Patents

Literature

75results about How to "Smooth and accurate delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

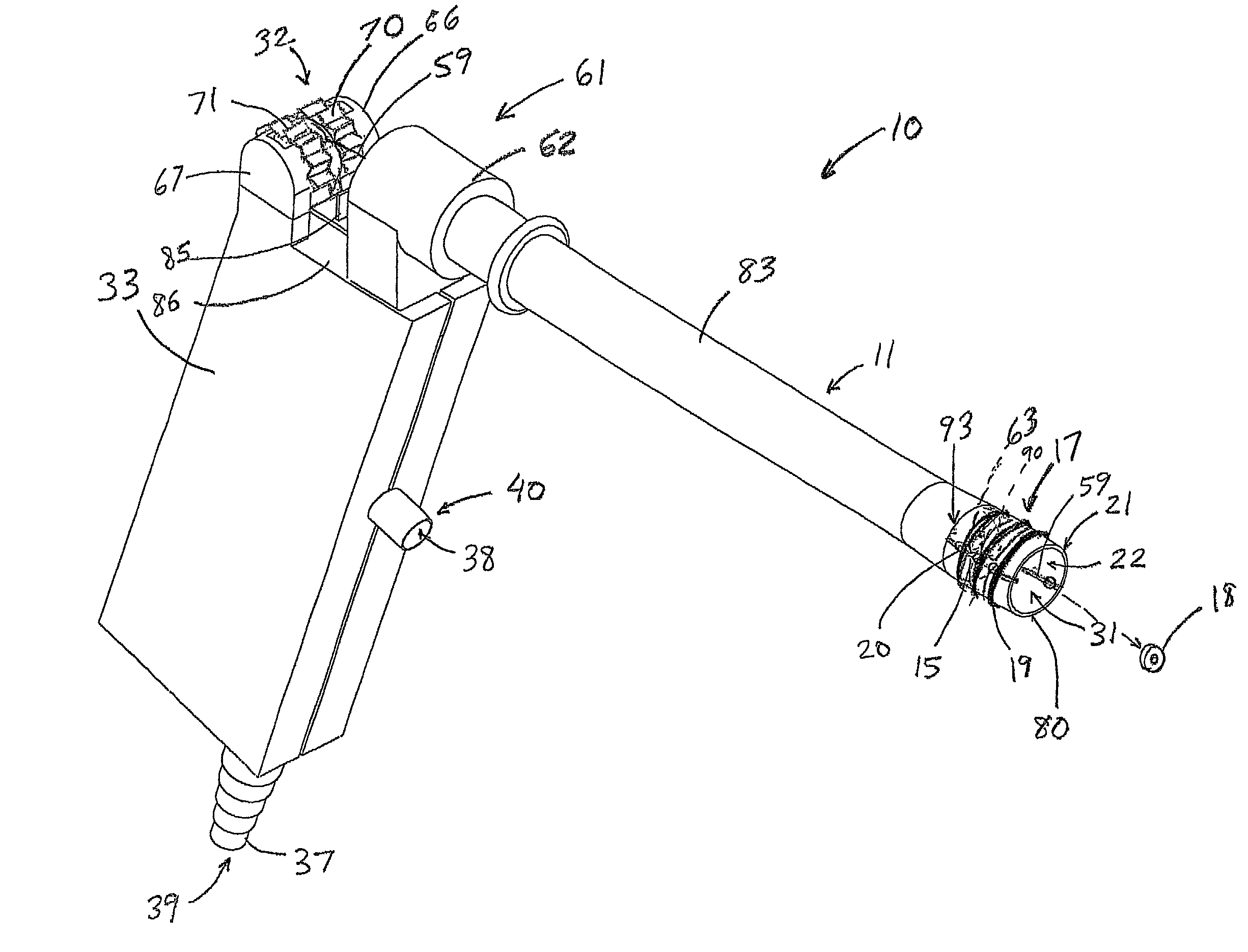

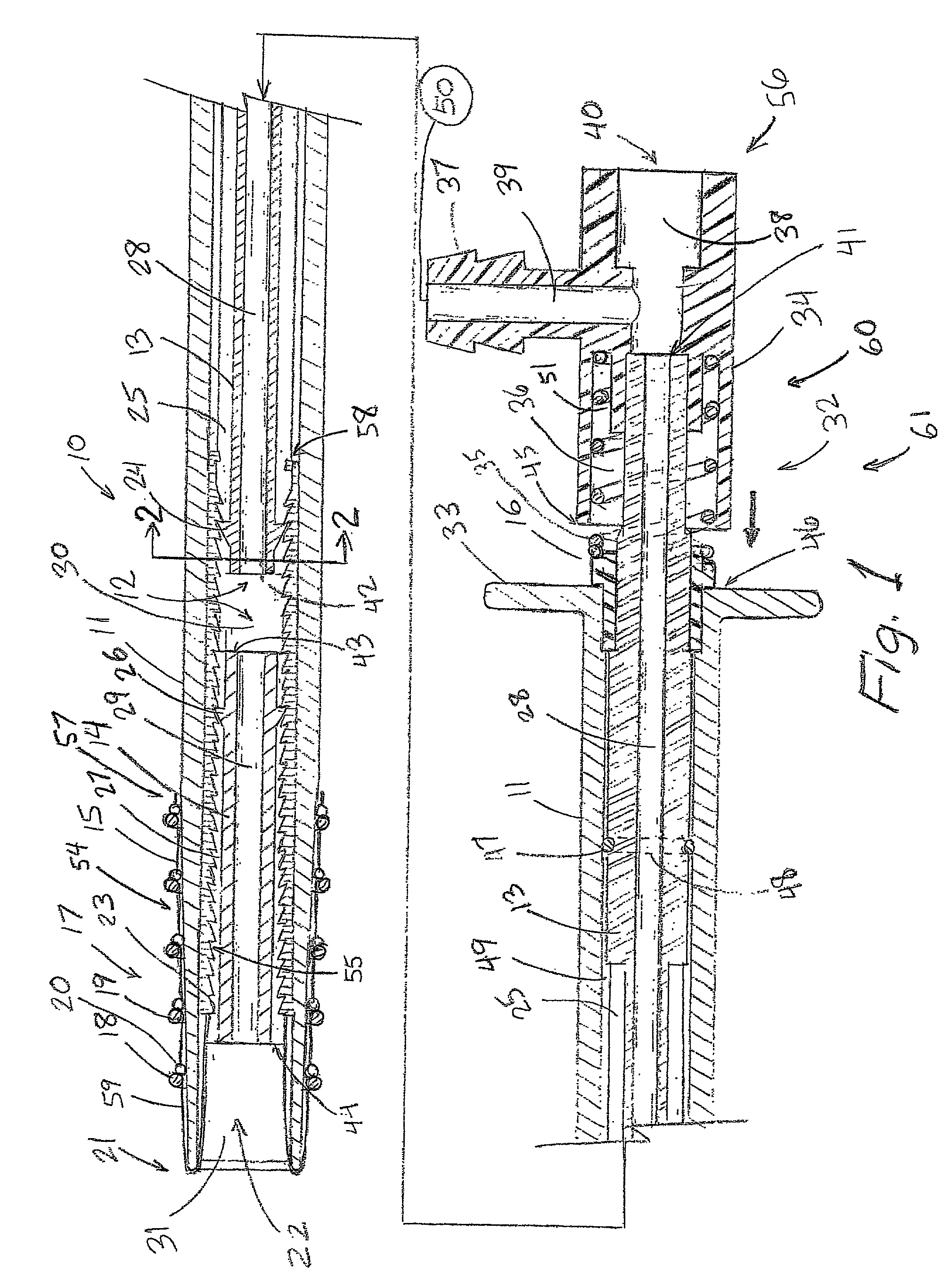

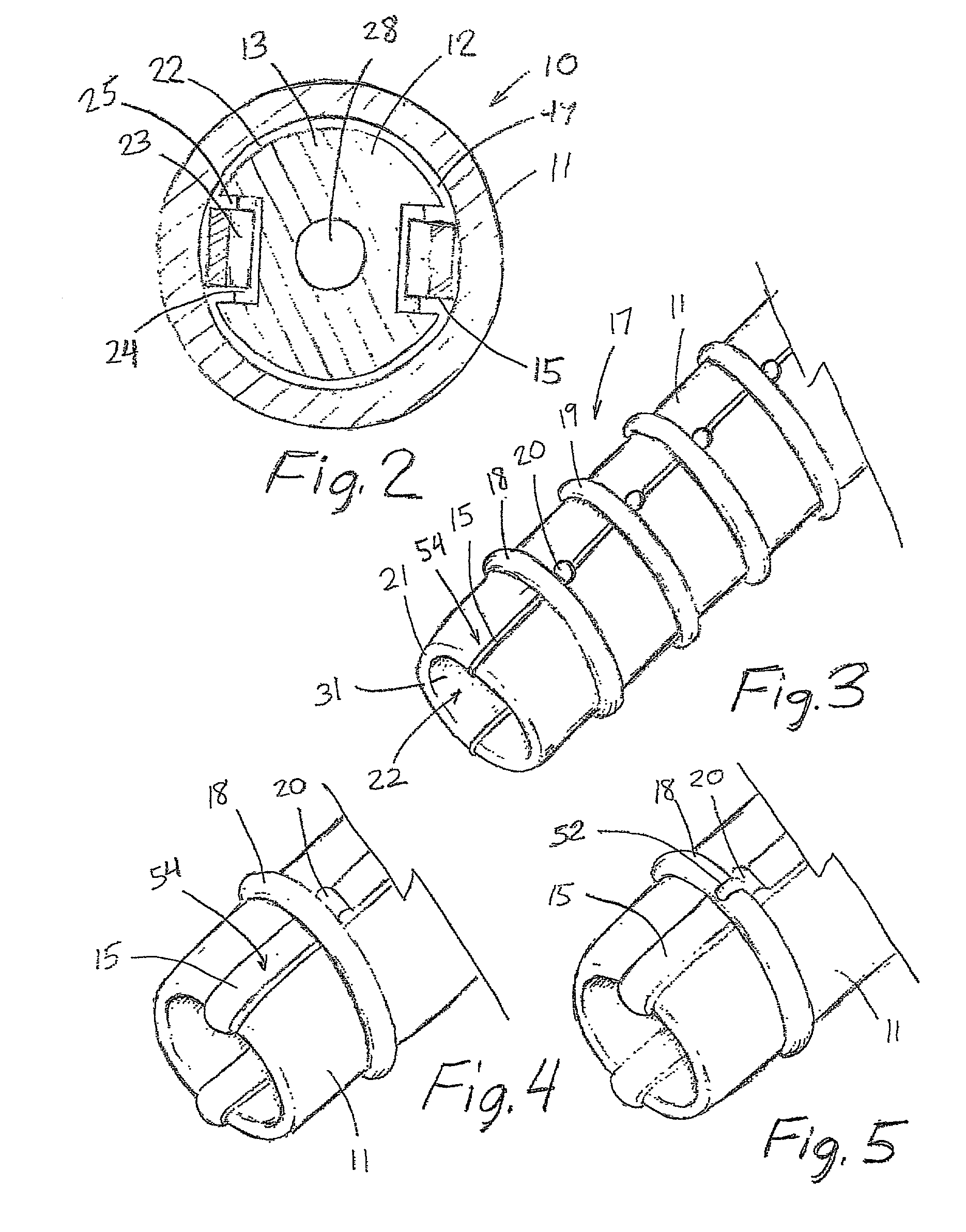

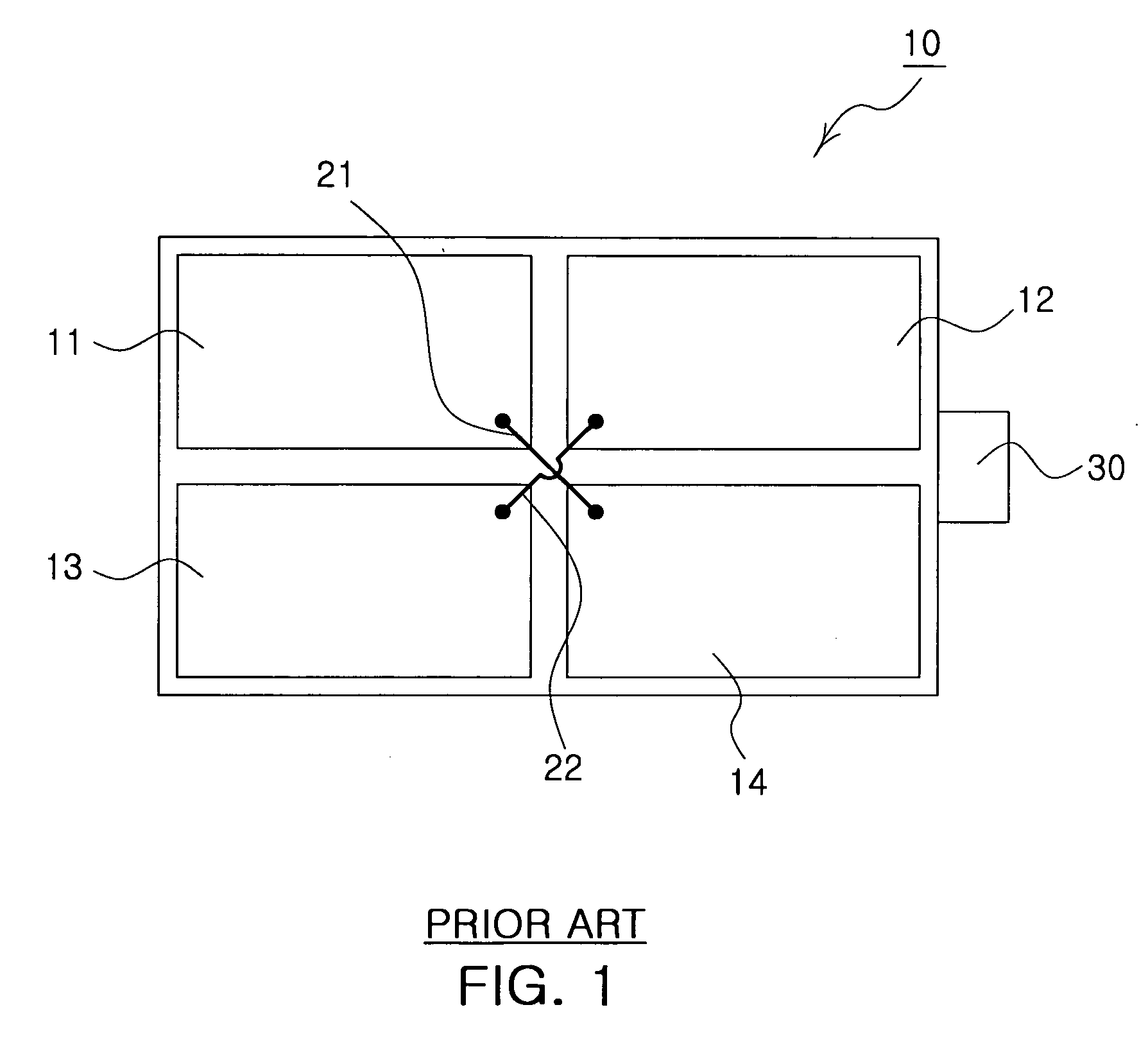

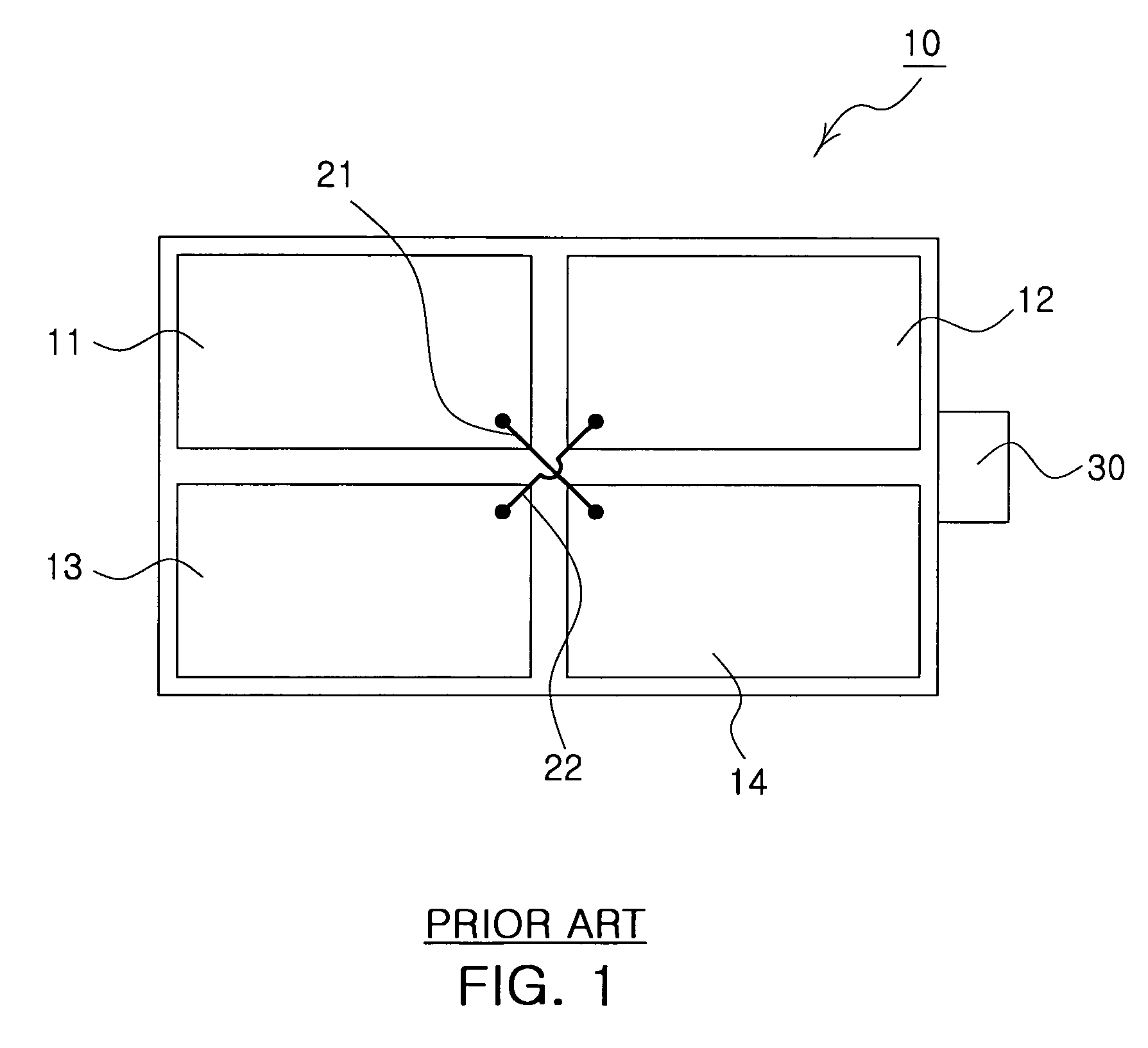

Ligating band delivery apparatus

InactiveUS6974466B2Smooth and accurate deliveryQuickly and smoothly dislodgedSurgical pincettesSurgical forcepsBiomedical engineering

