Patents

Literature

97results about "Fabric finishing guides/expanders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special automatic dust collecting cloth rolling machine for cloth processing

ActiveCN107938239AEfficient removalEasy to operateCombination devicesMechanical cleaningEngineeringElectric heating

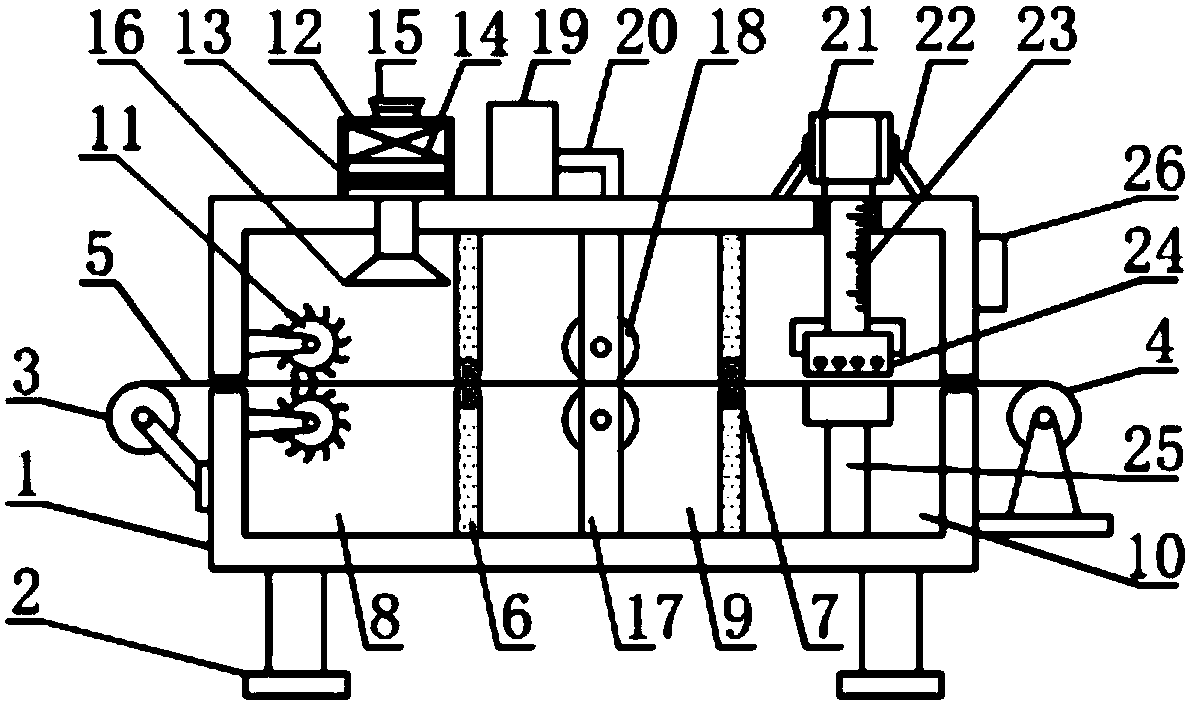

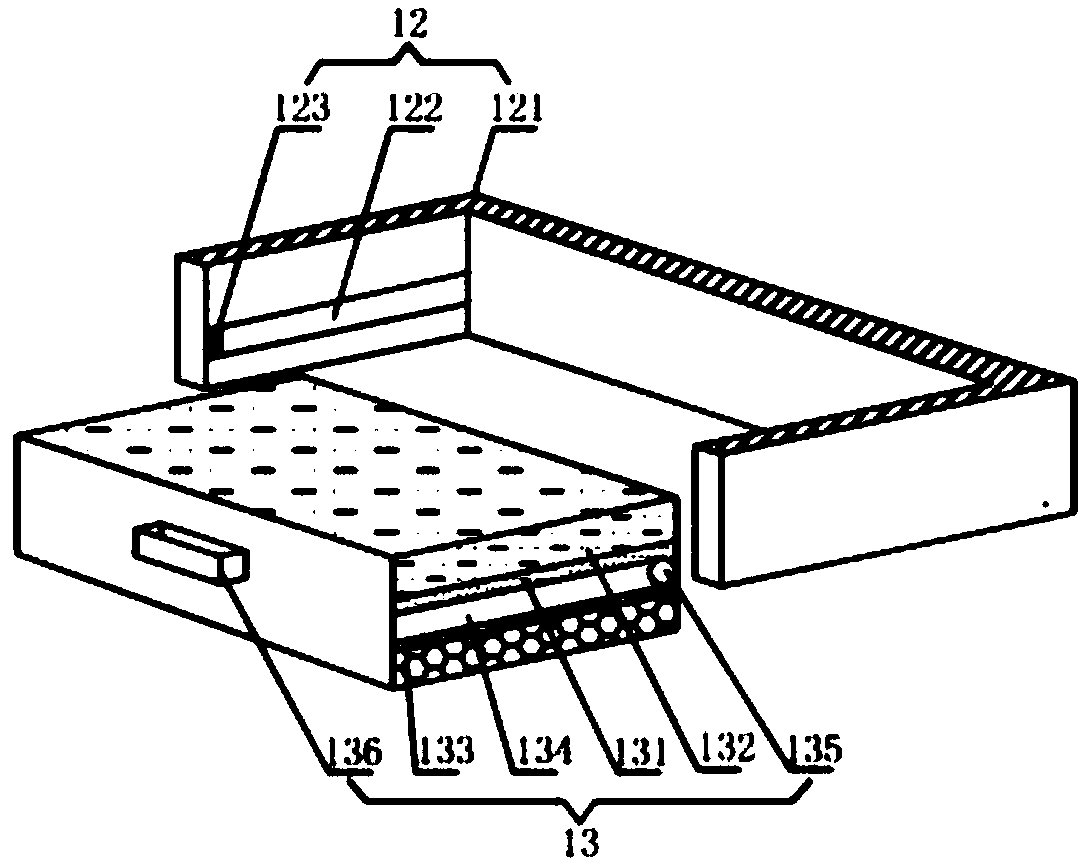

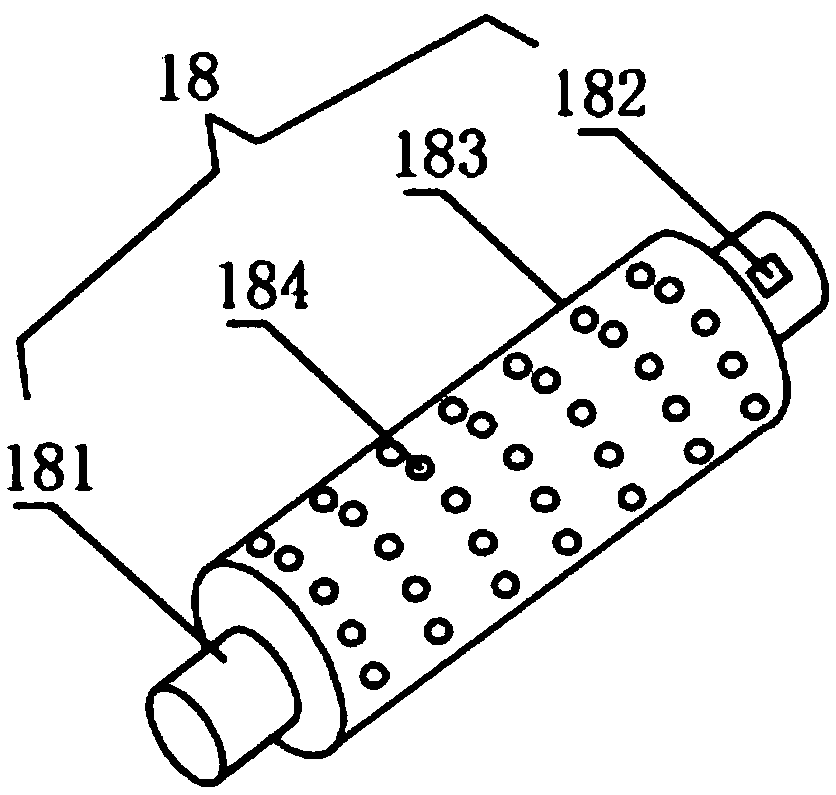

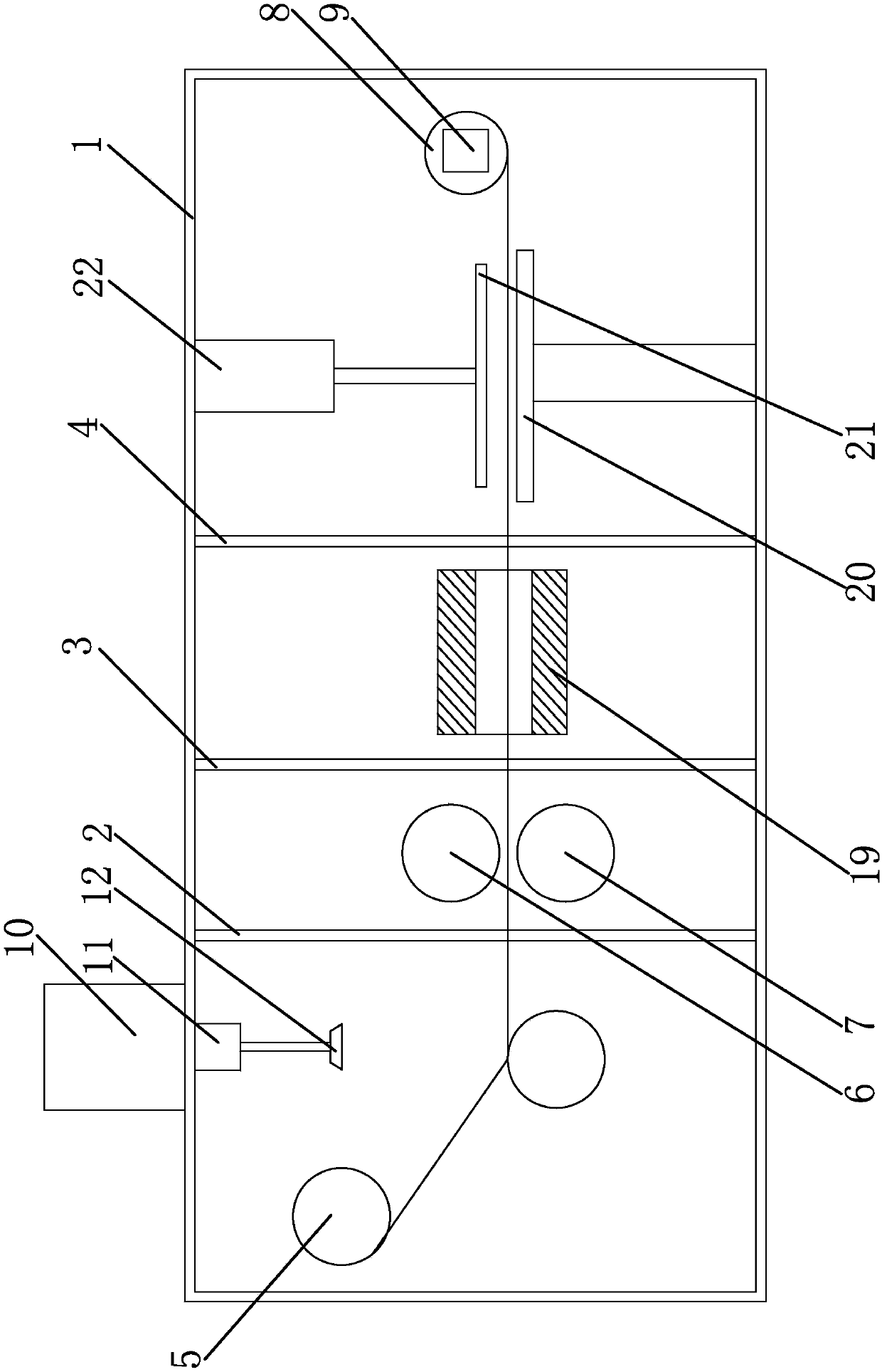

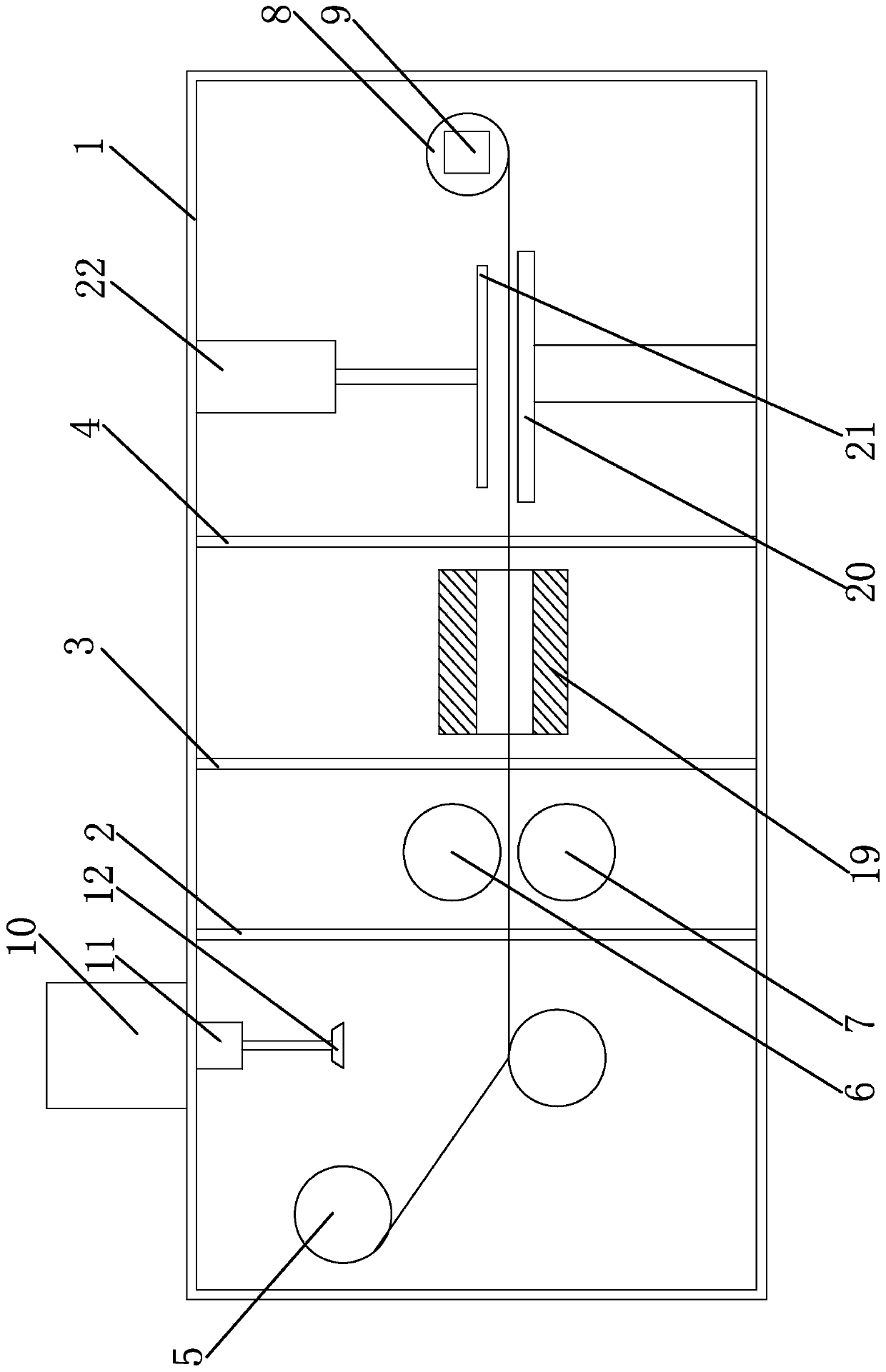

The invention discloses a special automatic dust collecting cloth rolling machine for cloth processing. The special automatic dust collecting cloth rolling machine for cloth processing comprises a rack, wherein an unreeling roller and a reeling roller are separately mounted on the left and right outer walls of the rack; two partition plates successively partition the inner cavity of the rack intoa dust collecting chamber, a steam drying chamber and a wrinkle-removing chamber; a dust collecting box is mounted on the top of the dust collecting chamber; and a steam drier is arranged on the steamdrying chamber. The special automatic dust collecting cloth rolling machine for cloth processing provided by the invention is simple to operate. Arc-shaped rubber brushing hairs are arranged on the outer walls of two dust collecting wheels, and the rotating directions of the two dust collecting wheels are opposite to the cloth forwarding direction, so that dust and cloth chips on the outer wall of the cloth can be eliminated effectively. Steam drying holes are formed in the surface of the steam drying roller, so that the cloth is dried, deodorized, enhanced in aroma, dry-washed and sterilizedconveniently, the storage period of the cloth without dust is improved effectively, the steam dried cloth is ironed by means of an electric heating plate, wrinkles on the surface of the cloth are eliminated conveniently, and the levelness of the cloth is improved effectively.

Owner:RUIAN BOAN STAB RESISTANT MATERIAL TECH

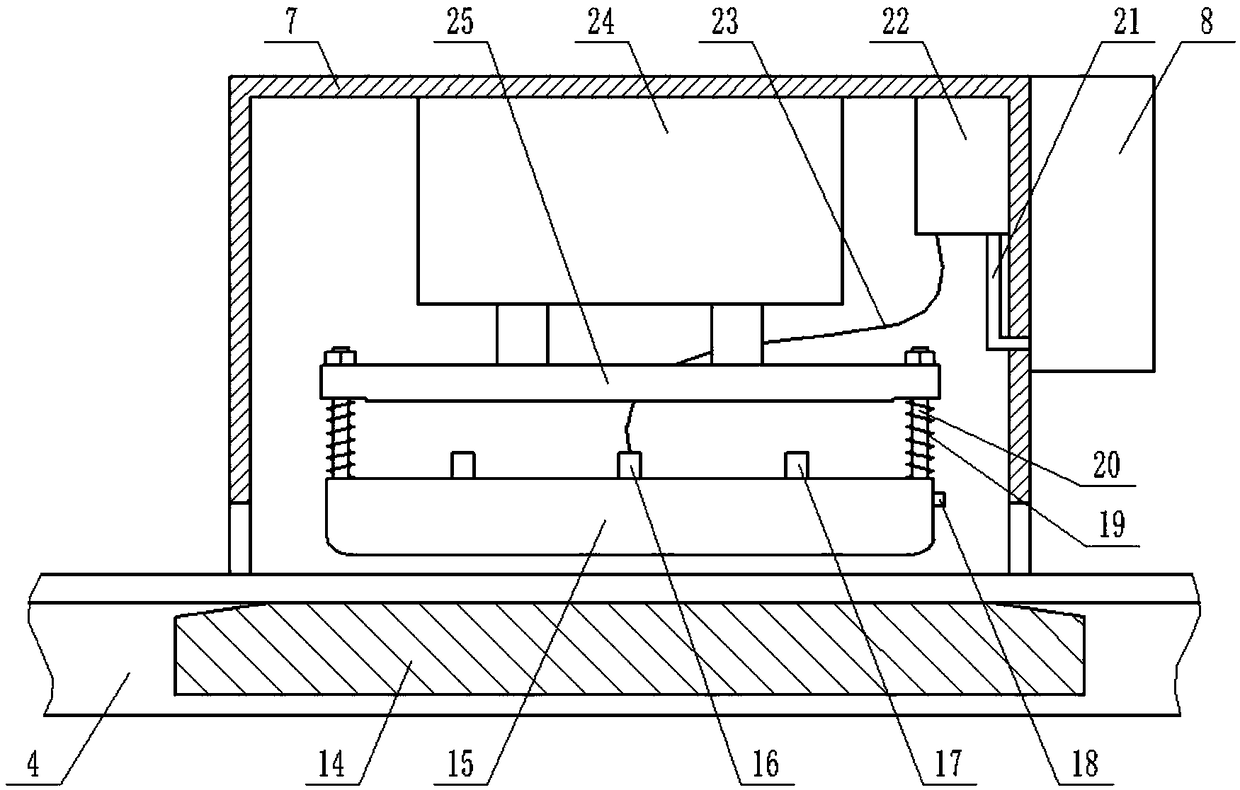

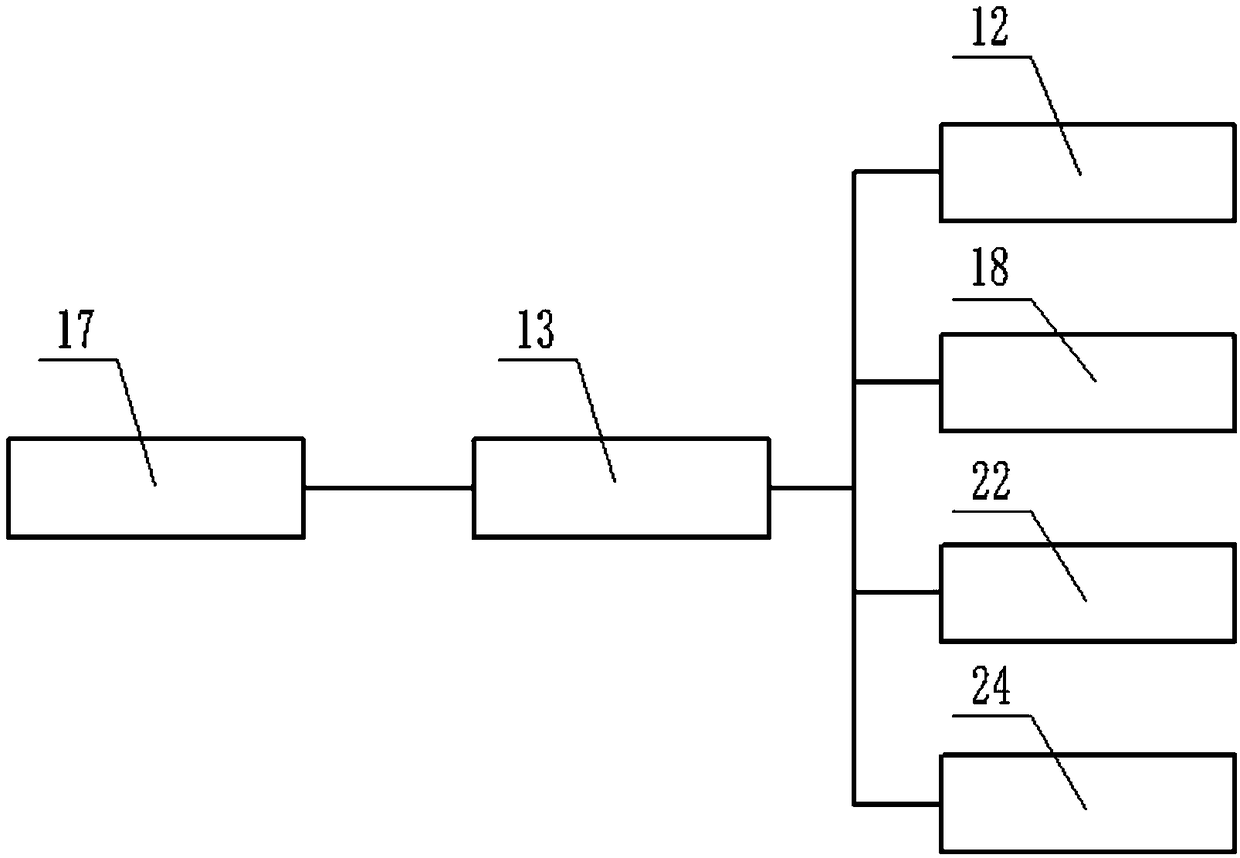

Textile fabric ironing and drying apparatus

InactiveCN107401018AAchieve the purpose of pavingAchieve the purpose of moving the ironing machineFabric finishing guides/expandersTextiles drying apparatusEngineeringAir heater

