Patents

Literature

73results about How to "Smooth and precise transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

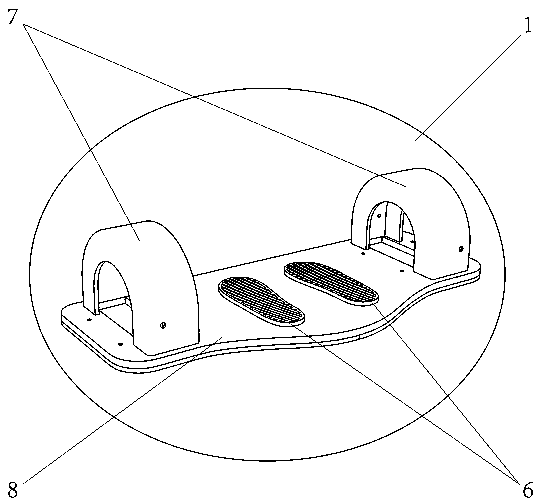

Cleaning Device for Mobile Phone Screen

InactiveUS20200220961A1Wide applicationEasy to replaceLiquid surface applicatorsHousehold cleanersEngineeringBevel gear

The invention relates to mobile phone peripheral devices, and discloses a cleaning device for a mobile phone screen which includes a frame. The frame is fixedly connected with a bracket, and a top end of the bracket is fixedly connected with a bearing sleeve. The inside of the bearing sleeve is rotatably connected with a rotating shaft. One end of the rotating shaft is fixedly connected with a rotating knob. One end of the rotating shaft is fixedly connected with a bevel gear. The inner of the bevel gear is fixedly sleeved with a threaded rod. Two ends of the threaded rod are rotationally connected with a bearing block. The surface of the threaded rod is fixedly connected to the limiting block. The cleaning device for the mobile phone screen is provided with a rotary knob and a bevel gear, and the rotary knob is rotated to drive the bevel gear so that the supporting plate can moves up and down. The position between the supporting plate and the cleaning sheet is located in accordance with the different thickness of the mobile phone, and the transmission is stable and precise. And it is possible to clean the screens of different sizes of mobile phones, thereby achieving a wide range of applications.

Owner:LAW CHUNG MAN

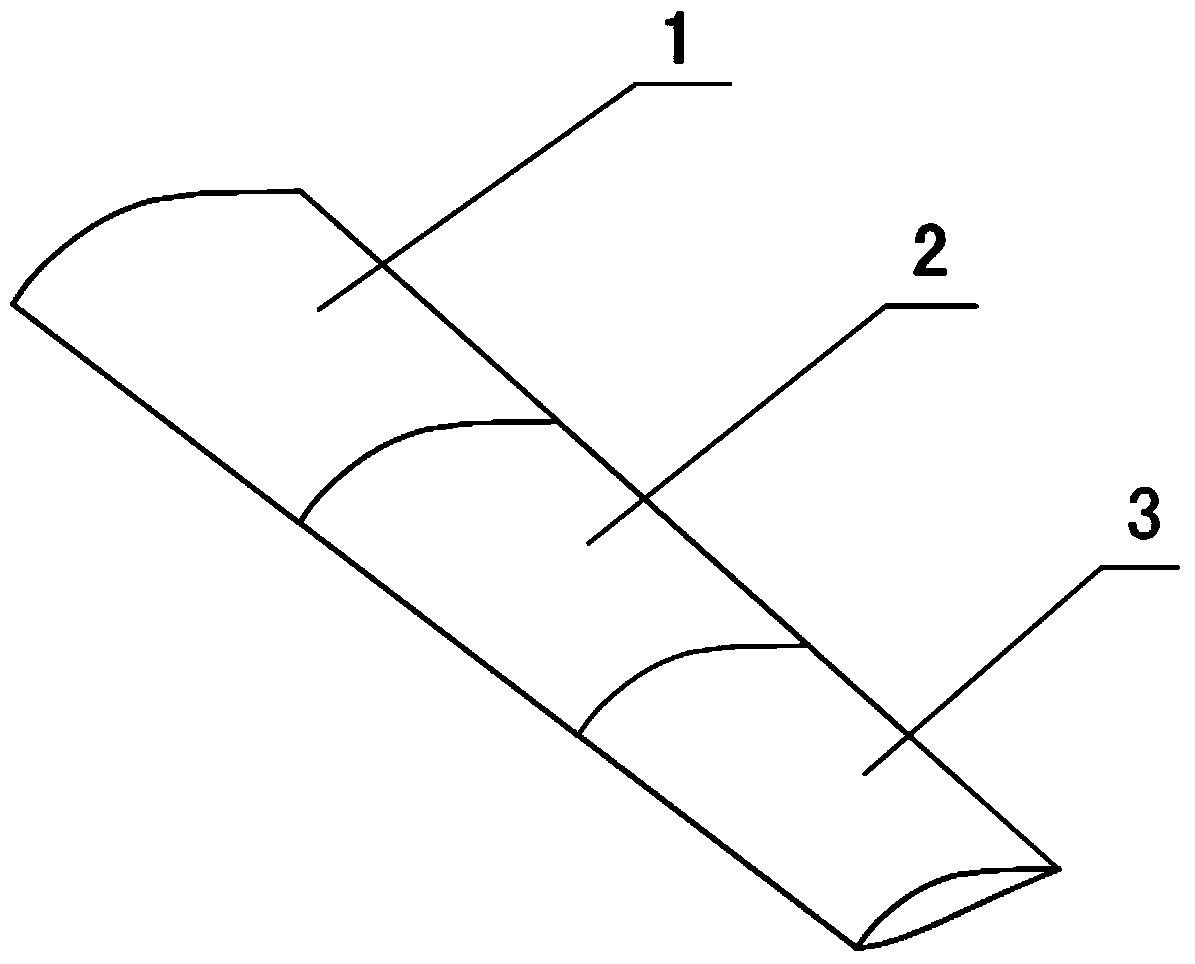

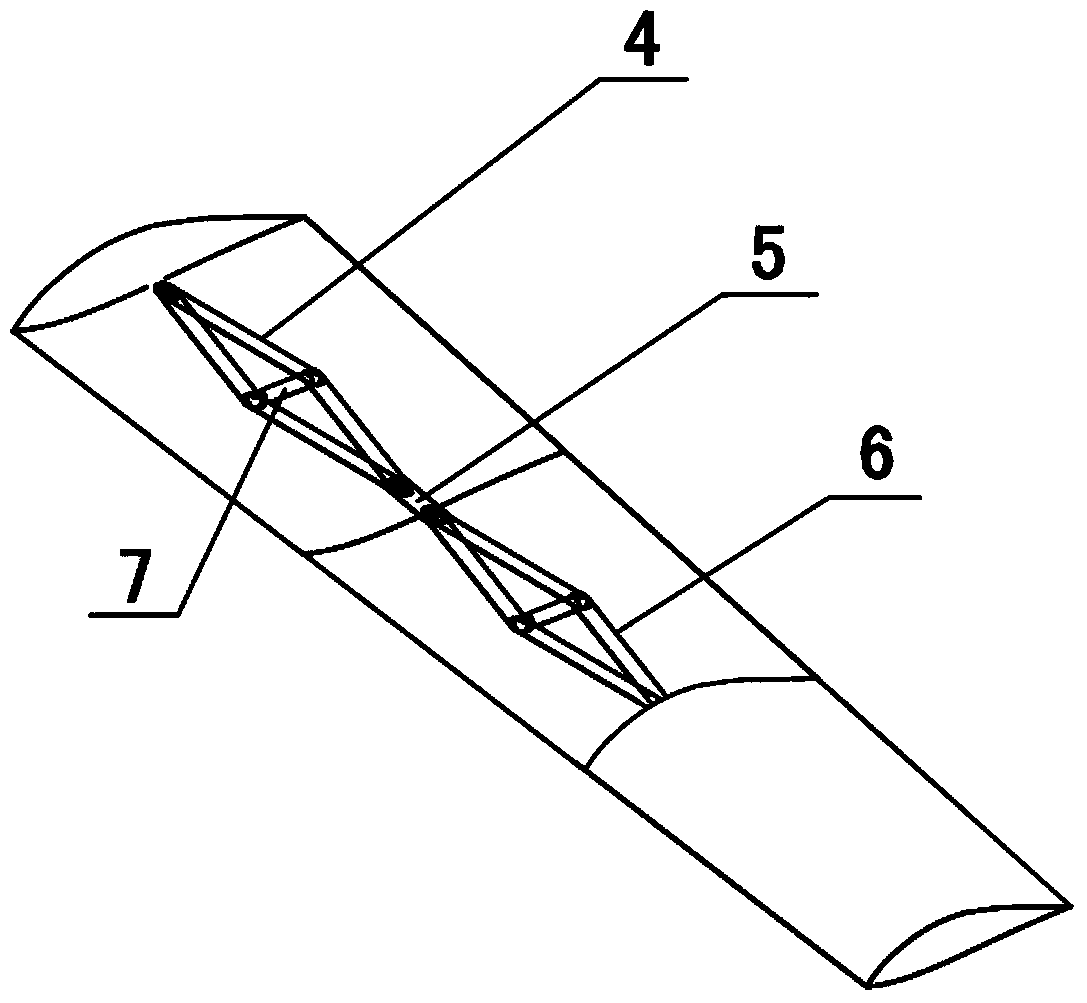

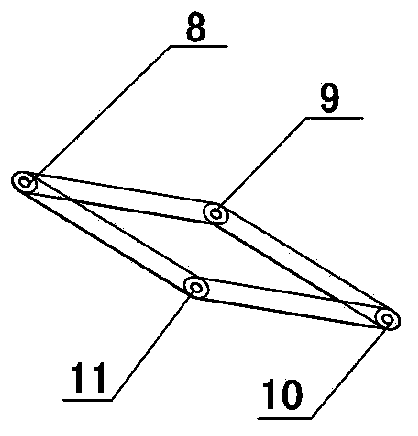

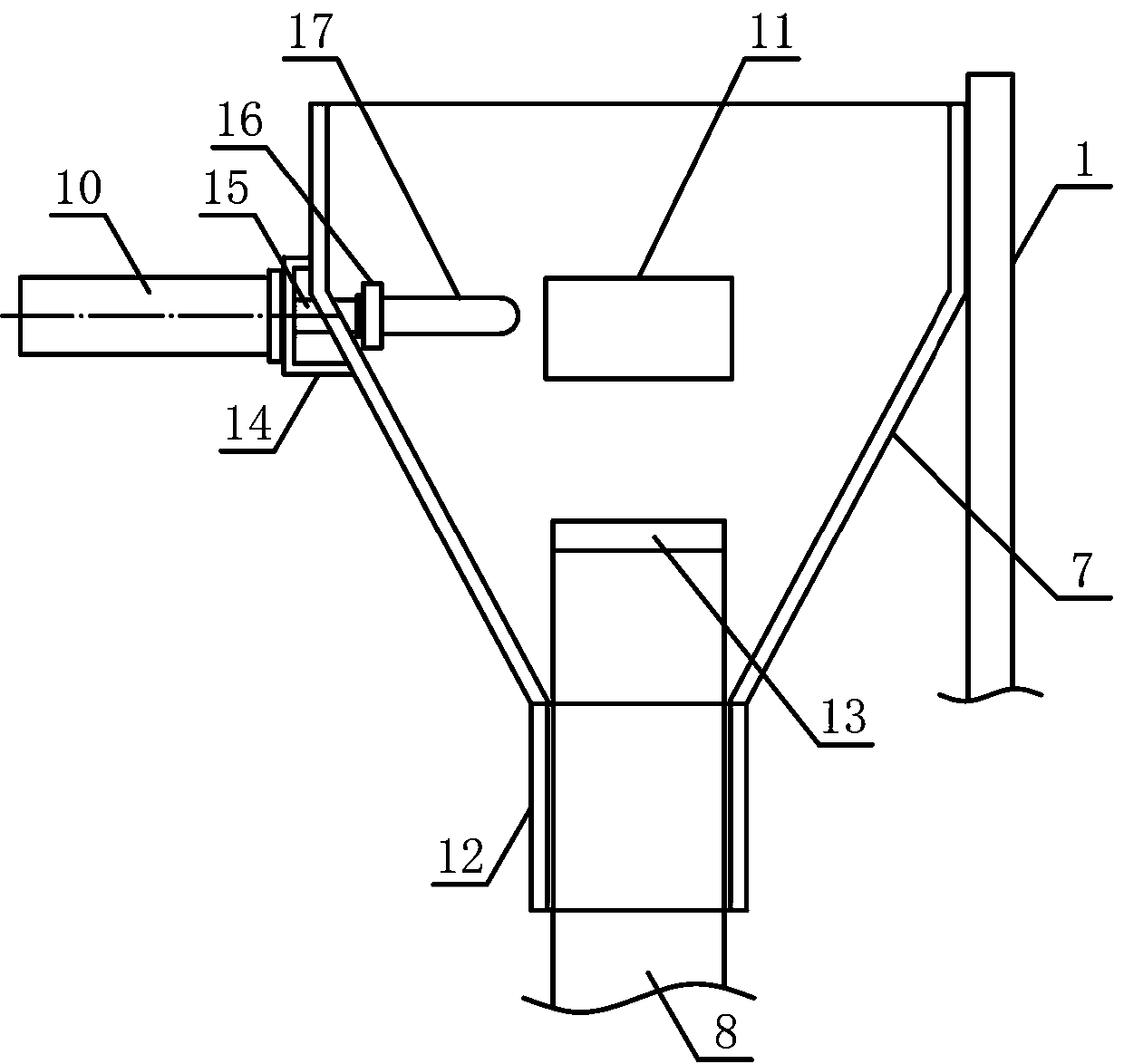

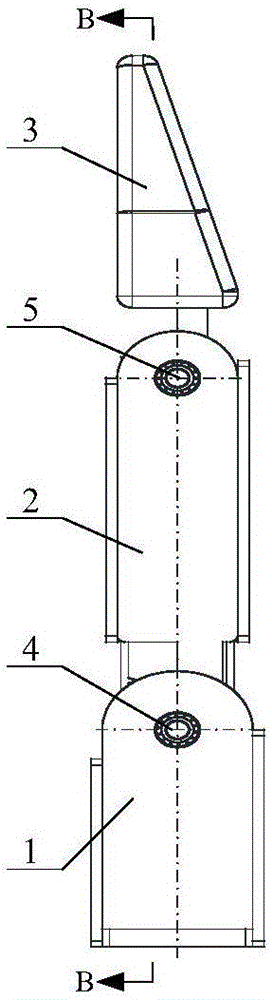

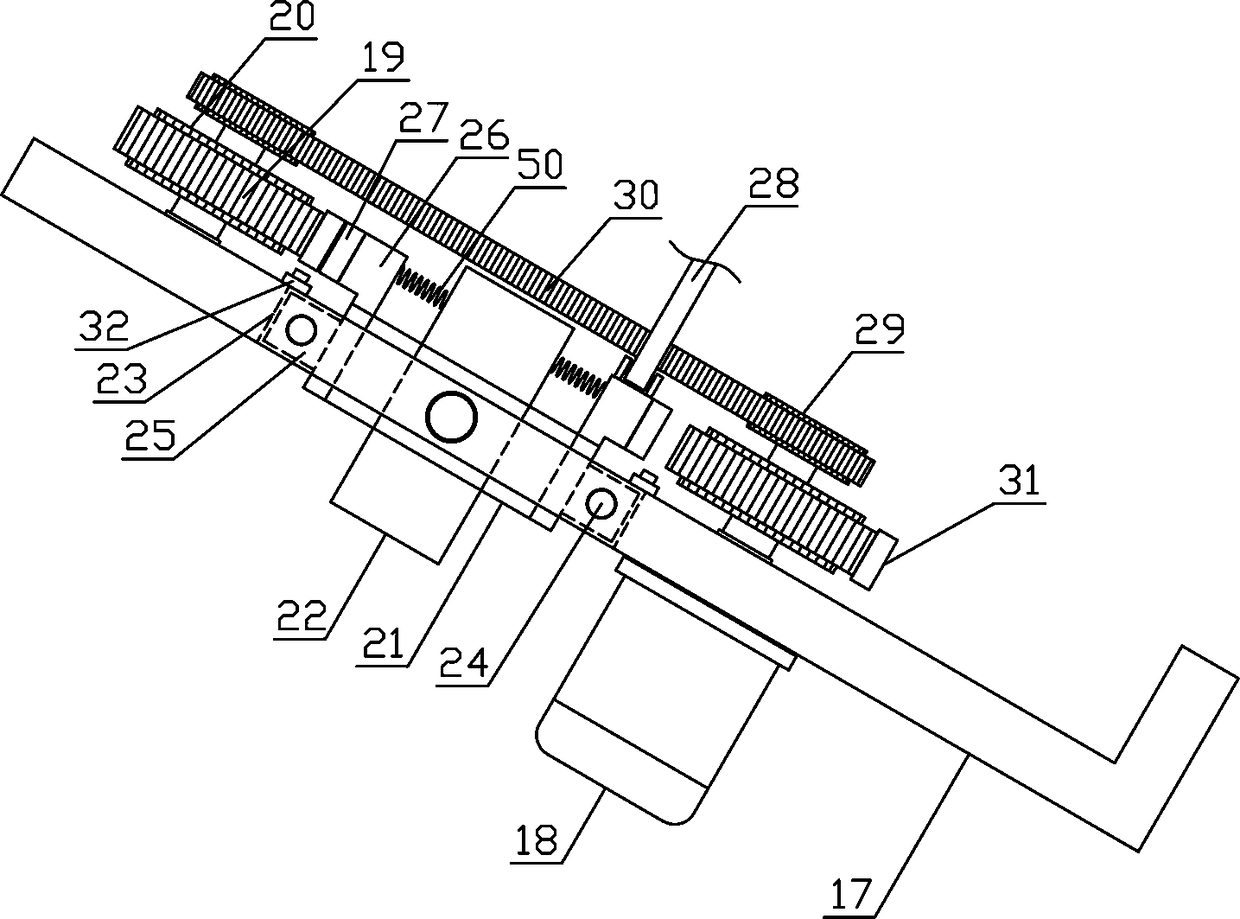

High-precision and light-weight controllable telescopic wing mechanism

InactiveCN104176238AAchieve shrinkageWill not affect the shapeWing adjustmentsFlight vehicleControl system

The invention discloses a high-precision and light-weight controllable telescopic wing mechanism. Deformation of an intelligent material is controlled by programming to realize expansion and contraction of drivers; when all the stages of the drivers contract, a four-connection-rod mechanism extends; a middle wing extends out of a fixed wing, and an outer wing extends out of the middle wing, so that extension of an overall wing is realized; when the drivers extend, the four-connection-rod mechanism is shortened; the outer wing returns into the middle wing, and the middle wing returns into the fixed wing, so that contraction of the overall wing is realized. Components in the mechanism are rigid elements in rigid connection, so that transmission is stable and accurate. Under the action of a control system, a telescopic wing can precisely realize expansion and contraction; the mechanism is light in mass, high in transmission speed and low in error; when a pneumatic appearance requirement of an aircraft in different stages is met, the total mass and the safety of the aircraft cannot be greatly affected; the telescopic wing controls the deformation of the intelligent material through programming, so that random extension and high-precision controllable contraction of the wing are realized, and an effect of controlling an element can be achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

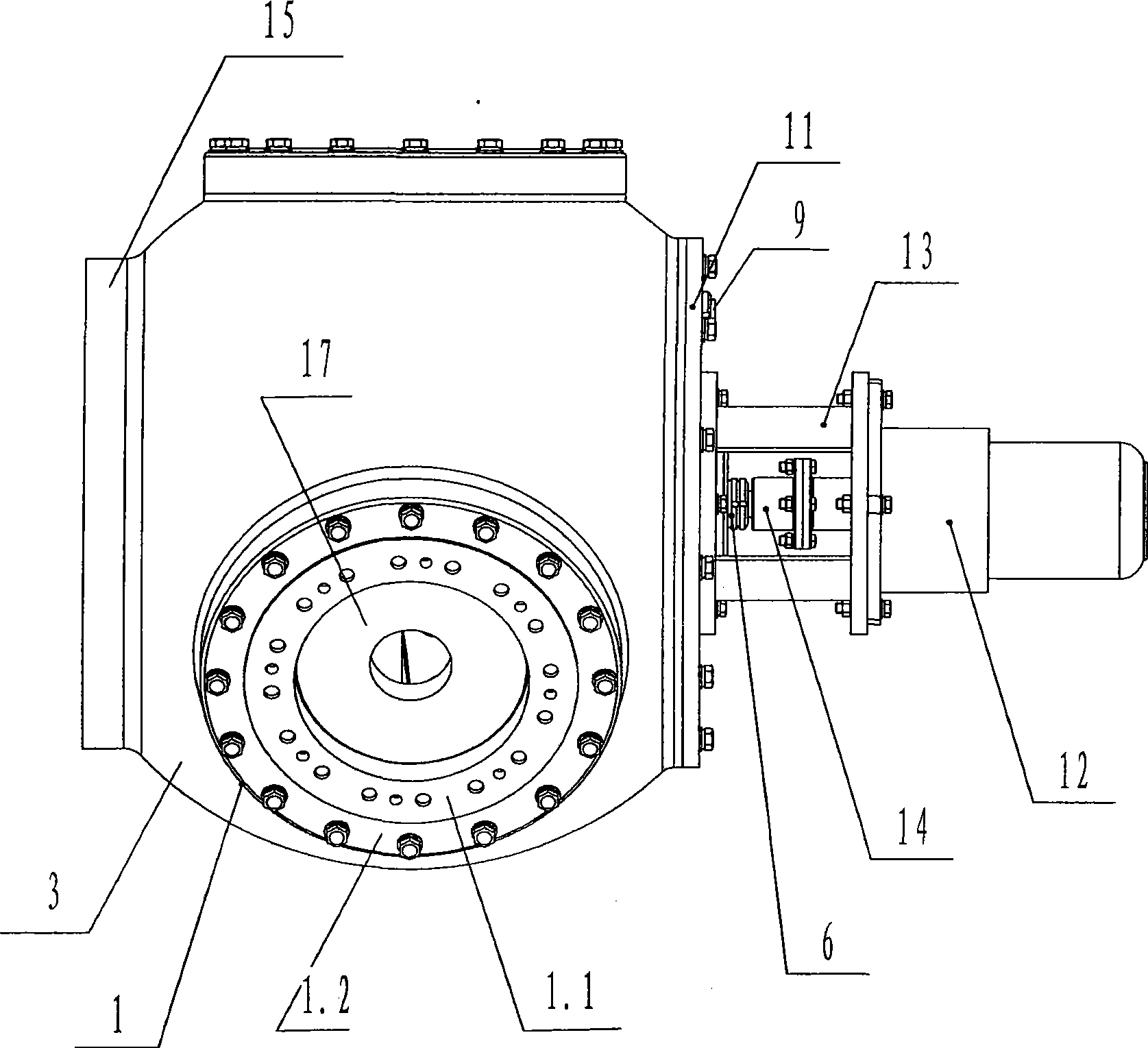

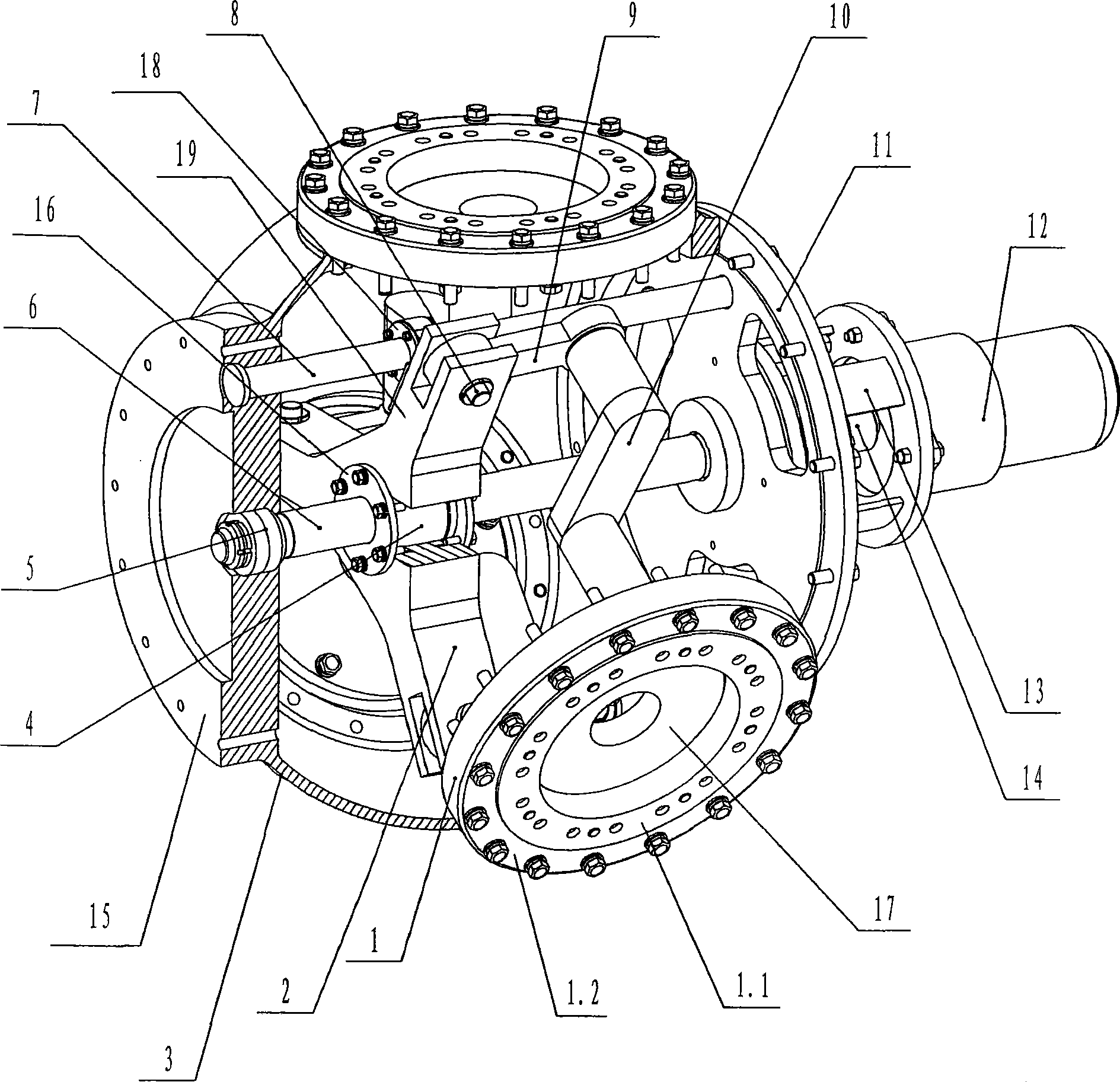

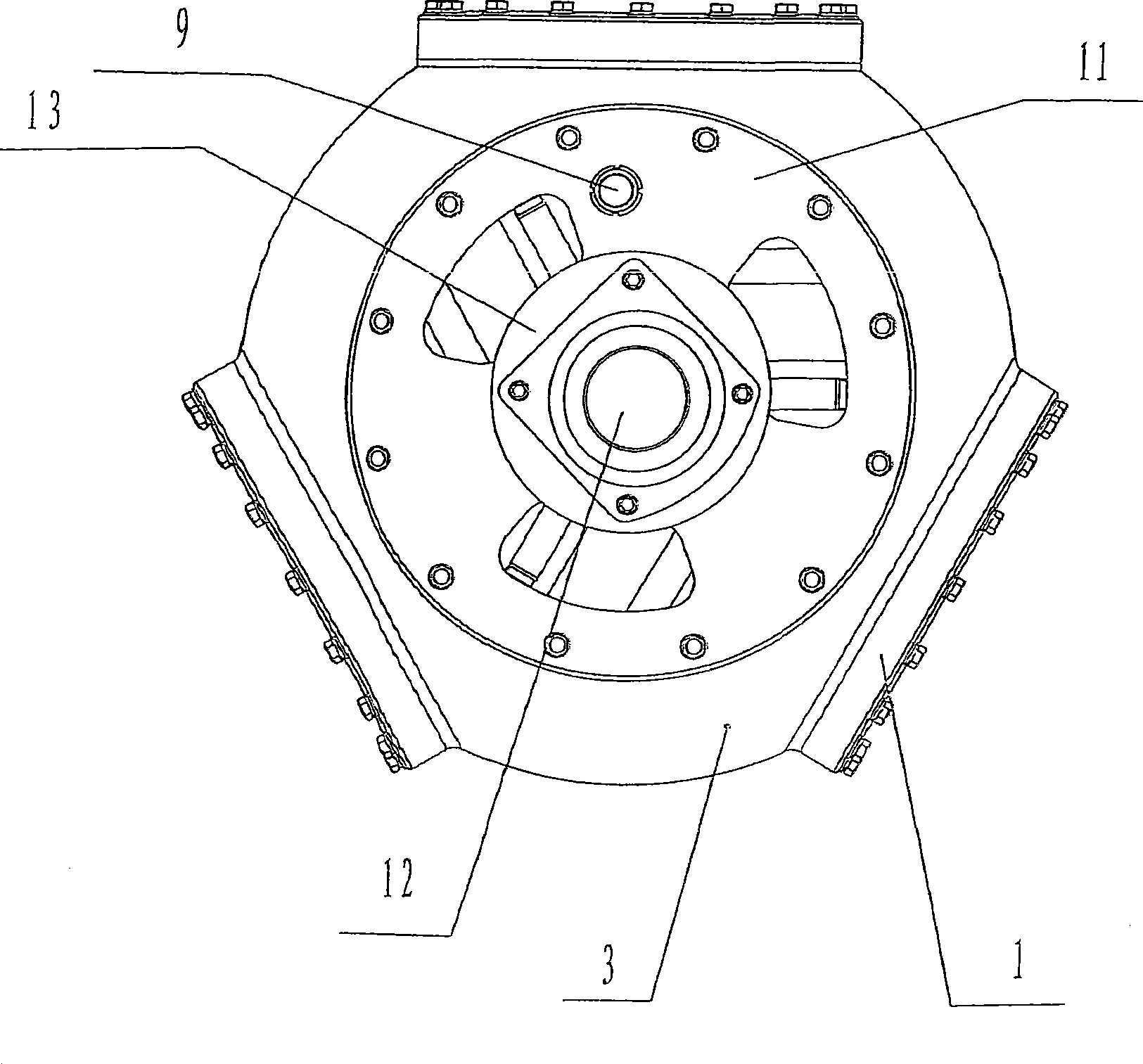

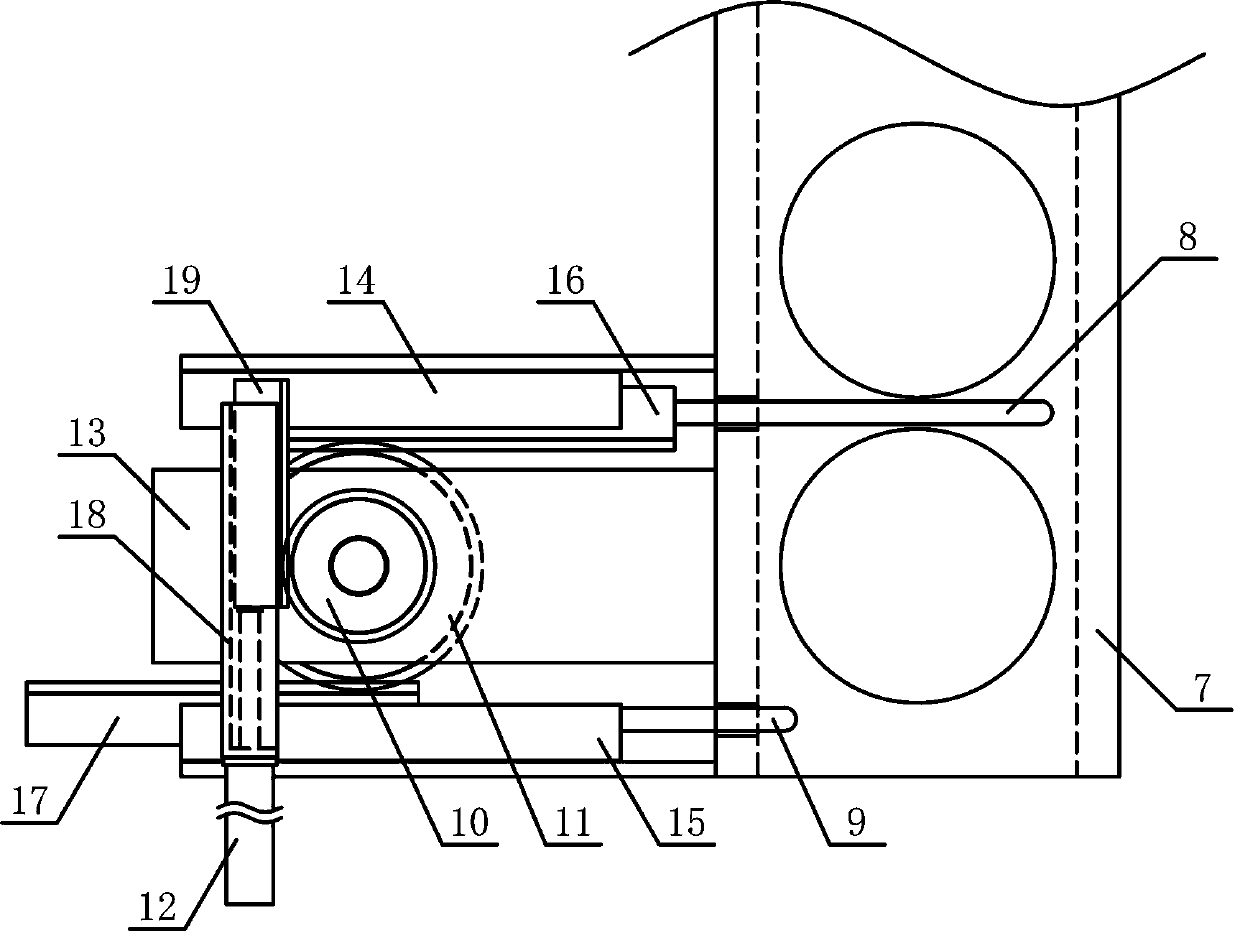

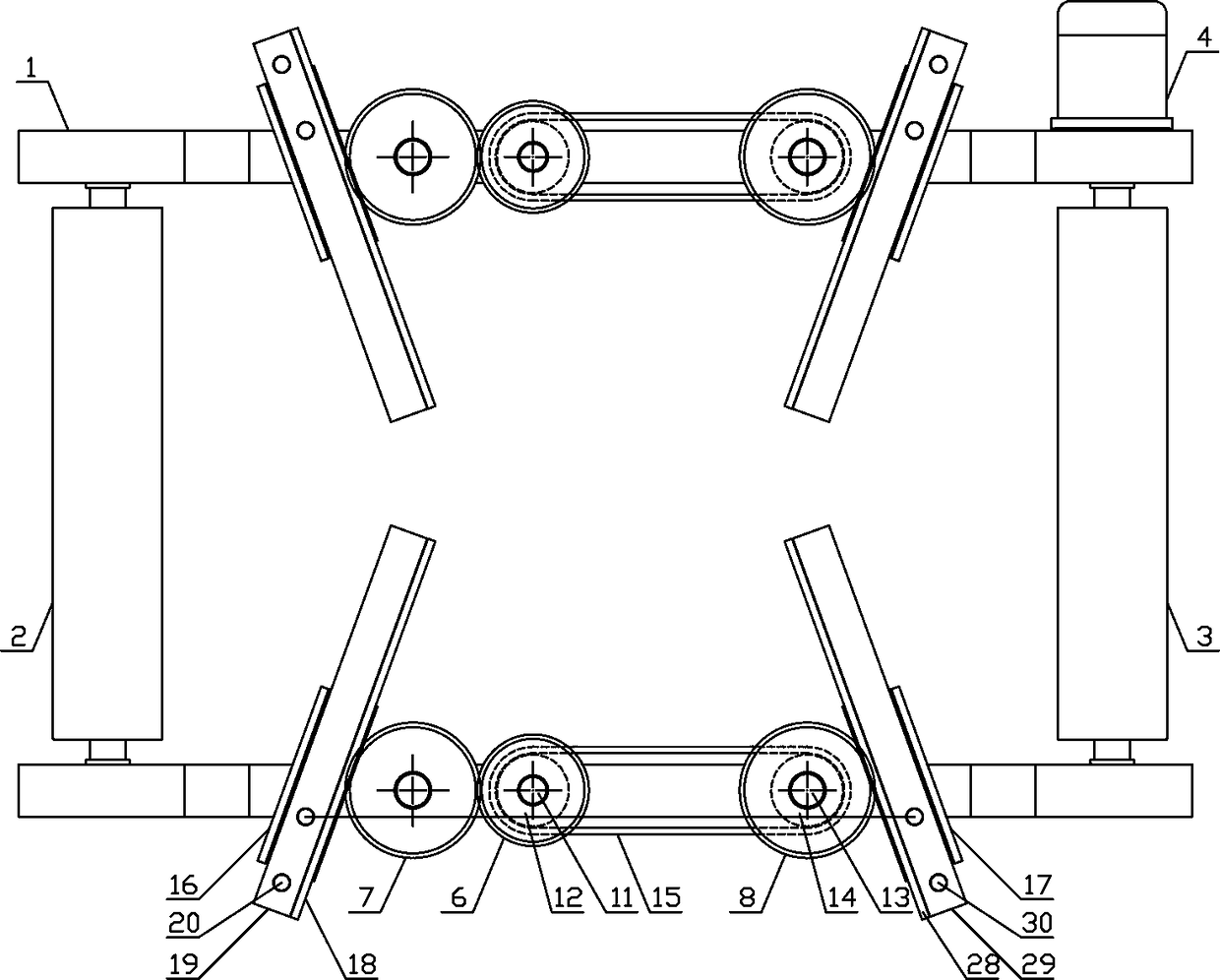

Pulp distance varying mechanism of wind power generator

InactiveCN101392726AQuick responseAvoid adaptationWind motor controlMachines/enginesPower componentWind force

The invention discloses a variable-pitch mechanism for an aerogenerator, which comprises a wheel hub, a power component, a plurality of variable-pitch bearings, wherein the wheel hub consists of a curved surface formed by the axes around the wheel hub, a front cover and a back cover which are vertical to the axes of the wheel hub; the outer circle of the variable-pitch bearing is fixedly connected with the curve surface of the wheel hub, and the variable-pitch bearing is evenly distributed on the curve surface of the wheel hub. The device also comprises a screw-driven component, a synchronous mounting rack, a connecting piece and a rotating component, wherein the screw-driven component is rotationally matched with central holes of the front cover and the back cover, and the screw-driven component is connected with the power component; the screw-driven component is fixedly connected with the synchronous mounting rack; the synchronous mounting rack is rotationally connected with each connecting piece, each connecting piece is evenly distributed on the circumference taking the center of the synchronous mounting rack as circle center, and circumference plane is vertical to the axes of the wheel hub; and the connecting piece is also rotationally connected with the rotating component, and the rotating component is fixedly connected with the inner circle of the variable-pitch bearing.