Owner:COOK MEDICAL TECH LLC

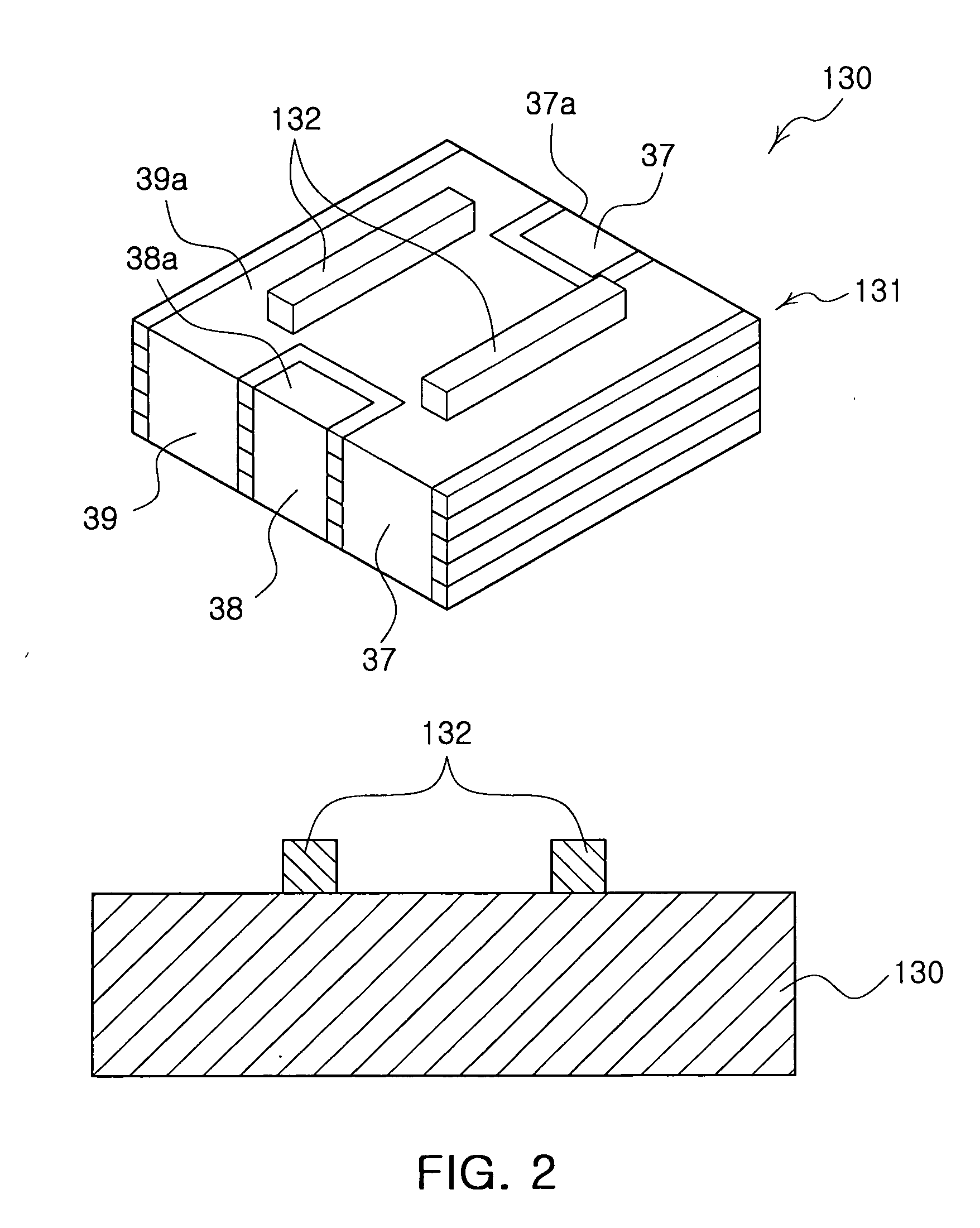

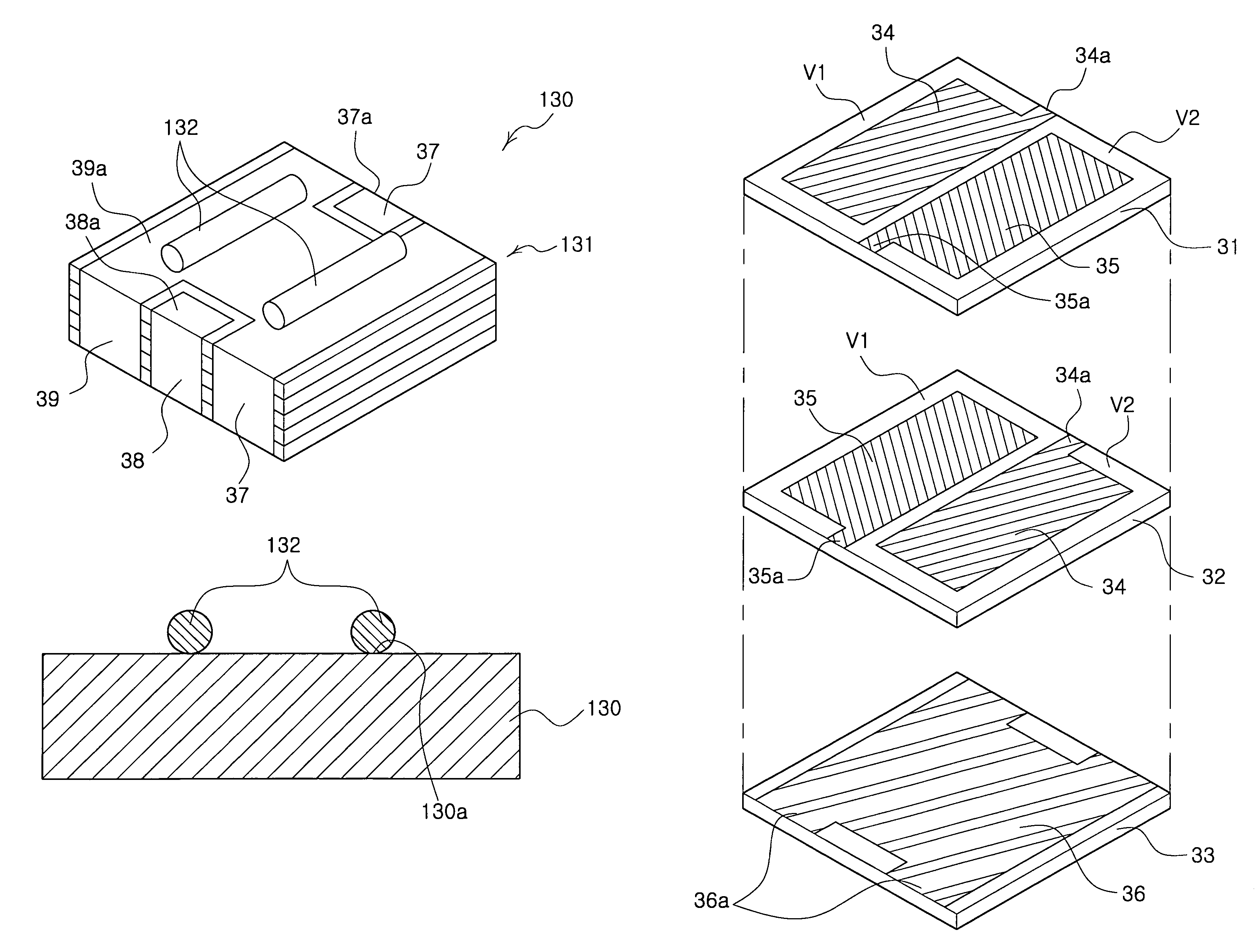

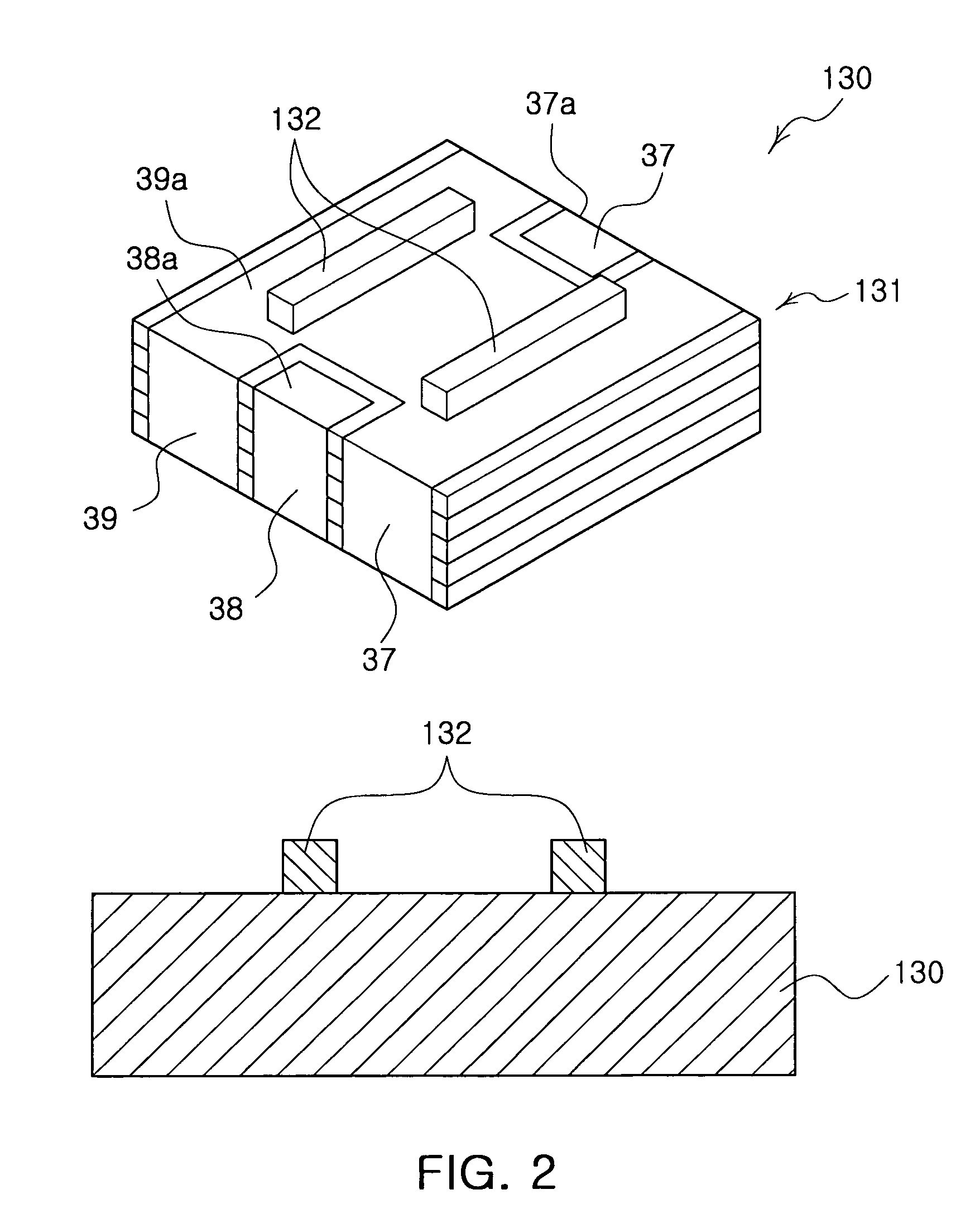

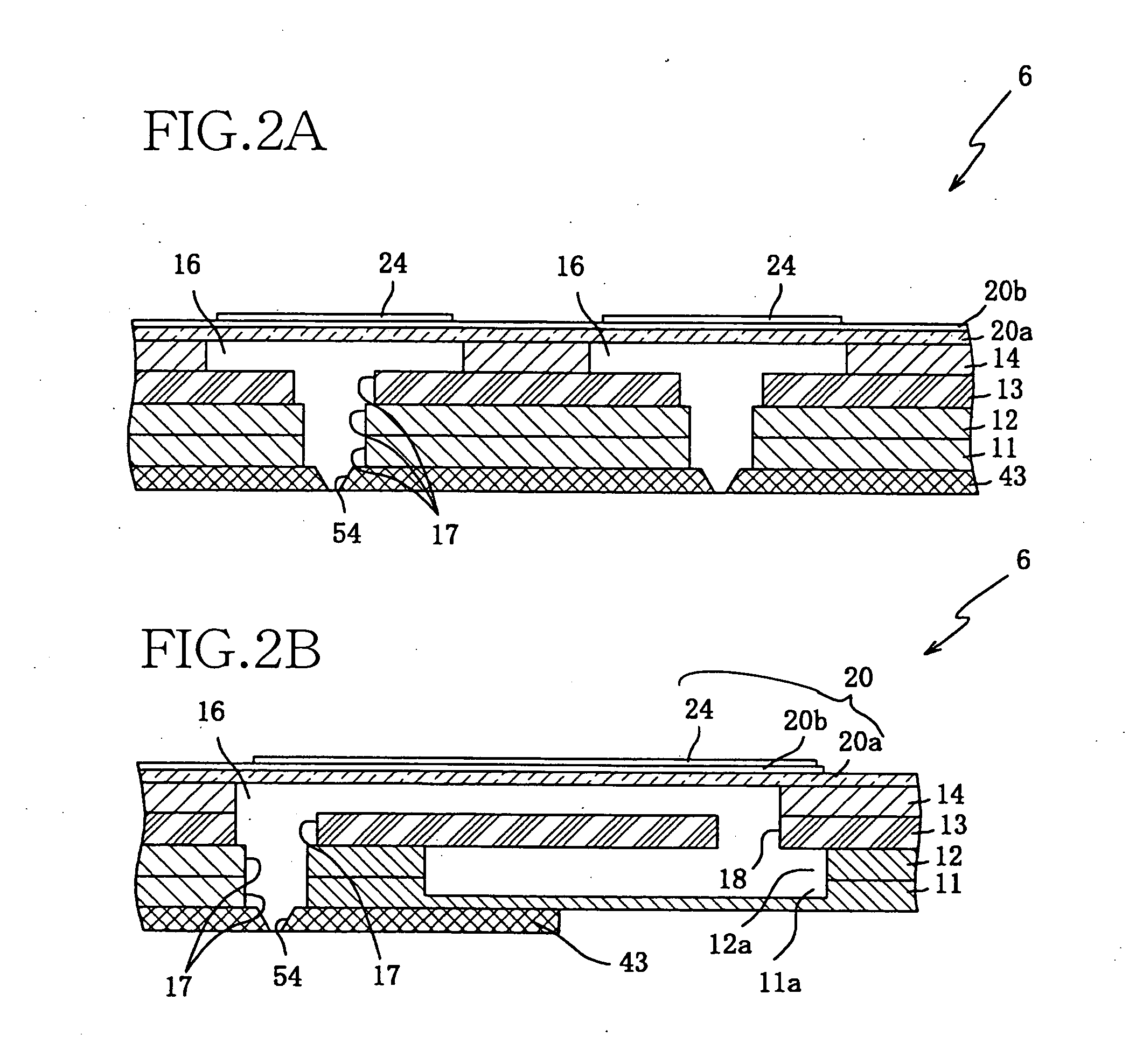

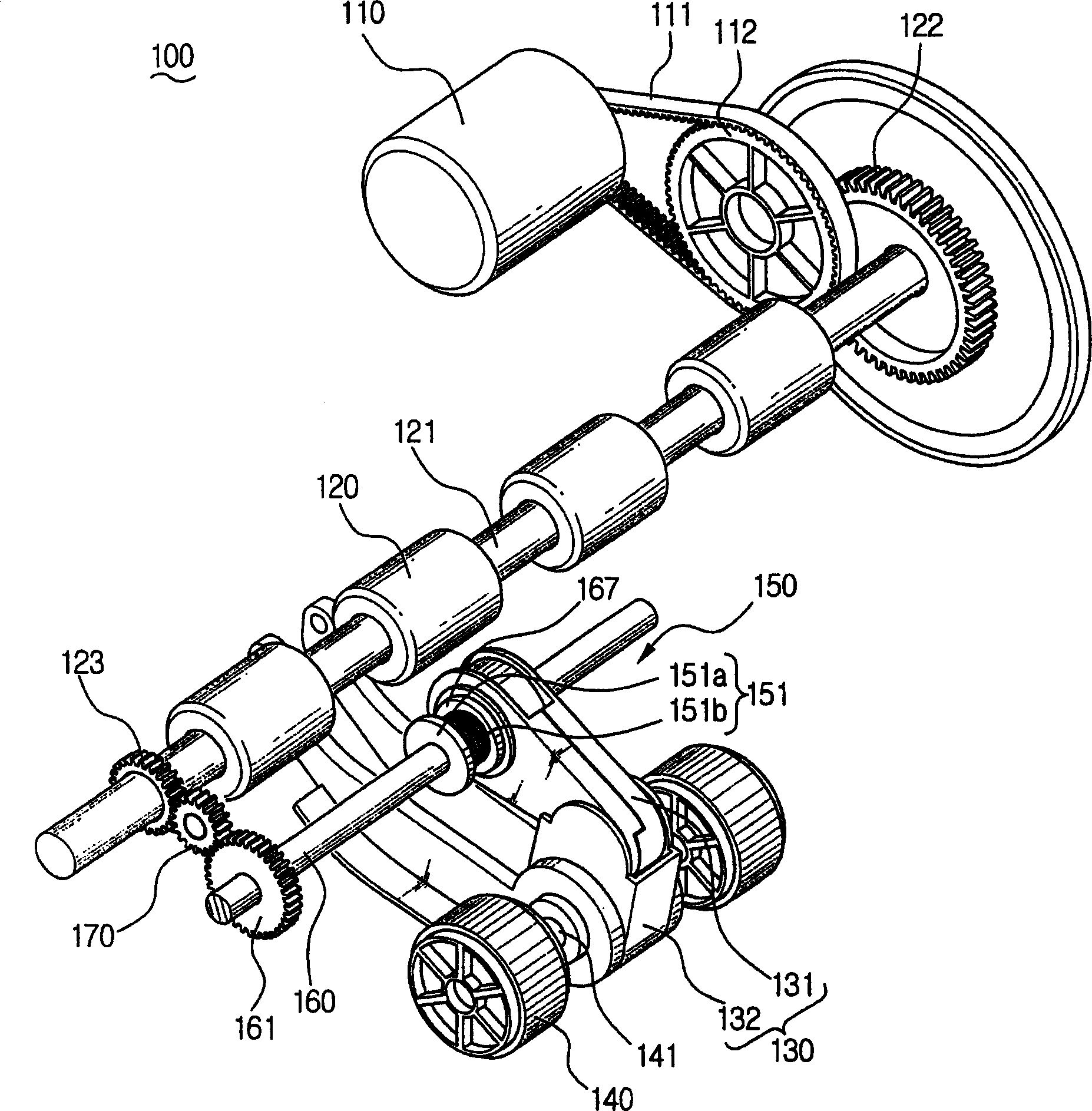

Piezoelectric actuator and lens driving device

InactiveUS20080297923A1Reduce manufacturing costLower the volumePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesOptical axisPiezoelectric actuators

There are provided a piezoelectric actuator and a lens driving apparatus having the piezoelectric actuator. The lens driving device includes: a lens barrel having a lens hole where at least one lens is disposed, and having a tip friction member on an outer surface thereof; a base having a guiding part guiding the lens barrel to move along an optical axis direction; a piezoelectric actuator having a piezoelectric body disposed at an edge of the base to apply a driving force when a power is applied, the piezoelectric body having at least one friction member at one side thereof to be in contact with the tip friction member; and a preload member applying an elastic force for elastically supporting the piezoelectric actuator against the lens barrel to keep the tip friction member and the friction member in contact with each other.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Piezoelectric actuator and lens driving device

InactiveUS7764449B2Lower the volumeSmall sizePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCamera lensOptical axis

There are provided a piezoelectric actuator and a lens driving apparatus having the piezoelectric actuator. The lens driving device includes: a lens barrel having a lens hole where at least one lens is disposed, and having a tip friction member on an outer surface thereof; a base having a guiding part guiding the lens barrel to move along an optical axis direction; a piezoelectric actuator having a piezoelectric body disposed at an edge of the base to apply a driving force when a power is applied, the piezoelectric body having at least one friction member at one side thereof to be in contact with the tip friction member; and a preload member applying an elastic force for elastically supporting the piezoelectric actuator against the lens barrel to keep the tip friction member and the friction member in contact with each other.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

