Material feeder of lathe

The technology of a feeding device and a pushing device, which is applied in the field of feeding devices and feeding devices of lathes, can solve the problems of workpiece transportation and cannot be used as a feeding device for lathes, and achieve accurate and stable transportation, simple structure, and stable transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

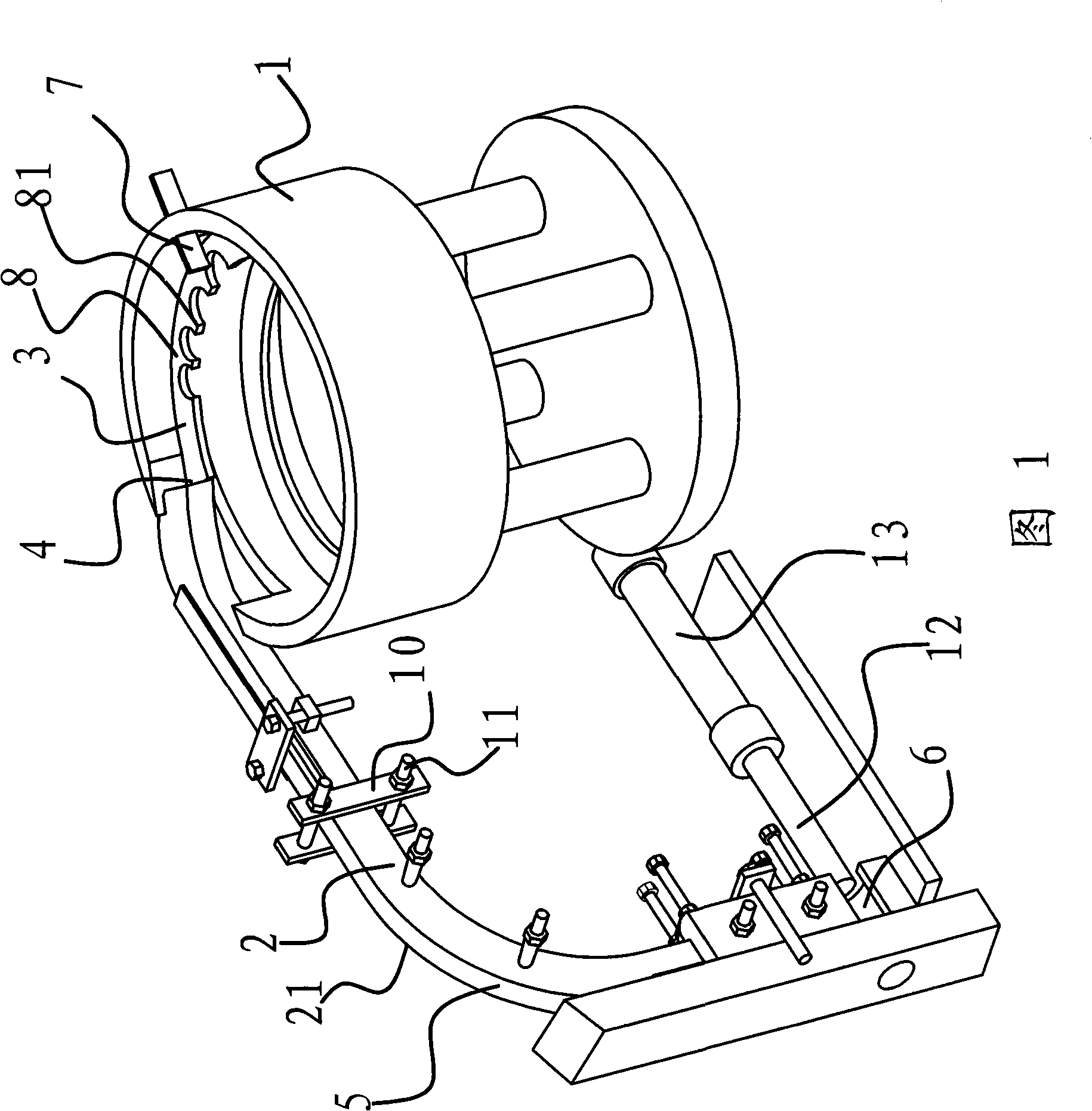

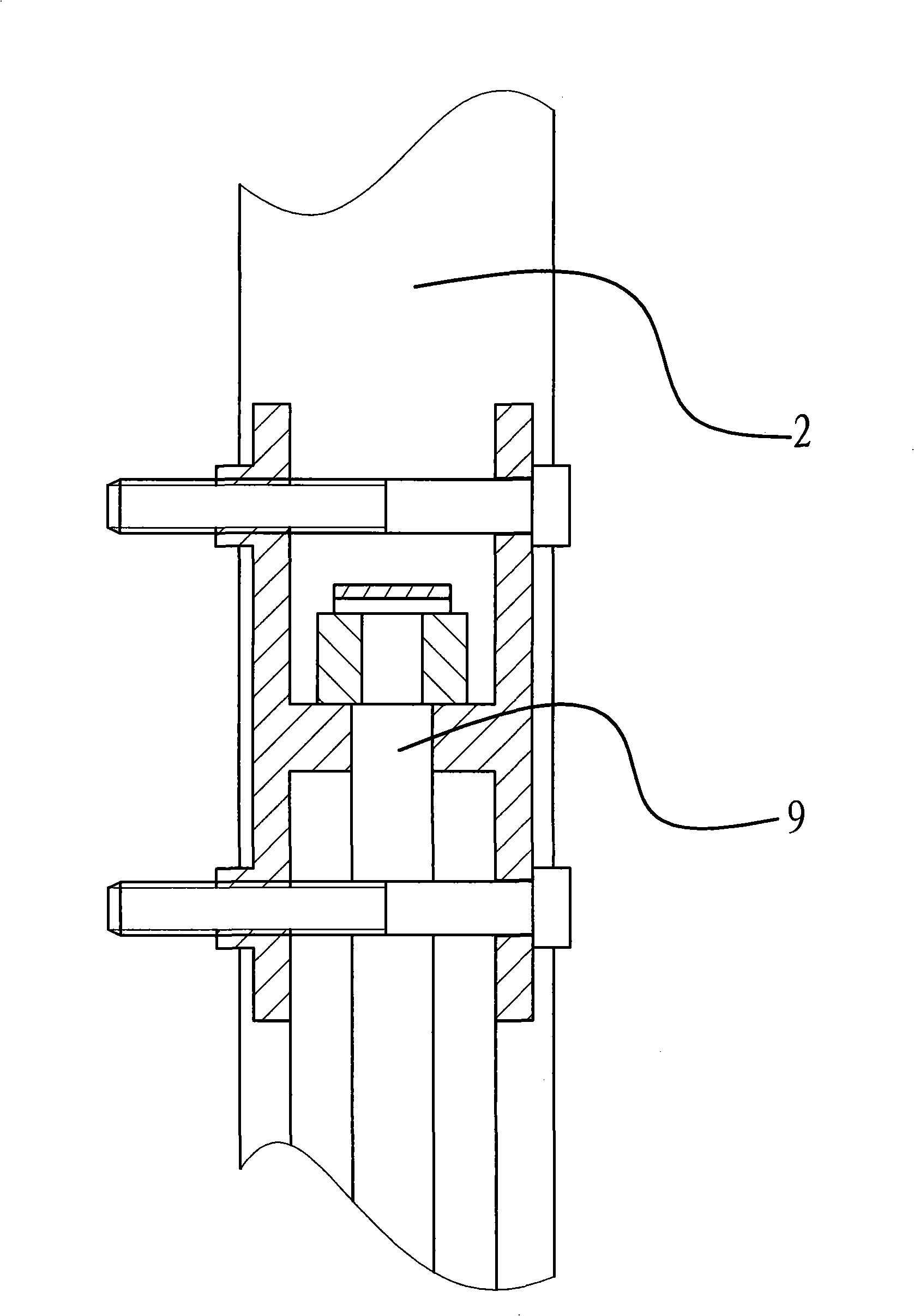

[0025] As shown in the figure: the feeding device of this lathe is used to arrange and transport the workpiece 9 to a processing procedure according to the set arrangement state, including the vibrating hopper 1 and the feeding guide rail 2, on the vibrating hopper 1 There is a spirally rising feeding channel 3, the lowest point of the feeding channel 3 is the feeding port and is located at the bottom of the vibrating hopper 1, the highest point of the feeding channel 3 is the feeding port 4, the feeding port 4 and the feeding end of the feeding guide rail 2 Connected, a screening mechanism is provided on the discharge channel 5 to arrange and output the workpieces 9 according to the set placement state. The discharge end of the feeding guide rail 2 is connected with the top of the feeding tube 6, and the workpieces 9 can fall into the feeding tube. In the pipe 6, a pusher device that can push the workpiece 9 to the next process is provided at the feed pipe 6.

[0026] Screeni...

Embodiment 2

[0030] The content of Embodiment 2 is basically the same as that of Embodiment 1. The difference is that the screening mechanism is a screening guide rail that is located on the feeding channel and communicates with the discharge port. The screening guide rail includes two parallel slide rails. A gap is provided between the rails to allow the workpiece to pass through and move the workpiece along the slide rail. The workpiece mentioned above is columnar and has a large end at one end and a small end at the other end. The small end of the workpiece is smaller than the gap between the two slide rails, and the large end of the workpiece is larger than the gap between the two slide rails. When the workpiece passes through the feeding channel and reaches the screening guide rail, the screening guide rail includes two slide rails arranged in parallel, and a gap is provided between the two slide rails to allow the workpiece to pass through and move the workpiece along the slide rails....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com