Cleaning device for steel pipe machining

A cleaning device and a technology for steel pipes, which are applied in the field of steel pipe processing, can solve problems such as reducing the service life of steel pipes, affecting the working environment, and reducing the quality of steel pipes, so as to achieve the effects of ensuring the working effect, improving the scope of application, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

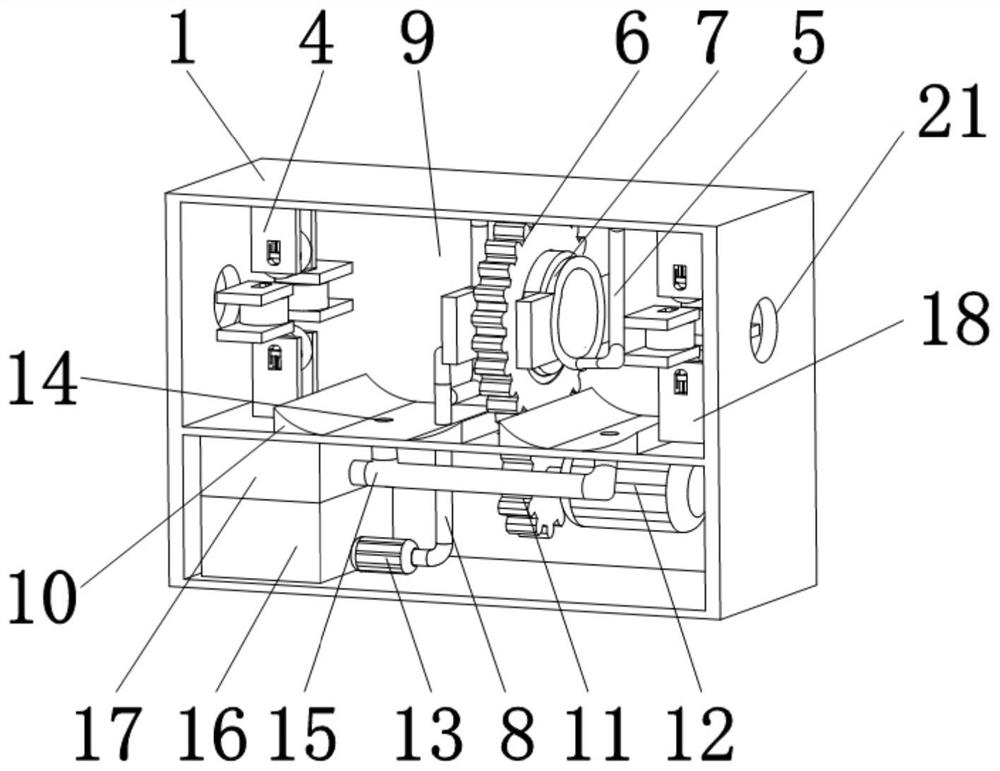

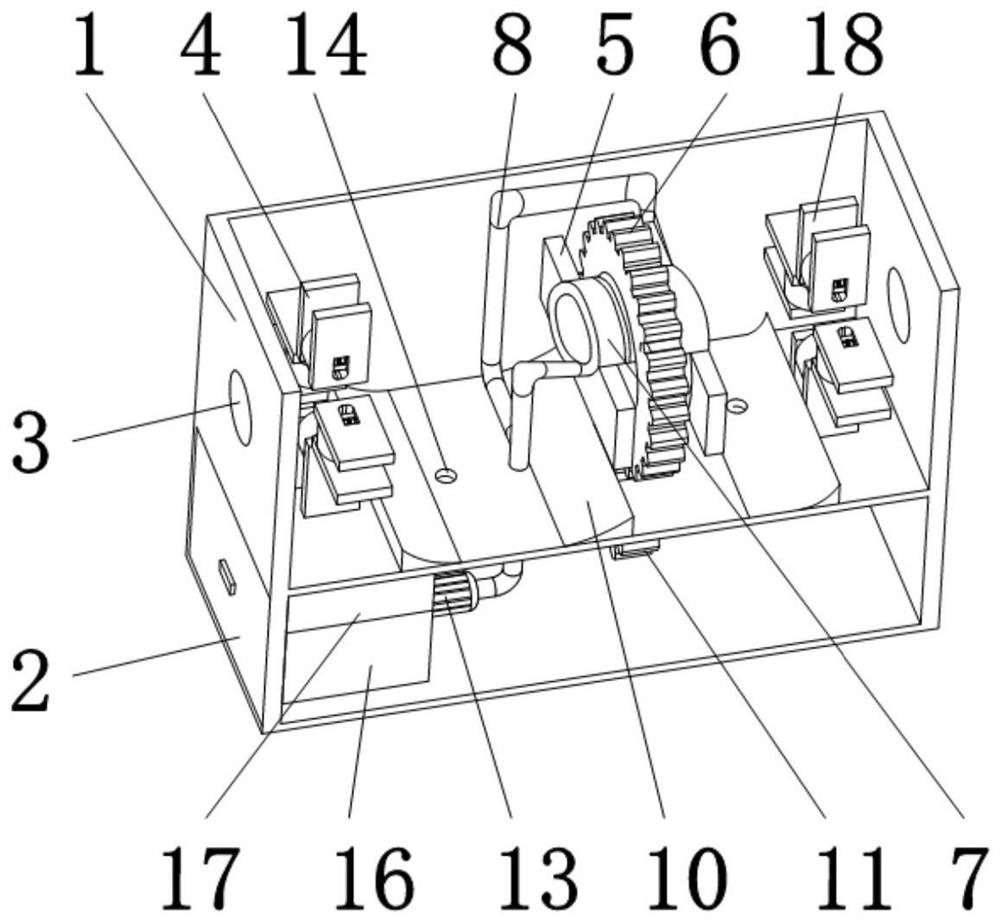

[0028] The impurities on the outer wall of the steel pipe generally include oil stains and rust, etc. In order to better clean the impurities, combined with Figure 1 to Figure 7 As shown, the present invention provides a cleaning device for steel pipe processing, including a housing 1, the housing 1 is divided into upper and lower layers, the double-layer structure can well carry out layering operation on the outer wall of the steel pipe, and facilitates the collection and treatment of impurities The lower layer of one side of the housing 1 is provided with a box door 2, and one side of the box door 2 is provided with a door handle 19. The lower layer of the housing 1 can be well cleaned through the box door 2, and one side of the housing 1 is provided with a The material inlet 3 is provided with a material outlet 21 on the other side of the housing 1 .