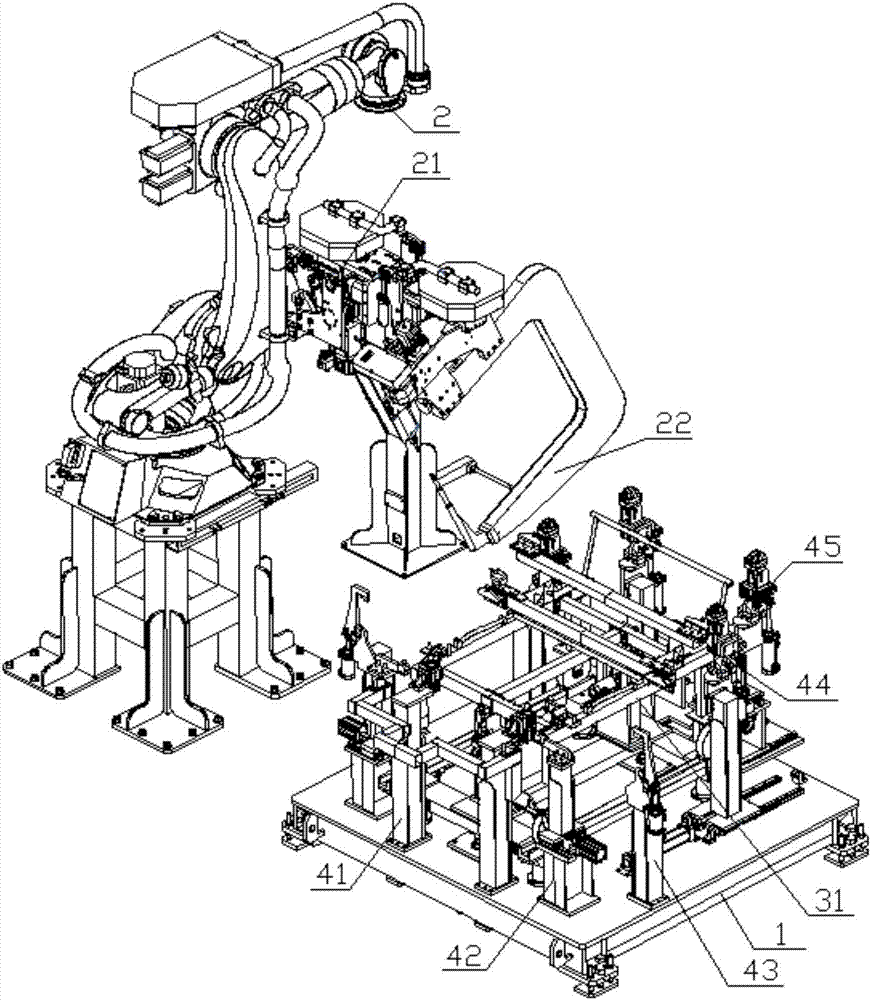

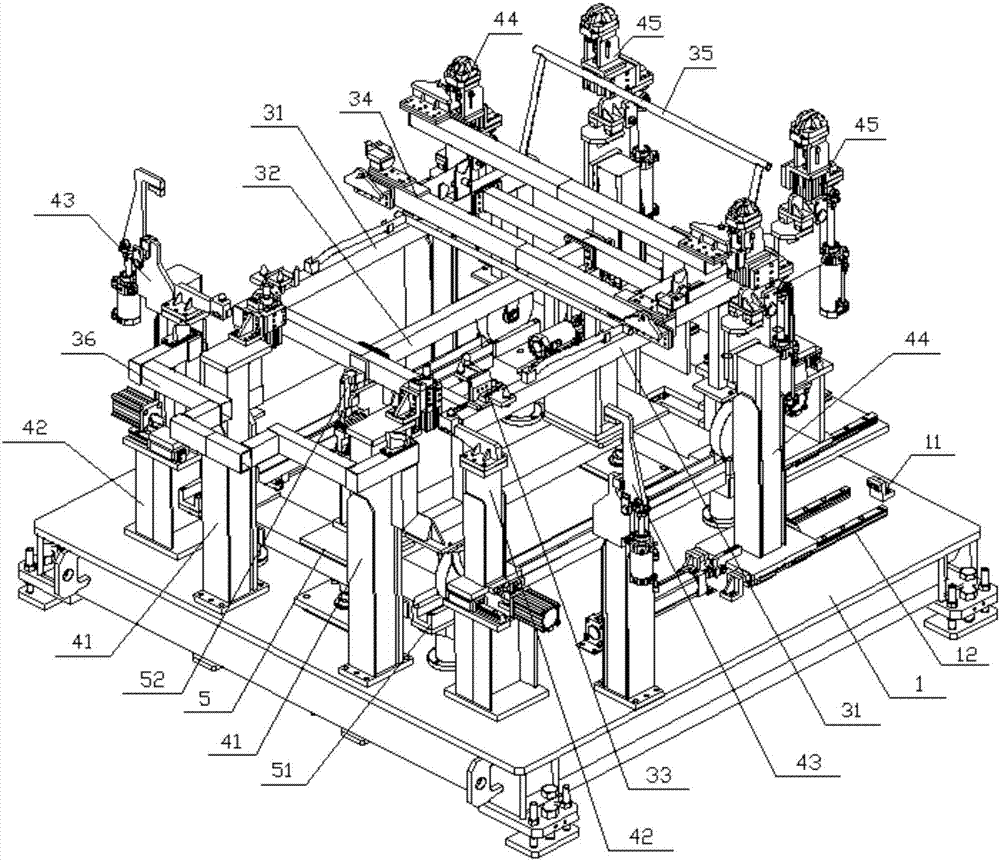

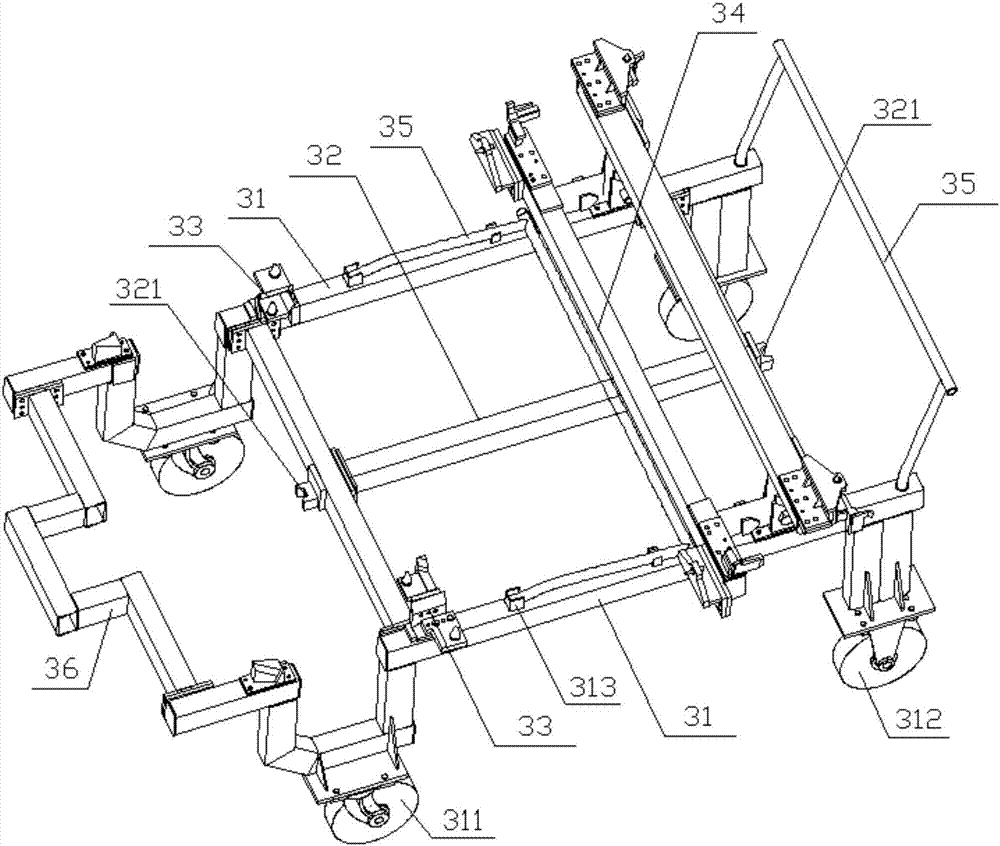

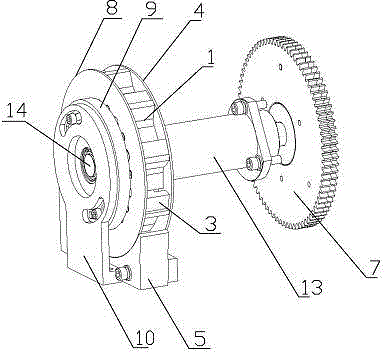

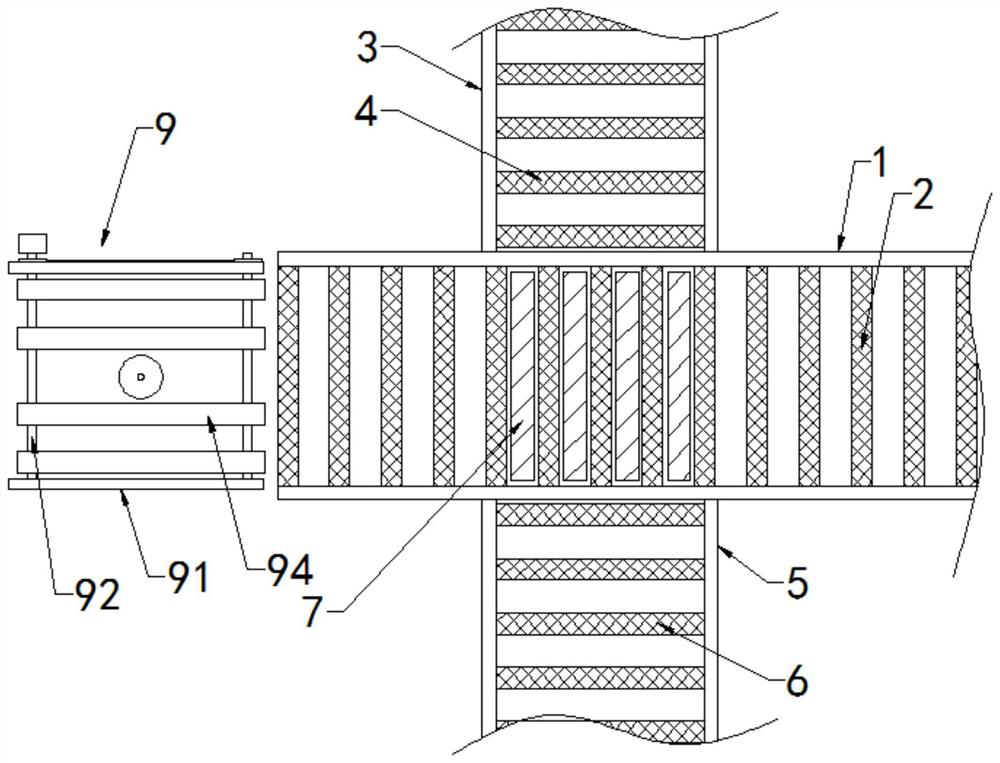

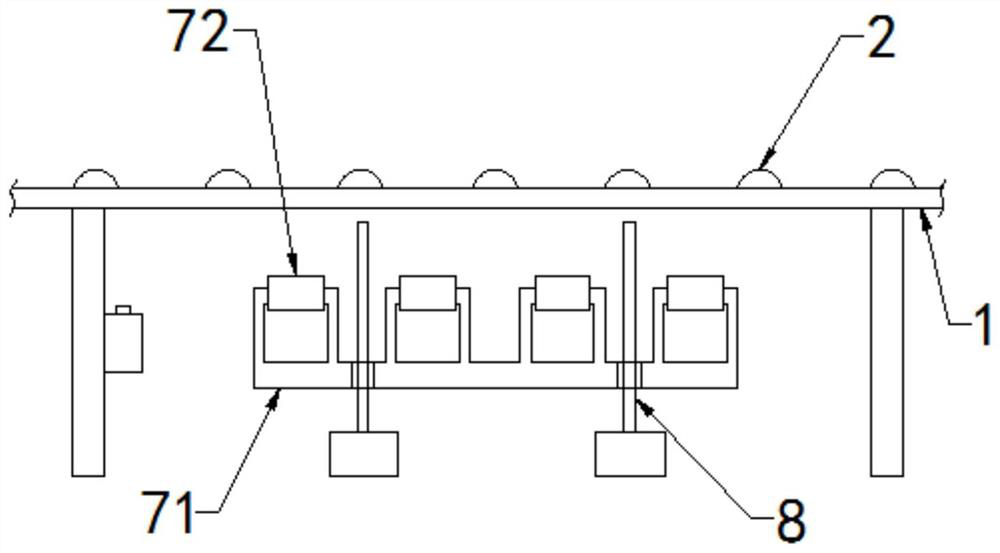

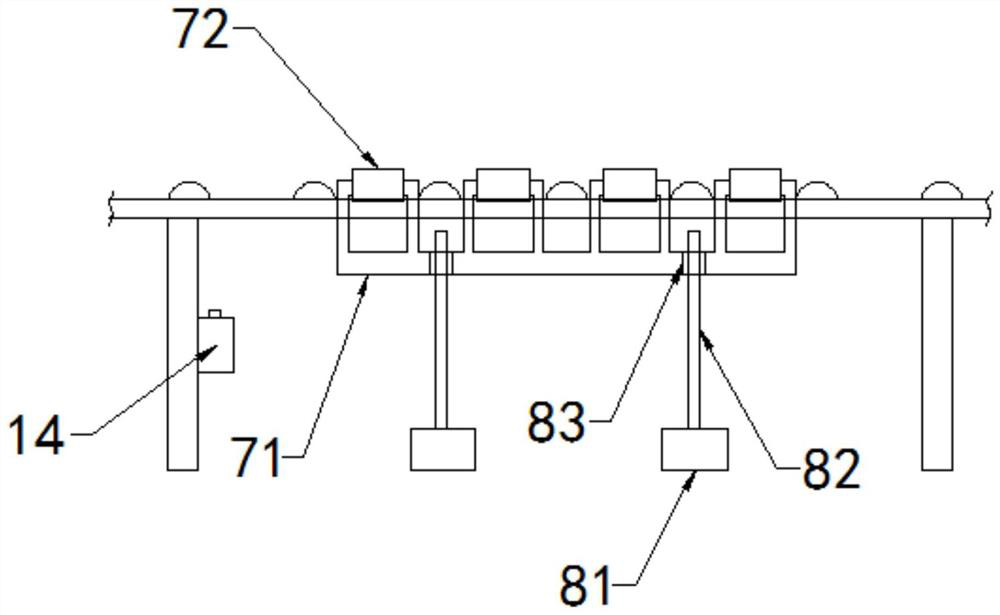

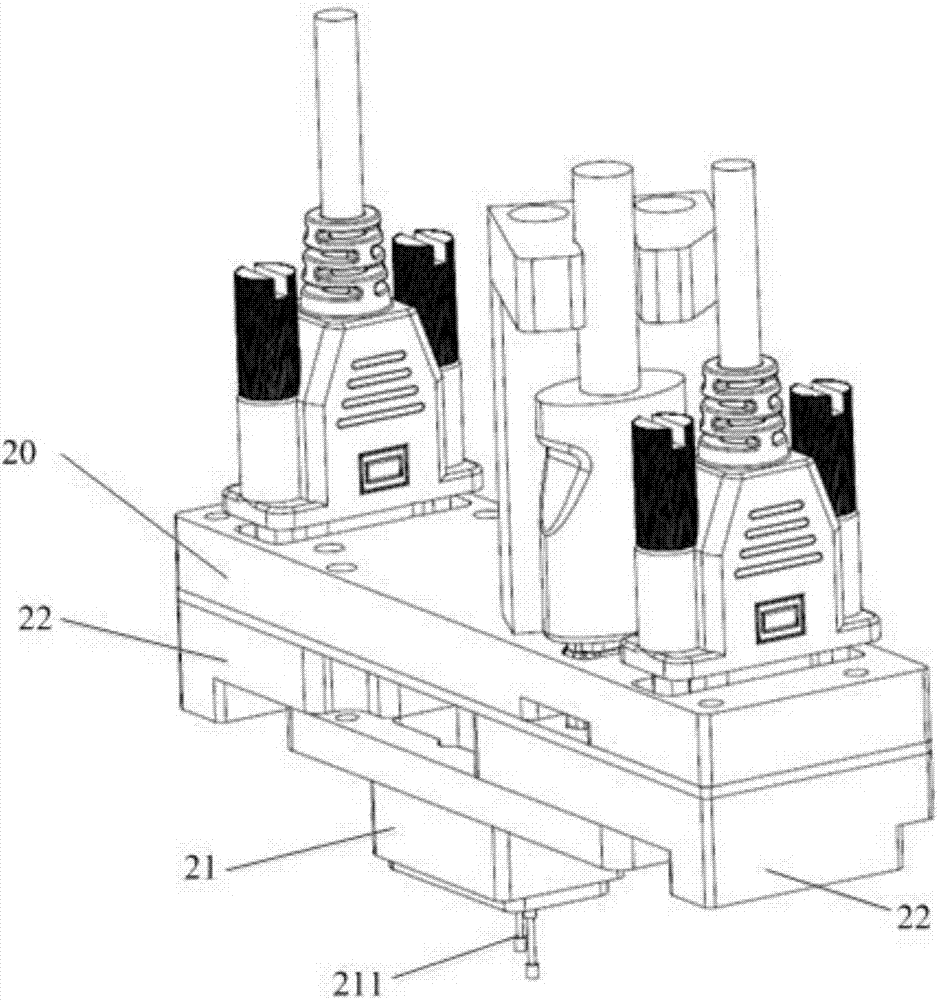

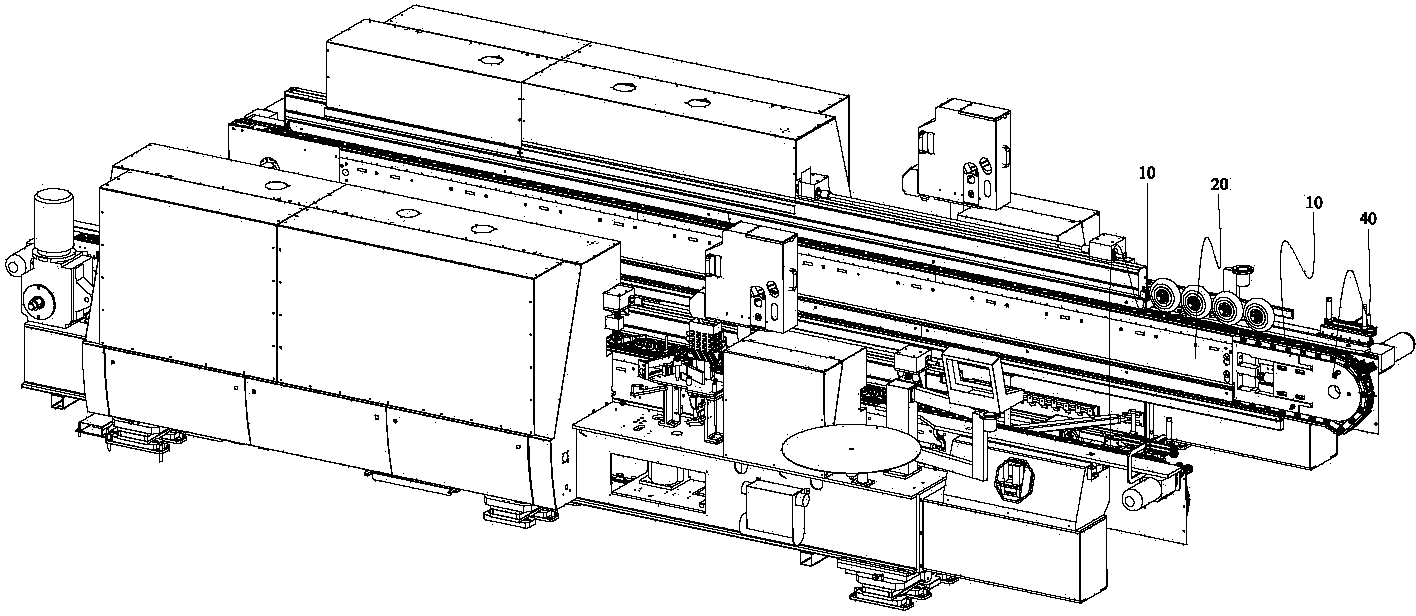

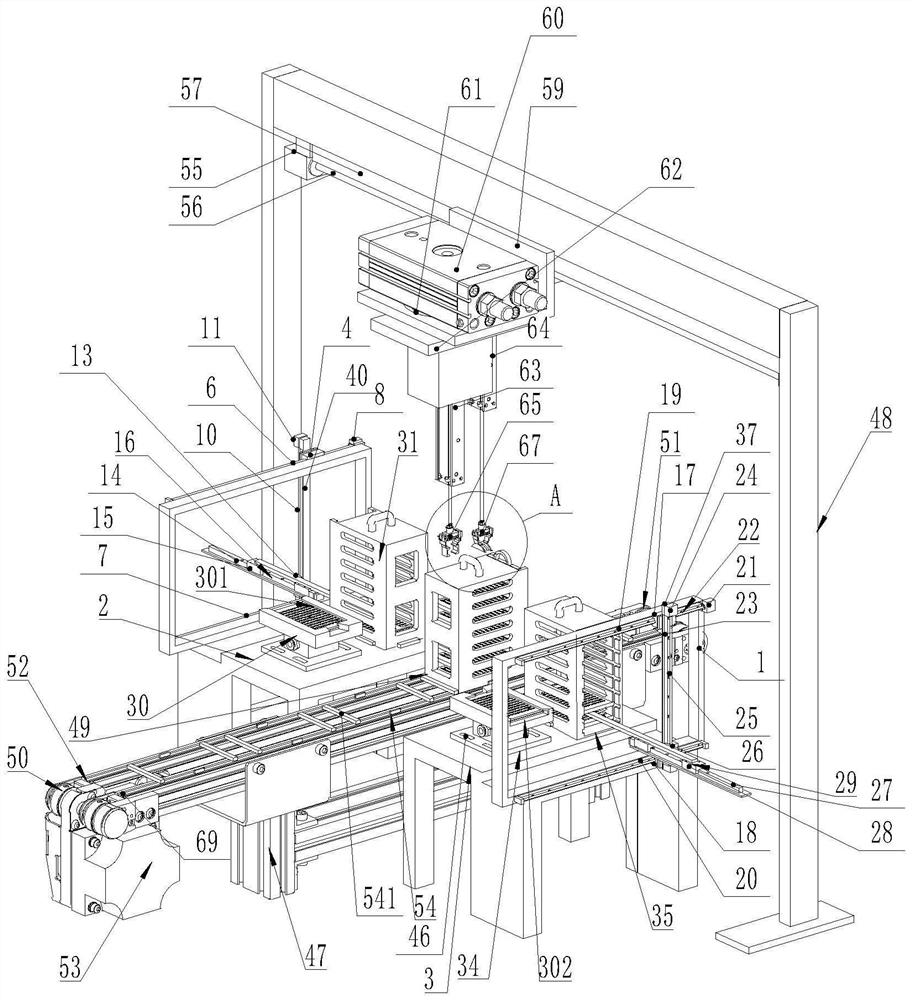

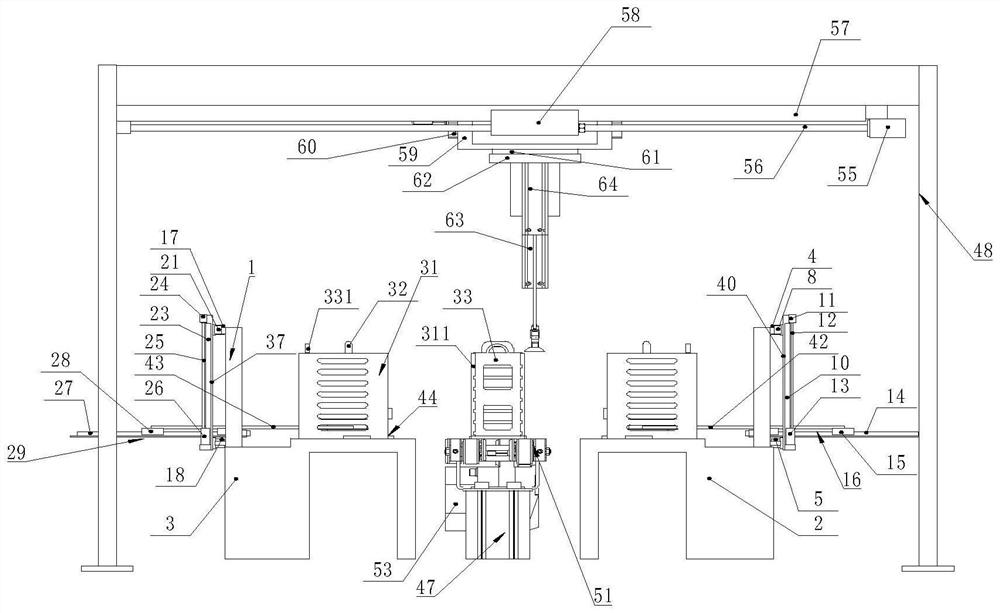

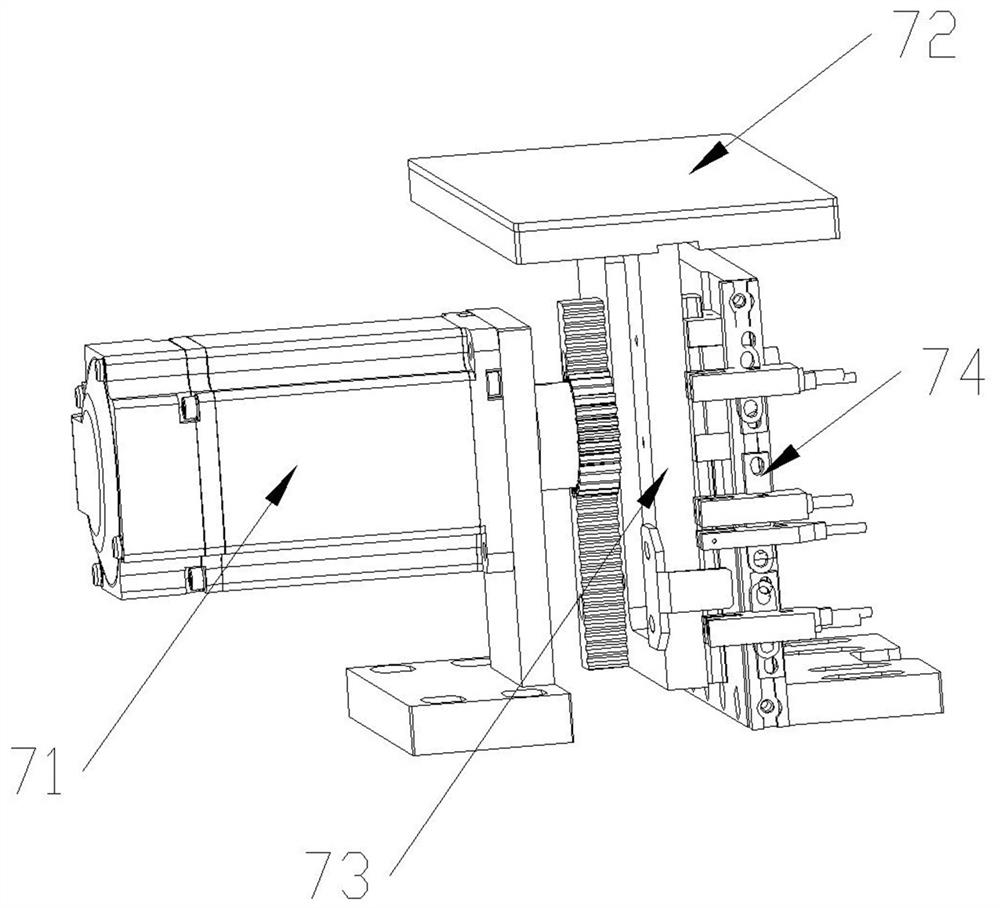

Tool for welding white car bodies by robot

ActiveCN107309587APrecision weldingHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesRobot weldingIndustrial engineering

The invention relates to the technical field of car bodies welding equipment, in particular to a tool for adapting to welding of white car bodies of multiple car types by a robot. The tool comprises a base, a lifting device, and a trolley for positioned conveying of the white car bodies; the base is provided with a positioning and clamping device for positioning and clamping the white car bodies; the white car bodies are placed on the trolley; the trolley is supported on the lifting device; and through lifting by the lifting device, the white car bodies enter or leave from a clamping position of the positioning and clamping device. The tool has the following beneficial effects: transfer and positioning of the white car bodies are realized through matching between the trolley and the lifting device; and the white car bodies are sent in an appointed position, so that the robot can accurately weld the white car bodies, the positioning precision is improved, the labor intensity is reduced, and the production efficiency is improved.

Owner:QINGLING MOTORS GRP +1

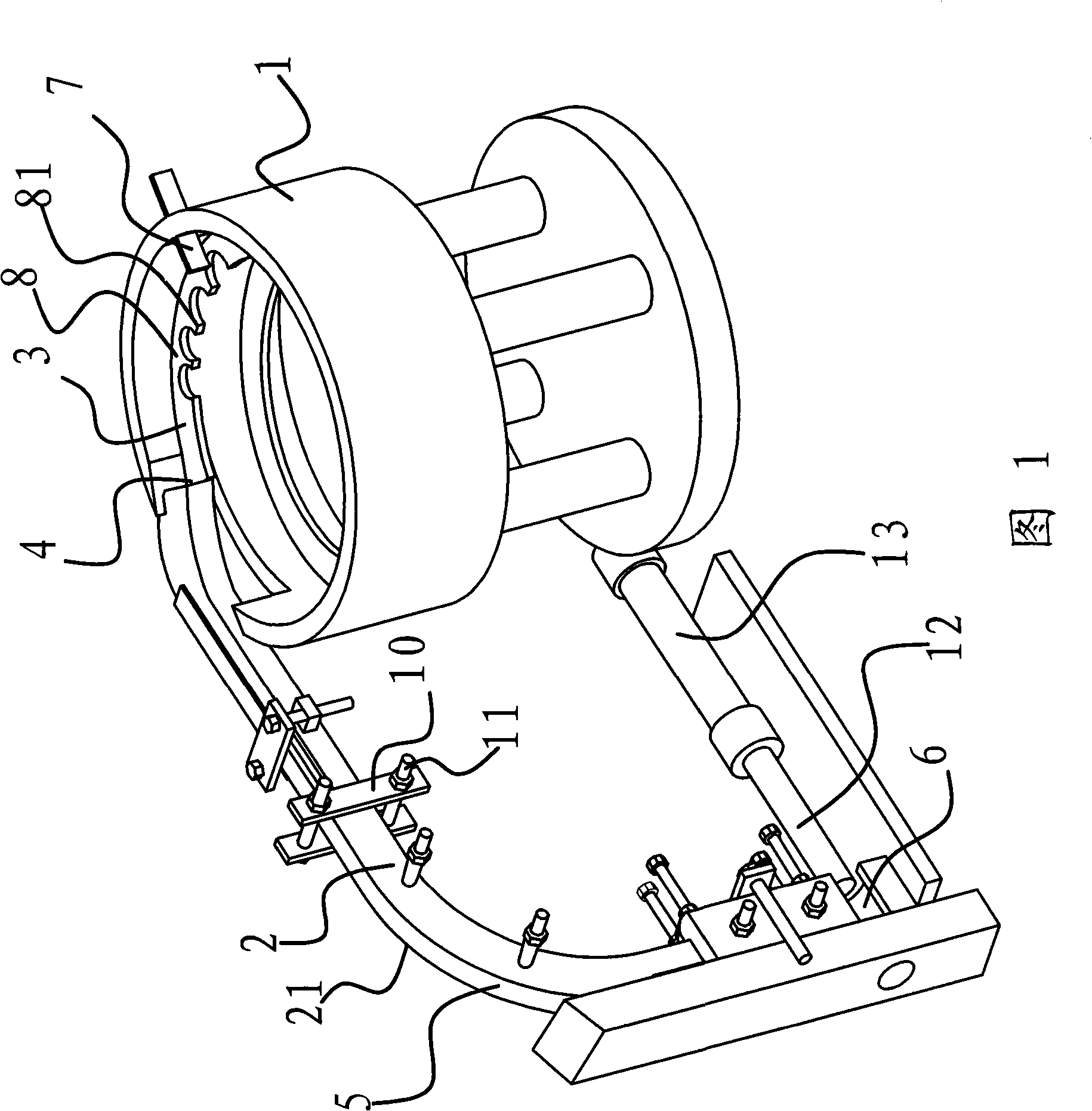

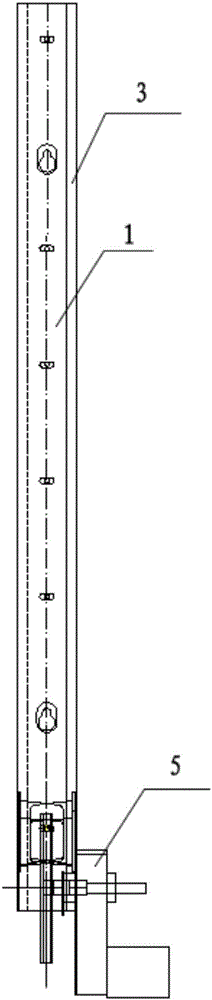

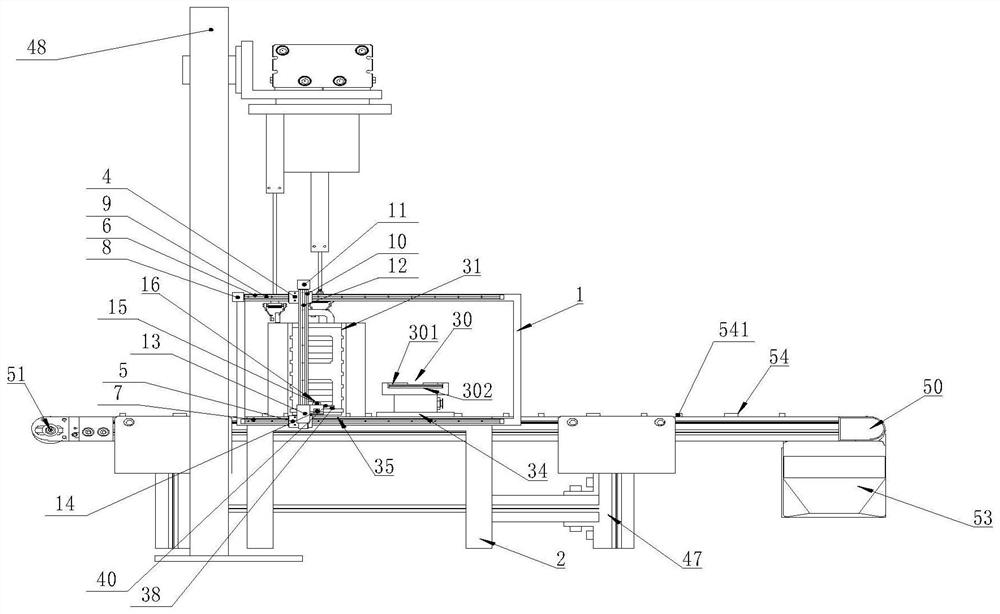

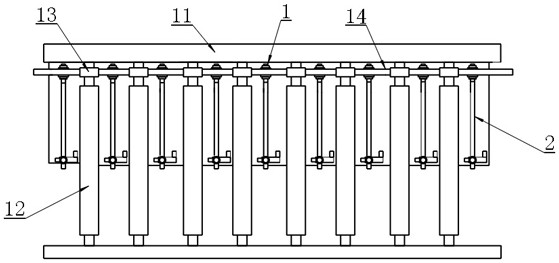

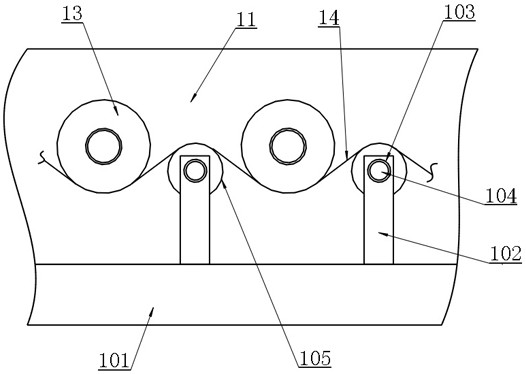

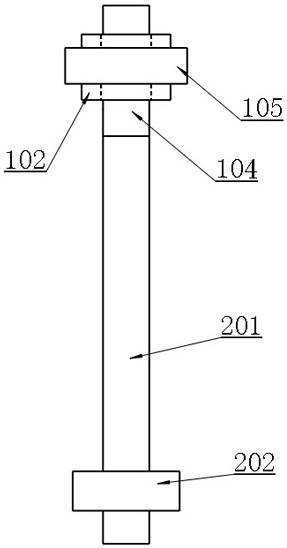

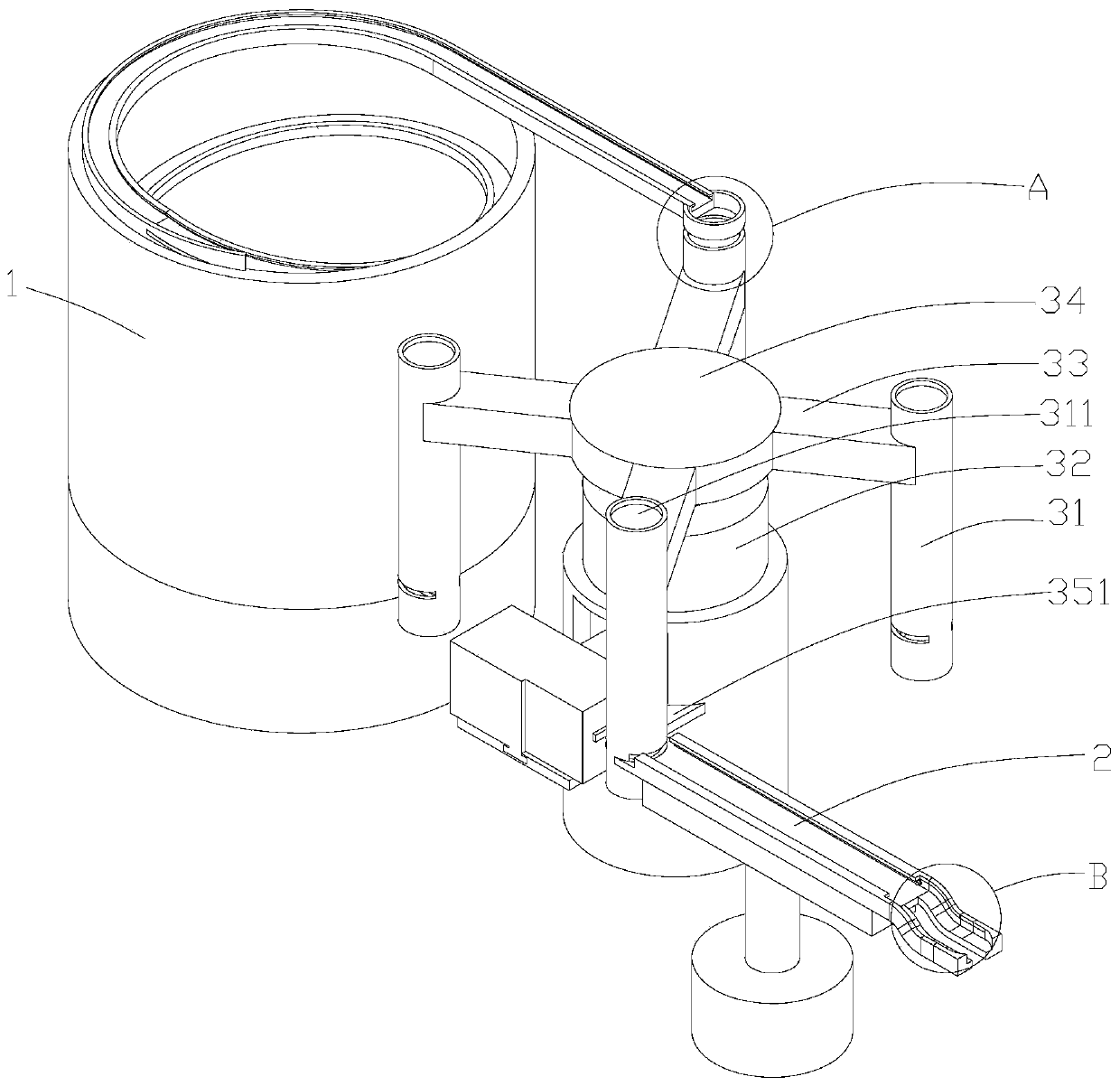

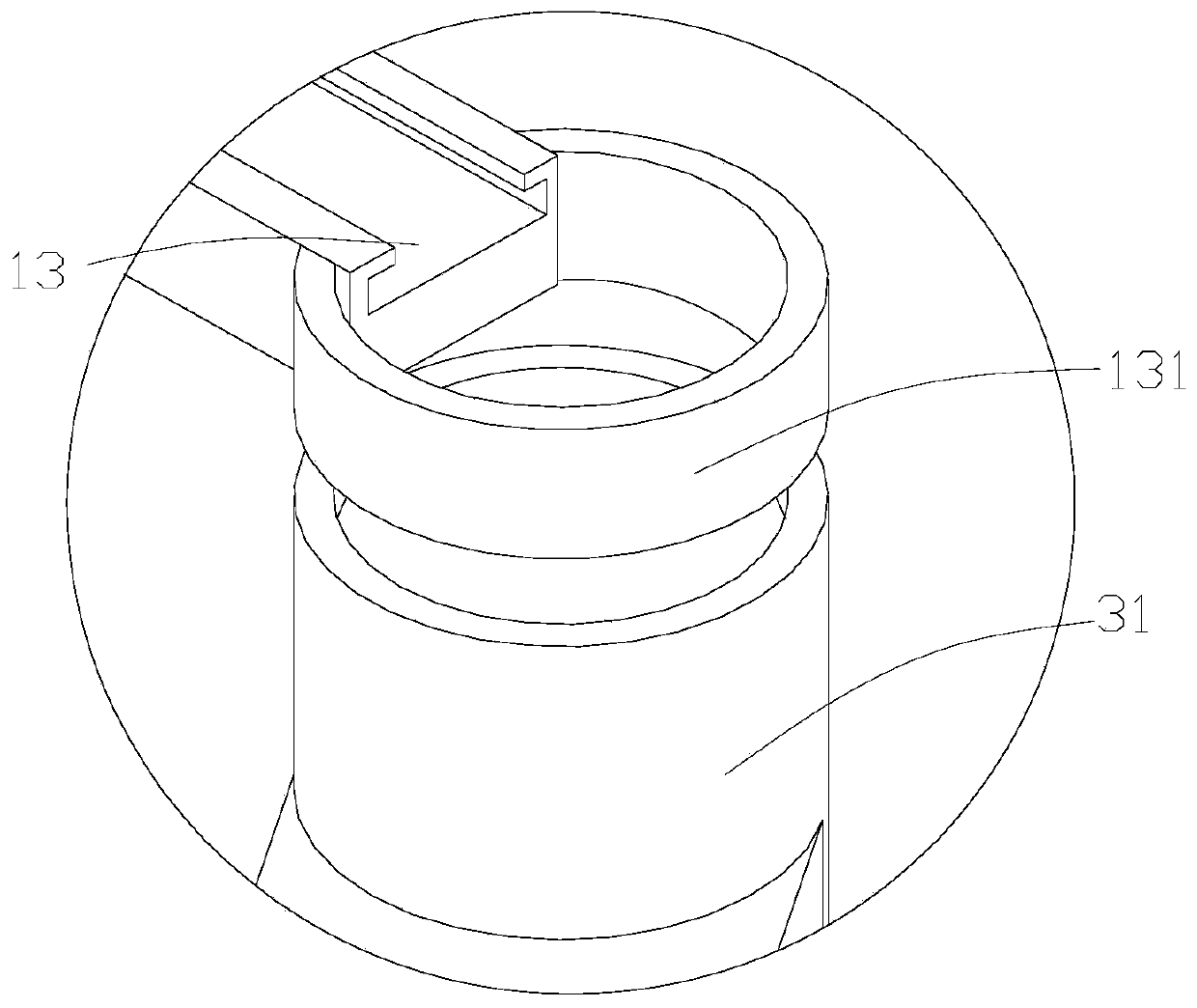

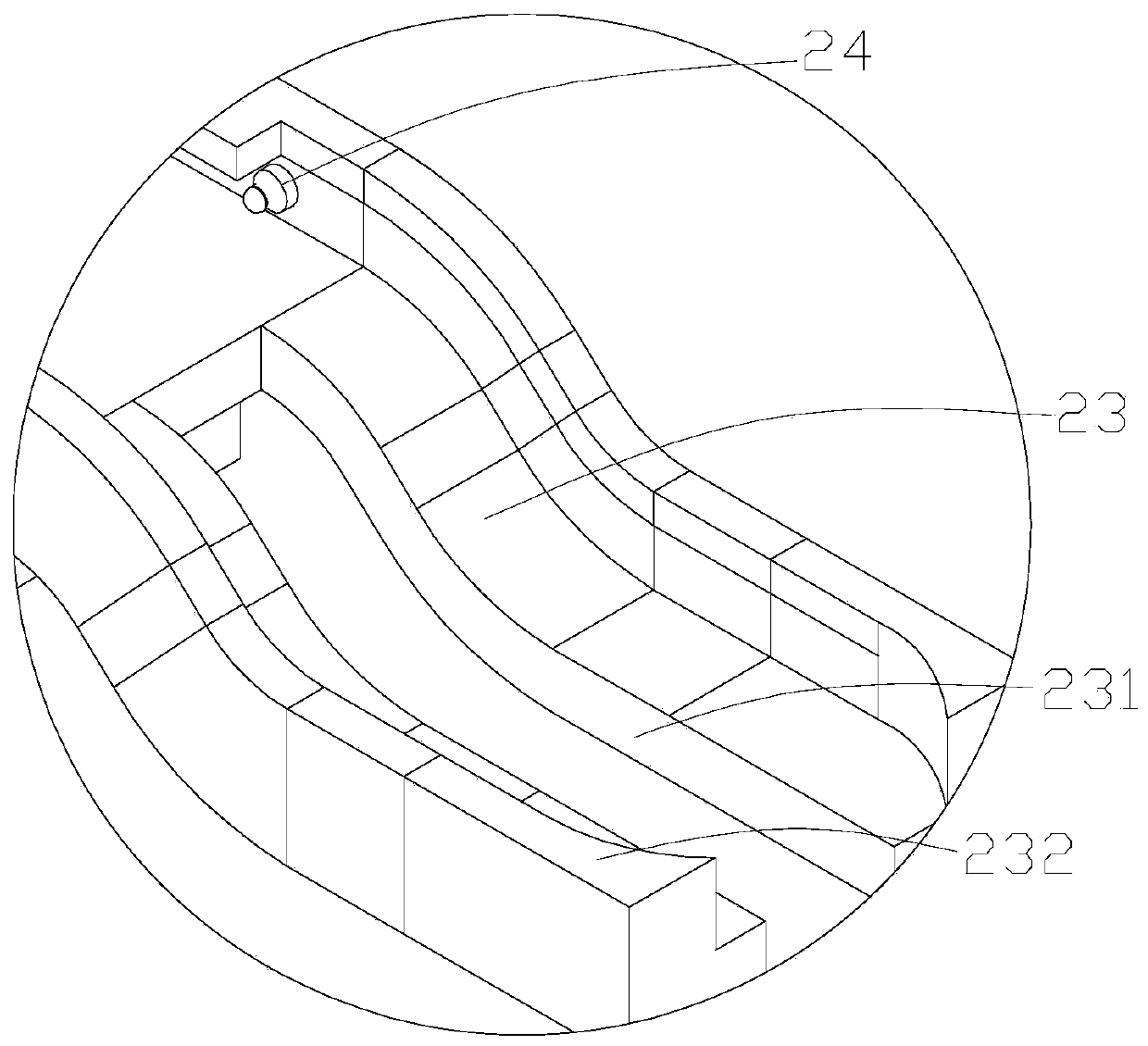

Material feeder of lathe

The invention provides a feeding device for a lathe, which belongs to the technical field of machinery. The feeding device for the lathe solves the technical problems that the prior feeding device of the lathe has a complicated structure, unsteady conveying and so on. The feeding device for the lathe comprises a vibratory hopper and a feeding guide rail, wherein the vibratory hopper is provided with a feeding channel which rises spirally, the lowest position of the feeding channel is a feed inlet and is positioned at the bottom of the vibratory hopper, the highest position of the feeding channel is a discharge outlet, the discharge outlet is connected with the feeding end of the feeding guide rail, the feeding channel is provided with a screening mechanism which ensures that workpieces are arranged and output according to the preset arrangement state, the discharge end of the feeding guide rail is communicated with the top of a material placing pipe, workpieces can fall into the material placing pipe, and a pushing device which can push the workpieces to the next working procedure is arranged at the material placing pipe. The feeding device for the lathe has the advantages of simple structure, accurate and steady conveyance, conveyance of more different workpieces and so on.

