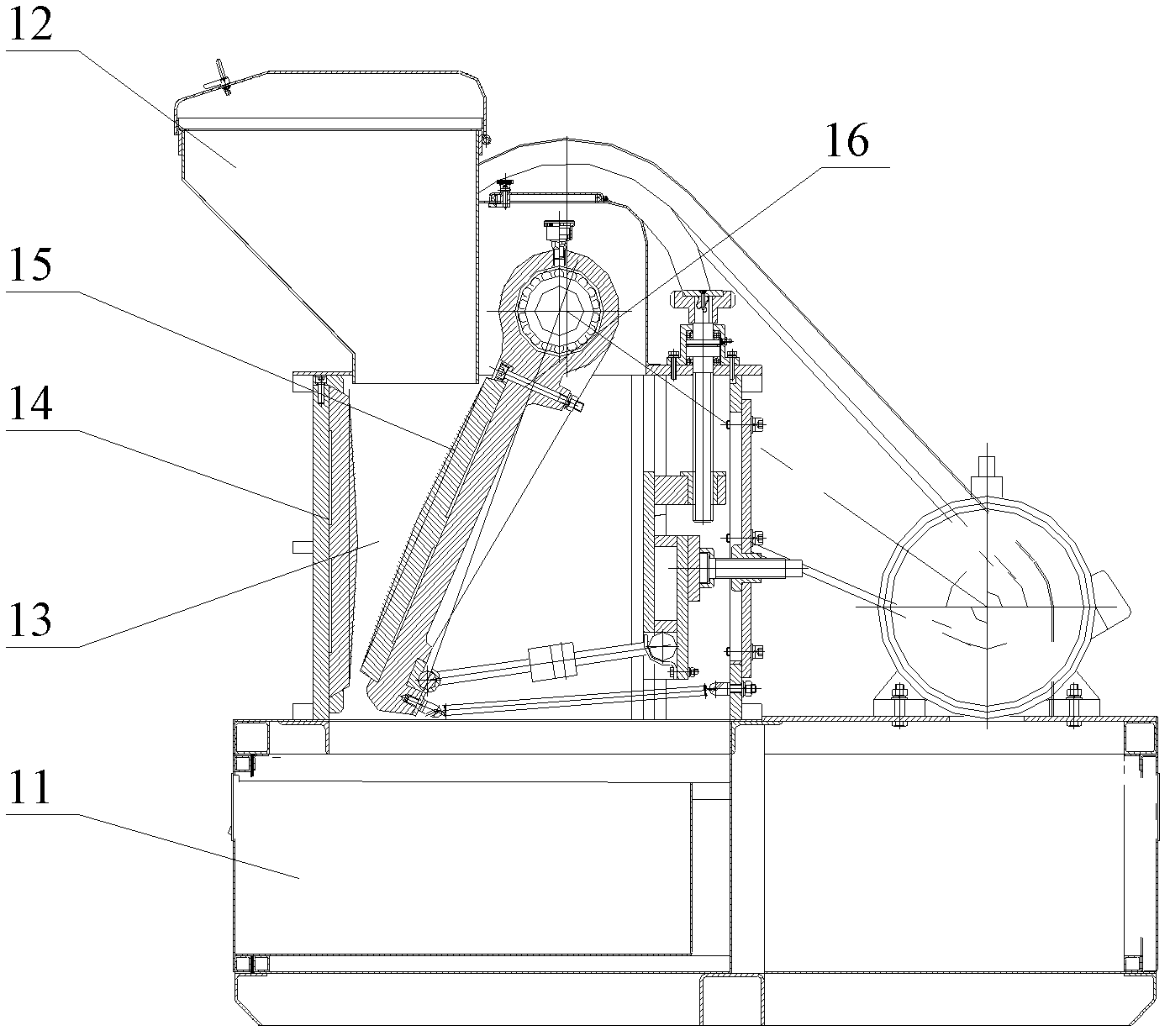

Jaw Crusher

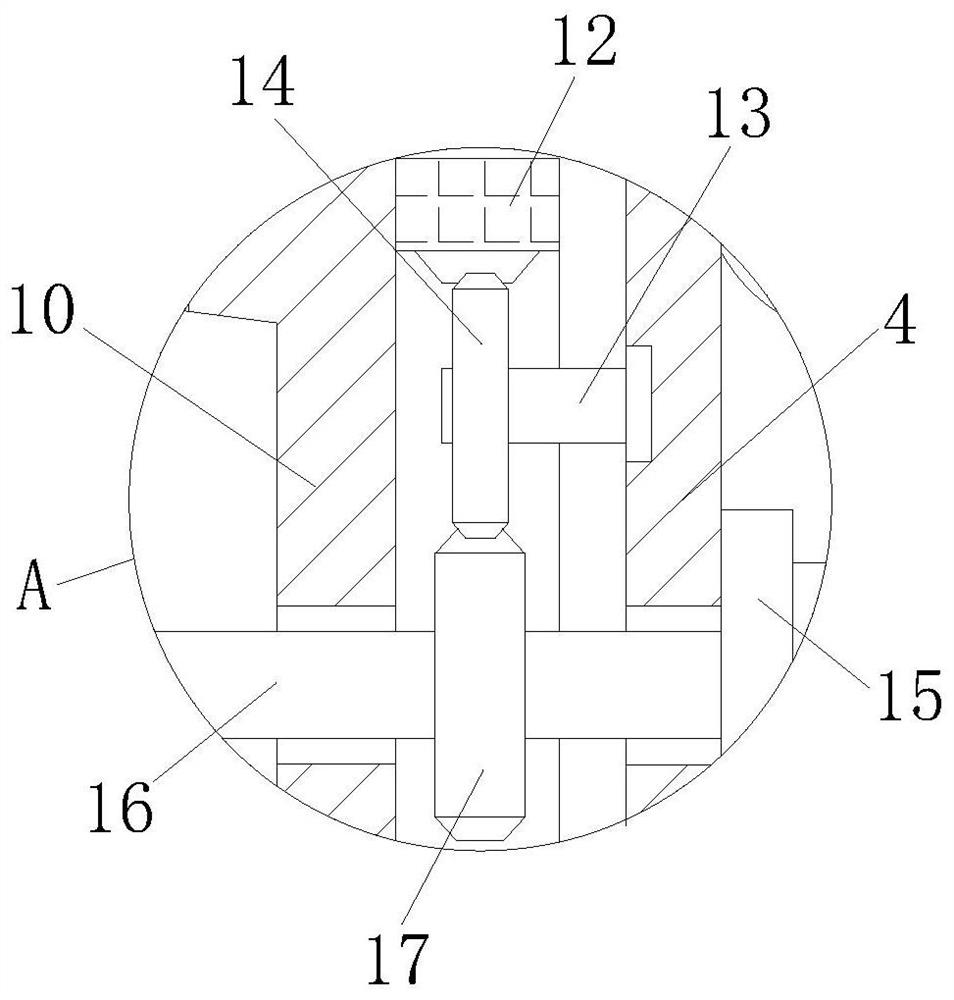

The invention discloses a jaw crusher, comprising a frame, a hopper is arranged on the top of the frame, a crushing chamber is arranged below the hopper, a fixed jaw plate is arranged on the crushing chamber, the crushing chamber The interior of the crushing chamber is provided with a movable jaw plate that matches the fixed jaw plate; the front part of the crushing chamber has a cleaning port, and the cleaning port is detachably provided with a door plate that matches the cleaning port . During use, the door panel is closely attached to the cleaning port to ensure the relative sealing of the interior space of the crushing chamber; when it is necessary to clean the residual materials inside the crushing chamber and its The door panel needs to be opened, and the residual materials inside the crushing chamber and on the fixed jaw plate, movable jaw plate and other related parts can be cleaned through the material cleaning port, and the whole cleaning process does not require a large number of parts disassembly operations , The cleaning work is simple and easy, and the workload of the operator is small, and the cleaning efficiency is high.

