High-precision and light-weight controllable telescopic wing mechanism

A high-precision, light-weight technology, applied in the field of aviation applications, can solve the problems of high application cost and achieve the effects of fast transmission speed, light mechanism weight and small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] This embodiment is a high-precision light-weight controllable telescopic wing mechanism.

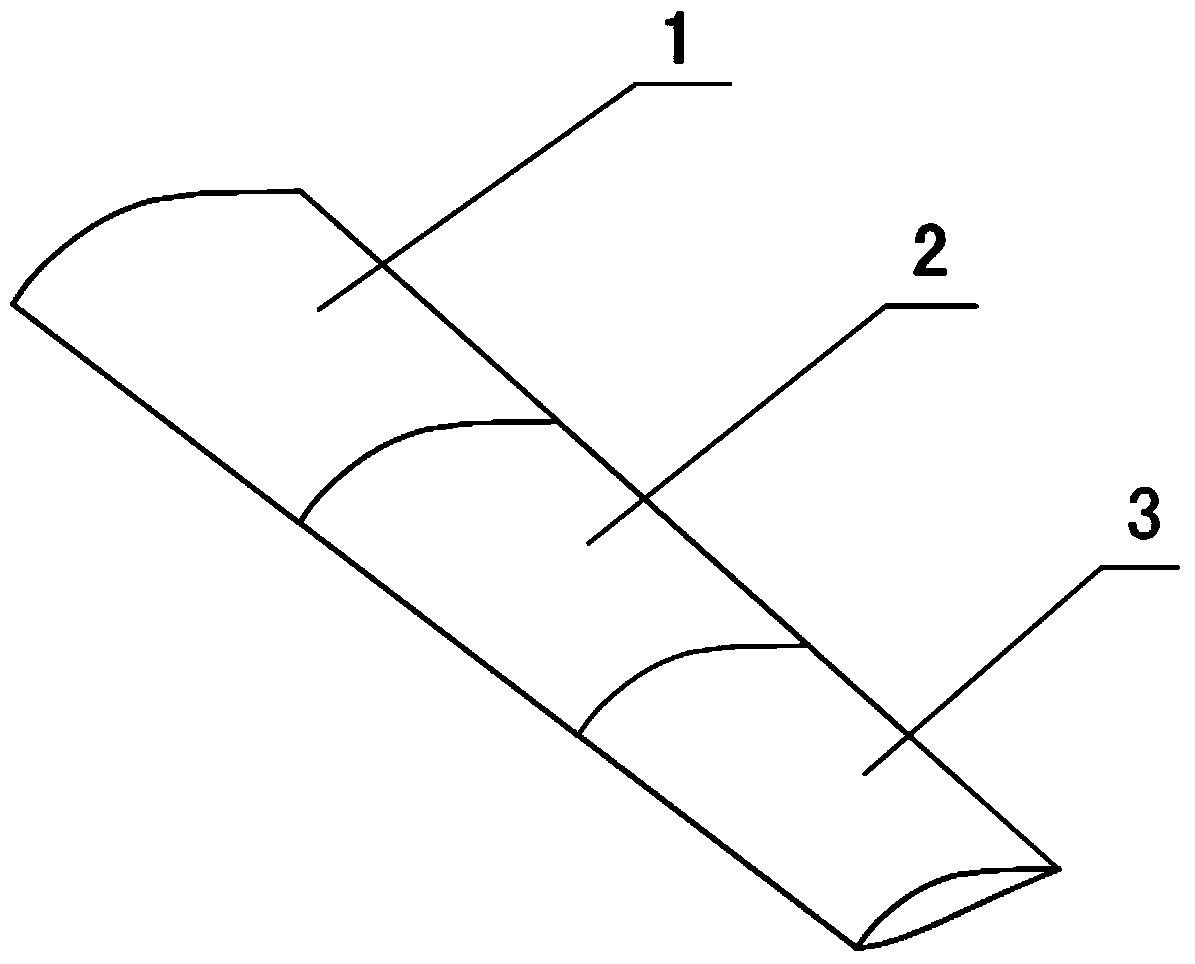

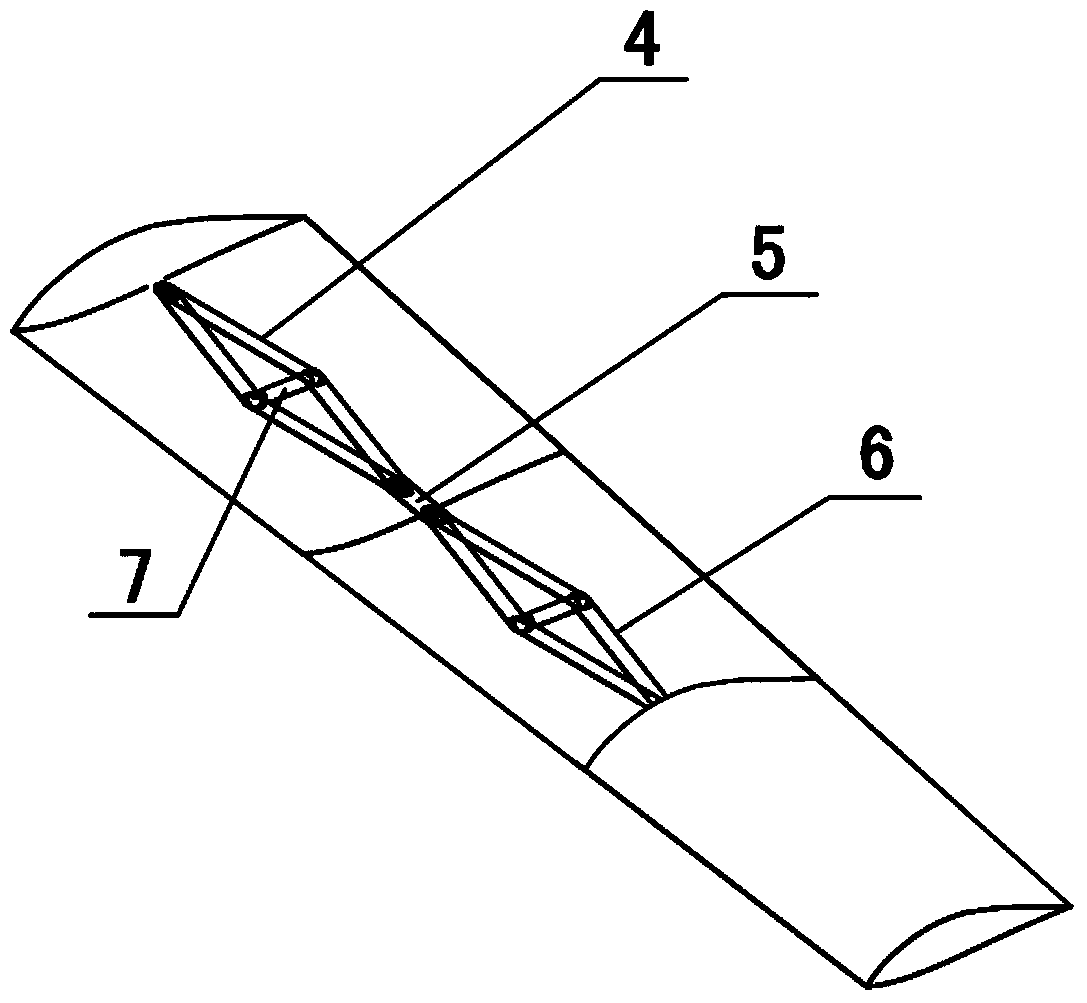

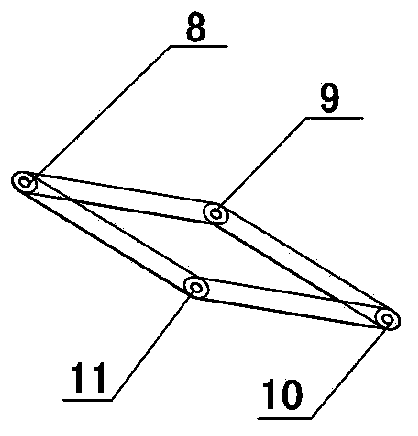

[0022] refer to Figure 1 to Figure 6 , the high-precision light-weight controllable telescopic wing mechanism of this embodiment includes a fixed wing 1, a middle wing 2, an outer wing 3, an inner four-link 4, an outer four-link 6, a driver 7, and a double-hole connecting plate 5,

[0023] The fixed wing 1 is the root of the wing, and the inner four connecting rods 4 are placed inside the fixed wing 1. One end of the fixed wing 1 is closed and the other end is open, and the closed end of the fixed wing 1 is fixed on the body. The middle wing 2 is installed between the fixed wing 1 and the outer wing 3, the chord length is 90% to 95% of the chord length of the fixed wing 1, the outer four-link 6 is placed inside the middle wing 2, the closed end of the middle wing 2 is connected to the fixed wing 1. The open end is fixed along the span direction through the double-hole connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com