Automatic plug wire testing device

A test device and automatic plug-in technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of poor HDMI signal test effect, inability to realize test automation, and poor signal transmission, so as to save manpower and improve Efficiency and effect, the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

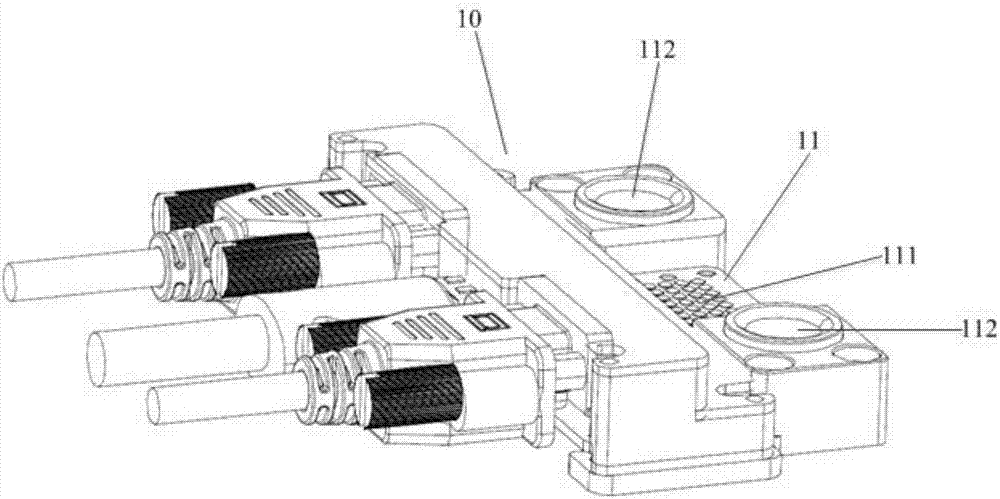

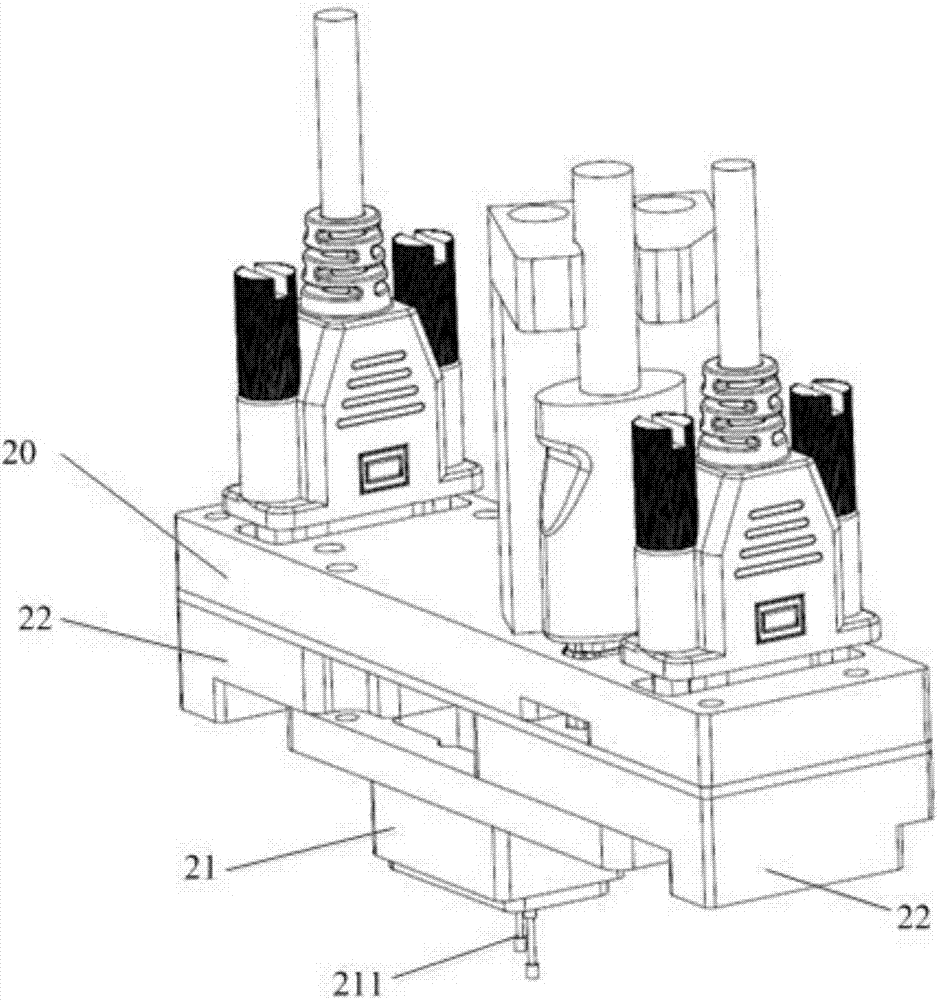

[0041] The embodiment of the present invention provides a kind of automatic plugging and unplugging test device 1, refer to Figure 1-Figure 6 As shown, the device includes a first substrate assembly 10, a second substrate assembly 20 and a direction adjustment assembly 30, and the direction adjustment assembly 30 is connected to the second substrate assembly 20;