Owner:CHANGSHA KAIYUAN INSTR

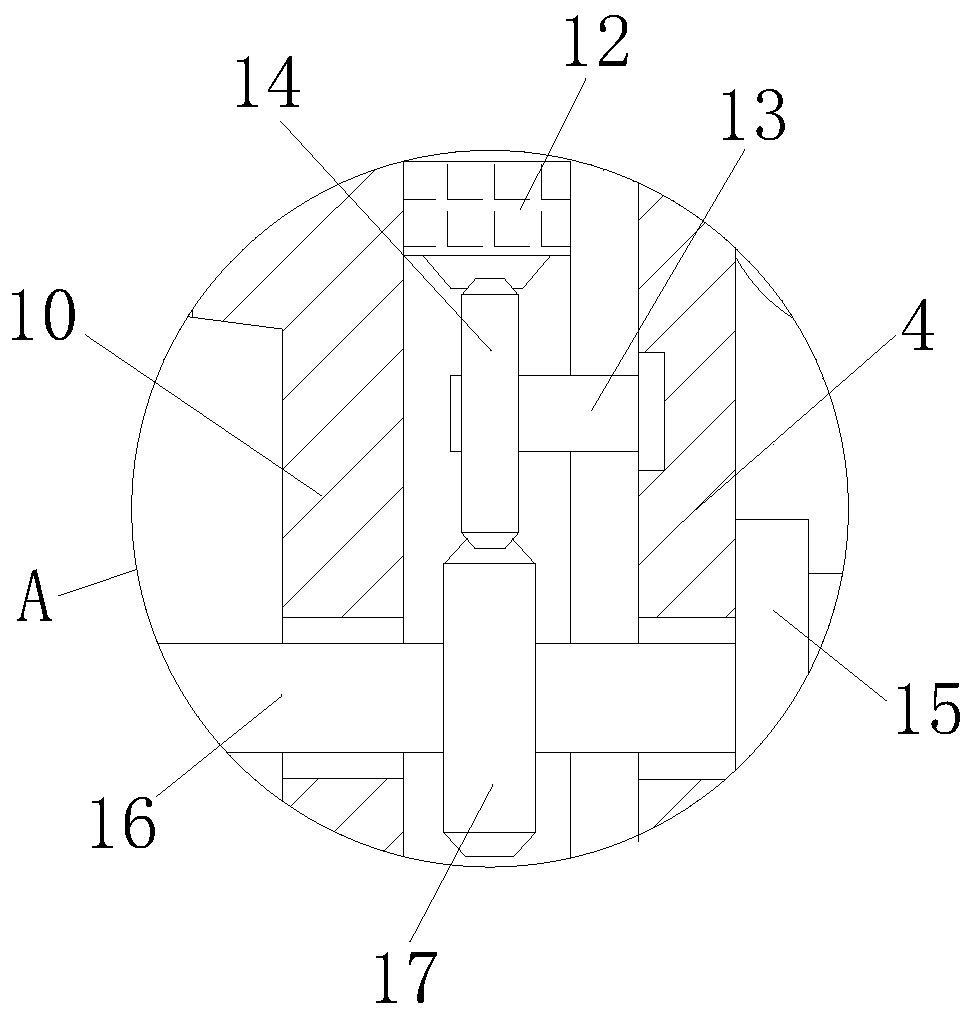

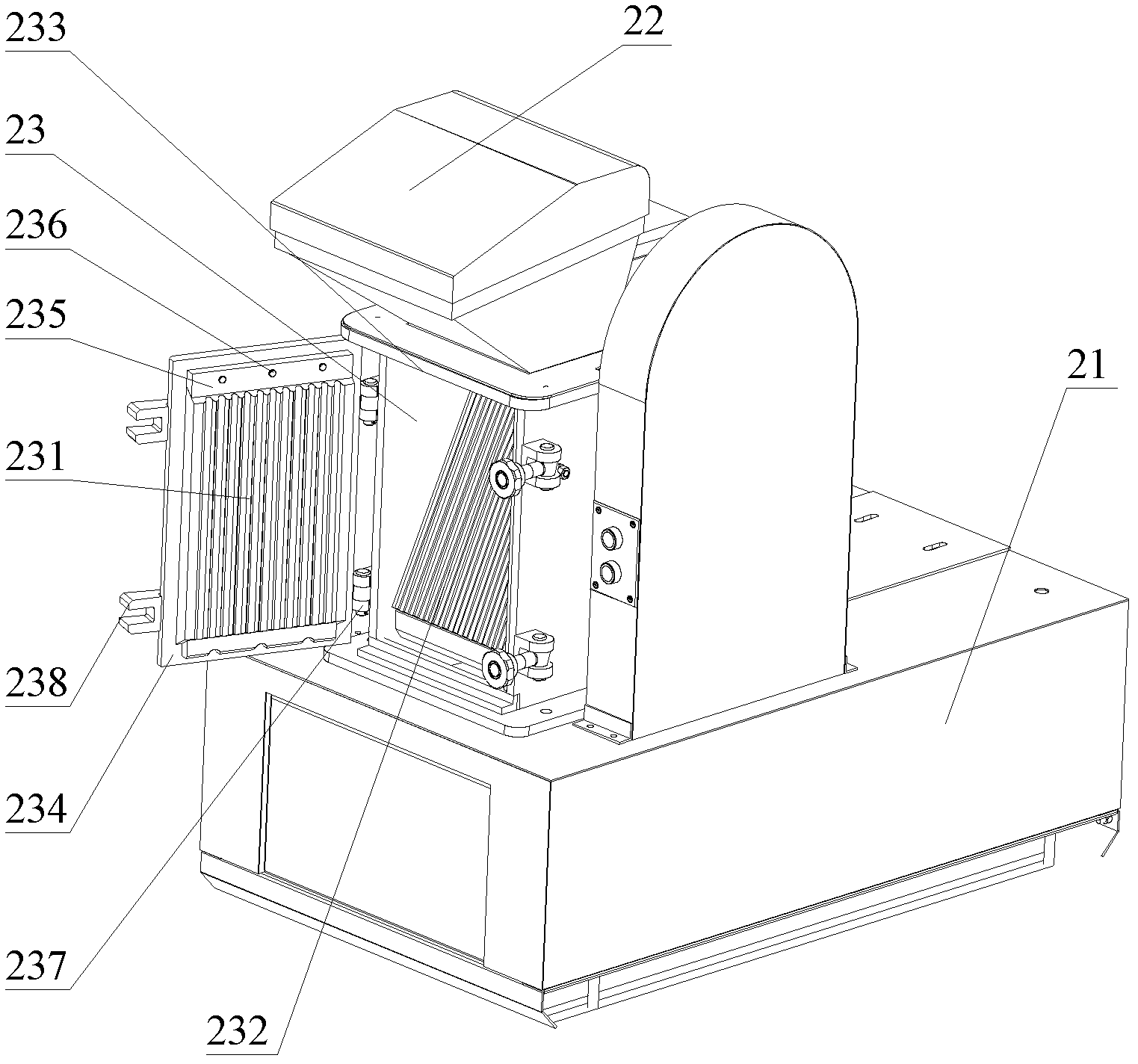

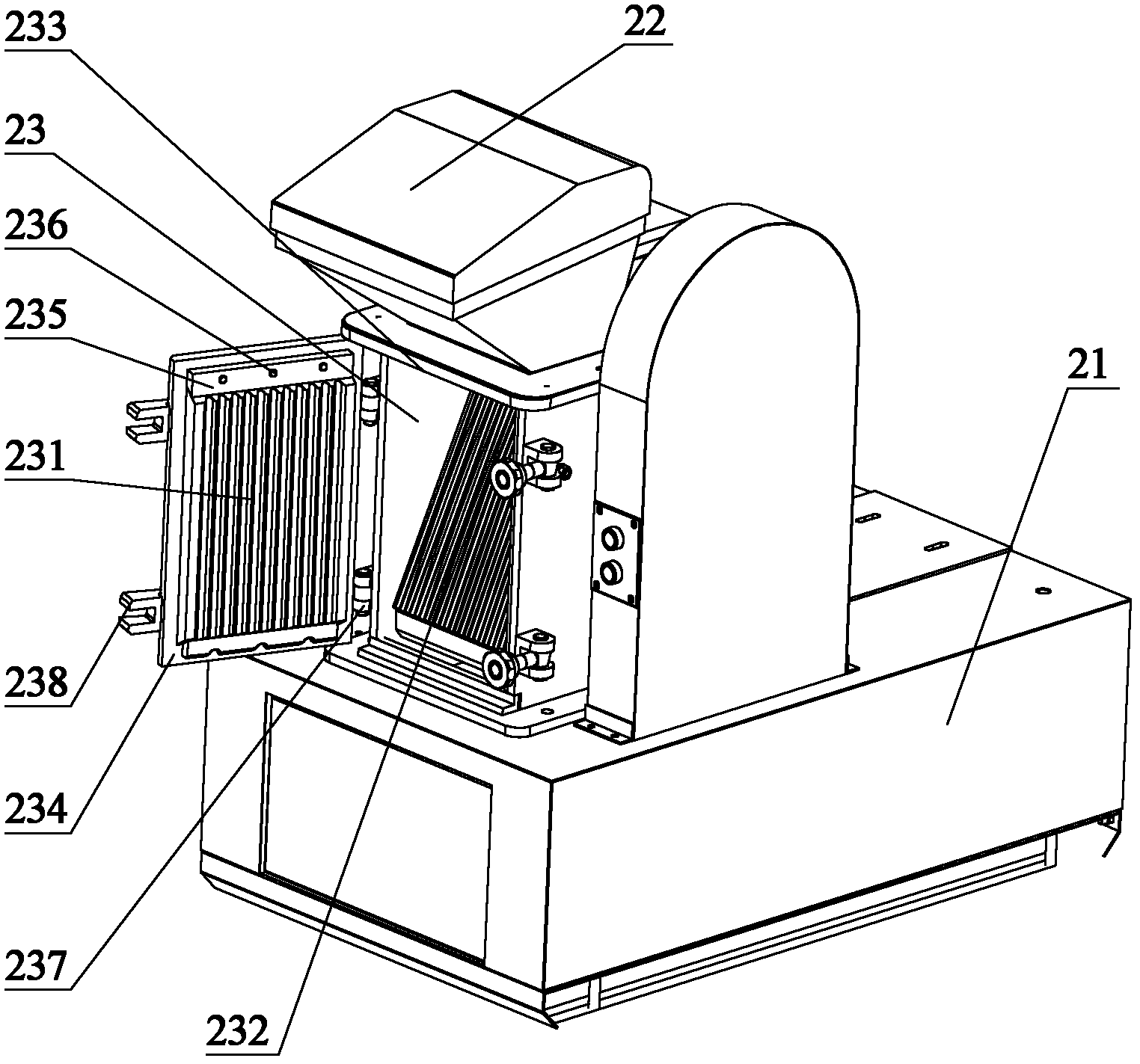

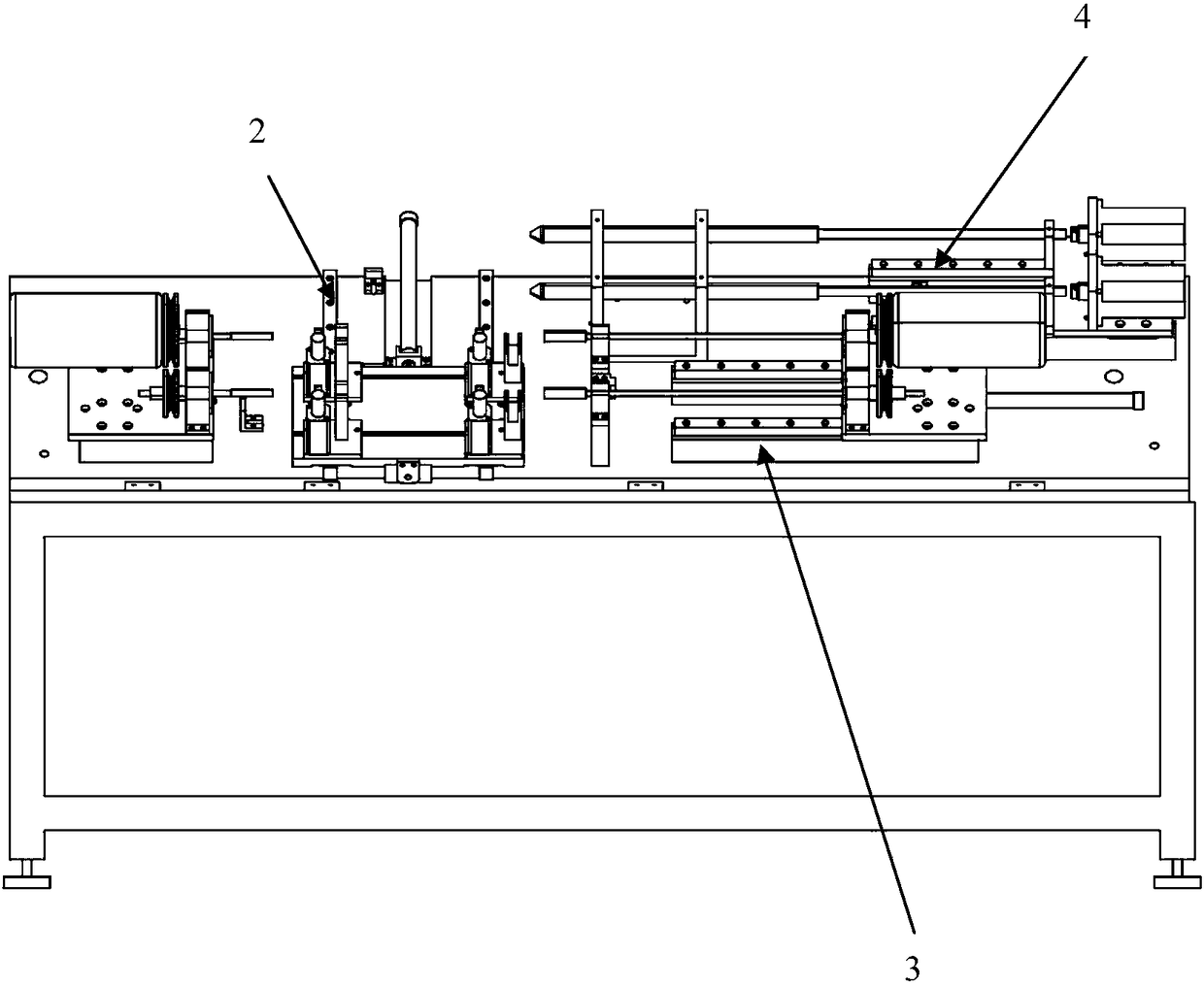

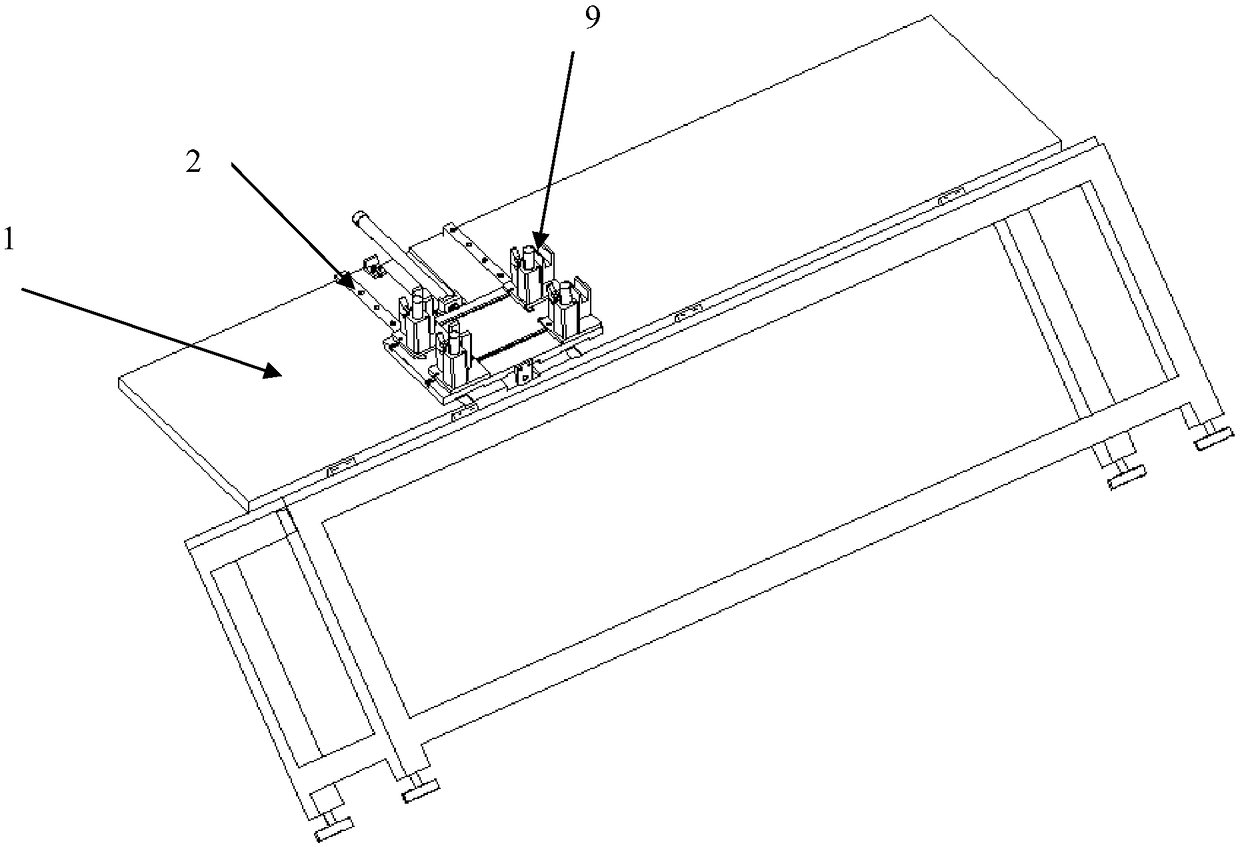

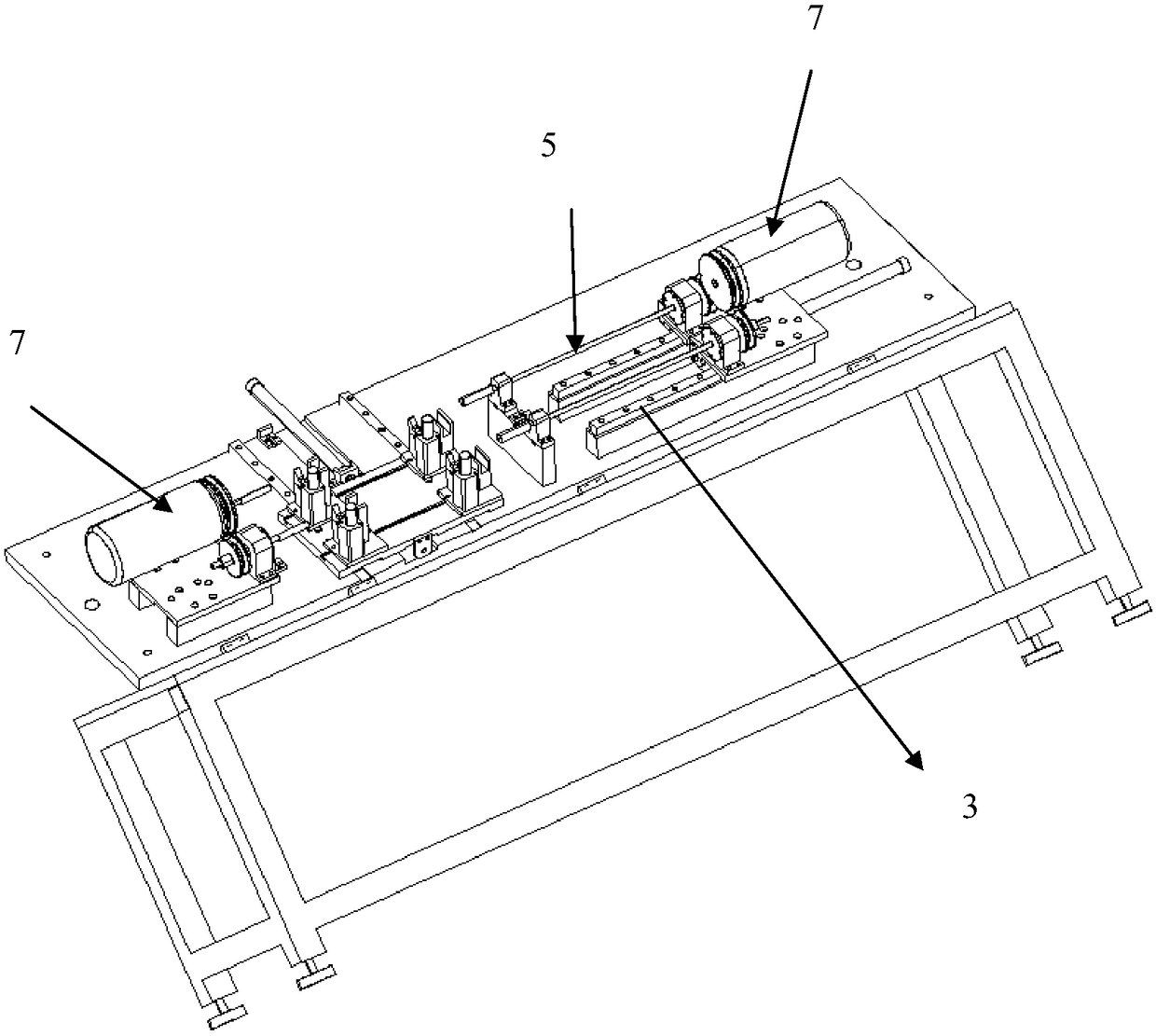

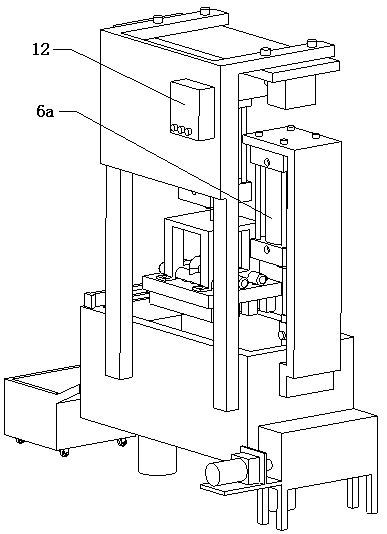

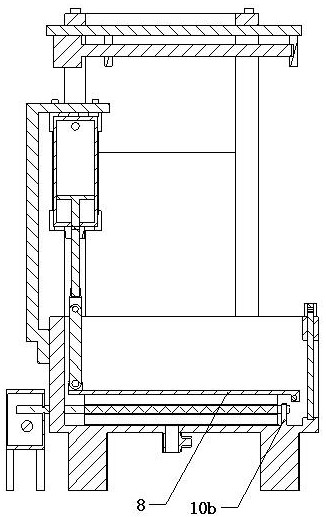

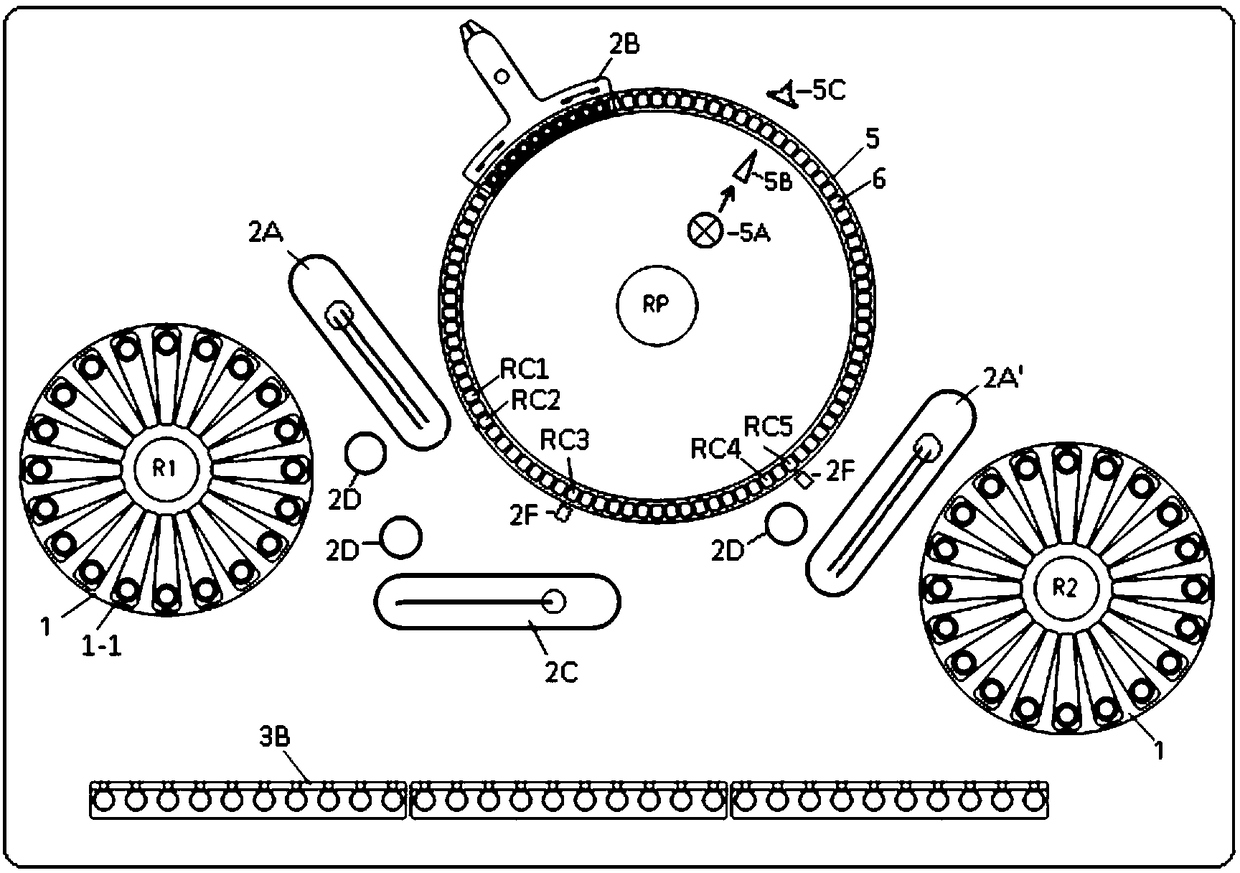

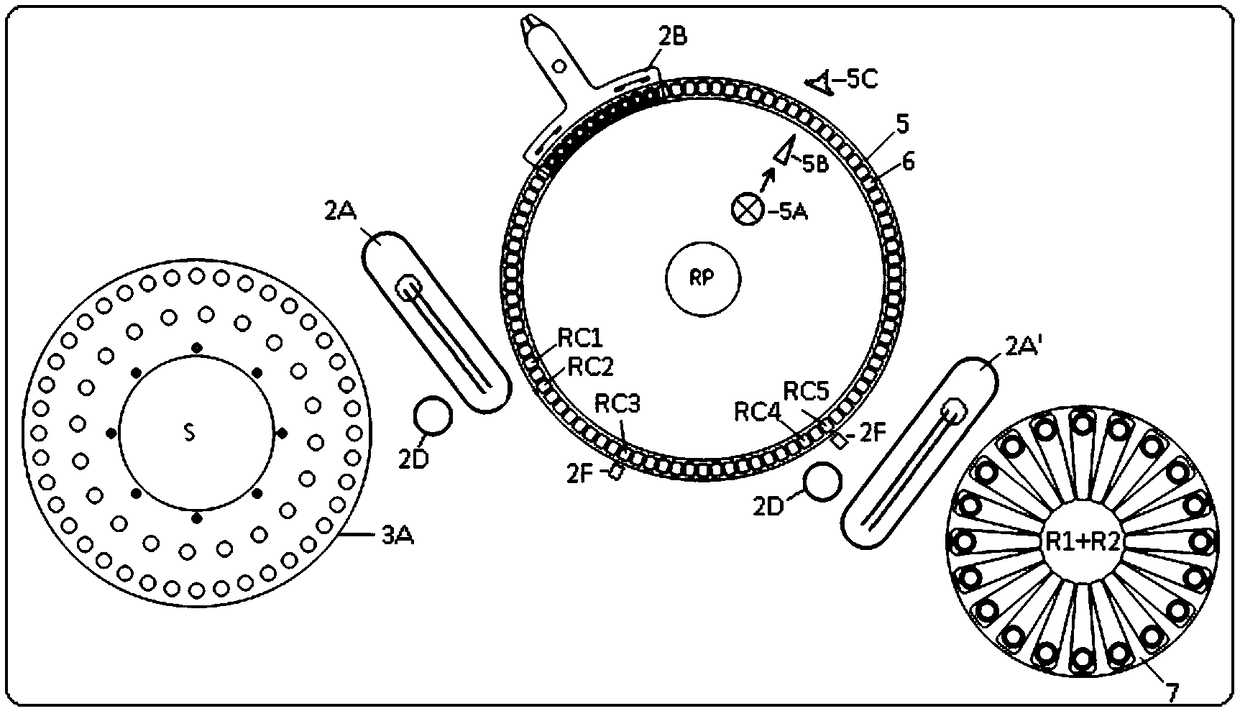

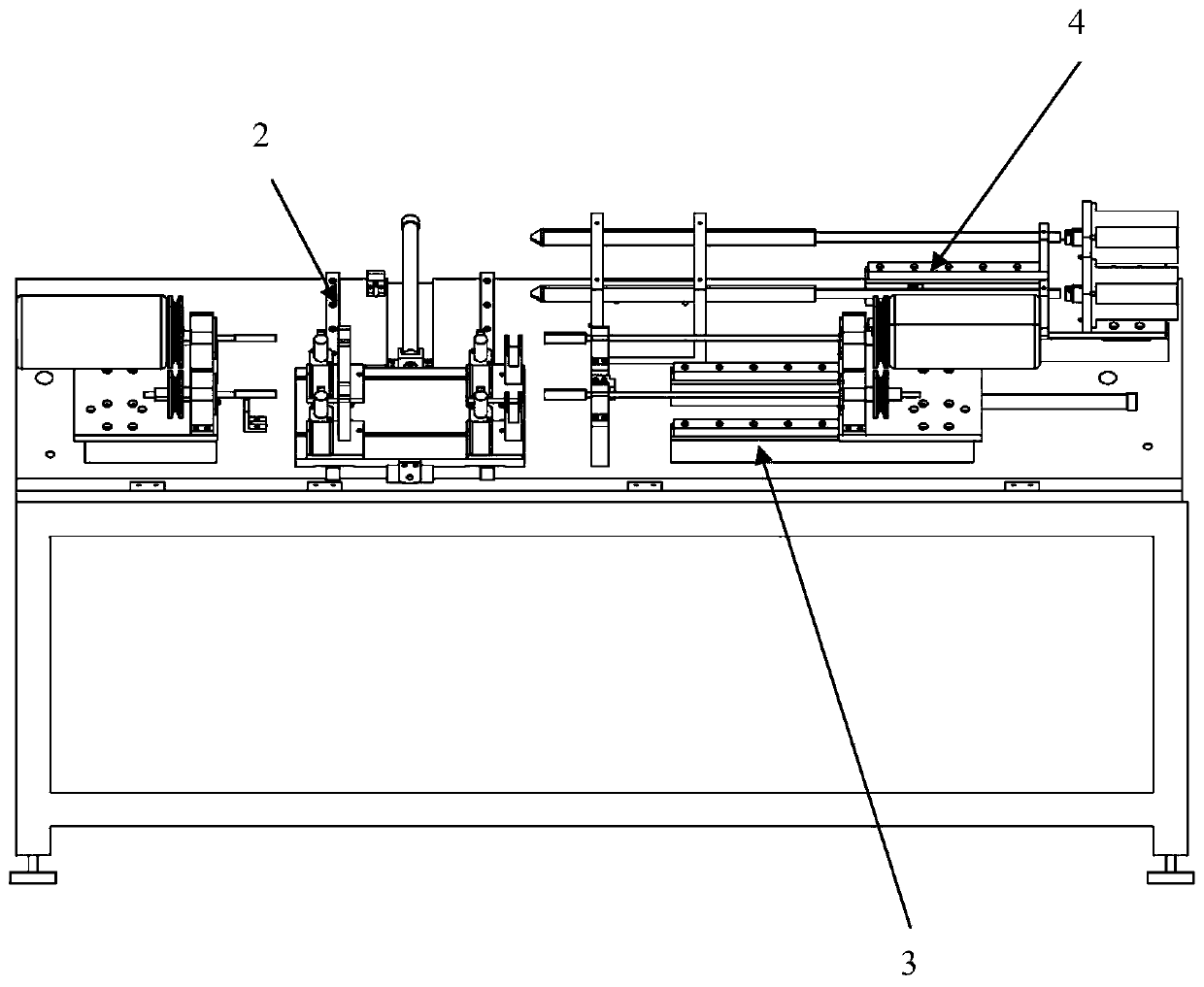

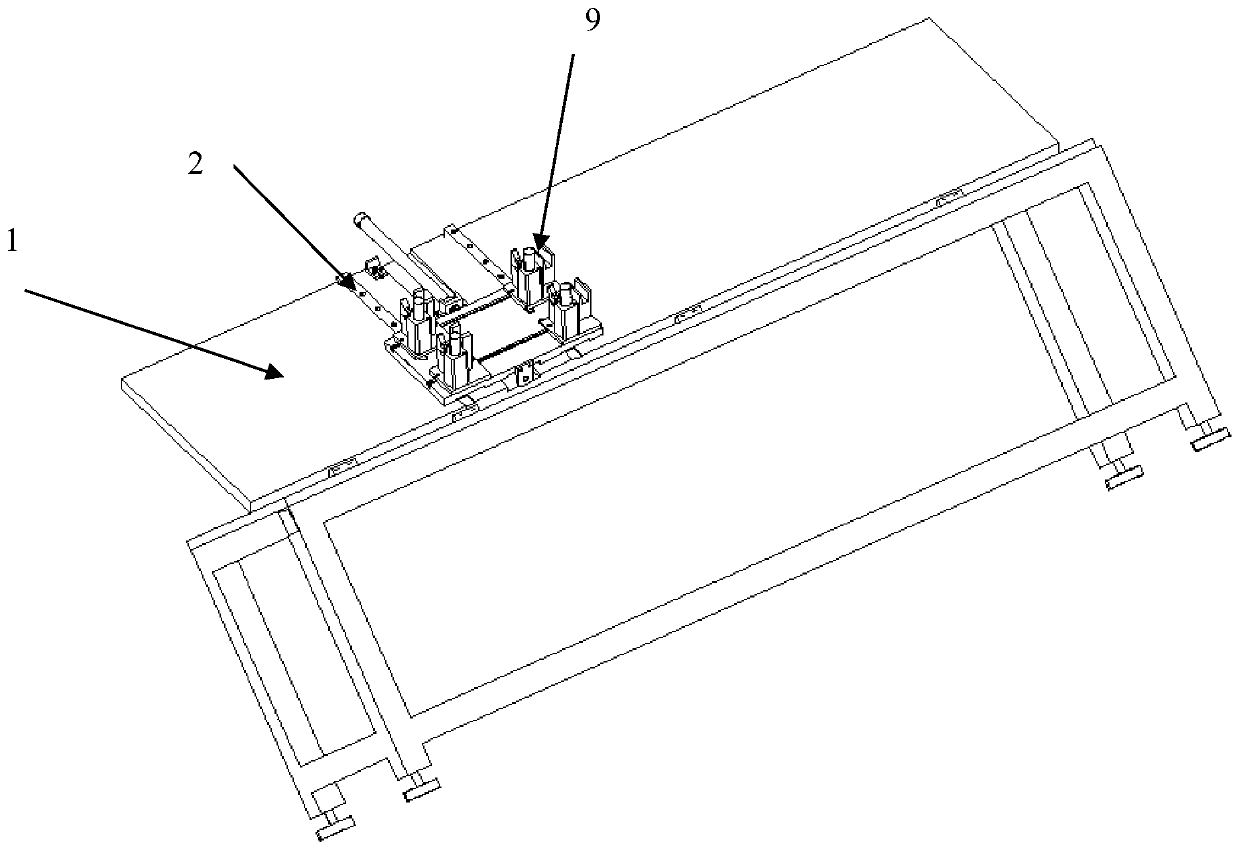

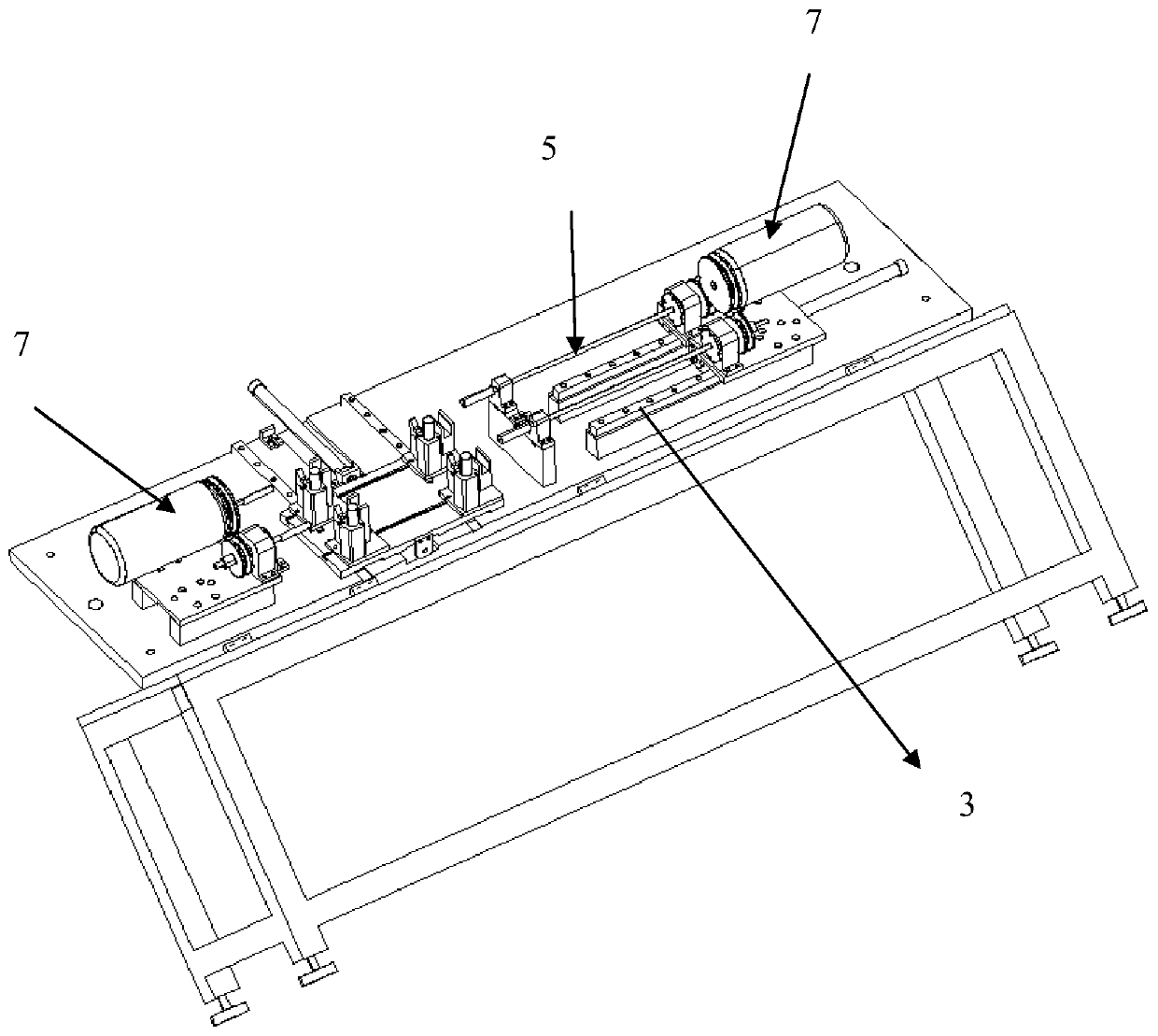

Shaft part inner bore deburring machine tool and shaft part inner bore deburring process

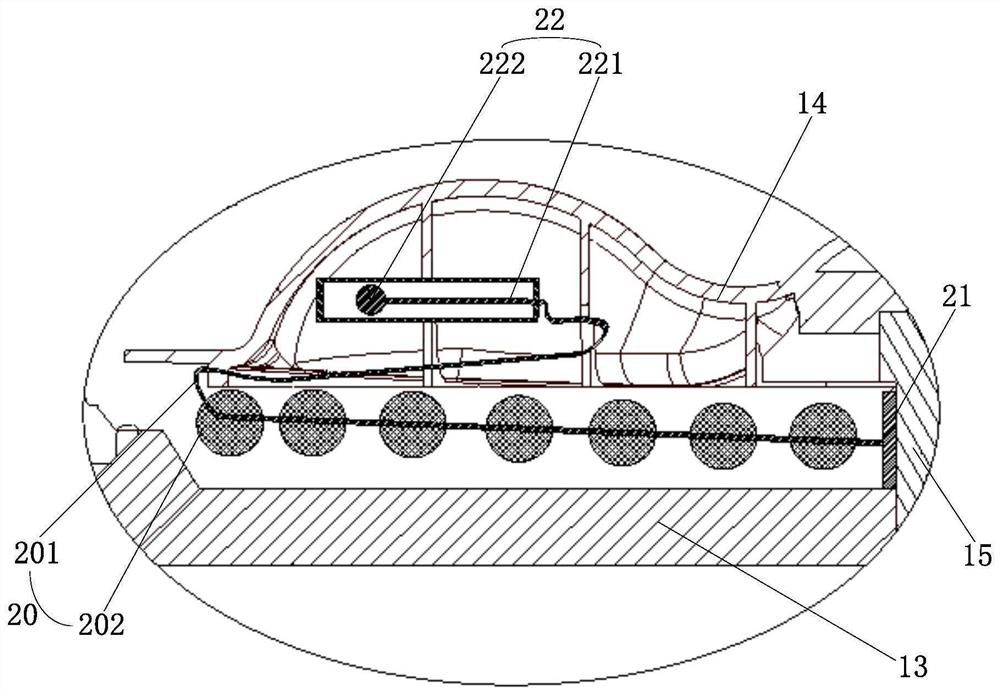

The invention relates to a shaft part inner bore deburring machine tool and a shaft part inner bore deburring process, and in particular to the shaft part inner bore deburring machine tool and the shaft part inner bore deburring process which relate to the field of machining of camshaft parts. The shaft part inner bore deburring machine tool provided by the invention comprises a worktable plate, apart positioning and clamping mechanism, a part station converting mechanism, a flexible reamer deburring device and a steel cable deburring device; and the part positioning and clamping mechanism, the part station converting mechanism, the flexible reamer deburring device and the steel cable deburring device are installed on the worktable plate. The shaft part inner bore deburring process provided by the invention comprises the following steps of: (A) positioning and clamping a part; (B) deburring by using a flexible reamer; and (C) deburring by using a steel cable. The shaft part inner boredeburring machine tool and the shaft part inner bore deburring process provided by the invention are convenient to use, realize high deburring efficiency and can effectively remove burrs of inner bores of casting and steel shaft part products.

Owner:MIANYANG BRILLIANCE RUIAN AUTOMOTIVE COMPONENTS