Owner:宁波欣达(集团)有限公司

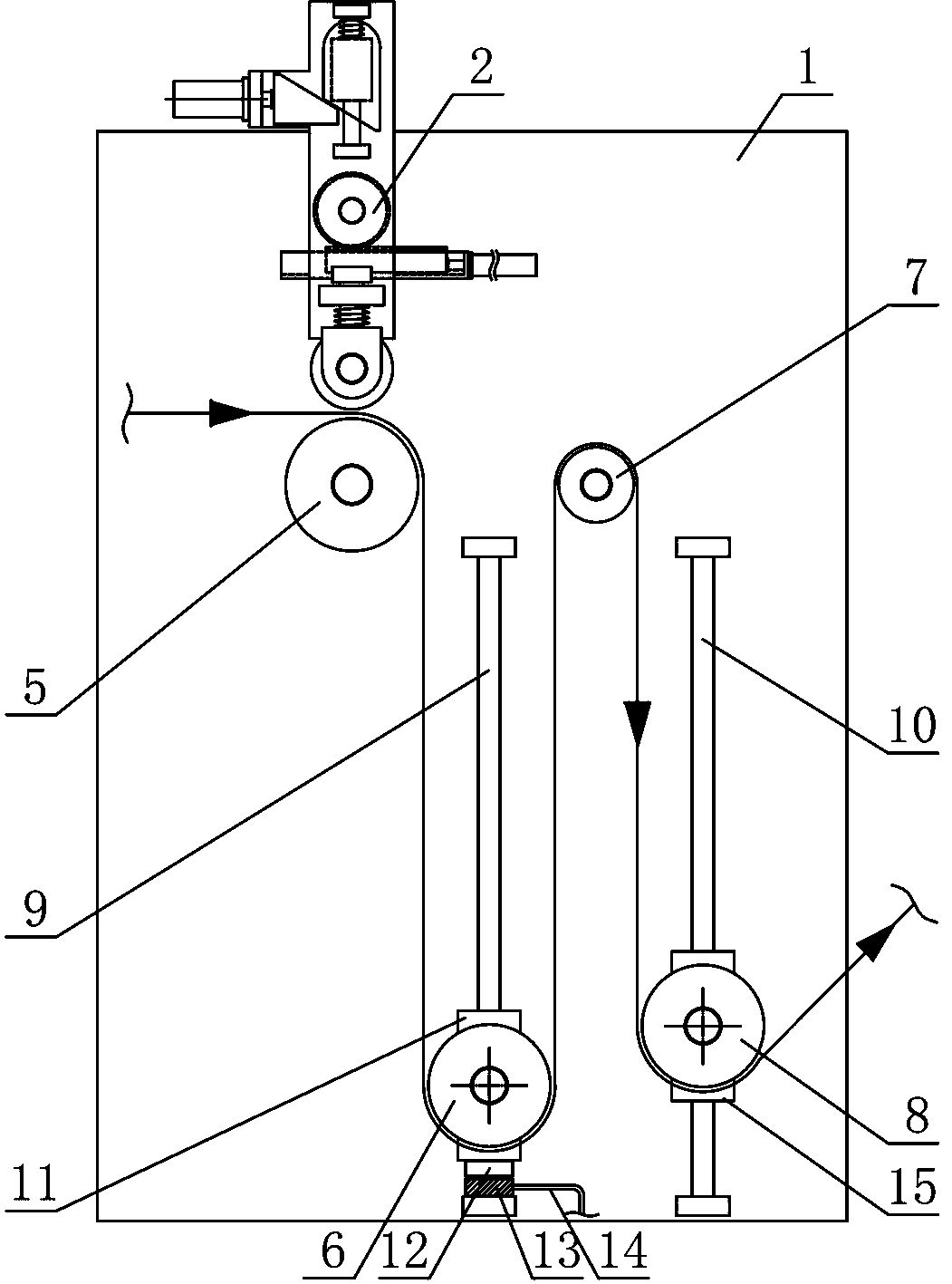

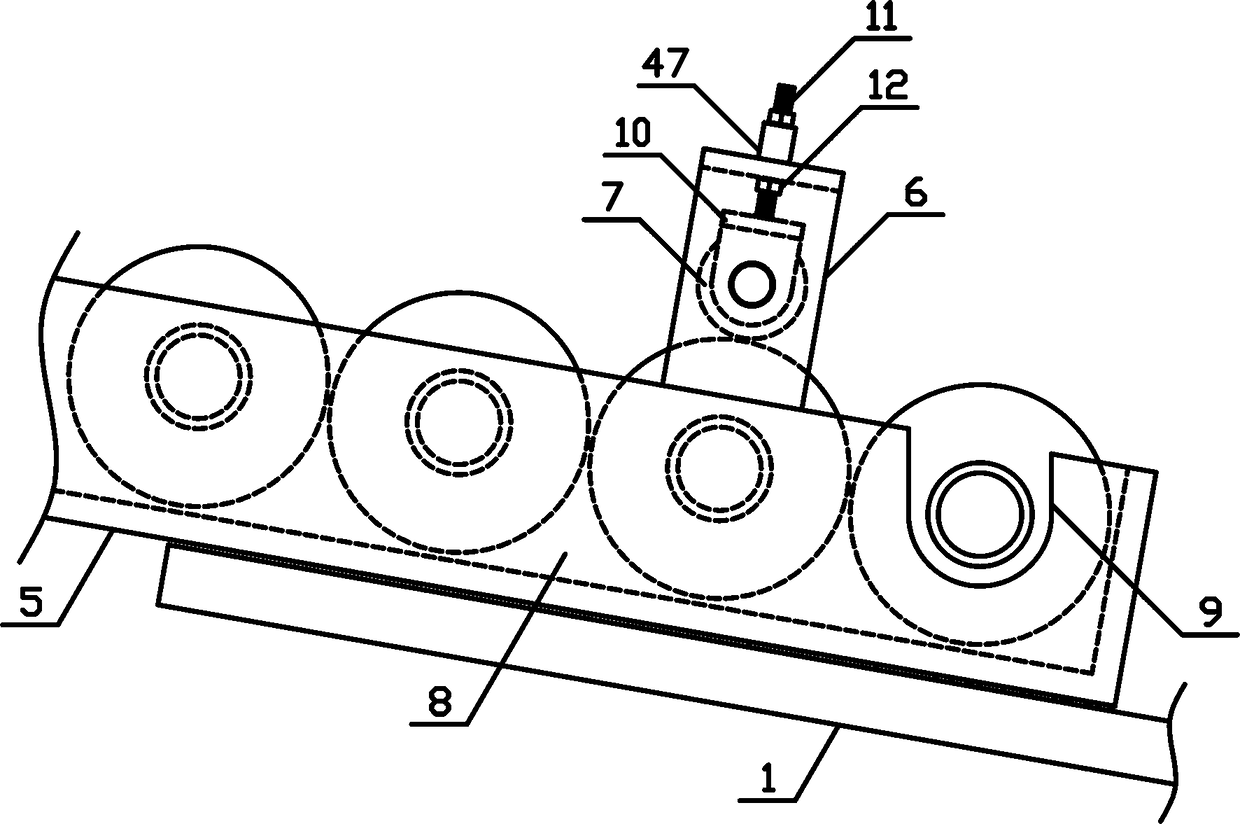

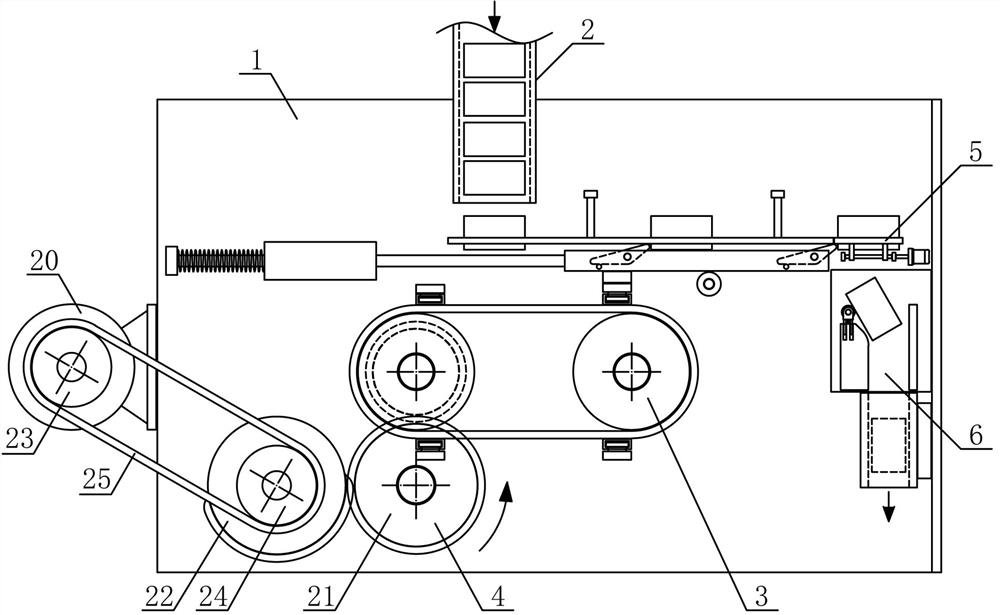

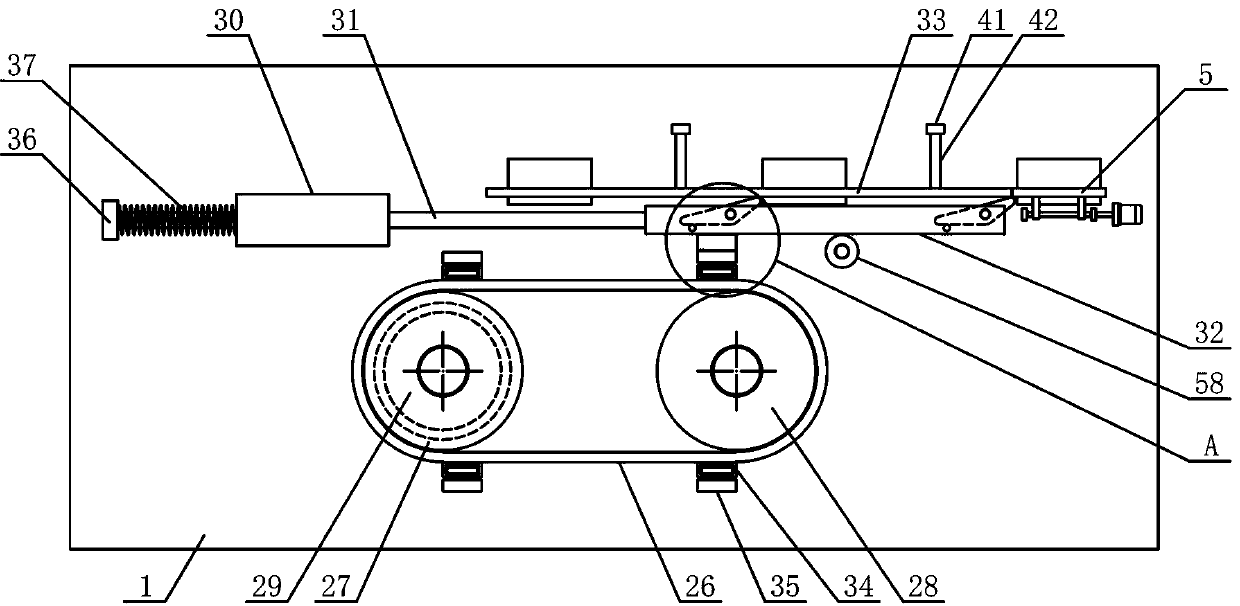

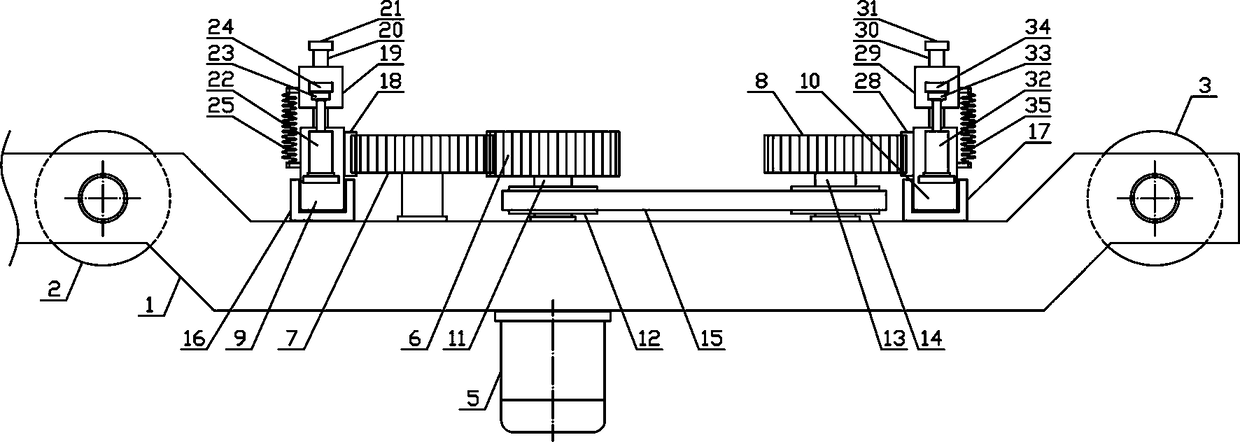

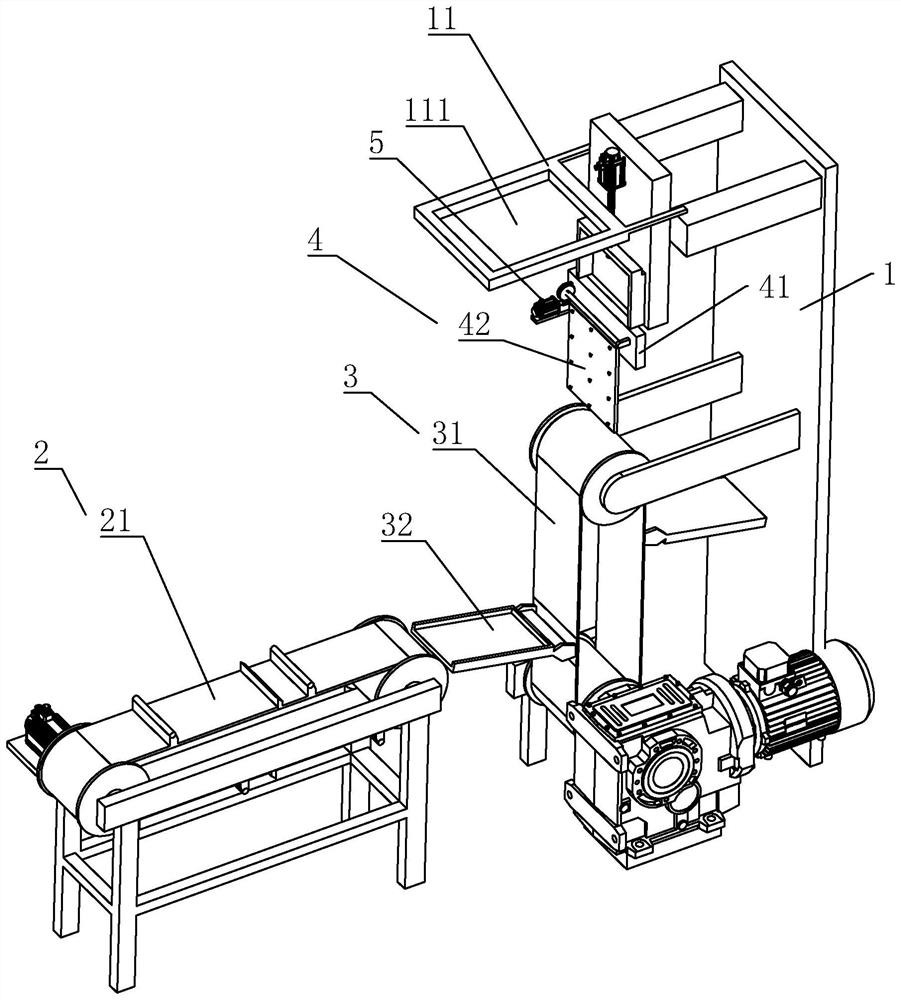

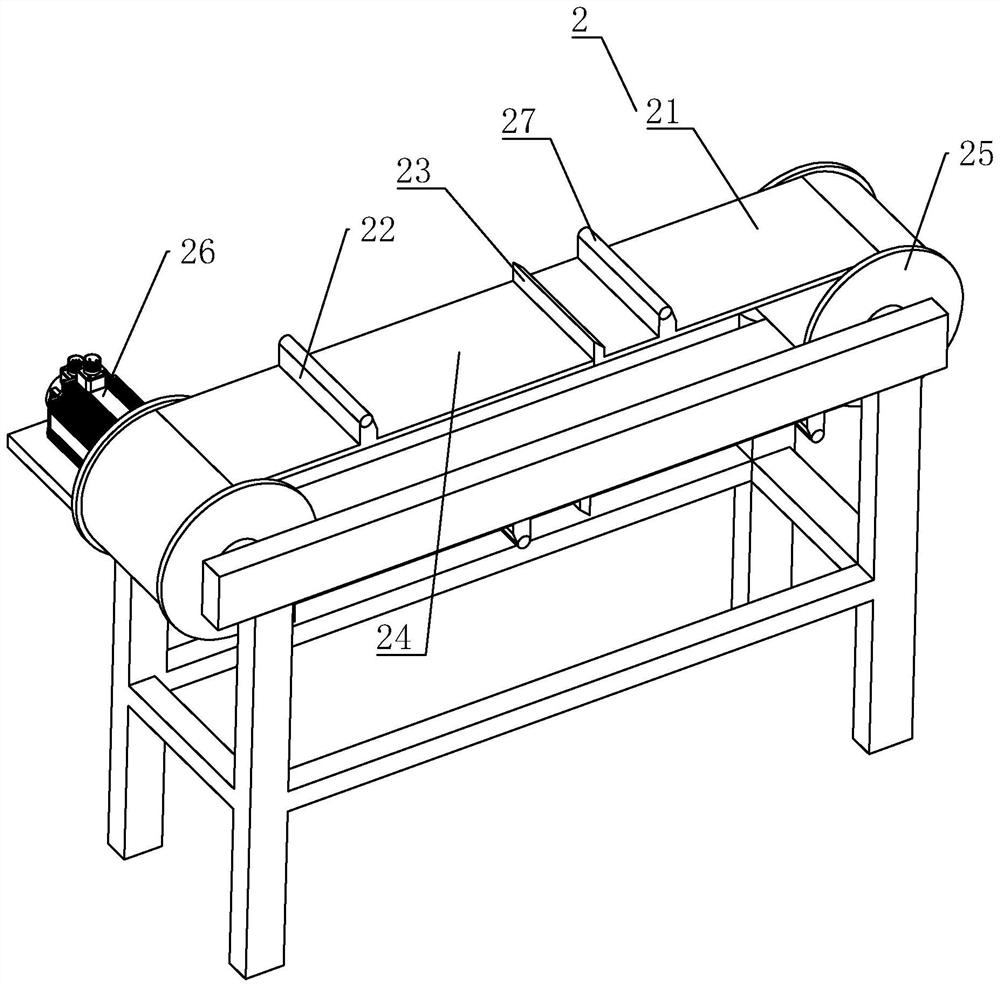

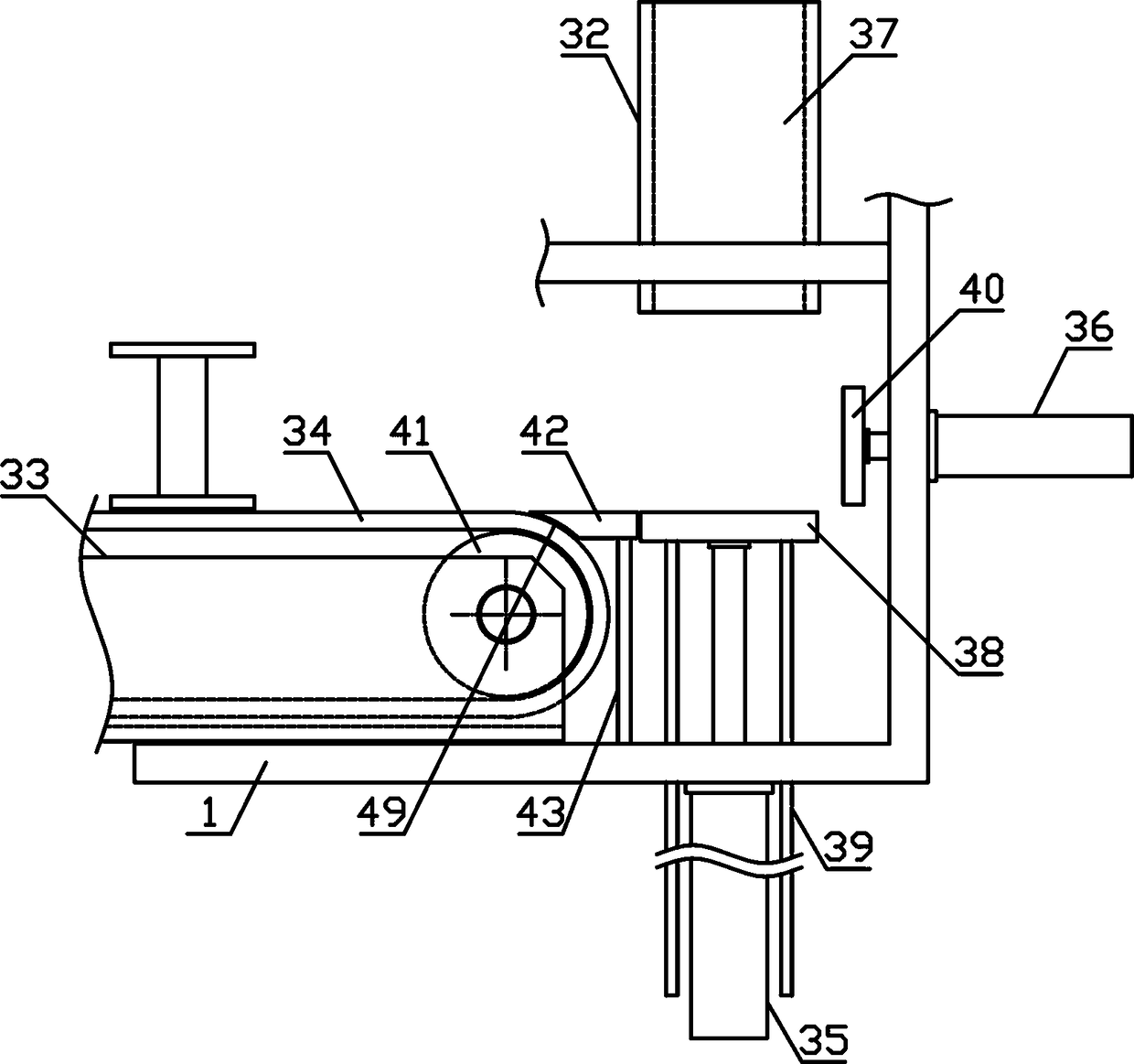

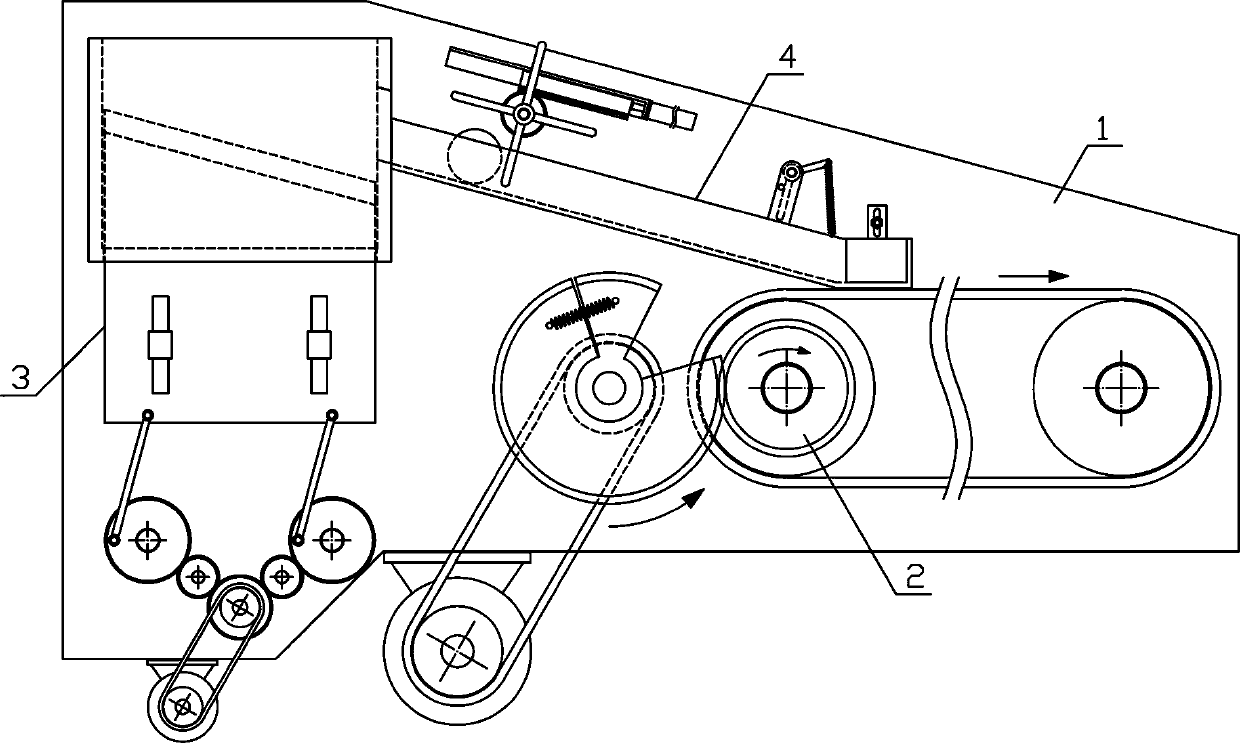

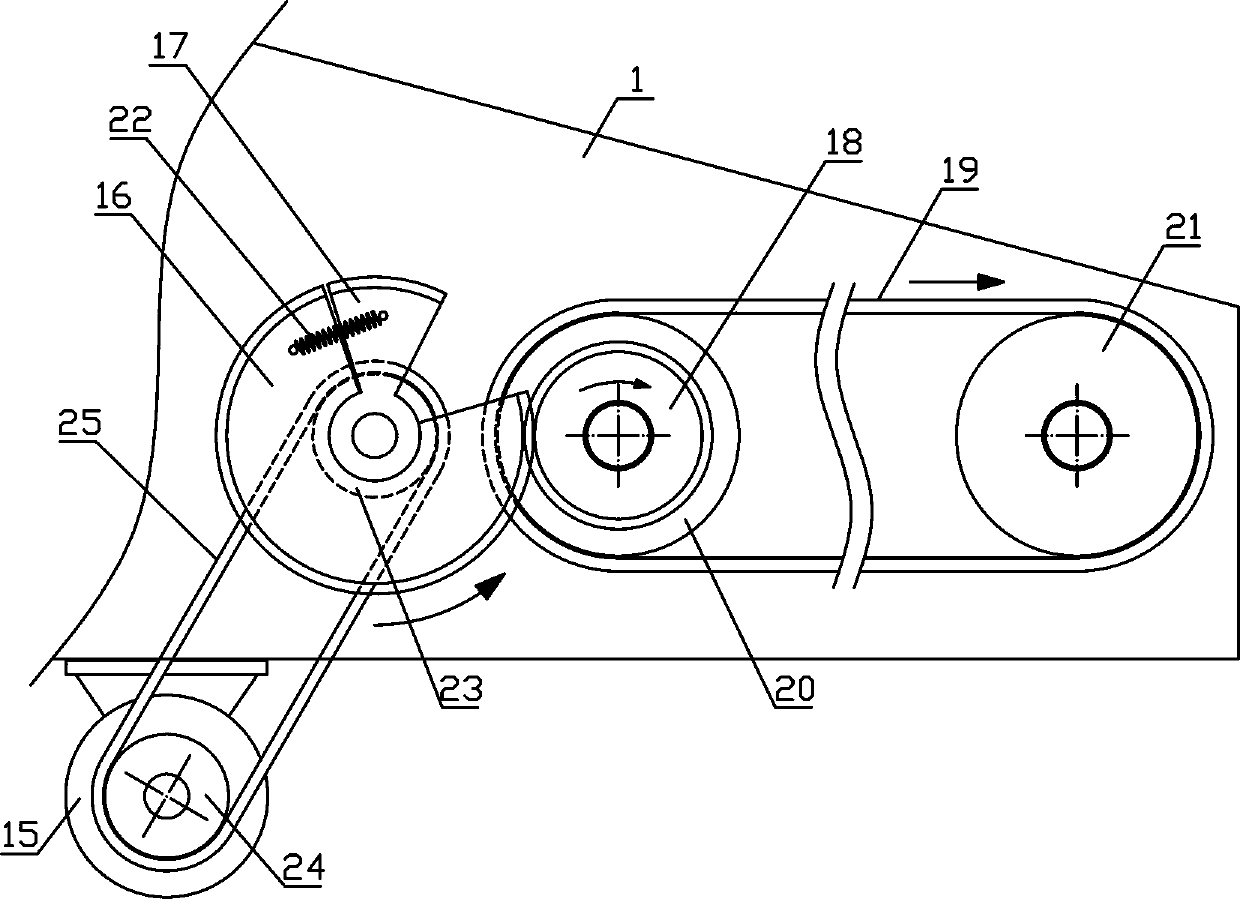

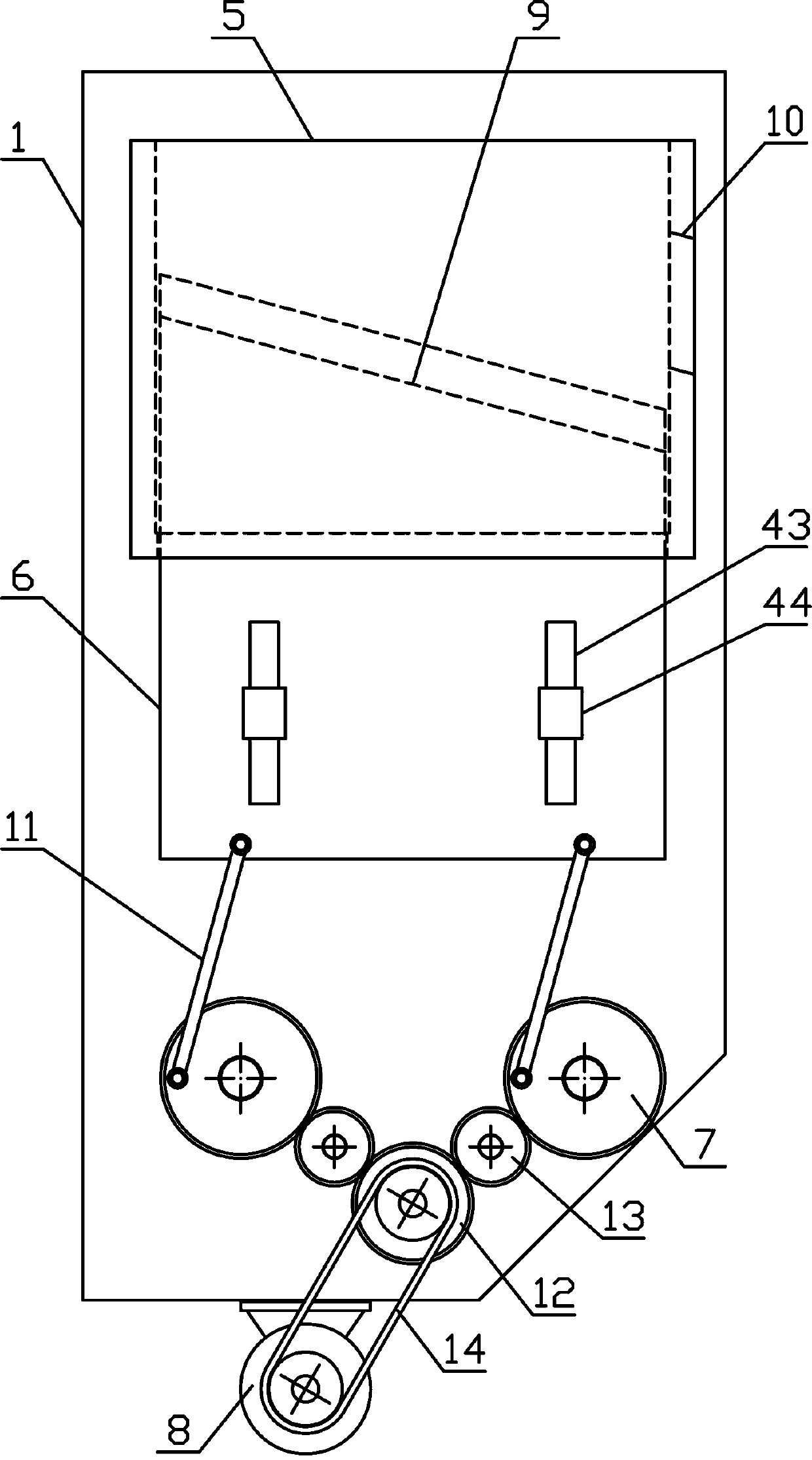

Textile fabric conveying device

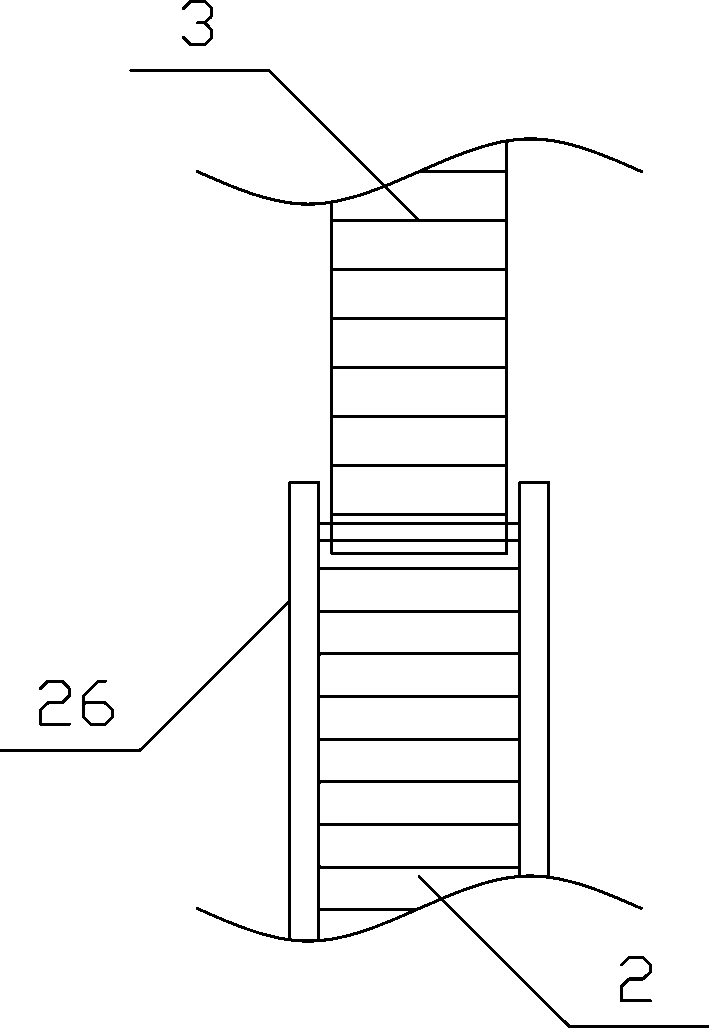

ActiveCN111532827ASmooth and orderly unwinding transmissionEfficient and smooth unwinding transmissionWebs handlingMechanical equipmentIndustrial engineering