Owner:ZHEJIANG SHUANGZHENG MACHINE TOOL CO LTD

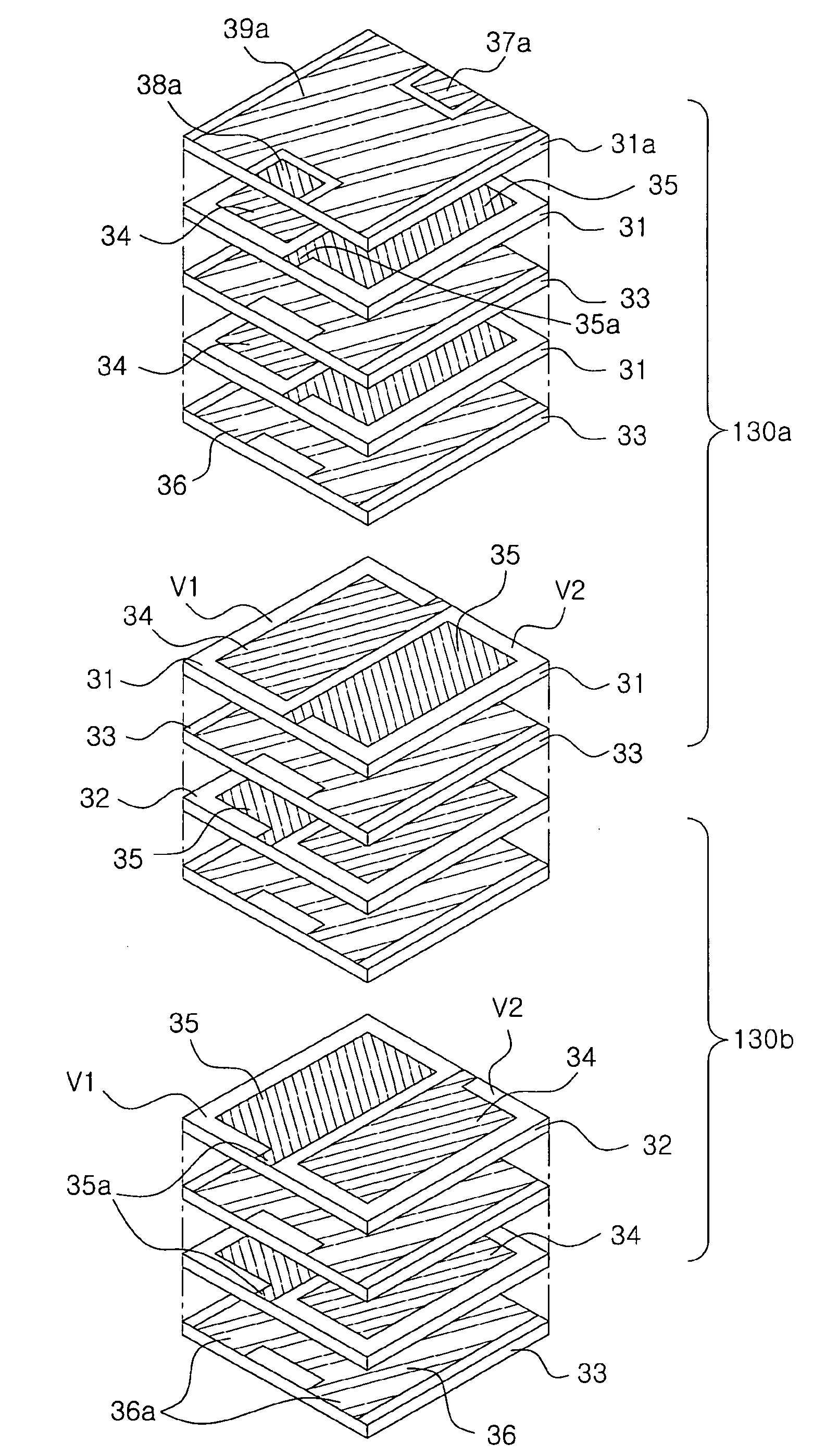

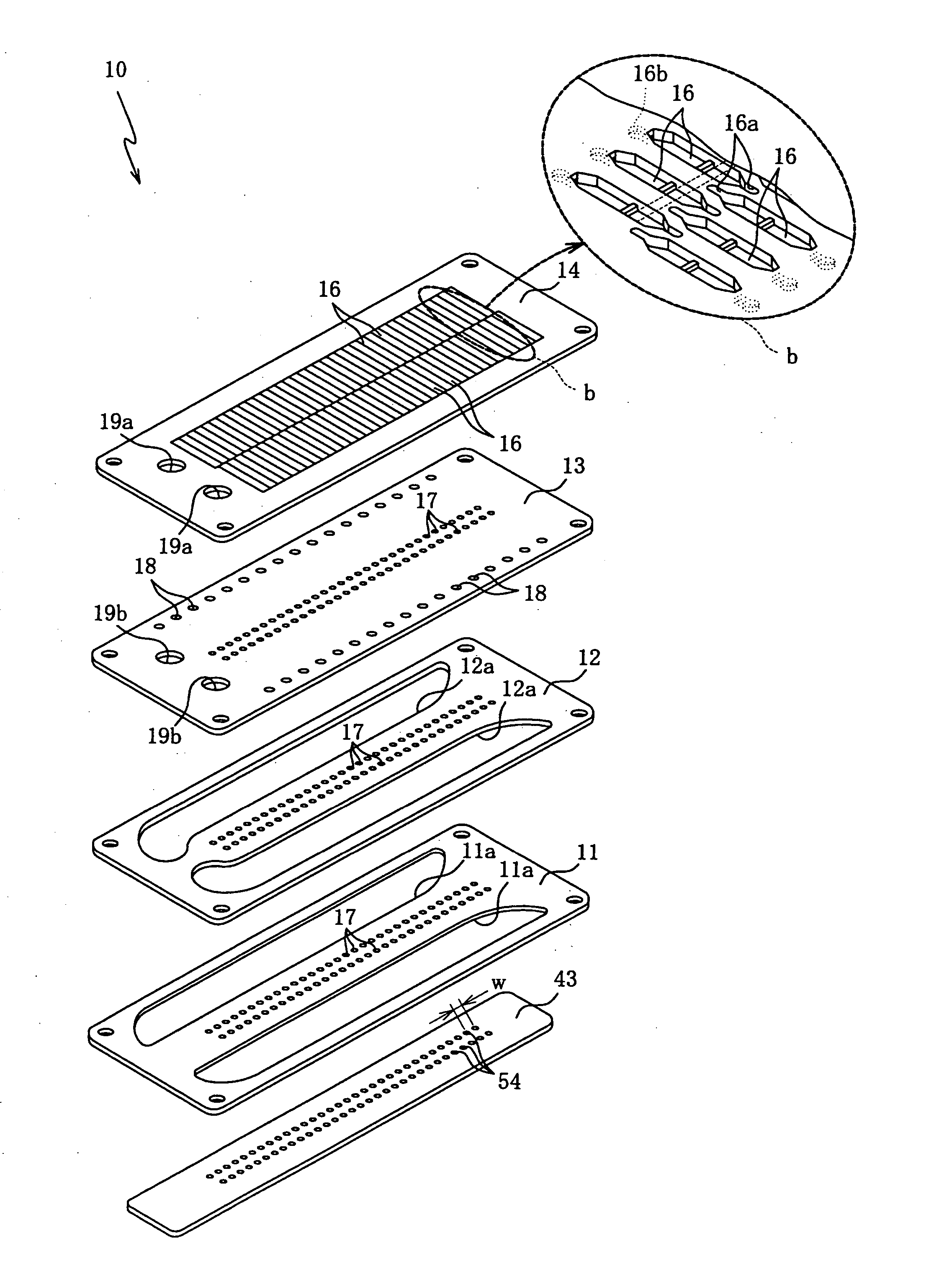

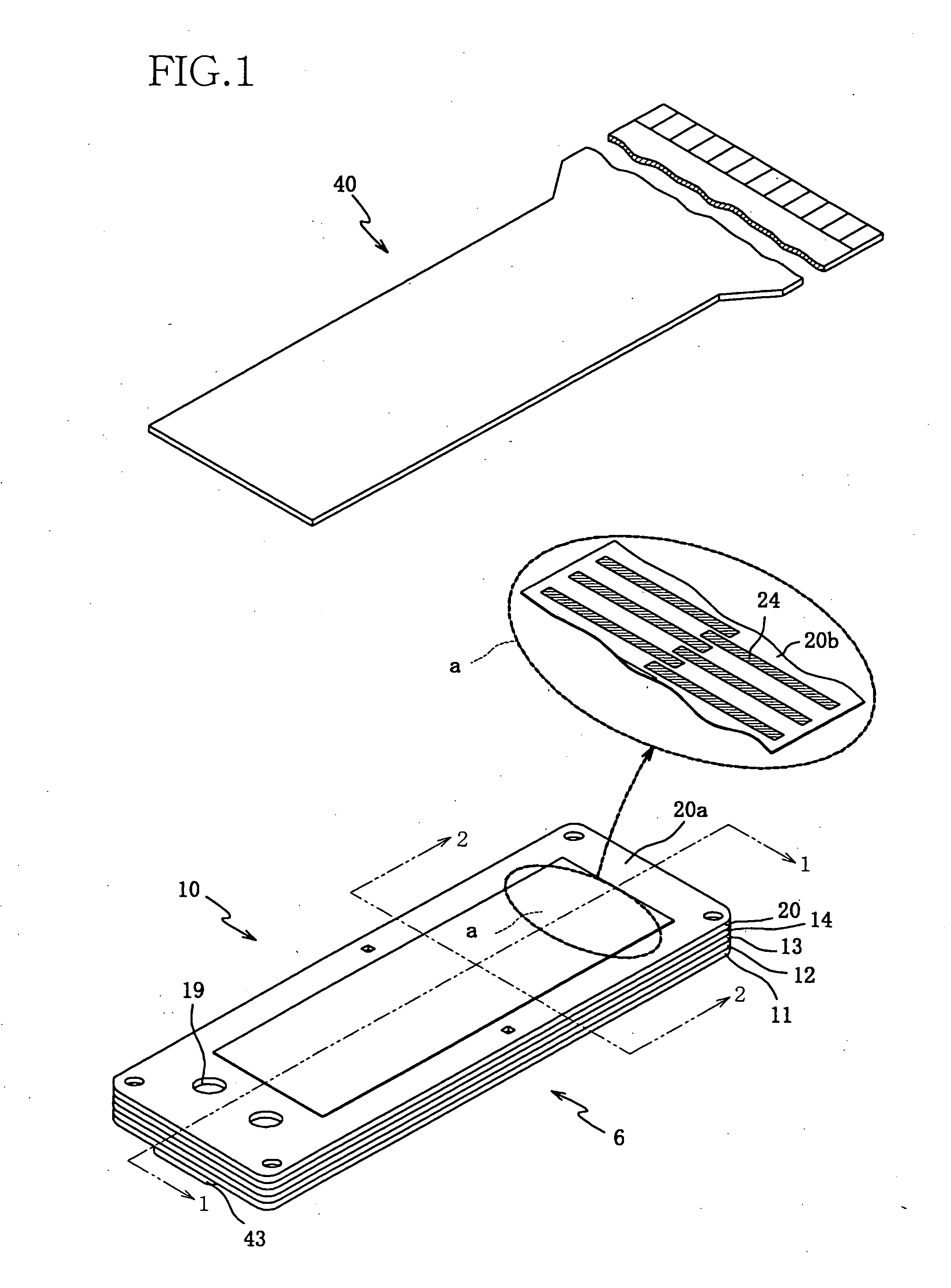

Liquid delivering apparatus and method of producing the same

A liquid delivering apparatus includes at least one piezoelectric element which deforms upon application of a drive voltage thereto, an oscillating plate on which the piezoelectric element is laminated and which is oscillated by deformation of the piezoelectric element, and at least one liquid chamber which stores liquid and which is formed adjacent to the oscillating plate on one of opposite sides thereof that is remote from the piezoelectric element. The liquid in the liquid chamber is given pressure by the deformation of the piezoelectric element, so that the liquid is delivered to an exterior of the apparatus. The liquid chamber is formed in a laminated member including a first layer and a second layer bonded integrally to each other, such that at least one portion of the first layer corresponding to the at least one liquid chamber is recessed by etching to such an extent that at least one portion of the second layer corresponding to the at least one portion of the first layer is exposed. The second layer constitutes the oscillating plate and has resistance to conditions under which the first layer is etched.

Owner:BROTHER KOGYO KK

Material cutting push device of candy molding machine

InactiveCN104642687ASmooth and accurate deliveryAchieve reductionConfectionerySweetmeatsMolding machineDrive shaft

The invention discloses a material cutting push device of a candy molding machine. The device comprises a transmission shaft seat; a transmission shaft is rotatably arranged in the transmission shaft seat; the shaft end of the transmission shaft is fixedly connected with a cutting disc; a plurality of cutting tool bits are evenly distributed on the surface of the cutting disc; a sliding groove is formed between every two adjacent cutting tool bits along the radial direction of the cutting disc; each sliding groove is internally connected with a push sliding block in a sliding way; each push sliding block is connected with a working surface of a cutting cam in a contacting way by a roller wheel arranged on the push sliding block; a material containing groove is formed between every two adjacent cutting tool bits along the circumferential direction of the cutting disc; arc-shaped material guide seats are arranged under the cutting disc at intervals. The material cutting push device of the candy molding machine not only is reasonable in structure, stable in material input and high in production efficiency, but also is compact in structure and simple in transmission.