Clinical laboratory equipment cleaning and disinfection device

ActiveCN109482598AImprove cleaning efficiencyAvoid secondary pollutionHollow article cleaningDrying gas arrangementsEngineeringHigh pressure water

The invention relates to the technical field of medical apparatus and instruments, and discloses a clinical laboratory equipment cleaning and disinfection device. The clinical laboratory equipment cleaning and disinfection device includes a disinfection box, a rotary plate is rotatably connected into the bottom wall of the disinfection box, a main shaft is fixedly connected to the top of the rotary plate, the top end of the main shaft is fixedly connected to an output shaft of a servo motor, the outer side of the main shaft is fixedly connected with main spiral teeth, and the main spiral teethare engaged with auxiliary spiral teeth fixedly connected with the inner side of a moving barrel. According to the clinical laboratory equipment cleaning and disinfection device, the condition of test tube breaking or damage due to interior and exterior high-pressure water cleaning can be avoided, the unnecessary loss of property is avoided, and meanwhile, the condition that stubborn residue on the inner wall of a test tube cannot be thoroughly cleared and consequently bacterial breeding or secondary pollution is caused can be avoided, troubles of manual scrubbing and consumption of the laborare avoided, the test tube can be cleaned and disinfected thoroughly and effectively, and the use effect and the working efficiency are effectively improved.

Owner:刘玲

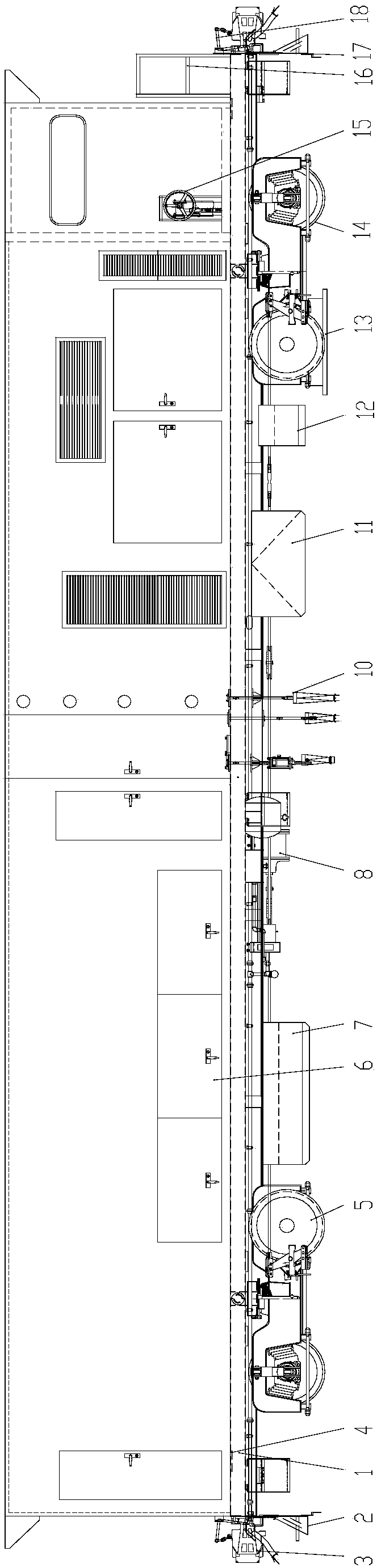

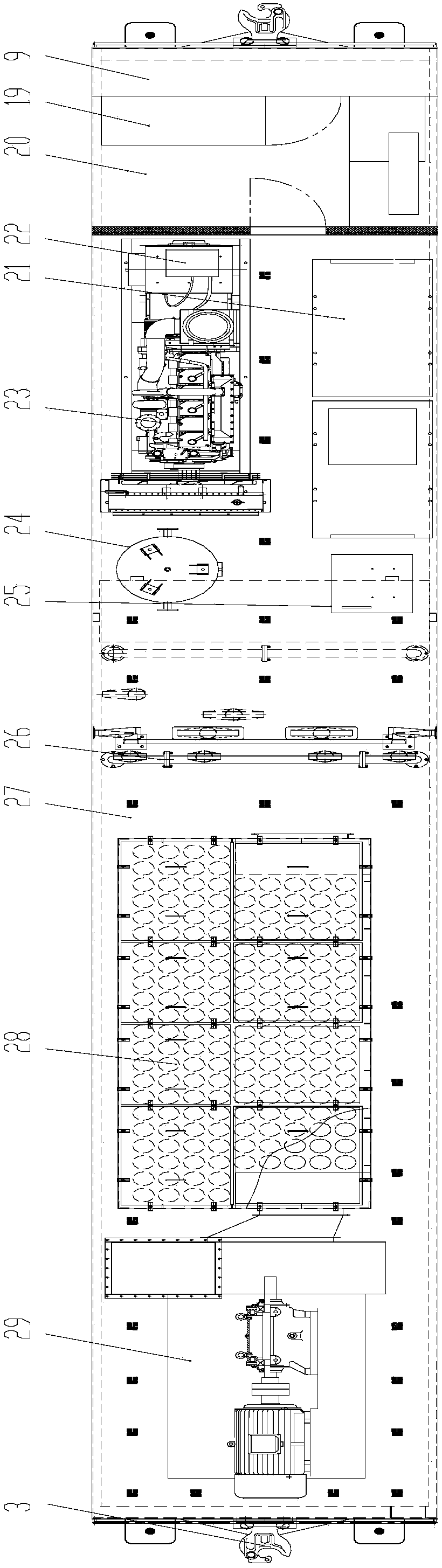

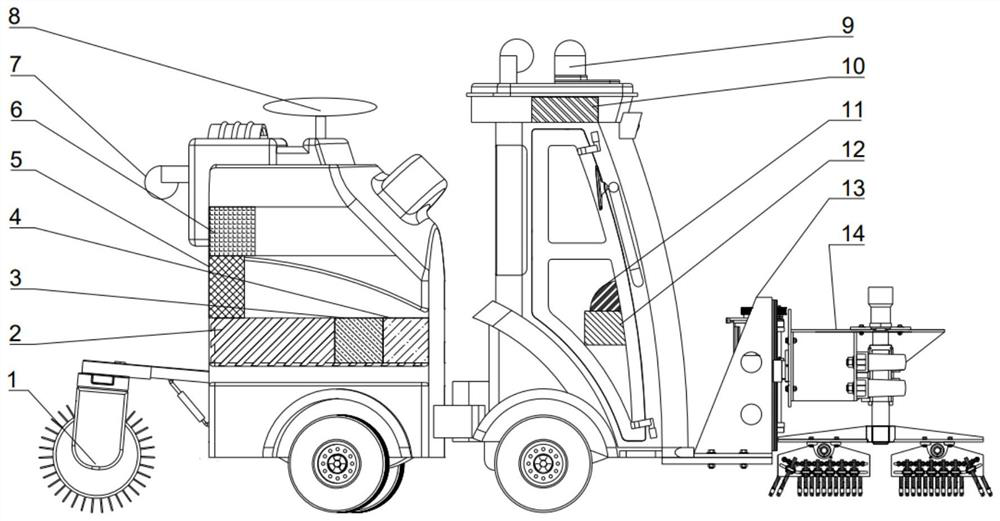

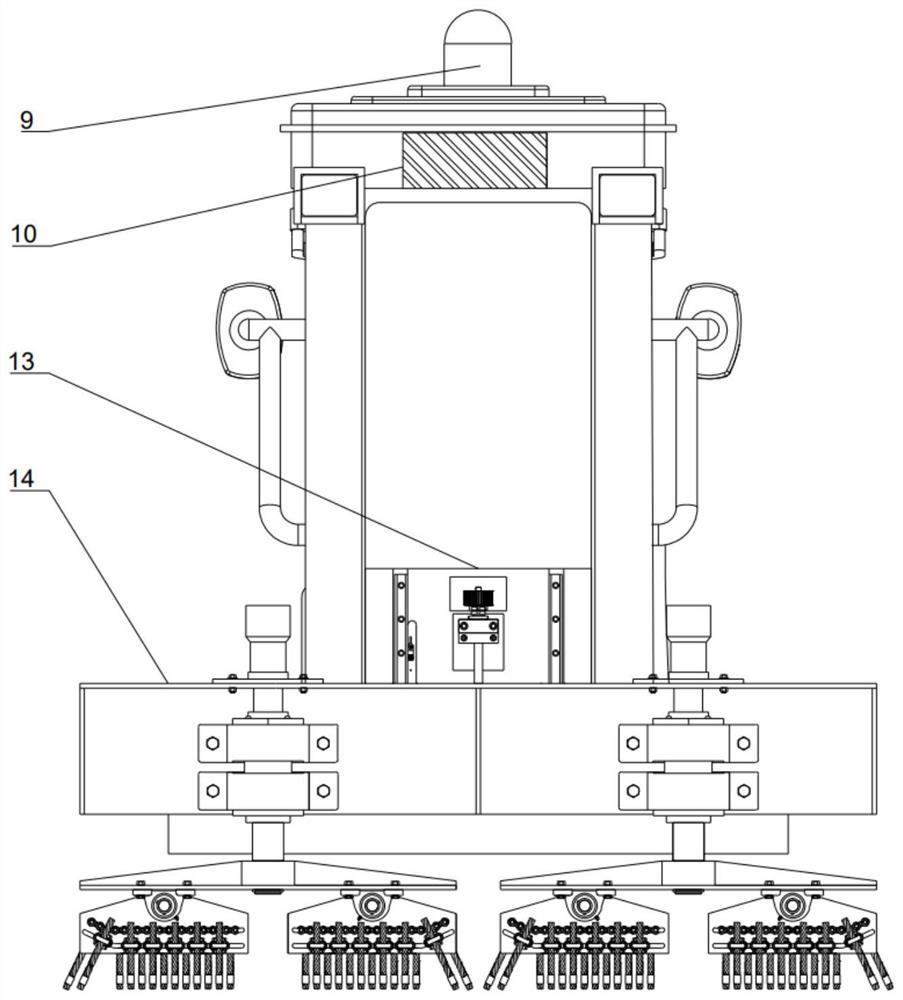

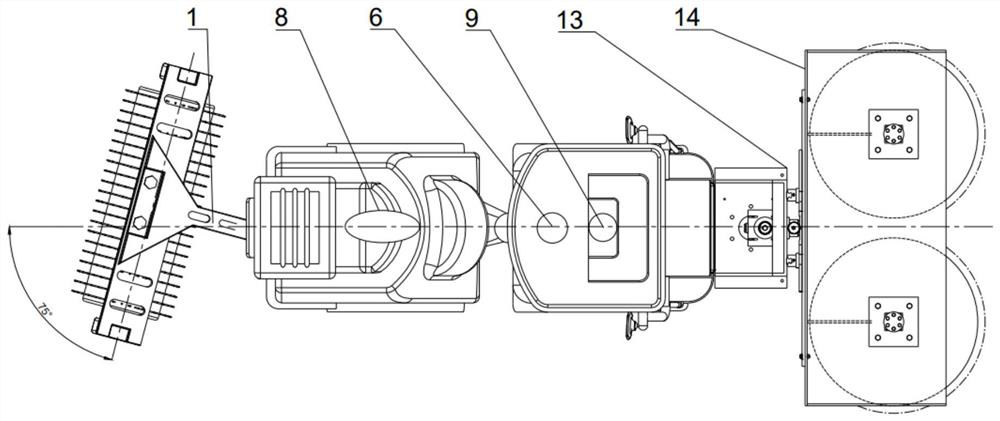

Negative air pressure cleaning vehicle for cleaning tunnel environment

InactiveCN105780701AImprove work efficiencyReduce labor burdenRoad cleaningCarriagesFuel tankGenerating unit