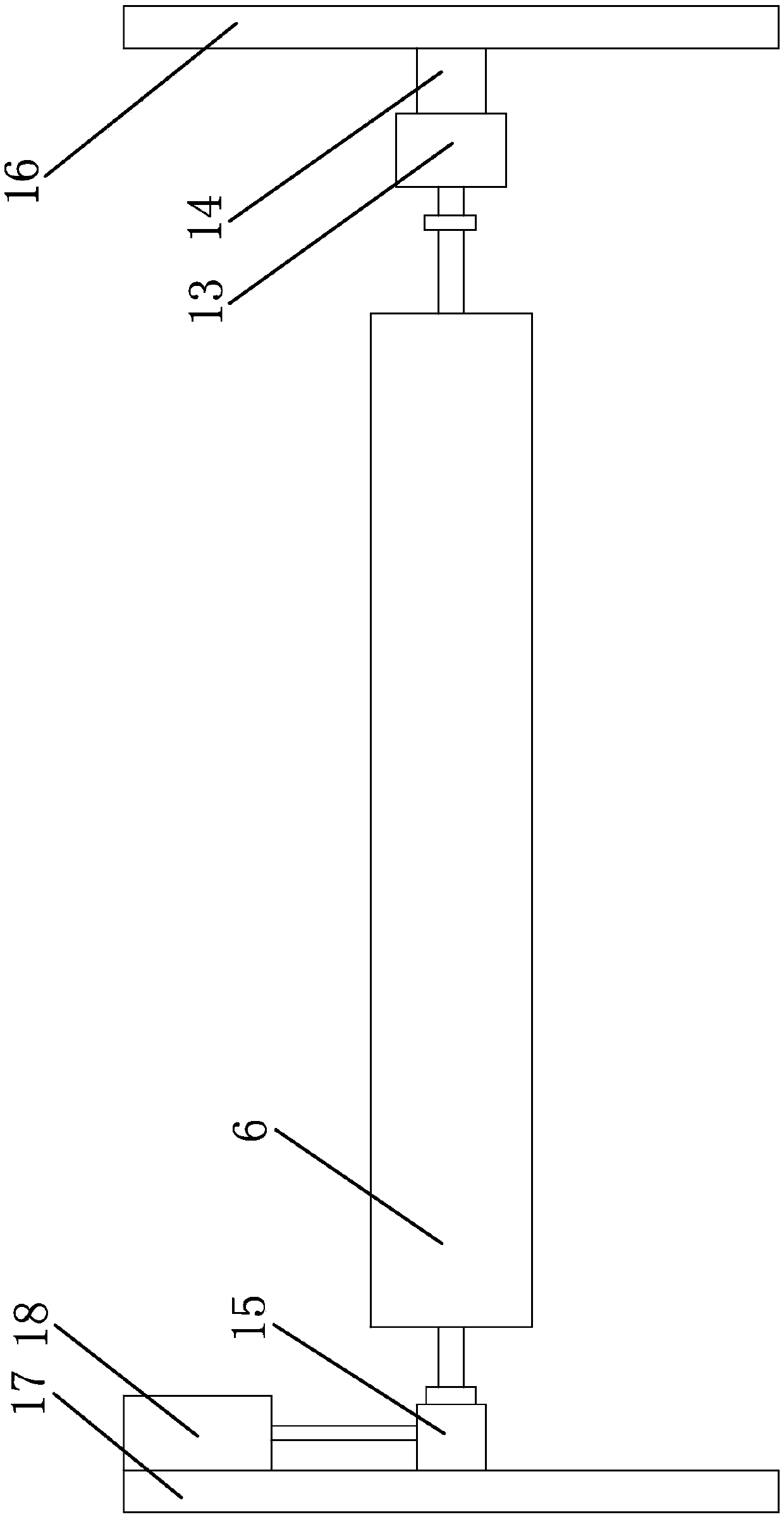

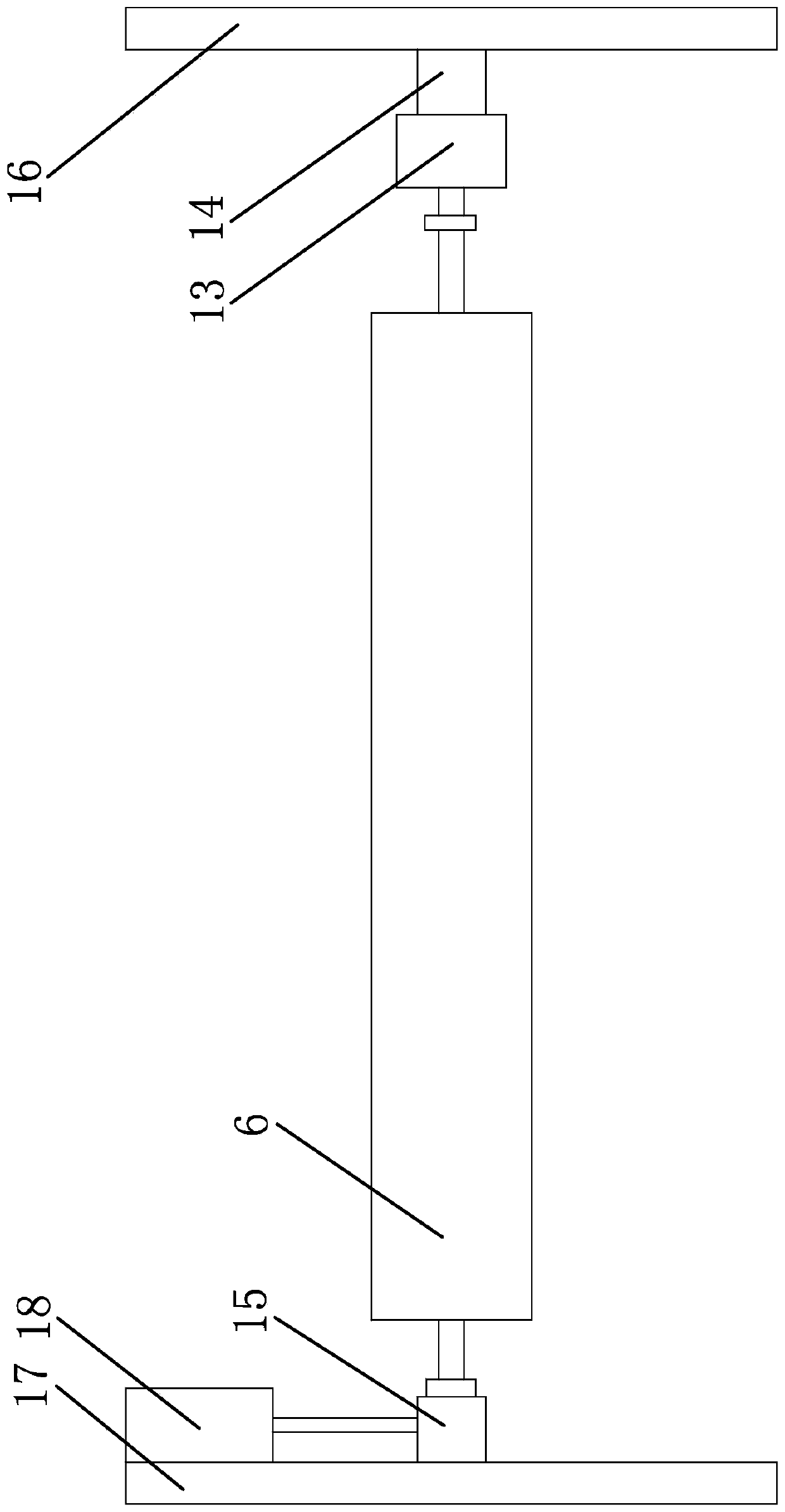

The invention discloses a textile fabric ironing and drying apparatus. The apparatus comprises an ironing chamber, the internal bottom end of the ironing chamber is fixedly connected with a lifting device, one end of a first pressure rod is fixedly connected with a first pressure roller, the first pressure roller is located at the top end of an ironing plate, a textile fabric compacting device is fixedly connected in a position, symmetrical to the first pressure roller, in the ironing chamber, the internal top end of the ironing chamber is fixedly connected with an ironing moving device, constant tension devices are fixedly connected to two sides of the ironing plate, an air heater is fixedly connected to the top end of a supporting plate and at the right side of a blower, and the right end of the air heater communicates with drying air outlet holes. The textile fabric ironing and drying apparatus relates to the technical field of textile device machines. The textile fabric ironing and drying apparatus solves the problems of no large-batch ironing and no automatic flattening during ironing of existing ironing devices needing manual operation, improves the ironing efficiency, and reduces the labor force.

Owner:HUZHOU BOREN TEXTILES

Fabric shaping machine

ActiveCN107938233AImprove stylingWrinkles disappearHeating/cooling textile fabricsFabric finishing guides/expandersEngineeringMechanical engineering

The invention provides a fabric shaping machine, belongs to the technical field of shaping machine, and solves the problem of poor shaping effect in the prior art. The fabric shaping machine includesa machine box; the machine box is vertically fixedly provided with a first partition board, a second partition board and a third partition board; the interior of the machine box is divided into a first cavity, a second cavity, a third cavity and a fourth cavity by the first partition board, the second partition board and the third partition board successively; the first cavity is provided with anunreeling roller, the unreeling roller is arranged on the inner wall of the machine box by a circumferential rotation and axial fixing way, and the first cavity is provided with a humidification mechanism for humidifying a fabric; the second cavity is provided with a first heating roller and a second heating roller, and the first heating roller is located right above the second heating roller; themachine box is provided with an adjusting structure for adjusting the distance between the first heating roller and the second heating roller; the third cavity is provided with a drying mechanism which can be used for drying the fabric; the fourth cavity is provided with a cooling shaping mechanism which can be used for cooling and shaping the fabric. The fabric shaping machine has the advantageof good shaping effect.