Owner:江苏海特尔机械有限公司

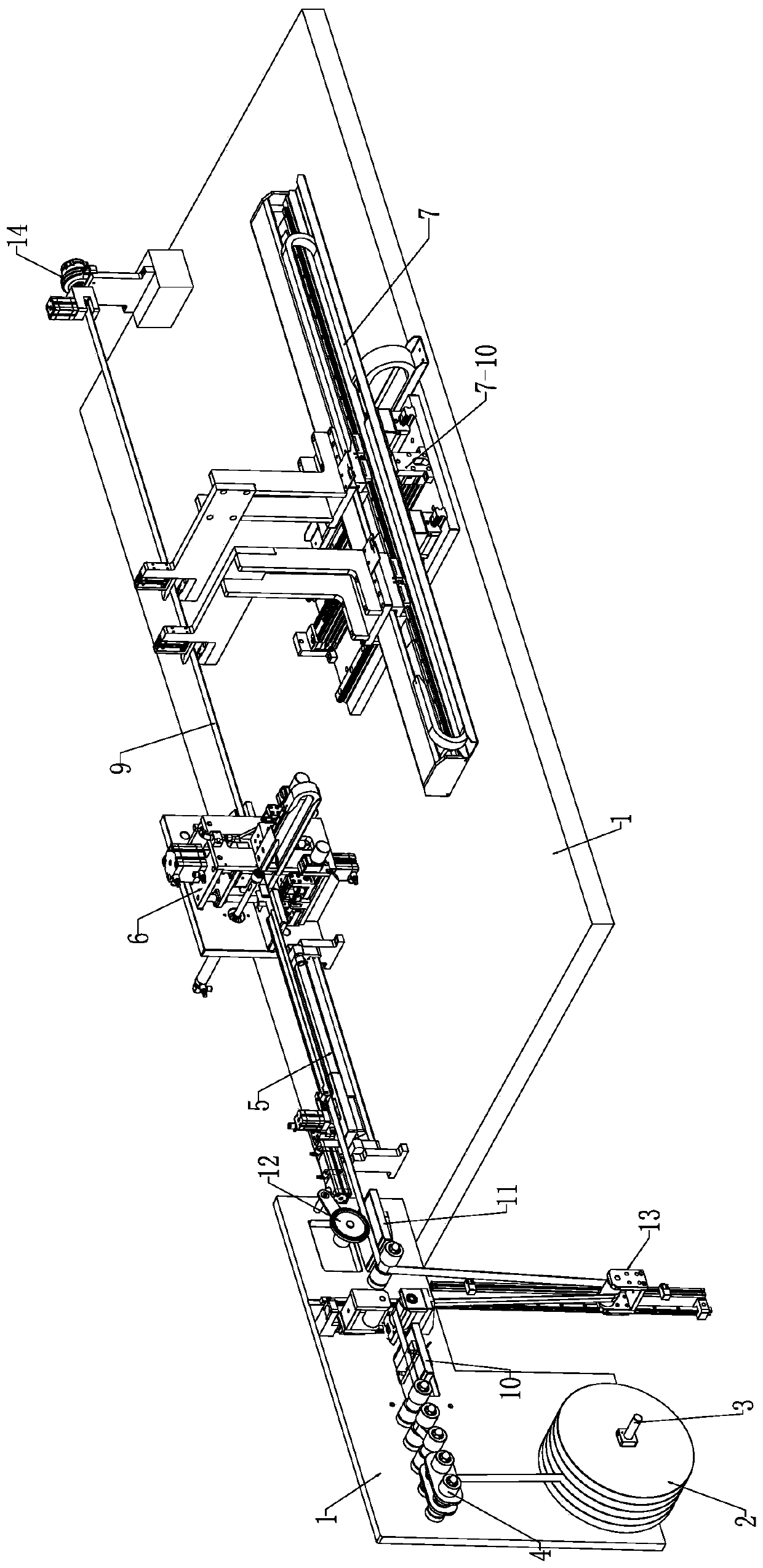

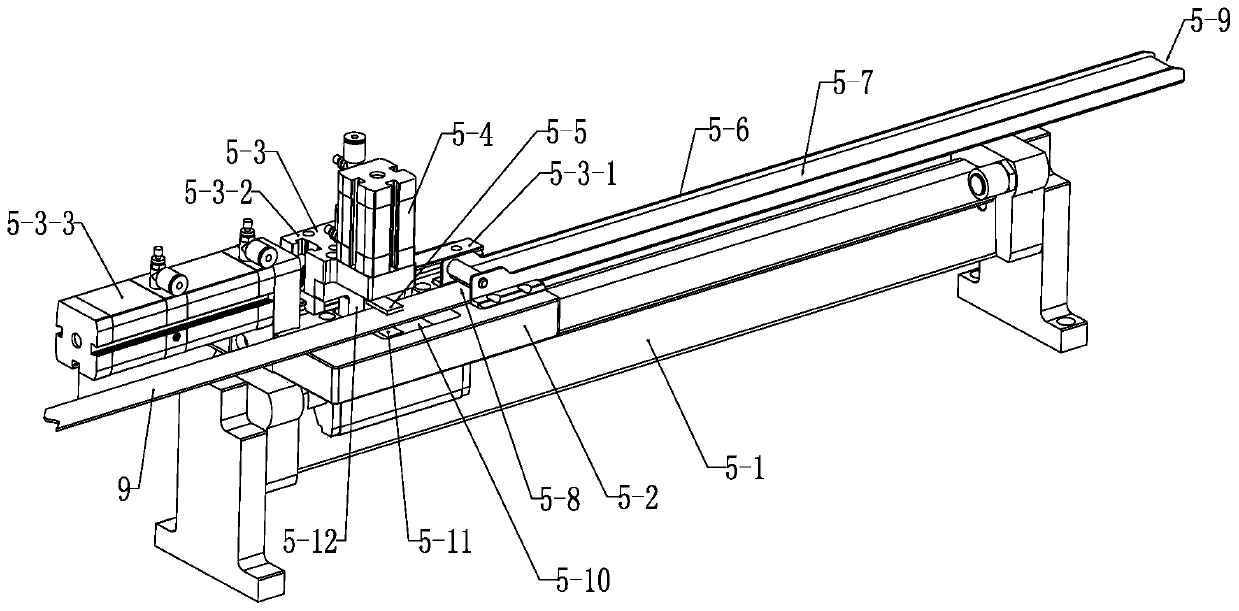

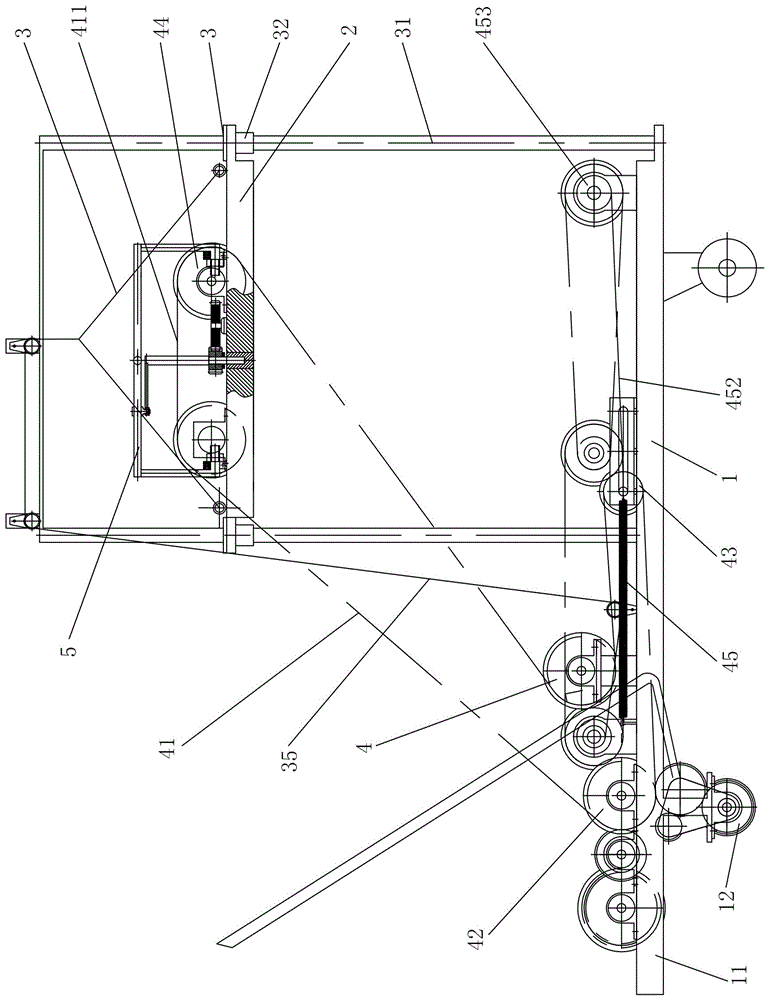

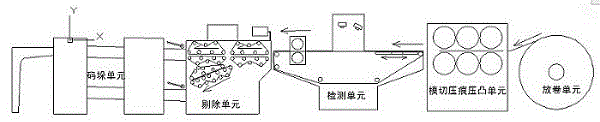

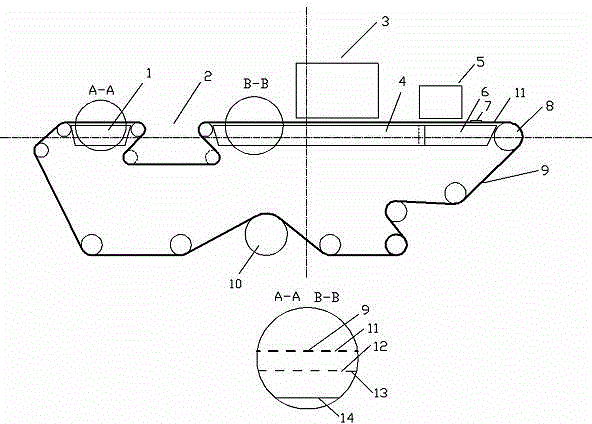

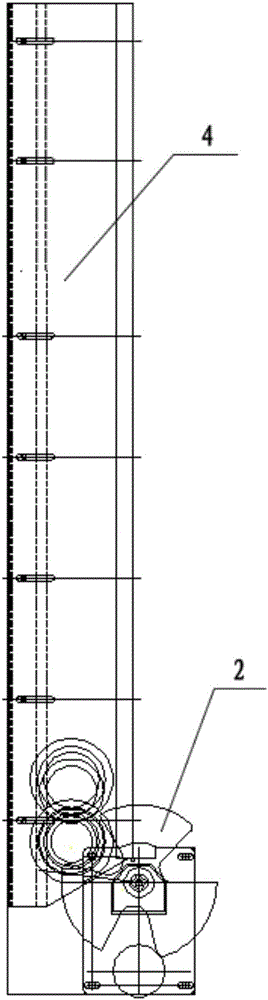

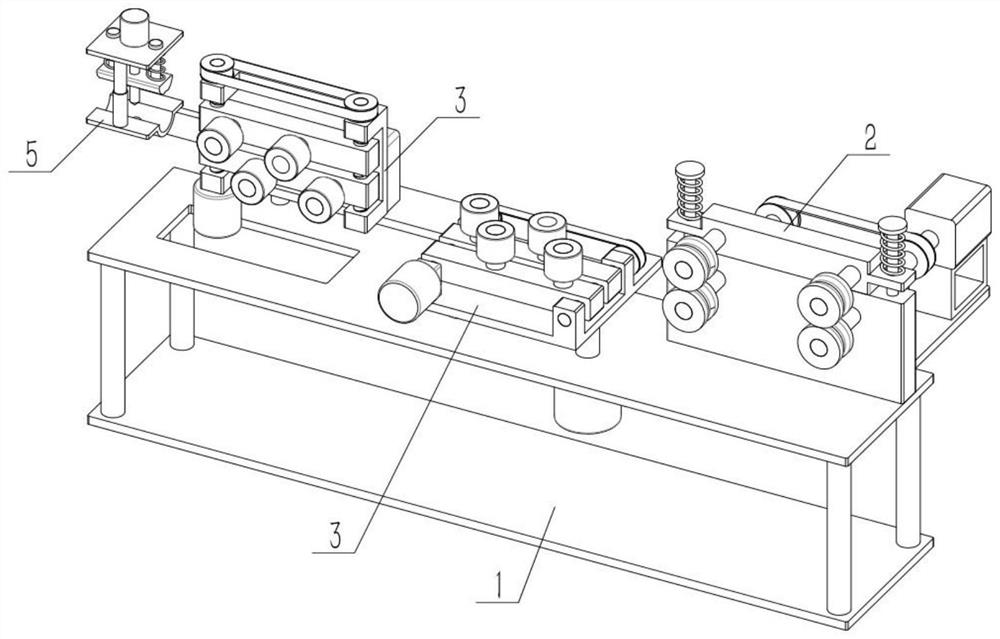

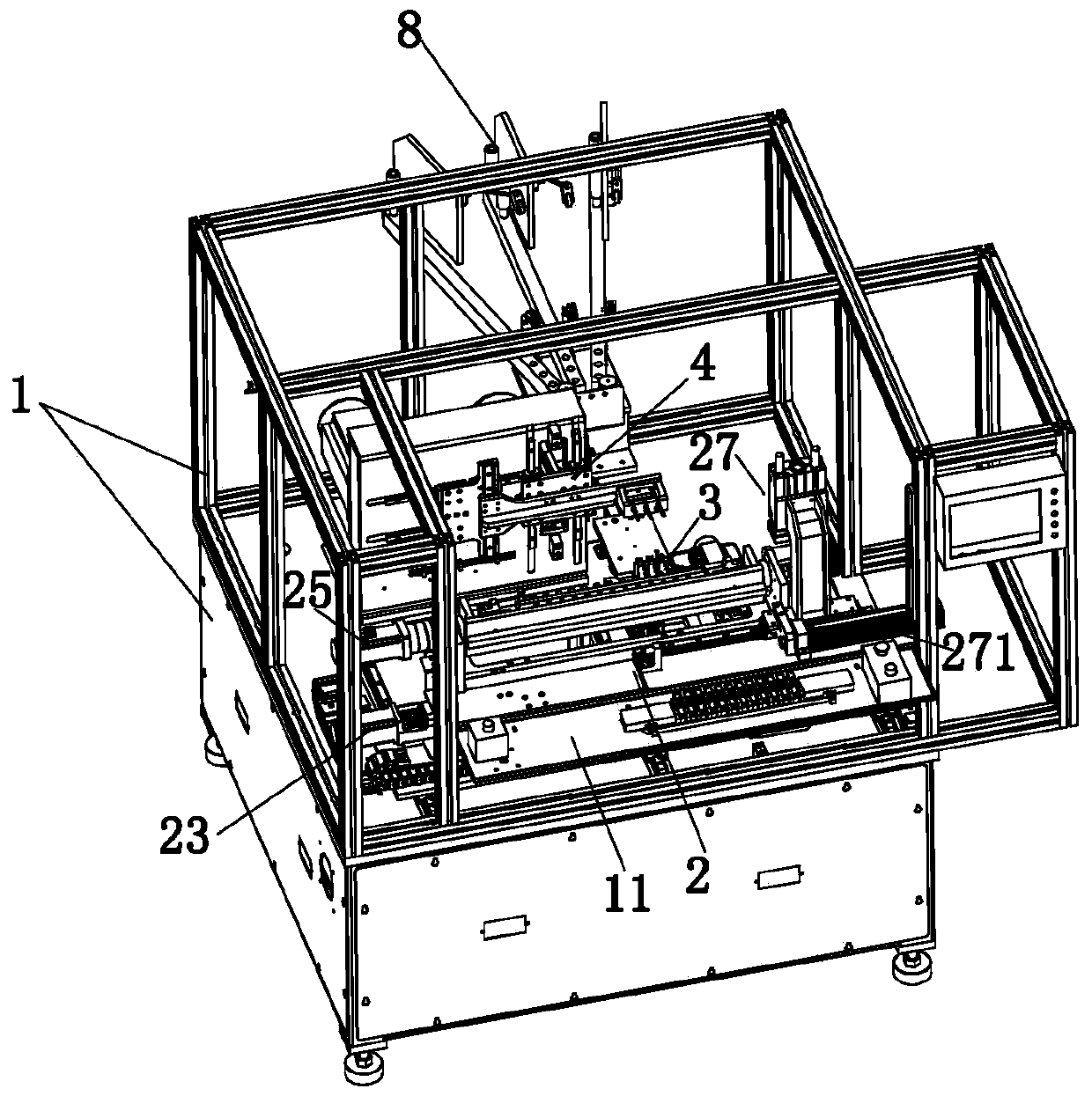

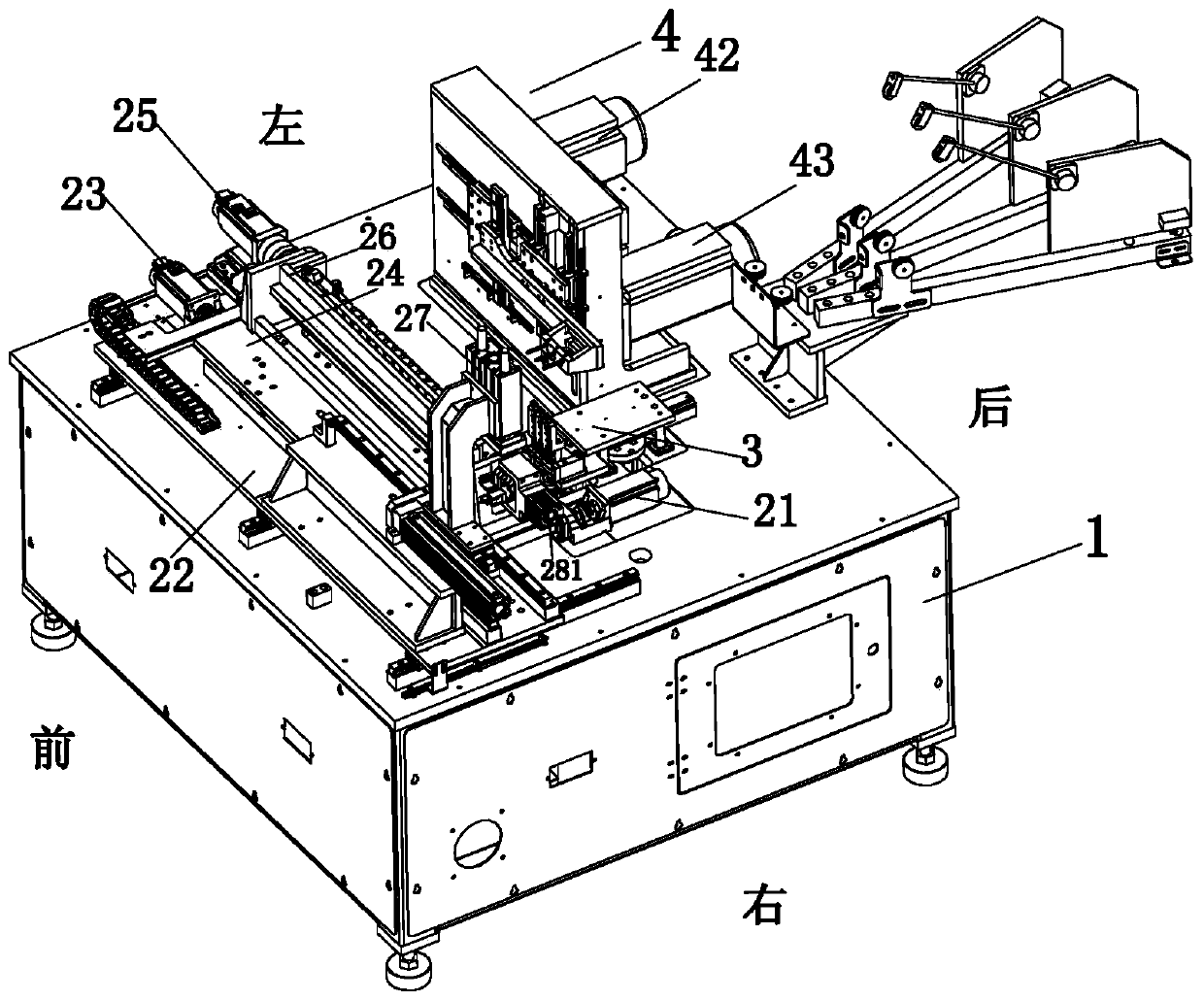

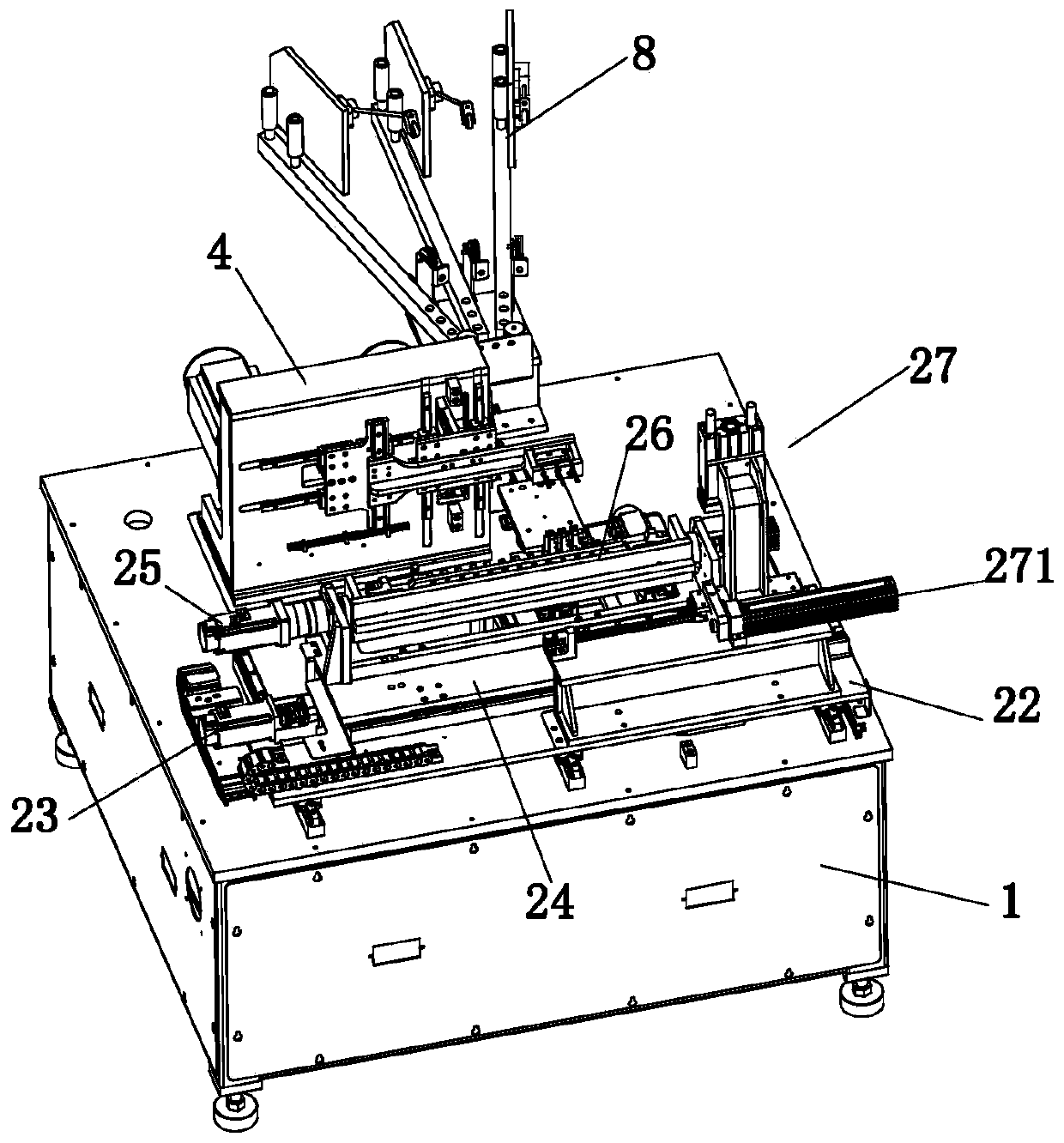

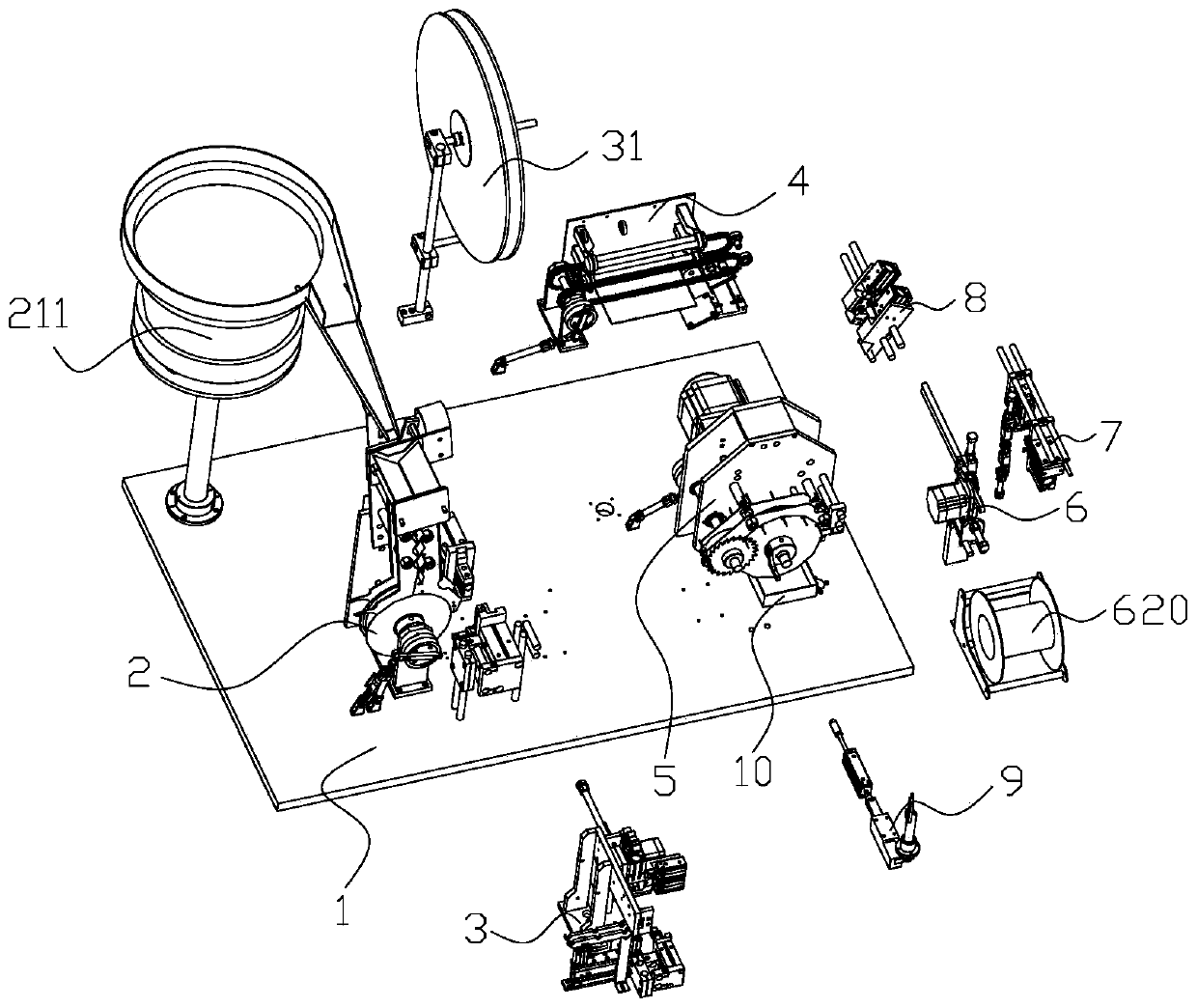

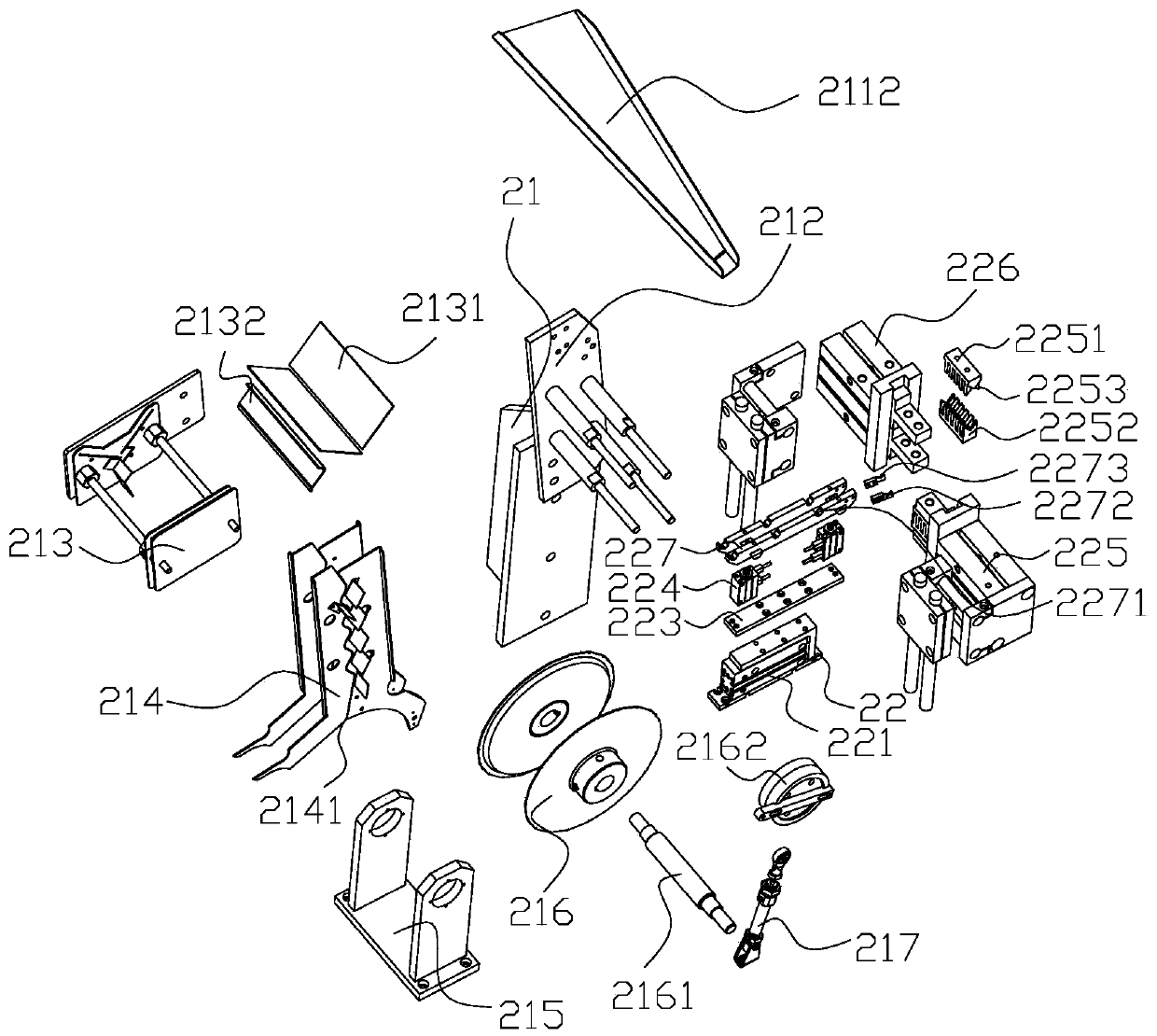

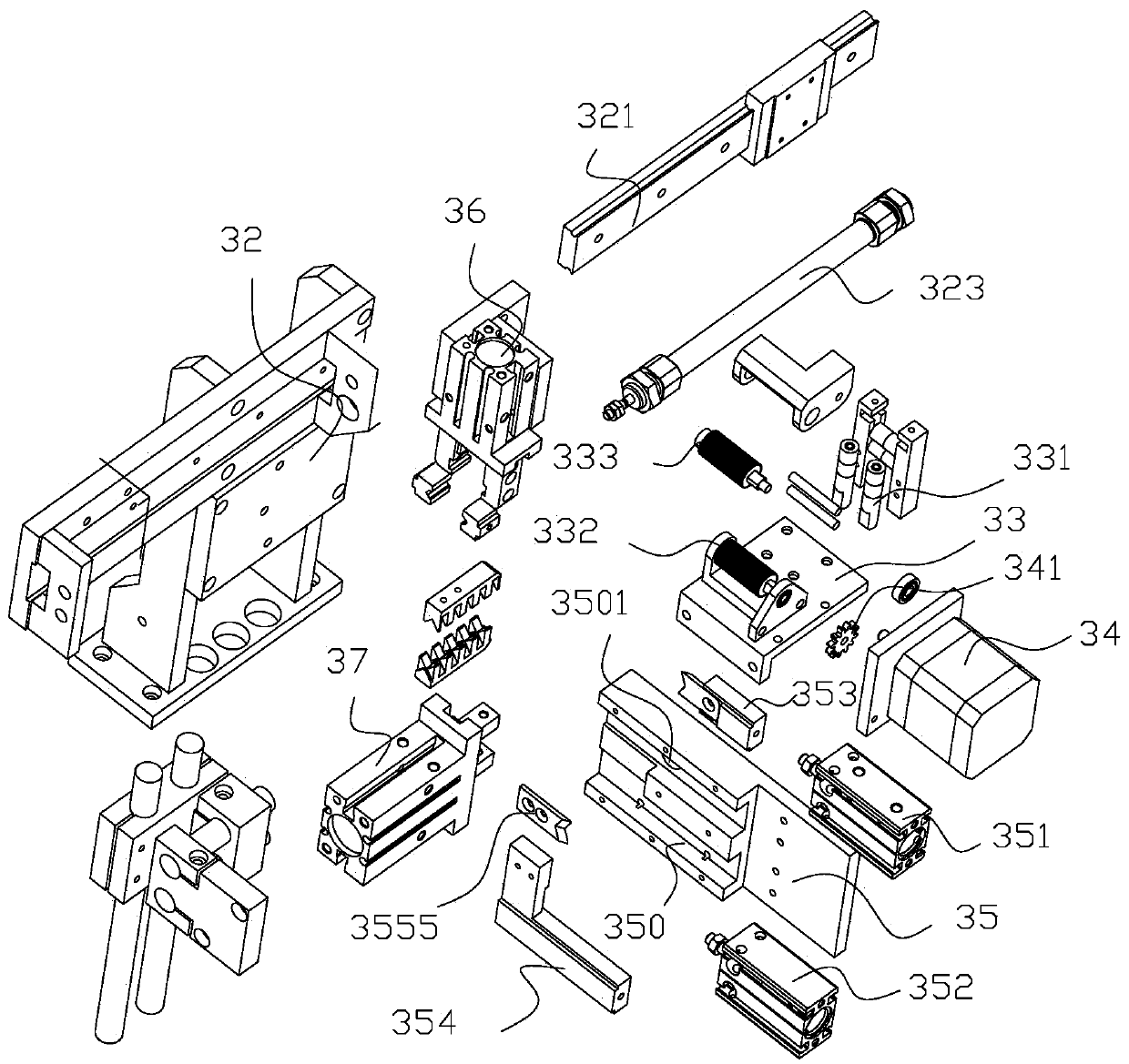

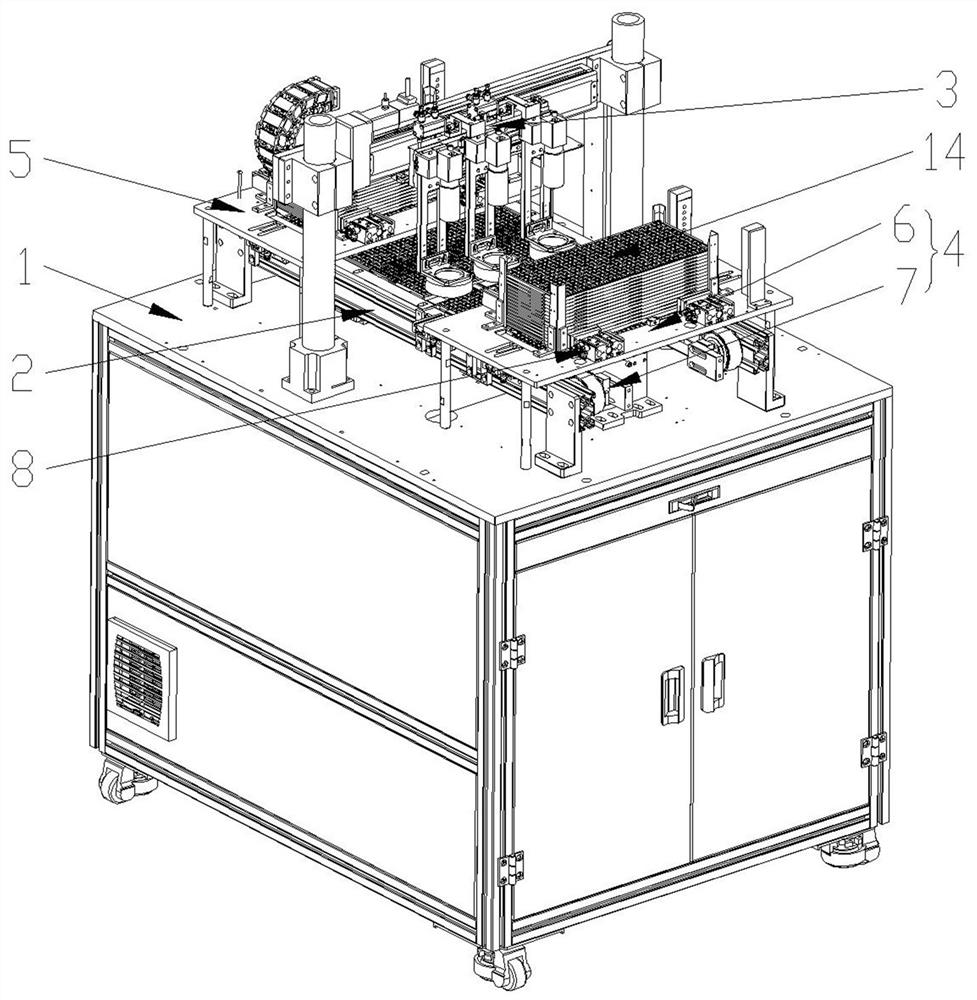

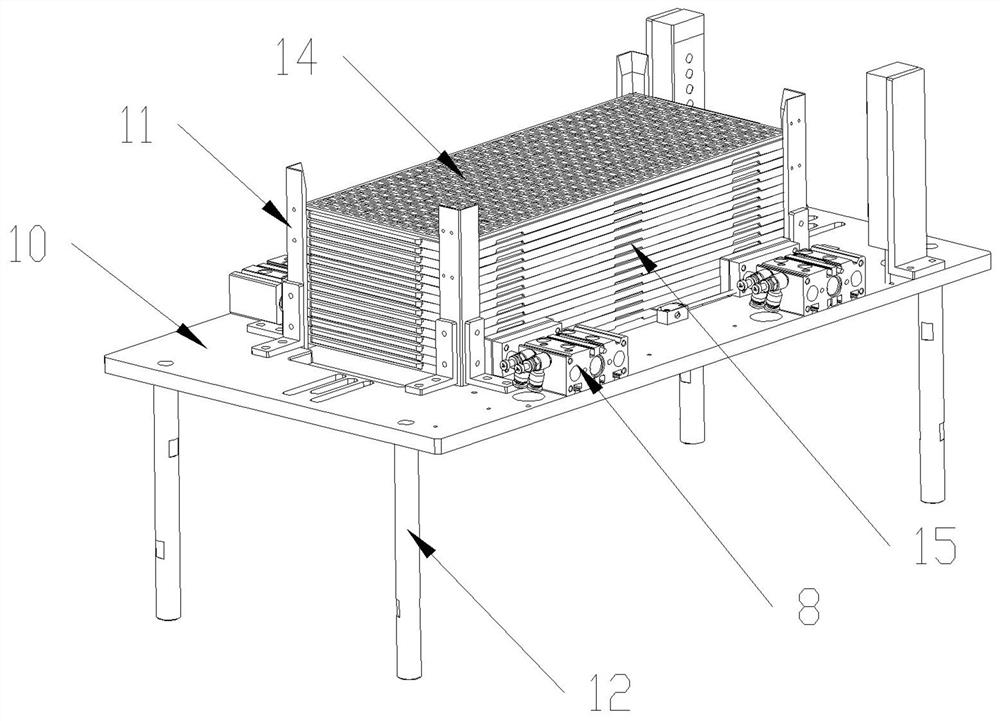

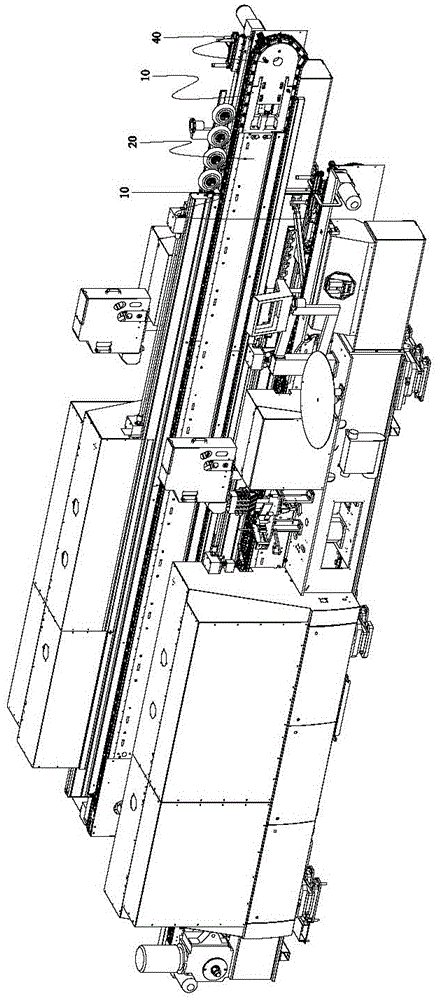

Automatic braid feeding device applied to automatic production of safety belts

PendingCN110480698APrecise deliveryRealize automated productionSevering textilesBeltsEngineeringMechanical engineering

The invention relates to an automatic braid feeding device applied to automatic production of safety belts. The automatic braid feeding device comprises a machine frame, wherein a material reel, a braid guide device, a first traction device, a cutting device, a second traction device, a controller and a power source are arranged on the machine frame, the material reel is used for mounting braid coils, the braid guide device is located above the material reel, the first traction device is located downstream of the braid guide device, the cutting device is located downstream of the first traction device, the second traction device is located on the downstream of the cutting device, and the controller and the power source are used for controlling the coordinate motion of the first traction device, the cutting device and the second traction device. The braid coils are supported by the material reel, the braid guiding device is used for adjusting the running direction of braids, the braidsare accurately conveyed, the first traction device and the second traction device are adopted to traction the braids before and after cutting, the braids are cut by the cutting device, the coordination action of each mechanisms is controlled by the controller, automatic production of automatic braid feeding is realized, and a foundation is laid for automatic production of the whole safety belts.

Owner:无锡平舍智能科技有限公司

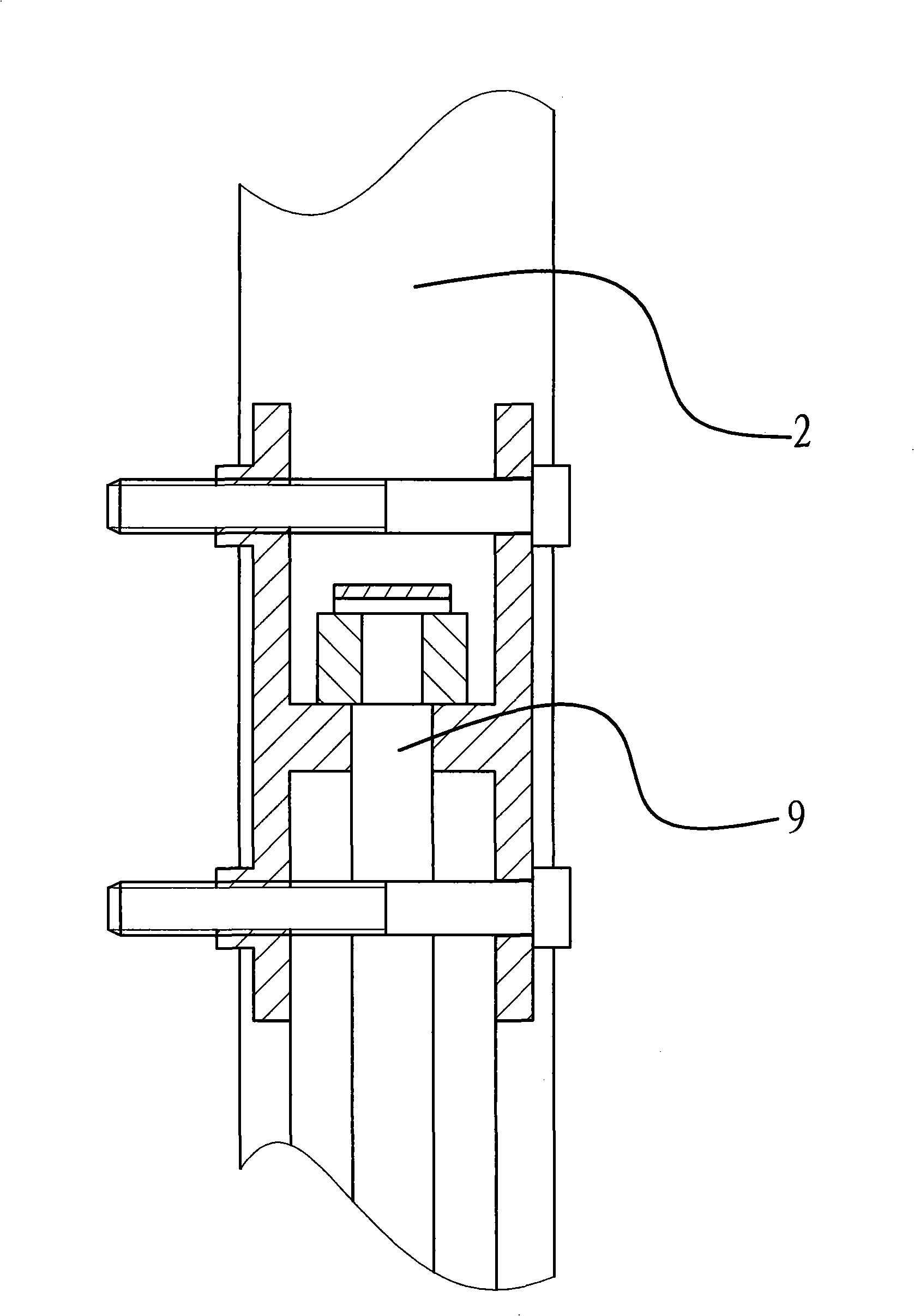

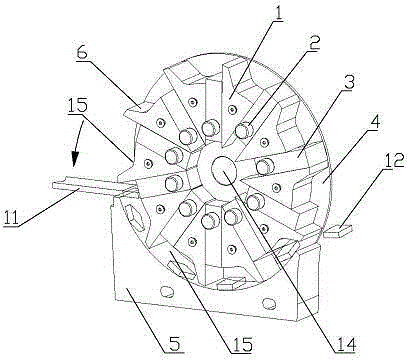

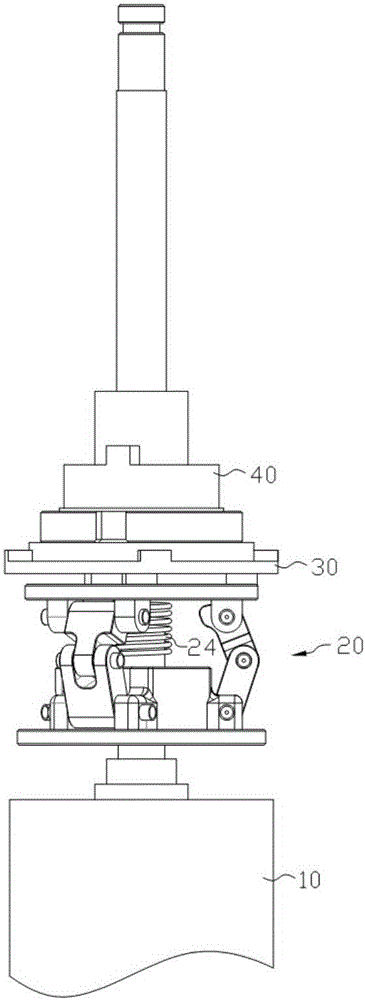

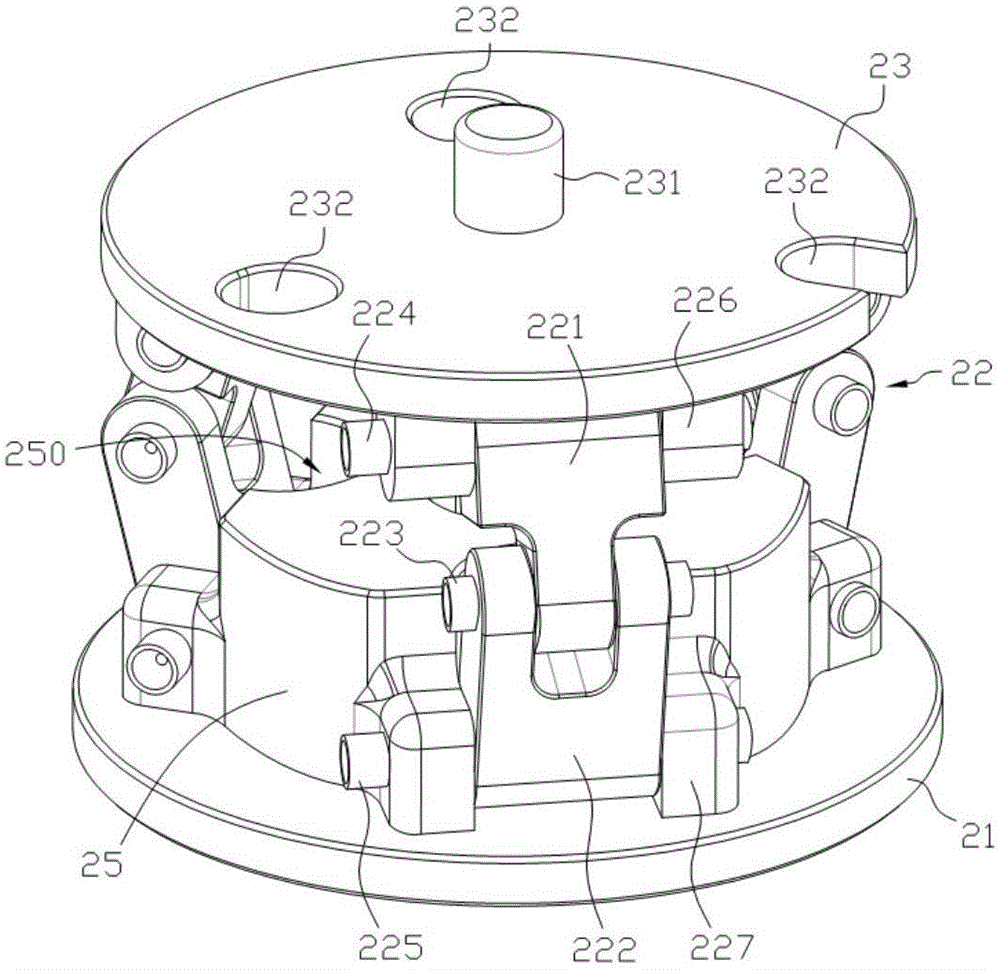

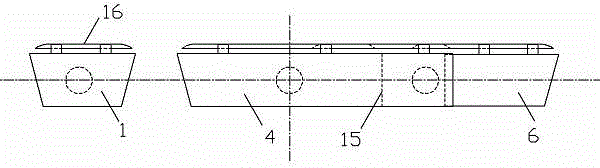

Connection mechanism for laparoscope operational robot devices

ActiveCN106137396AAccurate and stable deliveryPrecise positioningSurgical robotsElastomerEngineering

The invention discloses a connecting mechanism for a laparoscopic surgical robot instrument, which comprises a motor, an elastic body connected to the motor shaft, a bacteria-isolating plate connected to the elastic body, and a wheel shaft connected to the bacteria-isolating plate; the motor is installed on On the instrument base, the axle is installed on the laparoscopic surgical robot instrument. The elastic body includes an upper cover and a lower cover, a set of hinge assemblies connecting the upper cover and the lower cover, and a telescopic spring. According to the above-mentioned technical scheme, the working process of installing the laparoscopic surgical robot instrument to the instrument base is as follows: the motor is installed on the instrument base, and the elastic body is connected to the motor; the bacterial separation plate is installed on the elastic body; Robotic instruments for endoscopic surgery connected to hubs.