The invention discloses a textile fabric conveying device, and belongs to the field of textile processing mechanical equipment. According to the textile fabric conveying device, a fabric unwinding mechanism and a fabric conveying mechanism are arranged on the two sides of a fabric conveying support correspondingly, a lifting fabric guide roller is horizontally arranged on the fabric conveying support between the fabric unwinding mechanism and the fabric conveying mechanism, the lifting fabric guide roller is horizontally and rotationally connected to a reciprocating lifting guide block, a fabric unwinding roller is horizontally, coaxially and fixedly arranged in the middle of a fabric unwinding rotary plate, a pressing plate damping swing rod is arranged on a fabric conveying support on the lower side of the fabric unwinding rotary plate, the two sides of a fabric non-return support are horizontally and rotationally connected with a front material guiding rotary roller and a rear material guiding rotary roller correspondingly, and a lifting material pressing rotary roller is arranged on the lower side of a fabric conveying rotary roller. The textile fabric conveying device is reasonable in structural design, textile fabrics can be efficiently, smoothly, sequentially and intermittently conveyed, stable, accurate and continuous sectional conveying of textile fabrics is achieved,the automation degree of textile fabric conveying and processing is improved, and the requirements of production and use are met.

Owner:山东新天合包装制品有限公司

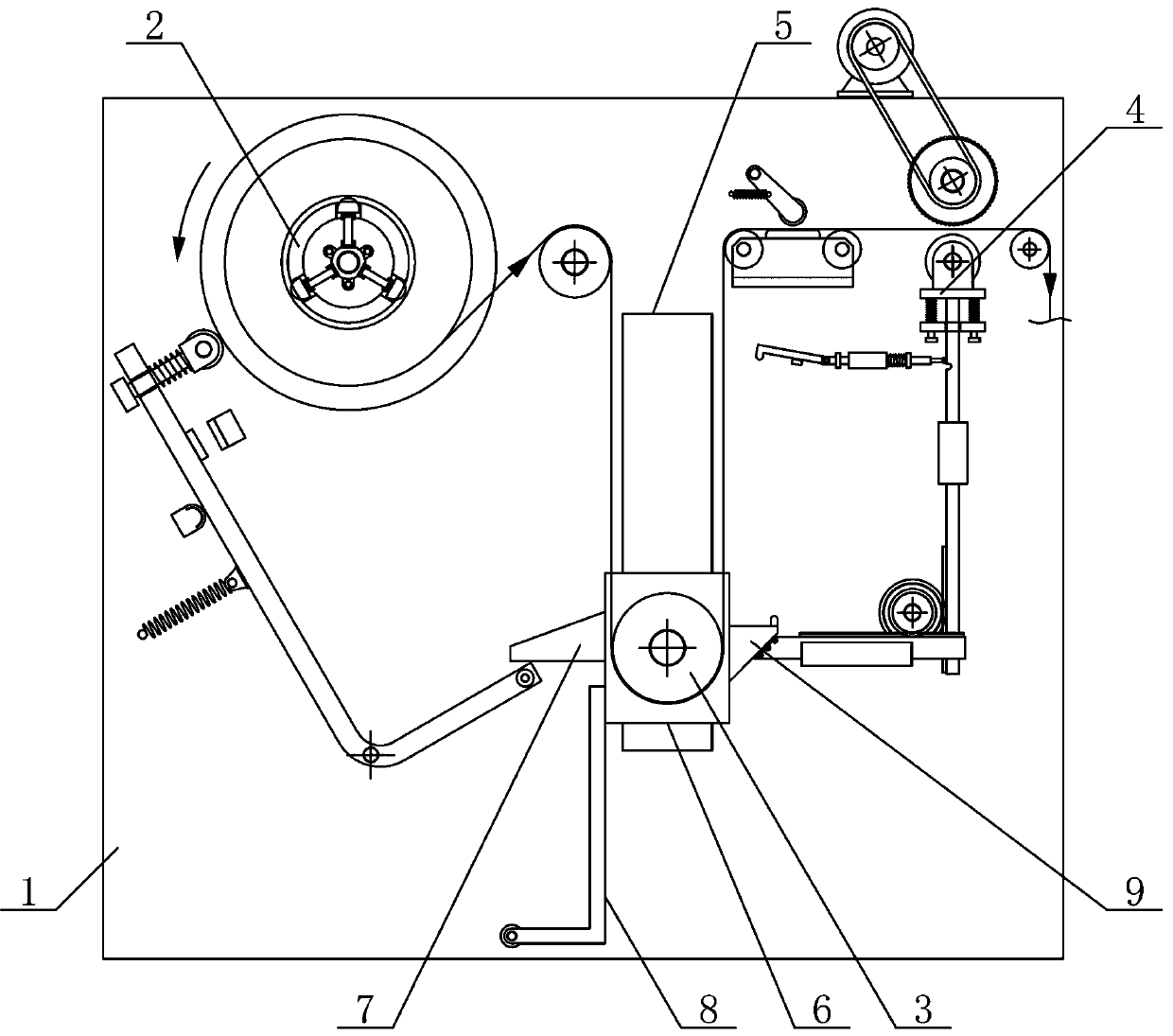

Yarn variable speed winding mechanism

The invention discloses a yarn variable speed winding mechanism, and belongs to the field of textile machining mechanical equipment. A yarn guide mechanism and a rolling mechanism are sequentially arranged on a conveying support in the horizontal direction, yarn is sequentially connected to a yarn inlet rotating roller, a yarn storage rotating roller, a yarn guide rotating roller and a lifting rotating roller in a wound manner, a yarn compressing mechanism is vertically arranged on at the position, on the upper side of the yarn inlet rotating roller, of the conveying support, a rolling motor is in transmission connection with an output gear, a rotating crank is arranged on one side of a rolling gear in the radial direction of the rolling gear, a crank sliding block of the outer end of therotating crank is in rotatable connection to the end of one side of the rotating crank, a rolling rotating shaft is horizontally and rotatably connected to the upper side of a rolling support, a rotating rocker arm is fixedly arranged on one side of the rolling rotating shaft in the radial direction of the rolling rotating shaft, and the crank sliding block is arranged in a rolling guide groove inthe rotating rocker arm in a sliding manner. The yarn variable speed winding mechanism is reasonable in structural design, yarn can be continuously rolled efficiently and compactly, the yarn conveying and rolling automation degree is improved, and the production use needs are met.

Owner:浙江云飞扬羊绒有限公司

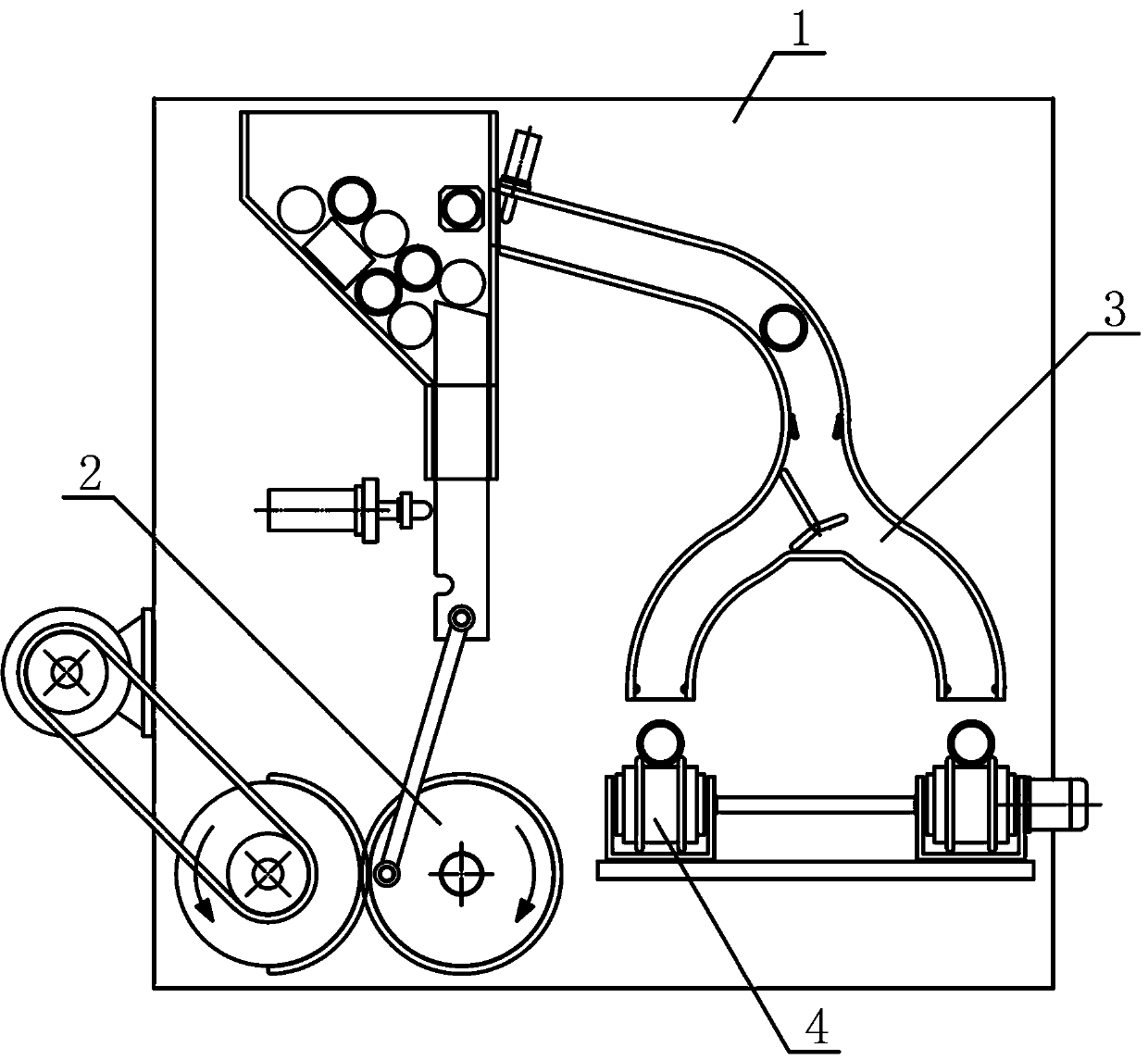

Directional guiding and branching mechanism for end-closed pipe fittings

InactiveCN109704041AReasonable structural designStable and smooth and even distribution of feeding and feedingConveyor partsEngineeringMechanical equipment

The invention discloses a directional guiding and branching mechanism for end-closed pipe fittings, and belongs to the field of mechanical equipment for processing and transmission of workpieces. A pushing plate sleeve is arranged on and vertically communicates with the lower side of a pipe storing hopper, a lifting pushing plate slides in the vertical direction and is arranged on the pushing plate sleeve, a feeding guiding pipe is fixedly arranged on a guiding pipe bracket besides the pipe storing hopper, branch guiding pipes are arranged on the two sides of the lower end of the feeding guiding pipe in a symmetrical and communicating mode, a rotating guiding plate is rotatably arranged at the end of the lower side of the feeding guiding pipe, a fixed bearing plate is horizontally and fixedly arranged on the guiding pipe bracket on the lower sides of the two branch guiding pipes, pipe transmitting brackets are horizontally and fixedly arranged on the two sides of the upper part of thefixed bearing plate, and pipe transmitting belts are horizontally arranged on the upper sides of the pipe transmitting brackets. The directional guiding and branching mechanism is reasonable in structural design, the pipe fittings can be conveniently and efficiently arrayed and guided one-by-one in a directional mode, the pipe fittings can be stably, smoothly and evenly branched, fed and transferred in a division mode, the automation degree of pipe fitting transferring and processing are improved, and the needs of processing and using are met.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

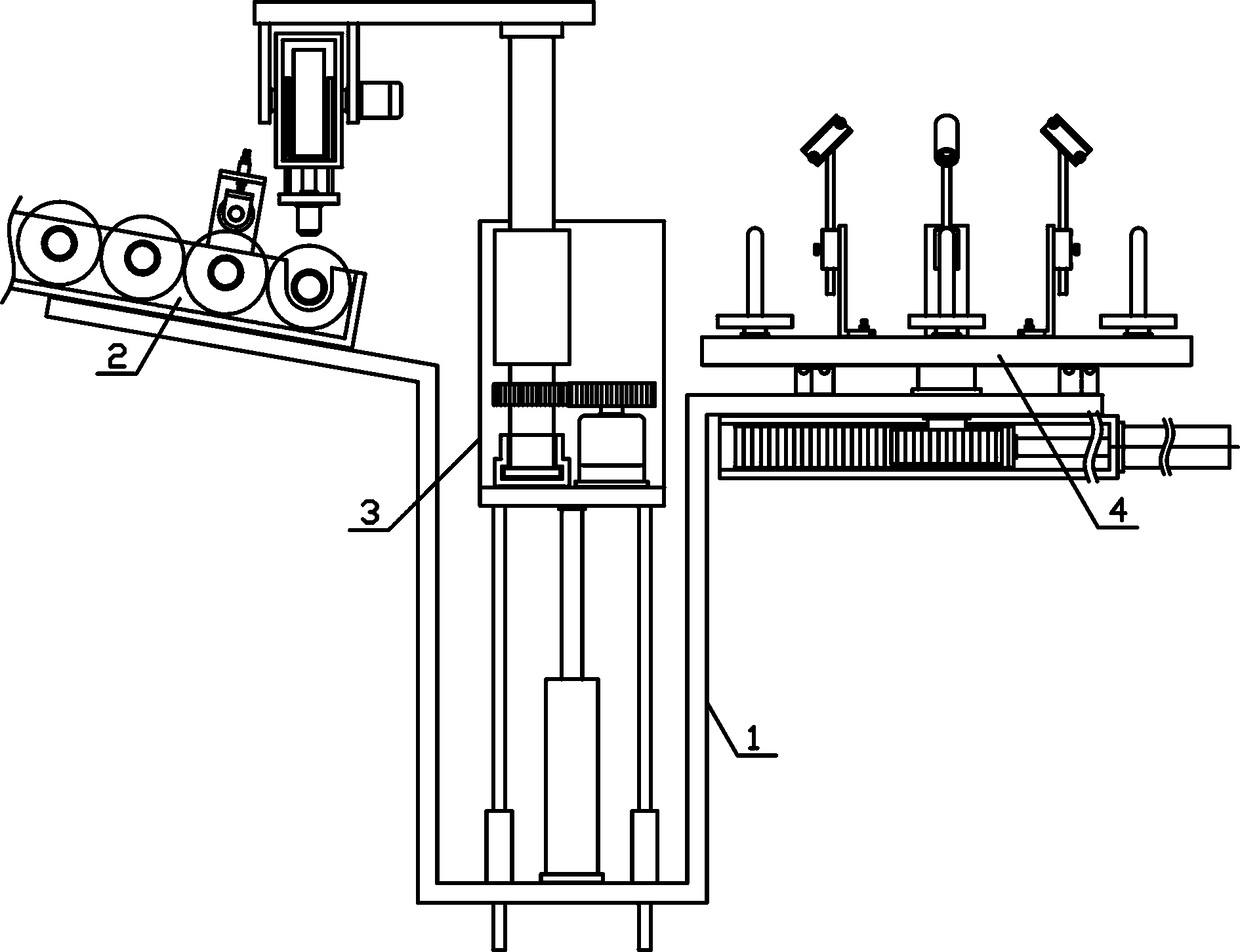

Chemical fiber bobbin yarn transferring and placing mechanism

InactiveCN109205393ARealize continuous feedingEasy and efficient replacementFilament handlingYarnFiber

The invention discloses a chemical fiber bobbin yarn transferring and placing mechanism, and belongs to the field of chemical fiber conveying and processing machine equipment. A bobbin transferring mechanism is vertically arranged on a fixing support between a bobbin guiding mechanism and a yarn placing mechanism. A discharging material pipe is obliquely downwards arranged on the upper side of thefixing support. The output end of a lifting air cylinder is vertically and fixedly provided with a lifting support. A bobbin transferring rotation rod is vertically and rotationally connected to a rotation rod sleeve. One end of the lower side of a reciprocating rotating plate is fixedly connected with the upper end of the bobbin transferring rotation rod. A bobbin taking mechanism is fixedly arranged at the other end of the lower side of the reciprocating rotation plate. A plurality of bobbin placing circular plates are evenly arranged at the outer end of the upper side of a yarn guiding rotation disc. A plurality of yarn guiding mechanisms are evenly arranged on the upper side of the yarn guiding rotation disc. The bobbin placing circular plates and the yarn guiding mechanism are sequentially arranged in the radial direction of the yarn guiding rotation disc from exterior to interior. The chemical fiber bobbin yarn transferring and placing mechanism is reasonable in structural design, a plurality of chemical fiber bobbin yarns can be continuously transferred and replaced conveniently and efficiently, a plurality of strands of chemical fiber filaments can be stably, accurately and synchronously conveyed, the automation degree is high, and the production and usage requirements are met.

Owner:桐乡市宏力纺织股份有限公司

Working method for pipe fitting translation conveying mechanism

InactiveCN112265803AImprove the degree of automation of transmission processingReasonable structural designConveyorsConveyor partsPipe fittingStructural engineering

The invention discloses a working method for a pipe fitting translation conveying mechanism and belongs to the field of workpiece conveying and machining mechanical equipment. According to the workingmethod for the pipe fitting translation conveying mechanism, a guide pipe material pipe is vertically and fixedly arranged on one side above a pipe moving support, translation armatures are arrangedon a plurality of armature sleeves fixedly arranged on the outer side of a pipe pushing belt, a plurality of pipe pushing rotating plates are arranged on a pipe pushing support at the end portion of atranslation guide rod in the horizontal direction, an adsorption electromagnet is arranged on one side below the pipe pushing support, guide pipe bearing rods are horizontally and symmetrically arranged on the two sides of the upper portion of the pipe pushing support respectively, a guide pipe inclined plate inclines downwards and is fixedly arranged on the part, on one side below a pipe movingmechanism, of the pipe moving support, and a conveying material pipe is vertically and fixedly arranged on the part, on the lower side of the guide pipe inclined plate, of the pipe moving support. Thepipe fitting translation conveying mechanism is reasonable in structural design, pipe fittings can be stably, accurately and sequentially pushed and fed in an intermittent translation mode in the horizontal direction and can be conveniently and smoothly rotated to adjust the conveying station, the automation degree of pipe fitting conveying and machining is improved, and the machining and using requirements are met.