The invention provides a negative air pressure cleaning vehicle for cleaning a tunnel environment. The negative air pressure cleaning vehicle is provided with a frame, wherein a front bogie and a rear bogie are respectively arranged at two ends of the lower part of the frame; an air system and an electrical system are arranged in the middle of the lower part of the frame; a vehicle body is arranged at the upper part of the frame, and comprises a cab and a machine compartment; a cleaning work mechanism is arranged on the frame and comprises a lower blowing and sucking opening formed in the lower part of the frame and an upper blowing and sucking opening formed in the top of the vehicle body as well as an air compressor, an air storage tank and an axial flow fan which are arranged in the machine compartment and are used for supplying air to the upper blowing and sucking opening and the lower blowing and sucking opening; the cleaning work mechanism further comprises a generator set, a dust collector and a dust collection fan which are arranged in the machine compartment, and a water tank, a high-pressure pump station and a fuel tank which are arranged at the lower part of the frame. The negative air pressure cleaning vehicle can efficiently and thoroughly clean a railway tunnel, without corroding and rusting contact net lines and other devices in the tunnel, and is safe, reliable and stable; the installation of the whole vehicle can meet the requirements on a metro working environment and a operation technology; the working efficiency is high, and the burden on a worker is relieved.

Owner:BAOJI CSR TIMES ENG MACHINERY

MLC blade cleaning tool

PendingCN109382338AClean thoroughlyThorough and effective cleaningCleaning using toolsMetal-working hand toolsSurface layerBristle

The invention relates to an MLC blade cleaning tool. The cleaning tool comprises a cutter head, a holding handle and a bristle assembly, the cutter head is connected with one end of the holding handle, the bristle assembly is connected with the other end of the holding handle, the cutter head is a multi-section cutter head, each cutter head section is flaky, indentations are formed in the parts between the cutter head section, and the ends of the cutter head sections are oblique tangent shapes. The bristle assembly is detachably connected with the holding handle, the bristle assembly compriseshair bundles and a hair bundle installing plate which is used for inserting in the hair bundles, the end of the holding handle is provided with a groove, and the hair bundle installing plate is clamped in the groove formed in the end of the holding handle. The surface of the holding handle is provided with a frosted surface layer. Compared with the prior art, the cleaning tool has the advantagesthat the cleaning is more thorough, the front end cutter head has a section arrangement, the service life is long, the cost is saved, and the carrying is convenient.

Owner:上海卓亚医疗科技有限公司

Cleaning device for steel pipe machining

InactiveCN112872061AThorough and effective cleaningIncrease profitHollow article cleaningGrinding machinesGear wheelMachining

The invention belongs to the technical field of steel pipe machining, and discloses a cleaning device for steel pipe machining. The cleaning device comprises a shell, wherein the shell is divided into an upper layer and a lower layer, one side of the shell is provided with a feed port, the other side of the shell is provided with a discharge port, one side of the inner surface of the upper layer of the shell is provided with a first clamping device, a second clamping device is arranged on the other side of the inner surface of the shell, a plurality of fixing buckles are arranged on the inner walls of the two ends of the upper layer of the shell respectively, a sleeving ring is arranged in the middle of the two fixing buckles, a first communicating pipeline is excavated in the sleeving ring, an electric rotating table is arranged on the outer surface of the sleeving ring, one end of the electric rotating table is rotatably connected with a rotating ring, the rotating ring is rotatably connected with the sleeving ring through a bearing, and a plurality of water cavities are evenly excavated in the rotating ring in arrays. According to the device, the outer wall of a steel pipe is deoiled through a rotating roller, so that the rust on the outer wall of the steel pipe is removed through the differential rotation of the first gear and the rotating ring, the cleaning effect is good and the cleaning efficiency is high.

Owner:徐敏旺

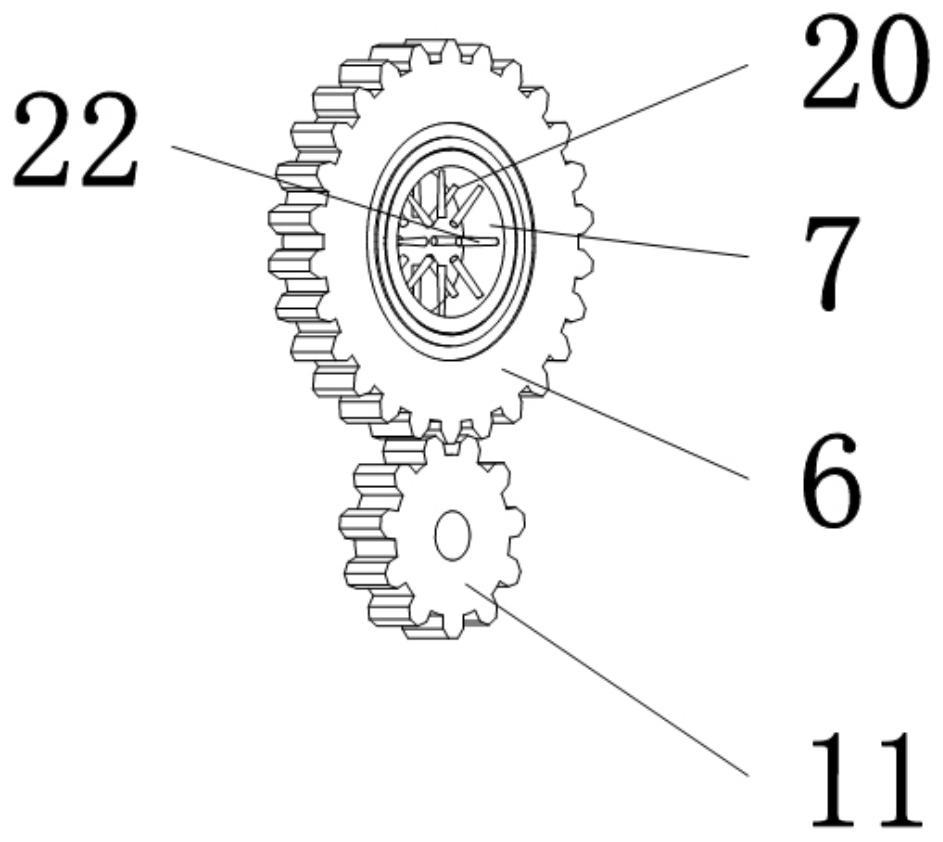

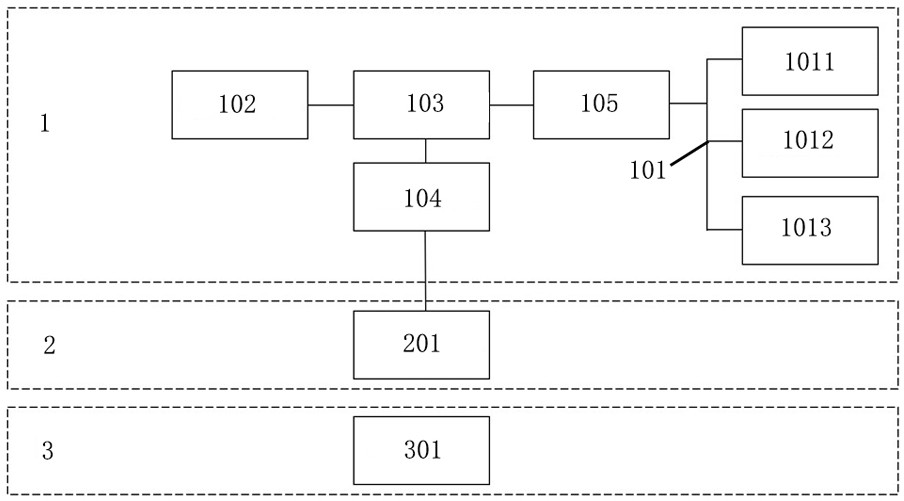

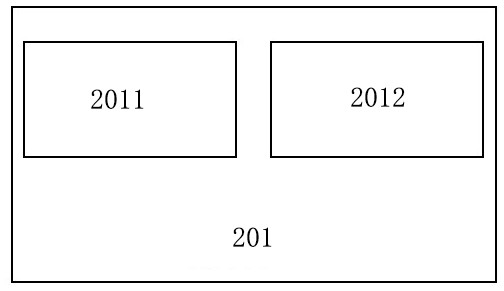

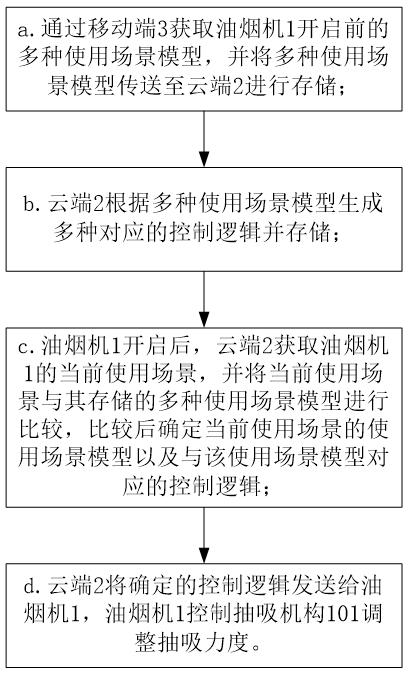

Range hood self-adaptive adjustment control system, adjustment control method thereof and range hood

ActiveCN114674023ASave cleanup timeImprove quality of lifeDomestic stoves or rangesLighting and heating apparatusSelf adaptiveMobile end

The invention relates to the technical field of intelligent household electrical appliances, and particularly provides a range hood self-adaptive adjustment control system and an adjustment control method thereof, the system comprises a range hood (1), the range hood (1) comprises a suction mechanism (101) used for sucking oil smoke; the cloud end (2) is in communication connection with the range hood (1), obtains and judges a current use scene after the range hood (1) is started, and sends a corresponding control signal to the range hood according to the current use scene to control the suction mechanism (101) to adjust the suction force; the mobile terminal (3) is in communication connection with the cloud terminal (2); the mobile terminal (3) obtains multiple use scene models before the range hood (1) is started in advance and transmits the multiple use scene models to the cloud terminal (2), and the cloud terminal (2) determines the use scene model to which the current use scene of the range hood (1) belongs according to the multiple use scene models. According to the scheme, it can be guaranteed that lampblack is thoroughly cleaned without residues.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