Owner:HARBIN SIZHERUI INTELLIGENT MEDICAL EQUIP CO LTD

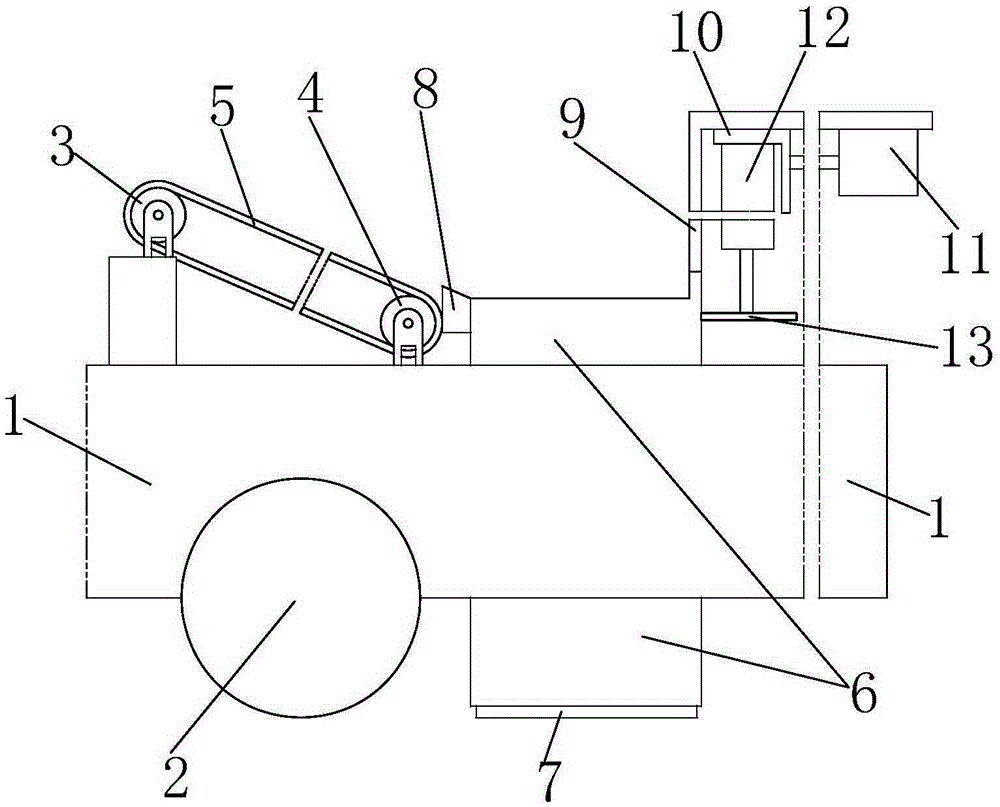

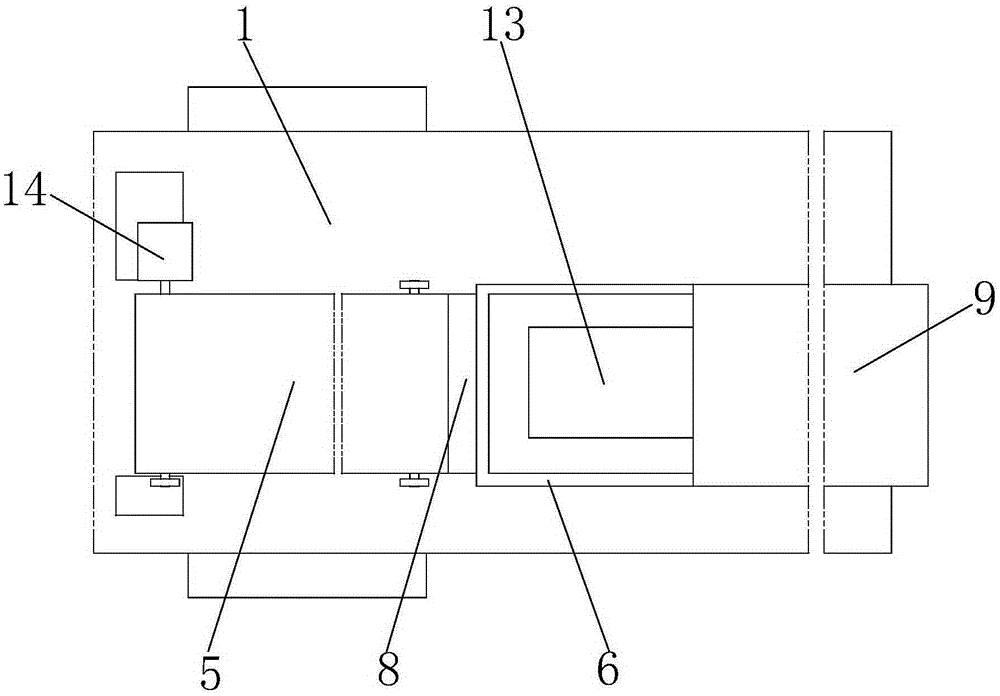

Positioning tile laying device for tile laying machine

InactiveCN105317204AStable and accurate deliveryPrecise positioning functionBuilding constructionsEngineering

The invention relates to a positioning tile laying device for a tile laying machine. The positioning tile laying device mainly comprises cart wheels, a cart body, a first rolling wheel, a second rolling wheel, a belt and a motor. The belt slants towards the lower right portion in the horizontal direction, and a guide plate sleeve is arranged on the right of the belt. The lower end of the guide plate sleeve is fixedly connected with an iron sheet sleeve, the lower end of the iron sheet sleeve is flush with the lower ends of the cart wheels, and a stopping block closely abutting against the right end of the belt is arranged at the left end of the upper portion of the iron sheet sleeve. The upper end of the stopping block is provided with a slant face with the slant angle matched with the slant angle of the belt, and the slant face at the upper end of the stopping block is higher than the upper end of the right side of the belt. An L frame plate is welded to the right end of the upper portion of the guide plate sleeve, a slipping base is horizontally installed at the lower end of the L frame plate in a sliding mode, a first air cylinder is connected to the right end of the slipping base, a second air cylinder is installed at the lower end of the slipping base, and the second air cylinder is connected with a loading plate which can be longitudinally displaced in the guide plate sleeve. By means of the positioning tile laying device, the accurate positioning effect can be achieved on the laying site of a tile; in addition, the tile can be stably conveyed to the specified laying site, placed and laid.

Owner:广东省装饰有限公司

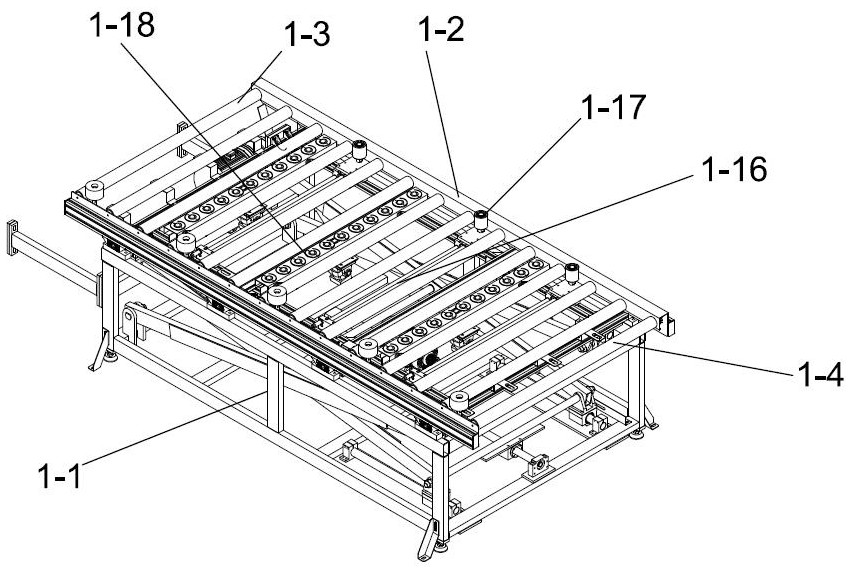

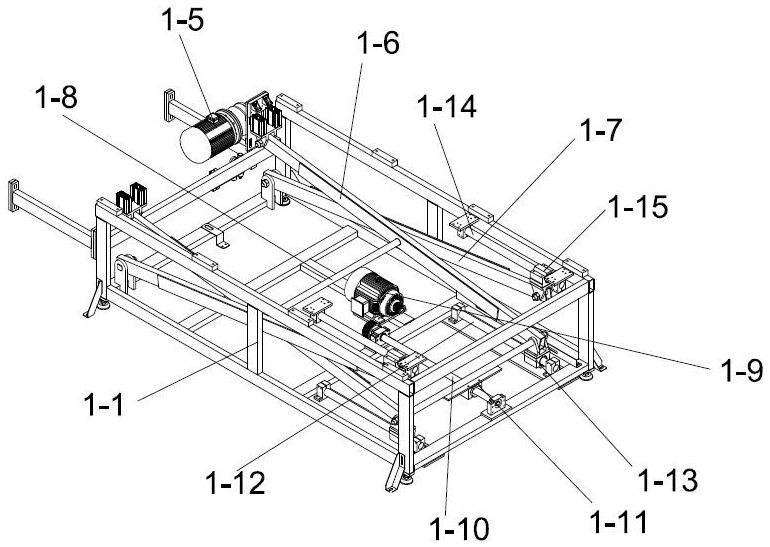

Reversible conveying mechanism for circuit board production and conveying

PendingCN113526096APhenomena that affect processingGuaranteed stabilityConveyor partsRoller-waysMechanical engineering

Owner:QUZHOU CHUANTE ELECTRONICS TECH CO LTD

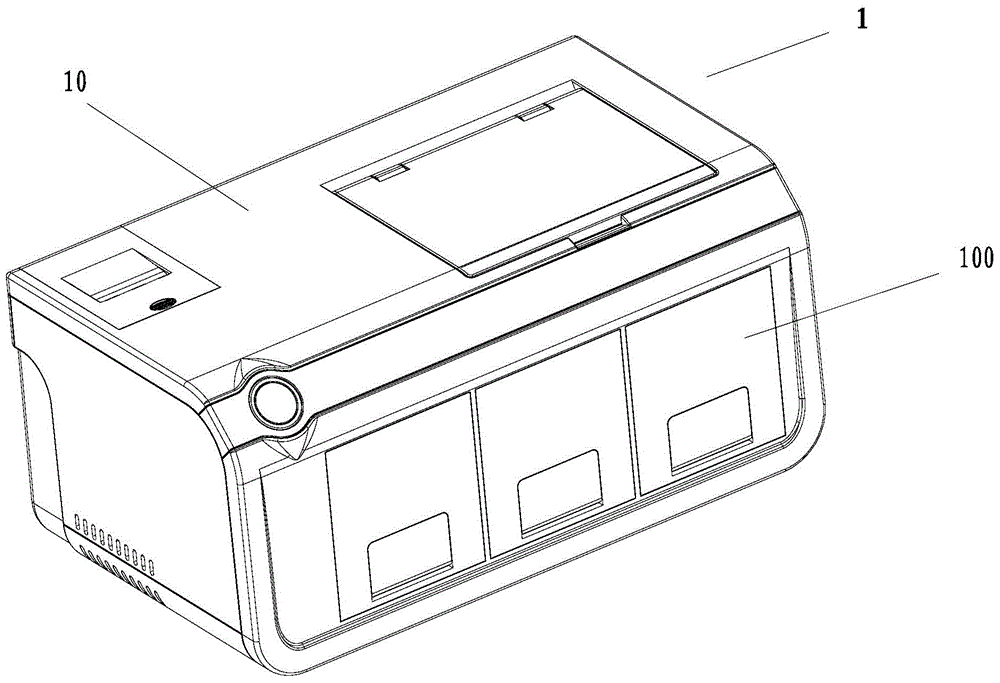

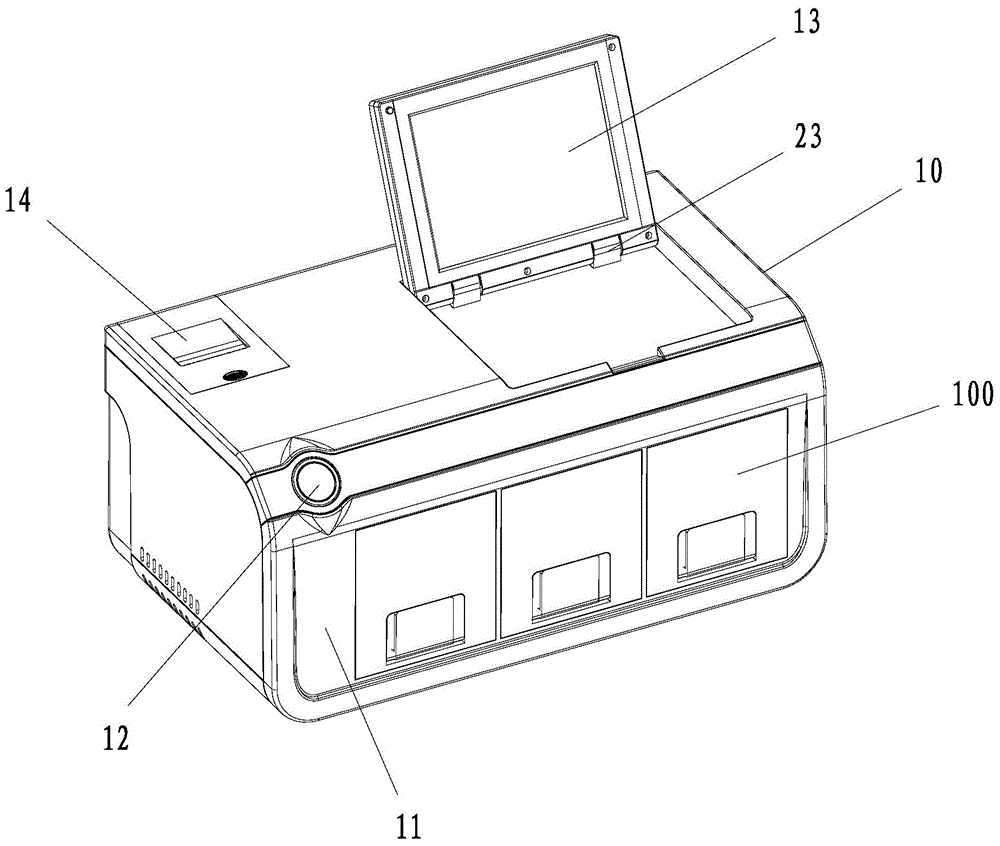

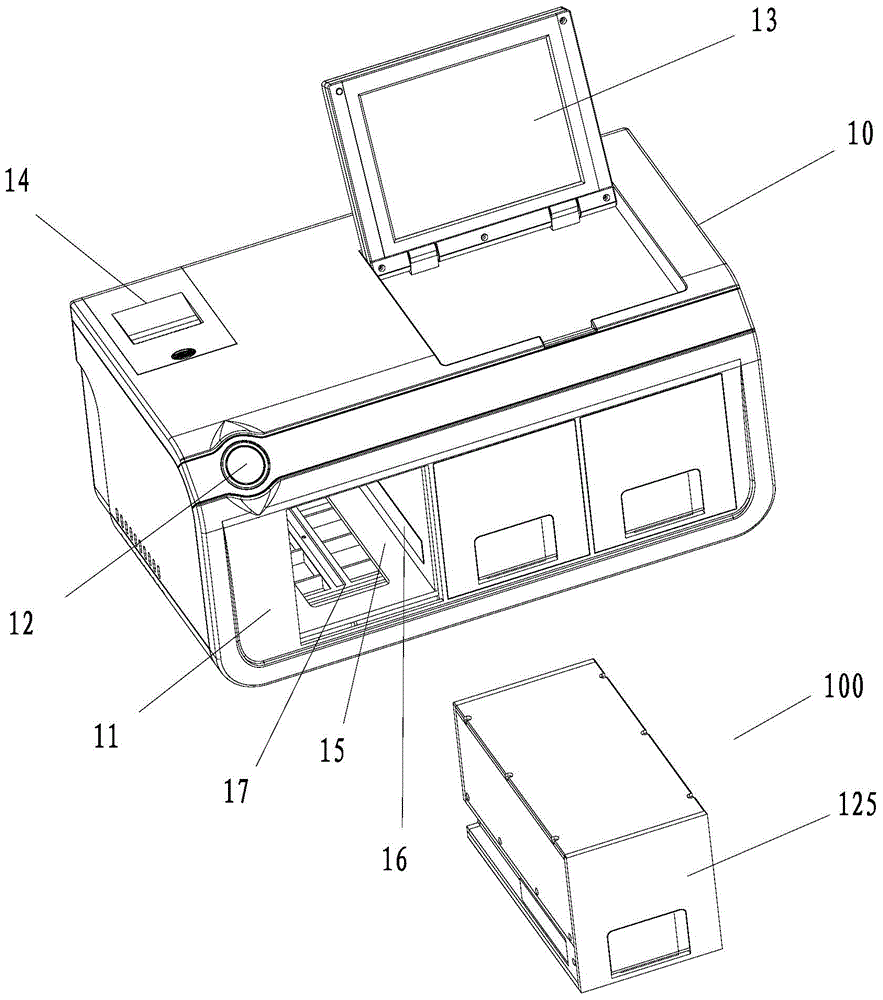

Biological sample analyzing device

The invention provides a biological sample analyzing device. The biological sample analyzing device comprises a main control unit and at least two mutually independent testing units; the main control unit is interconnected with a main power control switch, a data output / input control system, and the testing units respectively; and each of the testing unit at least comprises a sample delivering device and a light source device. The biological sample analyzing device can be used for detecting of a series of physiological and biochemical indexes including glucose, cholesterol, high density fatty acid, low density fatty acids, triglycerides, uric acid, bilirubin, total protein, hemoglobin, and ketone body.

Owner:ACON BIOTECH (HANGZHOU) CO LTD

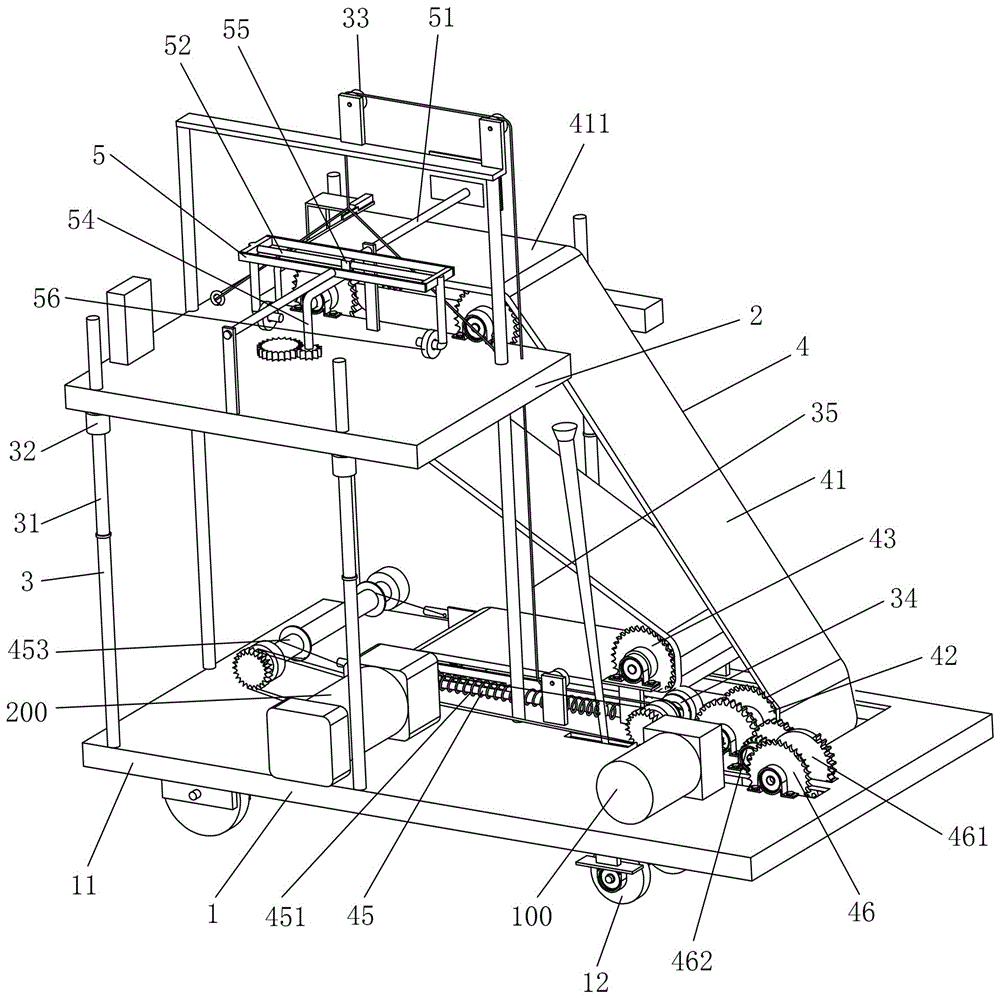

Cargo conveying on-frame machine

InactiveCN106167164ASmooth and accurate deliveryLow costConveyorsSupporting framesEngineeringMechanical engineering

The invention discloses a cargo conveying on-frame machine, which comprises a movable base and a lifting platform. The lifting platform is mounted on the movable base through a lifting device, and a cargo conveying device is arranged between the movable base and the lifting platform for conveying the cargos to the lifting platform The cargo conveying device comprises a loop conveyer belt and a driving unit for driving the loop conveyer belt. The loop conveyer belt includes a discharge section which is arranged on the lifting platform and moves up and down synchronously with the lifting platform. The lifting platform is provided with an on-frame pushing device for pushing the cargos on the discharge section. The cargo conveying on-frame machine has the advantages that efficiency is high, labor intensity and cost can be greatly reduced and so on.

Owner:HUNAN AGRICULTURAL UNIV

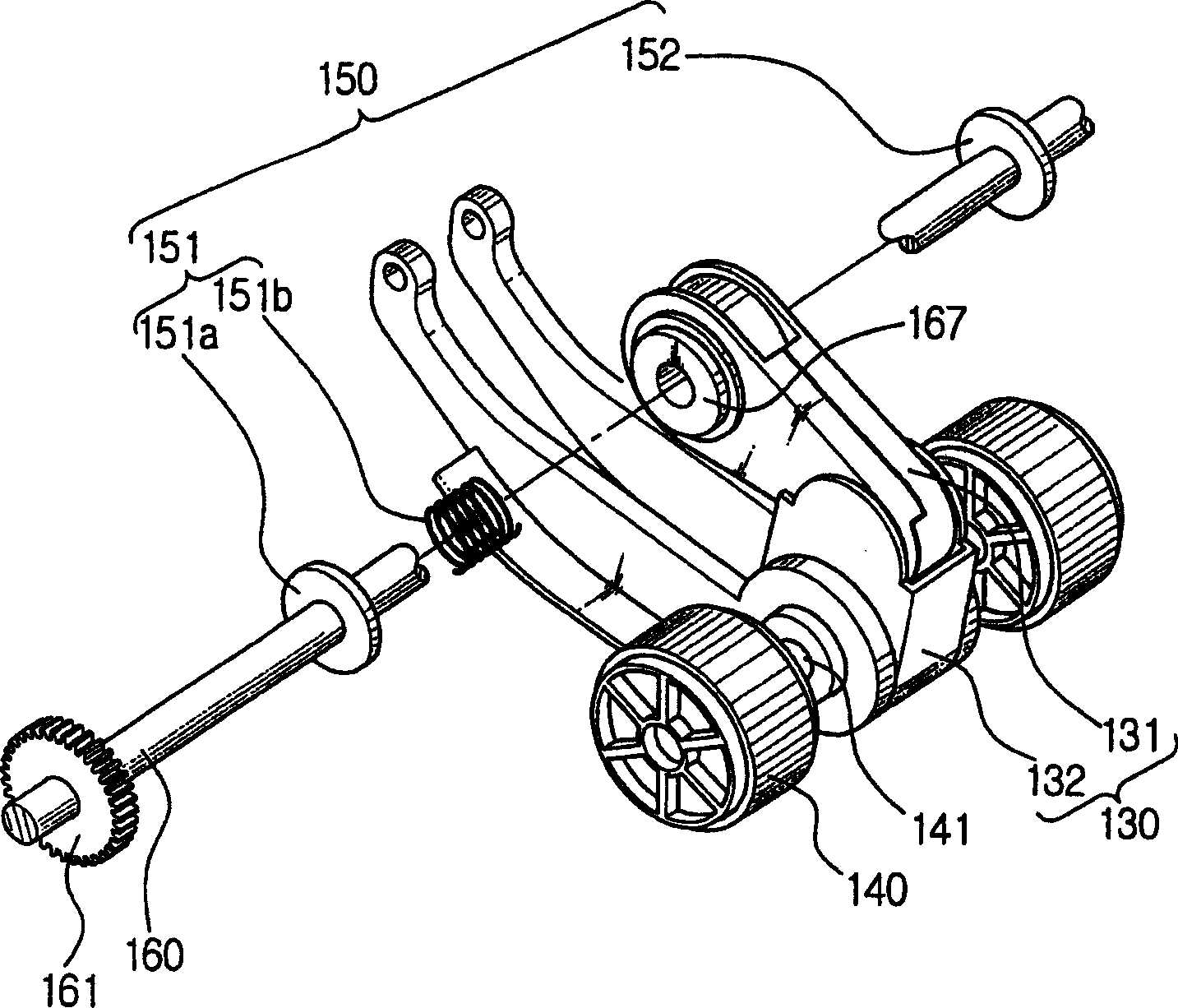

Paper supply device for ink-jet printer

InactiveCN1517230ASolve the real problemAvoid pressingOther printing apparatusPrinting press partsDrive shaftEngineering

A paper feeding device of an inkjet printer includes a motor generating a drive force, a pickup drive shaft rotated by the motor, a pivoting link housing disposed on the pickup drive shaft, a pickup roller connected to the ling housing, and a clutch enlinking the pickup drive shaft and the link housing enabling the link housing to pivot by a predetermined angle by rotation of the pickup drive shaft.

Owner:SAMSUNG ELECTRONICS CO LTD

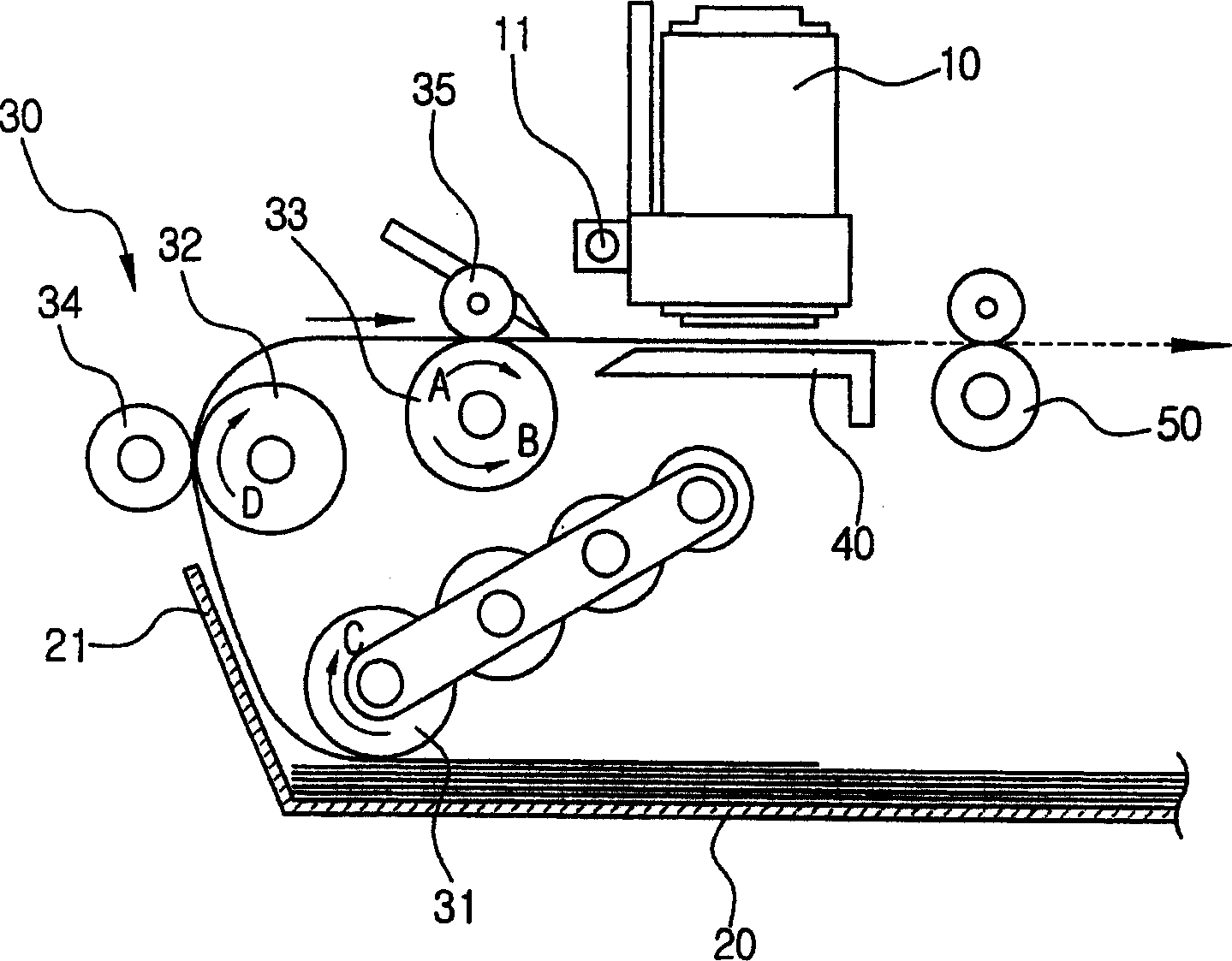

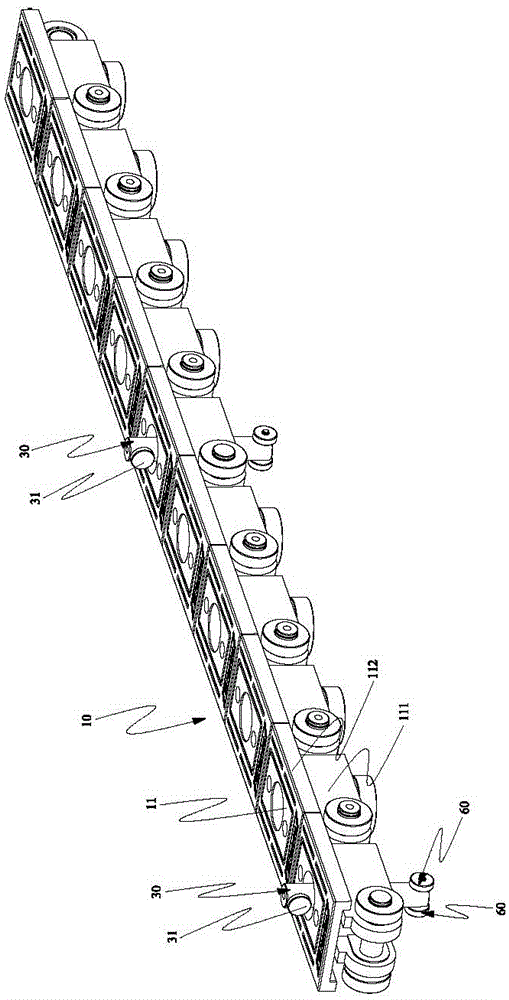

Detection unit for online negative pressure air suction conveying device of roll paper die-cutting machine belt

ActiveCN104528419AAccurate and smooth deliverySmooth and accurate deliveryCleaning using gasesArticle feedersRolling paperEngineering

The invention discloses a detection unit for an online negative pressure air suction conveying device of a roll paper die-cutting machine belt. The detection unit comprises the conveying device, negative pressure cavity boxes, a foldable negative pressure cavity box, a sliding device of the foldable negative pressure cavity box and a belt supporting frame. The negative pressure cavity boxes and the foldable negative pressure cavity box are arranged on the lower face of a conveyor belt and the foldable negative pressure cavity box can slide, stretch and retract in one negative pressure cavity box. A negative pressure cavity panel is arranged on the negative pressure cavity boxes and the foldable negative pressure cavity box. The negative pressure cavity boxes are fixed to a rack, the foldable negative pressure cavity box is fixed to the sliding device, and the sliding device is connected with a cylinder. The negative pressure cavity boxes and the foldable negative pressure cavity box are provided with connectors and connected with an exhaust fan. The belt supporting frame is a mesh type frame arranged on the negative pressure cavity panel. A dust removal device and a connection device can be additionally arranged on the detection unit. Products can be stably and accurately conveyed to a detection device through the negative pressure air suction conveying device.