Owner:章凌霞

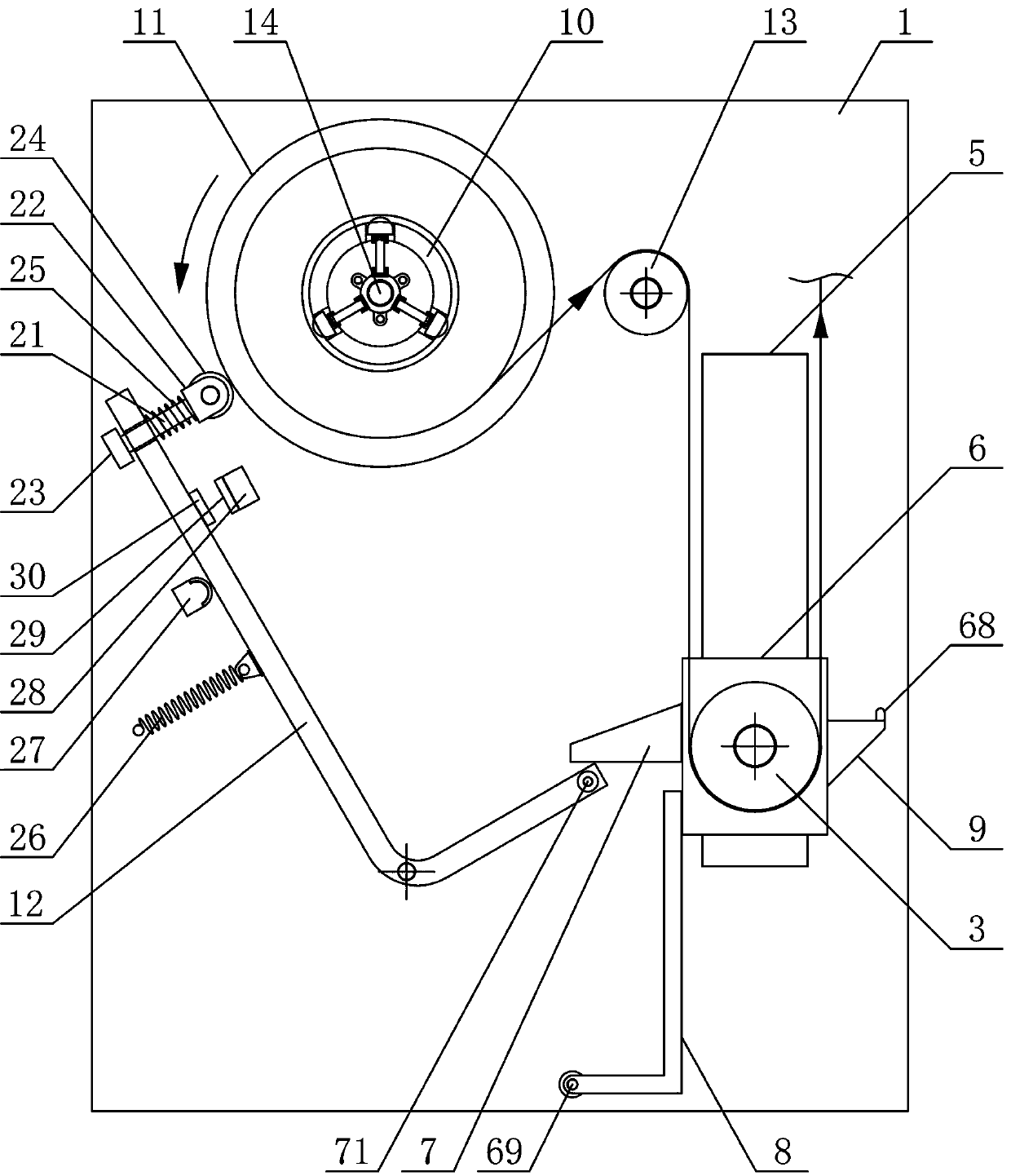

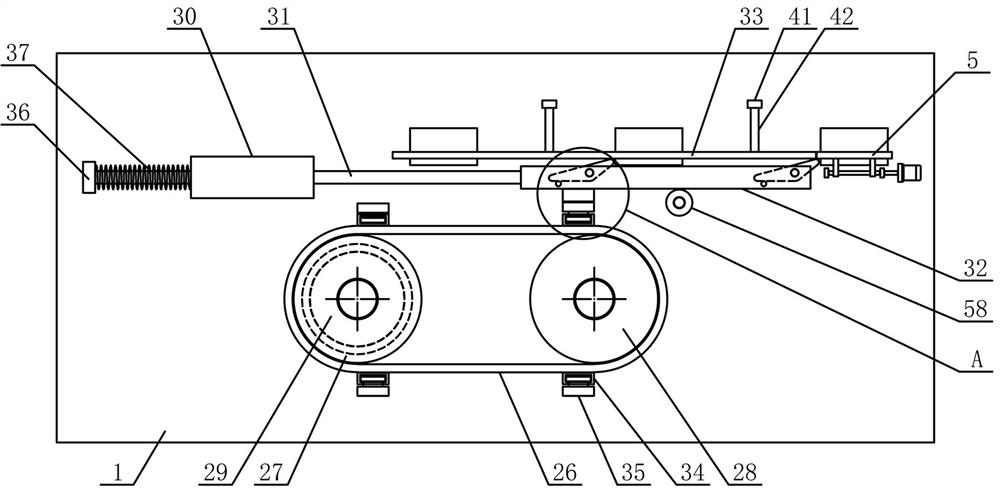

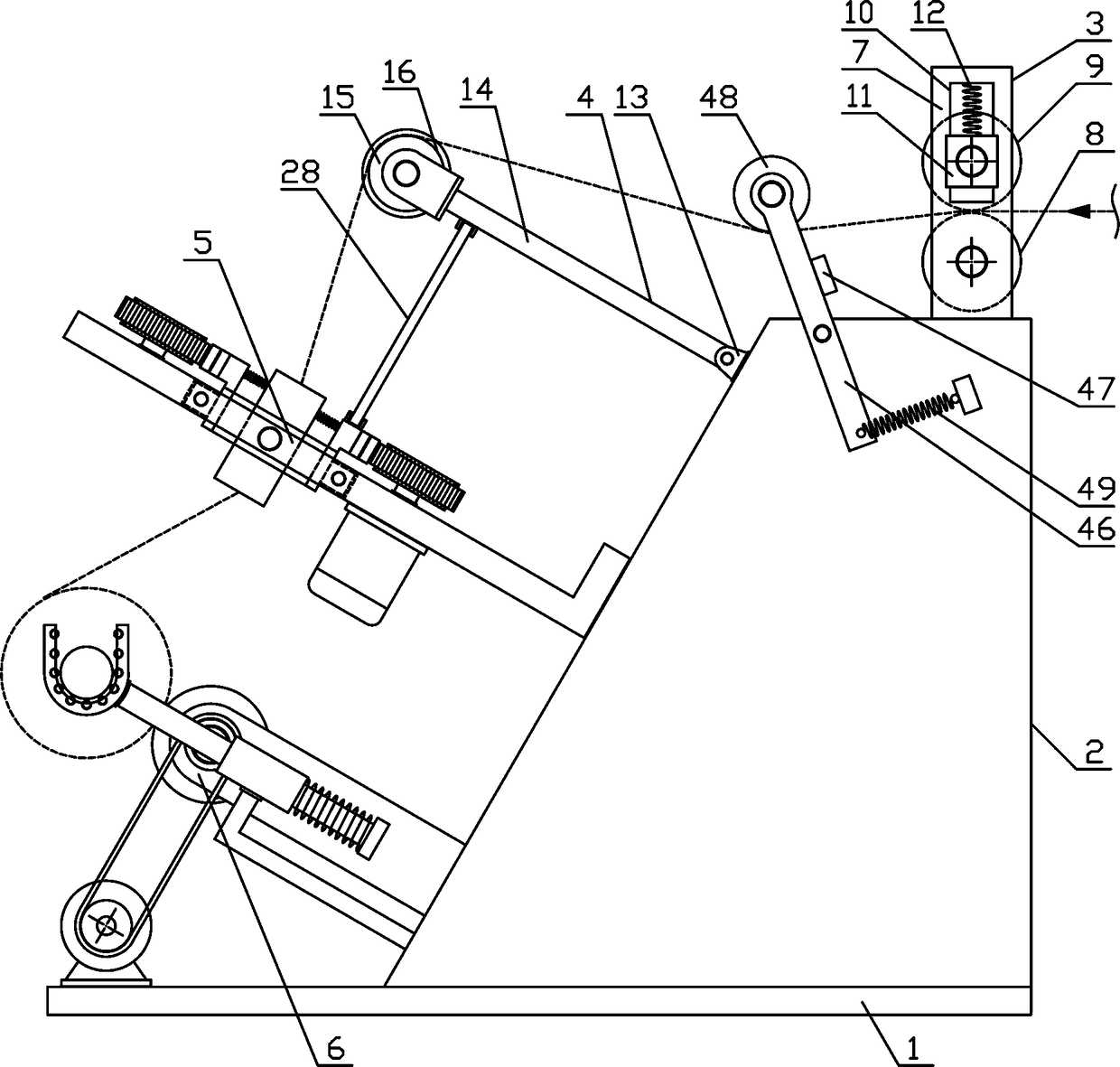

Iron bar automatic segmenting mechanism

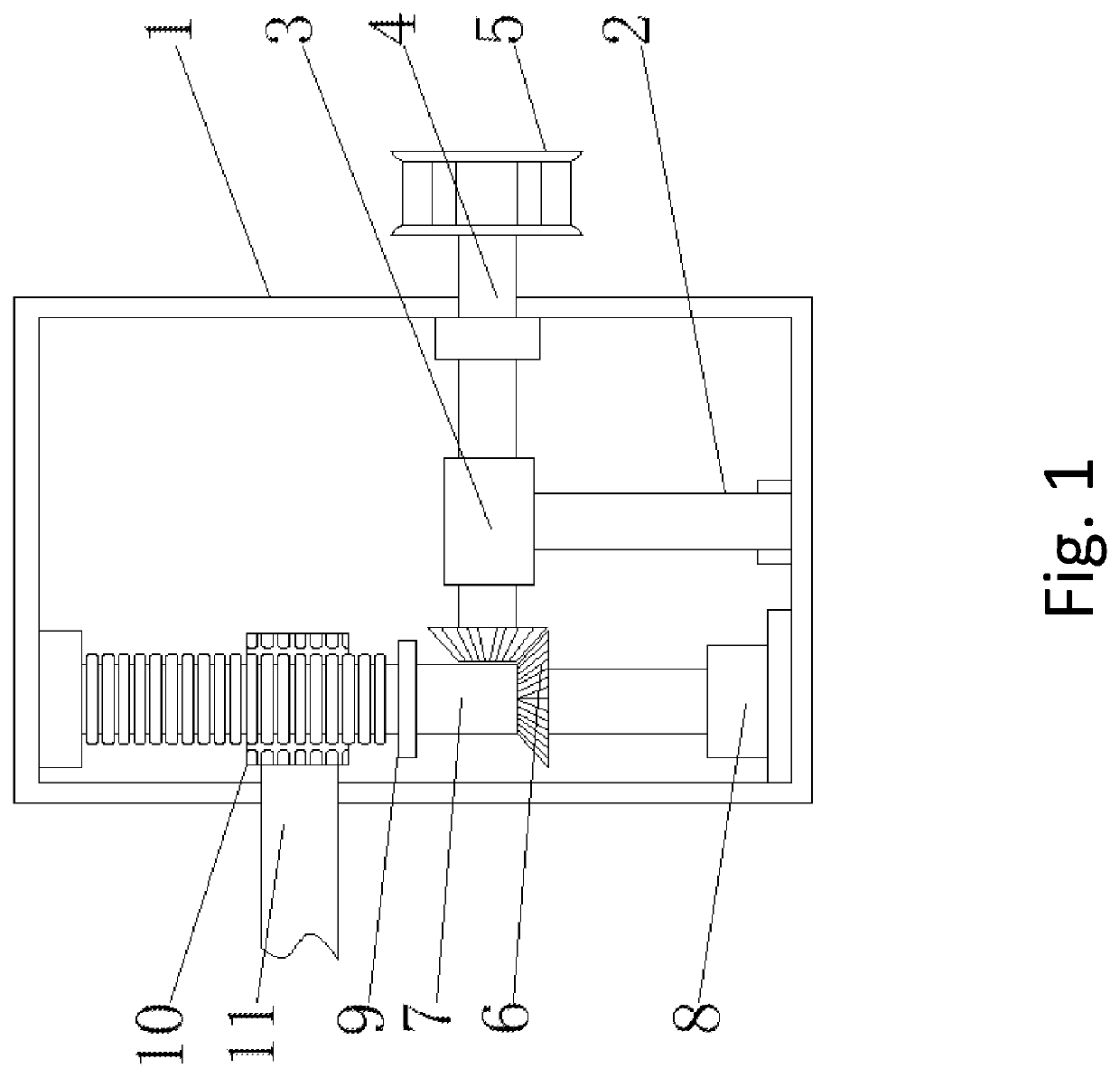

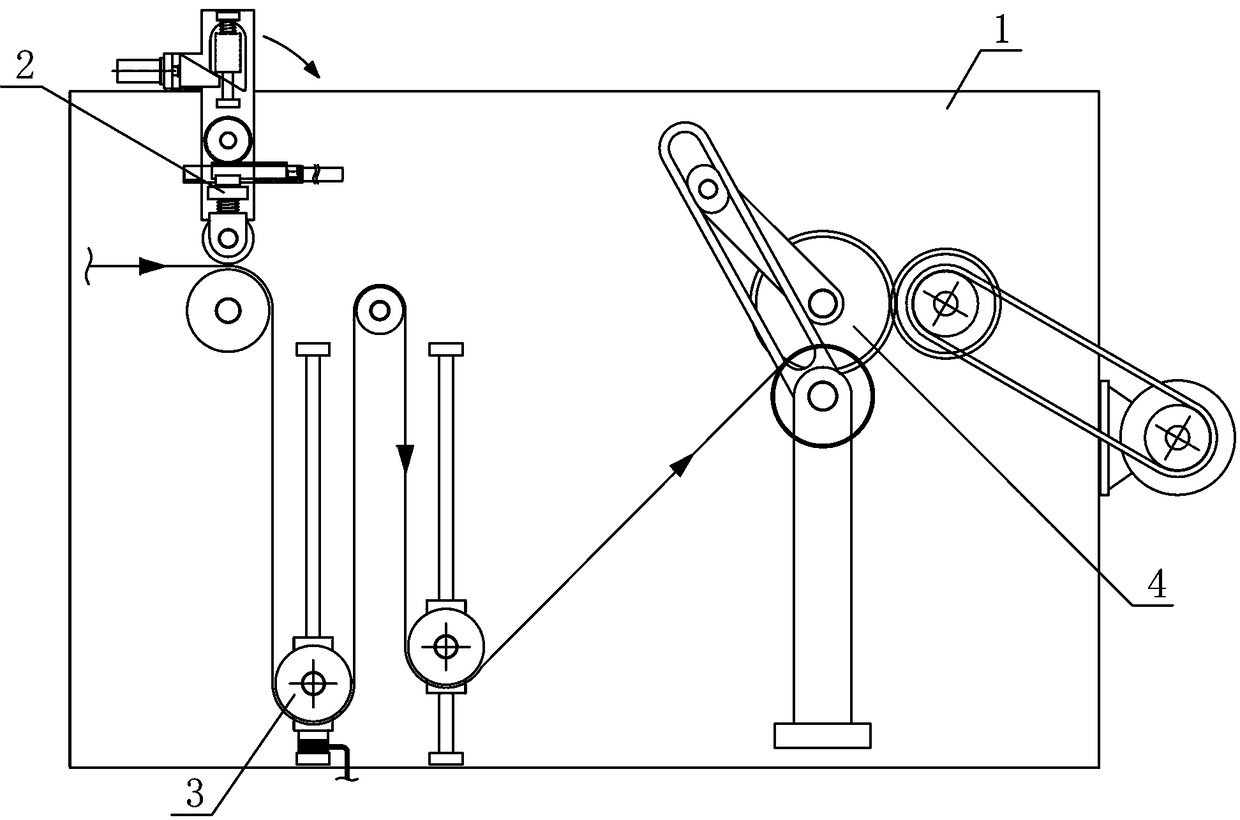

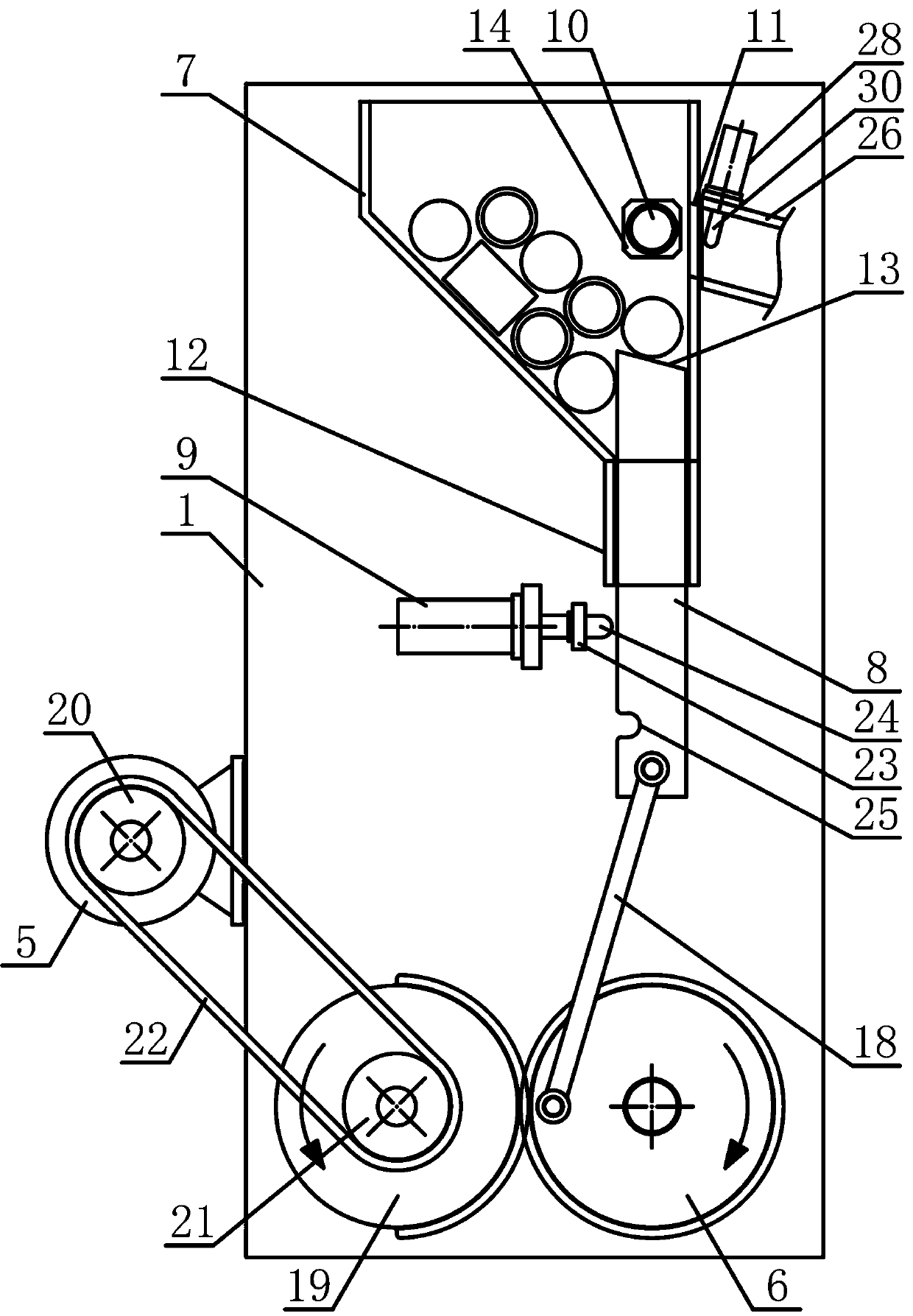

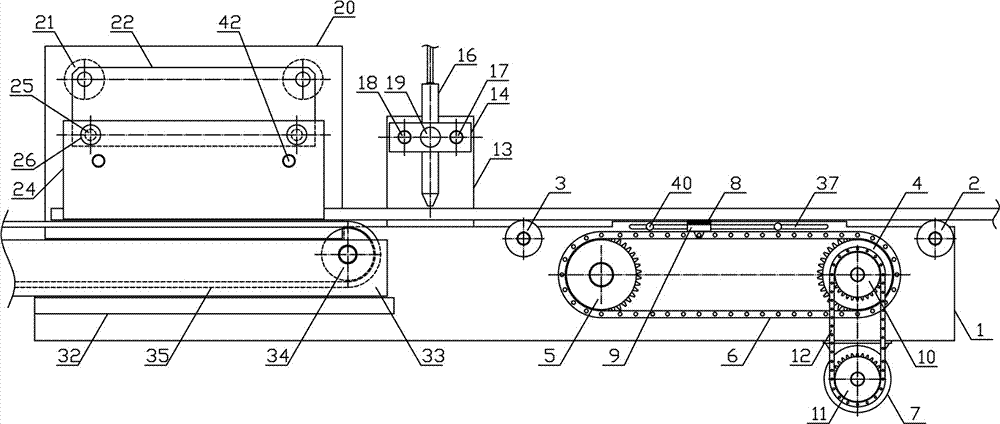

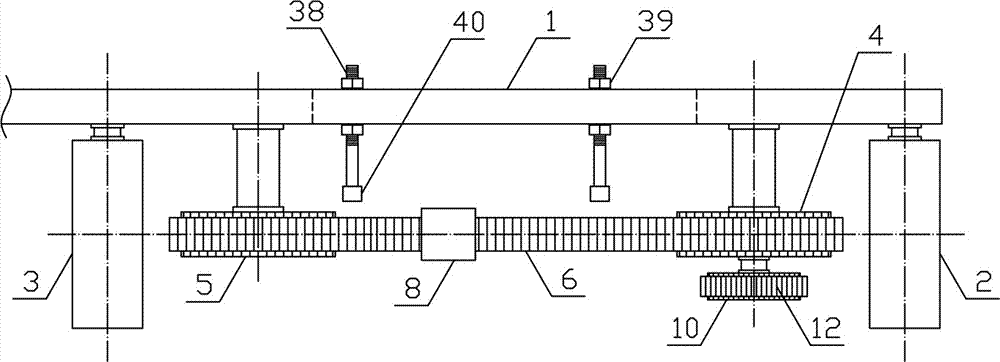

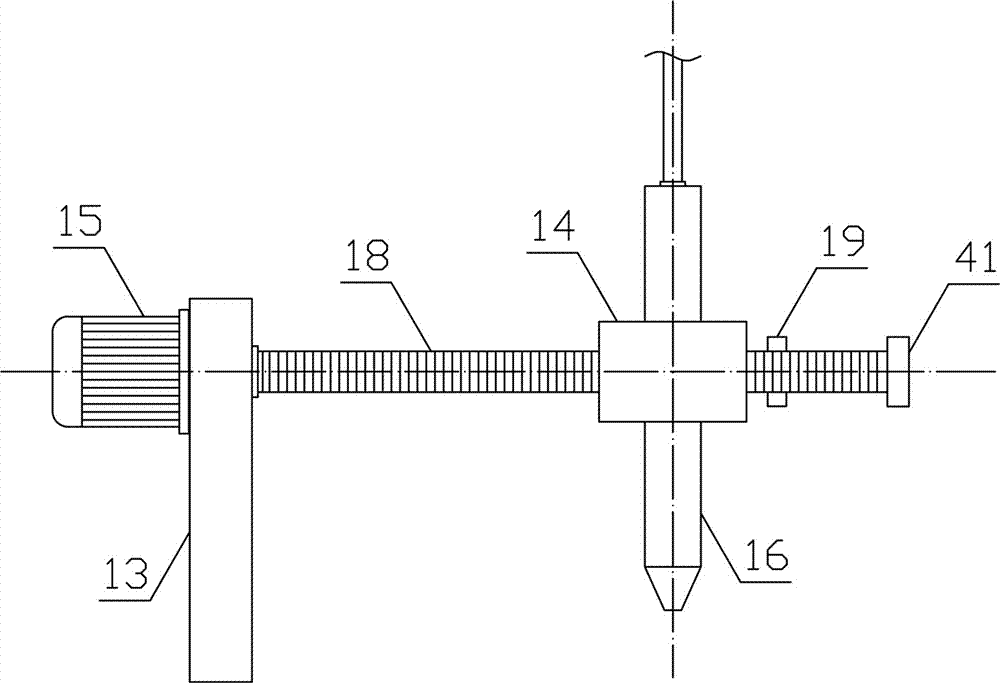

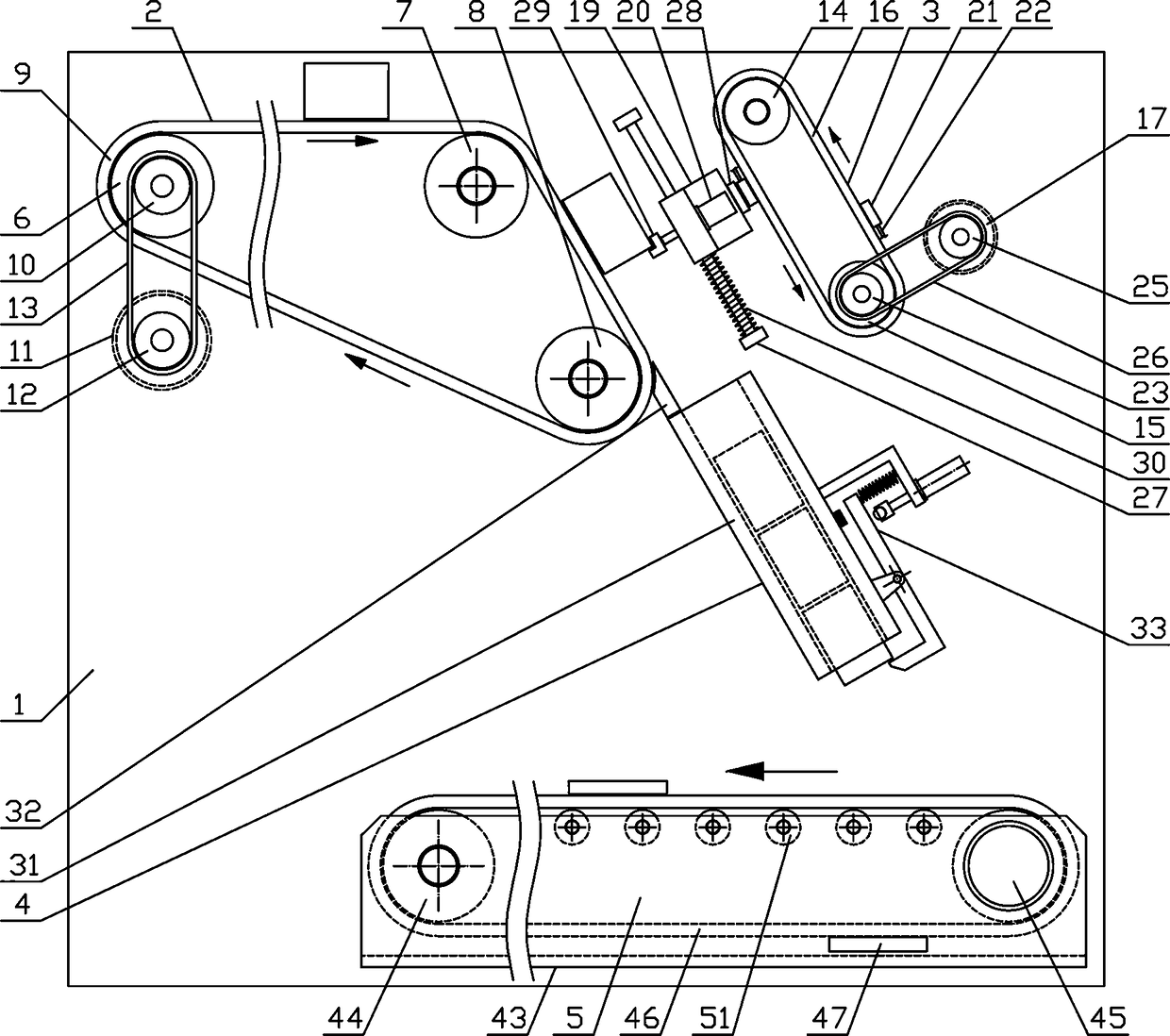

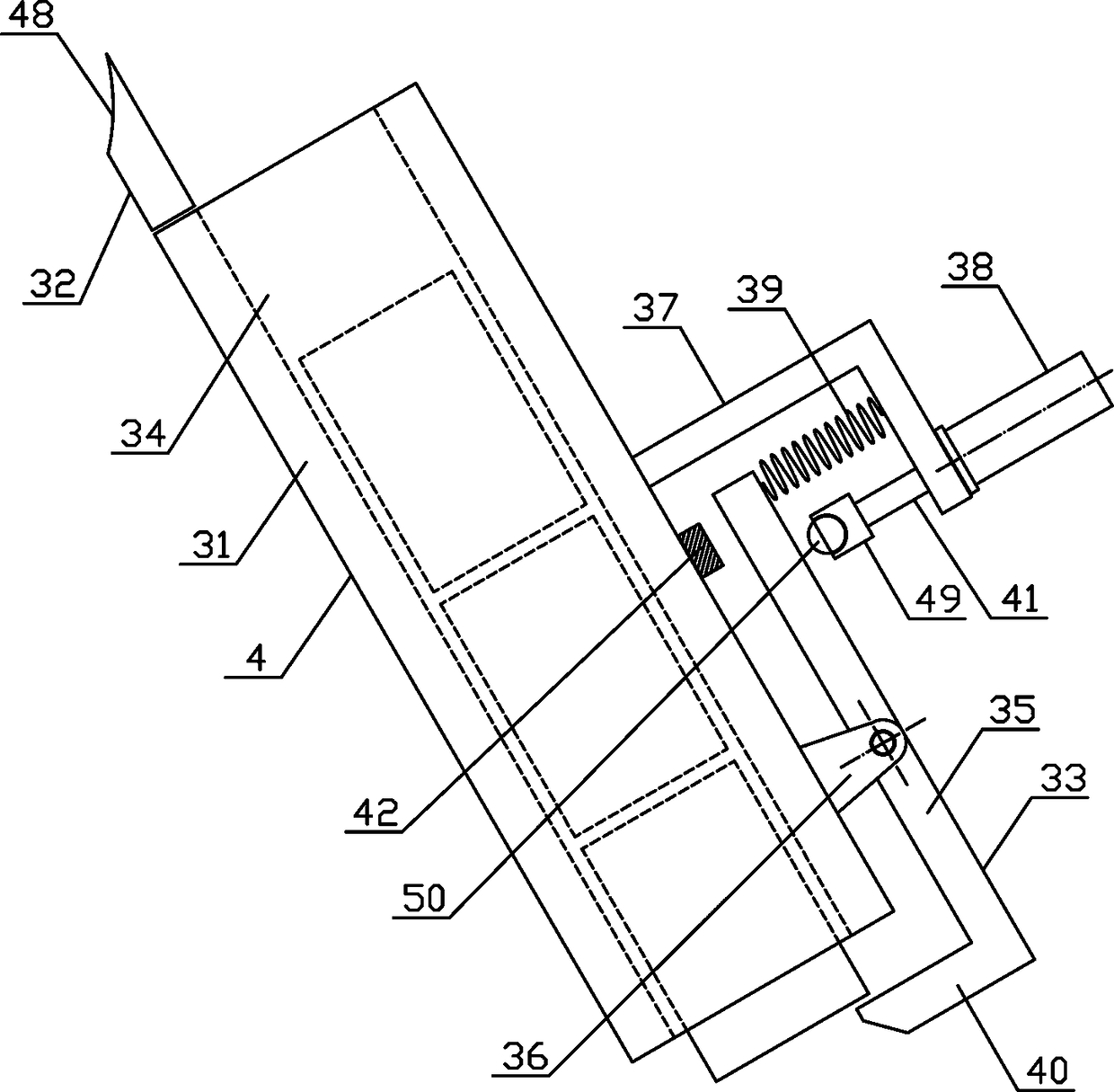

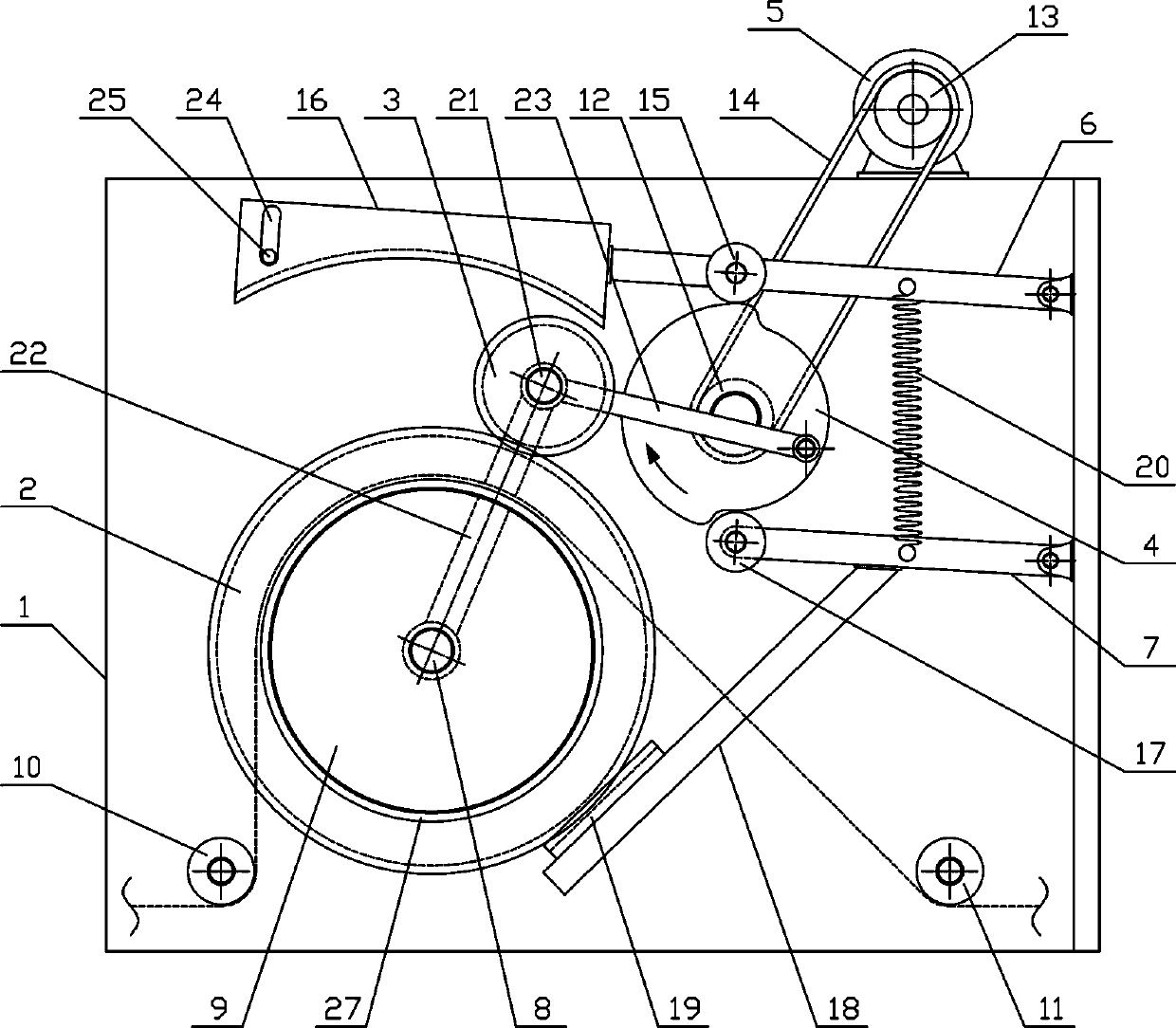

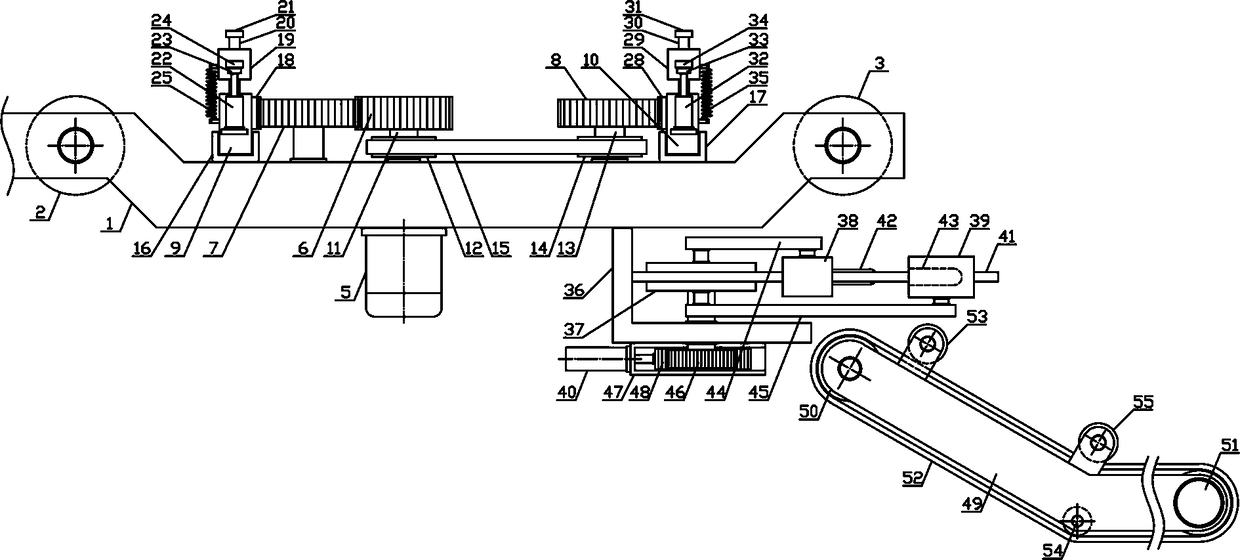

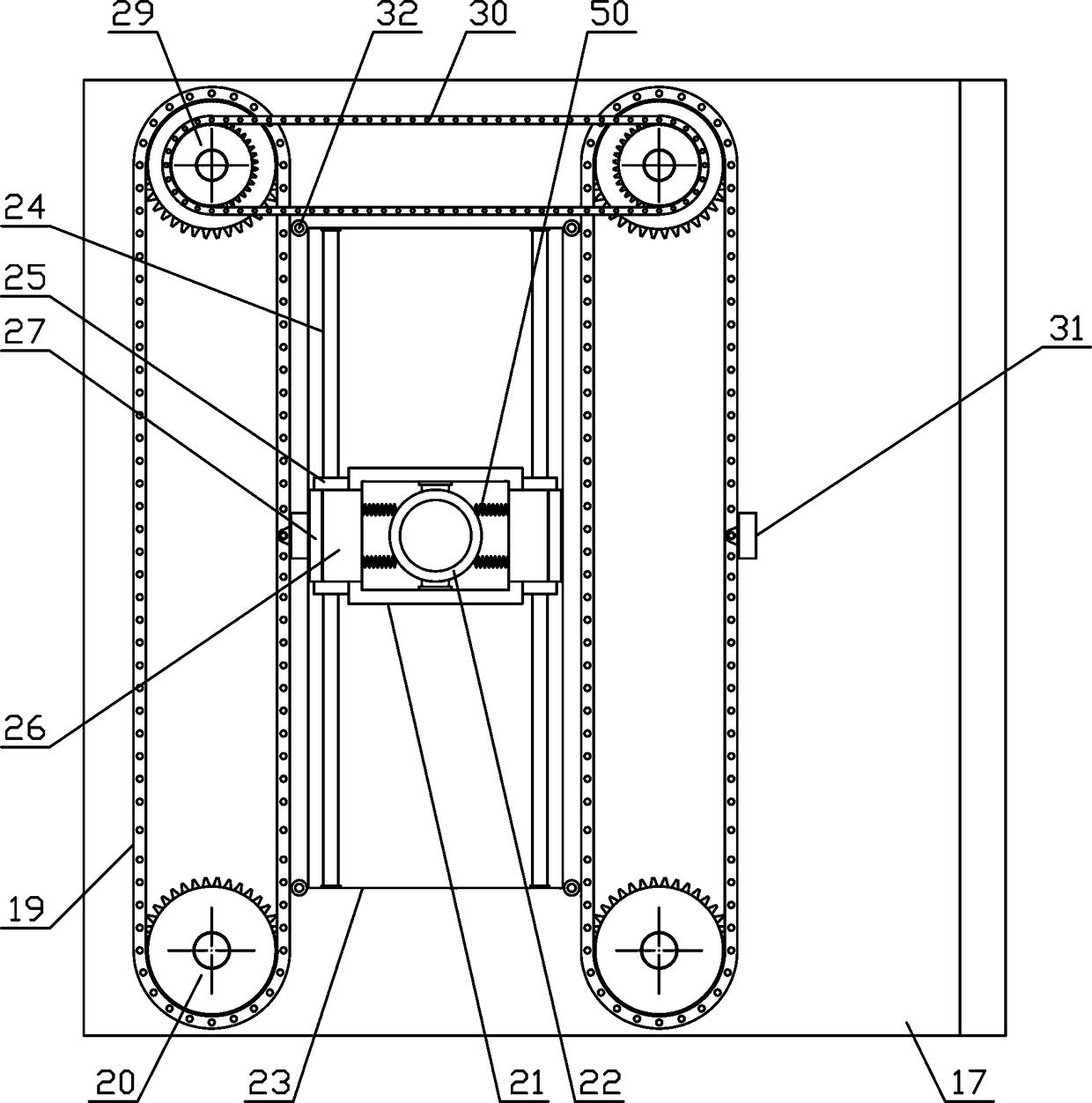

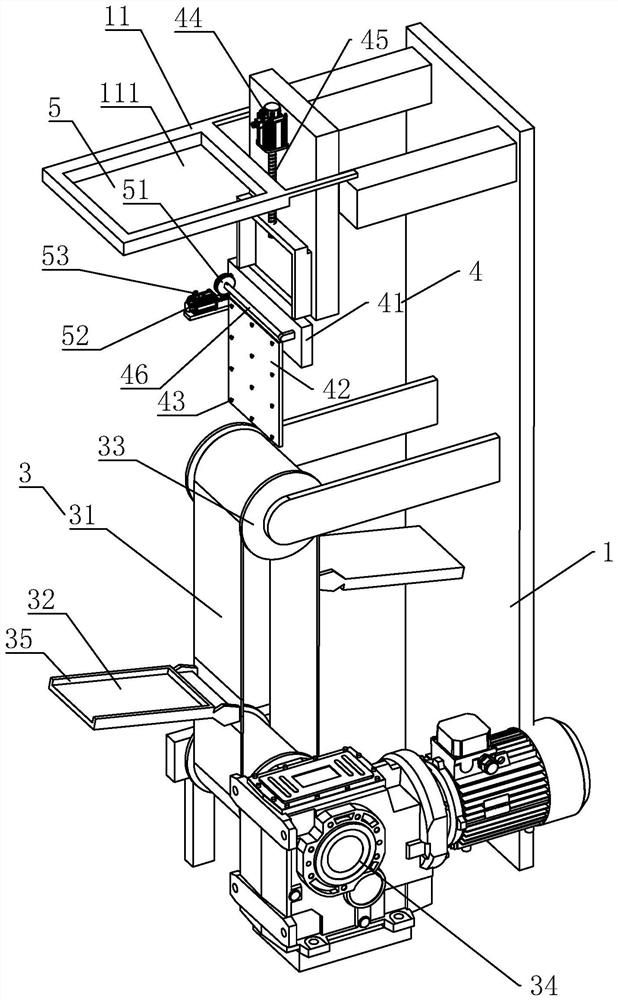

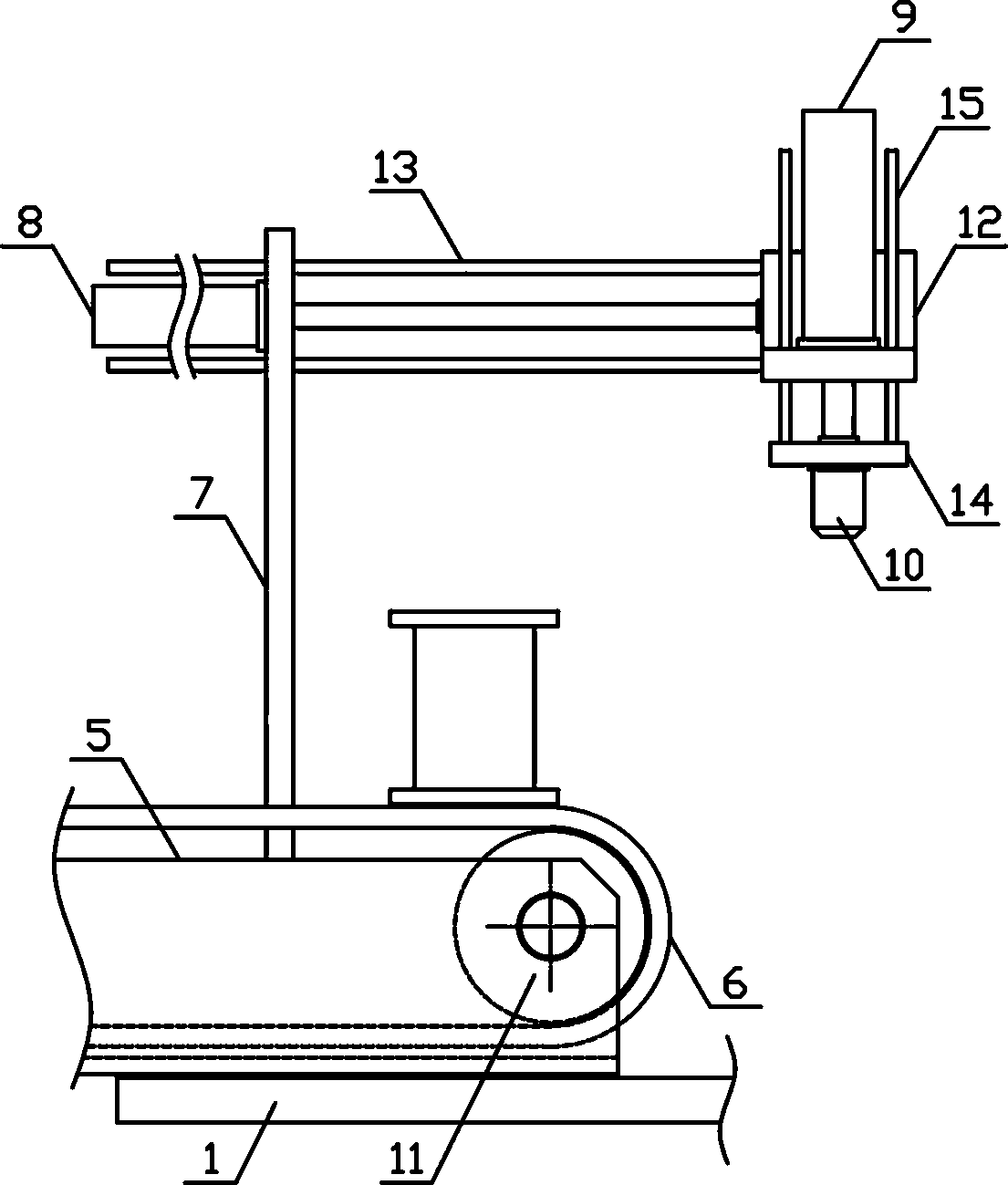

ActiveCN107971558AEasy to sendSmooth and precise transmissionNibbling shearing machinesShearing machine accessoriesMetallic materialsMechanical equipment

The invention discloses an iron bar automatic segmenting mechanism, and belongs to the field of metal material processing mechanical equipment. The iron bar automatic segmenting mechanism includes a material-carrying mechanism, a material-cutting mechanism and a fixing material-pushing mechanism which are sequentially and fixedly arranged at one side of a fixing support in the horizontal direction, and a material-carrying chain which is winded is horizontally arranged between a main material-carrying chain and a secondary material-carrying chain; a material-carrying electromagnet is fixedly arranged at the outer side of the material-carrying guiding plate, a reciprocating material-cutting plate is slidably arranged at a material-cutting guiding rod in the horizontal direction, and a cutting handpiece is slidably arranged at the reciprocating material-cutting plate in the vertical direction; and a horizontal-pushing guiding rod is separately and horizontally fixed to two sides below a horizontal-pushing connecting plate, a fixing guiding plate and a moving guiding plate are separately and vertically arranged at two sides of the horizontal-pushing guiding rod, and the material-transporting mechanism is horizontally and fixedly arranged at the upper side of a material-transporting supporting plate. According to the iron bar automatic segmenting mechanism, the structural design isreasonable, iron bars can be transferred horizontally, stably, accurately and intermittently according to needed length, the iron bars can be clamped and cut and automatic feeding can be realized, andthe need for machining using can be met.