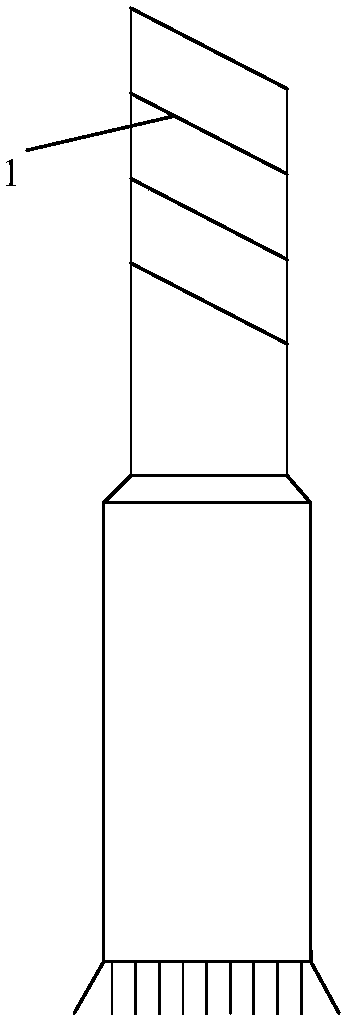

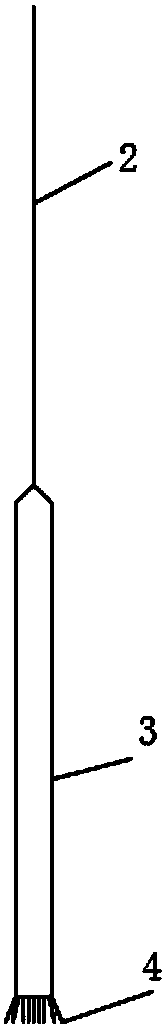

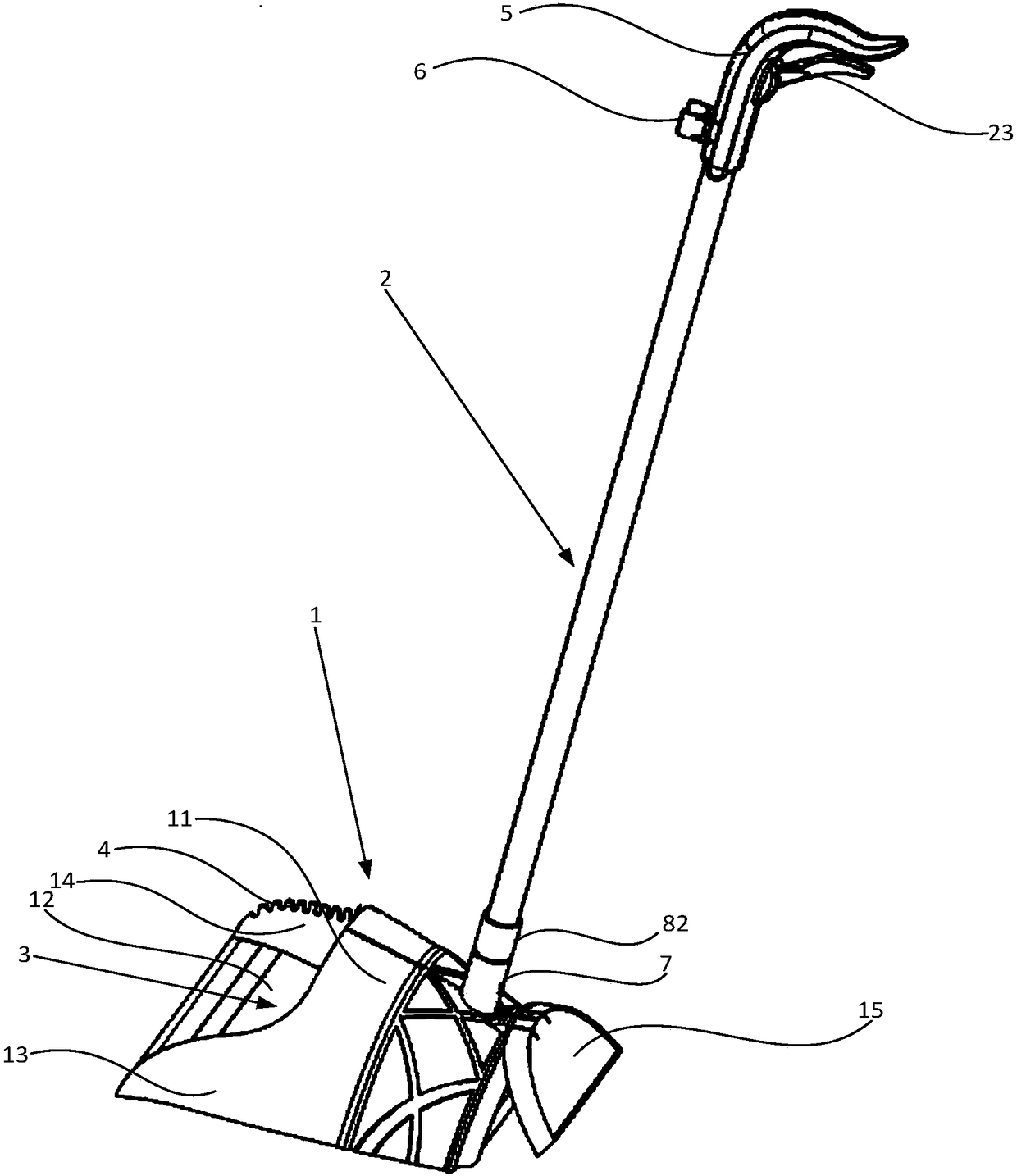

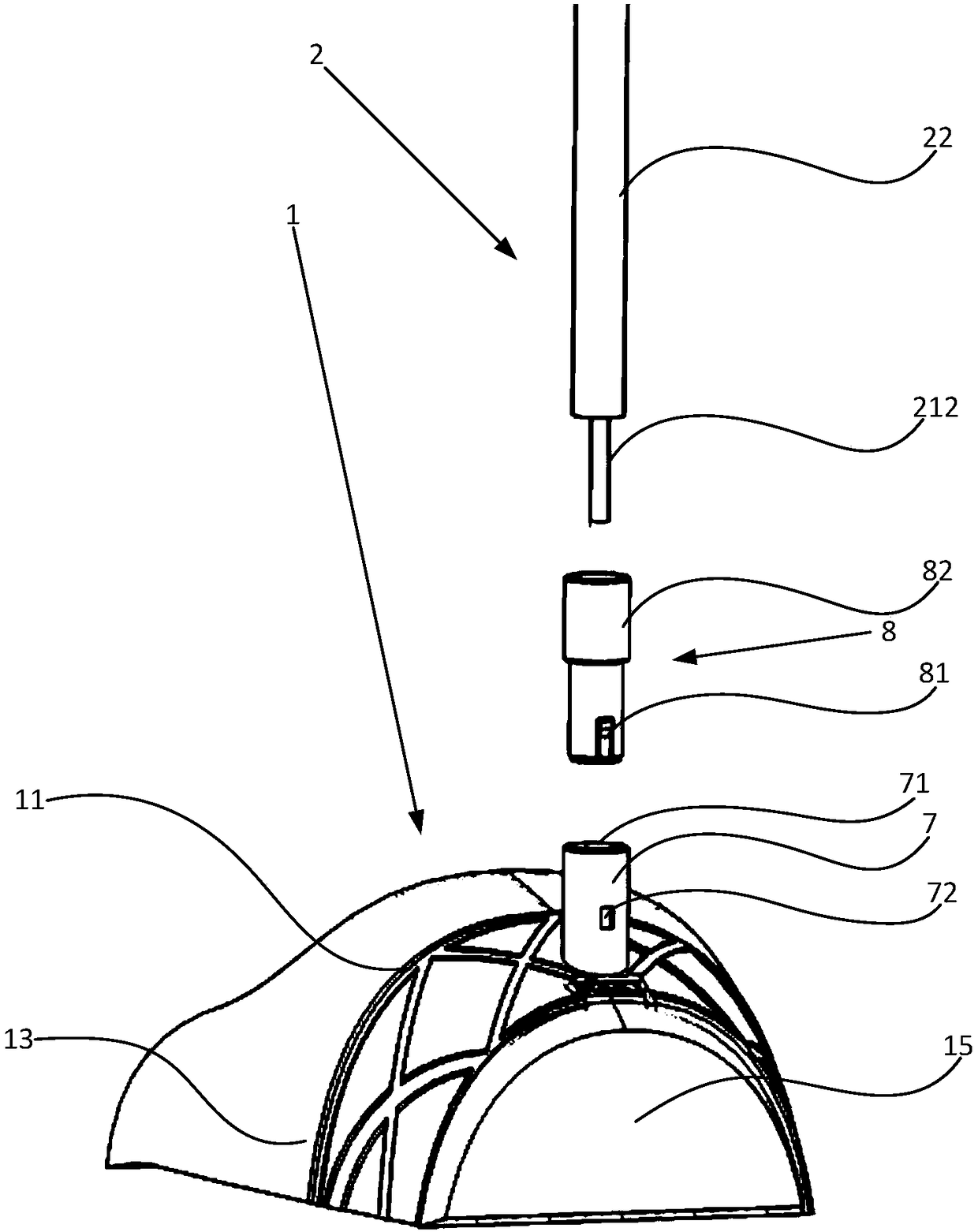

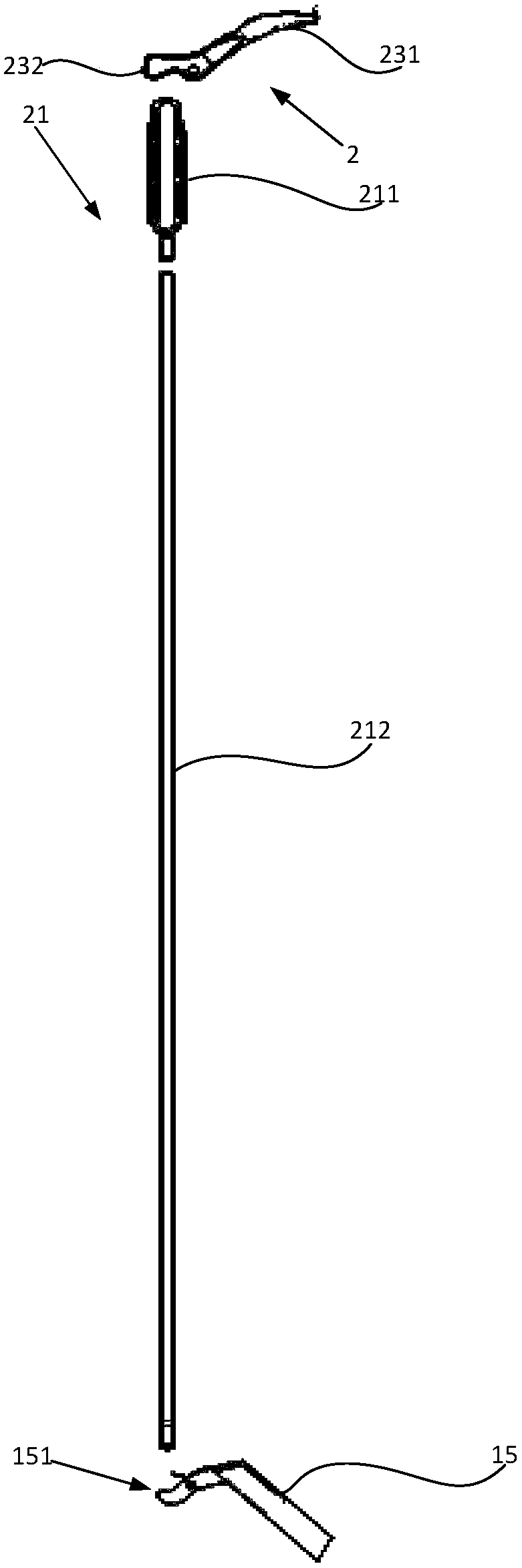

Multifunctional dustpan

PendingCN108309171AFlexible opening and closingEfficient and thorough pouringCarpet cleanersFloor cleanersEngineeringSupport point

The invention discloses a multifunctional dustpan. The multifunctional dustpan comprises a dustpan body and a handle rod, wherein the dustpan body comprises a top wall, a bottom wall, a left side ball, a right side wall and a back plate, the top wall, the bottom wall, the left side ball, the right side wall and the back plate are sequentially and integrally connected to form a barrel structure, arubbish inlet of the dustpan is formed in the front end of the barrel structure, and the back plate can close the back end of the barrel structure; the handle rod comprises a transmission rod and an outer rod, the transmission rod is located in the outer rod, a hand pulling handle is arranged at the upper end of the outer rod, is provided with a supporting point, can rotate around the supporting point, and comprises a hand pulling end and a pressing end, and the pressing end is located at the upper portion of the transmission rod and can press the transmission rod; the upper end of the back plate extends forwards to form a connecting block, the connecting block is rotationally connected with the back end and the upper end of the barrel structure, a reset spring is arranged at a rotating shaft, the connecting block extends forwards to form a pressure-bearing surface, and the pressure-bearing surface is located at the lower portion of the transmission rod and abuts against the lower endof the transmission rod. According to the multifunctional dustpan, the back plate is flexibly and conveniently opened, rubbish is cleanly and thoroughly dumped, rubbish containing space is large, andcilia of a besom is efficiently cleaned.

Owner:HEBEI JIESHIBAO DAILY PLASTIC PROD CO LTD

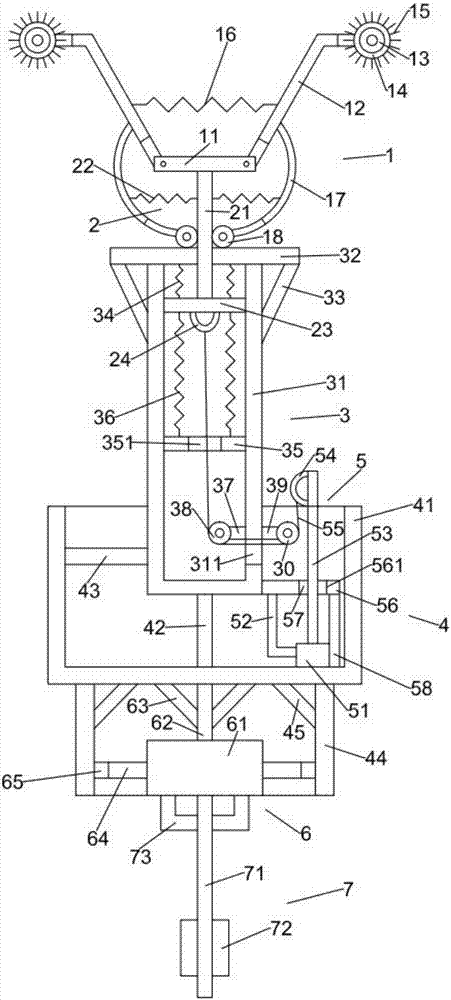

Efficient environment-friendly container inner wall cleaning device in mechanical field

InactiveCN106862205AImprove cleaning efficiencyThorough and effective cleaningHollow article cleaningBristleElastic rods

The invention discloses an efficient environment-friendly container inner wall cleaning device in the mechanical field. The device comprises a cleaning device, a connecting device, a support device, a frame device, a pushing device, a motor device and a holding device; the cleaning device comprises a first fixing rod, a rotating frame, a first roller, a sponge sleeve, bristles, a first spring, an elastic rod and a second roller; the connecting device comprises a first connecting rod, a first positioning rod, a second spring and a first connecting ring; the support device comprises a first support, a second positioning rod, a second fixing rod, a third spring, a fourth spring, a third positioning rod, a first supporting rod, a third roller, a second supporting rod and a fourth roller; the frame device comprises a rotating fame, a third fixing rod, a fourth fixing rod, a positioning frame and a fourth fixing rod. The inner wall of a container can be thoroughly and effectively cleaned, the cleaning efficiency is high, manual labor intensity is low, work efficiency can be effectively improved, and the device can be suitable for containers with different calibers.