Owner:浙江得伟科技股份有限公司

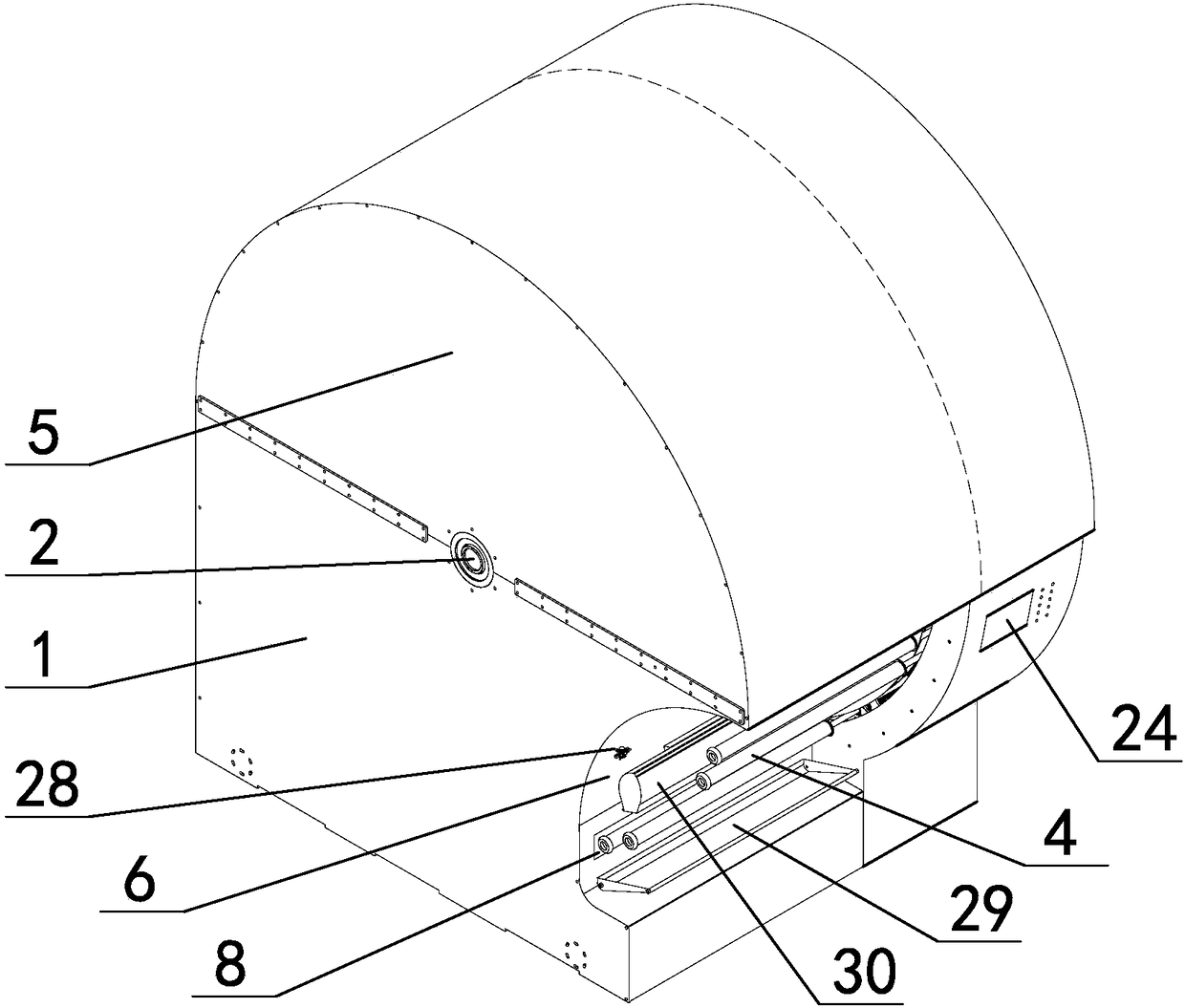

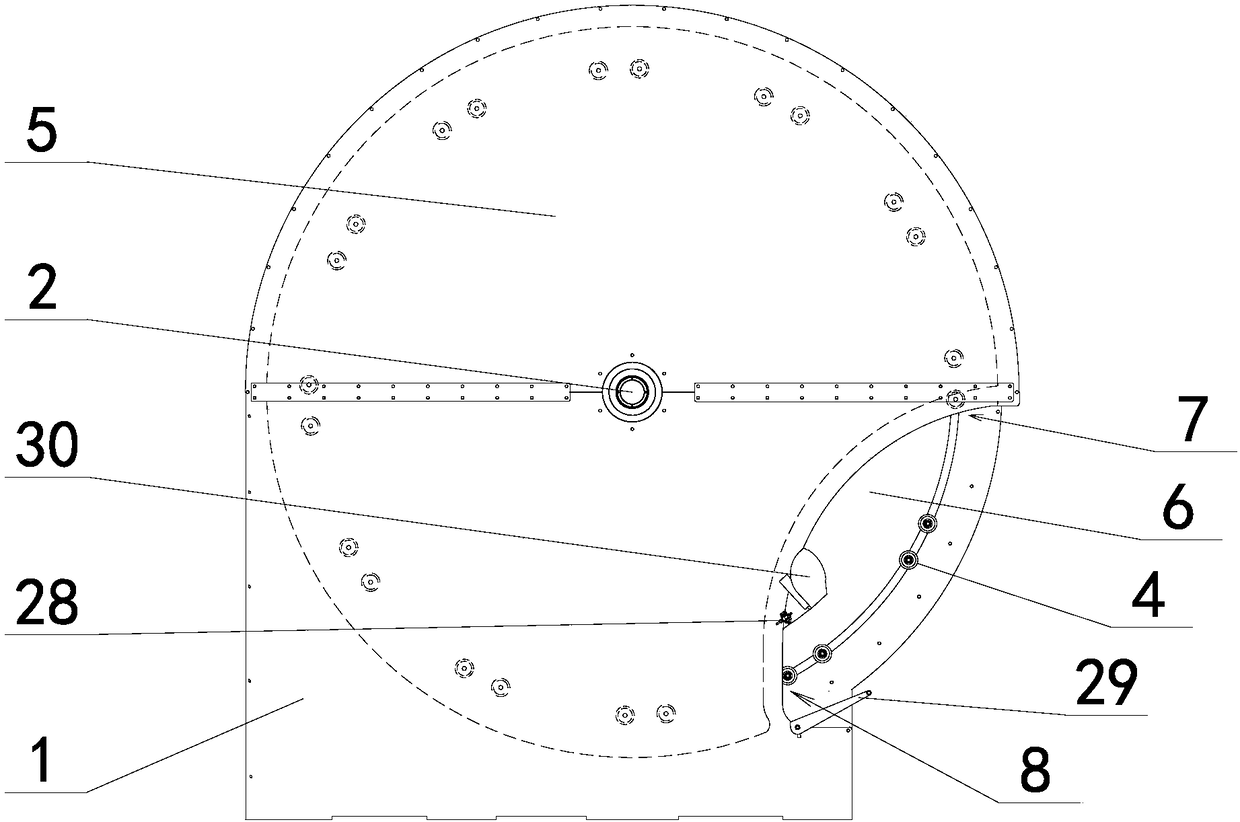

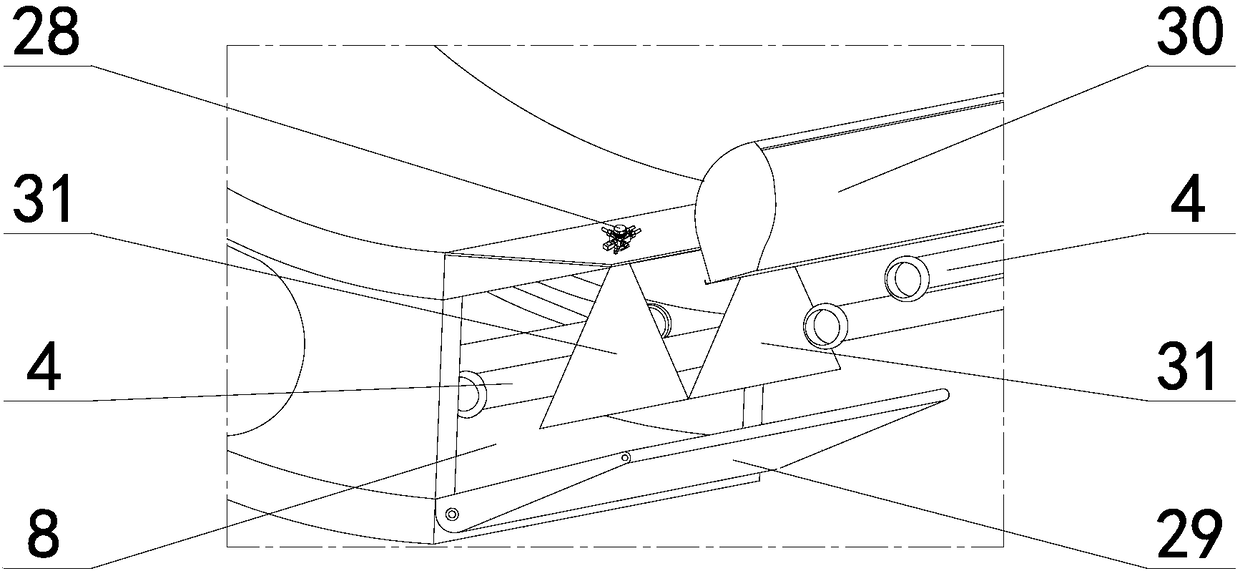

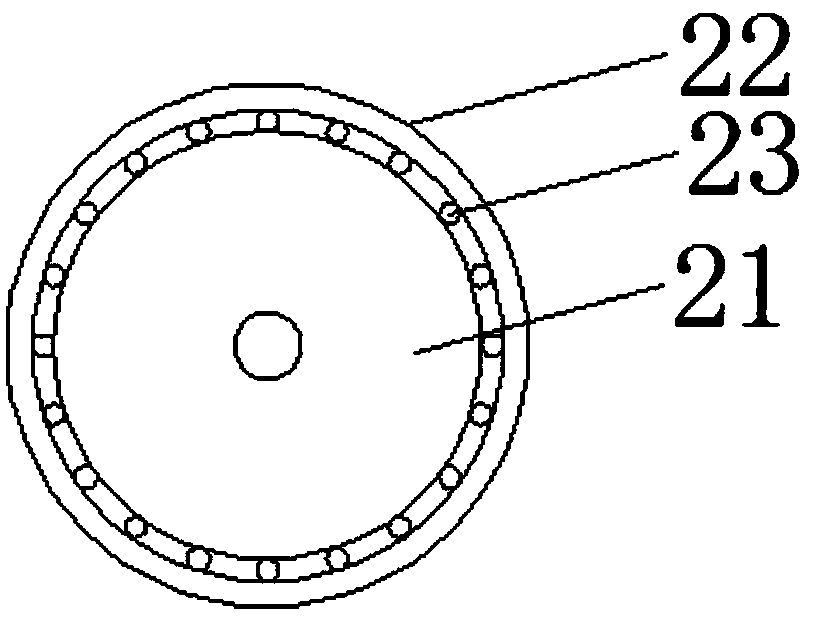

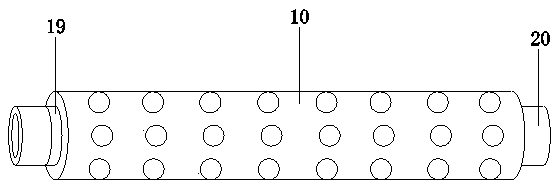

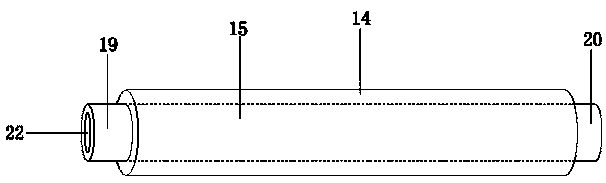

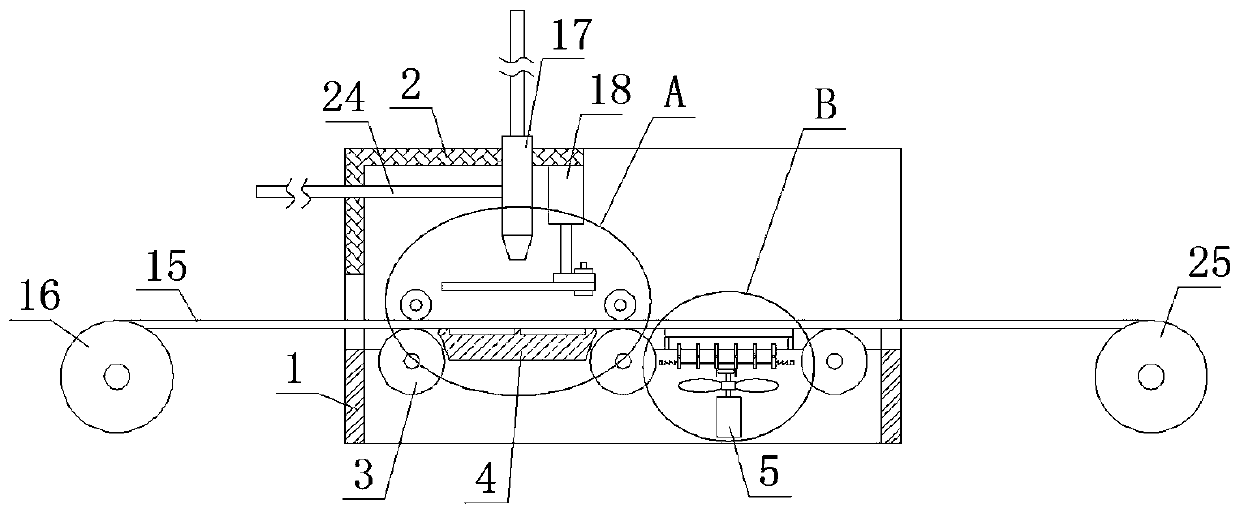

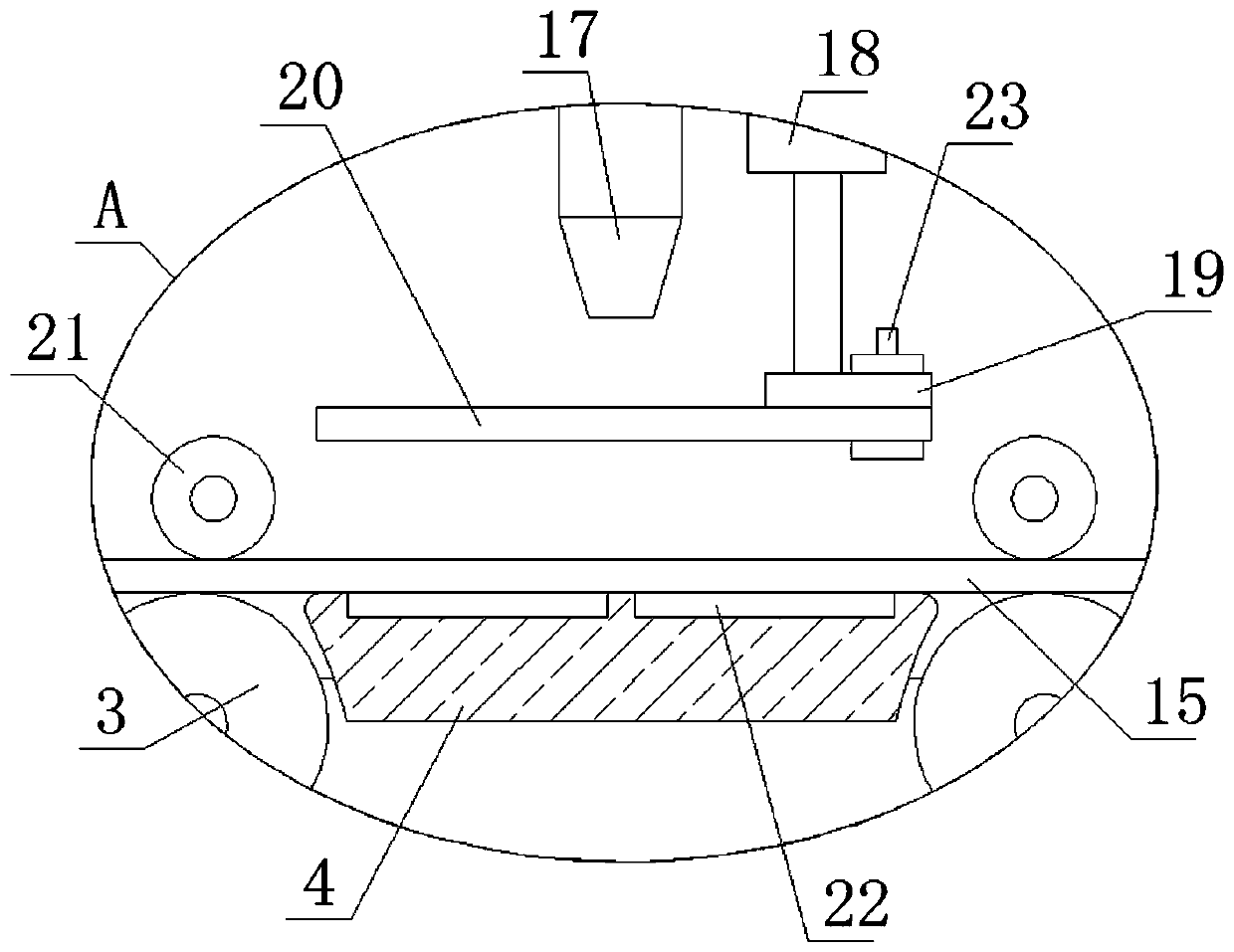

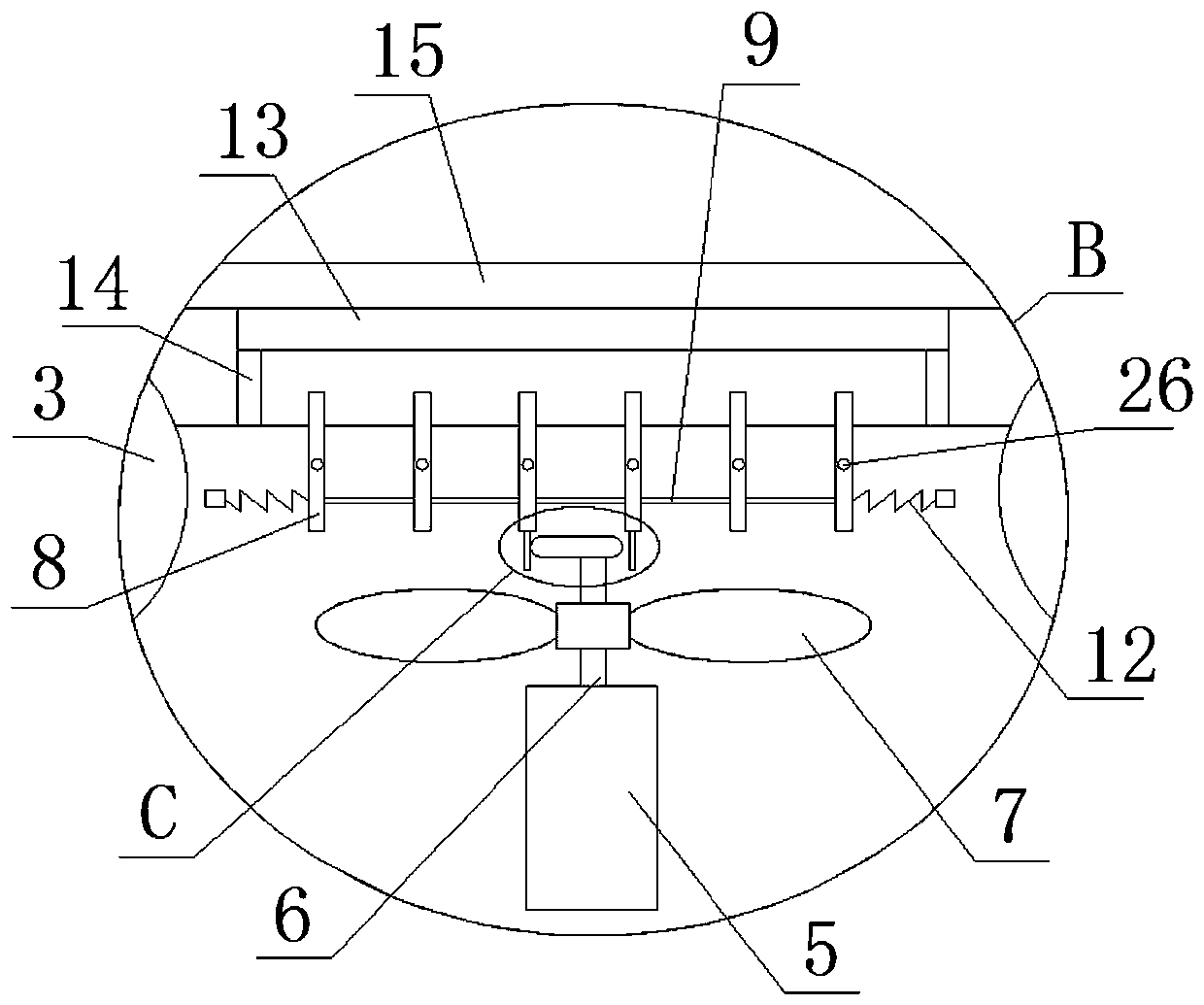

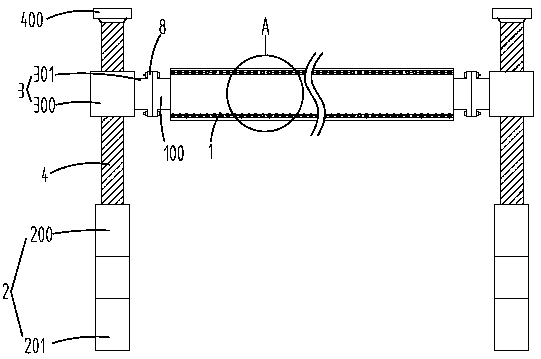

Seamless small tubular fabric setting machine and setting method thereof

ActiveCN109137347APrevent saggingImprove stylingFabric finishing guides/expandersShaping/stretching tubular fabricsEngineeringUltimate tensile strength

The invention discloses a seamless small tubular fabric setting machine. The setting machine comprises a rack, a controller and a setting cavity which is formed in the rack. The rack is provided witha rotary disc with a transverse rotary shaft, the disc surface on one side of the rotary disc is tightly attached to the setting cavity, a plurality of setting frames which are perpendicular to the disc surface of the rotary disc are arranged in the circumferential direction of the rotary disc, each setting frame comprises a fixed roller and a movable roller which are mutually parallel, the fixedrollers and the movable rollers can revolve on their axes, and the roller spacing between each fixed roller and the corresponding movable roller is adjustable. A gap is formed in one side of the setting cavity, a setting frame inlet and a setting frame outlet are formed in the gap, and the setting rack outlet is provided with an atomizing spray head capable of spraying a functional additive and anair cooling device. By means of the seamless small tubular fabric setting machine, the problems are effectively solved that in the prior art, manual setting efficiency of a tubular seamless fabric islow, and the labor intensity of workers is high. By means of the setting machine, the tubular seamless fabric can be automatically set, tensioned and leveled, and the functional additive can be sprayed onto the fabric, the production efficiency is greatly improved, and the setting machine is very high in practical value.

Owner:ZHEJIANG NEU MACHINERY EQUIP CO LTD

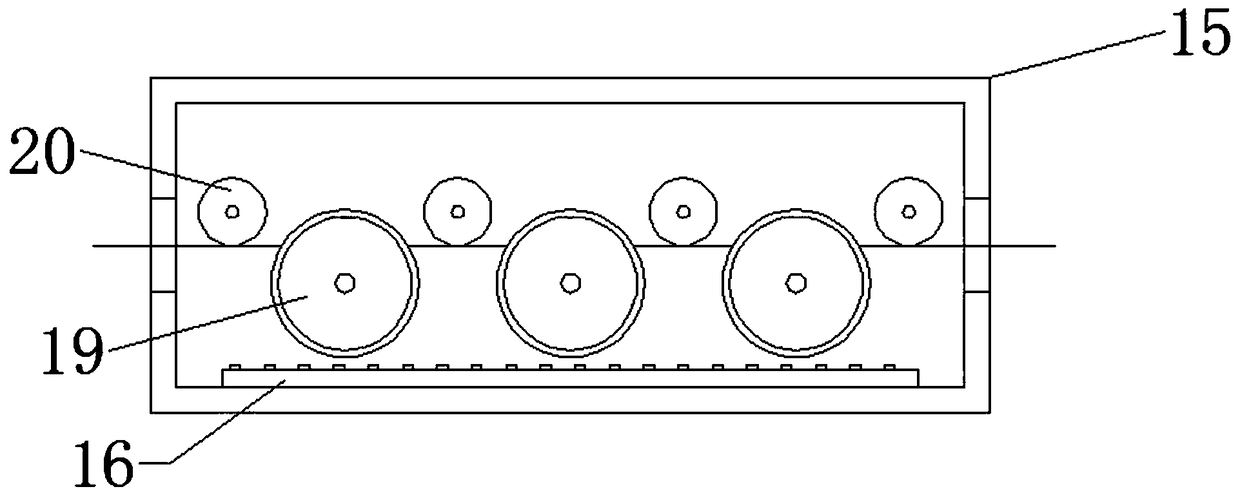

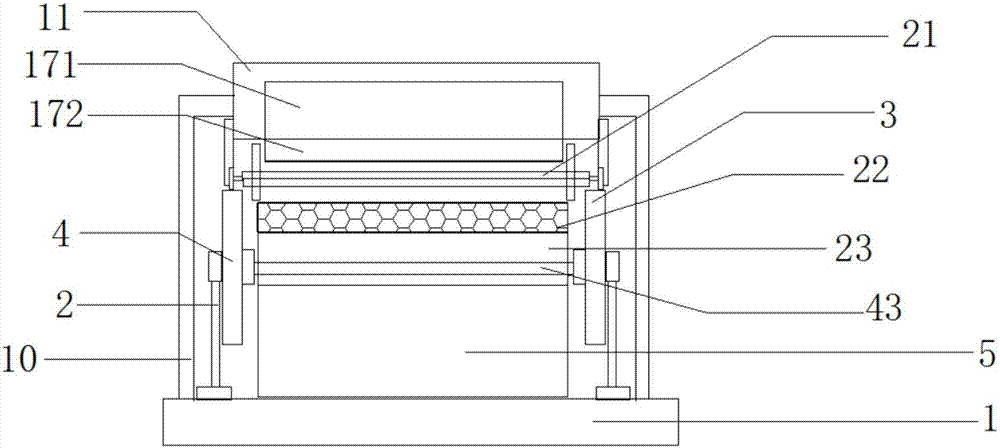

Cloth drying equipment with leveling function used for textile processing

InactiveCN109137334AHeating fastReduce absorptionTextile treatment machine arrangementsFabric finishing guides/expandersEngineeringMechanical engineering

The invention discloses cloth drying equipment with a leveling function used for textile processing. The equipment comprises a box body, a separation plate, a feed inlet, a discharge port, conveyor roller groups, material guide roller groups and a rolling roller. The outer side of the discharge port is correspondingly provided with the rolling roller with driving clicking. Two conveyor roller groups are installed in a drying chamber. A vertical and adjustable scrape plate is arranged between the two conveyor roller groups. The two sides of a drying box are provided with the material guide roller groups. Clothes are sent to the drying box through the material guide roller groups. The right side of the drying box is provided with a leveling device. In the invention, the water of the sent clothes can be scraped under the effect of the scrape plate in the drying chamber, the scrape plate can adjust pressure according to the different materials of the clothes and the like, the water in theclothes can be scraped safely, the water absorbed in the clothes is reduced and a drying effect is increased. A contact roller in the drying box is fully contacted with the clothes, and high temperature air blown into from a lower portion can directly heat the contact roller so that the clothes can be heated rapidly.

Owner:陈璐

Textile fabric shaping, production and processing device

InactiveCN110067105AGuaranteed flatnessGuaranteed cleanlinessMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention provides a textile fabric shaping, production and processing device. The textile fabric shaping, production and processing device comprises a processing box, wherein a mounting frame ismounted in the processing box; and a fabric is conveyed on the mounting frame, a negative-pressure neatening mechanism, an incineration mechanism, a smoothening mechanism and a dust cleaning mechanismare separately mounted on the mounting frame in the fabric conveying direction, a rolling mechanism is installed outwards during processing, and after being subjected to singeing treatment, home textile fabrics are subjected to rotary scraping cleaning of ash incineration by using the dust cleaning mechanism before rolling; and during cleaning, rotation switching of the dust cleaning mechanism isutilized, a pressing roller is used for carrying out rolling and tensioning adjustment and smoothening treatment on the fabric to be rolled, the fabric is always smooth in a rolling process, and theproblem that the fabric has wrinkles in the rolling process after singeing is solved.

Owner:浙江常鑫纺织品有限公司

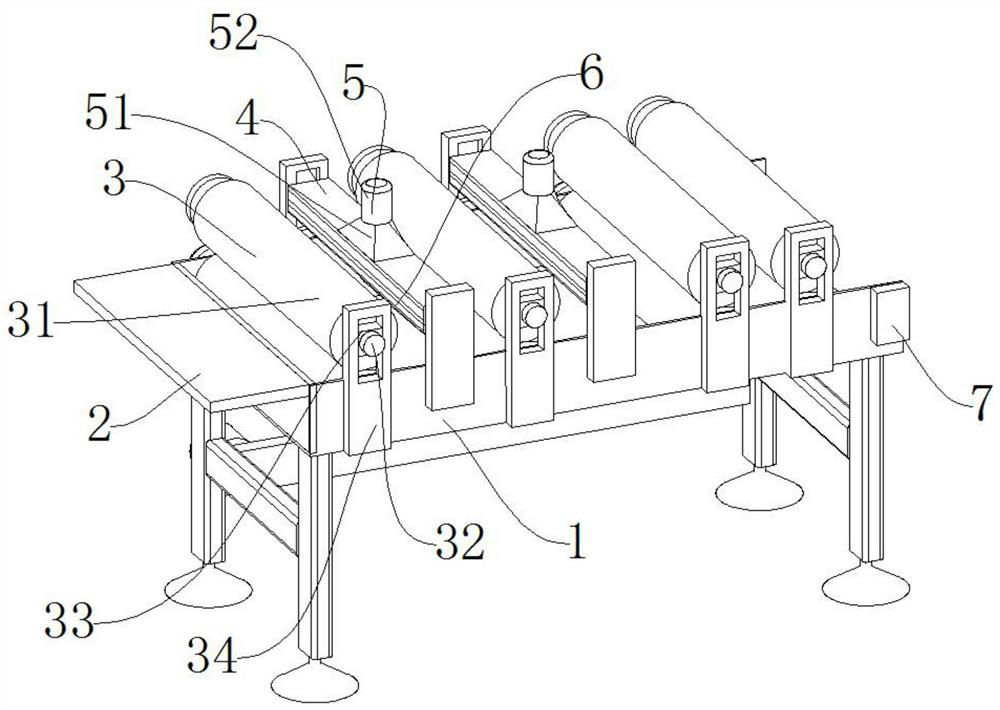

Continuous ironing device for textiles

InactiveCN108914472AImprove processing efficiencyIngenious structureFabric finishing guides/expandersFabric steaming/decatisingElectric machineryEngineering

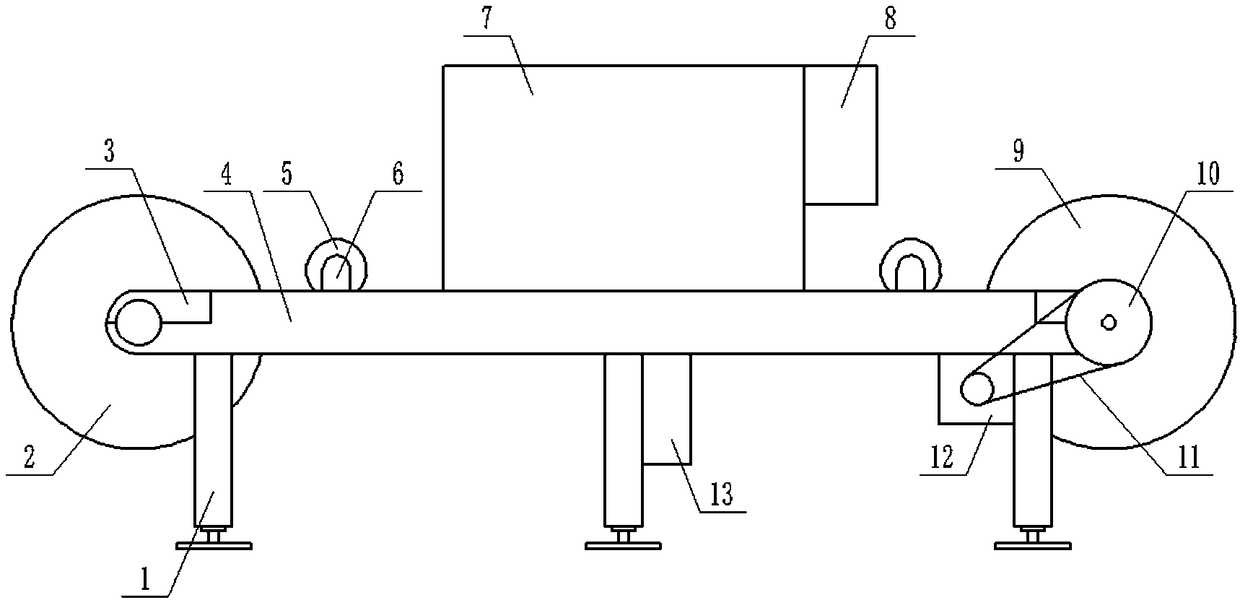

The invention discloses a continuous ironing device for textiles. The continuous ironing device comprises a frame and a device rack, wherein the frame is fixed on the ground; the device rack is suspended above the frame; the upper plane of the frame is provided with a conveyor belt; an unreeling roller and a wind-up roller are respectively arranged at two sides of the frame; a wind-up motor is arranged below the wind-up roller, is in transmission connection with the wind-up roller and controls the rotation of the wind-up roller; and a tension roller is arranged above the wind-up roller and fixed at the edge of the frame. According to the invention, a hollow ironing roller is arranged and inserted into a corrugated pipe used for supplying high-temperature steam, and the high-temperature ironing roller performs continuous ironing on cloth and jets high-temperature steam; compared with a conventional elevating hot-pressing ironing manner, the continuous ironing device of the invention issubstantially improved in processing efficiency; and the continuous ironing device is ingenious in structure and applicable to ironing of cloth of different thicknesses, and has good applicability.