Owner:ZHEJIANG ZHUOYI TEXTILE

Pipe fitting translation and turning conveying mechanism

ActiveCN110451217AImprove the degree of automation of transmission processingReasonable structural designConveyorsConveyor partsPipe fittingMechanical equipment

The invention discloses a pipe fitting translation and turning conveying mechanism, and belongs to the field of workpiece conveying and machining mechanical equipment. A pipe guiding material pipe ofthe pipe fitting translation and turning conveying mechanism is vertically and fixedly arranged on one side above a pipe moving support, and a plurality of armature sleeves which are fixedly arrangedon the outer side of a pipe pushing belt are provided with translation armatures, a plurality of pipe pushing rotary plates are arranged on a pipe pushing support at the end of a translation guide rodin the horizontal direction, an attraction electromagnet is arranged on one side below the pipe pushing support, pipe guiding supporting rods are horizontally and symmetrically arranged on two sidesabove the pipe pushing support correspondingly, a pipe guiding inclined plate is obliquely, downwards and fixedly arranged at the position, at the one side below of a pipe moving mechanism, of the pipe moving support, and a conveying material pipe is vertically and fixedly arranged at the position, at the lower side of the pipe guiding inclined plate, of the pipe moving support. The pipe fitting translation and turning conveying mechanism has the advantages that the structural design is reasonable, pipe fittings can be stably, accurately, successively and intermittently translated and pushed for feeding in the horizontal direction, the pipe fittings can be conveniently and smoothly rotated and adjusted to be conveyed to a station, the automation degree of pipe fitting conveying and machining is improved, and the requirement of machining and using is met.

Owner:上海固雅环境科技有限公司

Conveying and overturning mechanism for square tanks

InactiveCN108557433AReasonable structural designSmooth rotationConveyorsConveyor partsEngineeringMechanical equipment

The invention discloses a conveying and overturning mechanism for square tanks, and belongs to the field of mechanical equipment for continuous conveying of tanks. A tank carrying mechanism is arranged on a fixing support at one side of a front tank conveying mechanism obliquely and downwardly. A tank guide mechanism is arranged on a fixing support at the lower side of the front tank conveying mechanism obliquely and downwardly. A rear tank conveying mechanism is horizontally and fixedly arranged on a fixing support at the lower side of the tank guide mechanism. A tank carrying support is arranged on a lifting guide rod slidably. A tank-carrying clamp plate is arranged at the output end of a tank-carrying air cylinder fixedly. A reset spring sleeves the lifting guide rod on the lower sideof the tank carrying support. A tank guide pipeline is arranged on a fixing support at the lower side of a front tank conveying belt obliquely and downwardly. A tank clamping mechanism is arranged onthe upper side of the lower end of the tank guide pipeline. A plurality of material conveying electromagnets are arranged on the outer side of a rear tank conveying belt evenly. The conveying and overturning mechanism has the advantages that the structural design is reasonable, the square tanks can be conveyed efficiently and continuously and can be also overturned smoothly and vertically one by one, and production and application requirements are met.

Owner:屠明州

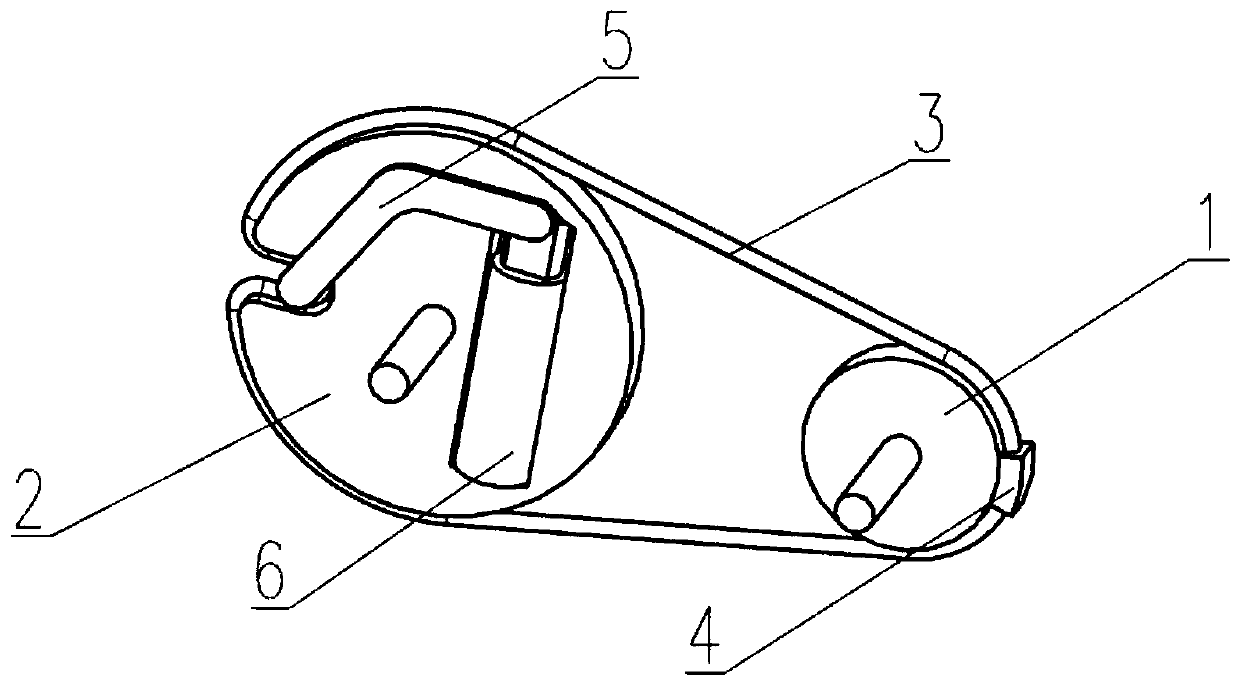

Automatic plug wire testing device

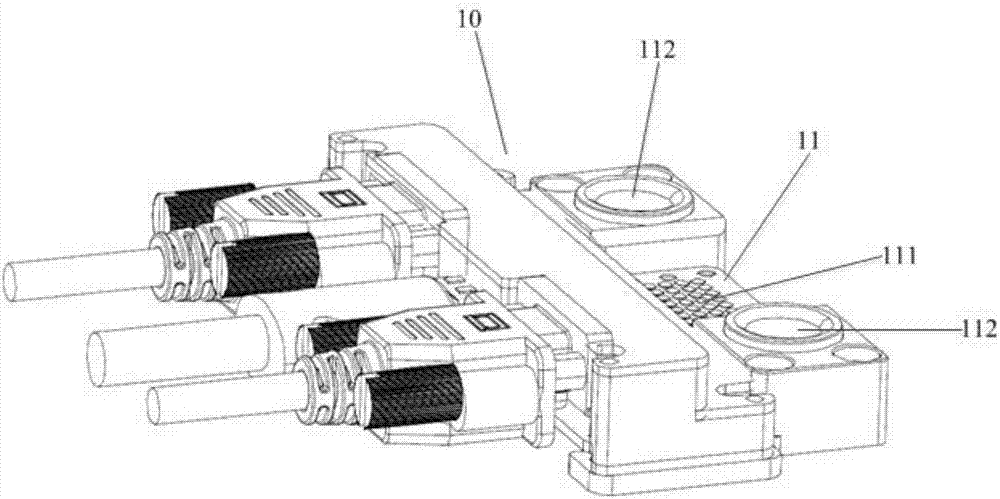

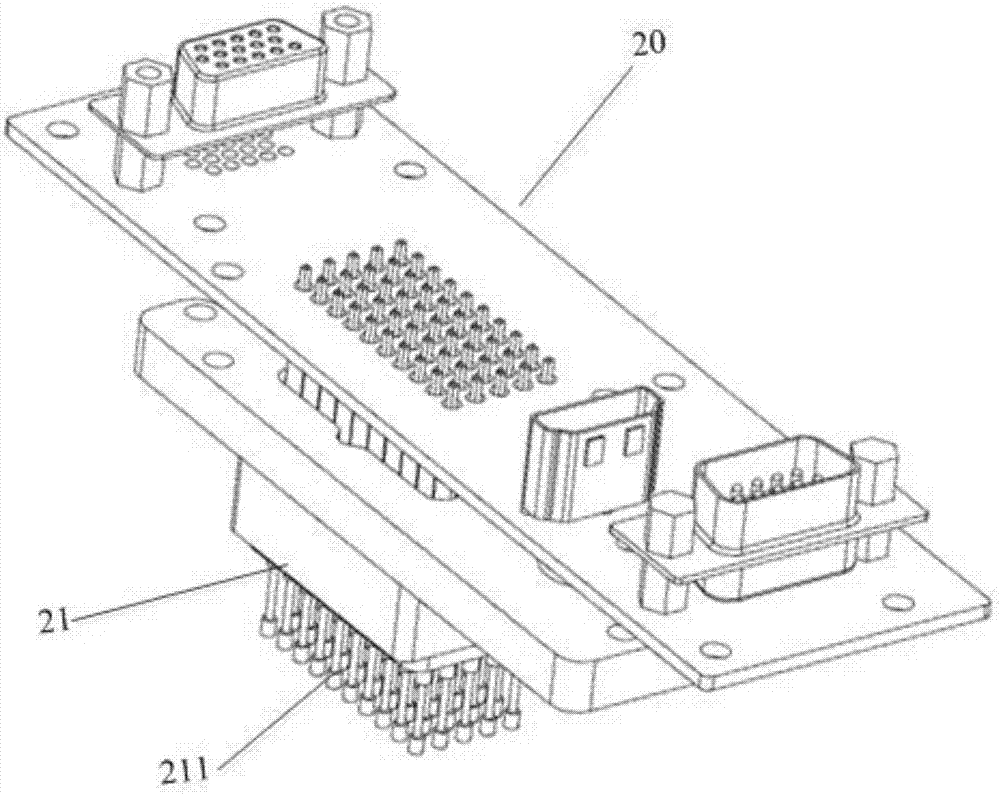

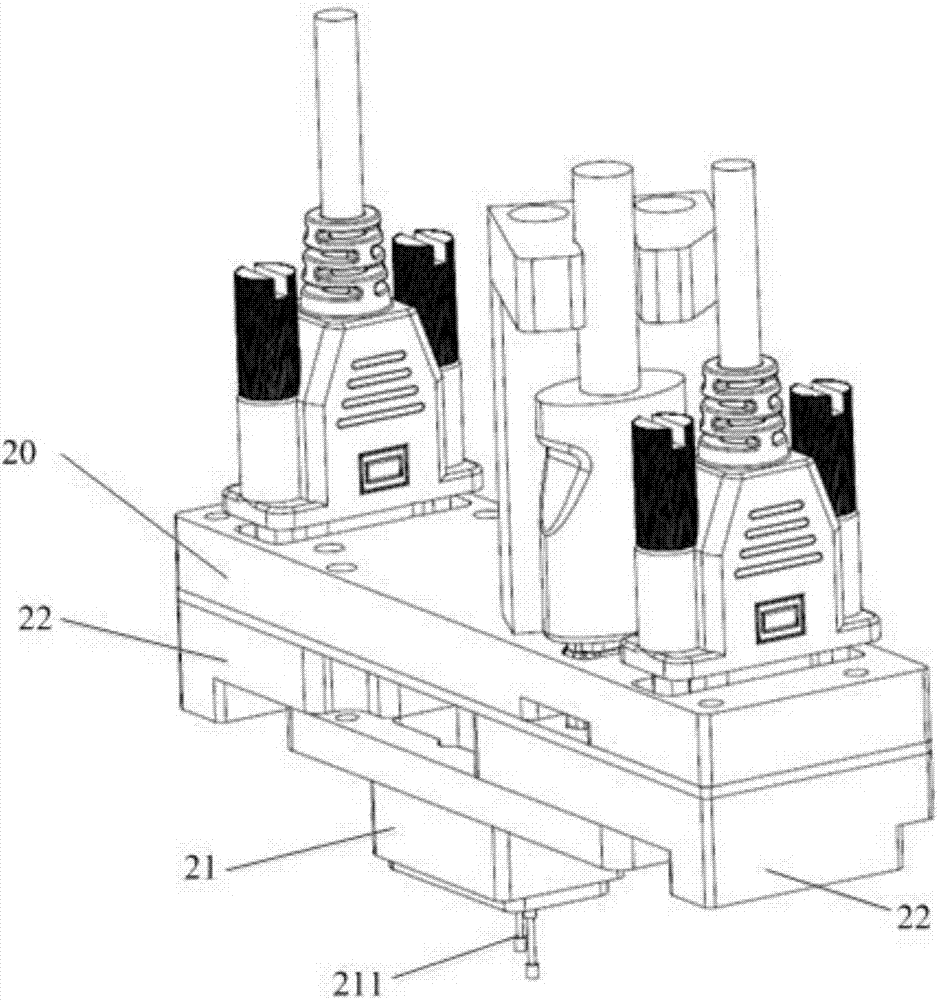

ActiveCN106918727ASmooth and precise transmissionTransmission is stable and accurateElectrical measurement instrument detailsElectrical testingTest efficiencyProduct base

The invention discloses an automatic plug wire testing device, and belongs to the field of testing equipment. The automatic plug wire testing device comprises a first substrate assembly, a second substrate assembly and a direction adjustment assembly, and is characterized in that the direction adjustment assembly is connected with the second substrate assembly; the first substrate assembly is electrically connected with a device at the end to be tested, and the first substrate assembly is provided with a probe welding pad; the second substrate assembly is electrically connected with a device at the test end, and the second substrate assembly is provided with a probe base; the probe welding pad is provided with a plurality of contacts, and the product base is provided with a plurality of corresponding probes; and the direction adjustment assembly adjusts the probes on the probe base to be aligned with the contacts on the probe welding pad in the process that the probes are contacted with the contacts. Alignment of the probes on the probe base and the contacts on the probe welding pad is adjusted by the direction adjustment assembly in the testing process through connection between the direction adjustment assembly and the second substrate assembly, so that automatic alignment adjustment is realized, alignment adjustment is not required to be performed manually, and the test efficiency and effect are improved.

Owner:QISDA SUZHOU

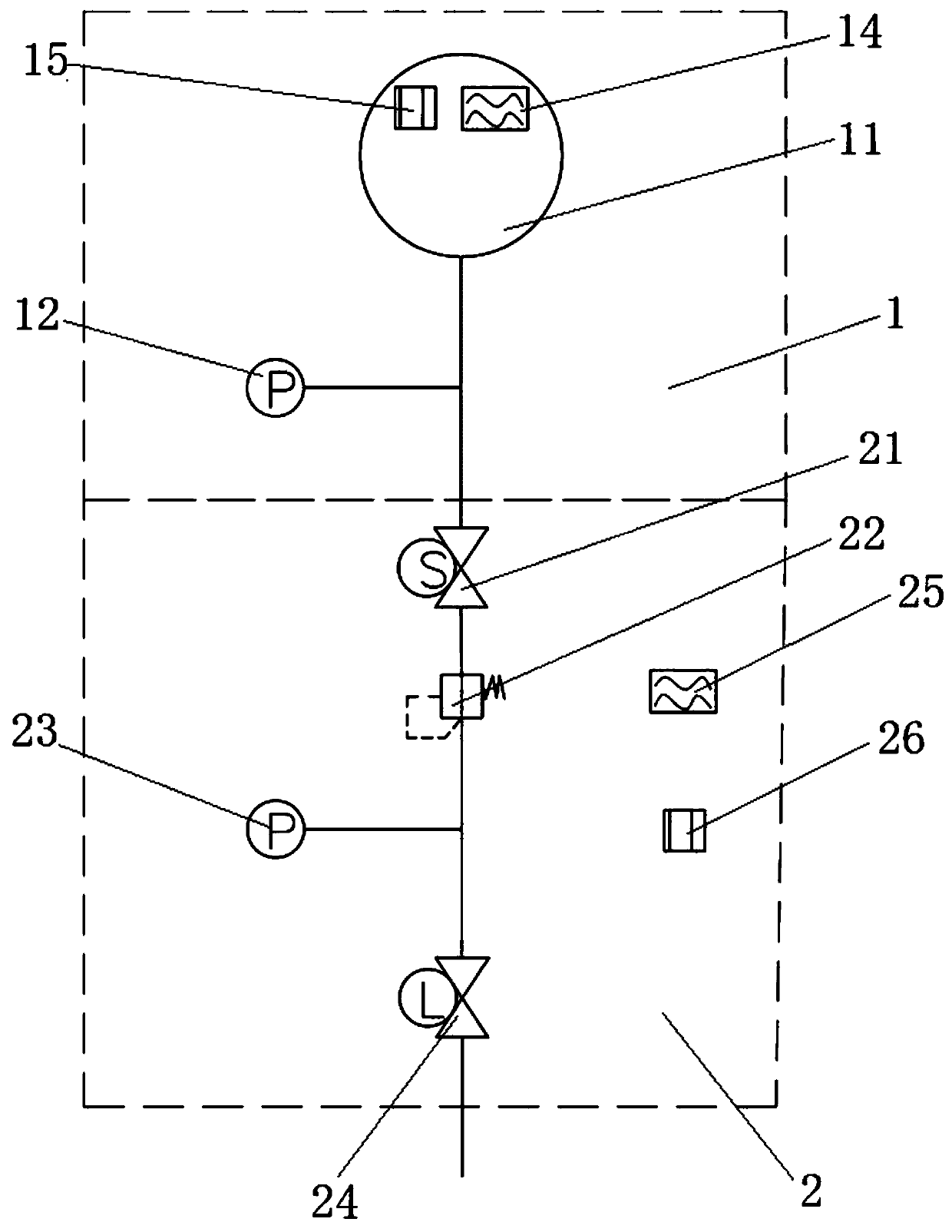

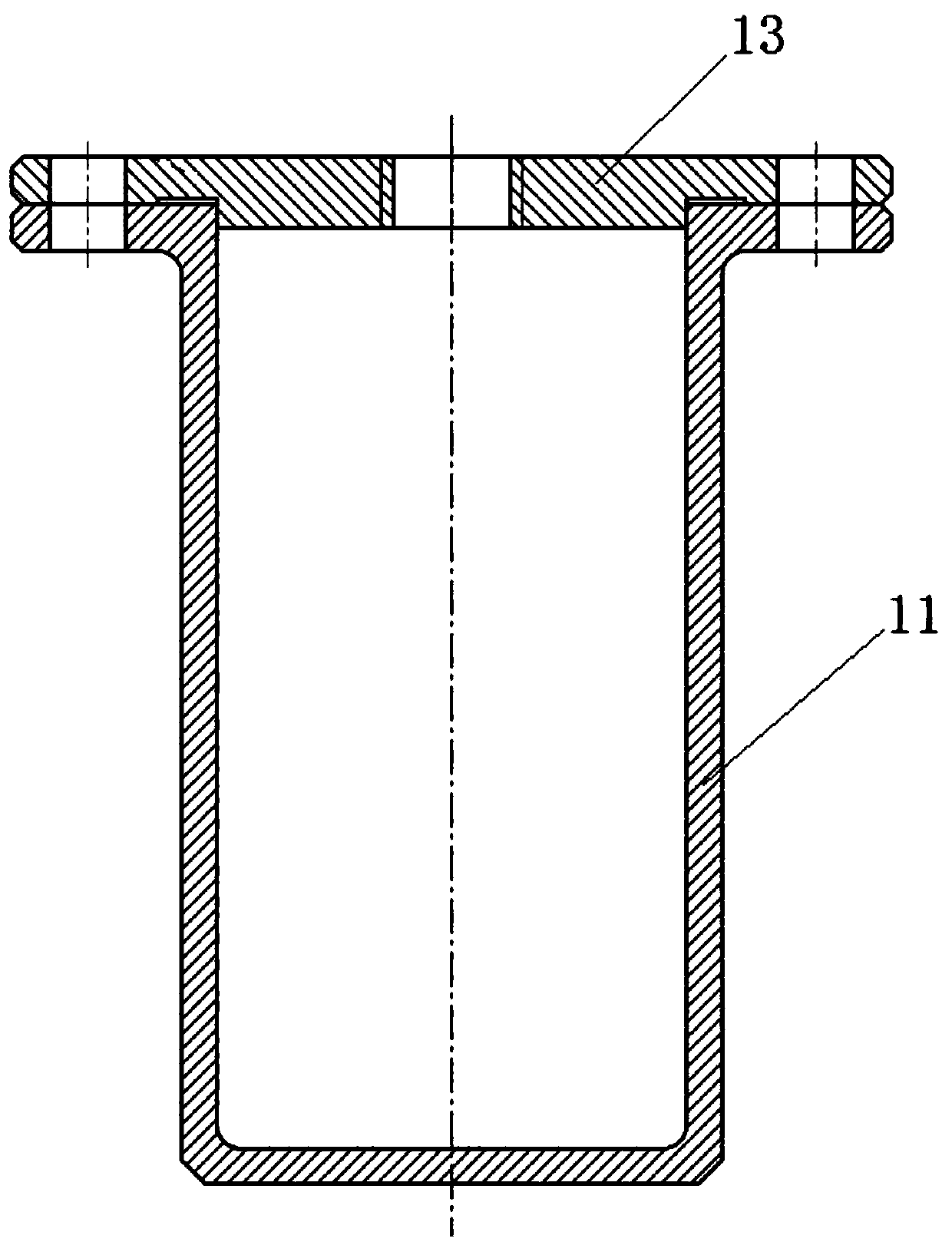

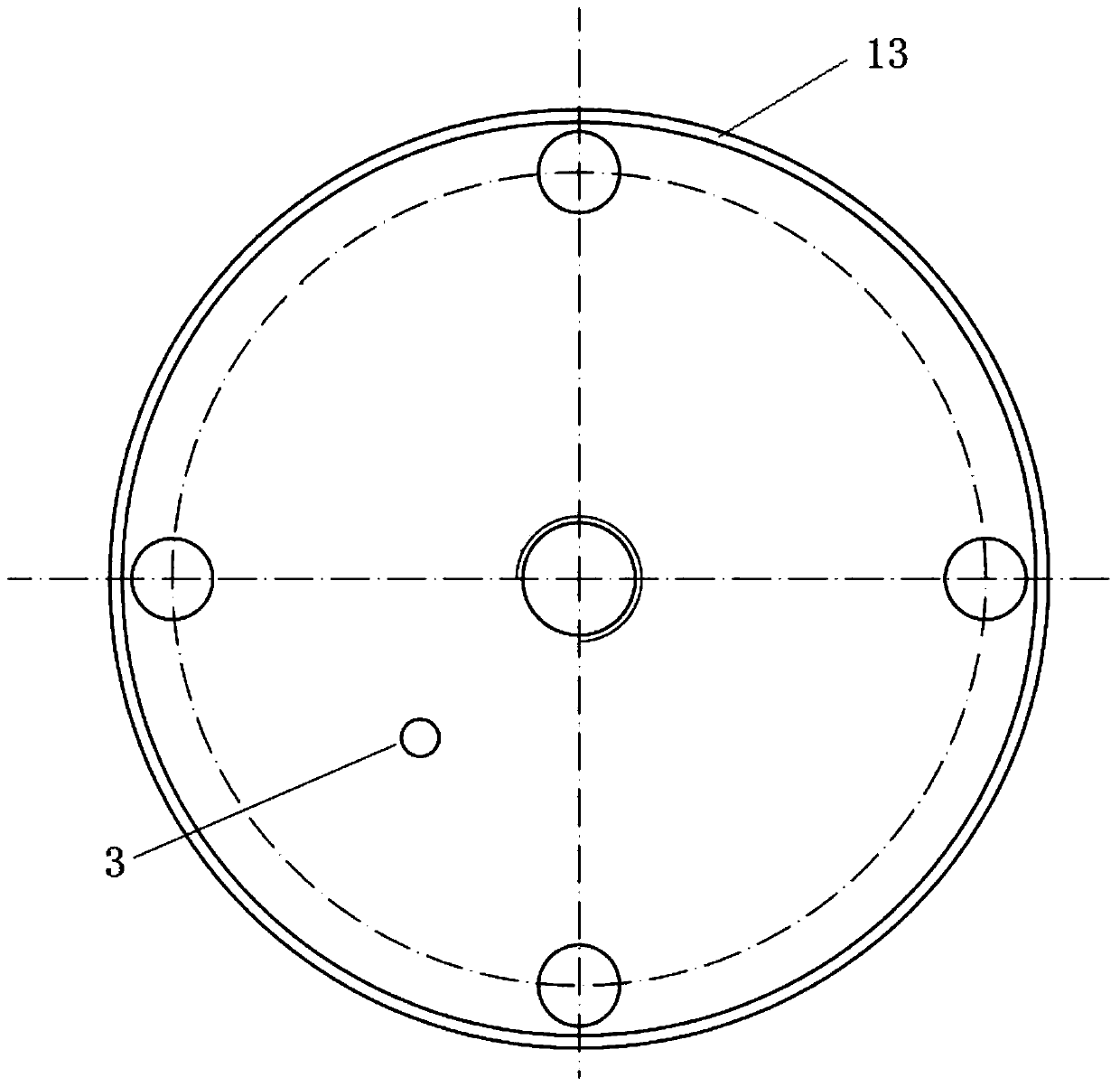

Iodine medium ground gas supply device for Hall thruster and using method

ActiveCN111140450ALower ionization energyLow priceMeasurement devicesMachines/enginesControl cellEngineering

The invention relates to the technical field of aerospace Hall electric propulsion, in particular to an iodine medium ground gas supply device for a Hall thruster and a using method. The iodine mediumground gas supply device includes an iodine vapor generating unit and an iodine vapor flow control unit, wherein the iodine vapor generating unit includes a solid iodine storage tank and a first pressure sensor. The iodine vapor flow control unit includes a shut-off valve, a pressure relief valve, a second pressure sensor and a flow control valve. The iodine medium ground gas supply device for the Hall thruster adopts an iodine medium propellant to achieve good thrust parameter performance, and the thruster is more efficient. An iodine medium is heated and sublimated into iodine vapor for transportation, the condensation of the iodine vapor in the transportation process is prevented, the flow rate of the iodine vapor can be controlled in real time, and it is ensured that the iodine vaporcan be stably and accurately transported to the Hall thruster.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Intermittent material guiding and processing mechanism

PendingCN107745992AReasonable structural designImprove processing efficiencyWebs handlingGear wheelElectric machinery

The invention discloses an intermittent material guiding and processing mechanism and belongs to the field of processing and transferring mechanical devices. The intermittent material guiding and processing mechanism comprises a fixing support, a material guiding gear, a reciprocating gear, a rotary cam, a material guiding motor, an upper driven swing rod and a lower driven swing rod; one side ofthe material guiding gear is horizontally and coaxially provided with a material guiding roll, and one end of the upper driven swing rod is provided with an arc-shaped gear plate; a limiting clampingplate is arranged on the lower side of the middle of the lower driven swing rod in a downward inclining mode, and a tension spring is arranged between the upper driven swing rod and the lower driven swing rod; the reciprocating gear is vertically arranged between the material guiding gear and the arc-shaped gear plate, and a material guiding swing rod is arranged between a reciprocating swing shaft and a material guiding rotary shaft; and a reciprocating connecting rod is arranged between the reciprocating gear and the rotary cam. According to the intermittent material guiding and processing mechanism, the structural design is reasonable, the material guiding roll can be driven to intermittently rotate according to the needs of processing so that belts can be driven by the material guidingroll to be intermittently and stably transferred, the belt processing efficiency and quality are improved, and the demands of production and use are met.

Owner:TONGXIANG YUESHUN WRAP KNITTING

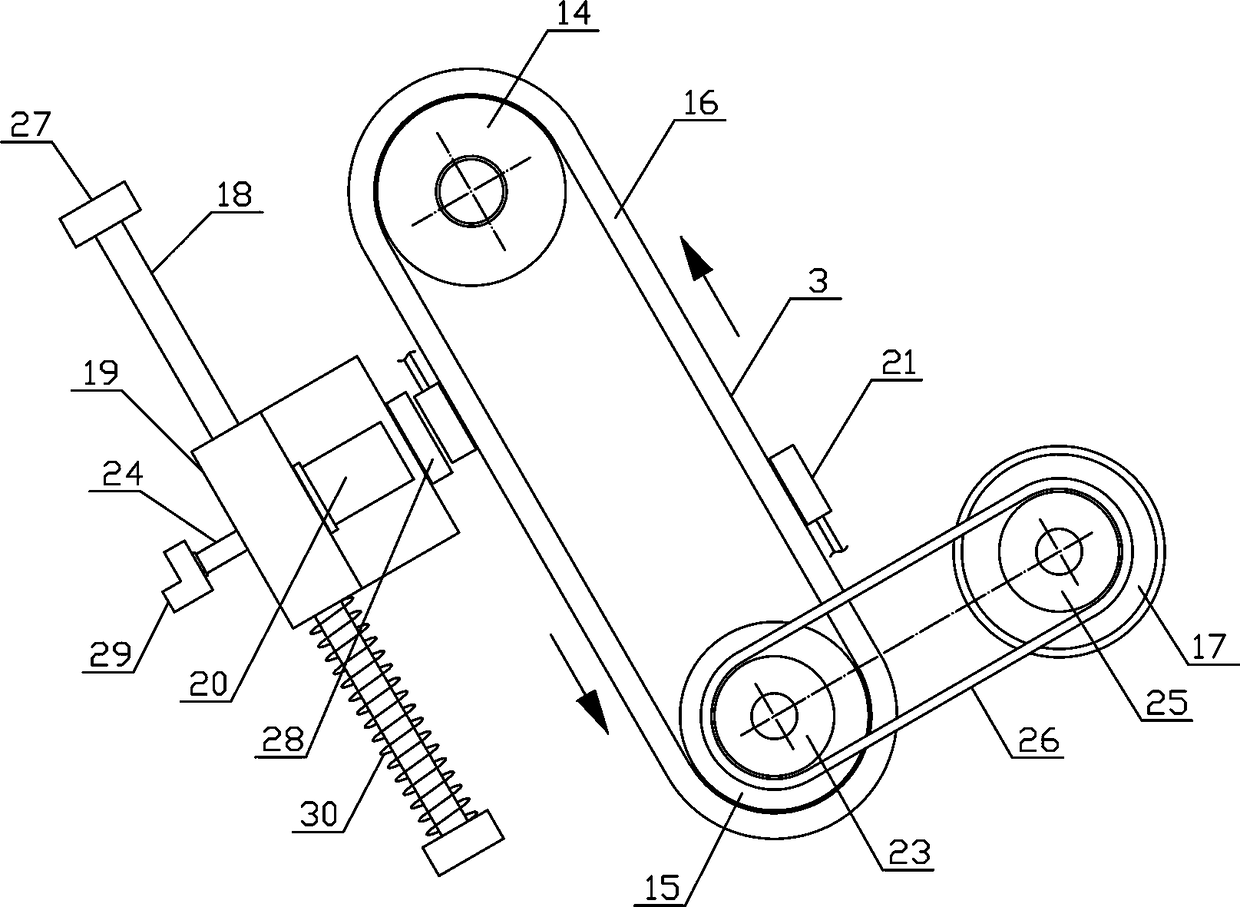

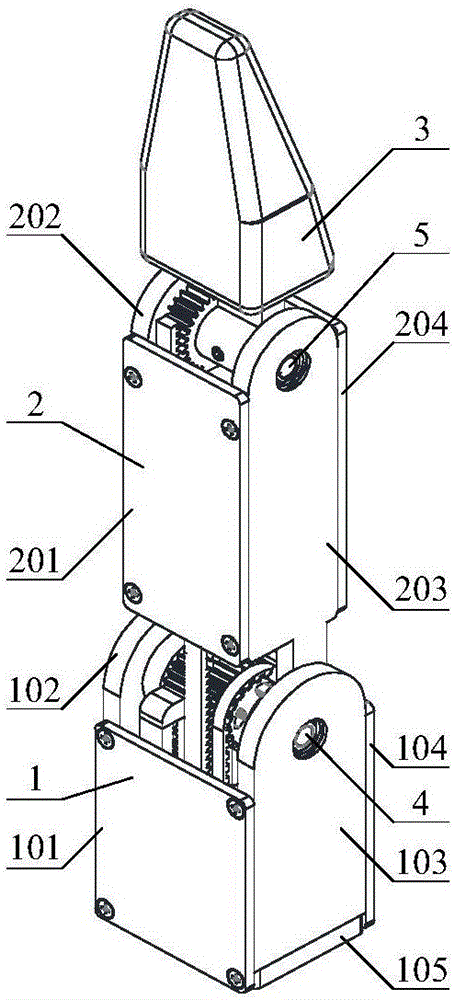

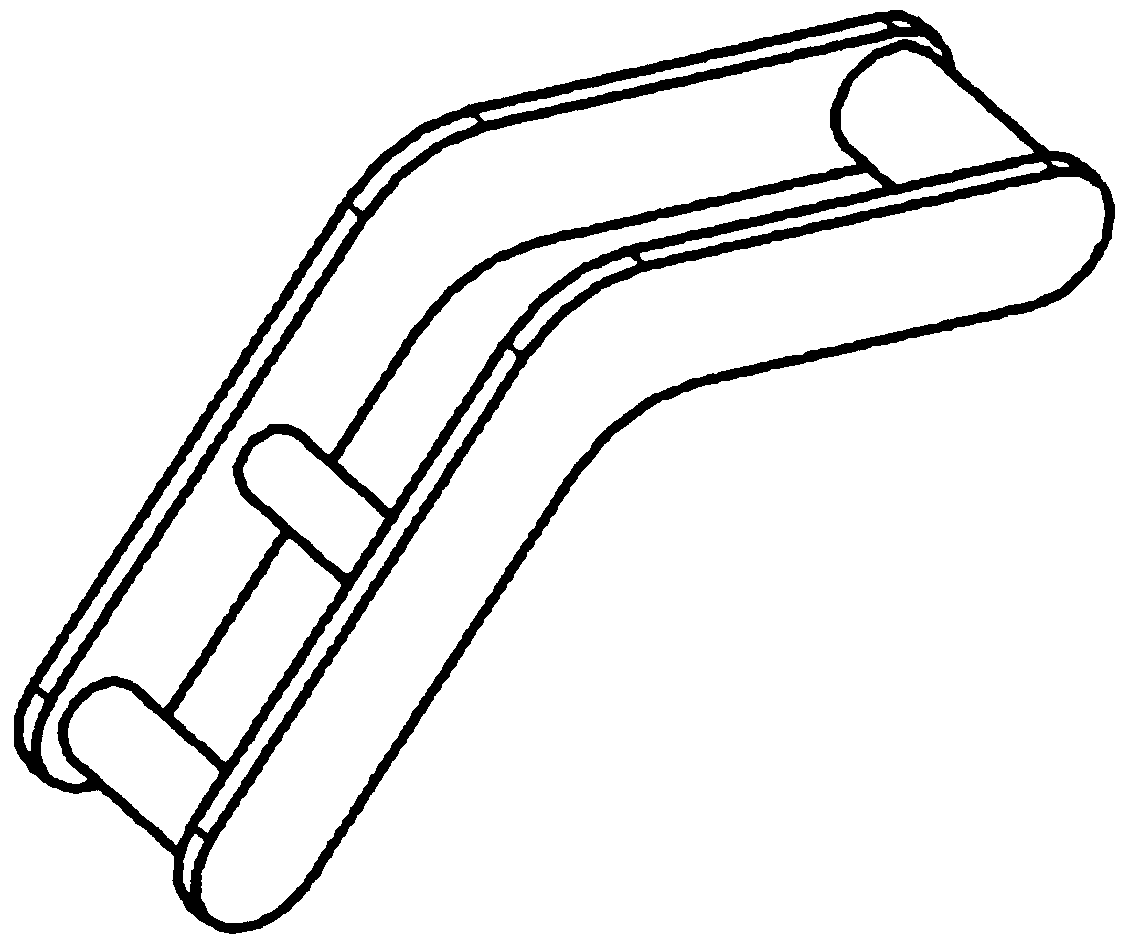

Translational motion idle-stroke transmission coupled and self-adaptive robot finger device

PendingCN106671113AAchieve adaptive crawling effectReduce in quantityGripping headsReal-time Control SystemTime control

The invention discloses a translational motion idle-stroke transmission coupled and self-adaptive robot finger device and belongs to the technical field of robot fingers. The translational motion idle-stroke transmission coupled and self-adaptive robot finger device comprises a base, two finger sections, two joint shafts, a driver, a transmission mechanism, three gears, three racks, two spring pieces, two shifting levers and two convex blocks. The translational motion idle-stroke transmission coupled and self-adaptive robot finger device achieves the coupled and self-adaptive combined grabbing mode integrally, the two joints can be linked to pinch an object with the tail ends, the actions highly simulate human beings, and besides, the first finger section can be rotated to touch the object firstly, and then the second finger section is rotated to cover and hold the object, so that the effect of self-adaptive grabbing of objects with different shapes and dimensions is achieved. According to the device, transmission is precise and stable, and grabbing is stable and reliable; the two joints are driven through only one driver instead of complex sensing systems and real-time control systems; and meanwhile, the translational motion idle-stroke transmission coupled and self-adaptive robot finger device is simple in structure, short in transmission chain, small in number of parts, small in size, low in weight, easy to assemble and low in manufacturing cost.