Owner:JIAXING MINHUI AUTOMOTIVE PARTS CO LTD

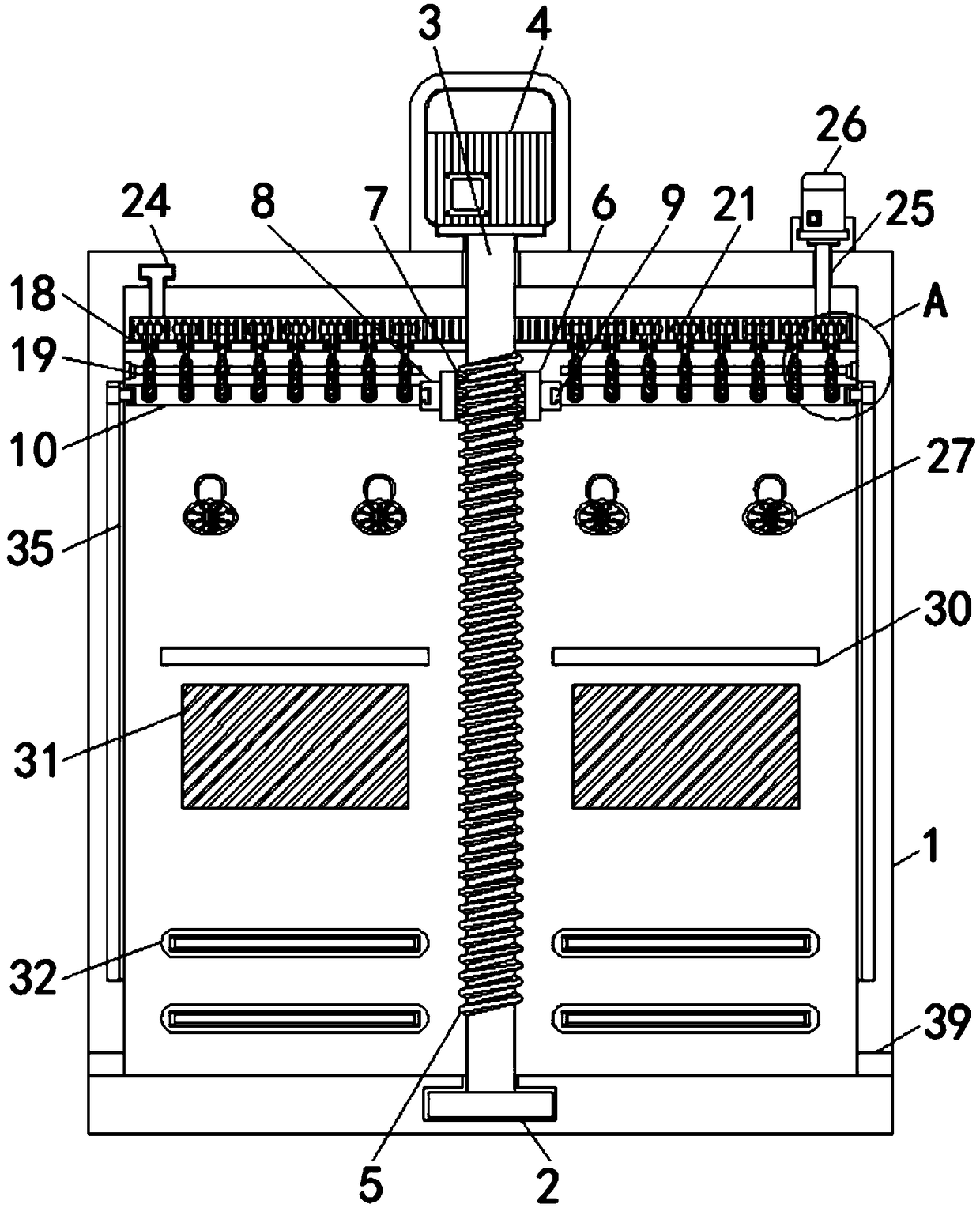

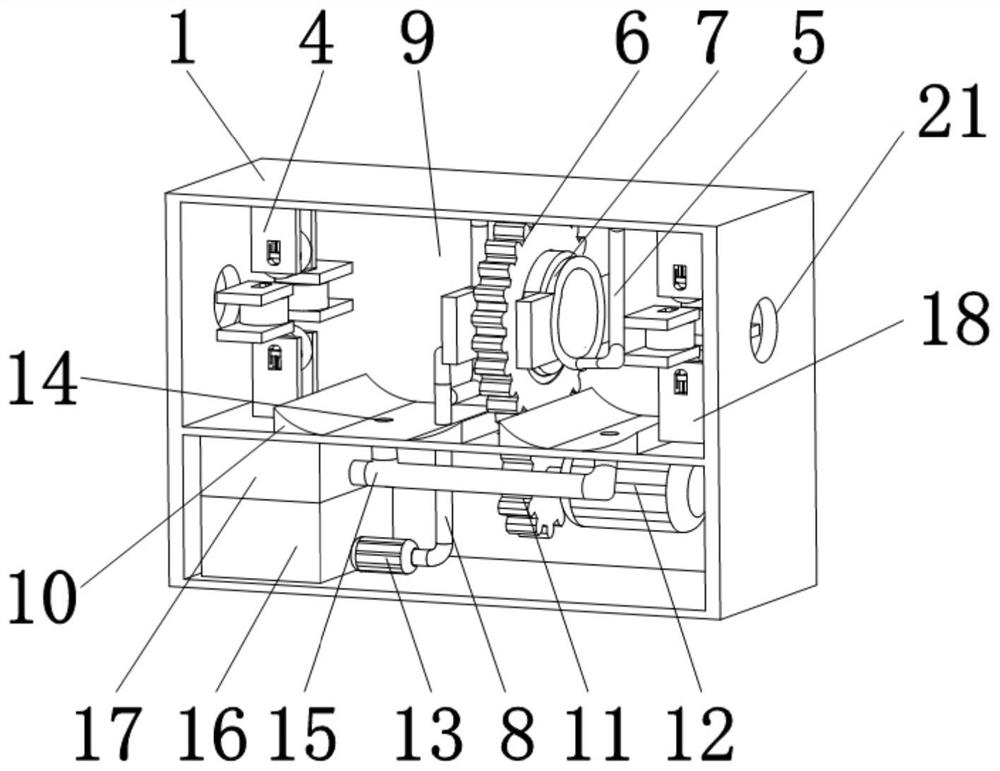

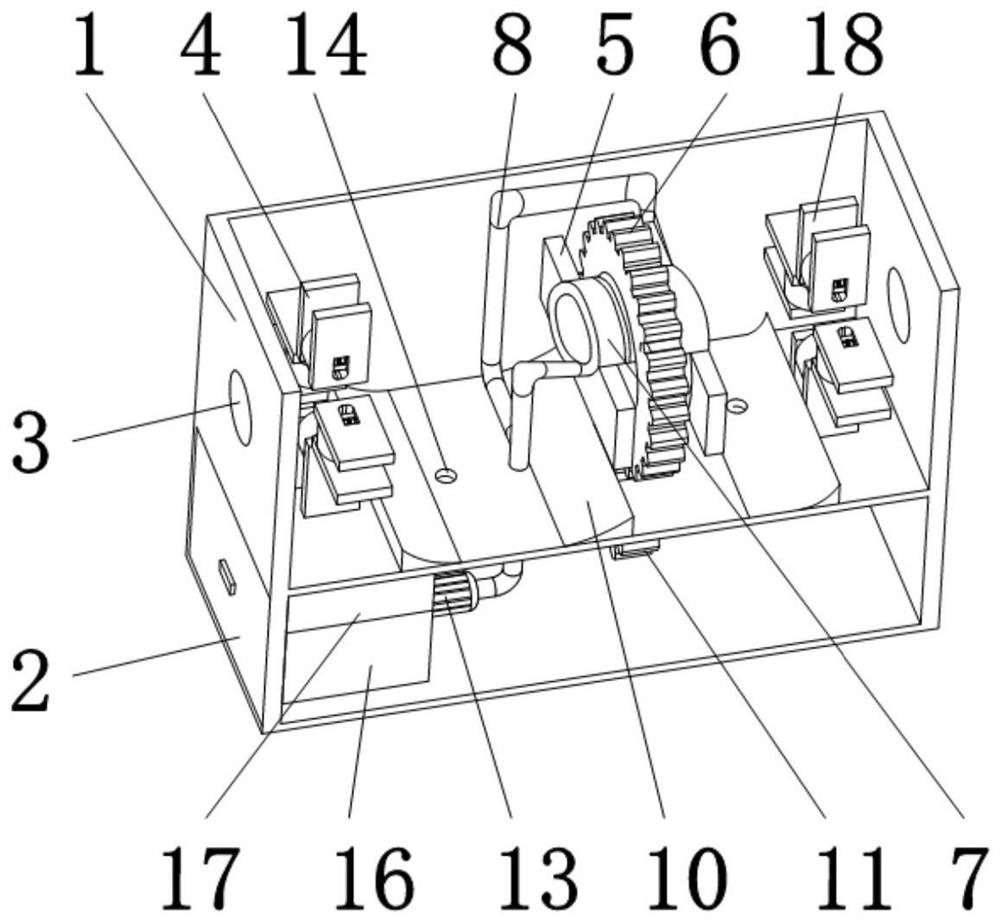

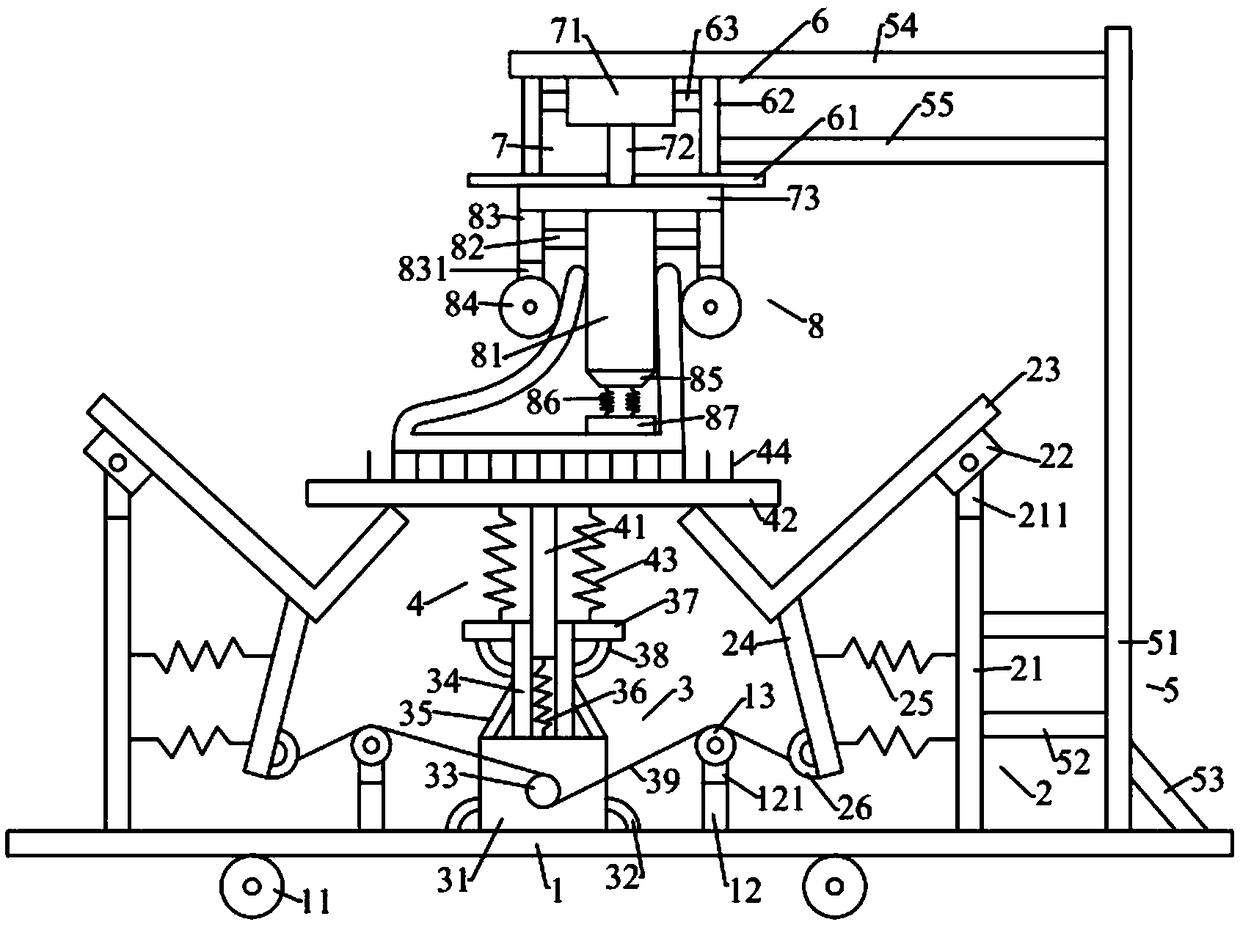

Stirring device for cleaning traditional Chinese medicines

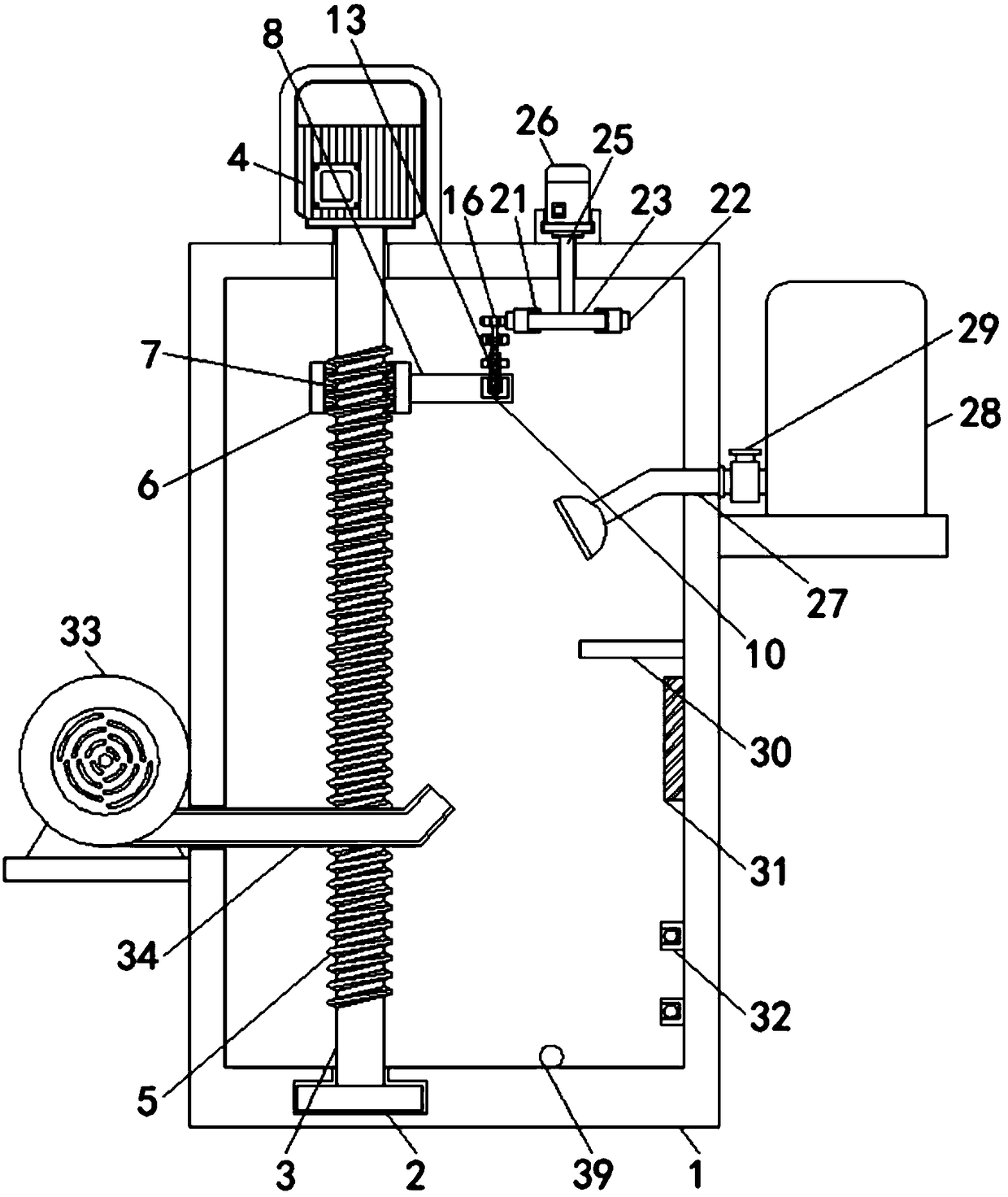

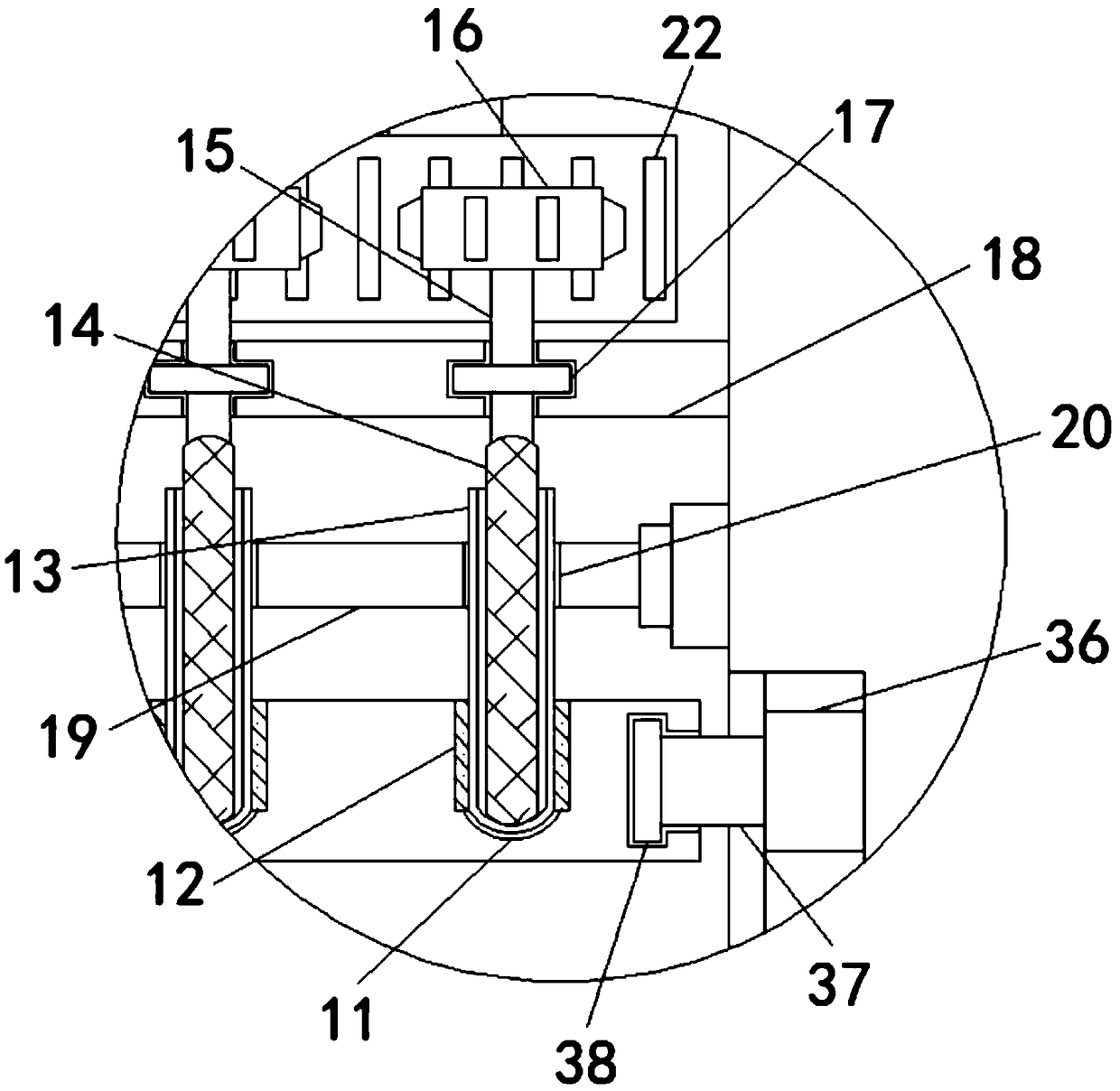

ActiveCN113714196AStir wellThorough and effective cleaningCleaning using liquidsAgainst vector-borne diseasesStructural engineeringMechanical engineering

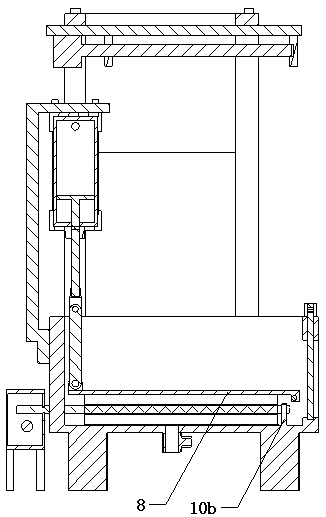

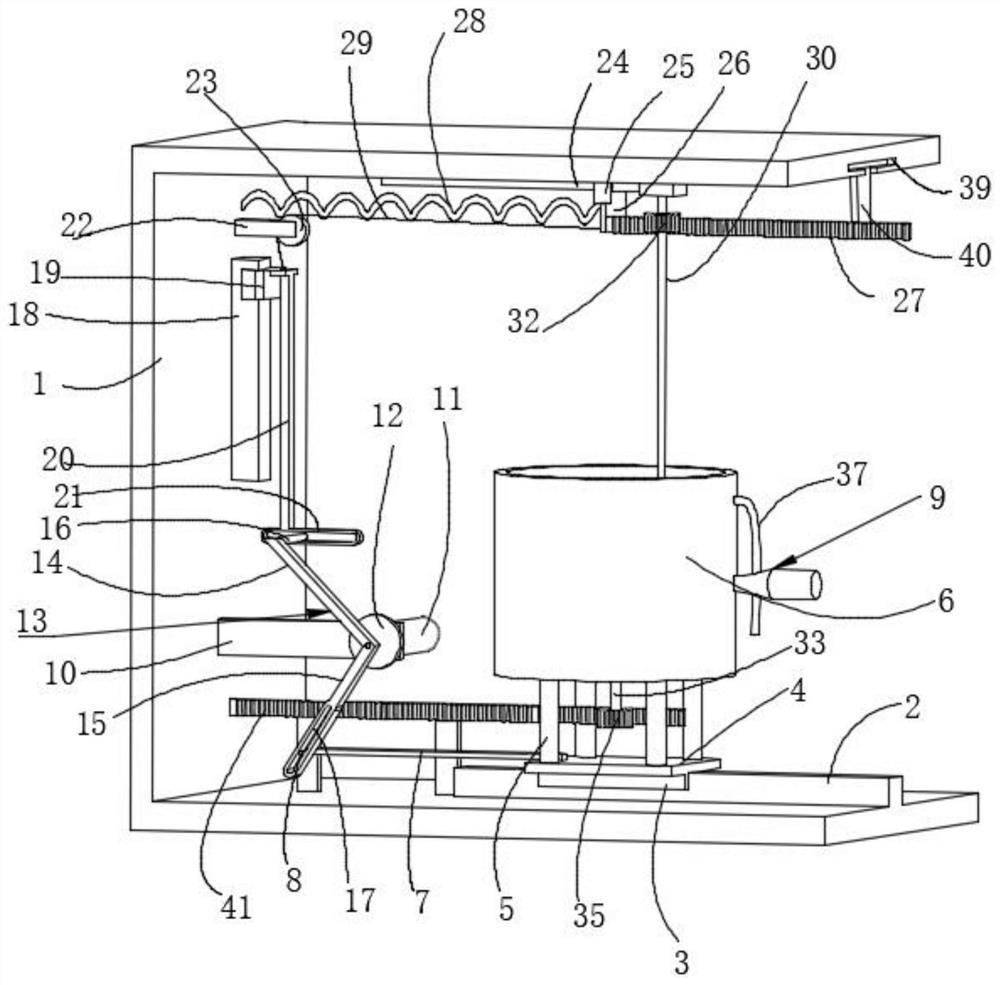

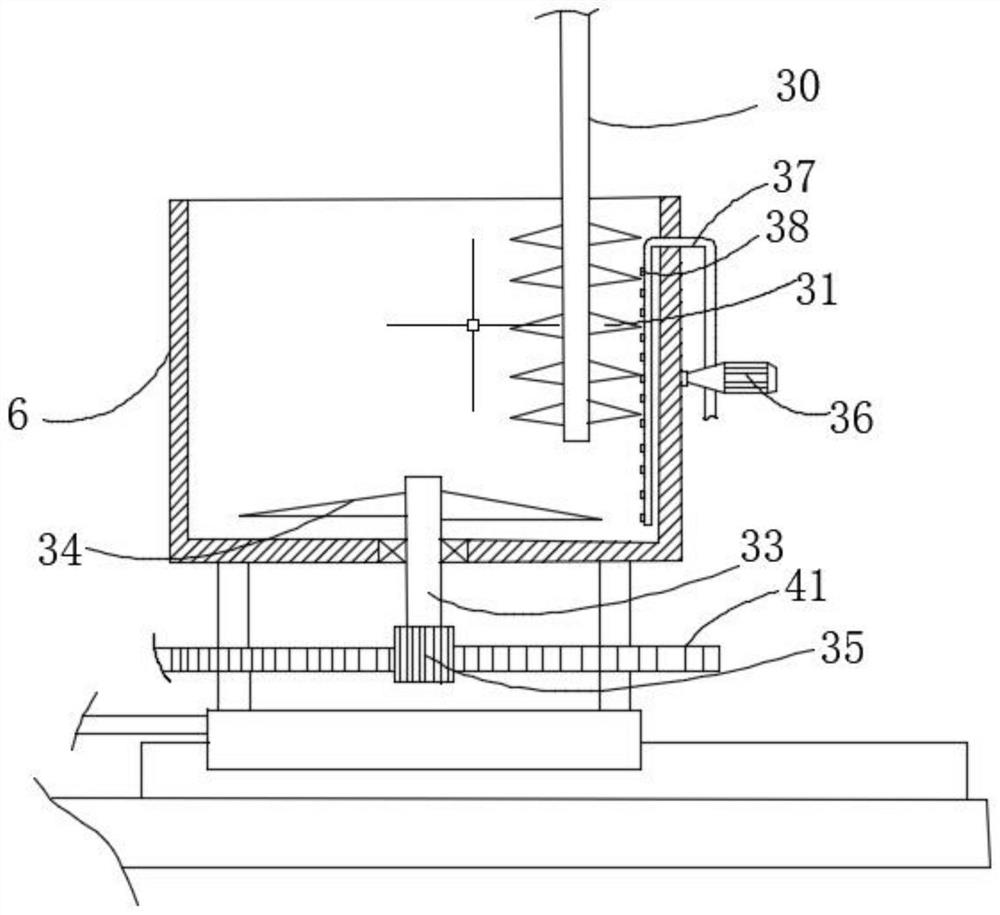

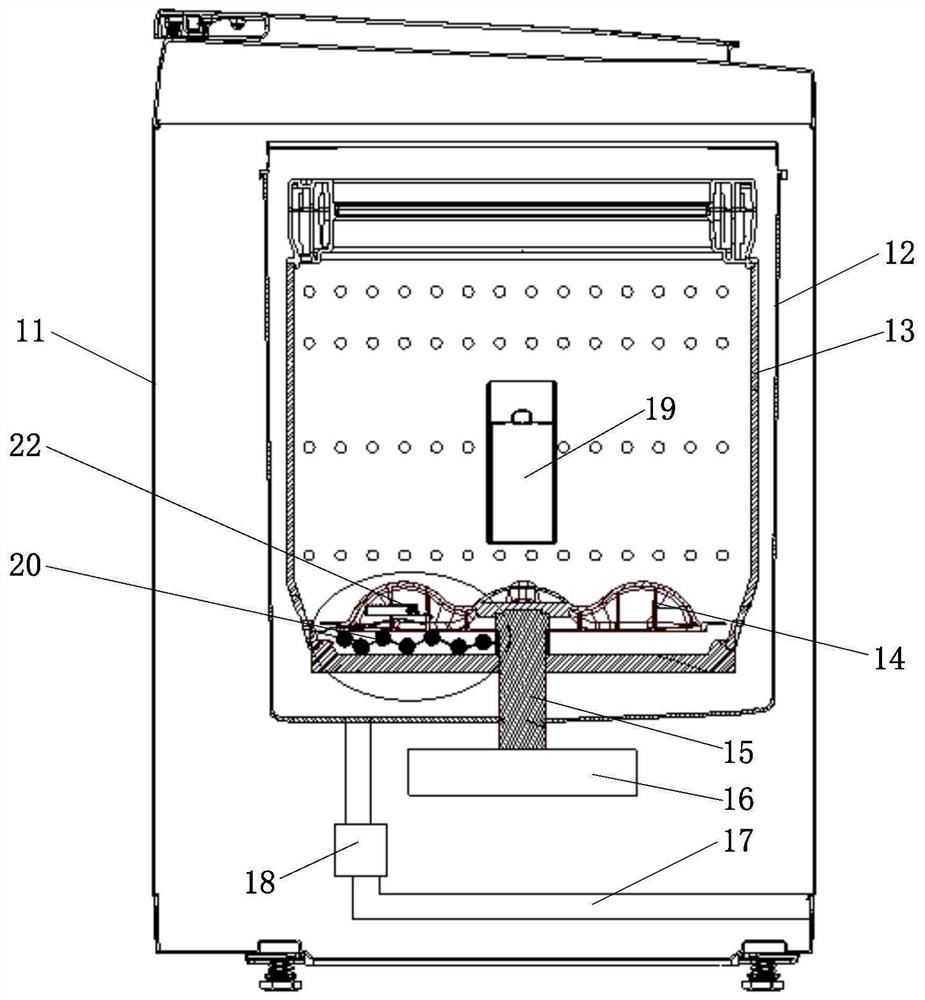

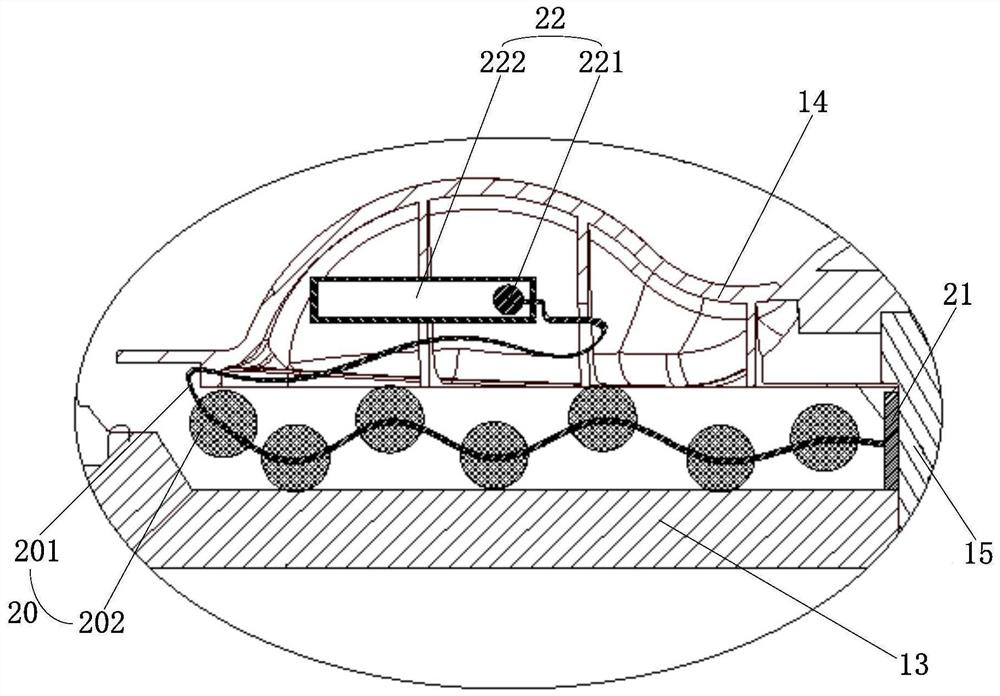

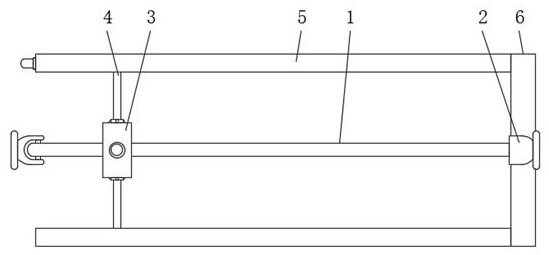

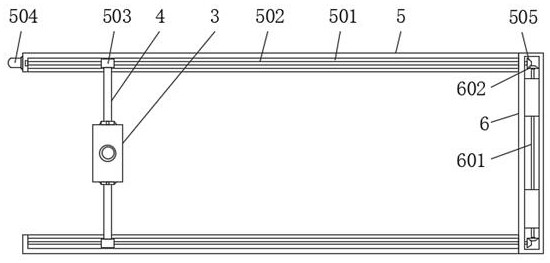

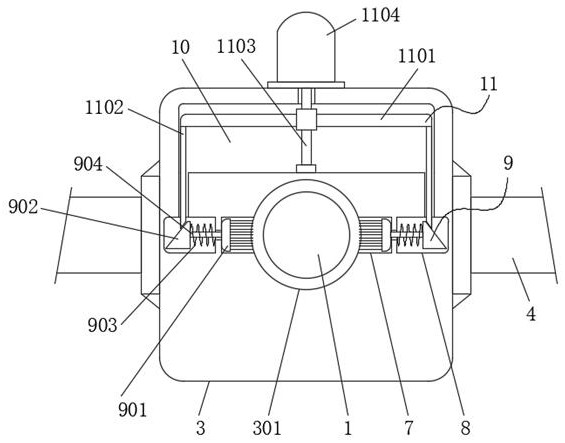

The invention discloses a stirring device for cleaning traditional Chinese medicines. The stirring device comprises a main body frame (1), a first sliding rail (2) is arranged on the main body frame (1), a first sliding block (3) is arranged on the first sliding rail (2), a supporting plate (4) is arranged on the first sliding block (3), a column (5) is arranged on the supporting plate (4), a mixing box (6) is arranged on the column (5), a connecting rod (7) is arranged at one side of the supporting plate (4), a push shaft (8) is arranged on the connecting rod (7), a washing mechanism (9) is arranged at the side portion of the mixing box (6), a side support (10) is arranged on a side plate of the main body frame (1), and a motor (11) is arranged on the side support (10). The cleaning device can uniformly turn over traditional Chinese medicinal materials, and the cleaning effect is improved.