Owner:伍超群

Textile cloth ironing and pressing device

PendingCN108642786ALow technical requirementsEasy to operateFabric finishing guides/expandersUltimate tensile strengthIndustrial engineering

The invention discloses a textile cloth ironing and pressing device which comprises a stand column, a feeding roller, a cover body and a rack. The stand column is arranged on the rack; the cover bodyis arranged on one side, far away from the stand column, of the rack; the feeding roller is arranged on one side of the cover body; a support frame is arranged on one side of the feeding roller; a guiding roller is arranged on the support frame; an ironing and pressing tank is arranged on one side, far away from the feeding roller, of the guiding roller; a water tank is arranged on one side of theironing and pressing tank; a winding roller is arranged on one side, far away from the guiding roller, of the ironing and pressing tank; a belt pulley is arranged on one side of the winding roller; an electromotor is arranged on one end, far away from the belt pulley, of a driving belt. The textile cloth ironing and pressing device provided by the invention has the beneficial effects of higher automation degree, simplicity in operation, low labor intensity, convenience in use, capabilities of greatly reducing the requirement on operation skills of workers, reducing the manpower cost, realizing automatic ironing and pressing, and improving the production efficiency, and higher economical efficiency.

Owner:SUZHOU CHENXUAN TEXTILE & TECH CO LTD

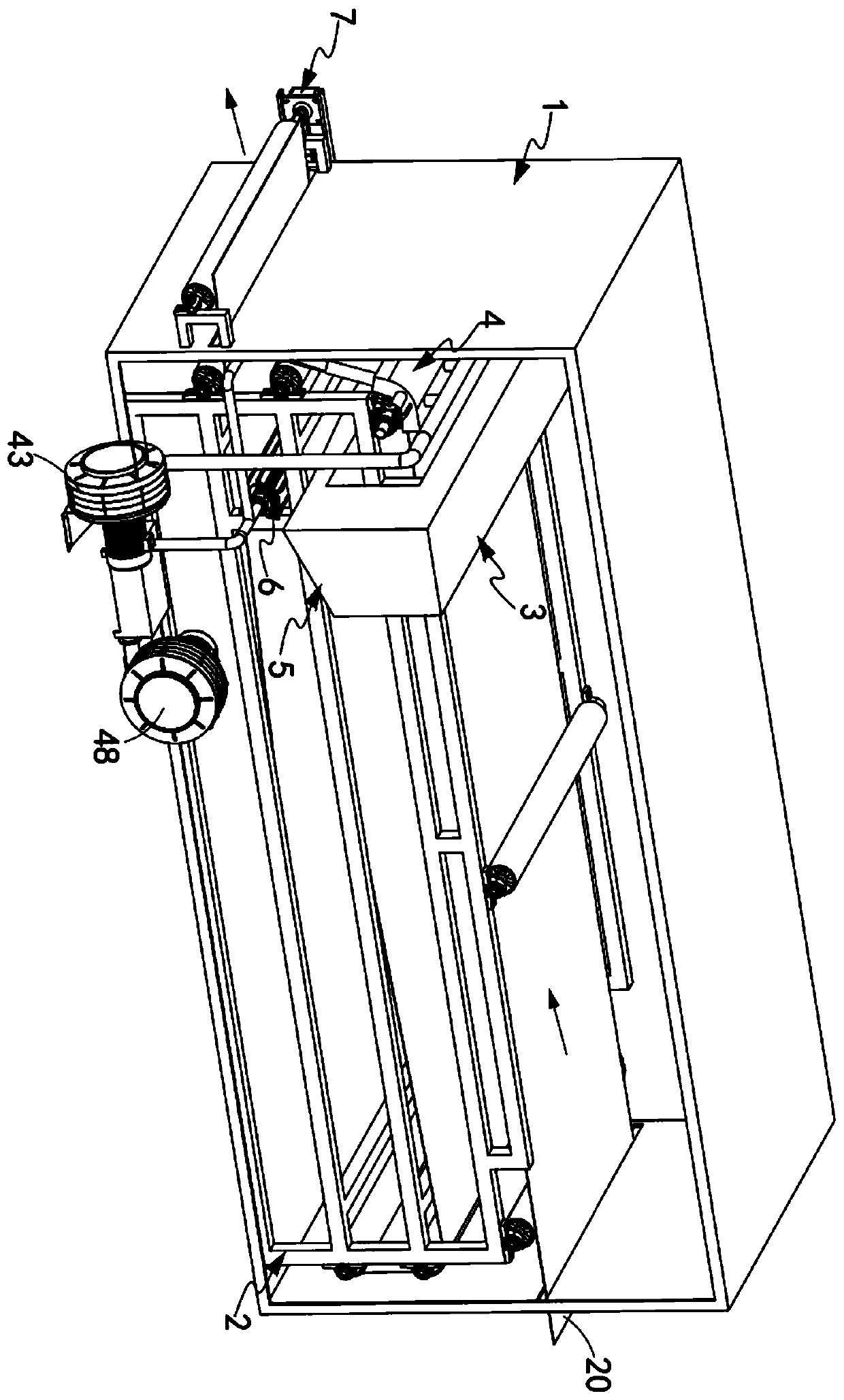

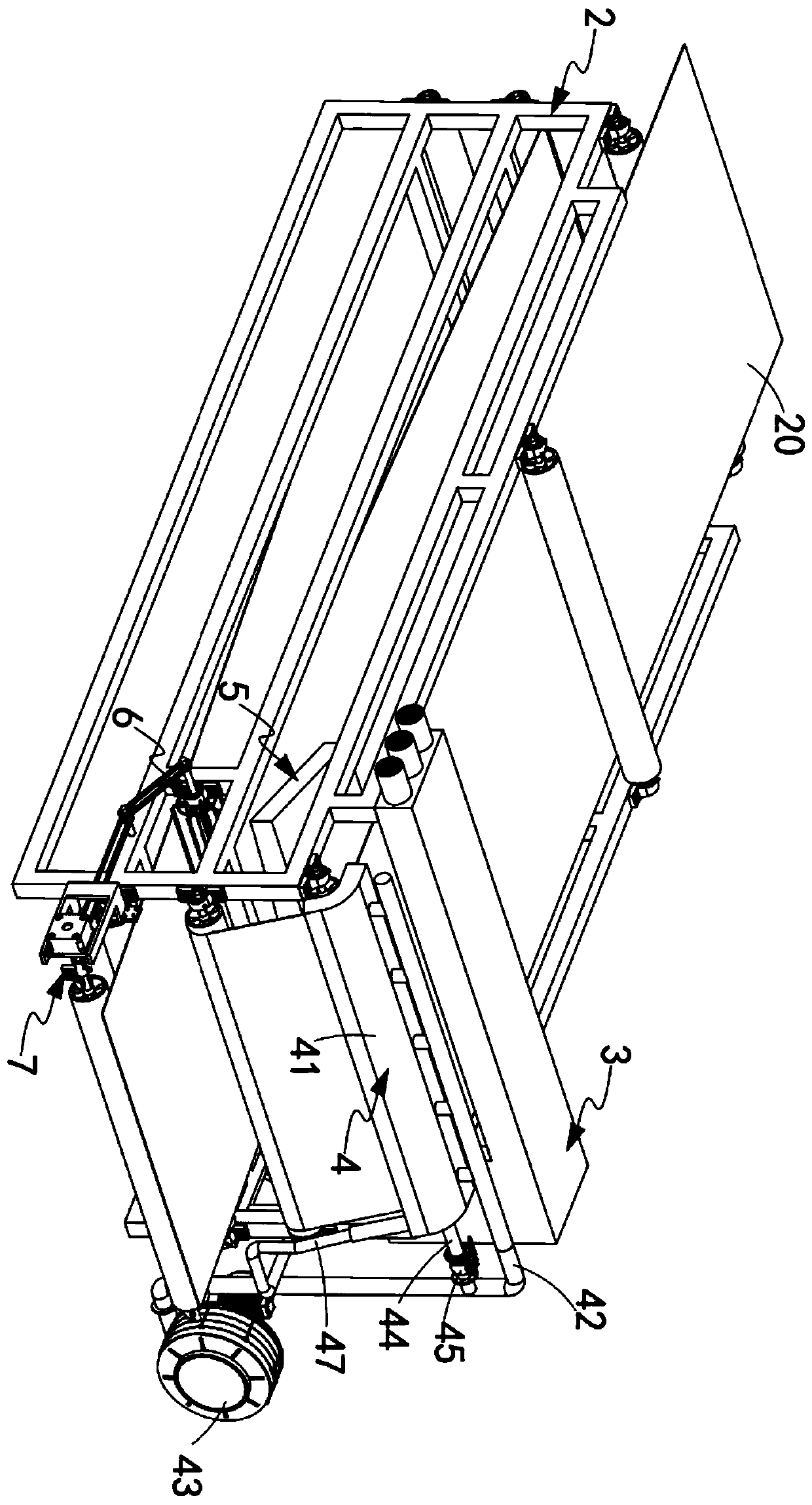

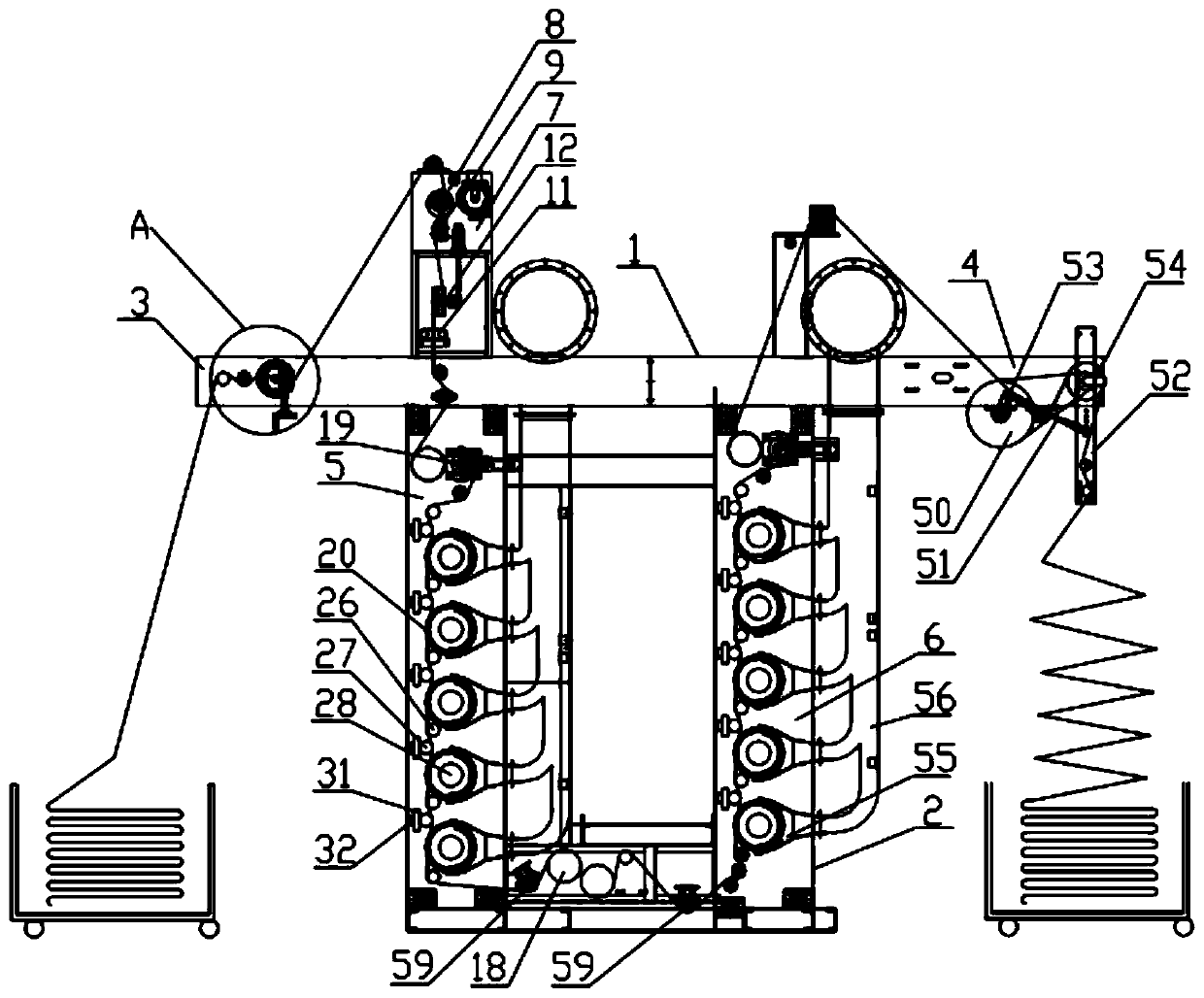

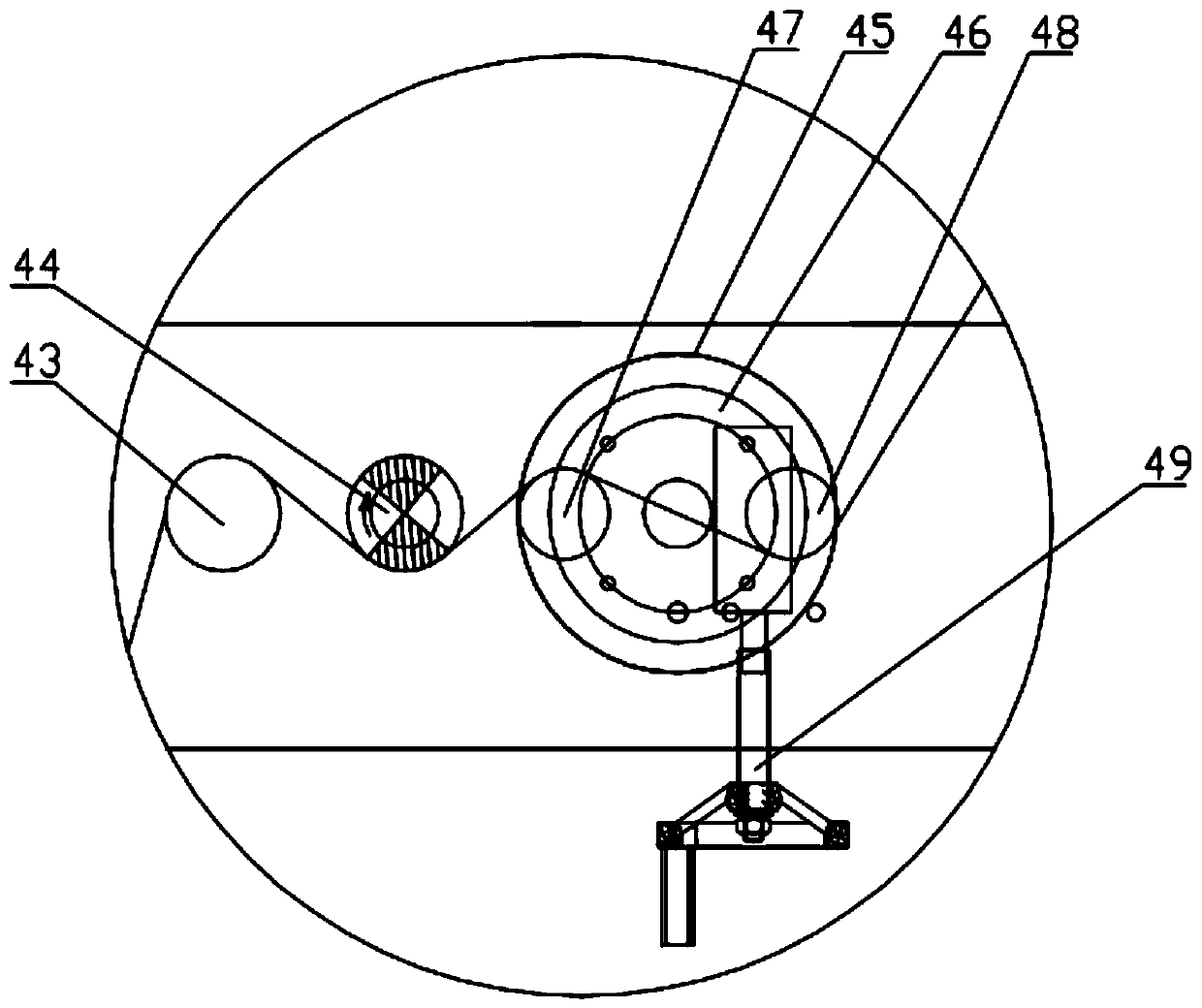

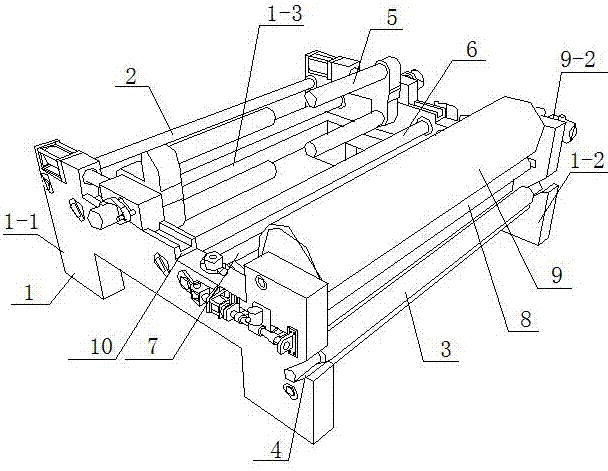

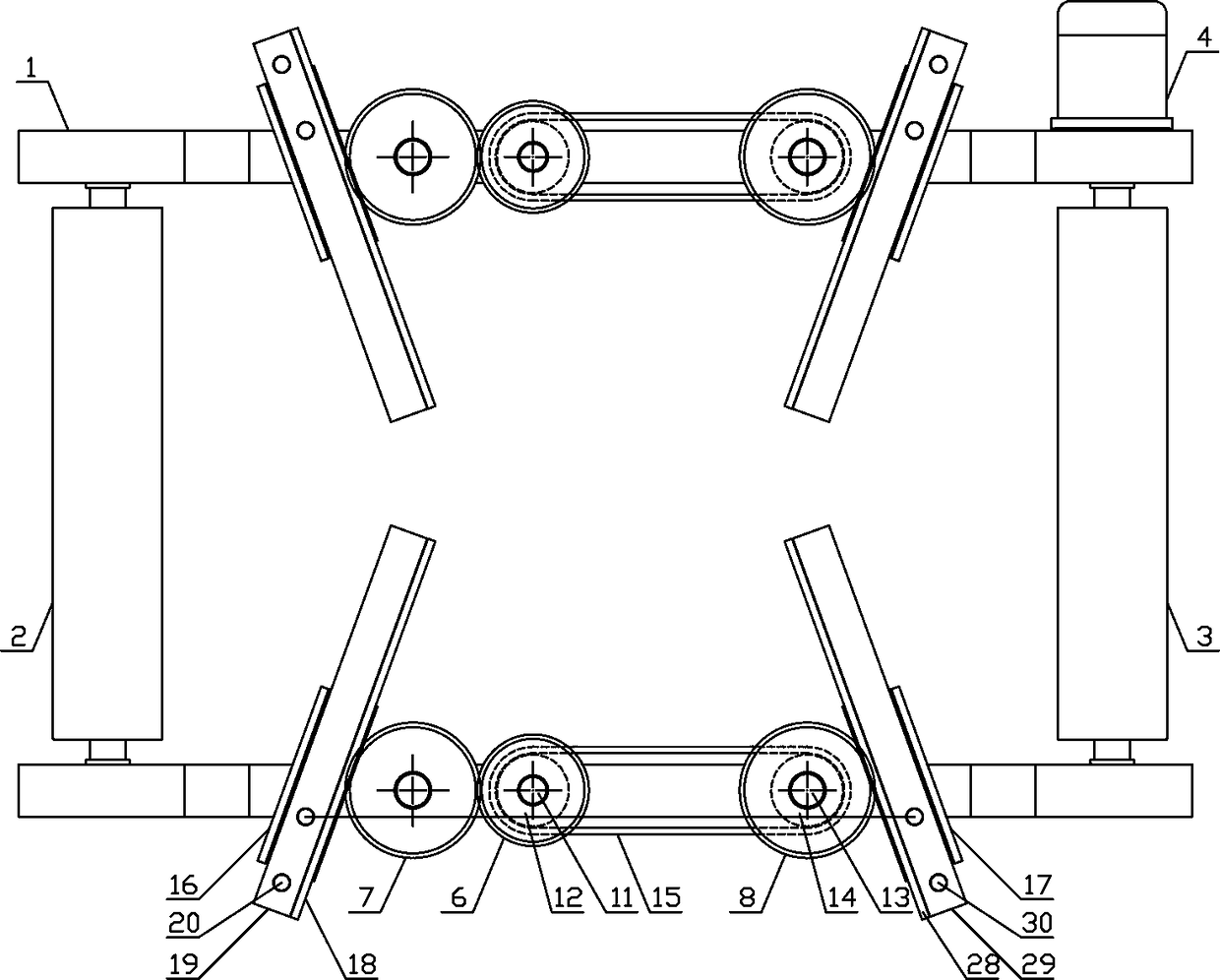

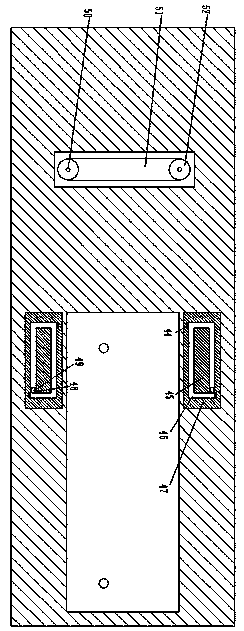

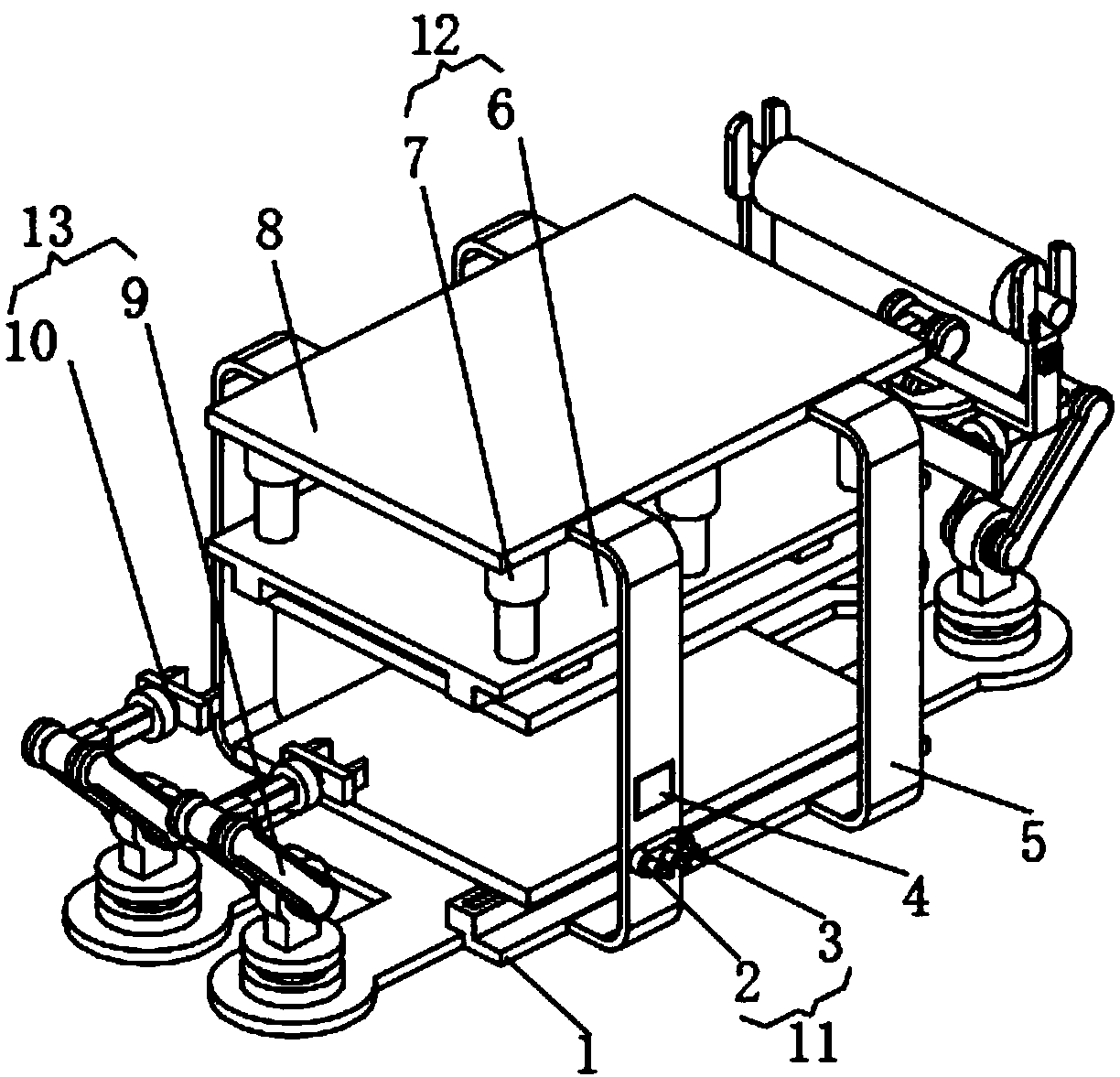

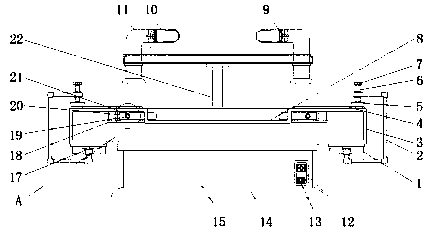

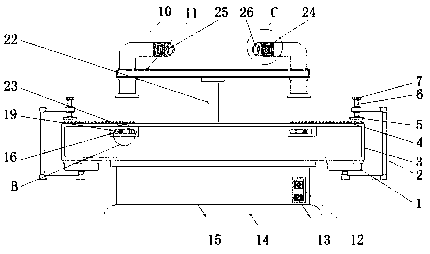

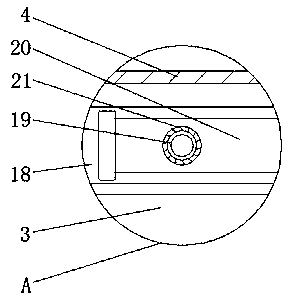

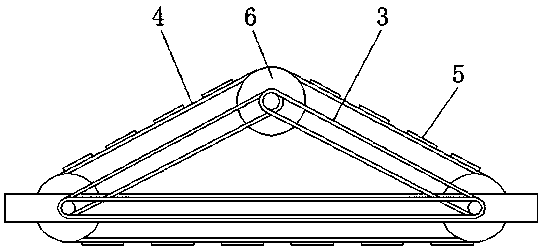

Front and back double-sided sueding machine