Owner:TSINGHUA UNIV

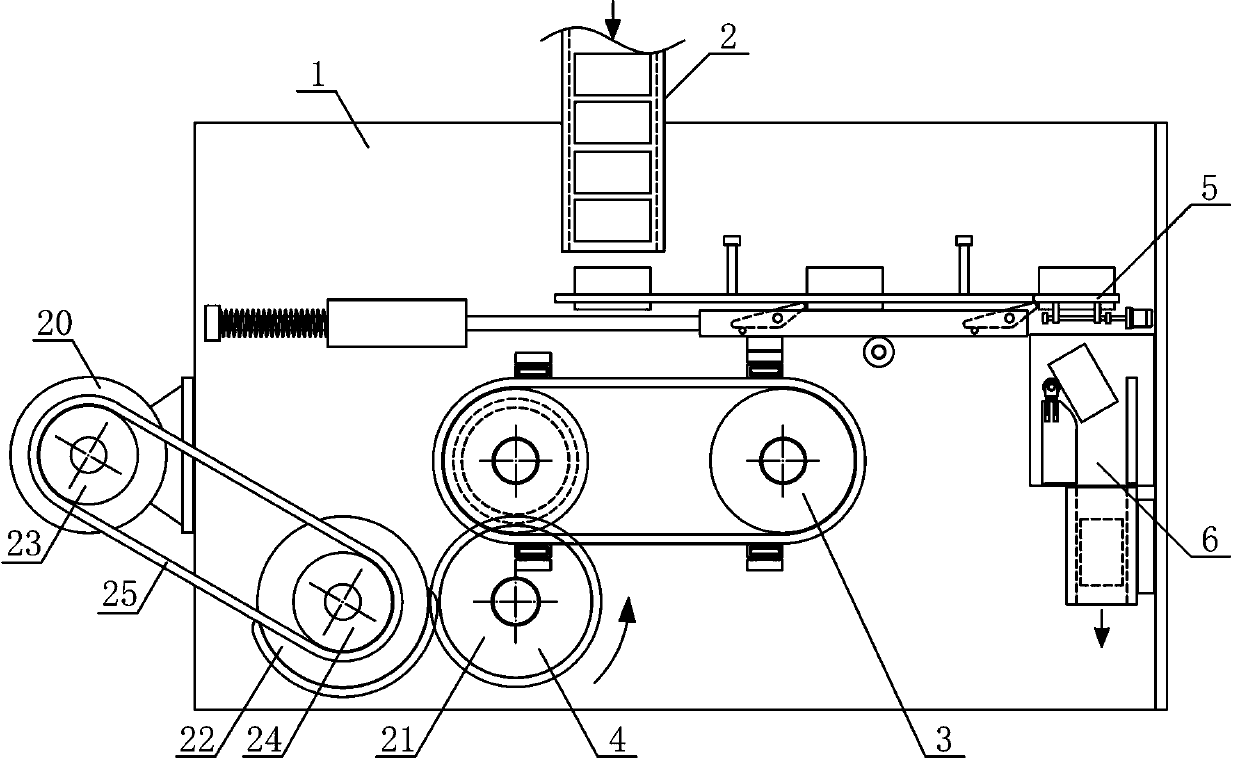

Grey cloth drafting cutting mechanism

InactiveCN108978166AEfficient and full cuttingHigh degree of automationSevering textilesFabric finishing guides/expandersMechanical equipmentCutting guide

The invention discloses a grey cloth drafting cutting mechanism and belongs to the field of textile processing mechanical equipment. A drafting mechanism is horizontally arranged on the portion, of aconveying support, between a cloth inlet rotation roller and a cloth outlet rotation roller, a cutting mechanism is horizontally arranged on the portion, of the conveying support, at the lower side ofthe cloth outlet rotation roller, and a conveying mechanism is obliquely and downwards arranged at the lower side of the cutting mechanism; main drafting connection plates are horizontally and slidingly arranged on the portions, in a main connection plate support, at the two sides of the conveying support; auxiliary drafting connection plates are horizontally and slidingly arranged in auxiliary connection plate supports, a cutter support and a cutter groove support are horizontally and slidingly arranged on a cloth cutting guide rod in sequence, and a cloth guide conveying belt winds cloth guide rotation rollers at the two ends of a cloth guide support. The grey cloth drafting cutting mechanism is reasonable in structural design, grey cloth can be continuously and stably subjected to width enlargement and drafting in the conveying process, the grey cloth after drafting can be accurately, efficiently and horizontally cut into cloth pieces for conveying, the automation degree of processing the grey cloth is increased, and the demands of production use are met.

Owner:戴杰

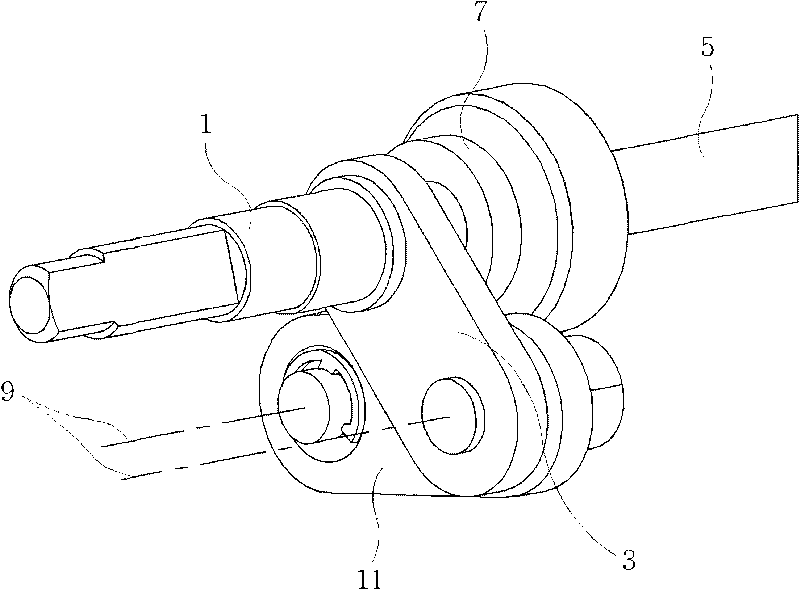

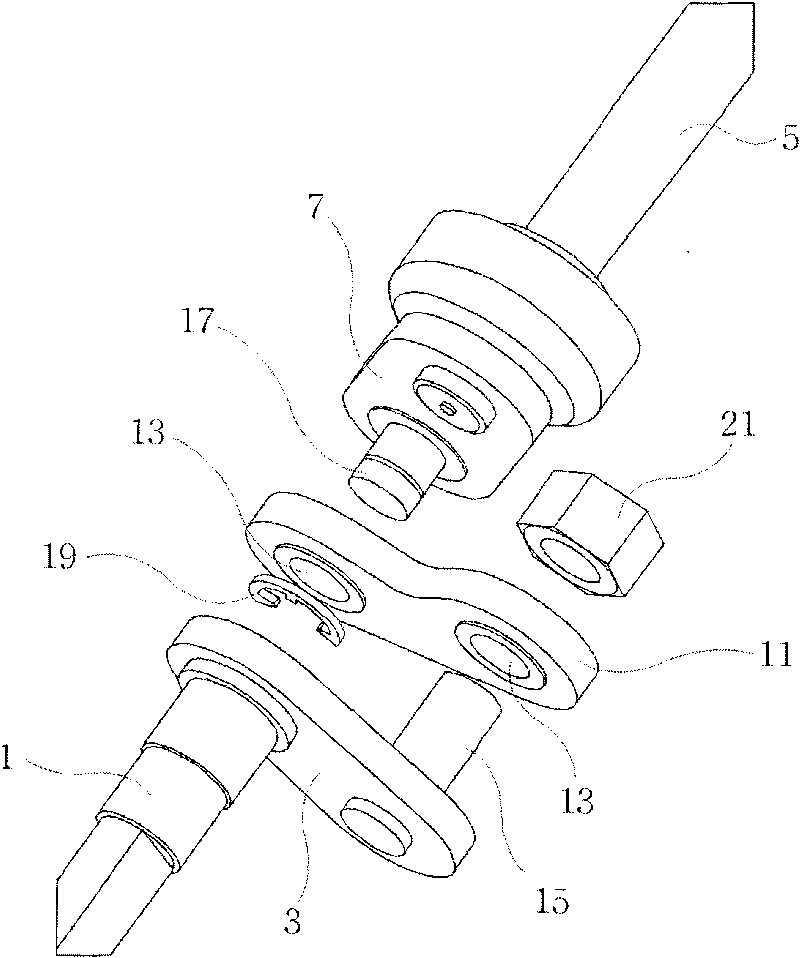

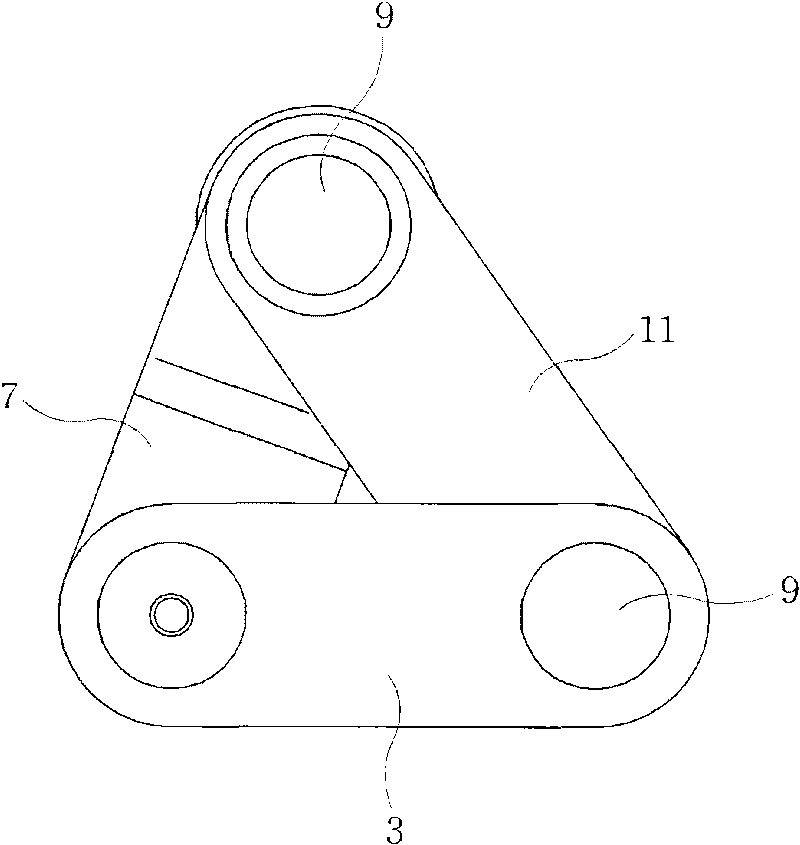

Coupling apparatus between drive shaft and driven shaft

A coupling for a driving shaft and a driven shaft may include a driving lever that extends in a radial direction from the driving shaft and being limited in rotation with respect to the driving shaft, a driven lever that extends in a radial direction from the driven shaft and being limited in rotation with respect to the driven shaft, and a connecting member that has two different rotational shafts spaced with a predetermined distance and pivotally coupled to one end portion of the driving lever and one end portion of the driven shaft respectively.

Owner:KIA MOTORS CORP +1

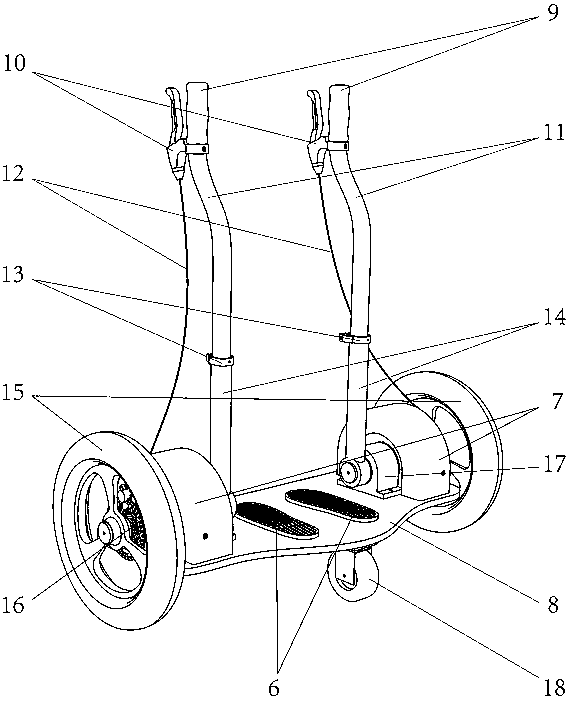

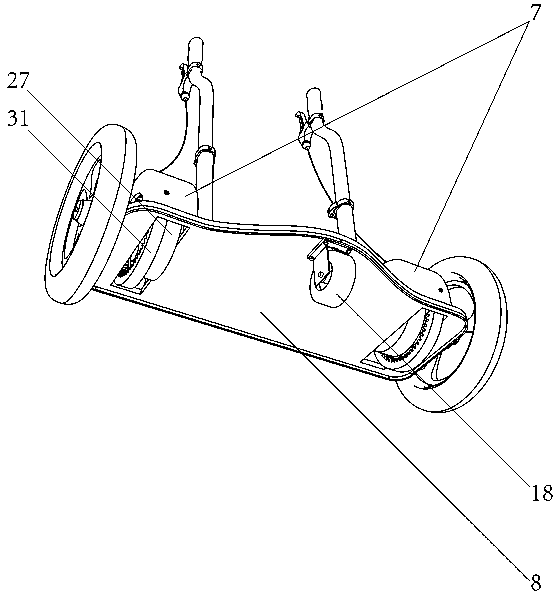

Hand drive and hand control differential gear transmission type walk alternative

ActiveCN108791633AEasy and comfortable operationDrive steering compactWheel based transmissionCycle brakesDisc brakeGear transmission

The invention discloses a hand drive and hand control differential gear transmission type walk alternative. The hand drive and hand control differential gear transmission type walk alternative comprises a trolley frame main body, a driving and steering mechanism, a speed changing mechanism and a braking mechanism. The trolley frame main body comprises a pedal and a semi-open trolley frame cover. The driving and steering mechanism comprises manipulation rockers, hollow casing pipes, ratchet mechanisms, side wheels and a rear omnidirectional wheel. The speed changing mechanism is arranged to bea planetary gear mechanism and achieves acceleration. A user holds handles at the upper ends of the manipulation rockers and pushes and pulls forwards and backwards to achieve power for moving forward. When the left hand pushes independently, turning right is achieved, and when the right hand pushes independently, turning left is achieved. The braking mechanism comprises a brake handle, a brake line and a disc brake. According to the walk alternative, the principle and structure break through the transmission method and steering operation mode of a traditional walk alternative, the user can operate in a stand mode, hand forward and backward pushing and pulling replace traditional walk alternative moving forward driven by foot treading, and therefore new human-computer interaction mode is achieved, and new potential of a brain is developed and physical coordination is developed.

Owner:SHANGHAI UNIV

Woolen strip tensioning and winding mechanism

InactiveCN108792786AWind evenlyThe winding mechanism conveys the wool sliver at a uniform speed and stablyFilament handlingEngineeringMechanical engineering

The invention discloses a woolen strip tensioning and winding mechanism, and belongs to the field of textile processing machinery equipment. The woolen strip tensioning and winding mechanism is characterized in that a strip pressing rotating roller is horizontally arranged on the upper side of a strip bearing rotating roller, one end of a tensioning rotating rod is vertically and rotationally connected with a strip guide rotating wheel, a translation support is arranged on a reciprocating guide rod in a sliding mode in the horizontal direction, a strip guide sleeve is obliquely arranged in thetranslation support, the two sides of strip swing guide groove are symmetrically provided with strip swing chains correspondingly, the outer sides of the two strip swing chains on the two sides of the strip swing guide groove are fixedly provided with strip swing electromagnets correspondingly, a winding rotating roller is horizontally and rotationally connected to the upper side of a rotating roller support, a bearing roller guide rod is obliquely and slidably arranged on a lifting sleeve, and a bearing roller limiting clamp is fixedly arranged at the upper end of the bearing roller guide rod. According to the woolen strip tensioning and winding mechanism, the structural design is reasonable, woolen strips can be efficiently, conveniently, fast, continuously and stably conveyed and wound, moreover, automatic tensioning can be achieved in the winding process of the woolen strips so that the automation degree and the winding quality of winding processing of the woolen strips can be improved, and the requirements of production and use can be met.

Owner:盛奇石

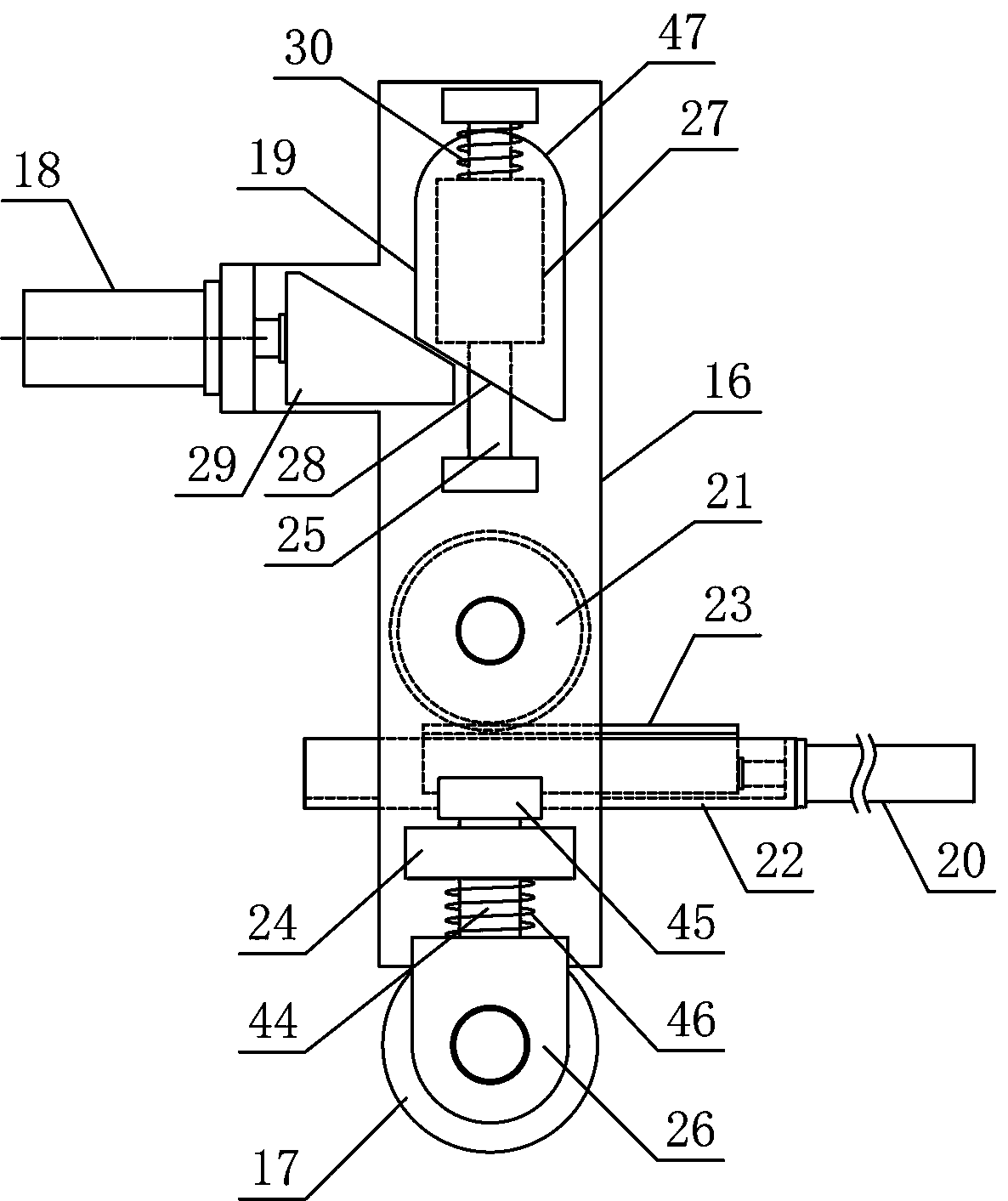

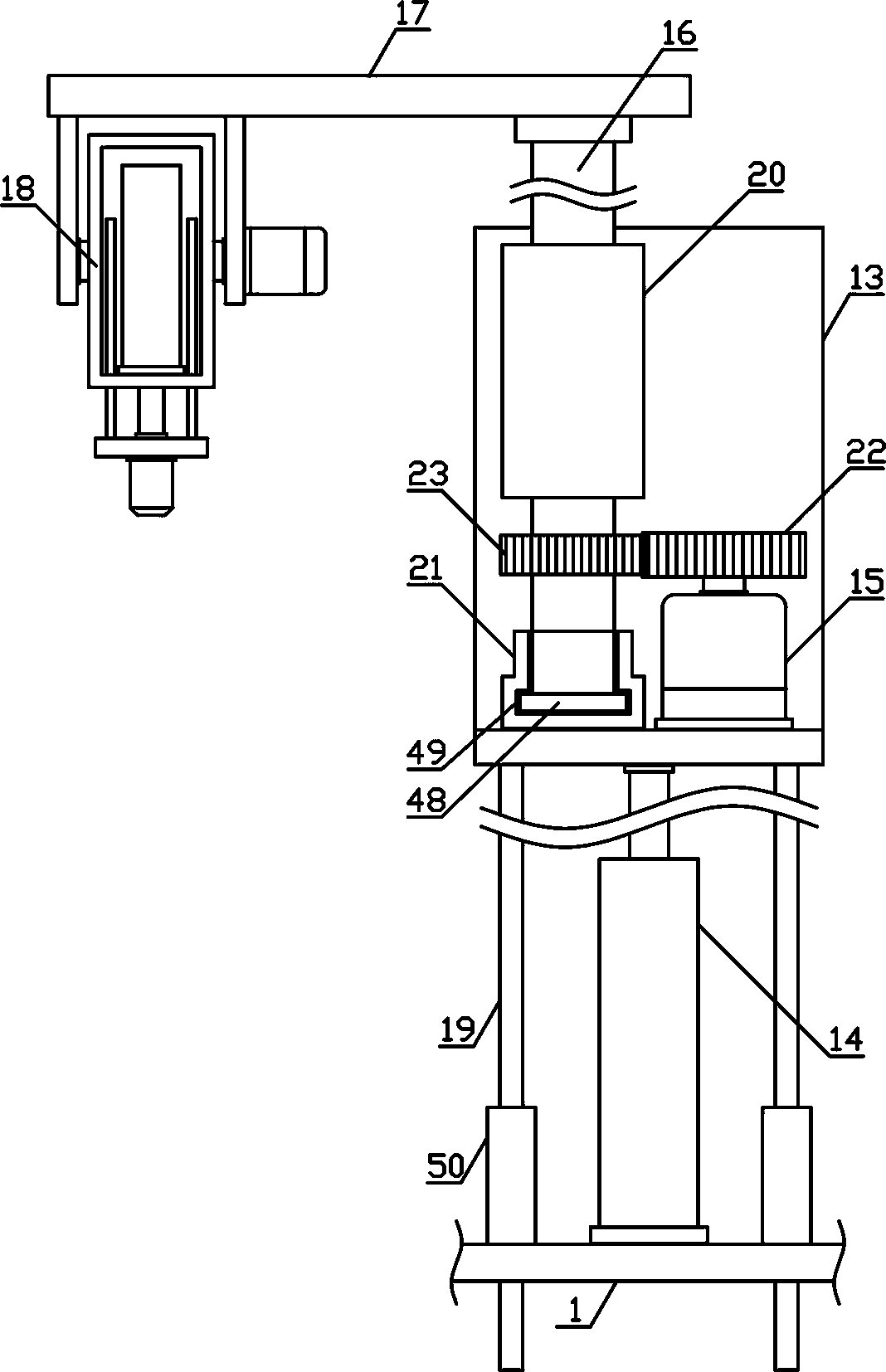

Moving contact terminal pressure detection mechanism

InactiveCN105784248AReduce the impactSmooth and precise transmissionMeasurement of force applied to control membersDisplay deviceEngineering

The invention relates to a moving contact terminal pressure detection mechanism comprising a positioning clamp which is used for placing a moving contact to be detected and flexibly connected on a base, a lead screw which is connected with a servo motor, wherein a pressing head moving upwardly and downwardly along the lead screw is arranged on the lead screw, and a displayer which is provided with a data processing module and receives pressure detected by the pressing head and displays pressure. Compared with mechanisms in the prior art, the moving contact terminal pressure detection mechanism has characteristics of being simple in structure, intelligent, high in compatibility, low in energy consumption, low in cost, high in effect, long in replacement cycle and convenient to maintain and provides a better detection prevention platform for guaranteeing the great quality of a circuit breaker.

Owner:DELIXI ELECTRIC

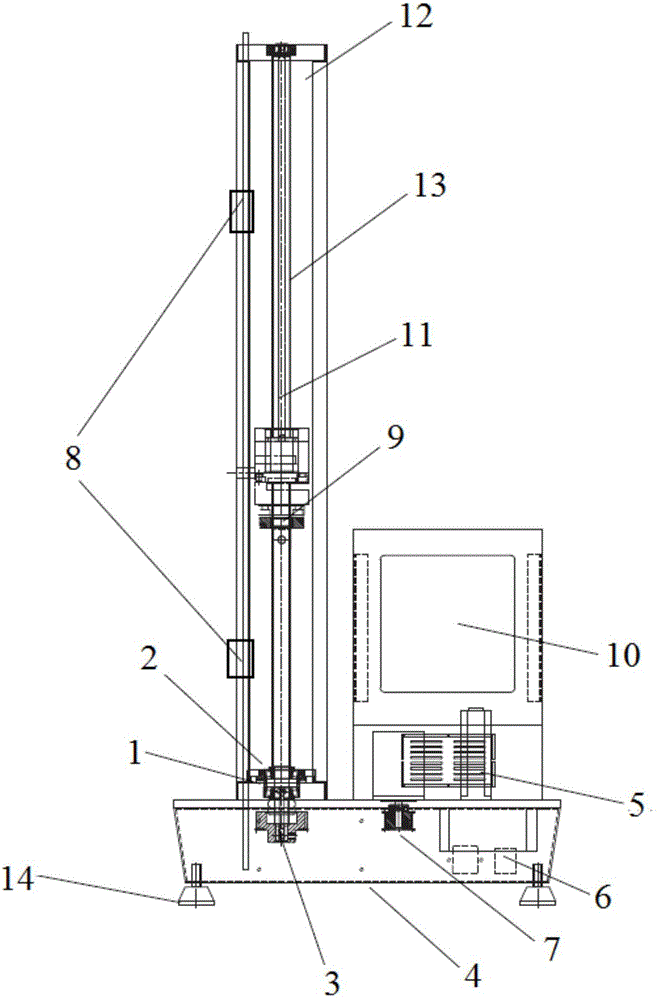

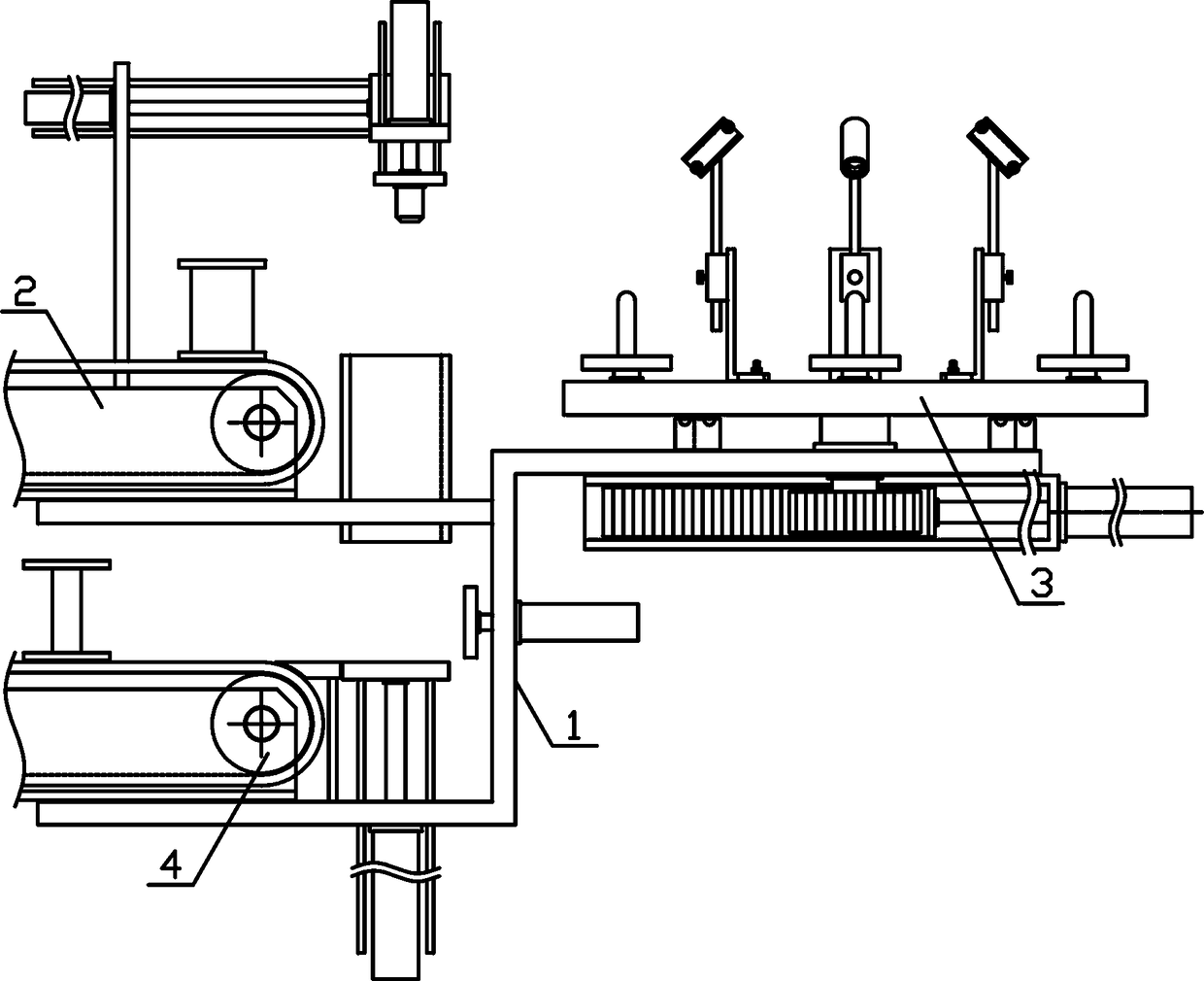

Photovoltaic cell surface passivation film production equipment

PendingCN114300399AIncrease feeding rateImprove mechanical propertiesFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSolar cell

The invention discloses photovoltaic cell surface passivation film production equipment, and relates to the technical field of solar cell production equipment. The equipment comprises a machine body, a workbench and a coating unit, a horizontal conveying part, a vertical lifting part and a transferring part are arranged on one side of the machine body from the outer side to the position of the workbench, and a battery panel can be conveyed to the position adjacent to the vertical lifting part through a horizontal conveying belt and enters an obliquely-arranged bearing plate; according to the solar cell panel feeding and transferring device, automatic feeding and transferring of the solar cell panel can be achieved, the solar cell panel is moved to the bottom of the working table through the horizontal conveying piece, and the solar cell panel is transferred to the top of the vertical lifting piece through the vertical conveying belt and then is transferred through the suction plate on the transferring piece, and the suction plate is rotated to the working table after being lifted. The solar panels are transferred to the suction plate at the bottom of the workbench through the vertical lifting piece, and finally the suction plate rotates to the position of the workbench for film coating, so that automatic feeding of the solar panels can be completed, the production efficiency is greatly improved, and the automatic production process of photovoltaic cells is improved.