Owner:CHANGDE JINPENG PRINTING

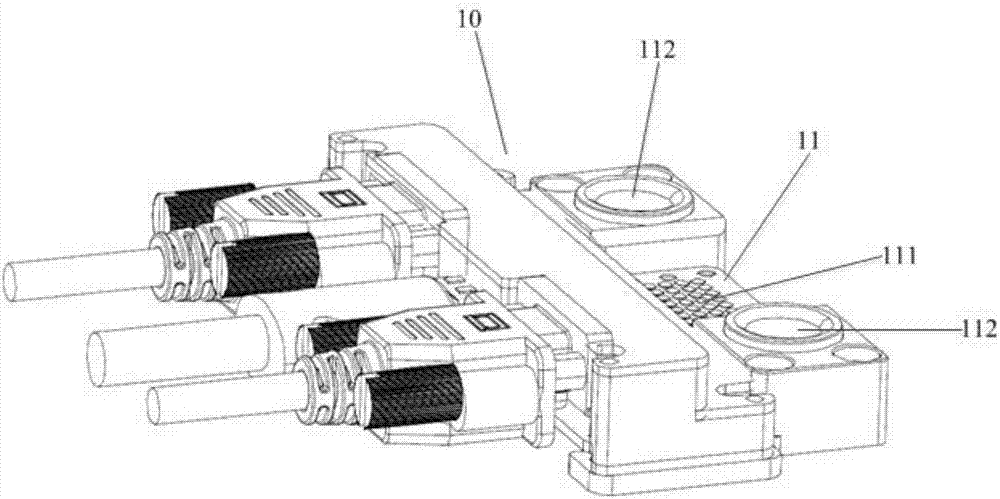

Automatic plug wire testing device

ActiveCN106918727ASmooth and precise transmissionTransmission is stable and accurateElectrical measurement instrument detailsElectrical testingTest efficiencyProduct base

The invention discloses an automatic plug wire testing device, and belongs to the field of testing equipment. The automatic plug wire testing device comprises a first substrate assembly, a second substrate assembly and a direction adjustment assembly, and is characterized in that the direction adjustment assembly is connected with the second substrate assembly; the first substrate assembly is electrically connected with a device at the end to be tested, and the first substrate assembly is provided with a probe welding pad; the second substrate assembly is electrically connected with a device at the test end, and the second substrate assembly is provided with a probe base; the probe welding pad is provided with a plurality of contacts, and the product base is provided with a plurality of corresponding probes; and the direction adjustment assembly adjusts the probes on the probe base to be aligned with the contacts on the probe welding pad in the process that the probes are contacted with the contacts. Alignment of the probes on the probe base and the contacts on the probe welding pad is adjusted by the direction adjustment assembly in the testing process through connection between the direction adjustment assembly and the second substrate assembly, so that automatic alignment adjustment is realized, alignment adjustment is not required to be performed manually, and the test efficiency and effect are improved.

Owner:QISDA SUZHOU

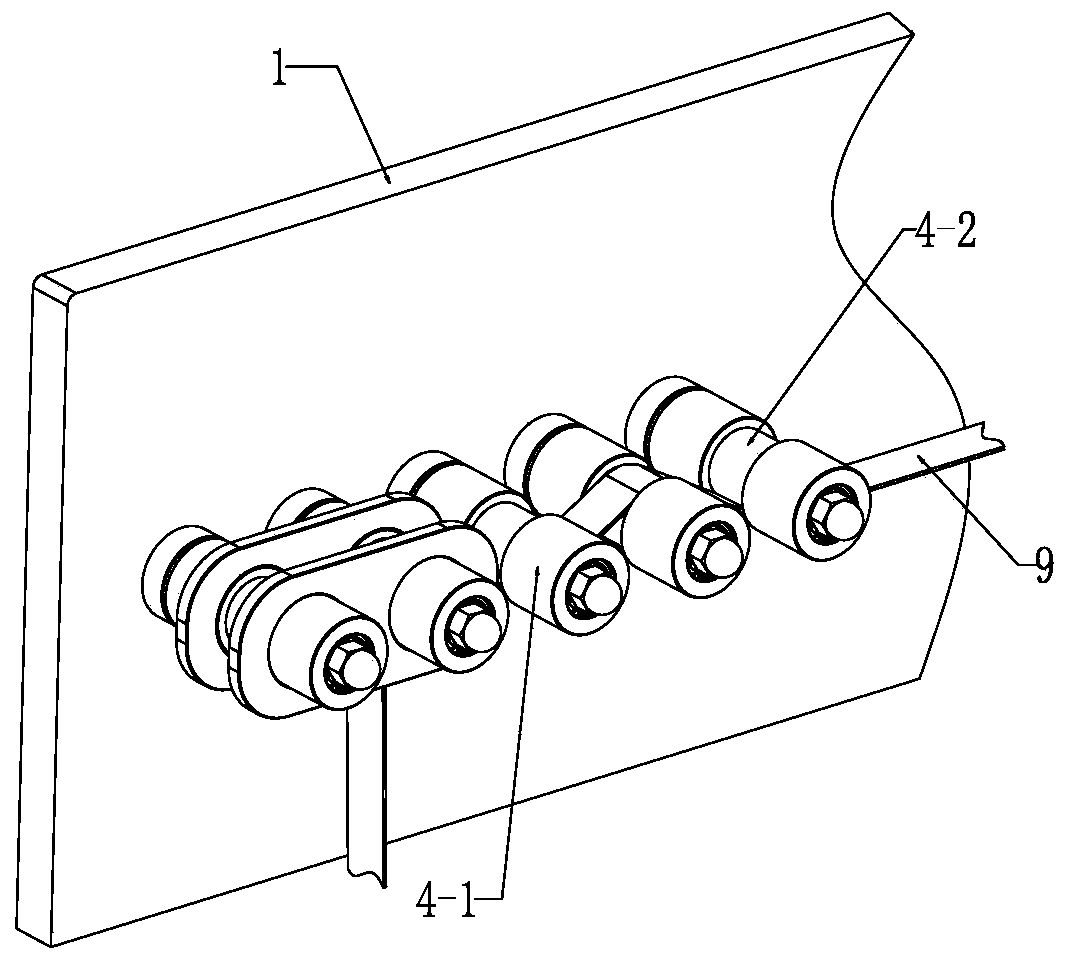

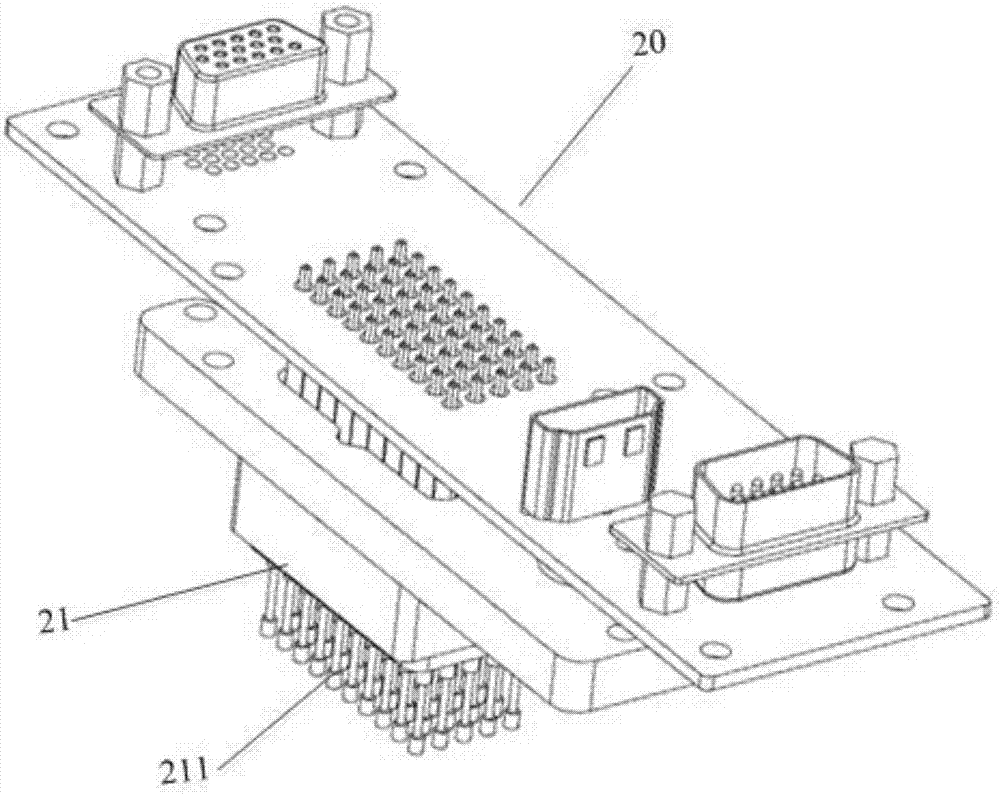

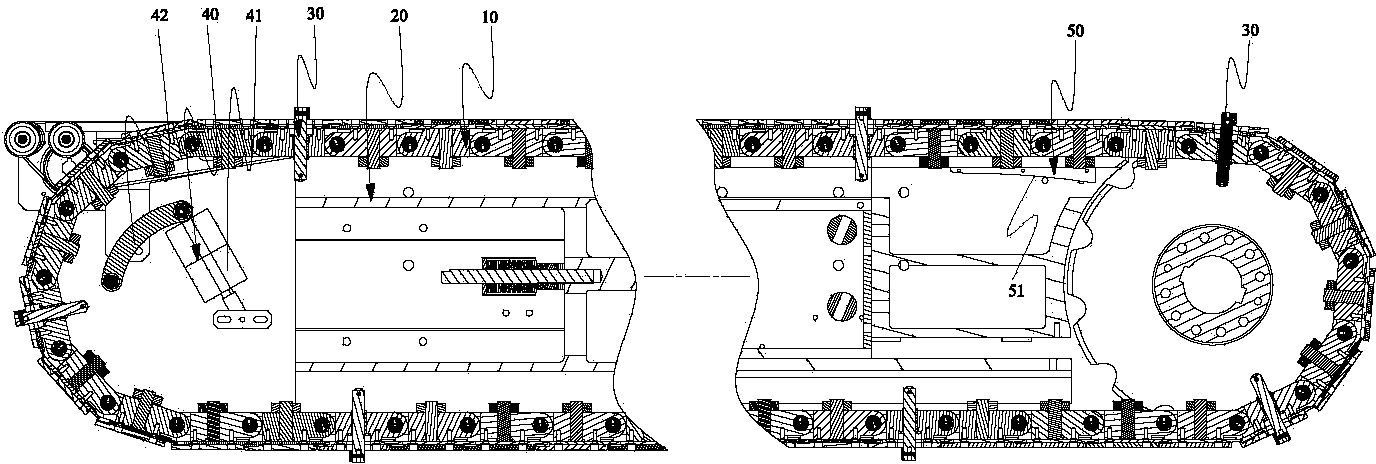

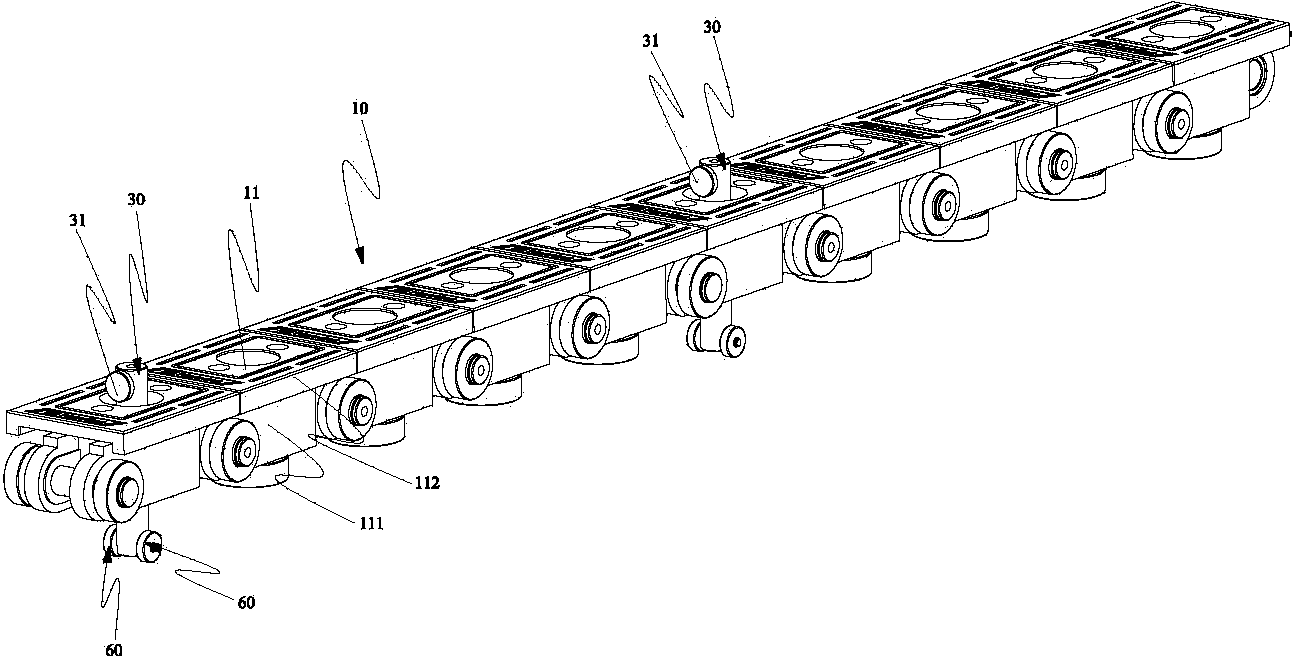

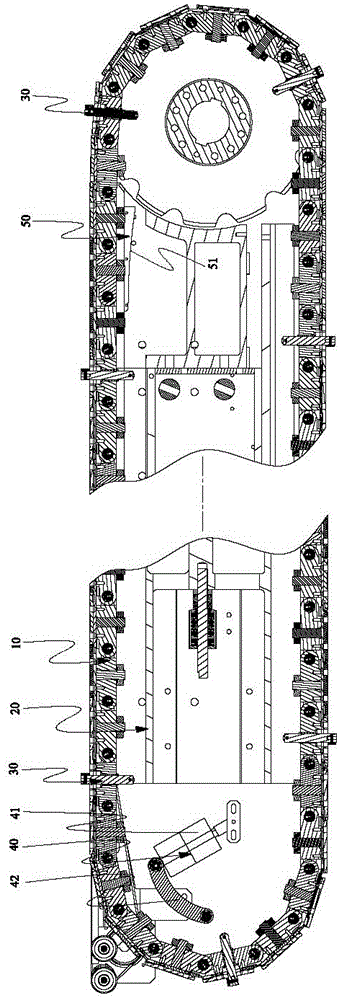

Transmission chain control device for double-end edge bonding machine

ActiveCN103878862ASmooth and accurate deliveryImprove the quality of machining operationsWood working apparatusDomestic articlesEngineeringMechanical engineering

The invention discloses a transmission chain control device for a double-end edge bonding machine. The transmission chain control device comprises two transmission chains, each transmission chain comprises a plurality of chain blocks and is provided with a plurality of hook heads capable of telescoping inside and outside, the plurality of hook heads are arranged at intervals and synchronously move along with the chain blocks, a push-up mechanism is arranged in a feeding end of each transmission chain, and a pull-down mechanism is arranged in a discharging end of each transmission chain. The plurality of hook heads which are capable of telescoping inside and outside and arranged at intervals on each transmission chain can be urged to outwardly extend above the chain blocks by the aid of the push-up mechanisms and inwardly retract below the chain blocks by the aid of the pull-down mechanisms. Therefore, the hook heads can be pushed out or retracted back according to needs, the hook heads extending out can be abutted against the rear end face of a board to complete positioning conveying of the board, a traditional way which only depends on friction driving is replaced, board conveying is more stable and accurate, and board machining quality is improved.

Owner:NANXING MACHINERY CO LTD

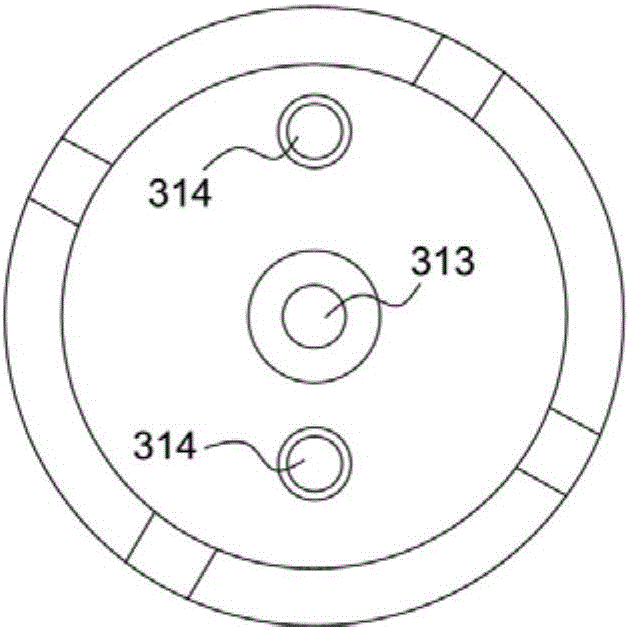

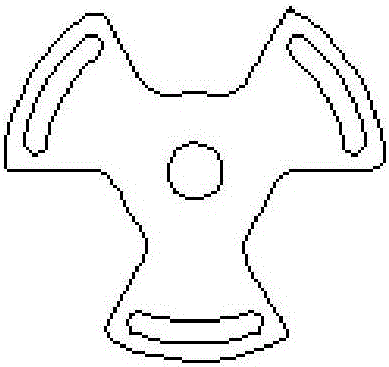

Microcomputer-based three-vane wheel delivery mechanism

InactiveCN105894666AAdjustable sizeEasy to processCoin-freed apparatus detailsApparatus for dispensing discrete articlesMicrocomputerMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to a microcomputer-based three-vane wheel delivery mechanism. The microcomputer-based three-vane wheel delivery mechanism comprises a main track and a delivery adjustable three-petal set, the main track is vertically arranged, a capsule inlet is formed in the top of the main track while a capsule outlet is formed in the bottom of the same, the delivery adjustable three-petal set formed by stacking of three pieces of three-petal set bodies is arranged on one side of the capsule outlet of the main track, each three-petal set body is formed by three arc flower pieces, each flower piece of the three-petal set bodies is provided with an elongated groove, a screw is arranged in the elongated groove, and capsules of different sizes can be applied by adjusting stacking positions of the three-petal set bodies through the screws. By the arrangement that capsule-structured goods are discharged by using a unique manner, the irregular capsules are arranged in a row by means of the track, machining, assembling and maintaining are simplified, assembling and testing time is short, manufacturing cost is low, however, commercial value is quite high.

Owner:SHANGHAI MIQUAN VENDING MACHINE CO LTD

Automatic chip discharging and conveying device

PendingCN114464562AGuaranteed synchronicityFirmly connectedSemiconductor/solid-state device manufacturingConveyor partsEngineeringChip carrier

The invention discloses an automatic chip discharging and conveying device which comprises a chip carrier transferring and conveying device and a containing box transferring and conveying device, the chip carrier transferring and conveying device comprises an adsorption supporting frame, a carrier table, a carrier containing box and a workbench, and the carrier table and the carrier containing box are placed on a bonding station and an adsorption station on the workbench respectively. An opening groove is formed in the carrier table, and an assembling opening facilitating pulling out of the carrier is formed in the feeding end of the opening groove. The carrier containing box is provided with a plurality of carrier containing grooves used for insertion of carriers, the device can automatically clamp the carrier containing box filled with the carriers which are not bonded to an adsorption station, the carriers are taken out of the carrier containing box one by one through a machine, and after bonding is completed, the carriers are put back into the carrier containing box. And then the carrier containing box filled with the bonded carriers is clamped to the conveying belt to be conveyed to the next working procedure, so that the labor force is reduced, and the production efficiency is improved.