PendingCN110331546AAchieve the effect of removing needle pathsImprove sanding effectFabric finishing guides/expandersRougheningActive tensionEngineering

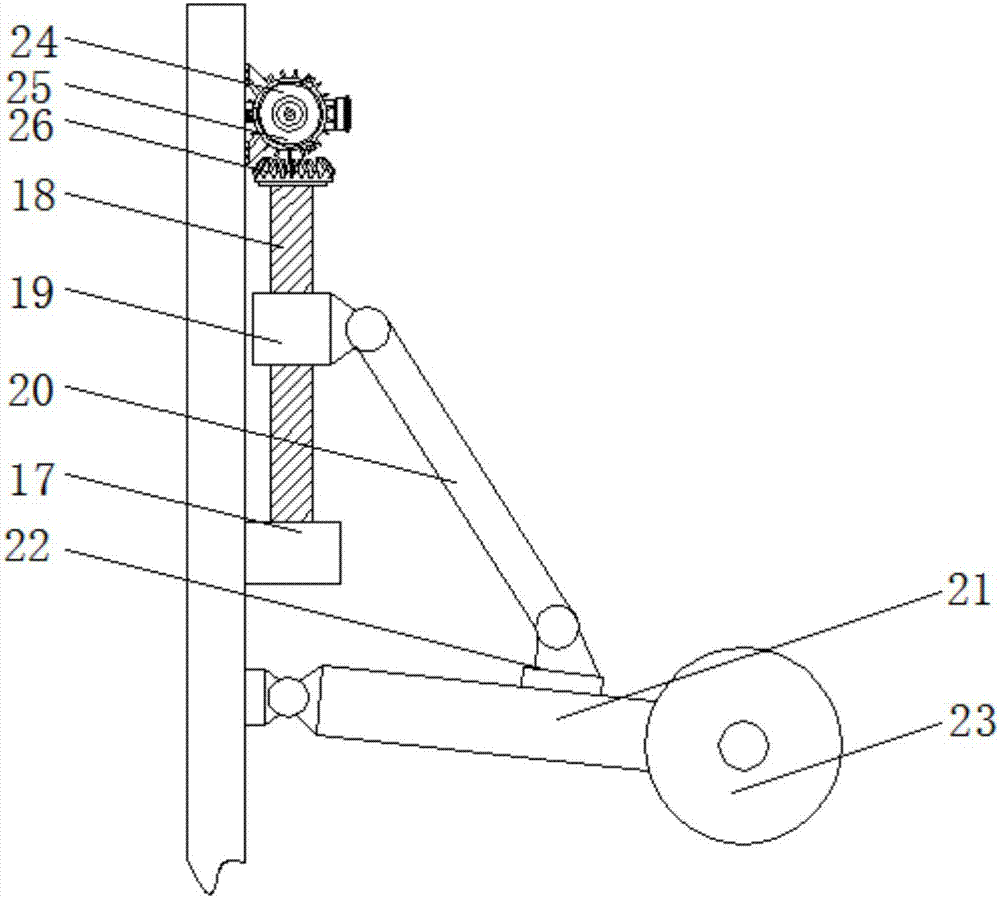

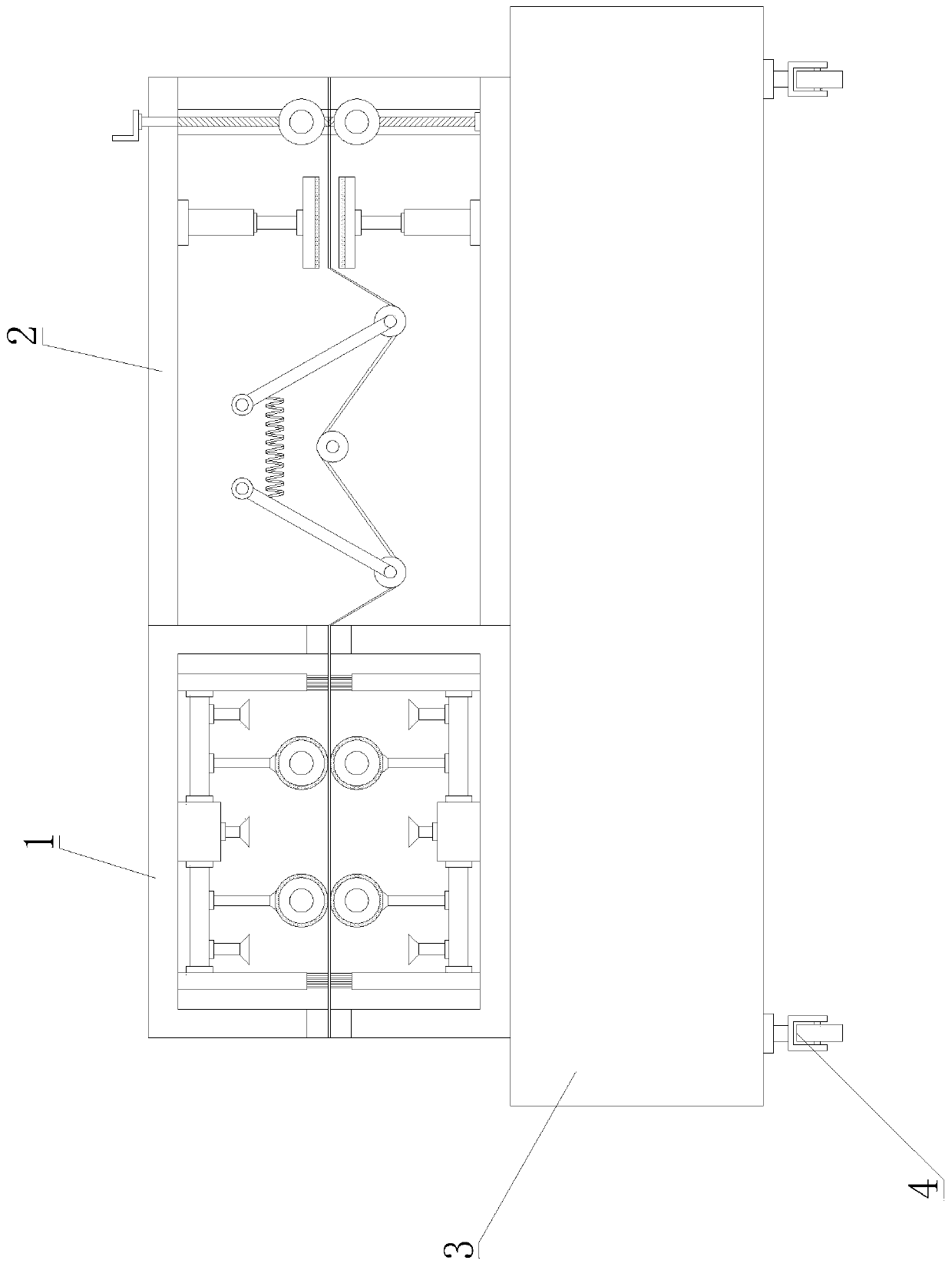

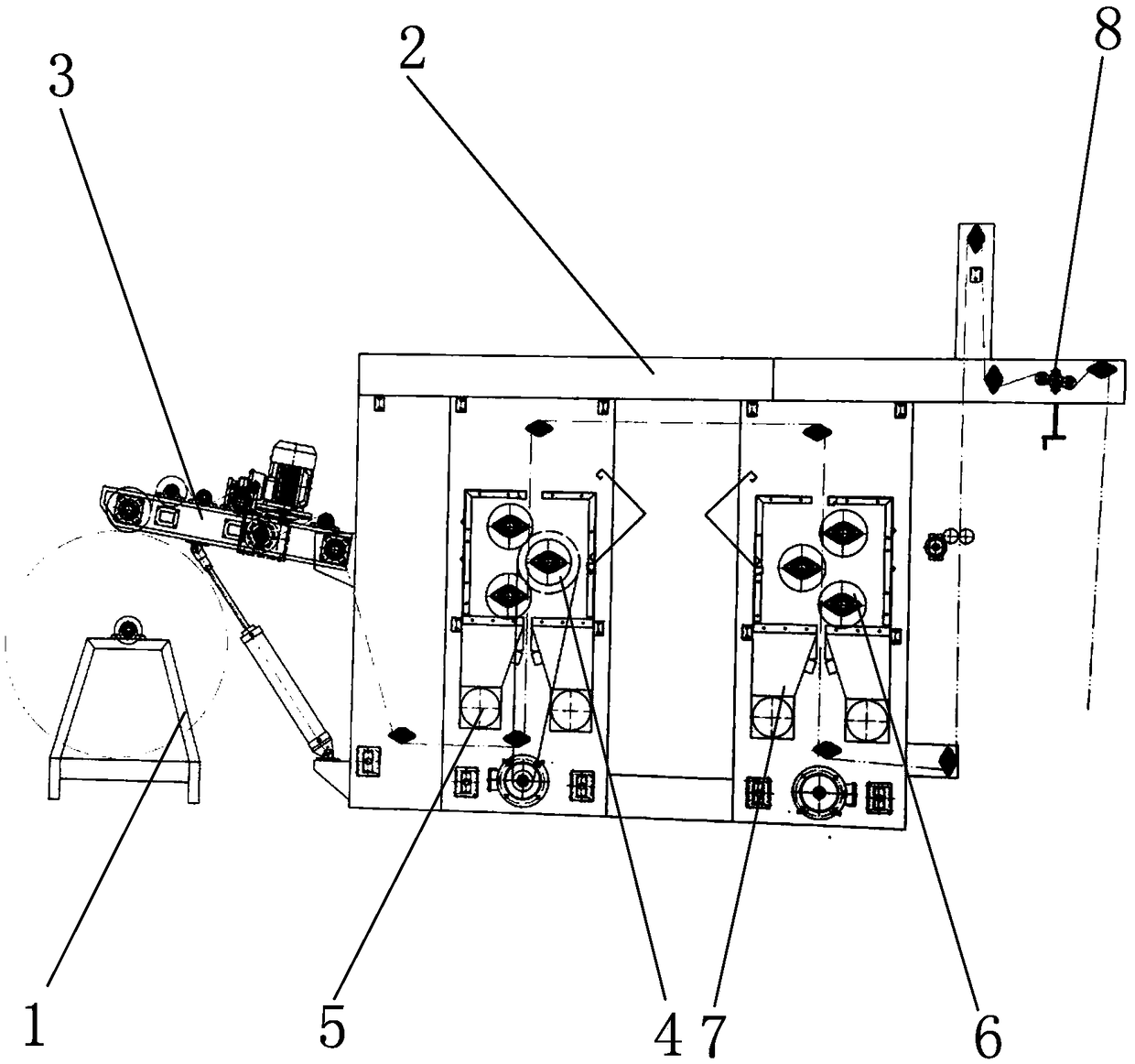

The invention relates to a front and back double-sided sueding machine. The machine comprises a cross frame and vertical frames, wherein a cloth feeding mechanism and a cloth discharging mechanism arearranged at two ends of the cross frame respectively, a front sanding mechanism and a back sanding mechanism are arranged in the vertical frames, a cloth centering mechanism is arranged right above the front sanding mechanism, and each of the front sanding mechanism and the back sanding mechanism comprises an active tension adjusting assembly and a sanding assembly; each sanding assembly comprises a pressing roller and a sanding roller, a pressing driving assembly is arranged on one side of the pressing roller, and a pressing fine adjustment assembly is arranged on one side of the pressing drive assembly. Front and back sides of cloth are sanded by the front sanding mechanism and the back sanding mechanism, the cloth is located at the center by the cloth centering mechanism, and the sanding effect is enhanced; tension of the cloth before sanding is adjusted by the active tension adjustment assemblies, the fitting degree of the cloth and the sanding rollers is adjusted by the pressingdrive assemblies and the pressing fine adjustment assemblies, so that sanding requirements of different cloth surfaces are met, the left and right shifting sanding is realized by the sanding assemblies, and the effect of removing needle lines is achieved.

Owner:佛山市南海区新元机械有限公司

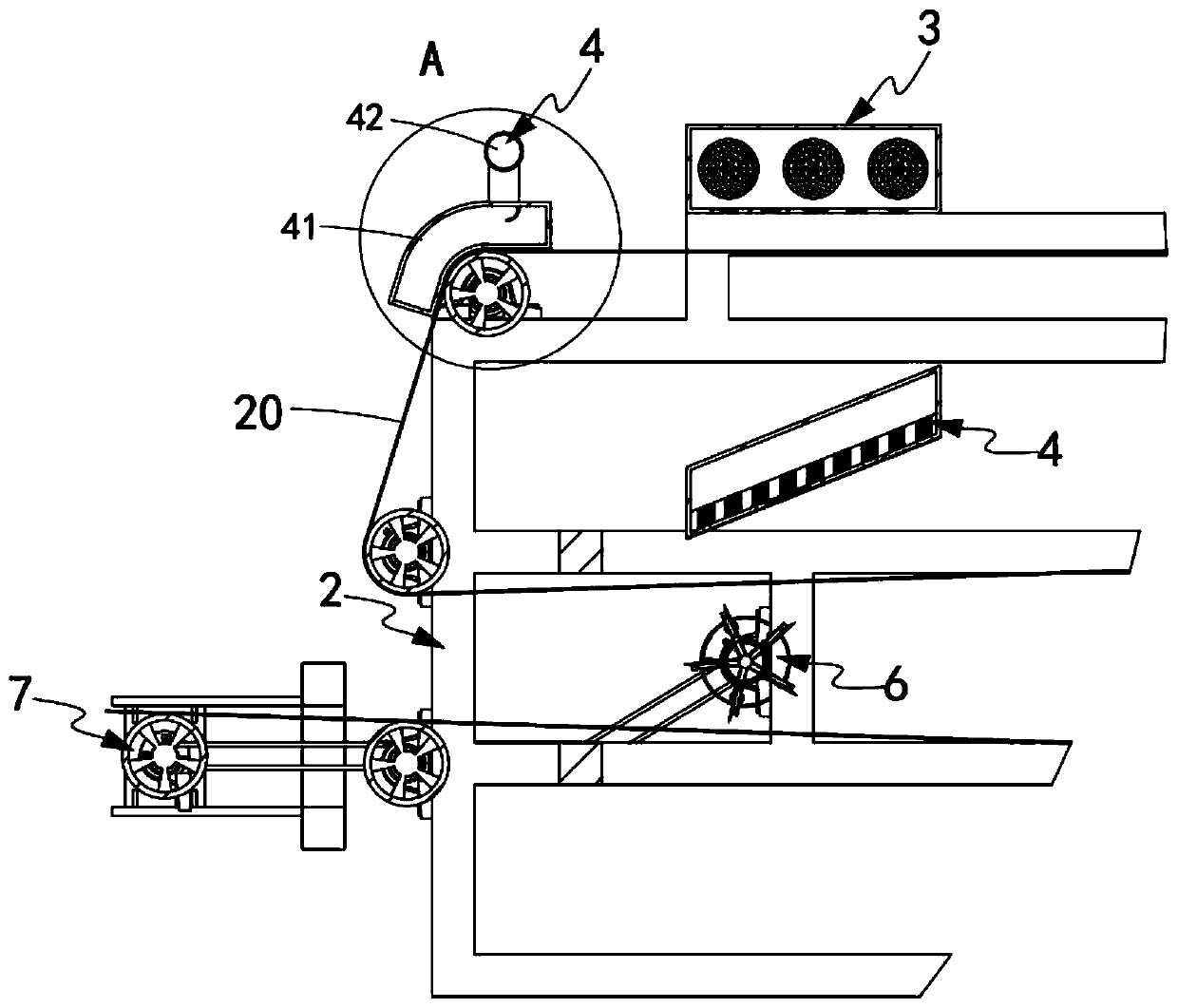

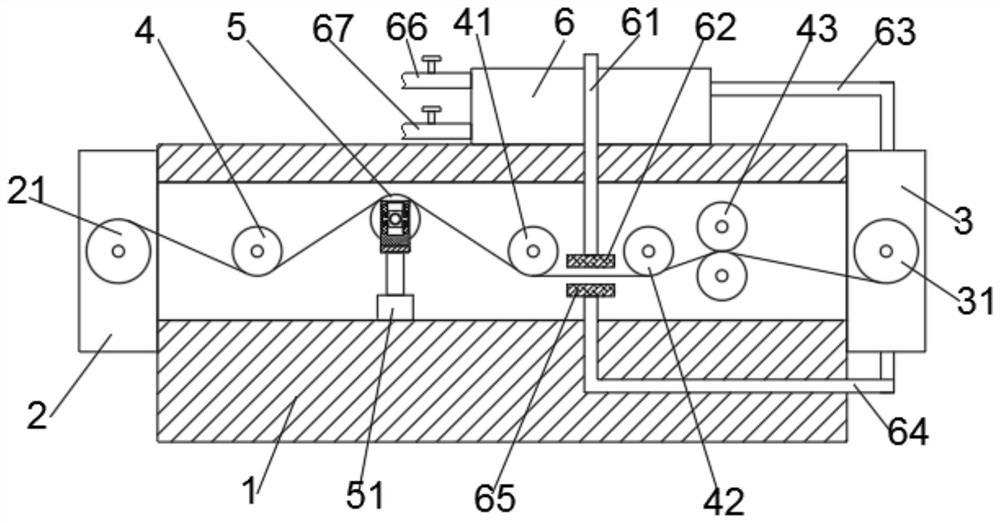

Jet-propelled ironing device with tensioning mechanism for garment processing

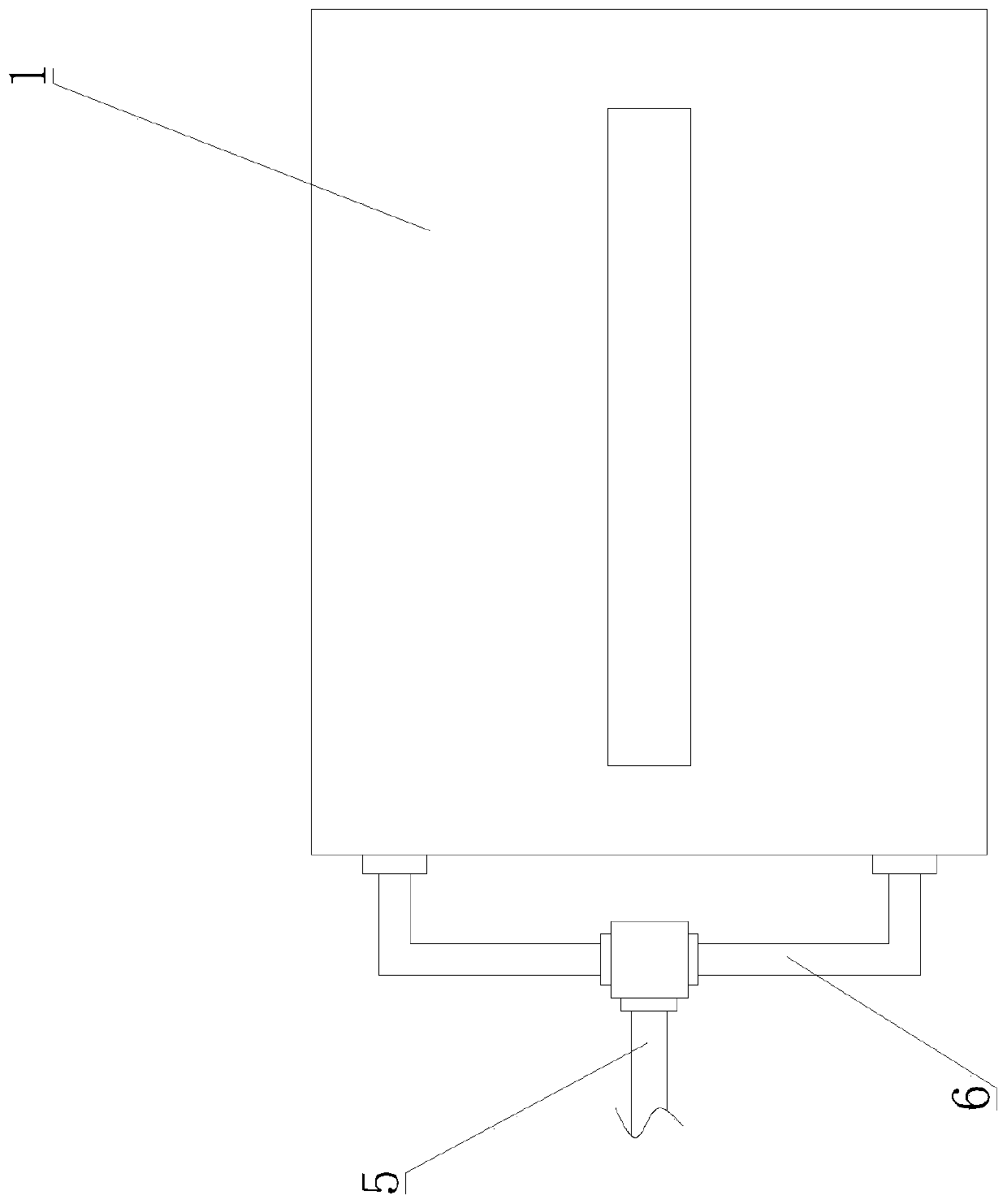

InactiveCN112726088AEasy to adjust tensionPlay the role of elastic tensionFabric finishing guides/expandersTextile treatment by spraying/projectingStructural engineeringMechanical engineering

