Shaft part inner bore deburring machine tool and shaft part inner bore deburring process

A technology for shaft parts and deburring, which is used in reaming devices, manufacturing tools, reaming devices, etc., to achieve accurate, thorough and effective cleaning and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

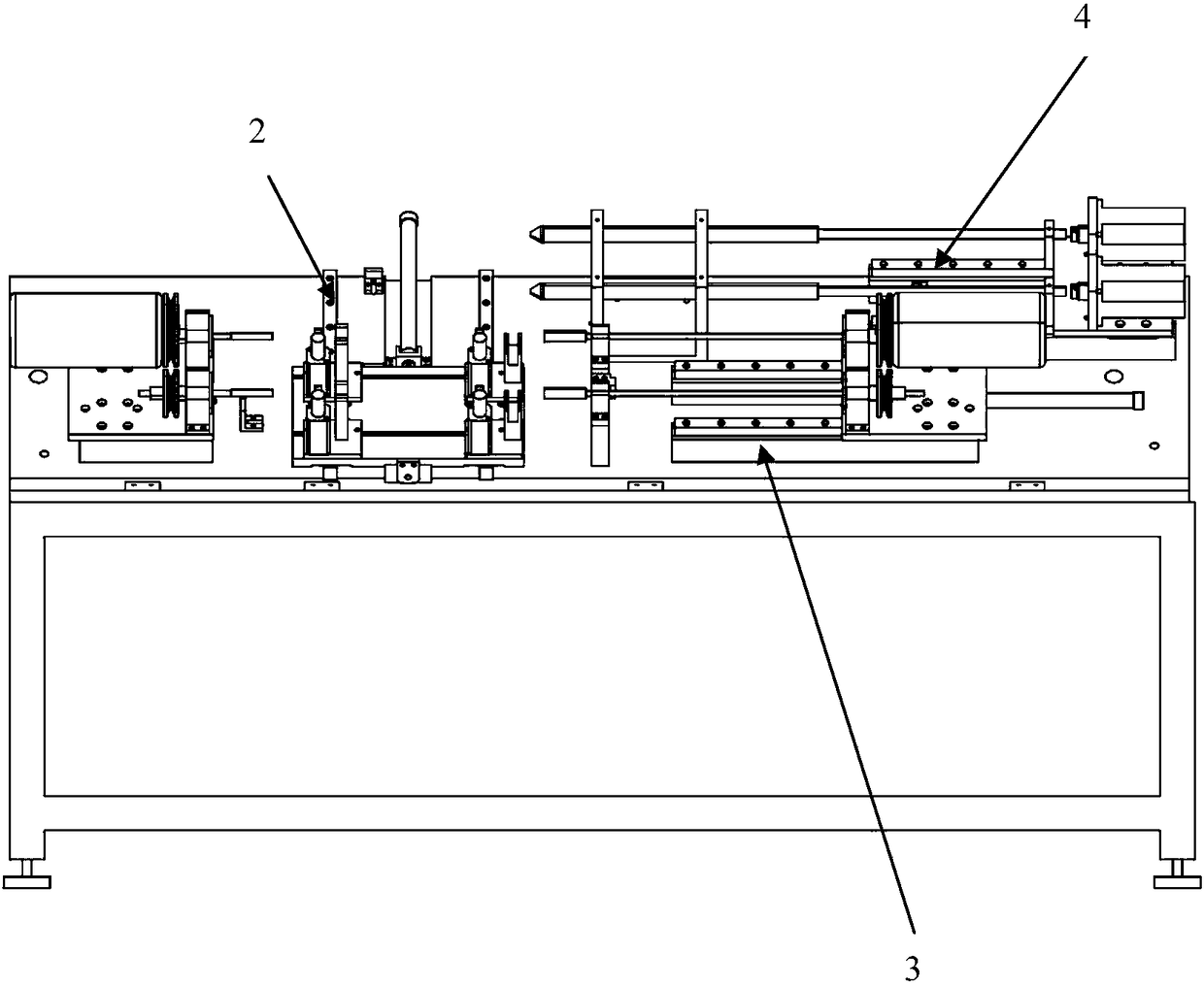

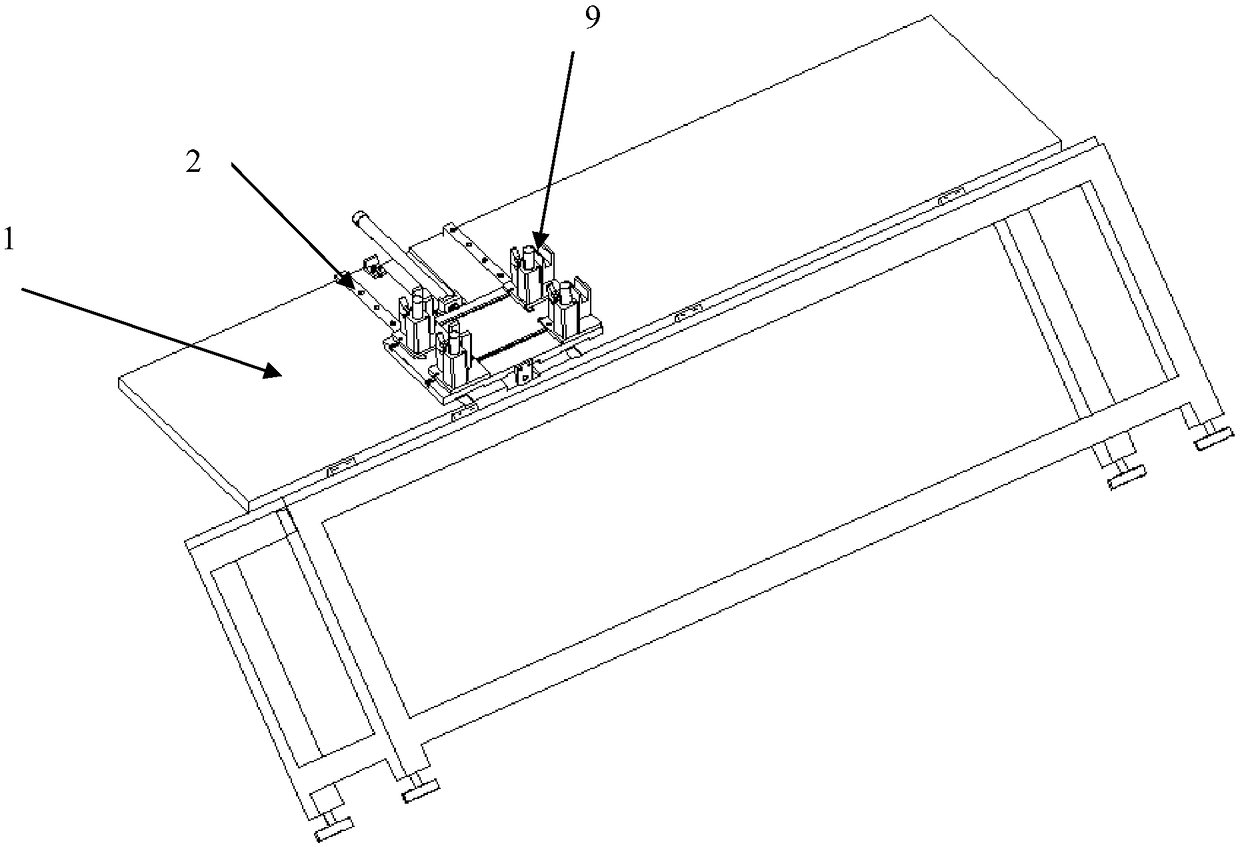

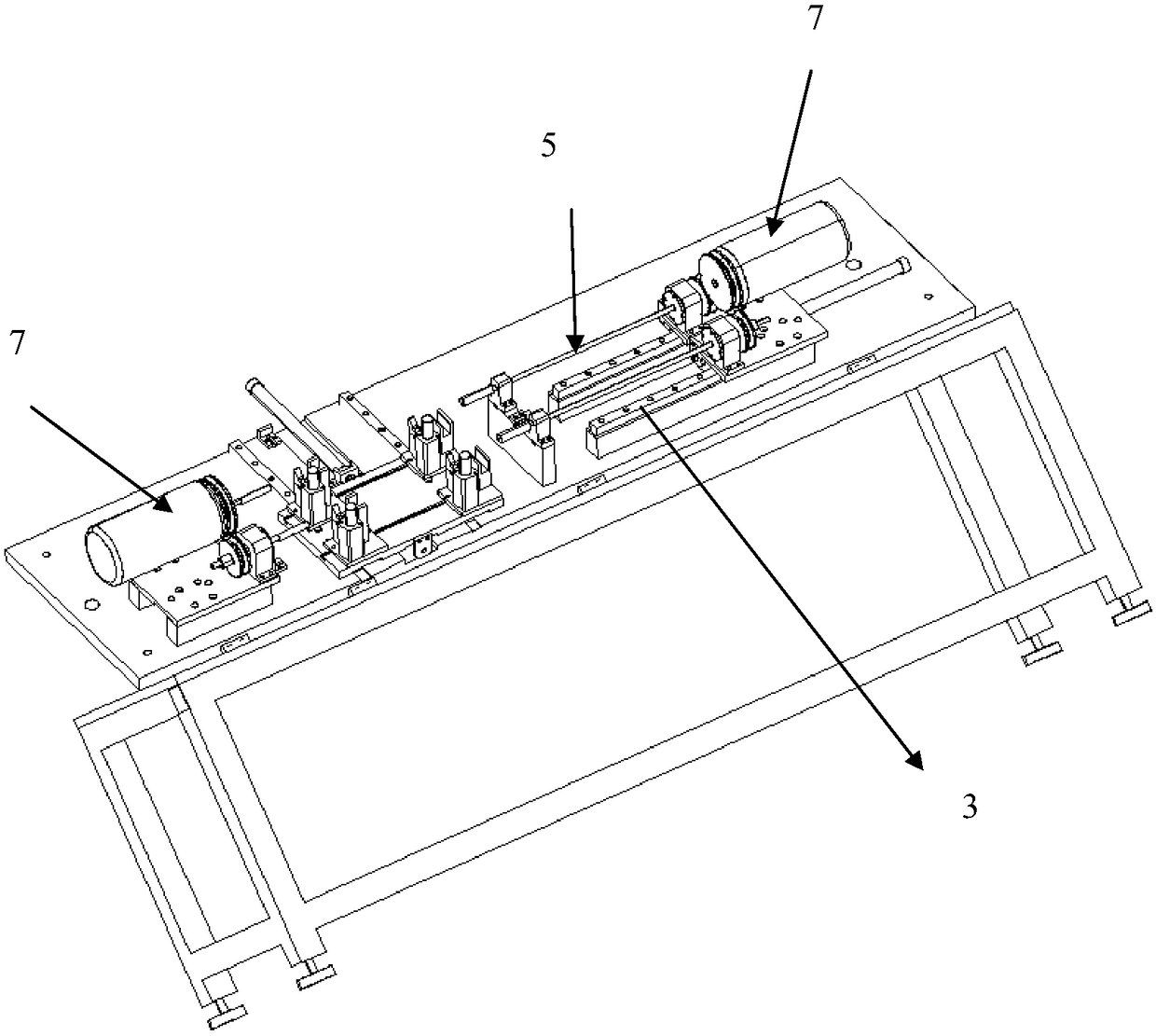

Embodiment 1

[0047] In this embodiment, a flexible reamer 5 deburring device is provided on both sides of the part positioning and clamping mechanism, so as to realize the deburring operation on the part from both ends of the part at the same time. In this embodiment, two sets of part positioning and clamping mechanisms are arranged side by side, and two sets of flexible reamers 5 and two sets of wire ropes 6 are used simultaneously, so that the two parts can be deburred at the same time. The two groups adopt the inclined bed layout to facilitate cutting. According to the characteristics of the camshaft product, the camshaft is placed horizontally on the positioning sliding plate, and the workpiece is pressed by the rotary cylinder + V-shaped block 9 + axial + circumferential positioning mechanism; the camshaft workpiece is supported by the V-shaped block 9, and the rotary cylinder Circumferential compression, the whole is on the positioning sliding plate, and the position conversion of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com