Moving contact terminal pressure detection mechanism

A detection mechanism and end-of-contact technology, which is applied to measure the direction of force applied to the control element, can solve problems such as easy-to-run transmission errors, large data errors, and poor transmission stability, achieving strong compatibility and small measurement errors , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

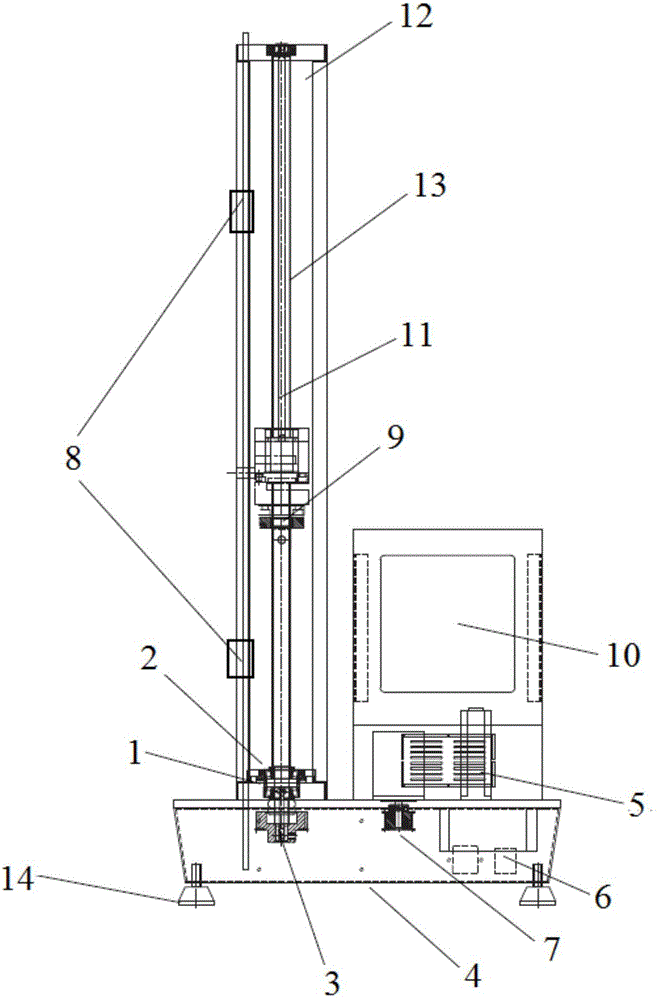

[0023] A moving contact final pressure detection mechanism, its structure is as follows figure 1 As shown, it includes a positioning fixture 2 for placing the moving contact 1 to be tested, which is movably connected to the base 4 through four screws, and can be disassembled and replaced according to the size of the moving contact 1 to be tested. Also be provided with the horizontal adjustment support 14 of adjusting its horizontal position below base 4, be connected with the lead screw 11 of servo motor 3, lead screw 11 is supported through support 12, be provided with on lead screw 11 and move up and down along lead screw 11. The pressure head 9 has a built-in pressure sensor, and the screw 11 is used to ensure the stability and accuracy of the transmission, reducing the error caused by the measurement system. In addition, the screw 11 is equipped with a scale 13, so that the pressure head 9 can be detected in real time. Location.

[0024] The display 10 with the data proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com