Iron bar automatic segmenting mechanism

An iron bar, automatic technology, applied in the direction of shearing device, device for cutting by nibbling action, attachment device of shearing machine, etc. Use and other issues to achieve a reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further describe the present invention, a specific implementation of an automatic iron bar cutting mechanism will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

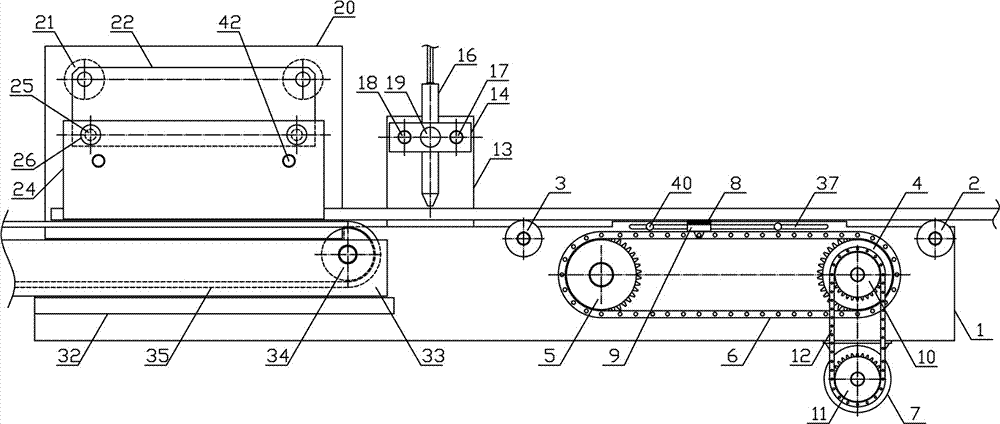

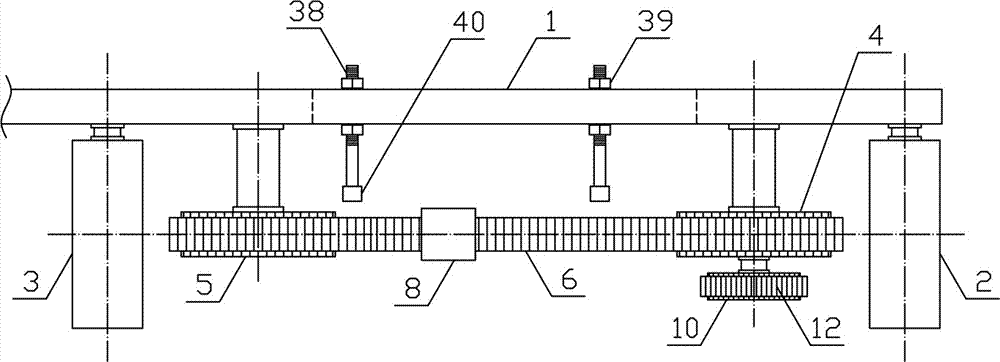

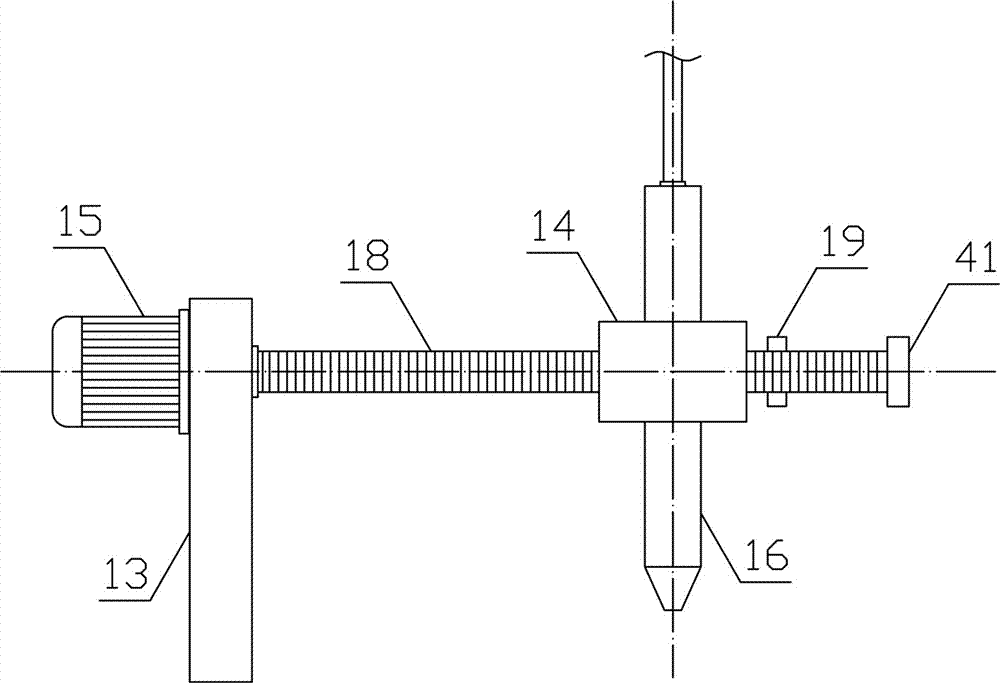

[0016] Such as figure 1As shown, an automatic section-cutting mechanism for iron bars of the present invention comprises a fixed bracket 1, a feeding mechanism, a material cutting mechanism and a fixed pushing mechanism, and the feeding mechanism, the cutting mechanism and the fixed pushing mechanism are fixedly arranged in a fixed position successively along the horizontal direction. On one side of bracket 1, the feeding mechanism includes feeding roller 2, guide roller 3, main feeding sprocket 4, auxiliary feeding sprocket 5, feeding chain 6, feeding motor 7 and feeding electromagnet 8, feeding roller 2 and feeding guide Roller 3 rotates h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com