Owner:湖南省自然堂中药饮片有限公司

Impeller type washing machine with self-cleaning device

PendingCN112853668AEasy to cleanAvoid the problem of not being able to clean the pulsatorHollow article cleaningWashing machine with receptaclesLaundry washing machineDrive shaft

The invention belongs to the technical field of washing, and particularly provides an impeller type washing machine with a self-cleaning device. The invention aims to solve the problem that the bottom of an impeller and the inner wall of an inner drum cannot be cleaned through an existing cleaning mode of the impeller type washing machine. Therefore, the impeller type washing machine comprises an inner drum, an impeller arranged in the inner drum and a driving shaft connected to the impeller.The self-cleaning device comprises a cleaning chain arranged between the impeller and the inner drum, wherein one end of the cleaning chain is connected with the driving shaft, so that when the driving shaft rotates, the cleaning chain can be driven to swing in the circumferential direction so as to clean the bottom of the impeller and the bottom of the inner drum. Due to the fact that the cleaning chain is connected with the driving shaft, the problem that the cleaning effect is affected due to the fact that the cleaning chain freely moves in a cleaning process can be effectively solved through such arrangement mode, and the problem that only one component can be cleaned by the existing cleaning mode can also be effectively solved, so that the cleaning effect of the self-cleaning device is greatly improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

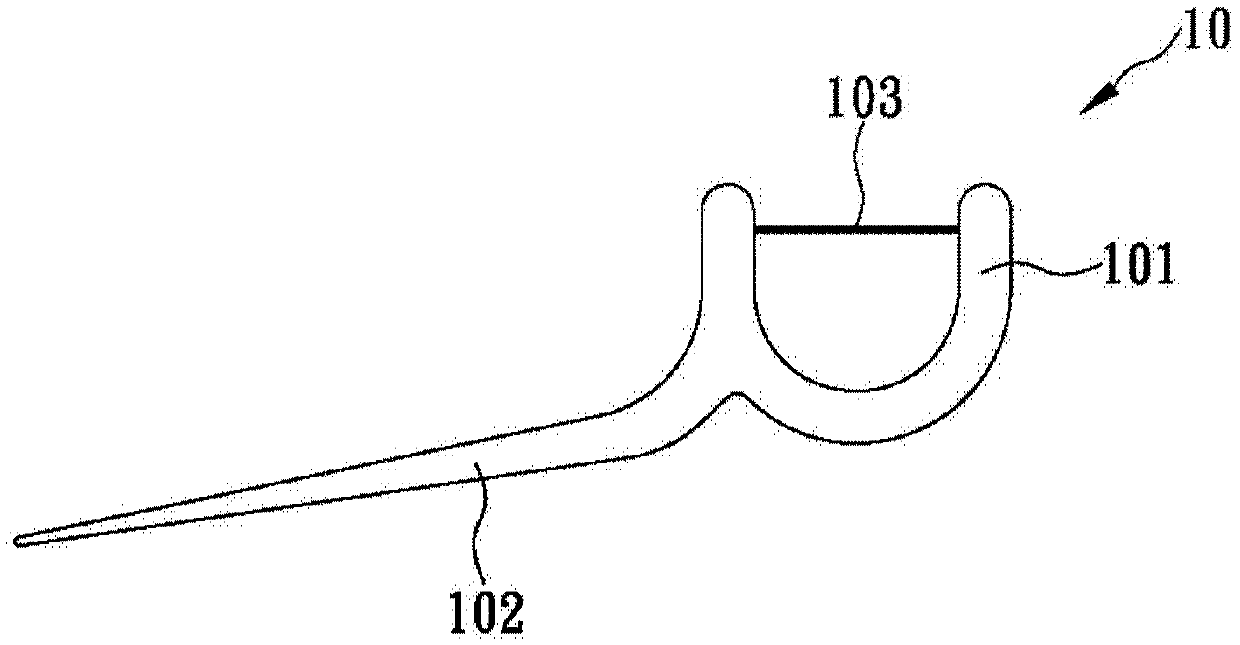

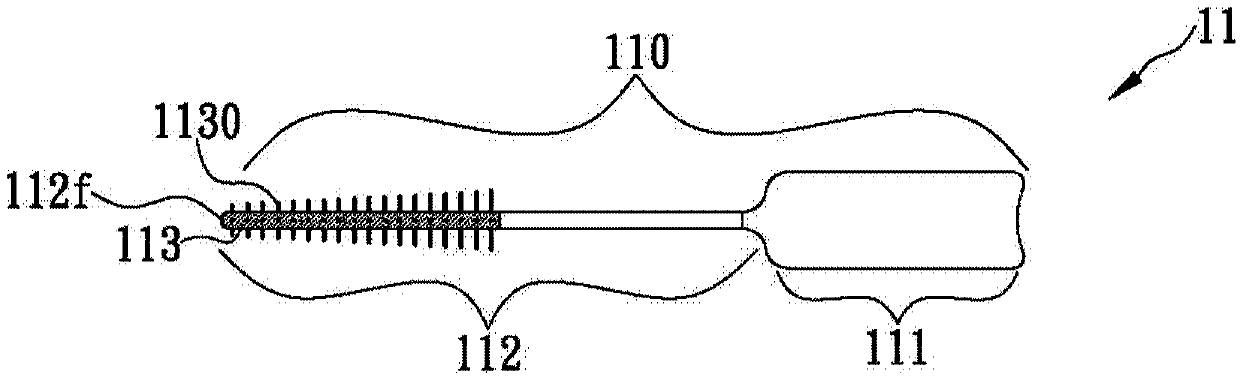

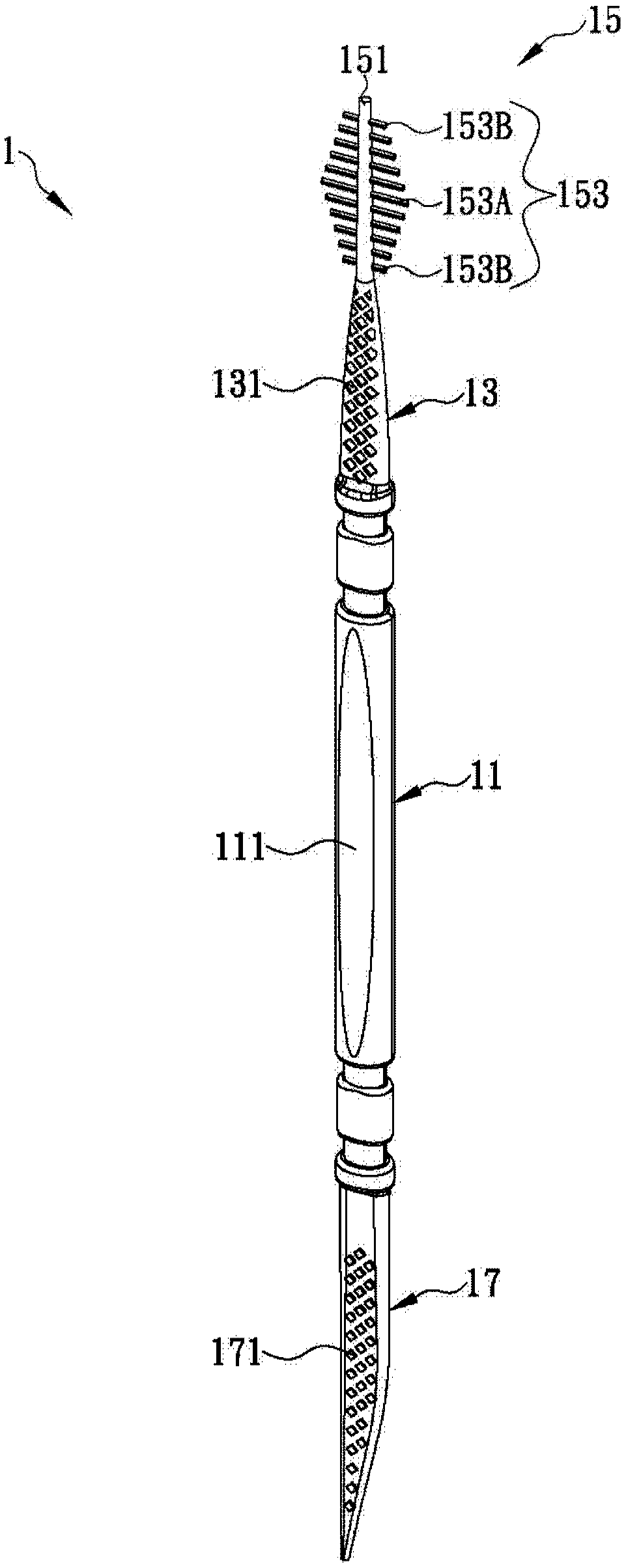

Three-in-one tooth cleaning rod with toothpick, interdental brush and dental floss pick structure

ActiveCN110623764ASmooth and accurate deliveryEasy and precise insertionGum massageBrushesBristleDental floss

The invention provides a three-in-one tooth cleaning rod with a toothpick, an interdental brush and a dental floss rod structure. The tooth cleaning rod comprises a body part and an interdental elastic bristle part, wherein the body part is made of a first plasticizing material through integral injection molding; a related structure of the dental floss pick is arranged at one end, the other end ofthe toothpick is provided with a toothpick related structure, furthermore, the interdental elastic bristle part is made of a second plasticizing material, the injection molding part is integrally formed on the outer edge of the body part close to the other end, a plurality of bristles are formed; the hardness of the second plasticizing material is smaller than that of the first plasticizing material, therefore, no matter what kind of tooth cleaning favor or habit the user belongs to, the three-in-one tooth cleaning rod needs to be carried, the effective cleaning work can be effectively and completely executed on tooth dirt, food residues or dental plaque on the surfaces and / or among teeth in the oral cavity anytime and anywhere, and therefore great help is generated for prevention of tooth decay (especially tooth decay among teeth) and periodontal diseases.

Owner:陈义聪

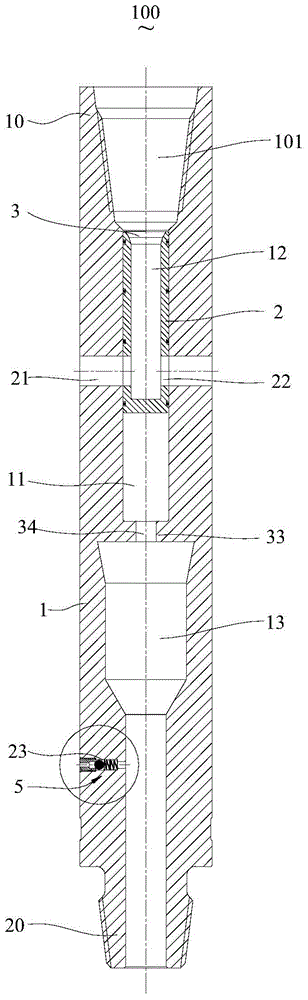

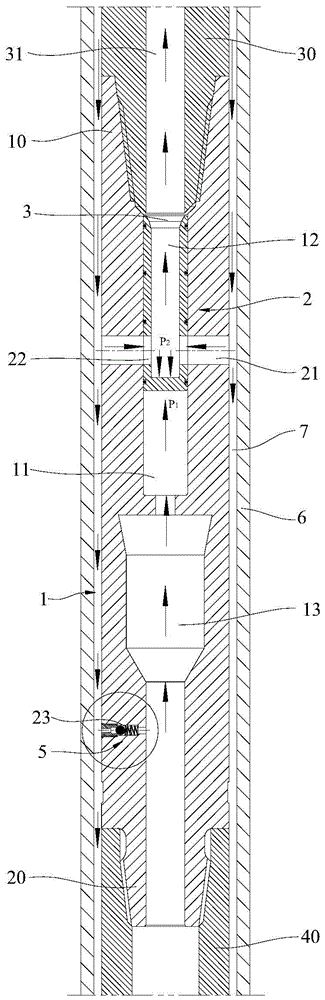

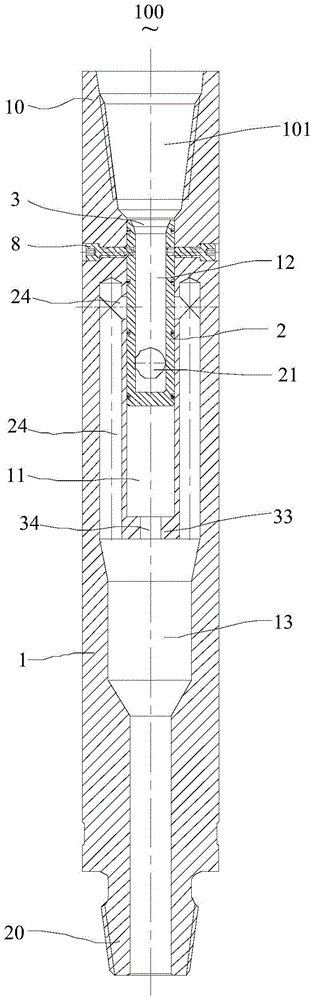

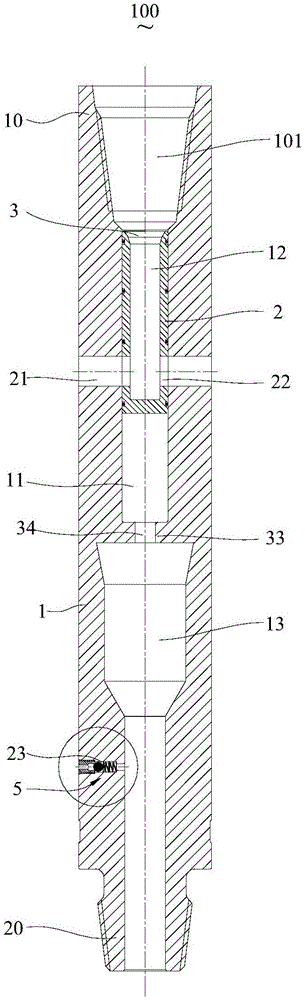

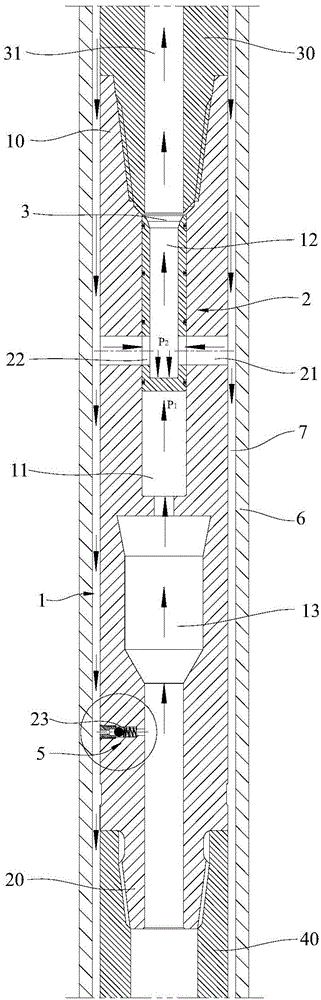

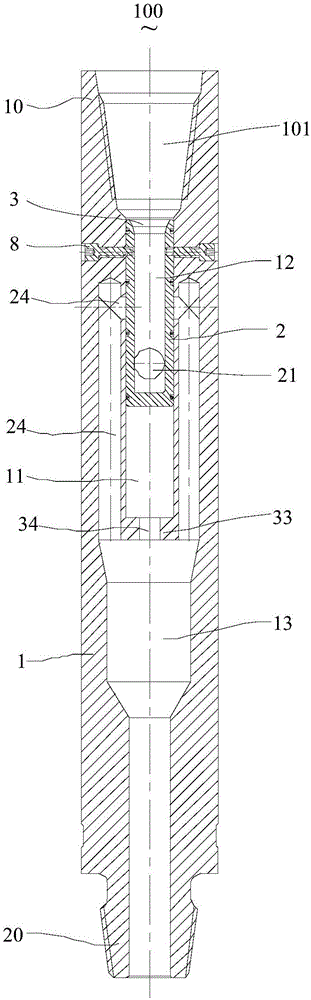

Column cleaning device

The pipe string cleaning device provided by the present application includes: a body extending lengthwise with a first end and a second end, the first end can be connected to the pipe string, and the second end can be connected to a downhole power drilling tool; The first chamber between the first end and the second end can communicate with the pipe string, and the side wall of the main body is provided with a first through hole communicating with the first chamber. In this application, by opening a first through hole communicating with the first chamber on the side wall of the body, the first chamber can communicate with the pipe string, thereby communicating with the pipe string and the annular space, forming a cleaning channel for the circulation of the cleaning liquid. The cleaning channel can change the flow direction of the cleaning liquid, realize the purpose of driving the cleaning liquid into the ground, cleaning the pipe string downhole, and returning the cleaned cleaning liquid to the ground, and overcome the time-consuming and laborious process of cleaning the pipe string on the ground in the prior art. The lack of complexity and affecting the construction process greatly improves the cleaning efficiency.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Tubular column cleaning device