Owner:江苏龙恒新能源有限公司

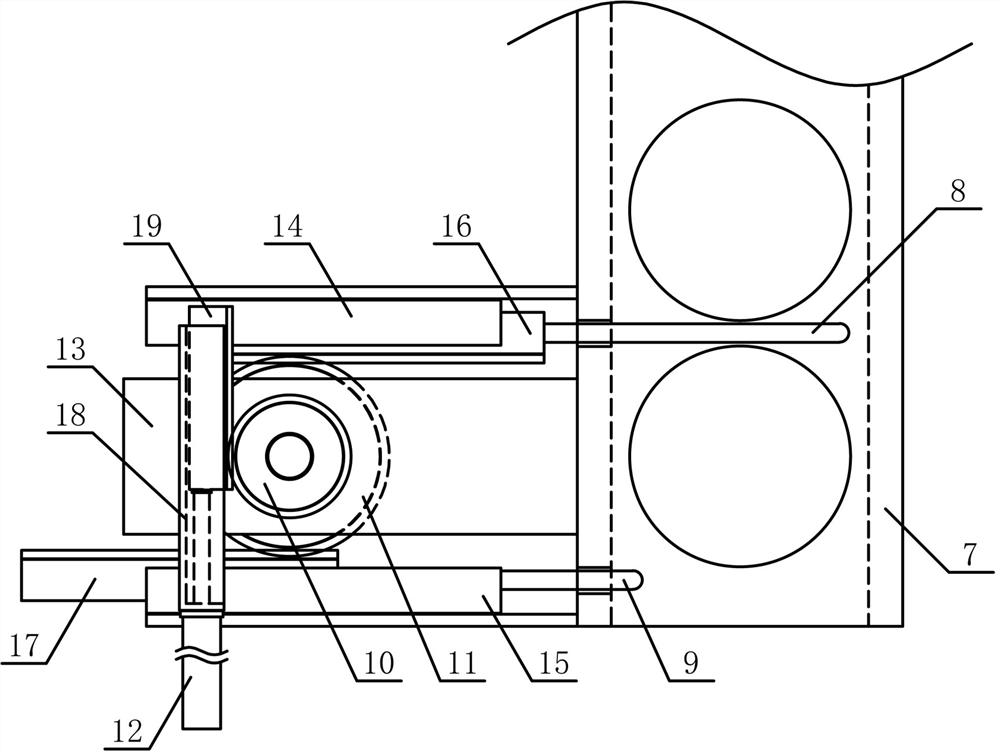

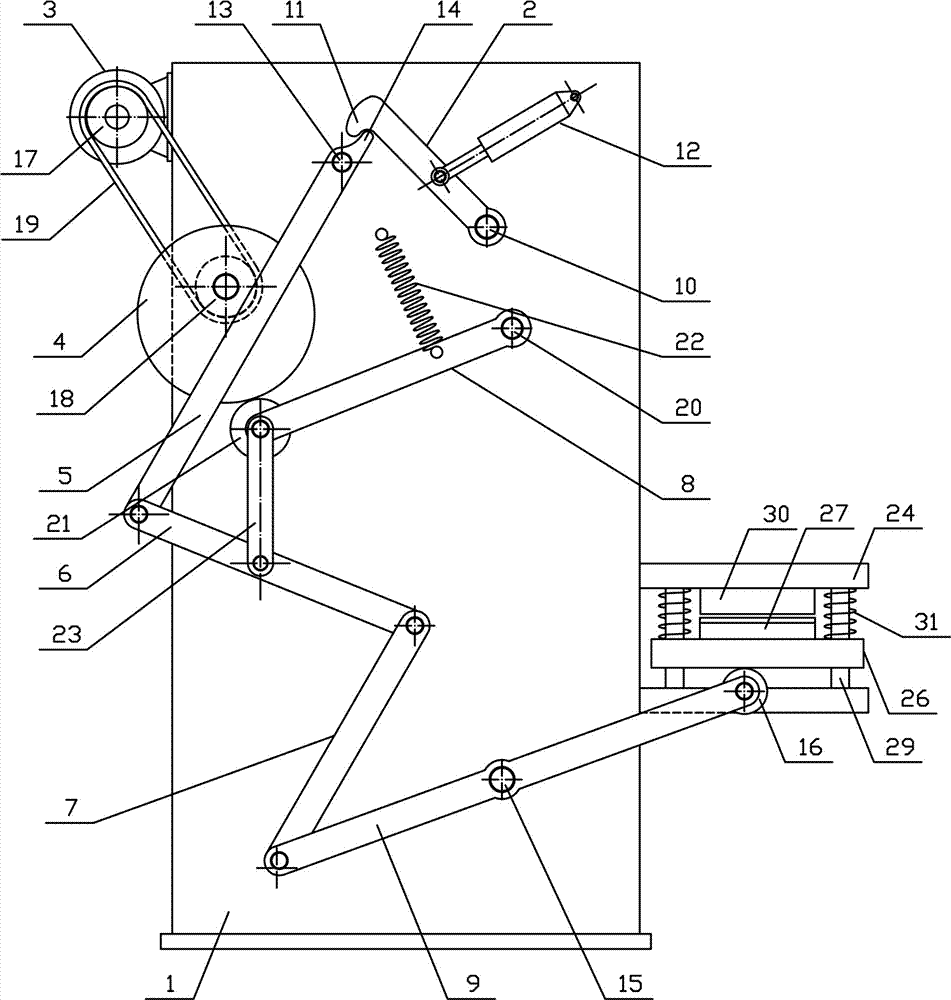

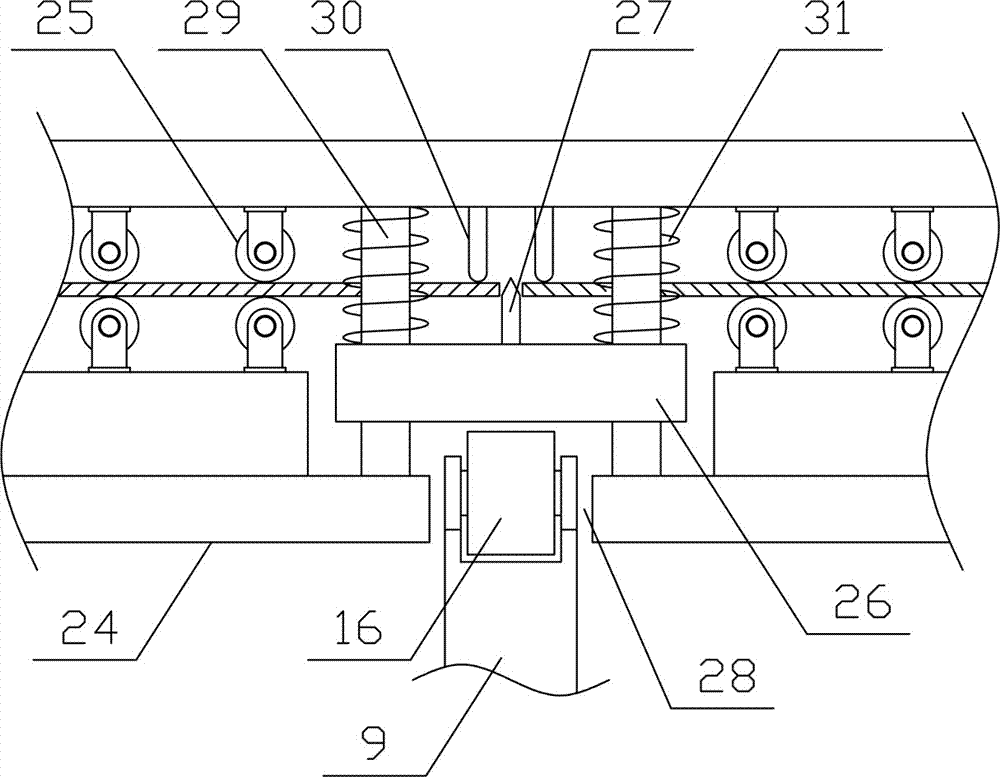

Strip material cut-off mechanism

ActiveCN107366153ASmooth and precise transmissionReasonable structural designSevering textilesEngineeringKnife blades

The invention discloses a strip material cut-off mechanism and belongs to the field of textile materials processing mechanical equipment. The strip material cut-off mechanism comprises a fixing bracket, a limiting clamp plate, a strip cutting motor, a strip cutting eccentric wheel, a first rotary plate, a second rotary plate, a third rotary plate, a reciprocating plate, a strip cutting pressing plate and a strip guide mechanism. The strip guide mechanism is horizontally arranged on one side of the fixing bracket, a clamp plate air cylinder is arranged between the limiting clamp plate and the fixing bracket, the strip cutting eccentric wheel is vertically and rotationally connected with one side on the upper portion of the fixing bracket, a tension spring is arranged between the upper side of the reciprocating plate and the fixing bracket, a strip cutting connecting rod is arranged between the lower end of the reciprocating plate and the second rotary plate, and the strip guide mechanism comprises a strip guide support, strip guide rollers, a lifting press plate and a strip cutting knife blade. The strip material cut-off mechanism is reasonable in structural design, transverse cutting can be quickly, efficiently, uniformly and continuously conducted in the conveying process of strip materials, the cut-off movement can be quickly and conveniently stopped in the use process, and the production use requirements are met.

Owner:盐城市星地通信设备有限公司

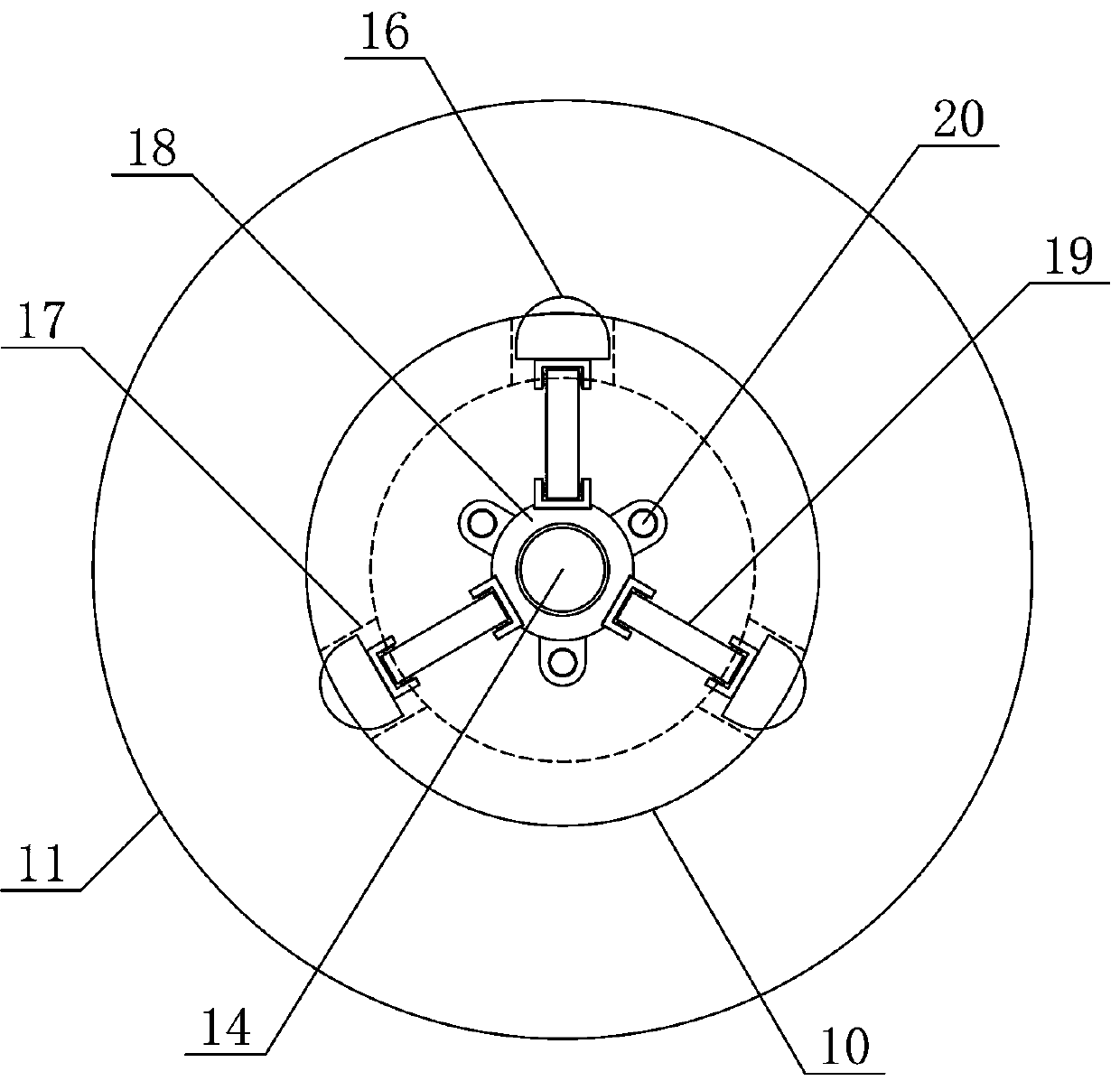

Automatic replacement mechanism for chemical fiber cone yarns

The invention discloses an automatic replacement mechanism for chemical fiber cone yarns, and belongs to the field of chemical fiber conveying processing mechanical equipment. A cone yarn feeding mechanism and a cone yarn retreating mechanism of the automatic replacement mechanism are arranged on a fixed bracket from top to bottom in sequence, a yarn unwinding mechanism is horizontally arranged atthe position, on one side of the cone yarn feeding mechanism, of the fixed bracket, a cone yarn feeding material belt is horizontally arranged on the upper side of a cone yarn feeding bracket, the output end of a cone yarn feeding air cylinder is fixedly provided with a cone yarn feeding connecting plate, and a cone yarn clamping gas expansion shaft is vertically and fixedly arranged at the portion, on the middle portion of the lower side of a cone yarn clamping connecting plate, of a cone yarn clamping air cylinder; and the middle portion of the lower side of a yarn guiding rotary disc is fixedly connected with the upper end of a reciprocating rotating shaft, a plurality of yarn guiding mechanisms on the upper side of the yarn guiding rotary disc and cone yarn containing circular platesare arranged correspondingly, the output end of a cone yarn bearing air cylinder is horizontally and fixedly provided with a cone yarn bearing connecting plate, and a cone yarn retreating material belt is horizontally arranged on the upper side of a cone yarn retreating bracket. The automatic replacement mechanism is reasonable in structure design, a plurality of chemical fiber cone yarns can be continuously and conveniently transferred and replaced one by one in a convenient and efficient manner, so that multi-strand chemical fiber silks can be stably, accurately and synchronously transmitted, and the needs of production and use are met.

Owner:桐乡市宏力纺织股份有限公司

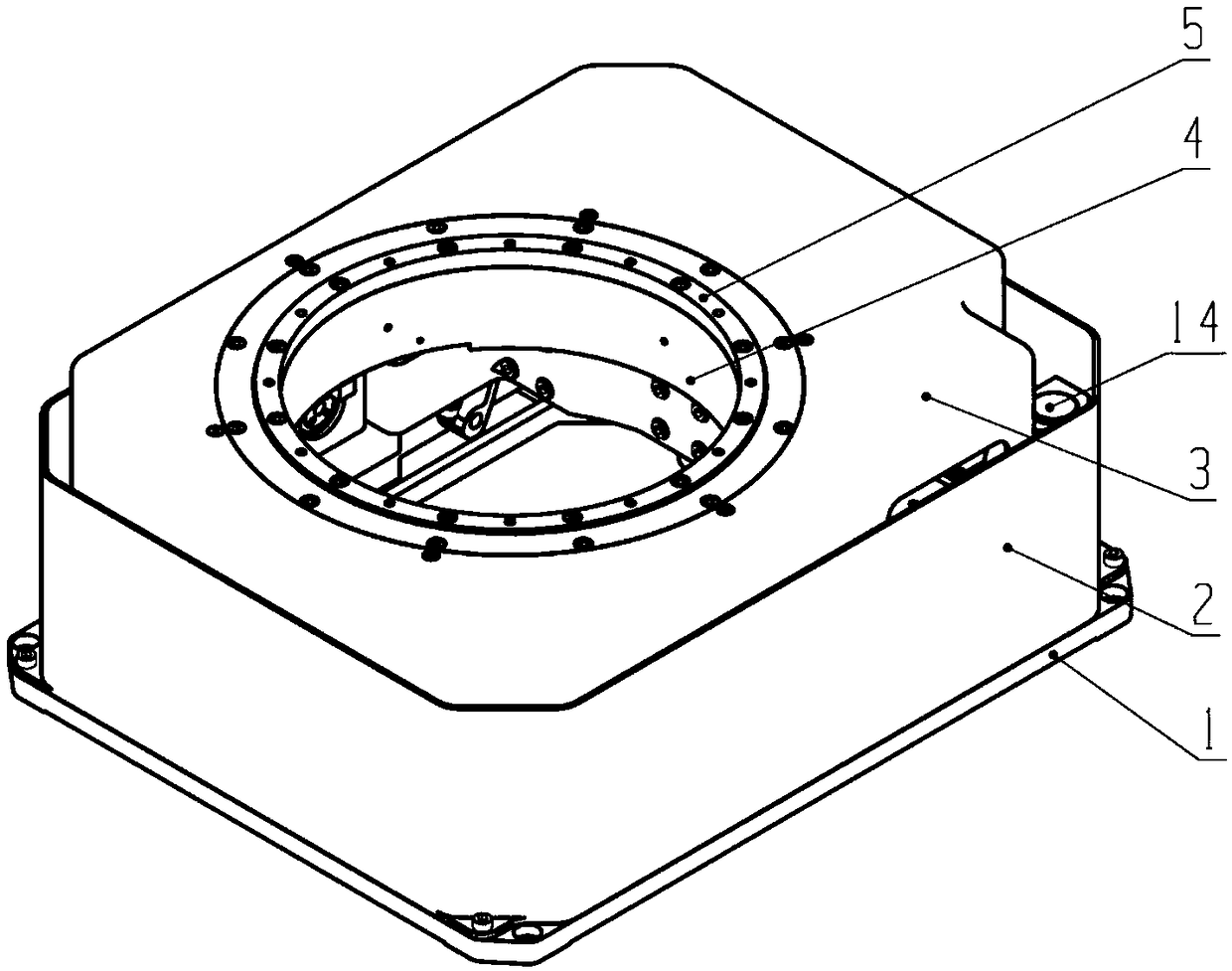

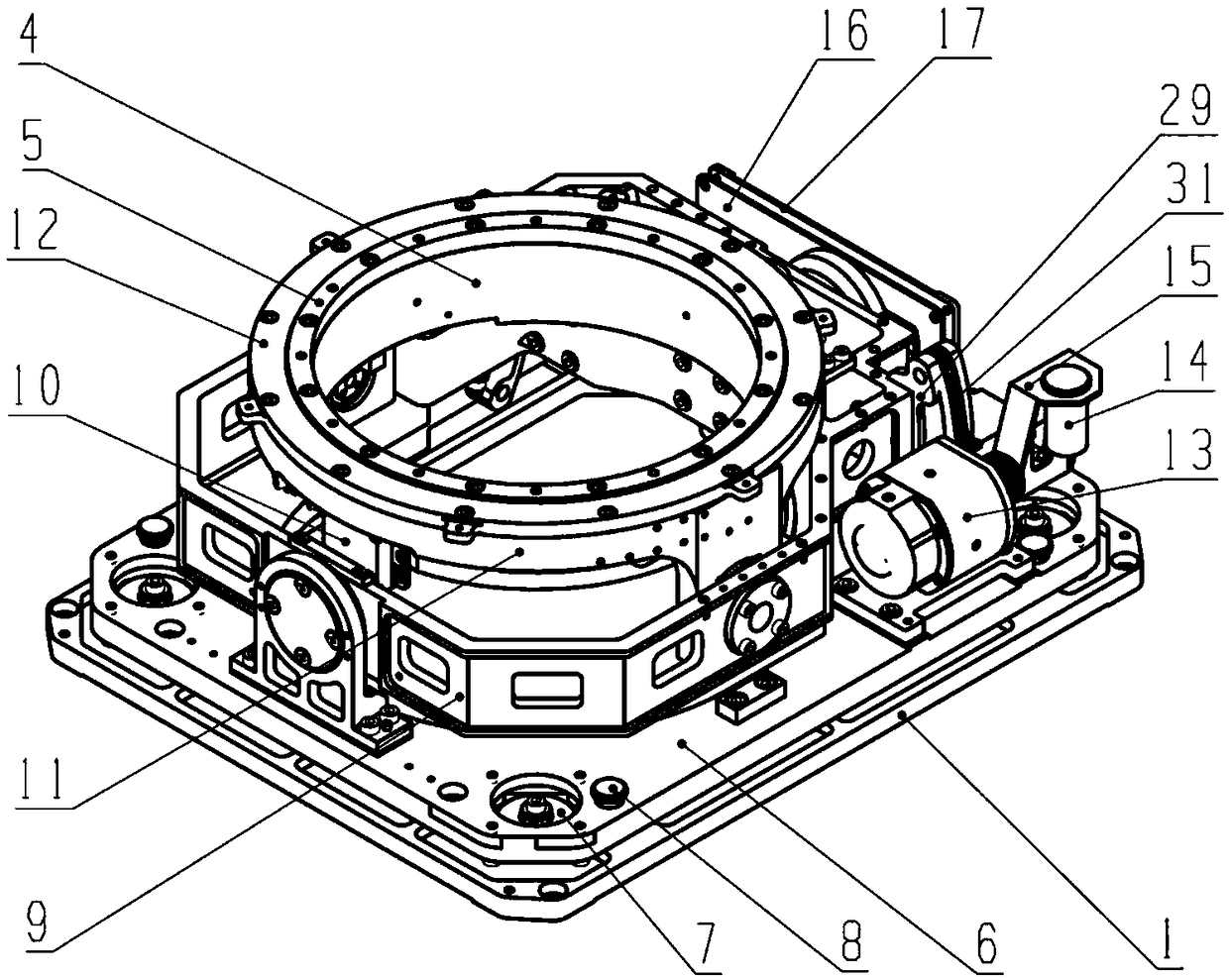

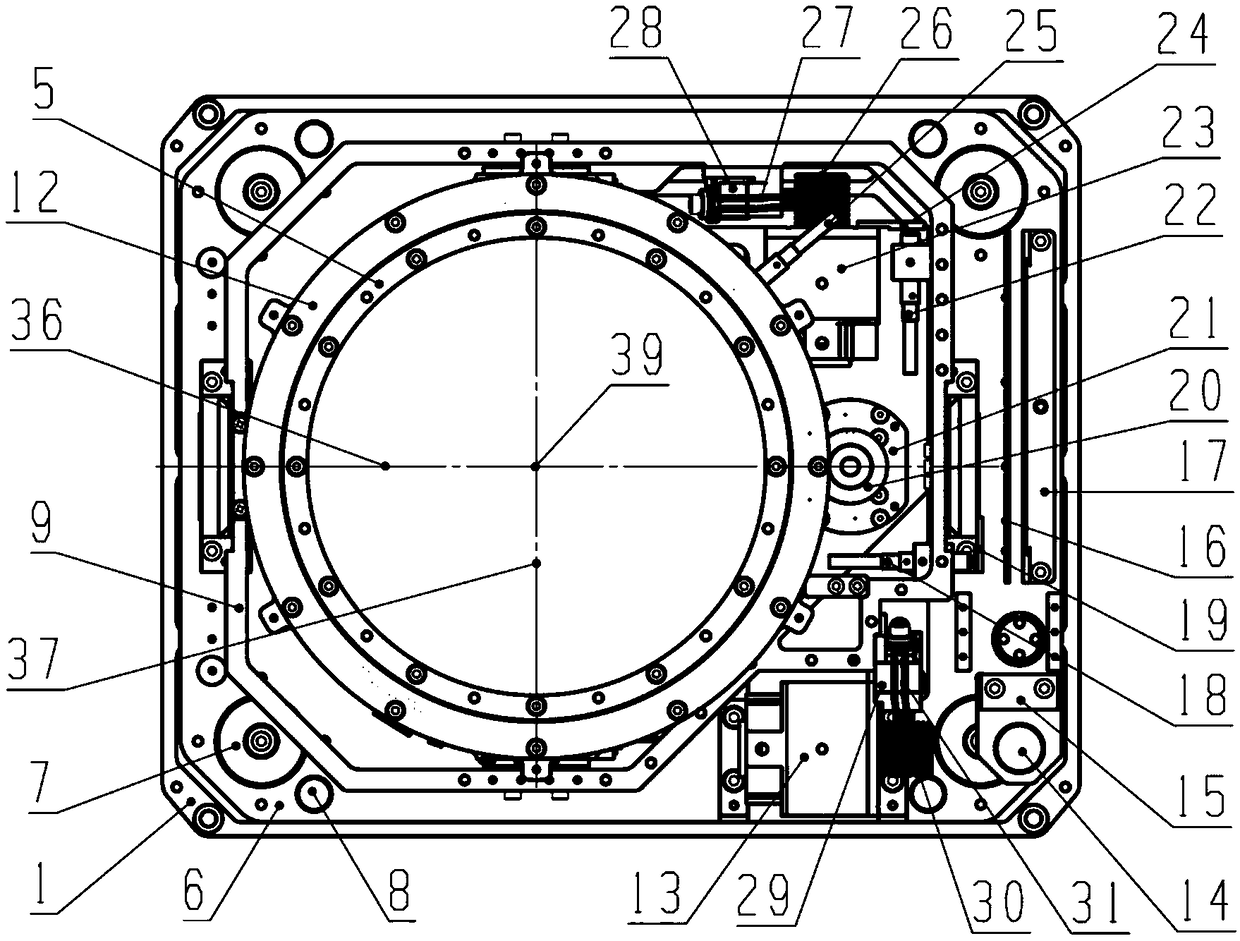

Three-axis inertial stabilization platform

ActiveCN109029436AImproved Dynamic Pointing AccuracySmooth and precise transmissionNavigation by speed/acceleration measurementsLow noiseHarmonic

The invention provides a three-axis inertial stabilization platform, applied to the field of photoelectric technology. All three-axis reduction transmission systems of the three-axis inertial stabilization platform adopt a flexible cable transmission mode, and the rigidity of the flexible cable transmission can reach 10 times or more of the same precision gear transmission or harmonic system; andmeanwhile, the flexible cable transmission has the characteristics of high precision, low noise, stable transmission, no lubrication, easy to install and maintain and the like. The high rigidity and no backlash characteristics of the flexible cable precision transmission ensure a fast dynamic response of a stable tracking servo system, and improve the dynamic pointing precision of the platform.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

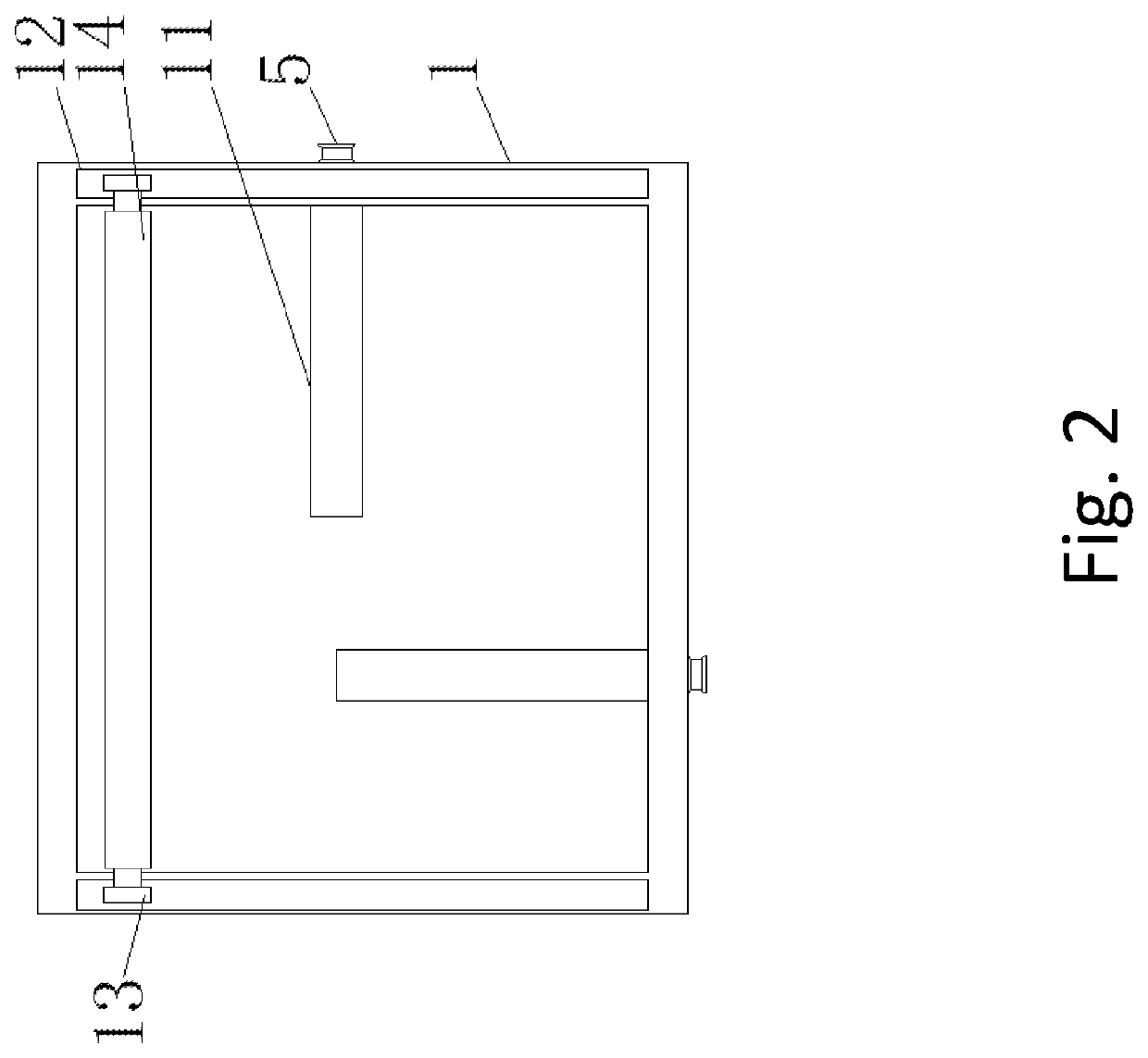

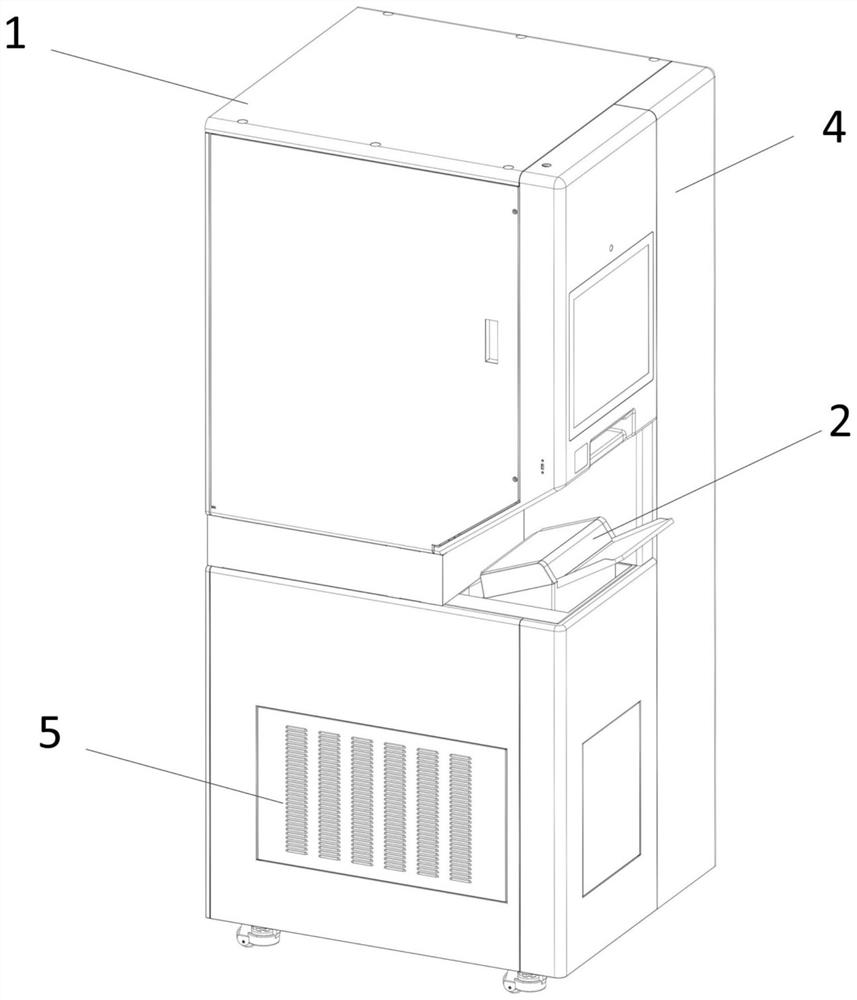

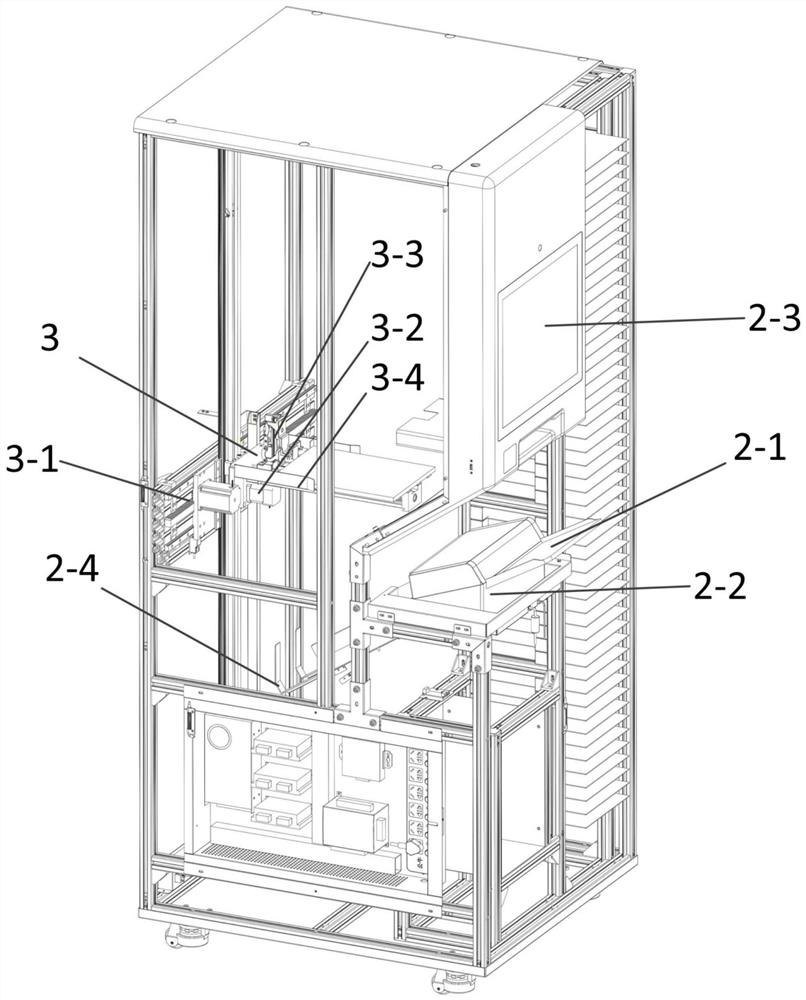

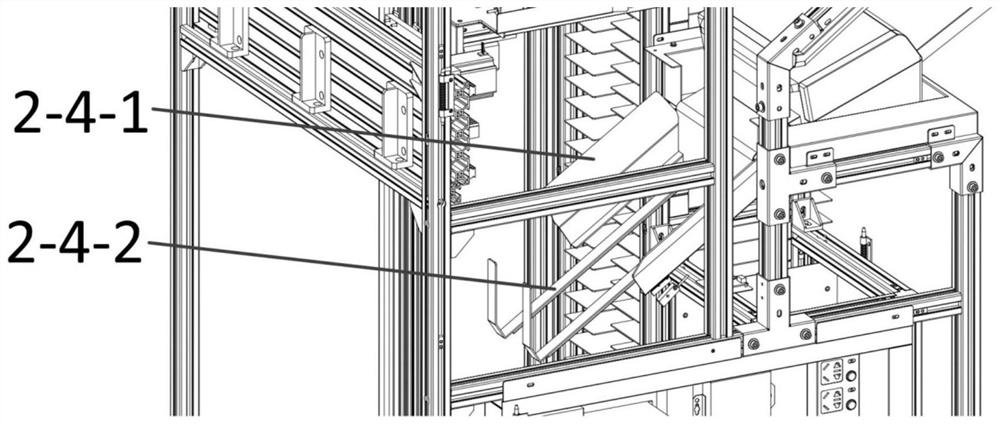

Intelligent file cabinet with automatic classified storage function

PendingCN112869408AEnabling Horizontal Transfer ScalingMeet the needs of different application scenariosBook cabinetsFurniture partsEngineeringElectric control

The invention discloses an intelligent file cabinet capable with an automatic classified storage function. The intelligent file cabinet comprises a cabinet body, a file scanning mechanism, a file transmission mechanism, a file storage bin and an electric control box. The back of the cabinet body is provided with a back plate made of industrial aluminum profiles, and the back plate made of the industrial aluminum profiles can be transversely expanded through industrial aluminum profile connecting pieces; the file scanning mechanism comprises a file inlet, a file scanner, a touch display screen and a first tray; the file transmission mechanism comprises a transverse movement mechanism, a longitudinal movement mechanism, a push-pull movement mechanism and a second tray; and the file storage bin comprises a bin body and a partition plate.