The invention discloses a jet-propelled ironing device with a tensioning mechanism for garment processing in the technical field of garment processing. The jet-propelled ironing device comprises a box body; an unwinding mechanism is arranged on the outer wall of one side of the box body; an unwinding roller is arranged on the unwinding mechanism; a winding mechanism is arranged on the other side of the box body; a winding roller is arranged on the winding mechanism; a first movable roller, a tensioning roller, a second movable roller, a third movable roller and a fourth movable roller are sequentially arranged in the box body from left to right; a tensioning mechanism is arranged outside the tensioning roller, so that double-sided ironing can be conveniently conducted on cloth needed by garment processing, the ironing effect is relatively excellent, and the tension degree of the cloth can be conveniently adjusted; and through arrangement of a spring, a limiting block, a limiting groove and other components, the cloth can be elastically tensioned, the ironing effect of the cloth can be improved through adjustment of the tension degree, the use effect is relatively excellent, and relatively high practicability is achieved.

Owner:SHAANXI INST OF INT TRADE & COMMERCE

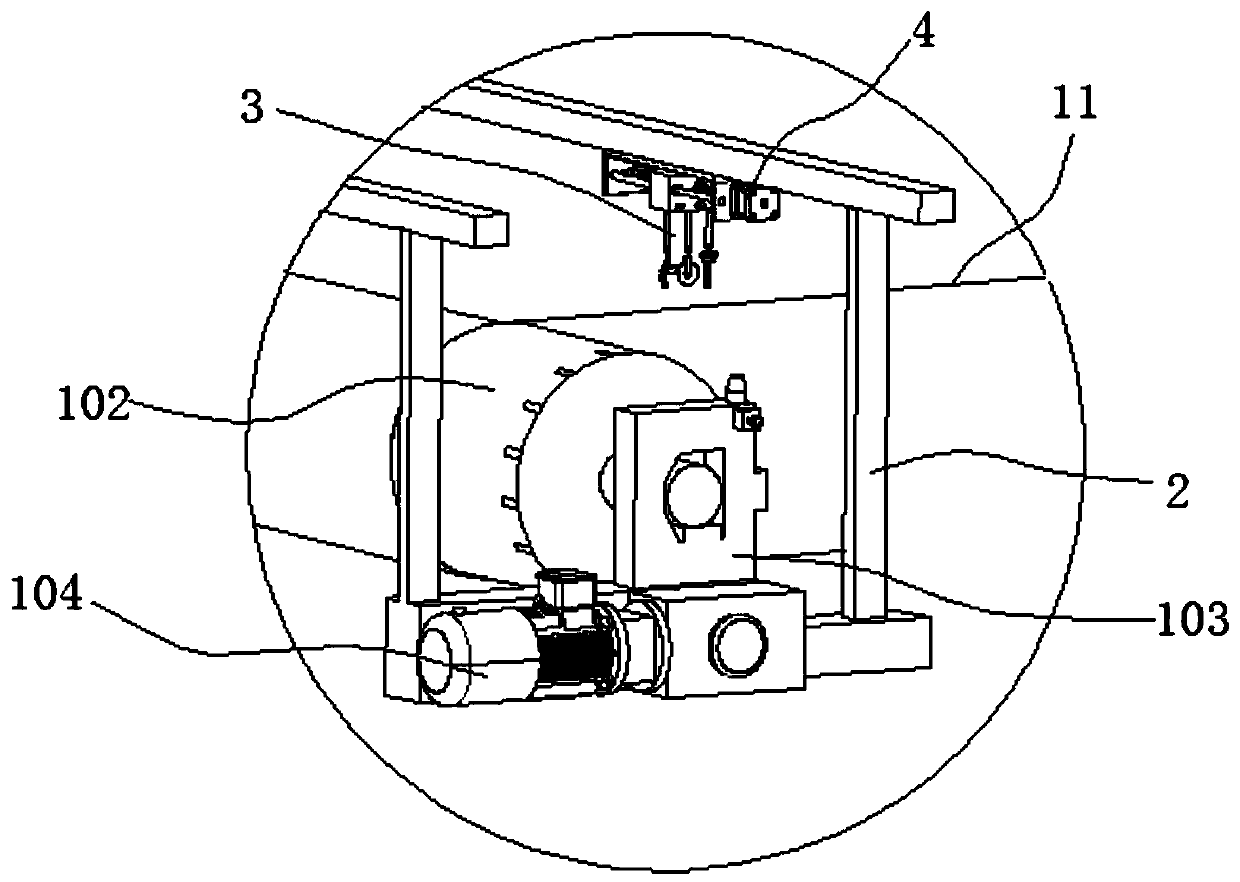

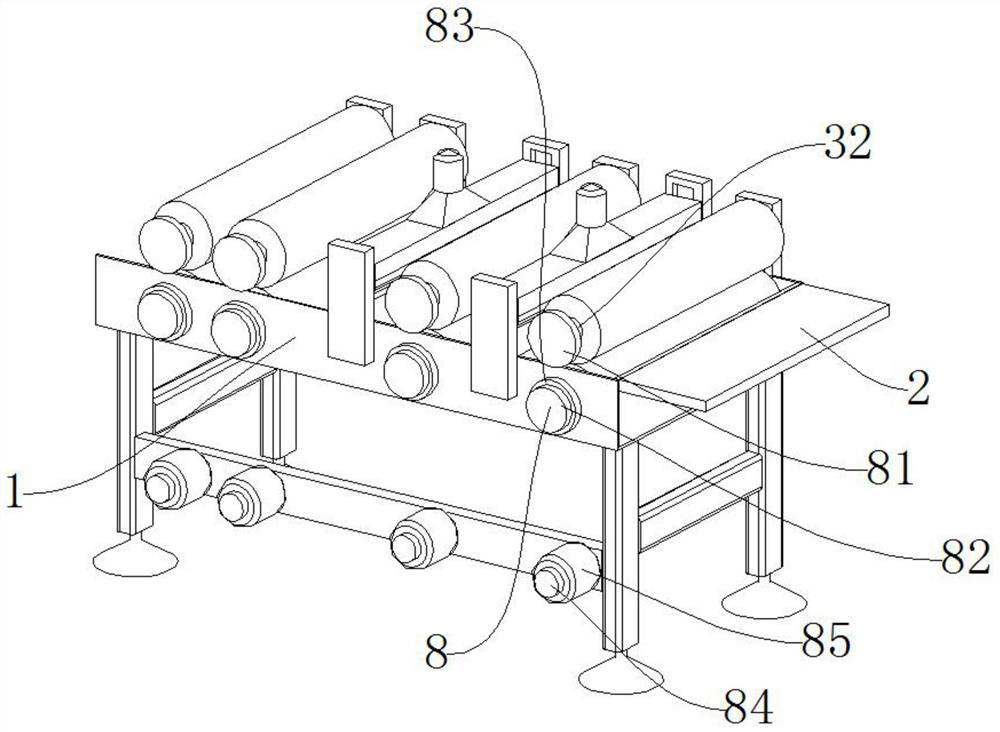

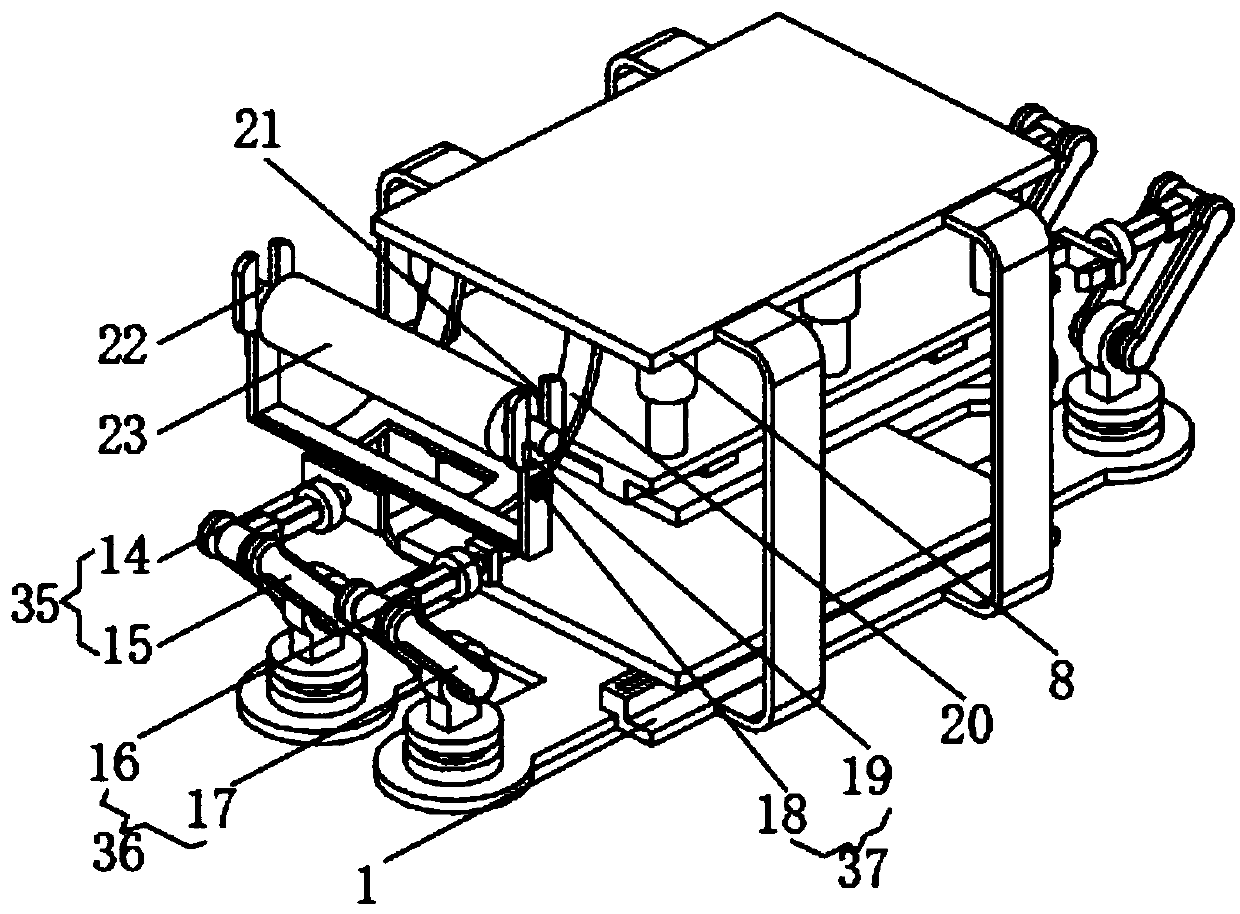

Unhairing equipment for waste textile fabric

InactiveCN109695120AStable deliveryAchieve anti-wrinkle levelingMechanical cleaningPressure cleaningWrinkle skinMechanical equipment

The invention discloses unhairing equipment for a waste textile fabric and belongs to the field of textile mechanical equipment. The unhairing equipment comprises a supporting table, an emptying device, a lower unhairing device, an upper unhairing device, a wrinkle-removing device, a spraying device, a drying device and a rolling device. The emptying device, the wrinkle-removing device, the dryingdevice and the rolling device are arranged on the supporting table along a straight line, an unhairing window is formed in the supporting table, the unhairing window is located between the emptying device and the wrinkle-removing device, the lower unhairing device and the upper unhairing device are separately located right below and right above the unhairing window, the spraying device is mountedon the wrinkle-removing device, positioning devices are arranged on two sides of the unhairing window, mounting seats are arranged between the drying device and the rolling device on the supporting table, and two transitional rollers are rotatably mounted on the mounting seats. The unhairing equipment unhairs the upper and lower surfaces of the waste textile fabric automatically and can remove wrinkles and level the waste textile fabric, so that the quality of the upper and lower surfaces of the waste textile fabric is improved.