[0042] The first substrate assembly 10 is electrically connected to the device to be tested, and a probe pad 11 is arranged on the first substrate assembly 10;

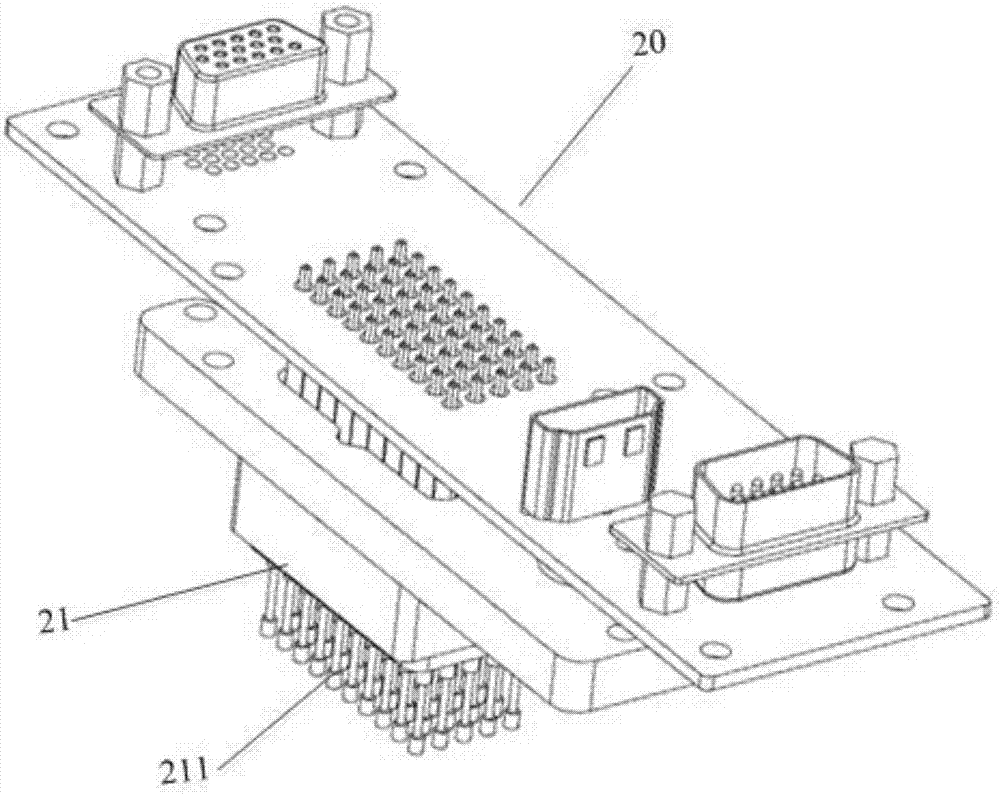

[0043] The second substrate assembly 20 is electrically connected to the test terminal equipment, and a probe base 21 is arranged on the second substrate assembly 20;

[0044] The probe pad 11 is provided with a plurality of contacts 111 for transmitting test signals, and the probe base 21 is provided with a plurality of probes 211 corresponding to the contacts, and the probes 211 transmit test signals by contacting the contacts 111; wherein, First Substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com