MLC blade cleaning tool

A technology for cleaning tools and blades, which is applied in the field of MLC blade cleaning tools, which can solve the problems of incomplete cleaning, contact with the surface of blade grooves, and excessive dust, and achieve the effects of saving gauze consumables, convenient use and portability, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

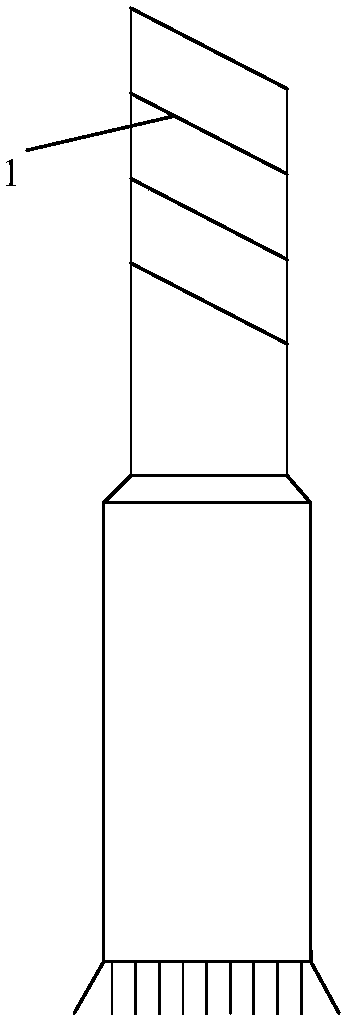

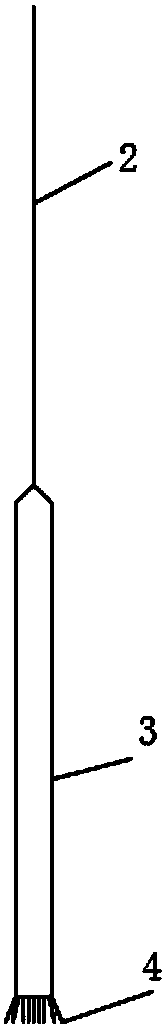

[0022] An MLC blade cleaning tool such as figure 1 with figure 2 As shown, the blade cleaning tool includes a cutter head 2, a handle 3 and a brush assembly 4, the cutter head 2 is connected to one end of the handle 3, the brush assembly 4 is connected to the other end of the handle 3, and the cutter head is a multi-section cutter head , each section of the cutter head is a sheet structure, there is an indentation 1 between each section of the cutter head, and the end of the cutter head is obliquely cut. The brush assembly 4 is detachably connected to the handle 3. The brush assembly includes a hair bundle and a hair bundle installation plate for inserting the hair bundle. The end of the handle is provided with a groove, and the hair bundle installation plate is connected with the hair bundle Grooves at the ends of the grips snap into place. The surface of the handle is provided with a frosted surface layer.

[0023] The first part is the cutter head, which is similar to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com