Owner:曹钧恩

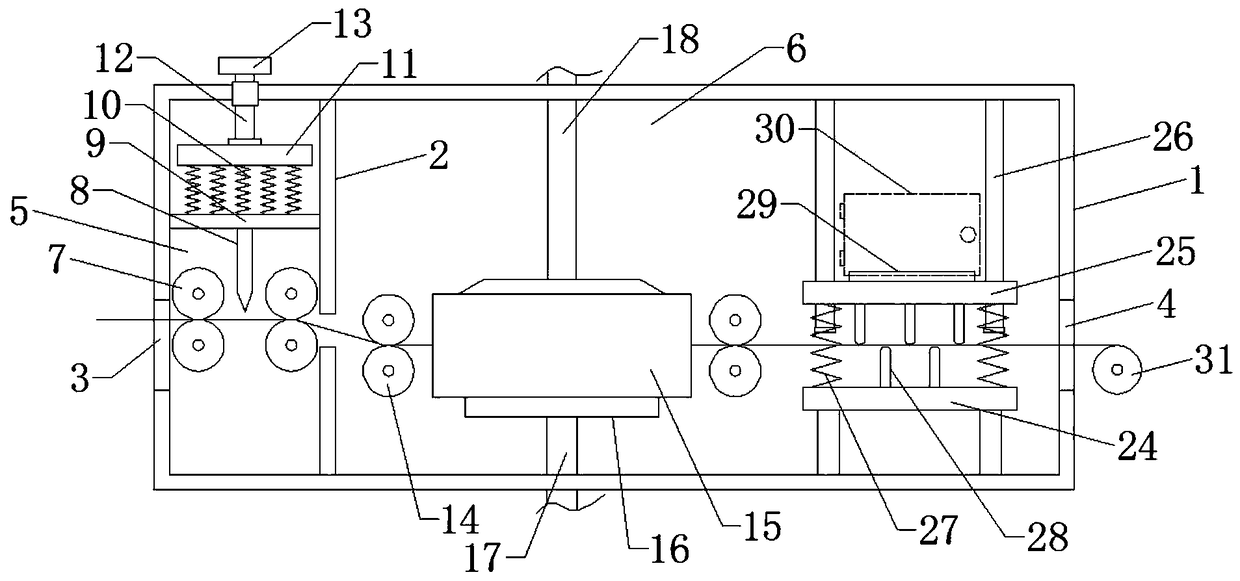

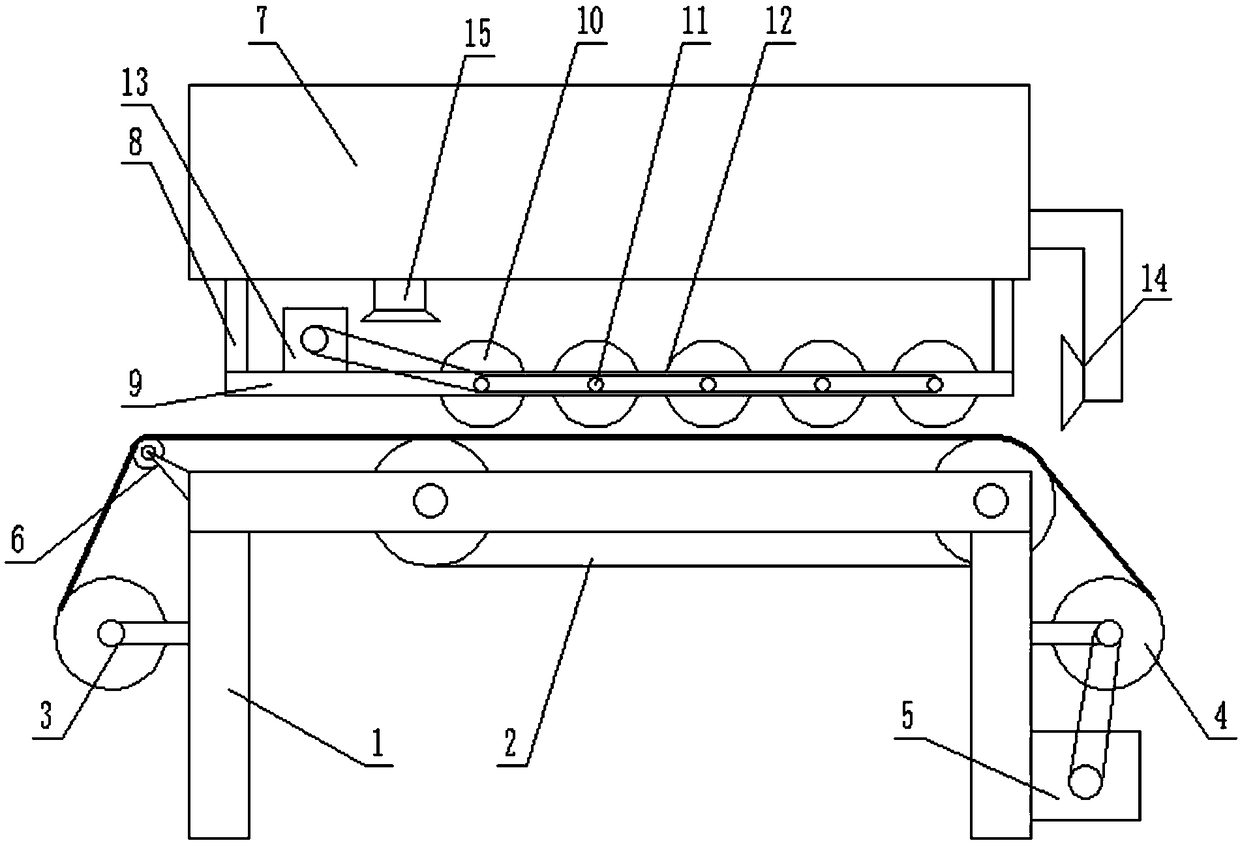

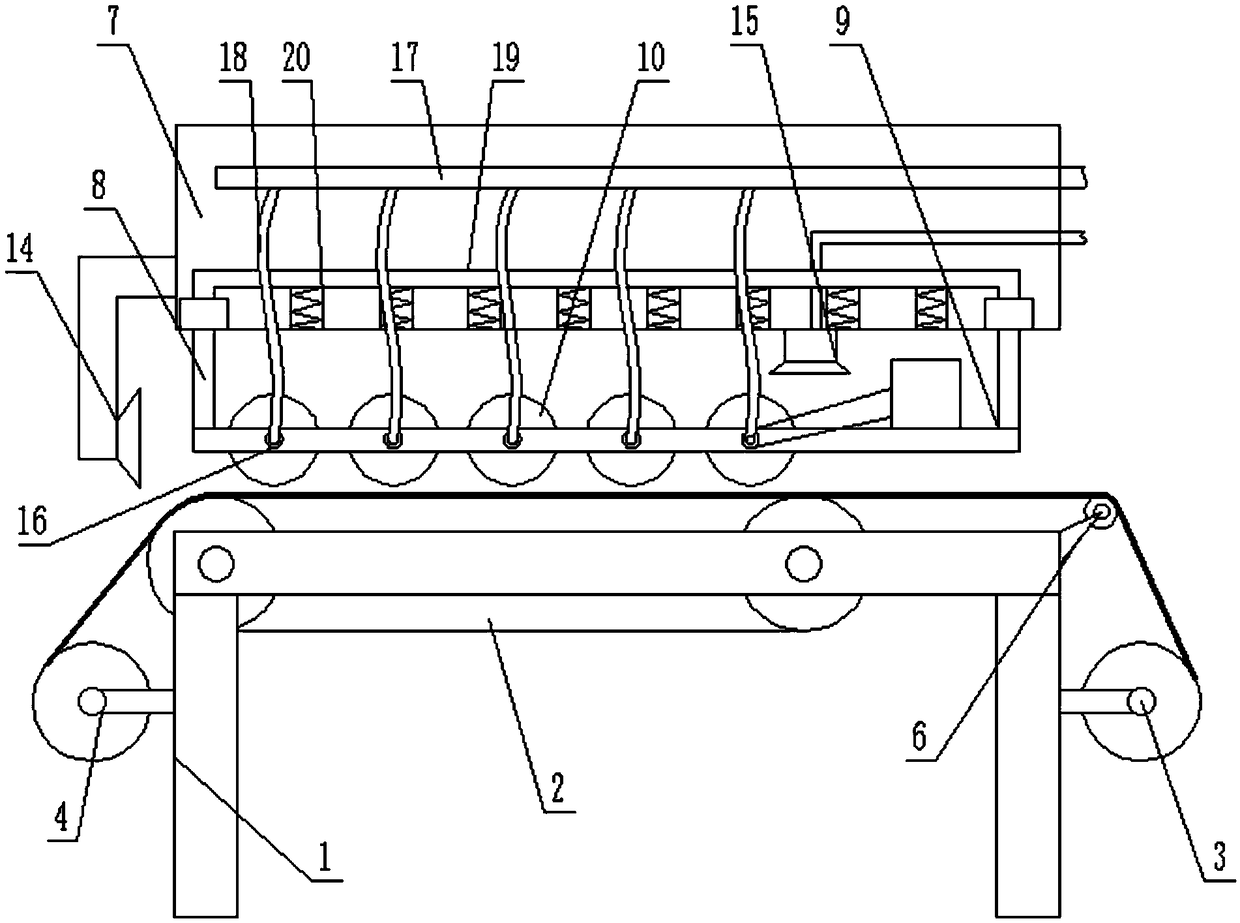

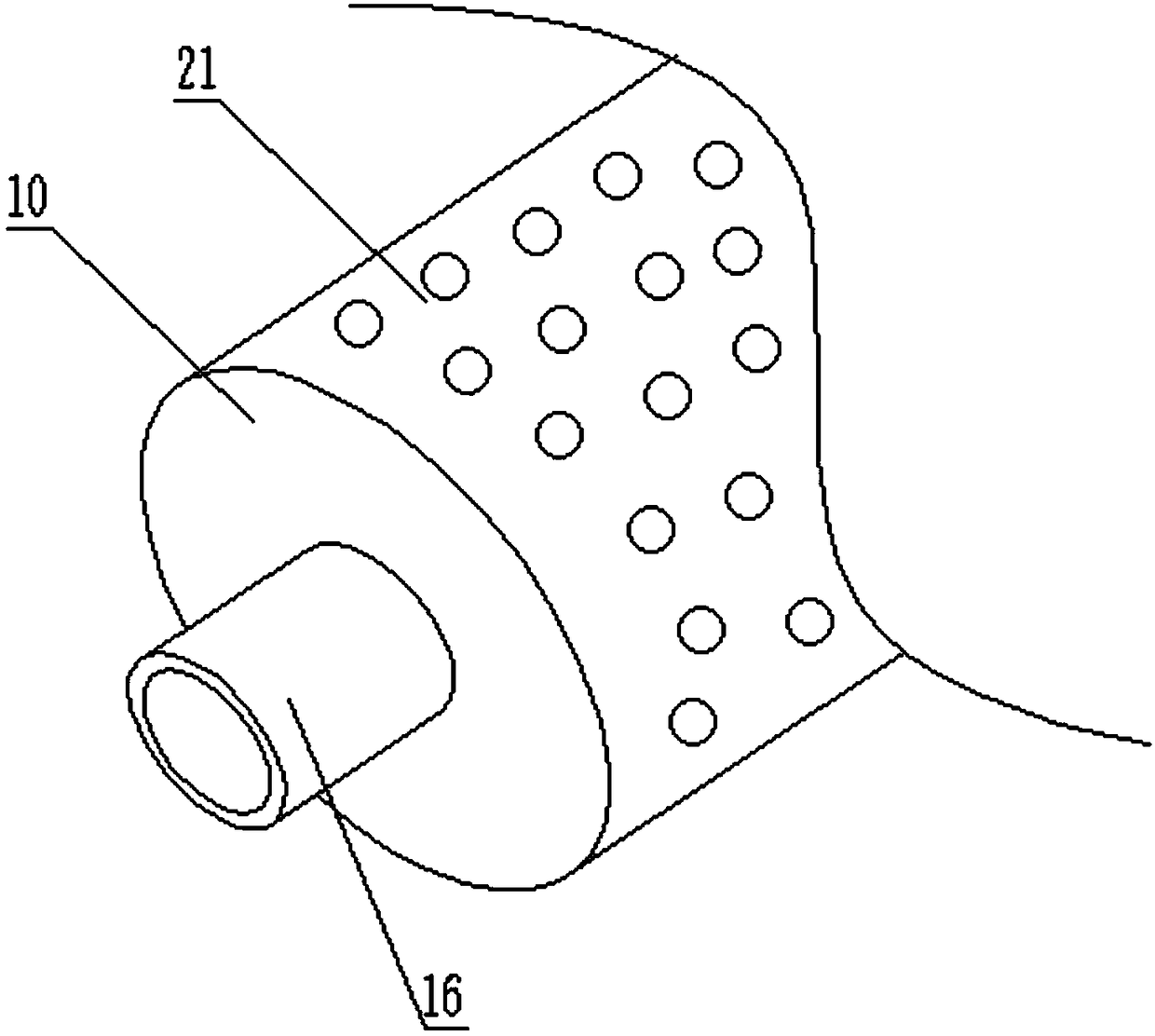

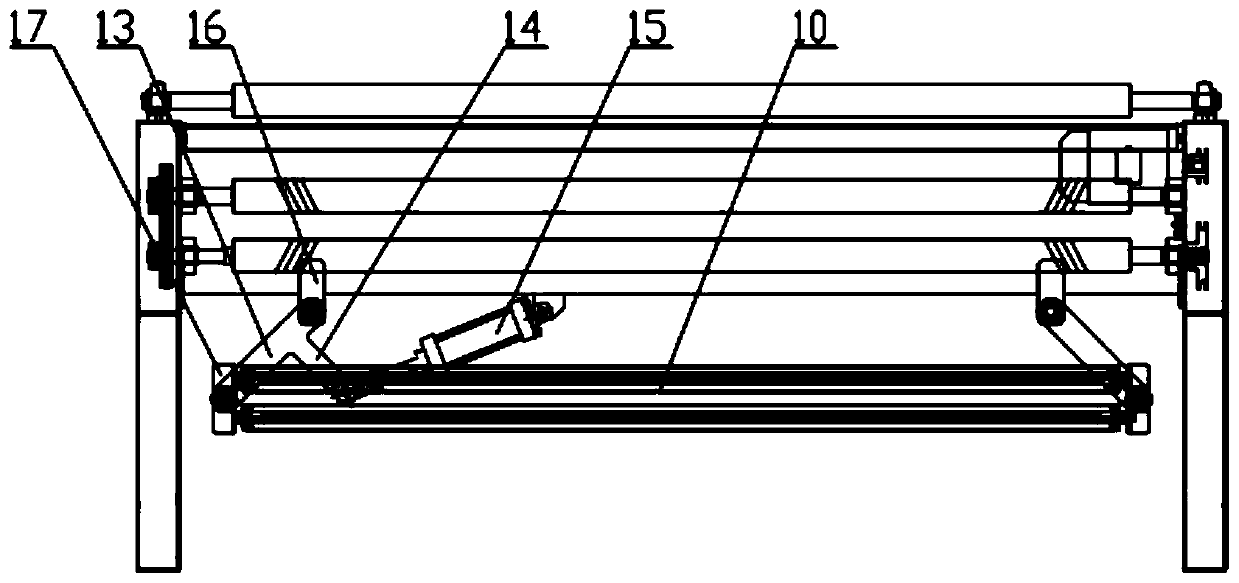

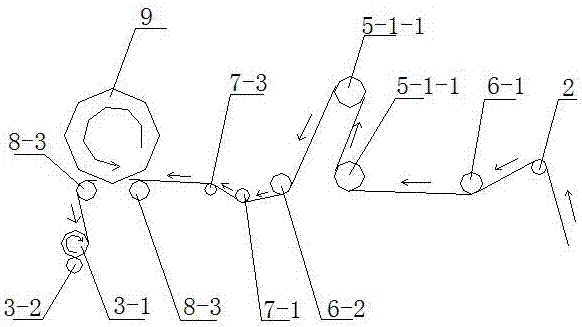

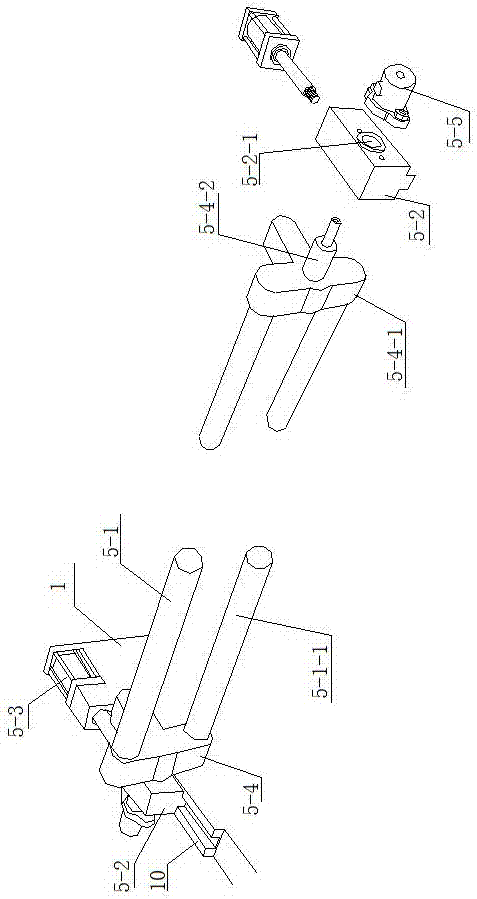

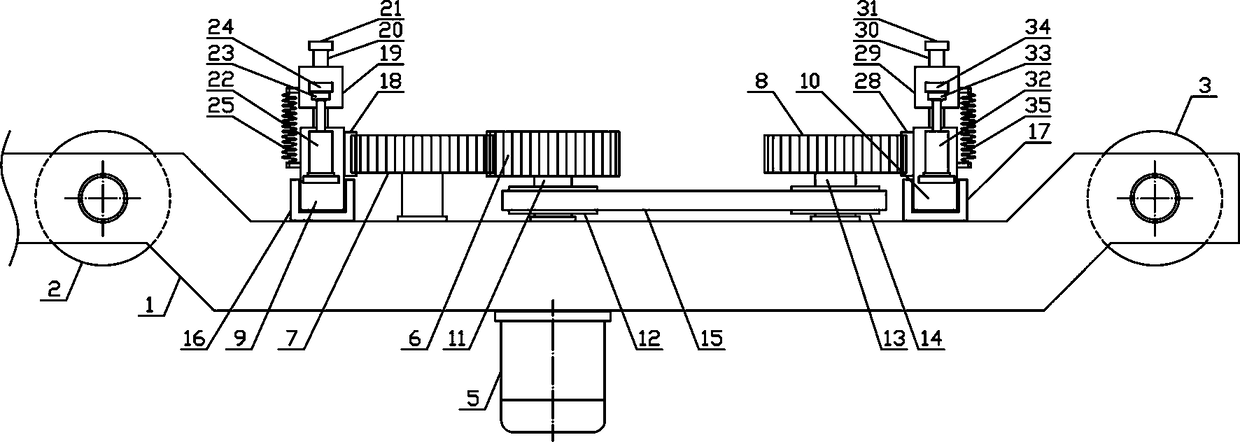

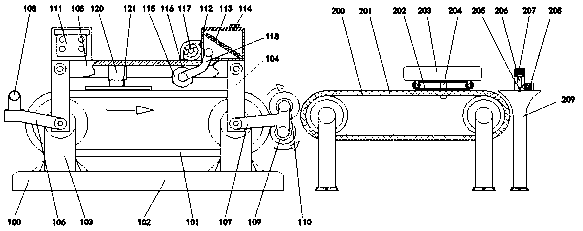

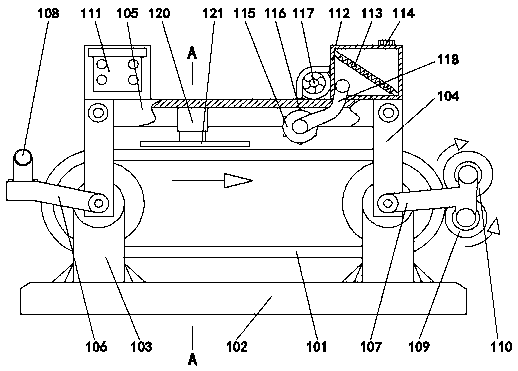

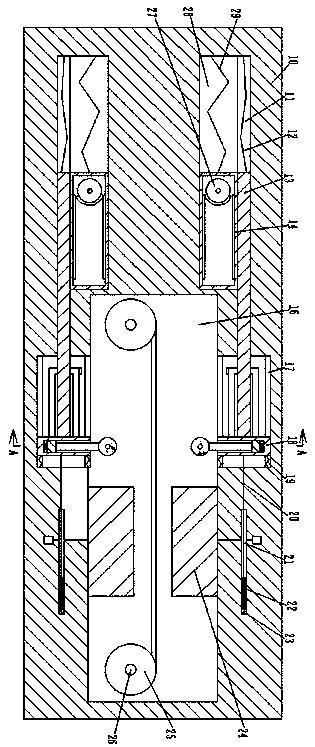

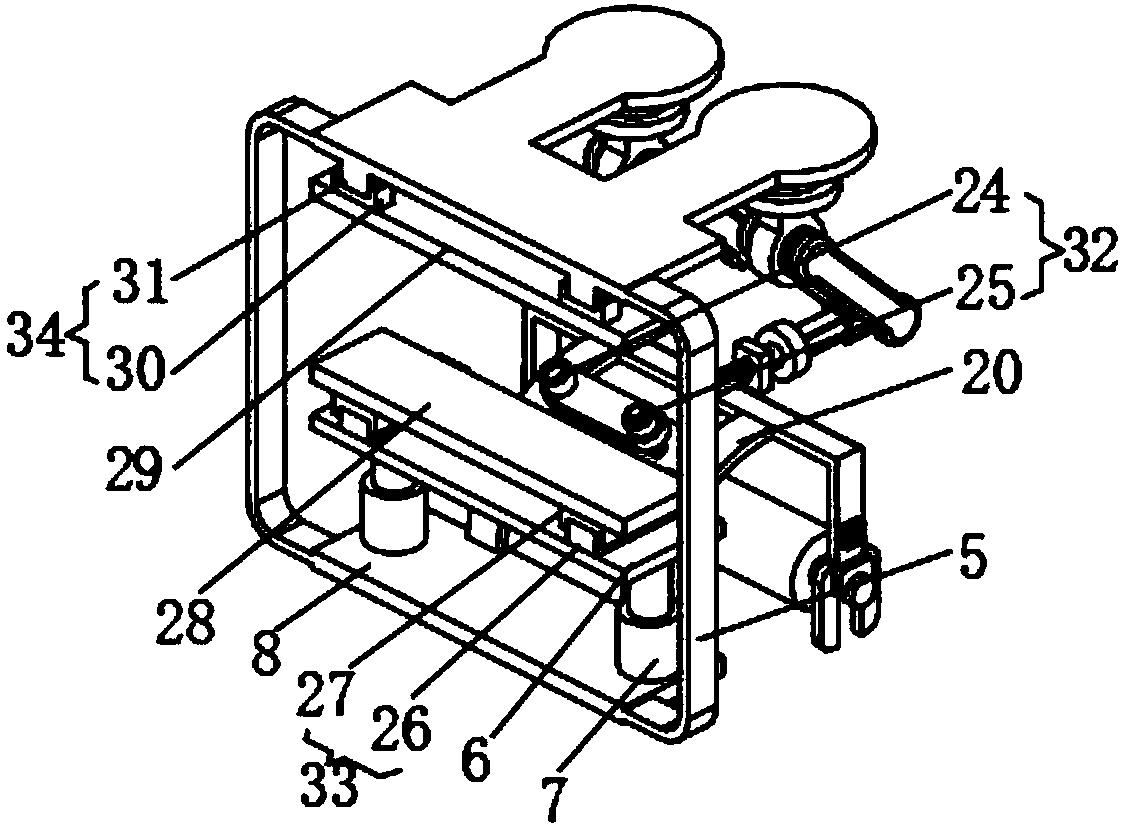

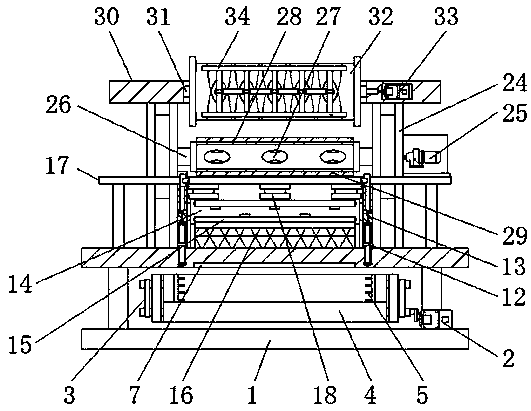

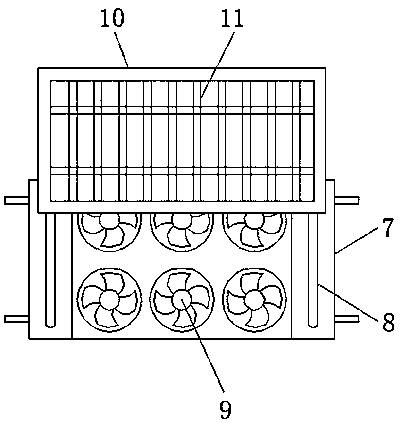

Efficient small sample cloth sueding machine

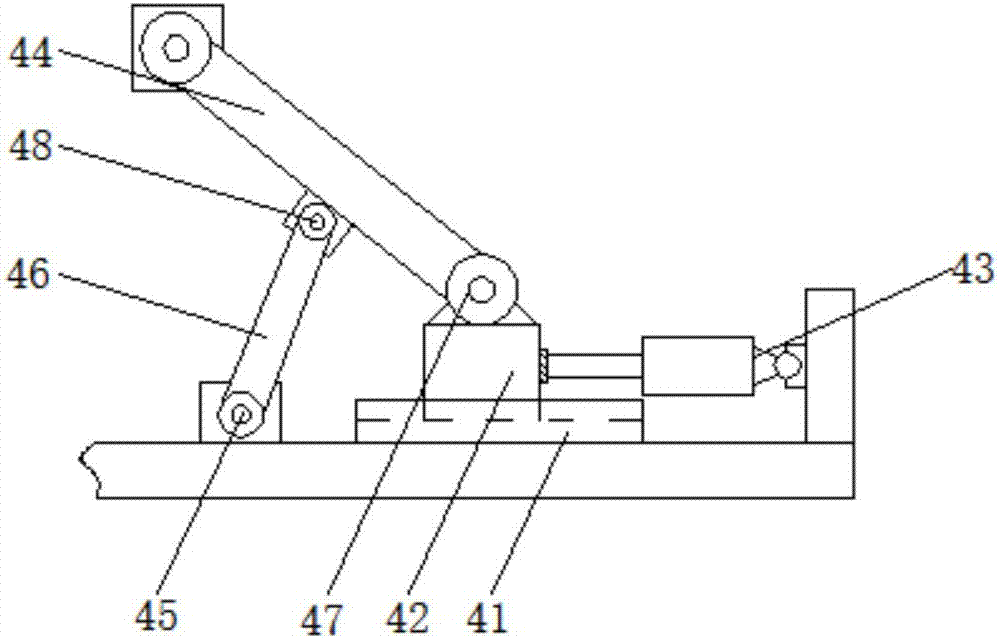

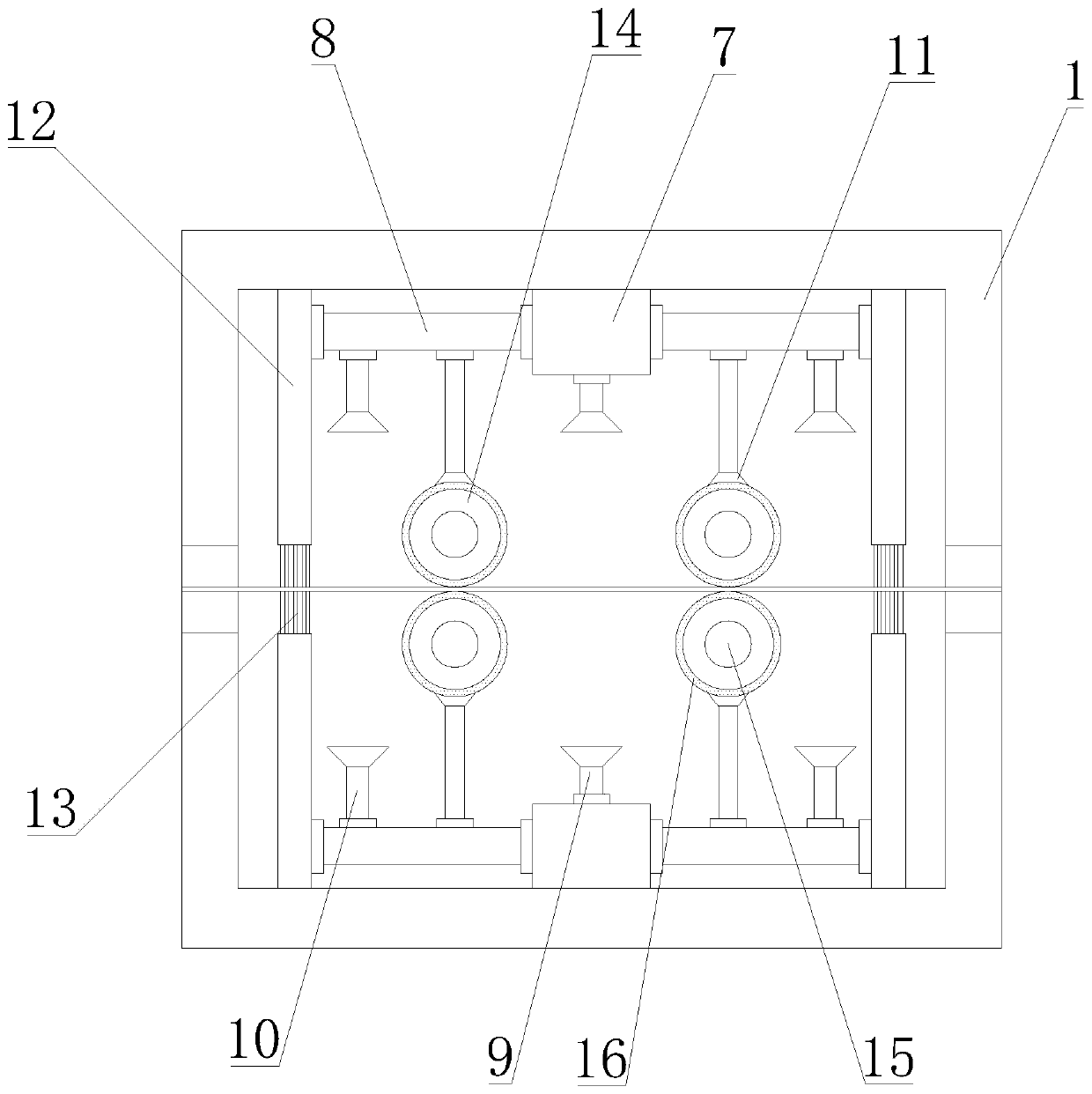

ActiveCN107881694AReduce vibrationSolve warp and weft pleatingInspecting textilesFabric finishing guides/expandersElectric machineryEngineering

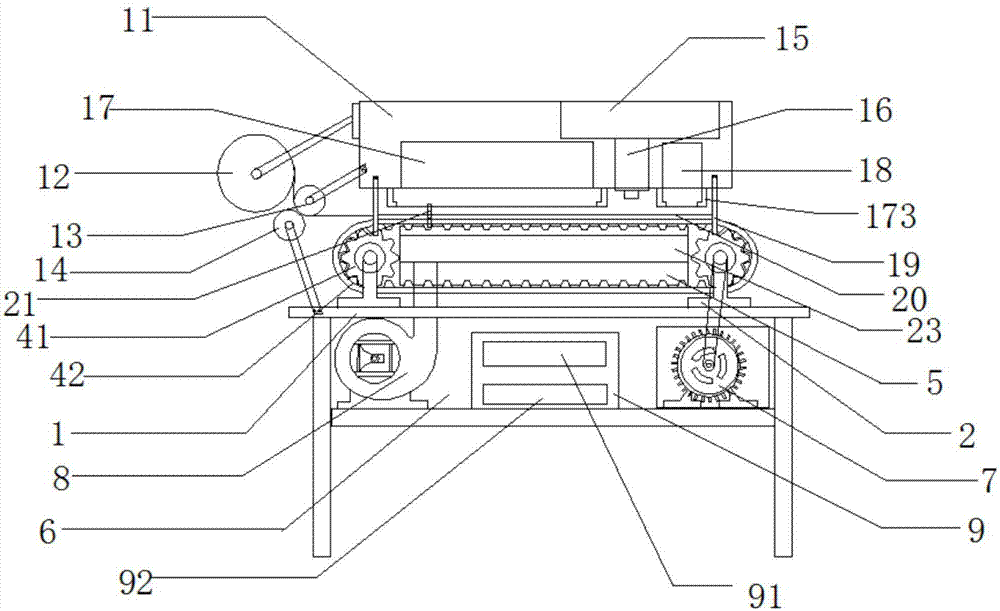

The invention provides an efficient small sample cloth sueding machine, and relates to the technical field of design of a small sample cloth sueding machine. The efficient small sample cloth sueding machine comprises a machine frame, a cloth inlet guide roller and a winding mechanism, wherein the machine frame comprises a left support frame, a right support frame and a bottom frame arranged between the left support frame and the right support frame; the two ends of the cloth inlet guide roller are respectively connected with the left support frame and the right support frame through bearings;the winding mechanism comprises a cloth winding roller, a winding rotating shaft and a winding driving motor with a speed reducing machine; a warp direction tension detection regulating device, a warpdirection lengthening detection device, a weft direction tension detection regulating device, a cloth surface vibration inhibition device and a sueding mechanism are respectively arranged on the machine frame between the cloth inlet guide roller and the winding mechanism. The efficient small sample cloth sueding machine has the advantages that the performance is stable and reliable; the sueding speed is high; the adaptability of different varieties of the small sample cloth is strong; the sueding effect is very good.