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

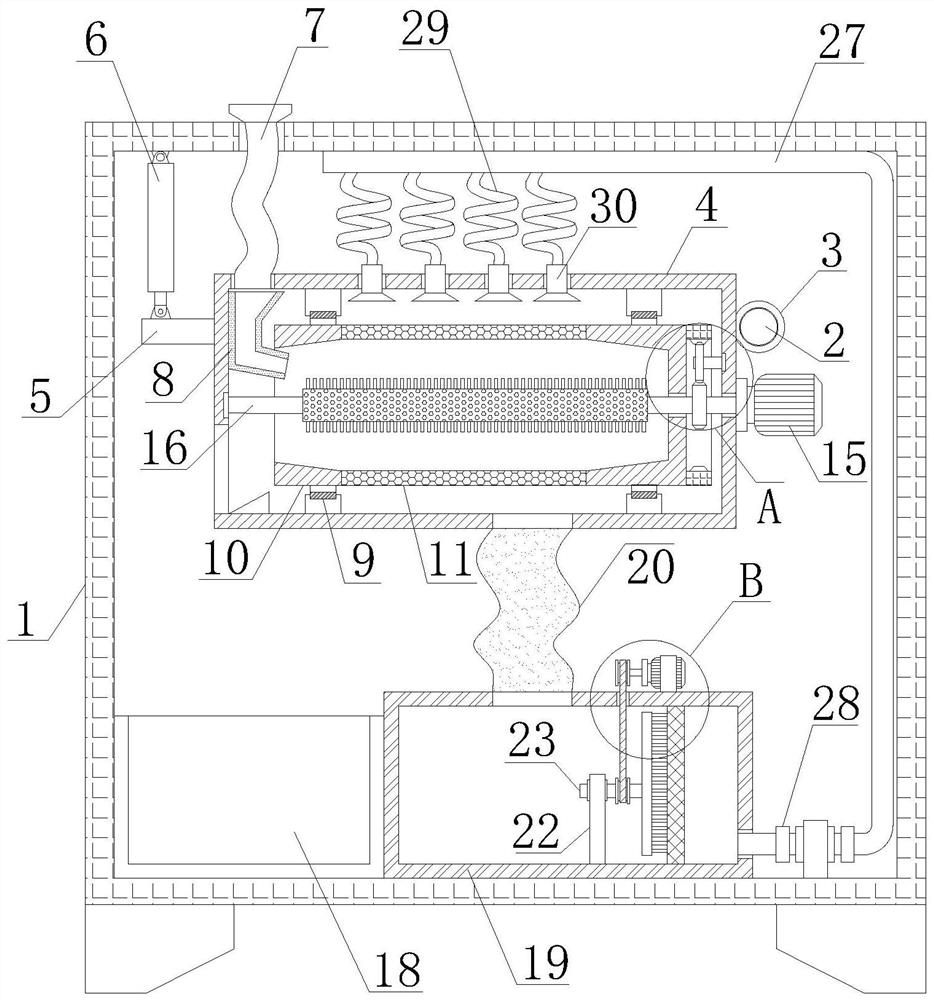

An environment-friendly glass fiber powder production and processing raw material cleaning equipment

ActiveCN111136043BThorough and effective cleaningImprove cleanlinessCleaning using toolsCleaning using liquidsGlass fiberHydraulic cylinder

The invention relates to the technical field of glass fiber powder raw material processing, and discloses an environmentally friendly glass fiber powder manufacturing and processing raw material cleaning equipment. There is the same round rod, the outer circular surface of the circular rod is movablely connected with a sleeve, and the outer circular surface of the sleeve is fixed with an inner box. The lower end of the left wall of the inner box is provided with a discharge port, and the upper end of the left wall of the inner box is A fixed plate is fixed, a hydraulic cylinder is movably hinged on the top of the fixed plate, the top of the hydraulic cylinder is movably hinged with the inner top wall of the box, and a first telescopic hose is connected between the top of the inner box and the feed port of the box. A guide cover is fixed on the upper end of the left inner wall of the inner box. The invention solves the problem that the existing cleaning equipment does not clean the glass fiber raw materials thoroughly, and a large amount of impurities still adhere to the raw materials after cleaning, resulting in poor quality of the processed products.

Owner:天长市天意玻璃制品有限公司

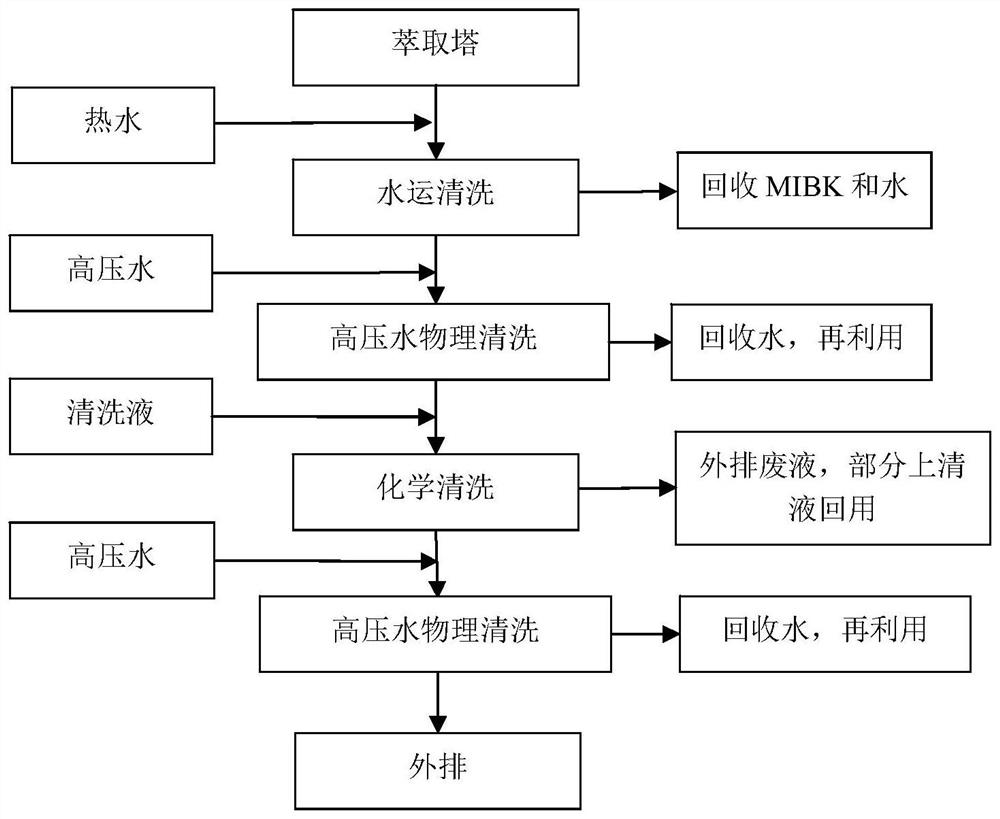

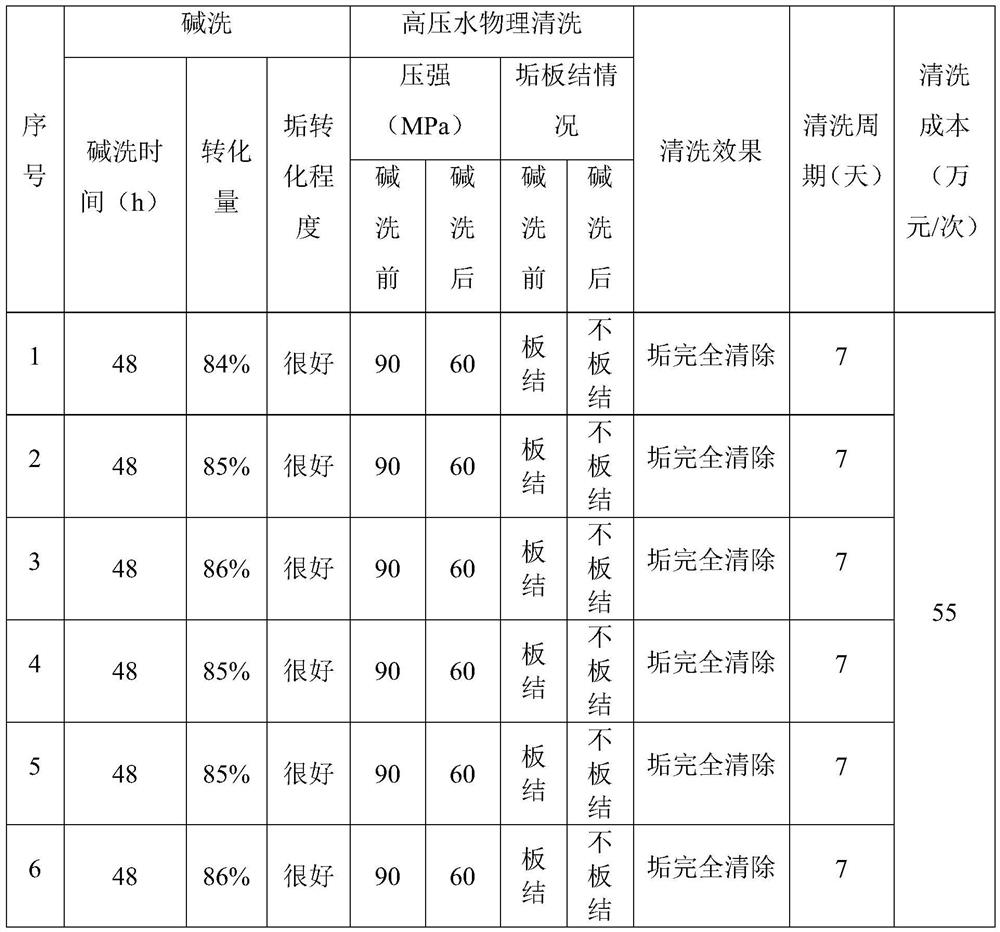

Wet-process phosphoric acid extraction tower cleaning method

ActiveCN113020064APromote full accessReduce security management costsCleaning using liquidsO-Phosphoric AcidEngineering

The invention discloses a wet-process phosphoric acid extraction tower cleaning method. The method comprises the following steps of performing high-pressure water physical cleaning on the interior of an extraction tower, and opening a channel in dirt; performing chemical cleaning on the interior of the extraction tower by adopting a cleaning solution with the temperature of 70 DEG C or above, and controlling the pressure intensity of the cleaning solution to be 0.05 MPa or above in the chemical cleaning process, so that the hard scale is converted into soft scale; and performing high-pressure water physical cleaning on the interior of the extraction tower, so that soft dirt falls off and is discharged outwards, and finishing cleaning of the extraction tower. The cleaning method has the advantages of being short in cleaning period, low in cleaning cost, high in cleaning efficiency, good in cleaning effect, safe, environmentally friendly and the like, efficient and thorough cleaning of the wet-process phosphoric acid extraction tower can be achieved, the use value is high, and the application prospect is good.

Owner:湖南瑞寰环境科技有限公司

Carbon fiber transmission shaft with high torque

PendingCN112224018AEasy to useReduce aging speedVehicle cleaningControl devicesCarbon fibersUniversal joint

The invention relates to the technical field of transmission shafts, and discloses a carbon fiber transmission shaft with high torque to solve problems that dust, water and pollutants adhered to the surface of an existing automobile transmission shaft cannot be effectively cleaned, so that the aging and oxidation of the transmission shaft are accelerated; the transmission shaft comprises a transmission shaft body, and universal joints are mounted at the two ends of the transmission shaft body; the surface of the transmission shaft body is sleeved with a sleeve block, connecting rods are fixedly mounted on the two sides of the sleeve block, a mounting plate is mounted at one end of each of the two connecting rods, a transmission connecting plate is fixedly mounted between one ends of the two mounting plates, storage grooves are symmetrically formed in the middle of the sleeve block, and reset grooves are formed in one sides of the two storage grooves. The carbon fiber transmission shaftwith the high torque has effective cleaning measures, adhered dust, water and pollutants can be cleaned effectively, effective use of the transmission shaft is guaranteed, the aging and oxidation speed of the transmission shaft is reduced, and the service life of the transmission shaft is prolonged.

Owner:吉林市圣赢碳纤维制品科技有限公司

A car parts cleaning device

ActiveCN109013499BReduce labor burdenThorough and effective cleaningCleaning using toolsCleaning using liquidsMotor vehicle partReciprocating motion

Owner:日照新睿招商发展有限公司

Road-friendly unmanned electric thin ice removing vehicle

PendingCN113737707ARealize intelligenceReasonable allocation of human resourcesAlarmsElectric transmission signalling systemsEngineeringRoad surface

The invention discloses a pavement-friendly unmanned electric thin ice removing vehicle, and belongs to the technical field of cleaning equipment. The pavement-friendly unmanned electric thin ice removing vehicle comprises a vehicle body; a computer; a sensing module which is in signal connection with the computer and is used for acquiring the position of the sensing module and real-time three-dimensional information around the sensing module; a communication module which is in signal connection with a computer and communicates with the outside; a control module which is in signal connection with the computer and converts the computer signal into an executable instruction; a deicing module which executes a deicing action; a sweeping module which sweeps ice and snow residues to the side of the vehicle body; a driving module which is in signal connection with the control module and drives the vehicle body, the deicing module and the sweeping module to act according to instructions of the control module; and a power supply module which provides electric energy for the vehicle body and all the modules. According to the pavement-friendly unmanned electric thin ice removing vehicle, snow and ice removing work can be completed in a manpower-free environment, intelligence of the snow and ice removing work is achieved, the snow and ice removing work on a road surface is completed by adopting a crushing and milling deicing mechanism, and the snow and ice removing robot is rapid and effective.

Owner:NANTONG UNIVERSITY

An efficient and environmentally friendly test tube automatic decontamination equipment for chemical engineering

ActiveCN107175245BThorough and effective cleaningFully contactedHollow article cleaningProcess engineeringIndustrial engineering

Provided is an efficient and environment-friendly test tube dirt automatic removal device for chemical engineering. The device comprises a bottom board, an electric cylinder device located on the bottom board, a supporting board device located above the electric cylinder device, a cleaning device arranged on the supporting board device, a frame device located on the supporting board device, and a shaking device arranged on the frame device. The device can perform thorough and effective cleaning on test tubes, the cleaning efficiency is high, the labor intensity is low, meanwhile water and the test tubes can make sufficient contact, and the cleaning effect is remarkable; and meanwhile, the degree of automation is high, the skin is not in contact with residual reagents in the test tubes, and the security of workers is guaranteed.

Owner:ZHEJIANG GUOGUANG BIOCHEM CO LTD

An efficient and environmentally friendly cleaning equipment for leather shoe soles

ActiveCN106859571BThorough and effective cleaningEfficient cleaningFootwear cleanersEngineeringIdler-wheel

The invention discloses efficient and environment-friendly leather shoe insole sweeping equipment. The efficient and environment-friendly leather shoe insole sweeping equipment comprises a base plate, an adjusting device, a first motor device, a sweeping device, a first support device, a second support device, a second motor device and a fixed device, wherein the base plate is provided with a universal wheel, a first vertical rod and a first idler wheel, the adjusting device comprises a first supporting rod, a first connecting block, an adjusting support, a first fixed rod, a first spring and a first connecting ring, the first motor device comprises a first motor, a second fixed rod, a first output shaft, a locating frame, a third fixed rod, a second spring, a first transverse rod, a fourth fixed rod and a first pulling cord, the sweeping device comprises a movable rod, a brushing disc, a third spring, and brushing fur, the first support device comprises a second supporting rod, a fifth fixed rod, a sixth fixed rod, a second transverse rod and a third transverse rod, and the second support device comprises a transverse plate, a seventh fixed rod and an eighth fixed rod. By means of the efficient and environment-friendly leather shoe insole sweeping equipment, the leather shoe insole can be thorough and effectively cleaned, the sweeping efficiency is high, and the sweeping effect is good.

Owner:盐城永安科技有限公司

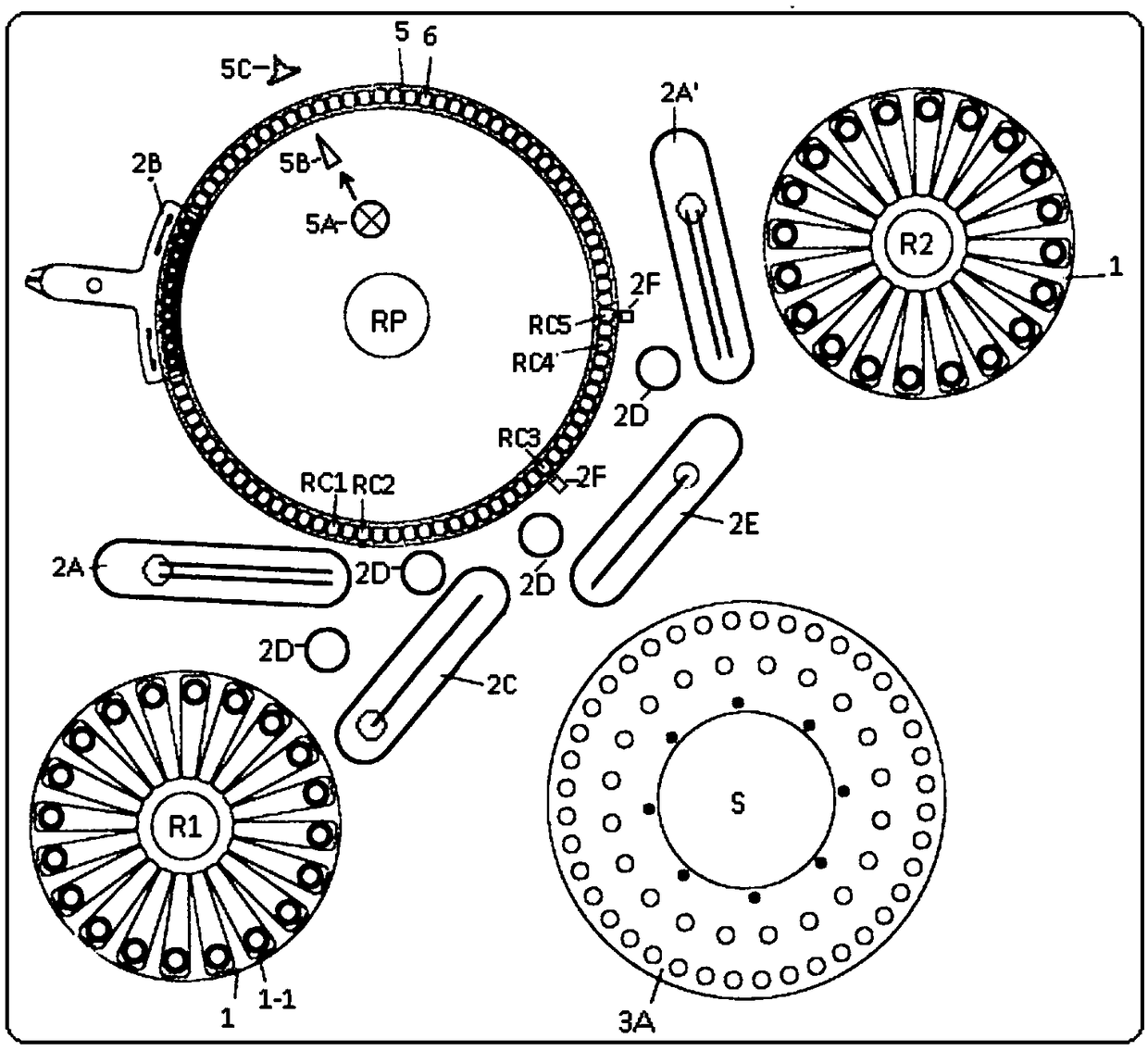

Fully automatic biochemical analyzer and method with multi-needle rotation device

ActiveCN106841646BGuaranteed working speedShorten cleaning timeMaterial analysisComputer sciencePollution

Owner:CLINDIAG SYSTEMS CO LTD

Machine tool for deburring inner holes of shaft parts and deburring process for inner holes of shaft parts

The invention relates to a shaft part inner bore deburring machine tool and a shaft part inner bore deburring process, and in particular to the shaft part inner bore deburring machine tool and the shaft part inner bore deburring process which relate to the field of machining of camshaft parts. The shaft part inner bore deburring machine tool provided by the invention comprises a worktable plate, apart positioning and clamping mechanism, a part station converting mechanism, a flexible reamer deburring device and a steel cable deburring device; and the part positioning and clamping mechanism, the part station converting mechanism, the flexible reamer deburring device and the steel cable deburring device are installed on the worktable plate. The shaft part inner bore deburring process provided by the invention comprises the following steps of: (A) positioning and clamping a part; (B) deburring by using a flexible reamer; and (C) deburring by using a steel cable. The shaft part inner boredeburring machine tool and the shaft part inner bore deburring process provided by the invention are convenient to use, realize high deburring efficiency and can effectively remove burrs of inner bores of casting and steel shaft part products.

Owner:MIANYANG BRILLIANCE RUIAN AUTOMOTIVE COMPONENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com