Owner:苏州声芯电子科技有限公司

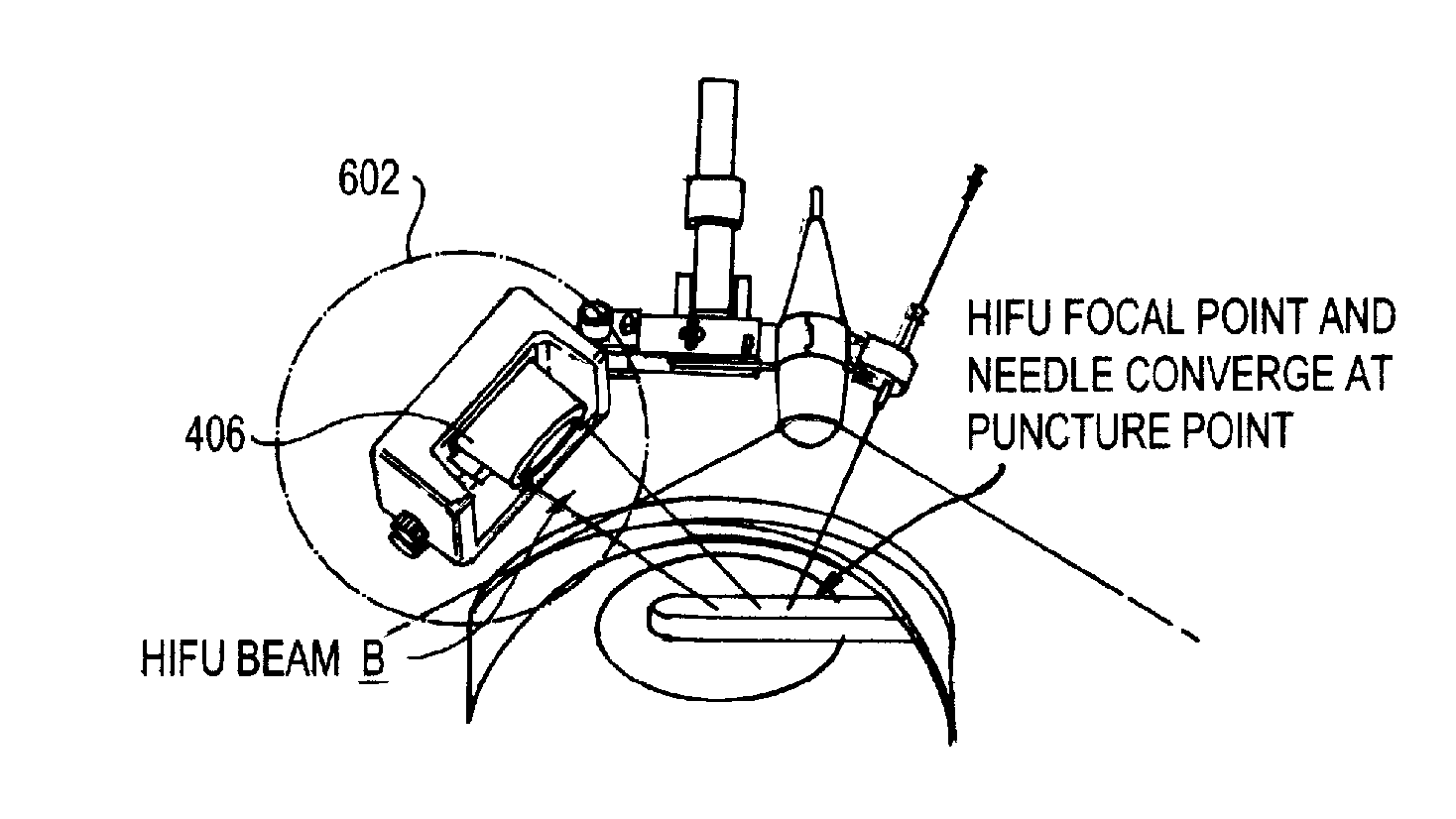

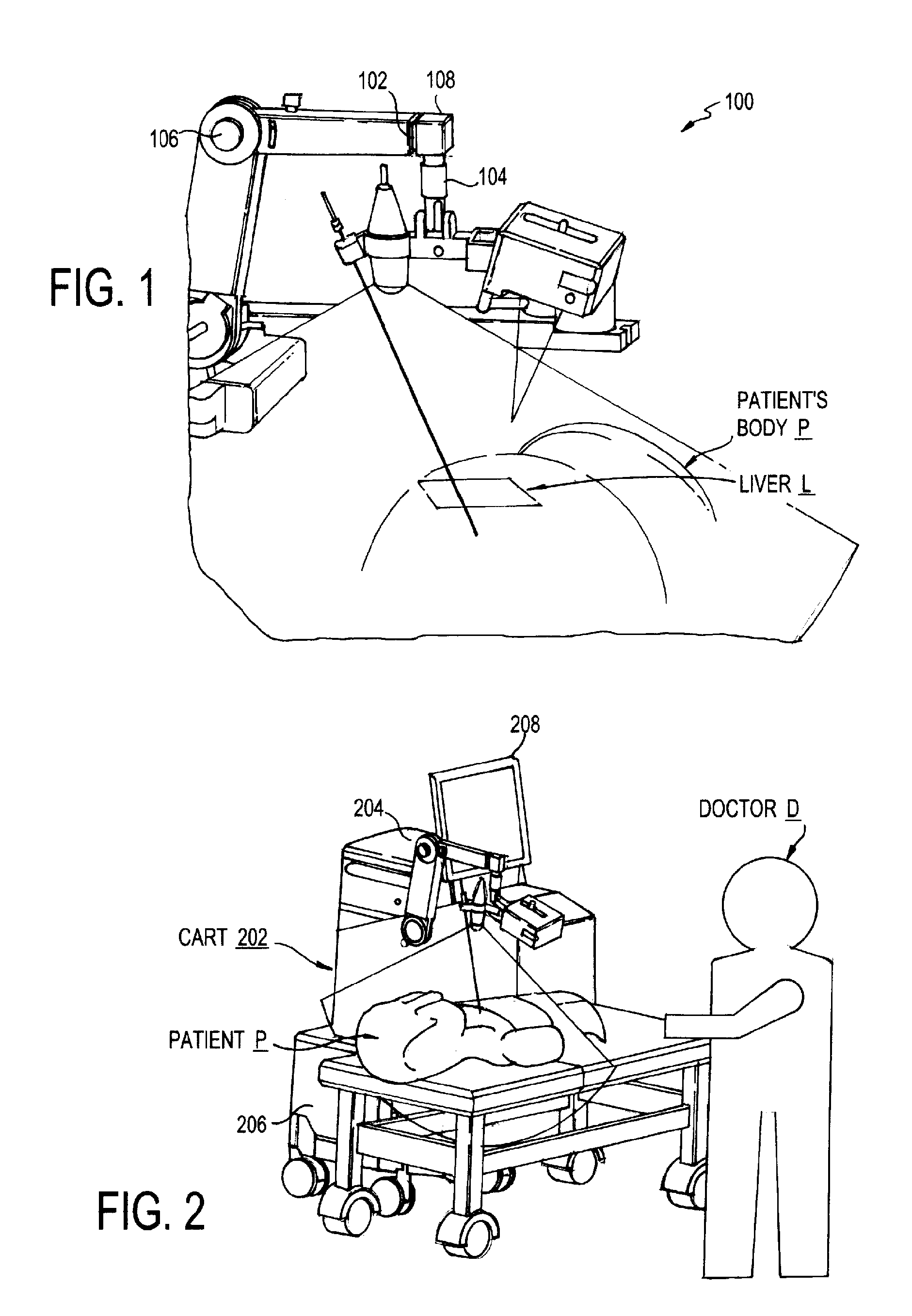

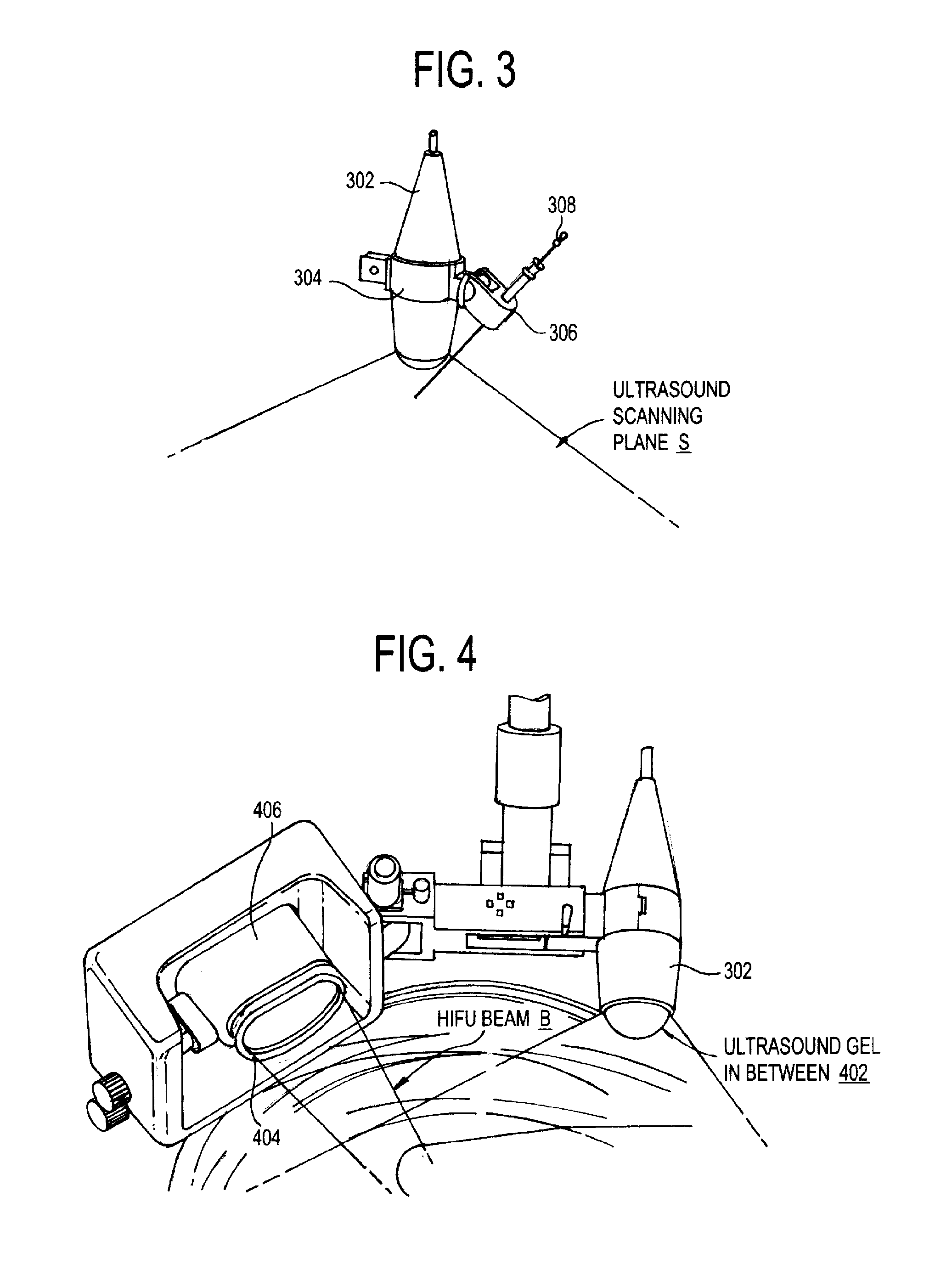

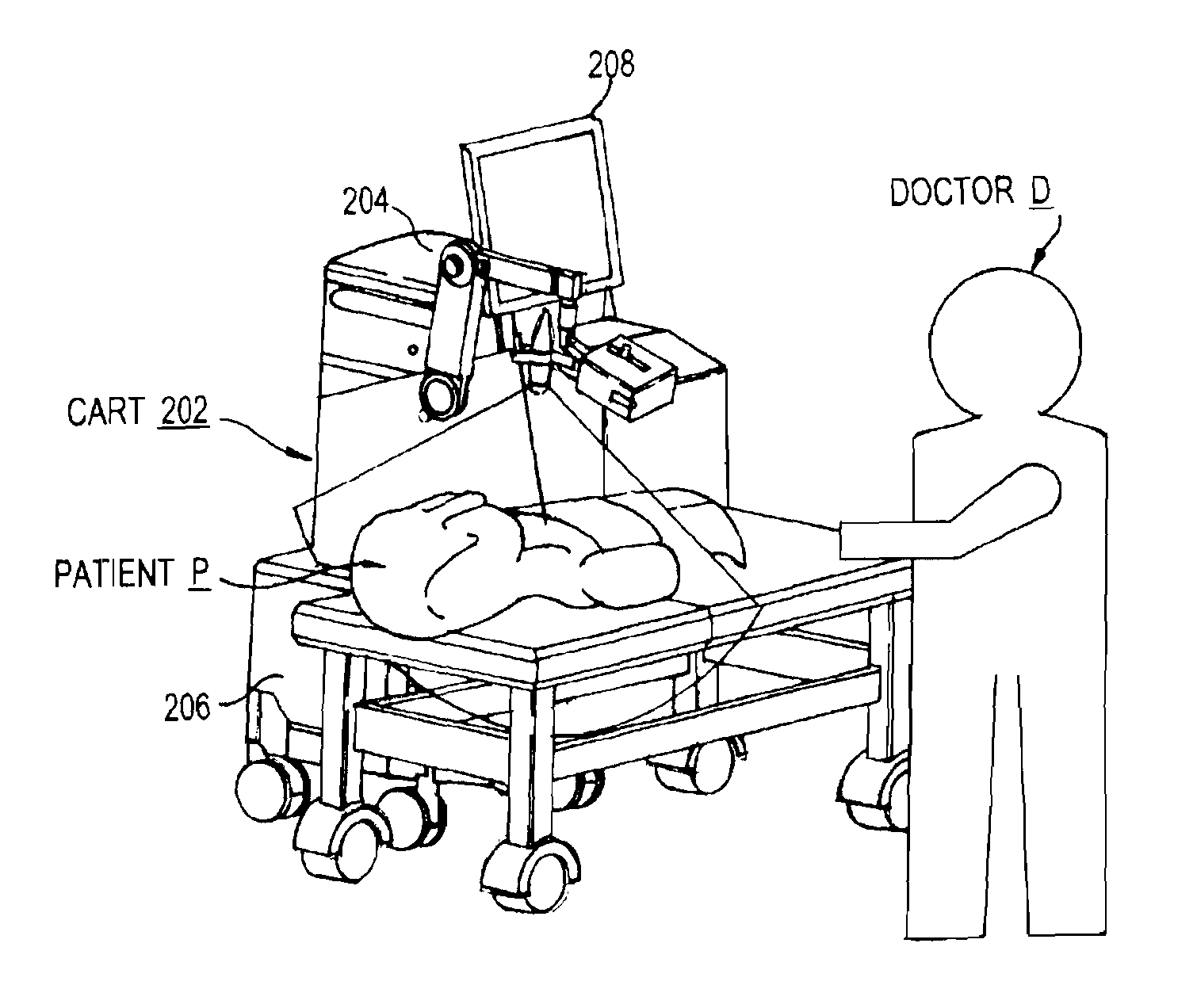

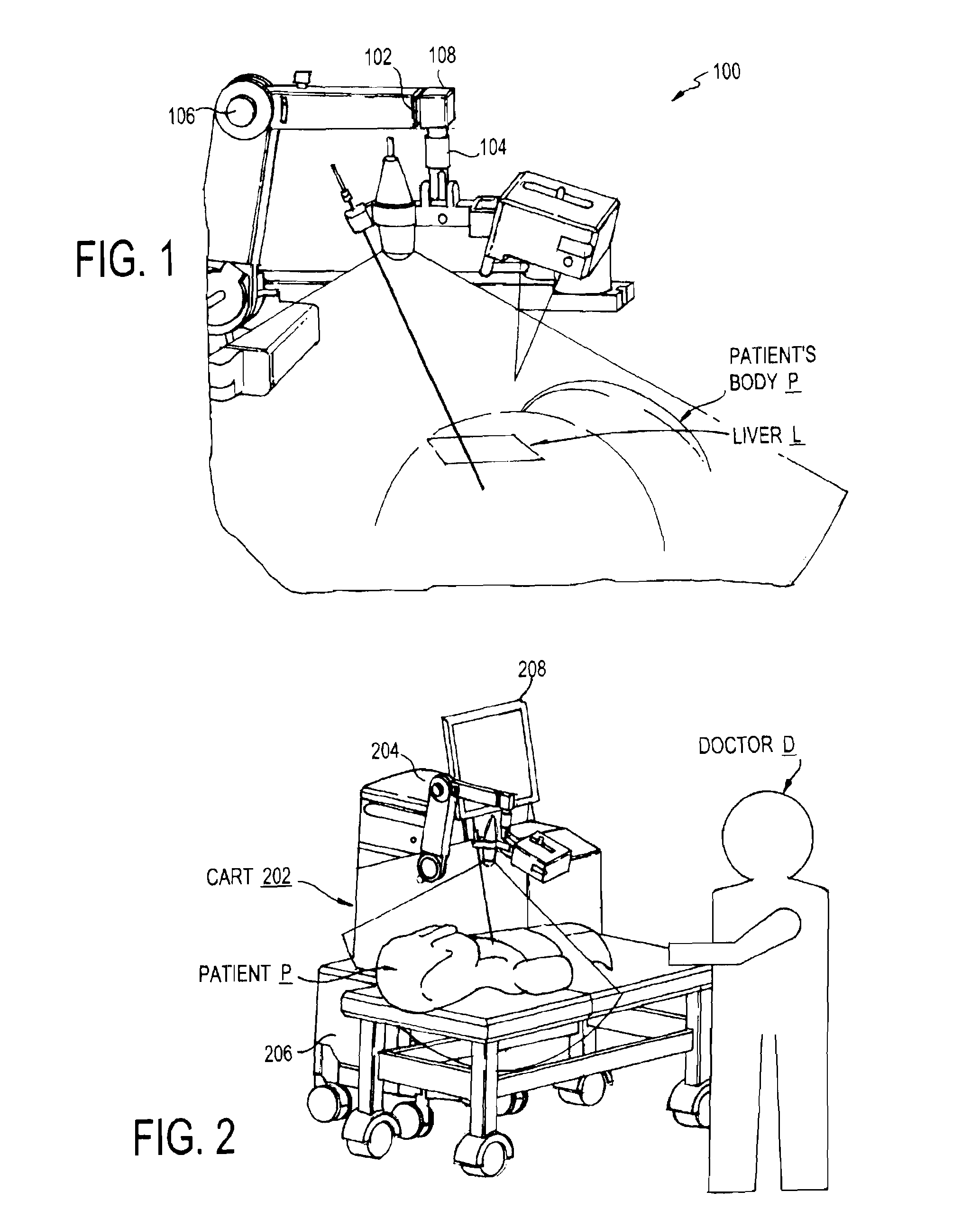

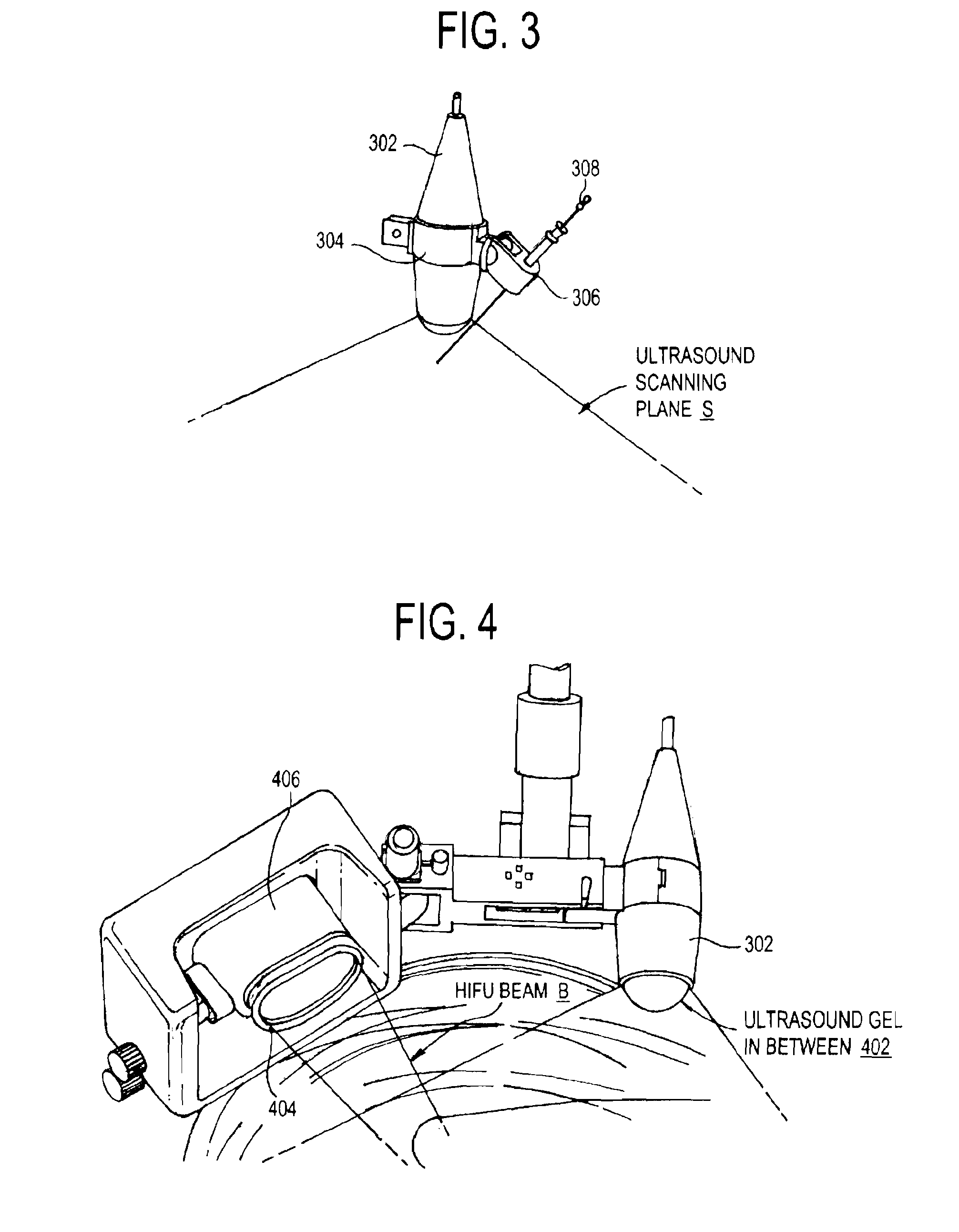

Robotic localizing aid for high-intensity focused ultrasound delivery

InactiveUS20120095336A1Easy to useAccurate placementUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyTransducerImaging ultrasound

A holding structure holds a biopsy needle and a HIFU transducer to allow smooth and accurate delivery of the HIFU beam at the interface of the liver, where bleeding will occur. This manipulator structure performs the biopsy and HIFU through the percutaneous approach. In addition, the procedure is imaged by an imaging ultrasound probe. The imaging ultrasound probe can track the needle entry site even when needle has been removed. The HIFU transducer fires a short pulse of HIFU in the needle tract to cause coagulation and stop bleeding.

Owner:UNIVERSITY OF ROCHESTER

Robotic localizing aid for high intensity focused ultrasound delivery

InactiveUS20140088422A1Easy to useAccurate placementUltrasound therapyOrgan movement/changes detectionPositioning aidsTransducer

A holding structure holds a biopsy needle and a HIFU transducer to allow smooth and accurate delivery of the HIFU beam at the interface of the liver, where bleeding will occur. This manipulator structure performs the biopsy and HIFU through the percutaneous approach. In addition, the procedure is imaged by an imaging ultrasound probe. This imaging ultrasound probe can track the needle entry site even when needle has been removed. The HIFU transducer fires a short pulse of HIFU in the needle tract to cause coagulation and stop bleeding.

Owner:UNIVERSITY OF ROCHESTER

Roller type conveying equipment used for plate machining

PendingCN113086524ASmooth and accurate deliveryNot easy to wearConveyorsConveyor partsGear wheelChain link

The invention belongs to the technical field of plate machining, and particularly relates to roller type conveying equipment used for plate machining. Through the manner of arranging a roller, a gear, a chain, a transmission unit, an eccentric wheel unit and a first jacking unit on a vertical frame, the aim that plates can be jacked up at a specific position while being conveyed so as to be subjected to taking and placing machining or sampling inspection and the like is achieved. The roller type conveying equipment has the advantage of accurately and stably conveying plates, the plates can be jacked up at the preset position so that the plates can be lifted and separated from the roller to be conveyed, and therefore the technological production requirements of taking and placing machining or sampling inspection and the like for the plates can be met; and the roller type conveying equipment further has the advantages that the plate lifting position is flexible and adjustable, the plates are not prone to being worn, and the equipment is suitable for plates with medium or low hardness.

Owner:ZHEJIANG YASHA DECORATION

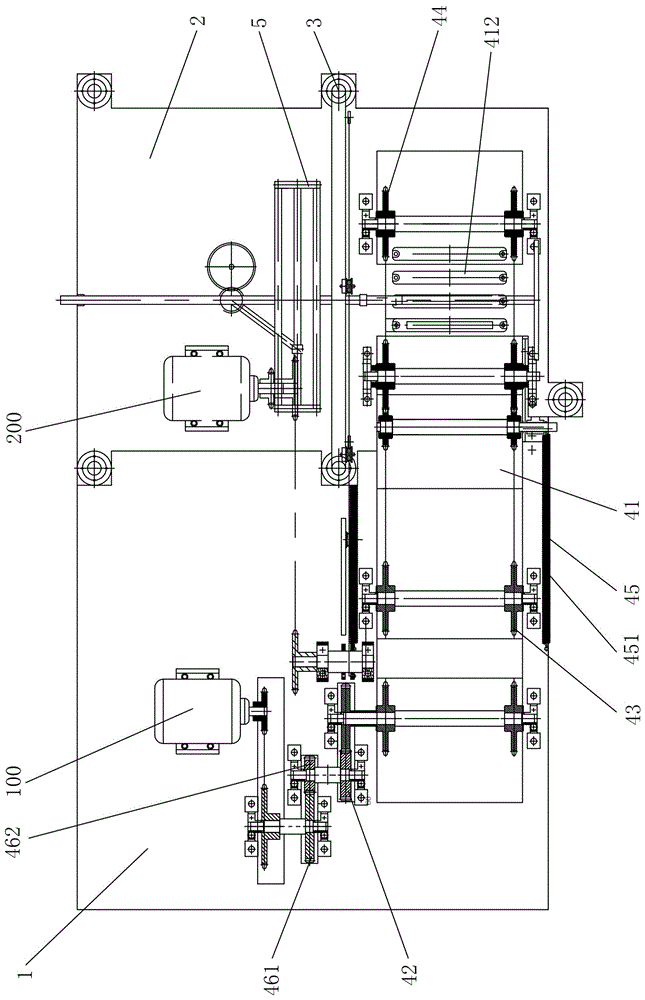

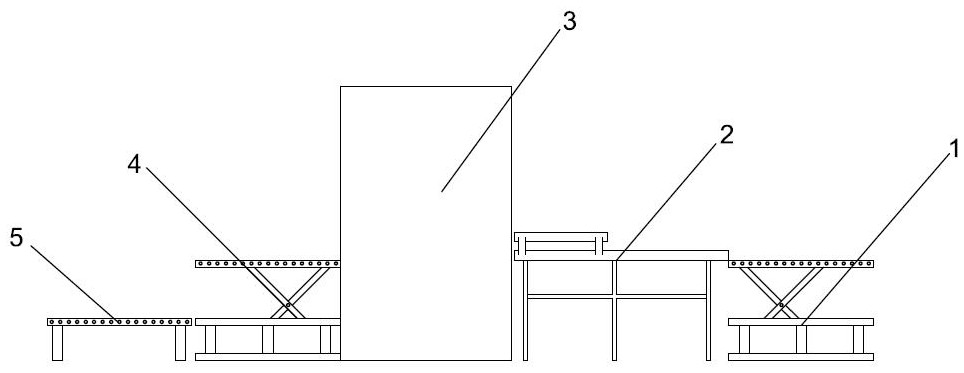

A hot pressing production line for door processing

ActiveCN113911669BReduce labor costsGuaranteed to work at a comfortable heightPlywood pressesLaminationProcess engineeringBack door

The invention discloses a hot-pressing production line for door processing, which relates to the technical field of plastic film hot-pressing forming, and is suitable for hot-pressing forming processing of film-coated rear door products. With the setting of the material device and the buffer platform, the automatic circulation hot pressing forming process of the door product surface coating can be realized, which reduces a lot of labor costs and realizes automatic high-quality and efficient production. In the first conveying unit, the second conveying unit, With the setting of the edge guide component and the adsorption component, the stable and precise conveying of heavy materials can be realized, thereby ensuring the processing accuracy of subsequent hot pressing forming equipment and product quality; the conveyor belt, sliding frame and materials are always kept relatively static state, the upper and lower double-layer conveying ensures the stability of the material conveying process, and reduces the friction between the material and the conveyor belt to ensure the quality of the material to be processed.

Owner:四川和乐门业有限公司 +1

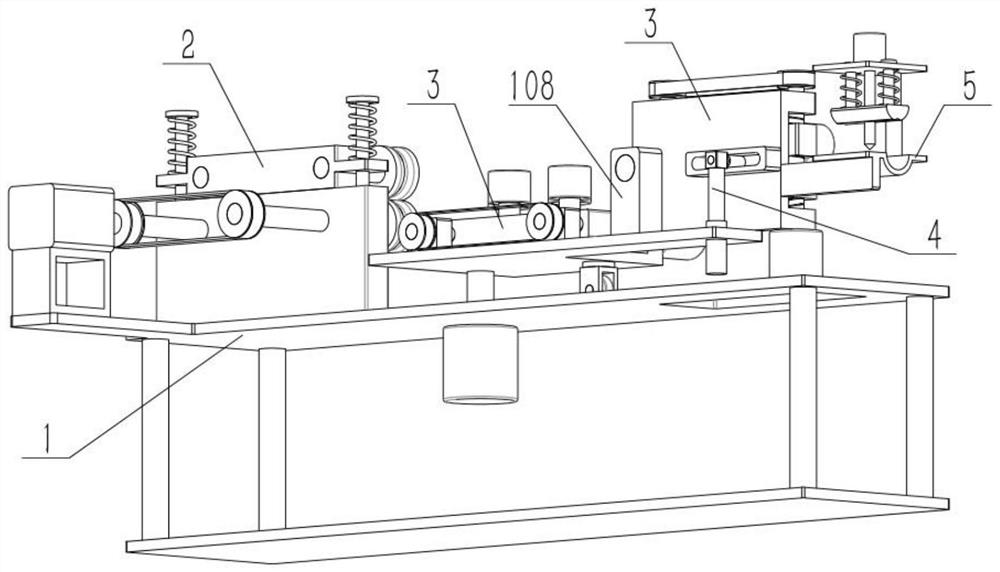

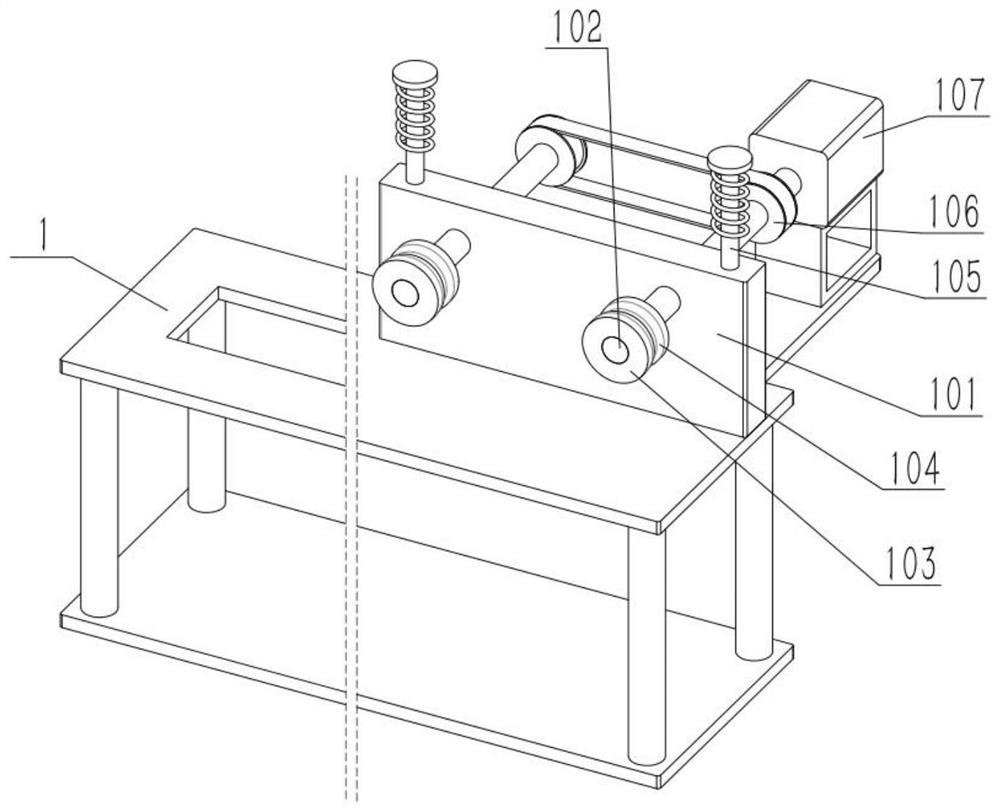

Metal wire machining system and method

InactiveCN112388008AEasy to squeeze inHigh precisionMetal working apparatusBoring/drilling machinesEngineeringClassical mechanics

The invention relates to wire machining, and particularly relates to a metal wire machining system and method. The metal wire machining system comprises a supporting table, a shaft seat I, a shaft I,a driving limiting wheel, a groove I, a rod I, a belt wheel I, a motor I, a displacement frame, a shaft II and a driven wire wheel, wherein the driving limiting wheel can enable metal wires to be conveyed leftwards, and then the metal wires with different diameters can be conveyed. The metal wires can be directly extruded into a groove II conveniently, initial placement is facilitated, and the groove I and the groove II are combined for use so that the holding force for conveying the metal wires with the different diameters can be increased conveniently. Two rows of auxiliary wheels are utilized for limiting the front sides and the rear sides of the metal wires, and the accuracy and stability of conveying of the metal wires on the horizontal plane are improved. A base swings to change theconveying direction, staggered arrangement is matched, during swinging and direction changing, the metal wires are uniform in stress point distribution and easy to bend and reverse, and conveying is stable after reversing. A vertically-arranged guide mechanism stabilizes the upper sides and the lower sides of the metal wires, then the circumferential stress points are distributed in the long direction, and the metal wires with the different diameters are conveyed stably and accurately.

Owner:周晓光

Automatic button finishing and feeding device for garment production

ActiveCN110067086AEasy to collectImprove button efficiencySewing apparatusCleaning using liquidsEngineeringMechanical engineering

Owner:JIANGSU WEINA FASHION CO LTD

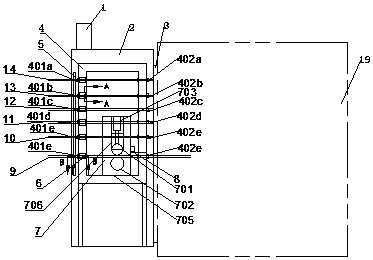

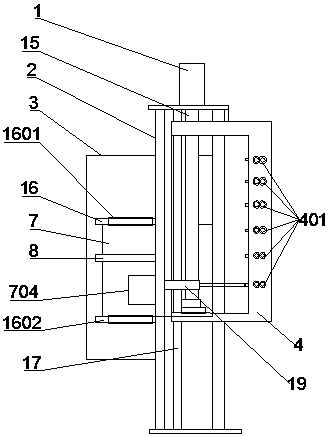

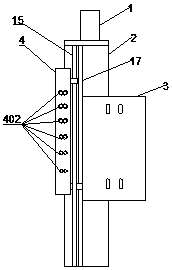

Needle type winding machine for straight-bar stator core

PendingCN111245184APrecise deliverySmooth and accurate deliveryManufacturing dynamo-electric machinesNeedle typeWinding machine

The invention relates to a needle type winding machine for a straight stator core. The winding machine comprises a rack, and a stator iron core feeding mechanism, a wire clamping and cutting mechanism, a winding mechanism and an incoming wire tensioning mechanism are arranged on the rack. The stator iron core feeding mechanism is used for conveying, fixing and rotating a straight stator iron core,so that the winding mechanism can wind the straight stator iron core. The winding mechanism is used for winding the straight stator core. The wire clamping and cutting mechanism is used for cutting off a copper wire between the straight stator core and the winding mechanism and clamping the cut-off copper wire. Through the stator iron core feeding mechanism, the wire clamping and cutting mechanism and the winding mechanism, the processes of conveying, fixing, rotating, winding, cutting and the like of the stator iron core are realized; in addition, rapid sliding of the winding needle and thestraight-bar stator iron core is driven by the servo motor, so that the sliding distance of the winding needle and the straight-bar stator iron core is accurate, the winding speed is high, and conveying is accurate and stable.

Owner:SANHE IND AUTOMATION EQUIP CO LTD SHUNDE DISTRICT FOSHAN CITY

Resistor and production method thereof

InactiveCN110364323ARealize fully automatic productionPrevent disengagementResistor manufactureEngineeringResistor

The invention relates to the field of electronic components. The production method of the resistor includes the following steps: fuse feeding, heat shrinkable tube feeding, heating, Teflon feeding, cutting and bending. The advantages of the invention are that the full automatic production of the resistor is realized, and a series of processing operations such as assembling, conveying, heating, cutting and trimming and pin bending are completed.

Owner:楼显华

Chip character detection and counting device

PendingCN111781211AKeep stackingRealize automated detectionMaterial analysis by optical meansEngineeringMachine

The invention aims to provide the chip character detection and counting device which is simple in structure, can save manpower, can improve the detection efficiency, can avoid the problems of missingdetection, false detection and the like, and ensures the detection quality of chip characters. The device comprises a machine table, a conveying mechanism, a CCD detection mechanism, a feeding mechanism and a discharging mechanism. The conveying mechanism is arranged below the feeding mechanism and the discharging mechanism. The detection end of the CCD detection mechanism is arranged above the conveying mechanism; the feeding mechanism and the discharging mechanism are arranged on the two sides of the CCD detection mechanism respectively. The feeding mechanism and the discharging mechanism each comprise a tray module and a lifting module. The tray module comprises a first machine frame arranged on the machine table and a plurality of first air cylinders arranged on the first machine framein a surrounding mode, the lifting module is arranged below the first machine frame, the output ends of the first air cylinders are provided with bearing protrusions, and the bearing protrusions arematched with grooves in a tray. The device is applied to the field of automatic detection.

Owner:珠海市捷锐科技有限公司

Automatic material changing and feeding device for multi-specification steel bars

The invention provides an automatic material changing and feeding device for multi-specification steel bars. The automatic material changing and feeding device comprises a mounting plate connected with a main machine, a sliding rail and a driving device are mounted on the mounting plate, and the driving device can move along the sliding rail; an upper driving wheel and a lower driving wheel whichcan clamp the steel bars for conveying are mounted on the driving device; a bracket is mounted on the mounting plate, a transmission device driven by a hydraulic motor is mounted on the bracket, and adistribution frame which can realize locking and conveying of the multi-specification steel bars conduct reciprocating movement along a guide rail and the transmission device; and a displacement sensor controls starting and stopping of a hydraulic cylinder and the hydraulic motor. The automatic material changing and feeding device has the beneficial effects that one-time material preparation canbe achieved, the multiple sets of steel bars with different specifications penetrate into simultaneously, the automatic material changing and feeding device is controlled by a sensor and driven by hydraulic pressure, automatic conveying and material changing are achieved stably and accurately, and conveying of the singe bar and double bars with the same specification can be automatically switched,transmission is stable, and the automation degree is high.

Owner:山东连环机械科技有限公司

Transmission chain control device of double-end edge banding machine

ActiveCN103878862BSmooth and accurate deliveryImprove the quality of machining operationsWood working apparatusDomestic articlesMachine controlPush out

The invention discloses a transmission chain control device for a double-end edge bonding machine. The transmission chain control device comprises two transmission chains, each transmission chain comprises a plurality of chain blocks and is provided with a plurality of hook heads capable of telescoping inside and outside, the plurality of hook heads are arranged at intervals and synchronously move along with the chain blocks, a push-up mechanism is arranged in a feeding end of each transmission chain, and a pull-down mechanism is arranged in a discharging end of each transmission chain. The plurality of hook heads which are capable of telescoping inside and outside and arranged at intervals on each transmission chain can be urged to outwardly extend above the chain blocks by the aid of the push-up mechanisms and inwardly retract below the chain blocks by the aid of the pull-down mechanisms. Therefore, the hook heads can be pushed out or retracted back according to needs, the hook heads extending out can be abutted against the rear end face of a board to complete positioning conveying of the board, a traditional way which only depends on friction driving is replaced, board conveying is more stable and accurate, and board machining quality is improved.

Owner:NANXING MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com