[0029]The inner surface of the upper layer of the housing 1 is provided with a first clamping device 4 near the side of th...

no. 2 example

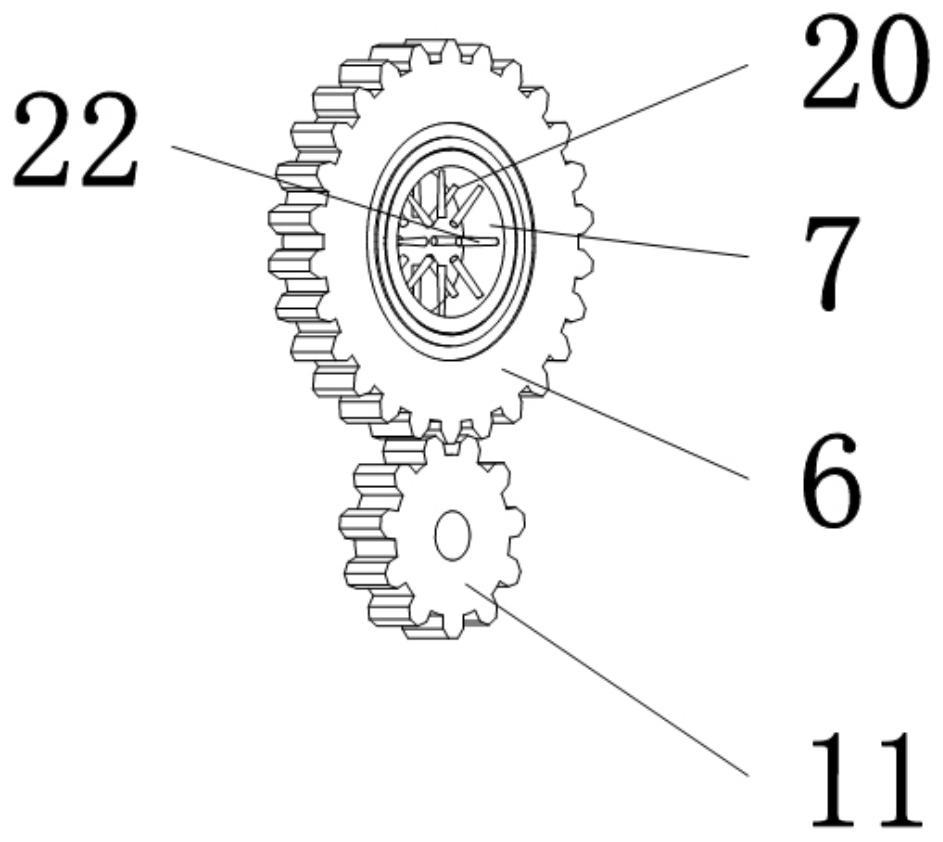

[0035] Based on the cleaning device for steel pipe processing provided in the first embodiment, the rust on the outer wall of the steel pipe is only driven by the first gear 6 to rotate the thick wire brush 20 and the thin wire brush 22 for rough grinding and fine grinding. In actual work, due to the relatively tight adhesion of the rust on the outer wall of the steel pipe, and the thickness of the outer wall of the steel pipe is not the same due to the difference in the height of the rust on the outer wall of the steel pipe, only the thick wire brush 20 and the thin wire brush 22 rotate around the outer wall of the steel pipe to grind the rust. The grinding effect is poor, and the grinding efficiency is slow, and the degree of grinding is uncontrollable. In order to solve this problem, the grinding effect of the outer wall of the steel pipe is improved, combined with Figure 8 , the cleaning device used for steel pipe processing also includes: from the side sectional view, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com