Owner:北京派诺威盛技术有限公司

Self-adaptive limited angle pretightening transmission device suitable for limited space

ActiveCN110594372AGood basic transmission rigidityPrecise transmission performanceGearingDrive wheelSelf adaptive

The invention discloses a limited angle pretightening transmission device suitable for a limited space. The limited angle pretightening transmission device suitable for the limited space mainly comprises a driving wheel, a driven wheel, a transmission medium, a pretightening pressing block, a self-adaptive pretightening mechanism, a force displacement sensor and the like, wherein an input shaft and an output shaft are parallel and are connected through the transmission medium; the pretightening pressing block is installed on the input shaft and can fix the transmission medium; and the force displacement sensor is embedded into the input shaft and can perform real-time correction and compensation on a pretightening state of the transmission medium by virtue of the leverage of the self-adaptive pretightening mechanism. Compared with a traditional transmission and pretightening scheme, the self-adaptive pretightening transmission device has the characteristics of high precision transmission, compact structure, small occupied space, dynamic compensation, light weight, high reliability and the like.

Owner:西安应用光学研究所

Metal can lid feeding and conveying mechanism

InactiveCN109775303AReasonable structural designLifting is smooth and accurateConveyor partsEngineeringMechanical equipment

The invention discloses a metal can lid feeding and conveying mechanism, and belongs to the field of container equipment processing mechanical equipment. A lid feeding mechanism of the metal can lid feeding and conveying mechanism is vertically arranged on a fixing bracket and on one side of a lid transferring mechanism, a lid guiding mechanism is obliquely arranged on the fixing bracket and on the upper side of a lid conveying mechanism downwards, a lid feeding connecting plate is slidably arranged on the lower side of a lid bearing hopper in the vertical direction, the two sides of a lid conveying belt are connected to a main lid conveying roller and an auxiliary lid conveying roller in a winding manner, a tooth missing gear and a lid conveying gear are connected in a meshed manner, a lid guide chute is arranged in a lid guide rail, the upper end of the lid guide rail communicates with a lid outlet guide hole, and a buffer mechanism and a lid blowing mechanism are sequentially arranged on the upper side of the lower end of the lid guide rail in the oblique direction from top to bottom. The metal can lid feeding and conveying mechanism is reasonable in structure design, can lids can be continuously and efficiently fed one by one in a sliding manner, the can lids can be smoothly and accurately conveyed intermittently, the automation degree of feeding and conveying of the can lids is improved, and the production and use requirements are met.

Owner:海宁市波菲特进出口有限公司

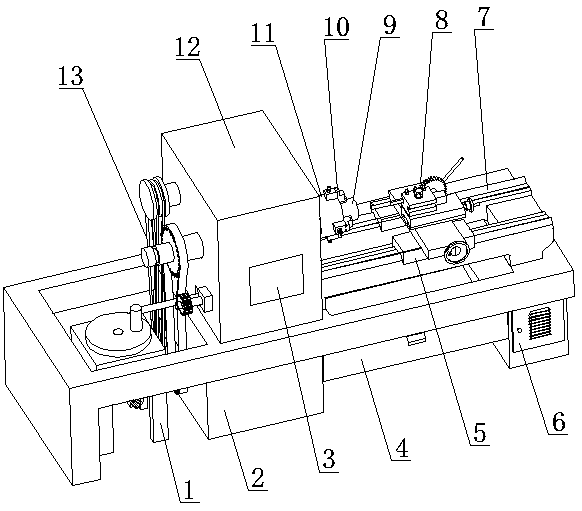

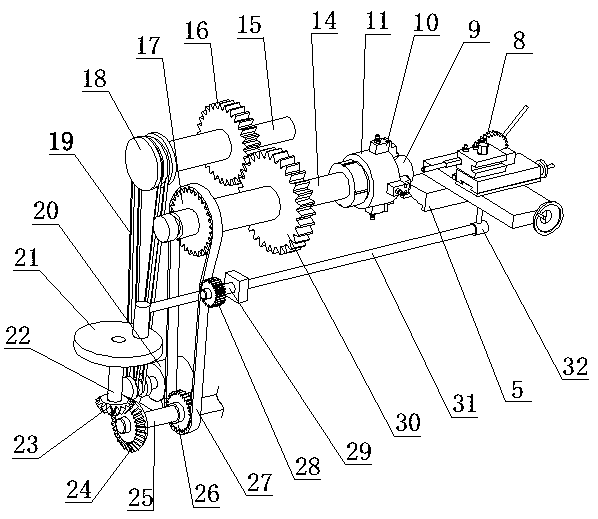

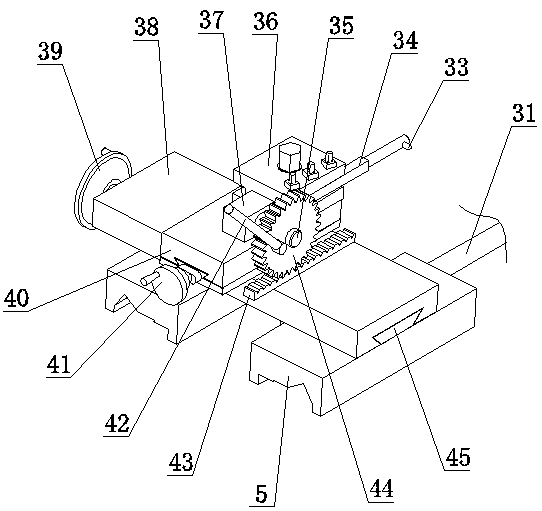

Shaft sleeve oil groove machining lathe

InactiveCN109332726AGuarantee processing qualityGuaranteed processing efficiencyFeeding apparatusDriving apparatusAgricultural engineeringWaste material

The invention discloses a shaft sleeve oil groove machining lathe. The shaft sleeve oil groove machining lathe comprises a rack, a main shaft box, a guide rail, a transmission mechanism and an oil groove machining mechanism. The shaft sleeve oil groove machining lathe is characterized in that the main shaft box is located below the rack, and the front face of the main shaft box is provided with anoperation panel; the guide rail is arranged at the right side of the main shaft box, and a waste material box is arranged below the guide rail; a storage box is arranged at the right end of the rack;the transmission mechanism comprises a motor, a first driven shaft, a main shaft, a driving shaft, a second driven shaft and a swing rod; the left end of the motor and the left end of the first driven shaft are each provided with a belt wheel; a belt is arranged at the outer sides of the belt wheels; a first driving gear is arranged in the middle of the first driven shaft; a first driven gear isarranged in the middle of the main shaft; a chuck is arranged at the right end of the first driven gear; and a second driving gear is arranged at the left end of the main shaft. By means of the shaftsleeve oil groove machining lathe, machining quality and efficiency of a shaft sleeve oil groove can be guaranteed; the labor intensity of workers is lowered; and the shaft sleeve oil groove machininglathe is reasonable in structural design and easy and convenient to operate.

Owner:泉州市金典机械发展有限公司

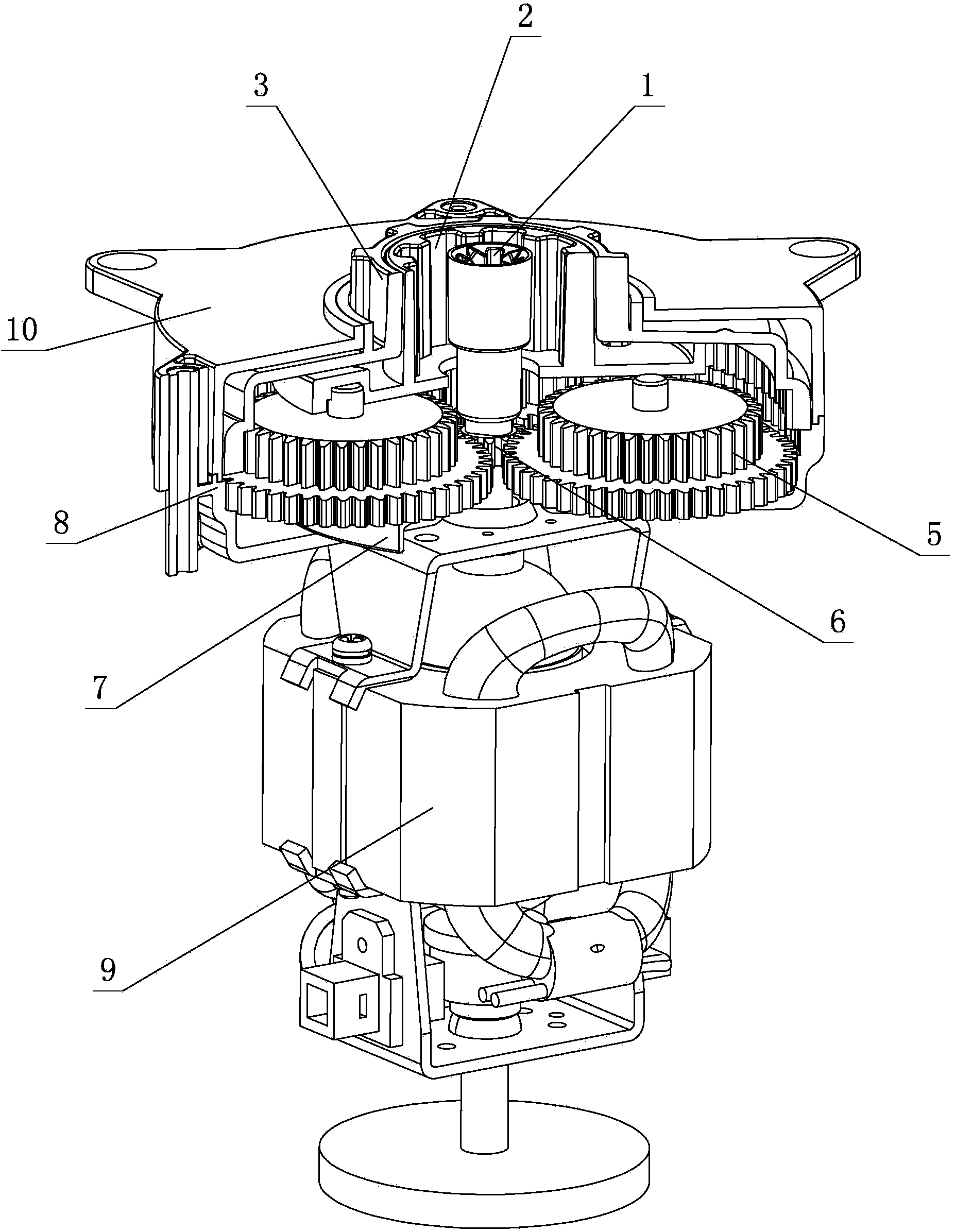

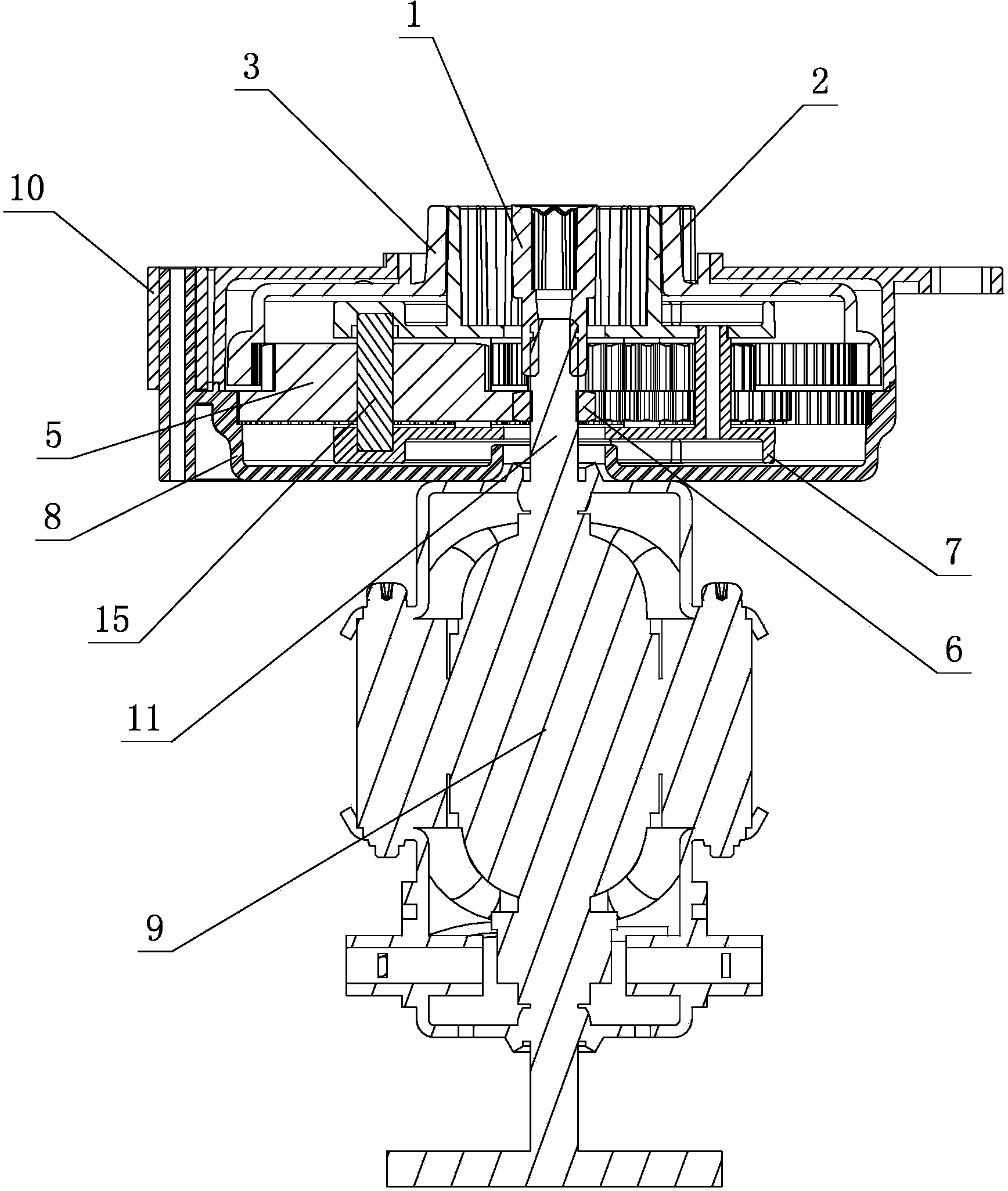

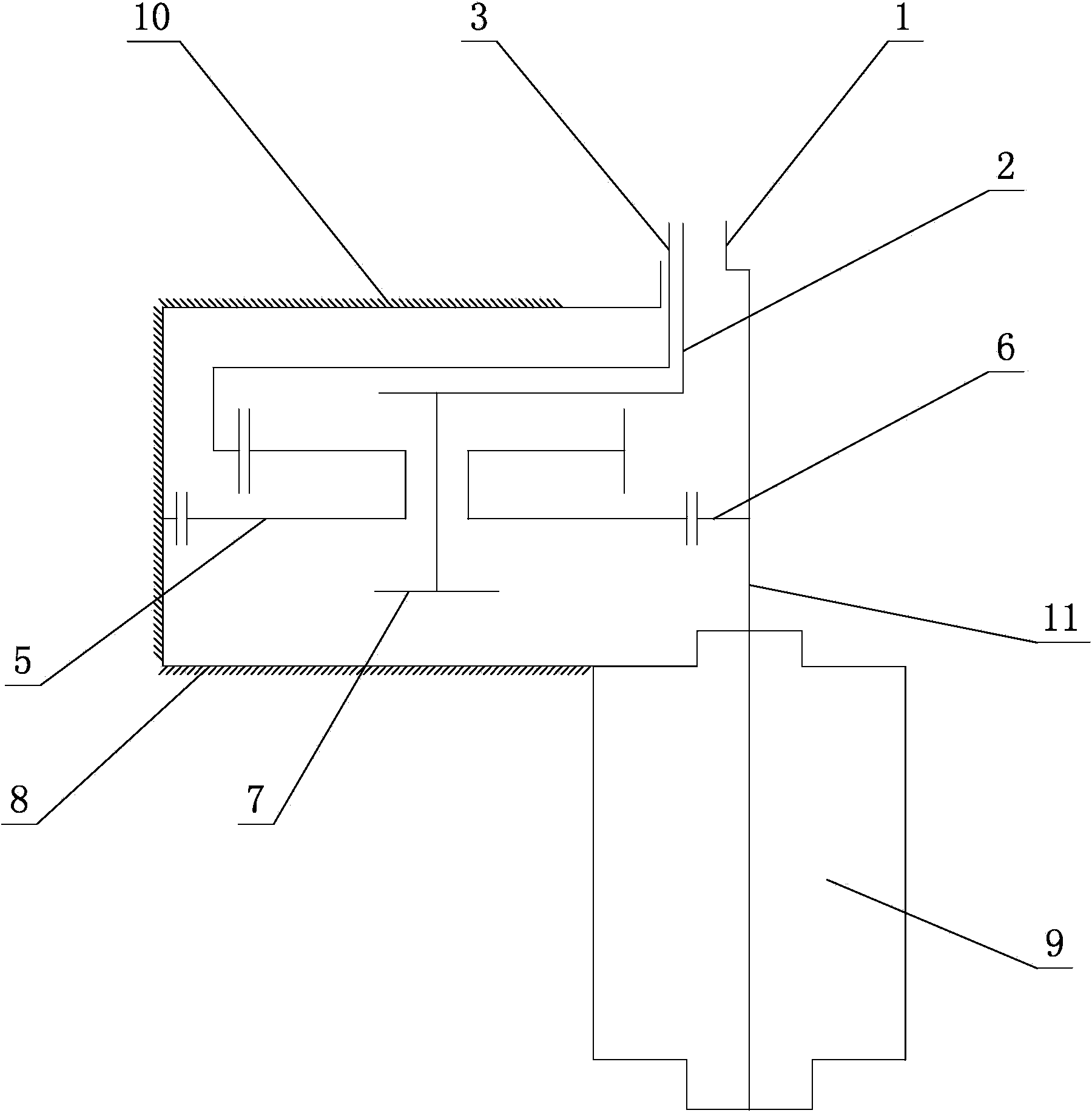

Differential multi-drive device

ActiveCN104367215AReduce in quantityHigh output speedDifferential gearingsKitchen equipmentLow speedRotation velocity

A differential multi-drive device comprises a gearbox, a plurality of connectors connected with an installing and machining tool are arranged in the gearbox, the connectors are in drive connection through a motor installed below the gearbox, and the connectors comprise the high-speed connector, the intermediate-speed connector and the low-speed connector; the high-speed connector is in drive connection with the tail end of an output shaft of the motor and generates a first-level rotation speed; the intermediate-speed connector is located on the periphery of the high-speed connector, is in drive connection with the output shaft through a gear train and generates a second-level rotation speed; the low-speed connector is located on the periphery of the intermediate-speed connector, is directly driven by a planetary gear of a planetary gear train, is in drive connection with the output shaft through the planetary gear train and generates a third-level rotation speed. The differential multi-drive device has the advantages that the structure is simple and reasonable, the number of parts is small, the manufacturing cost is low, performance is reliable, transmission is stable and accurate, and the work efficiency of a complete machine is high, and is high in practicability.

Owner:NINGBO BORINE ELECTRIC APPLIANCE

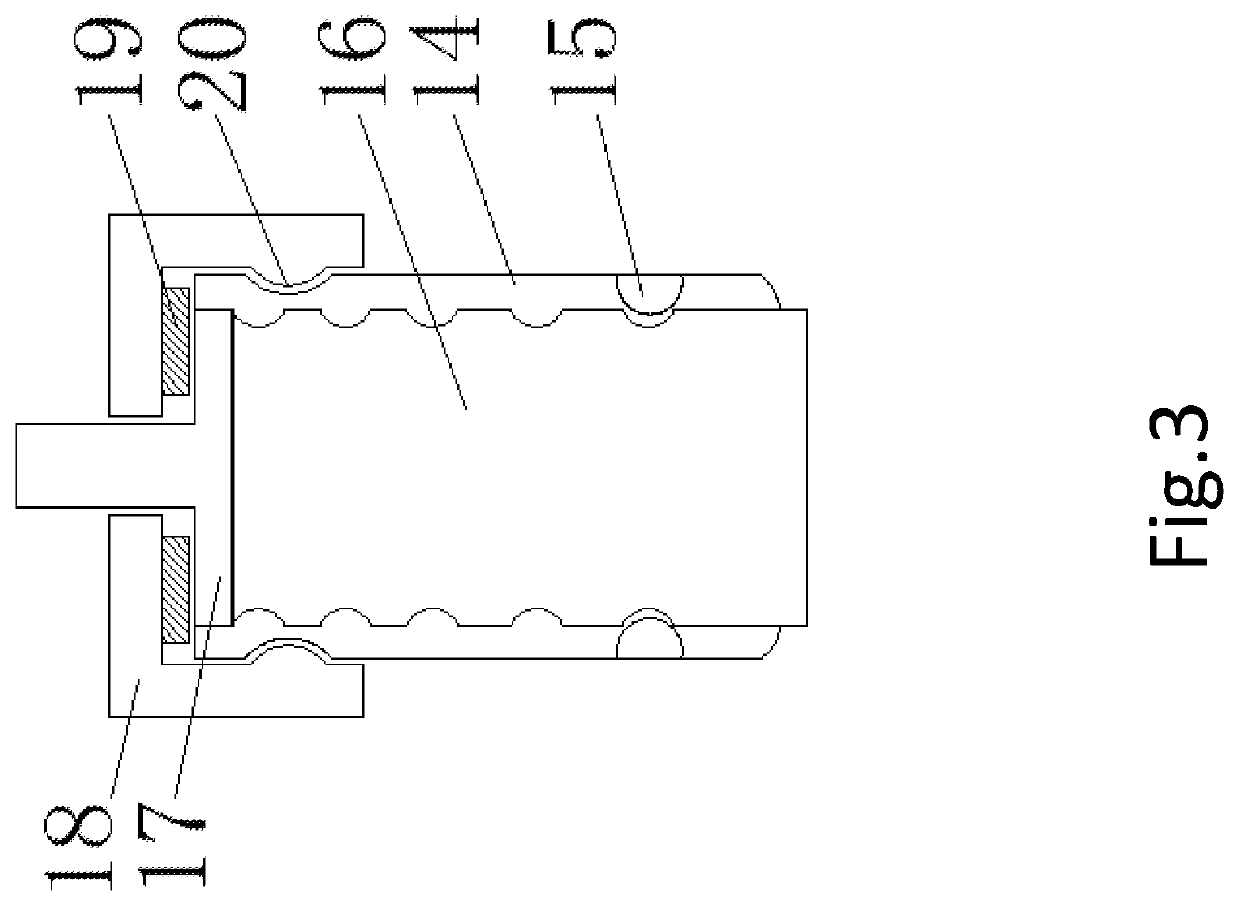

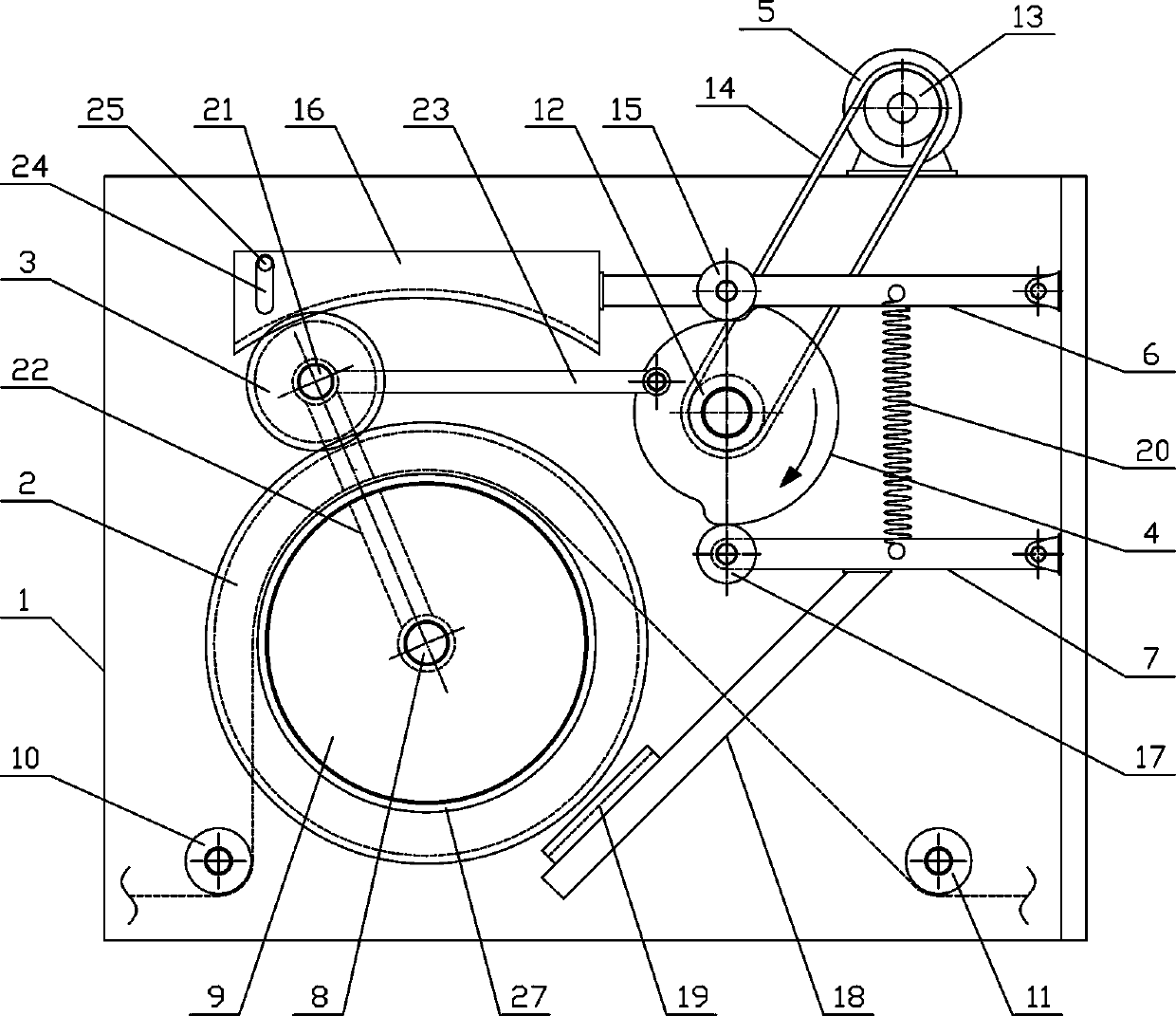

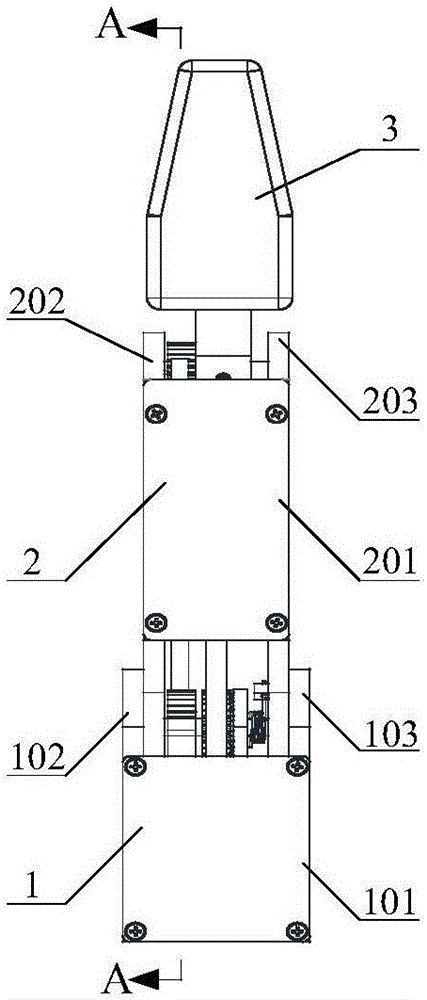

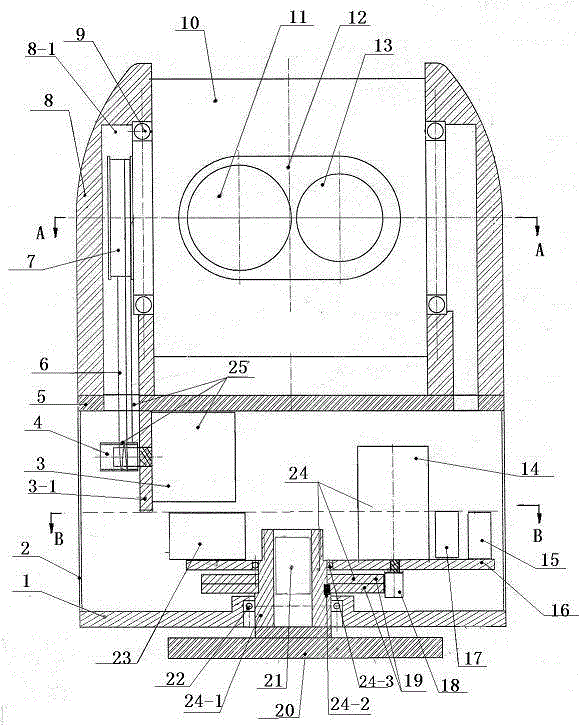

Two-dimension video stabilization tracking detection instrument

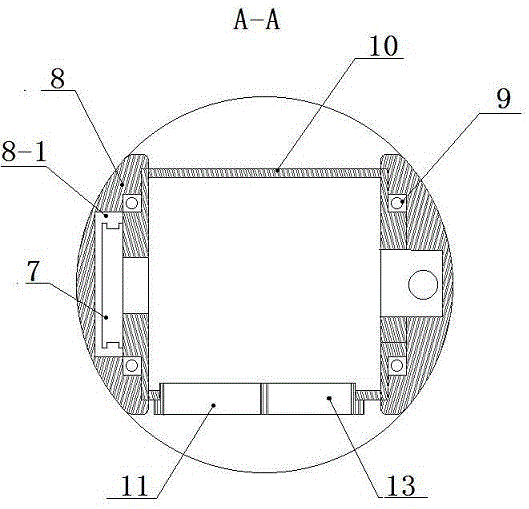

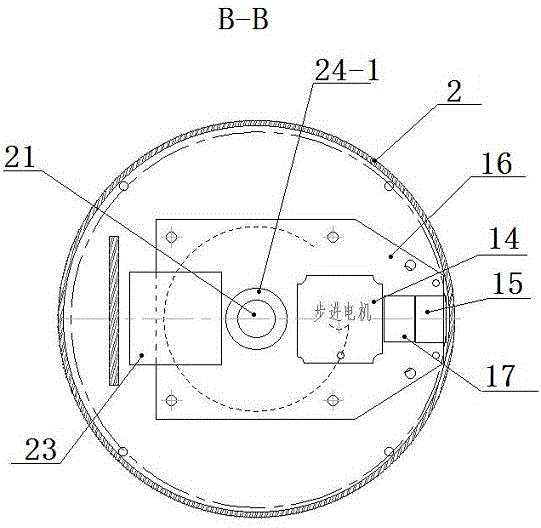

InactiveCN105072424AStable and precise cameraSmooth and precise transmissionTelevision system detailsColor television detailsGyroscopeElectrical control

The invention belongs to a two-dimension video stabilization tracking detection instrument comprising a base (20), a lower supporting plate (1), and an upper cover plate (5). A tracking detection instrument lower shell (2) is arranged between the lower supporting plate (1) and the upper cover plate (5). A tracking detection instrument upper shell (8) is arranged on the upper cover plate (5). The two-dimension video stabilization tracking detection instrument is characterized in that the cavity of the tracking detection instrument upper shell (8) is equipped with a vertical transmission mechanism (25) and a lens cabin (10); the middle of the lens cabin (10) is provided with a camera window (12); the cavity of the lens cabin (10) is equipped with a visible light camera (11) and a thermal imaging camera (13); and a vertical gyroscope (15) and a horizontal gyroscope (17) are arranged at the right side above an upper supporting plate (16), and an electrical controller (23) is installed at the left side. The two-dimension video stabilization tracking detection instrument is not affected by any vibration, swing, weather or temperature change, always maintains stable and accurate video shooting and transmission and clear image, is resistant to limiting temperature, and is firm and durable.

Owner:DALIAN XUANSHENG INTELLIGENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com