Owner:JIANGSU LIANFA TEXTILE

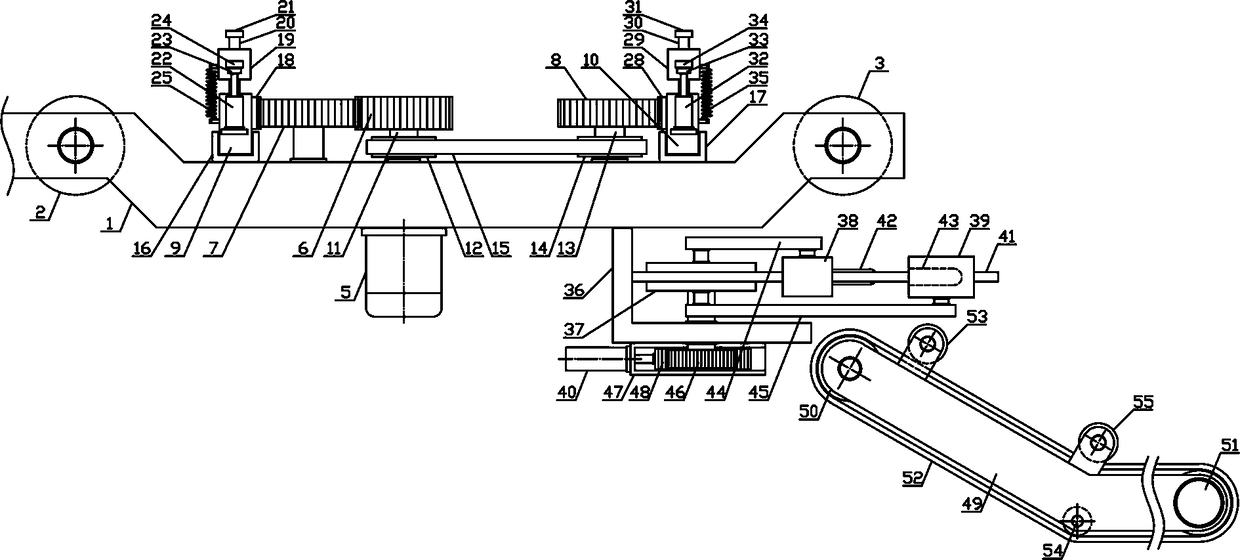

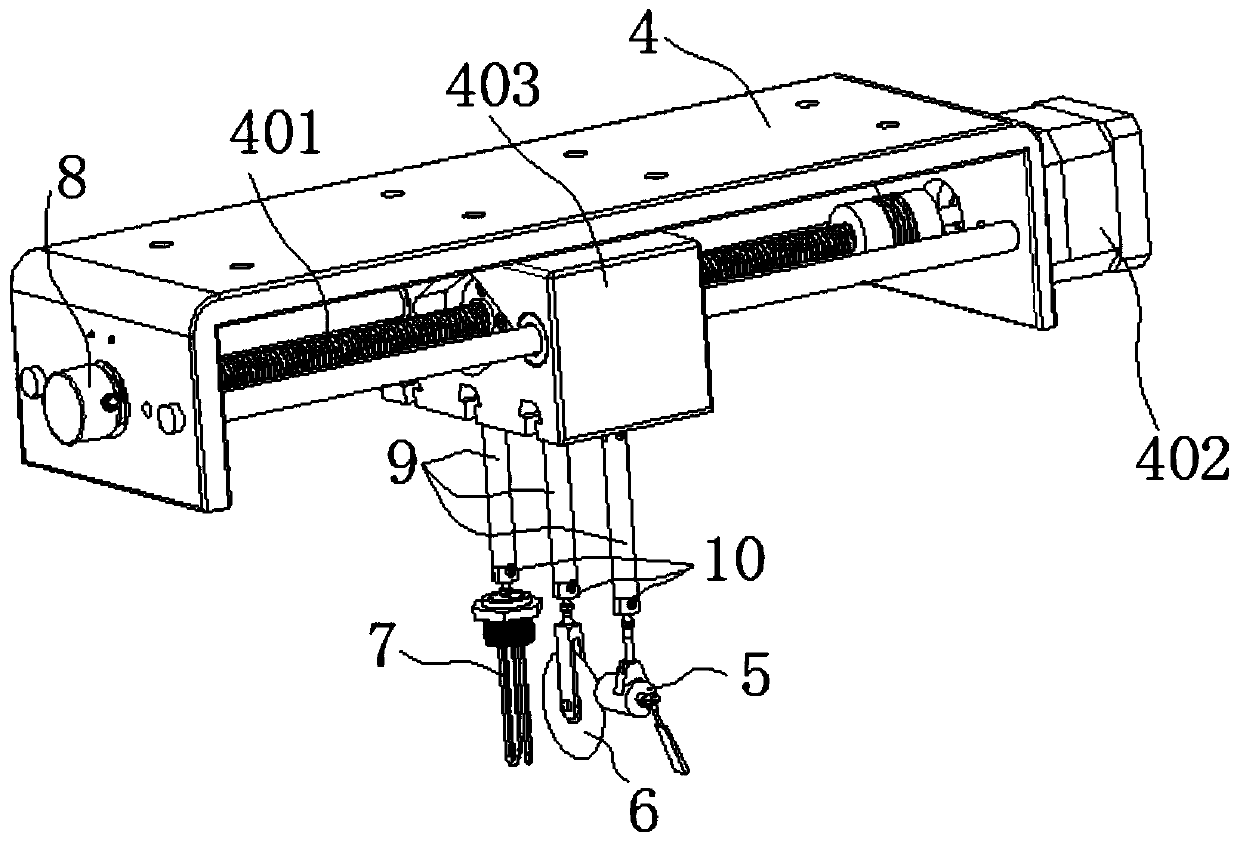

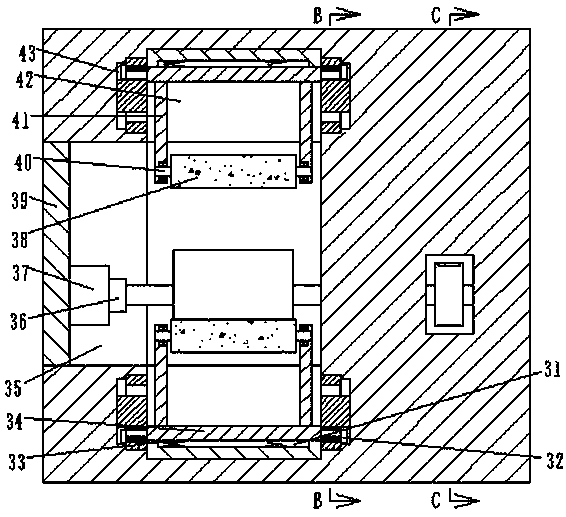

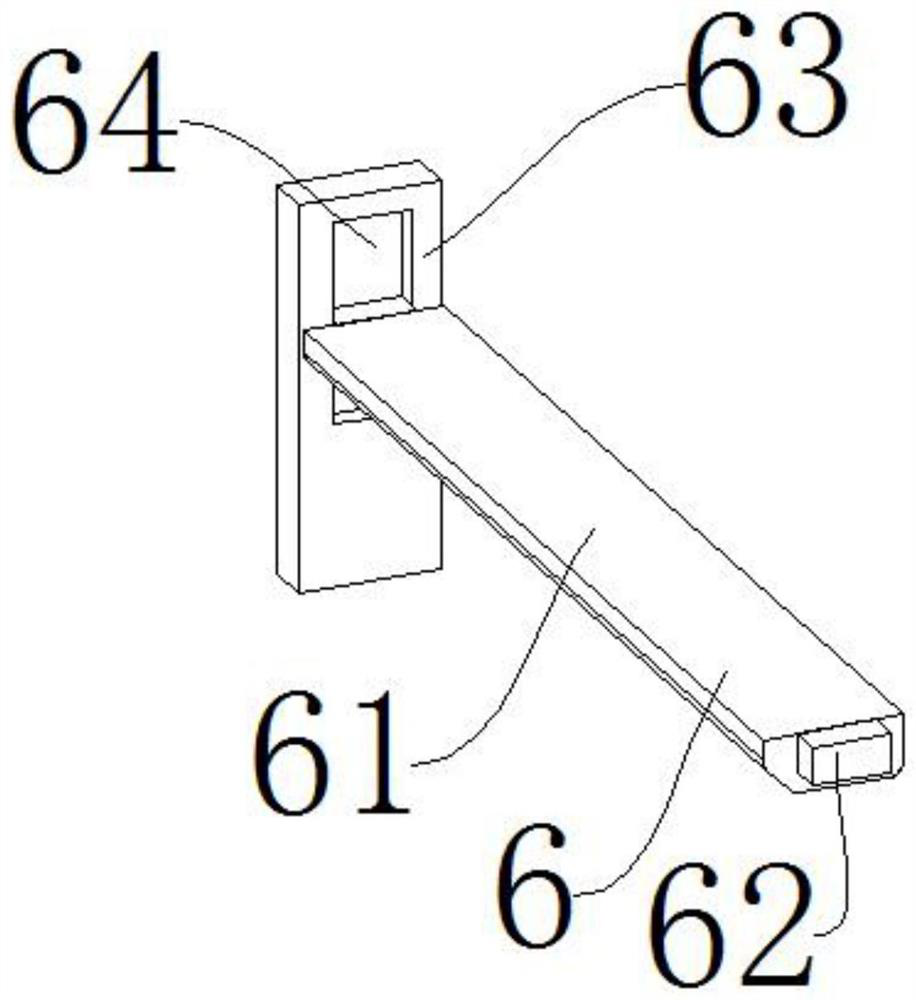

Grey cloth drafting cutting mechanism

InactiveCN108978166AEfficient and full cuttingHigh degree of automationSevering textilesFabric finishing guides/expandersMechanical equipmentCutting guide

The invention discloses a grey cloth drafting cutting mechanism and belongs to the field of textile processing mechanical equipment. A drafting mechanism is horizontally arranged on the portion, of aconveying support, between a cloth inlet rotation roller and a cloth outlet rotation roller, a cutting mechanism is horizontally arranged on the portion, of the conveying support, at the lower side ofthe cloth outlet rotation roller, and a conveying mechanism is obliquely and downwards arranged at the lower side of the cutting mechanism; main drafting connection plates are horizontally and slidingly arranged on the portions, in a main connection plate support, at the two sides of the conveying support; auxiliary drafting connection plates are horizontally and slidingly arranged in auxiliary connection plate supports, a cutter support and a cutter groove support are horizontally and slidingly arranged on a cloth cutting guide rod in sequence, and a cloth guide conveying belt winds cloth guide rotation rollers at the two ends of a cloth guide support. The grey cloth drafting cutting mechanism is reasonable in structural design, grey cloth can be continuously and stably subjected to width enlargement and drafting in the conveying process, the grey cloth after drafting can be accurately, efficiently and horizontally cut into cloth pieces for conveying, the automation degree of processing the grey cloth is increased, and the demands of production use are met.

Owner:戴杰

Fully-automatic setting machine edge cutting and ironing device and control method thereof

InactiveCN110699943AImprove work efficiencyHigh precisionTextile selvedgesSevering textilesPolyesterEngineering

The invention relates to the technical field of setting machines, in particular to a fully-automatic setting machine edge cutting and ironing device and a control method thereof. The device comprisesa support mounted on a setting machine, edge cutting and ironing components and driving components are arranged on two sides of the support, the driving components drive the edge cutting and ironing components to linearly move along the support, the edge cutting and ironing components comprise sensors, cutting knives and heating devices, the sensors are used for measuring distances among the edgecutting and ironing components and the edges of objects to be processed, the cutting knives are used for cutting the edges, the heating devices are used for ironing the edges. According to the controlmethod, the edge cutting and ironing components are accurately controlled. According to the edge cutting and ironing device, the edge of a polyester wire mesh can be fully automatically cut and ironed, edge cutting and ironing efficiency and edge cutting and ironing accuracy of the polyester wire mesh are improved, and the labor intensity of a worker is reduced.

Owner:GUANGDONG UNIV OF TECH

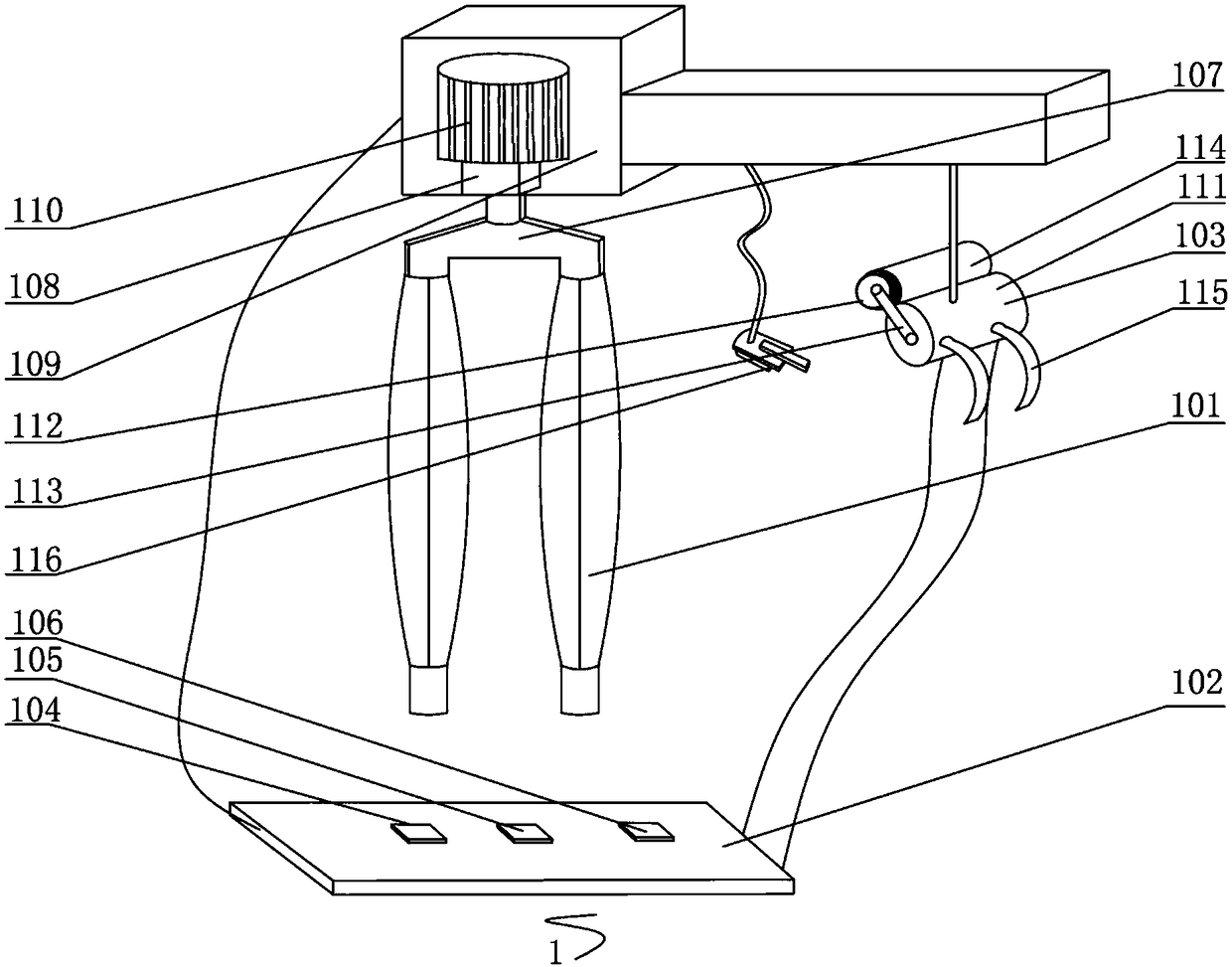

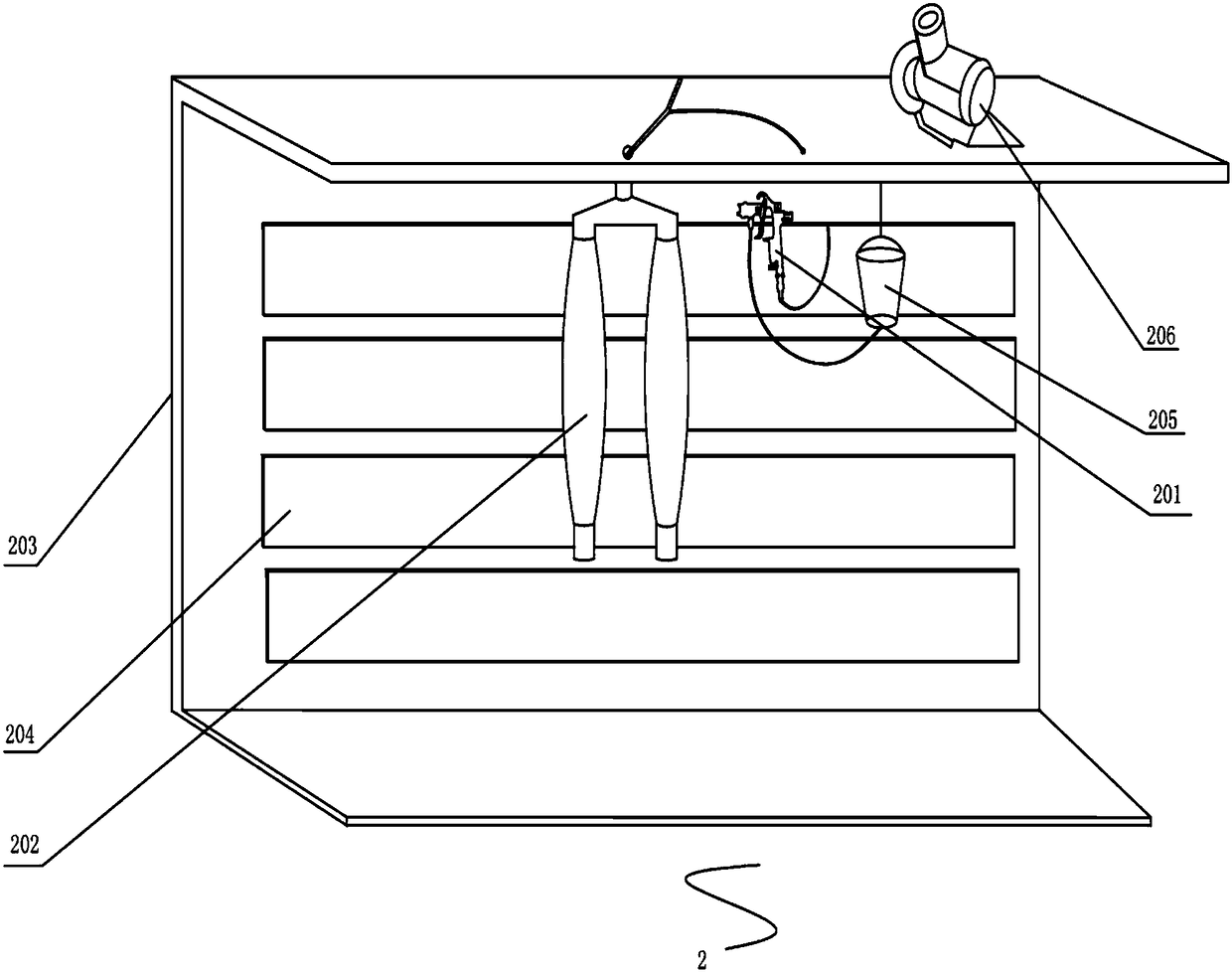

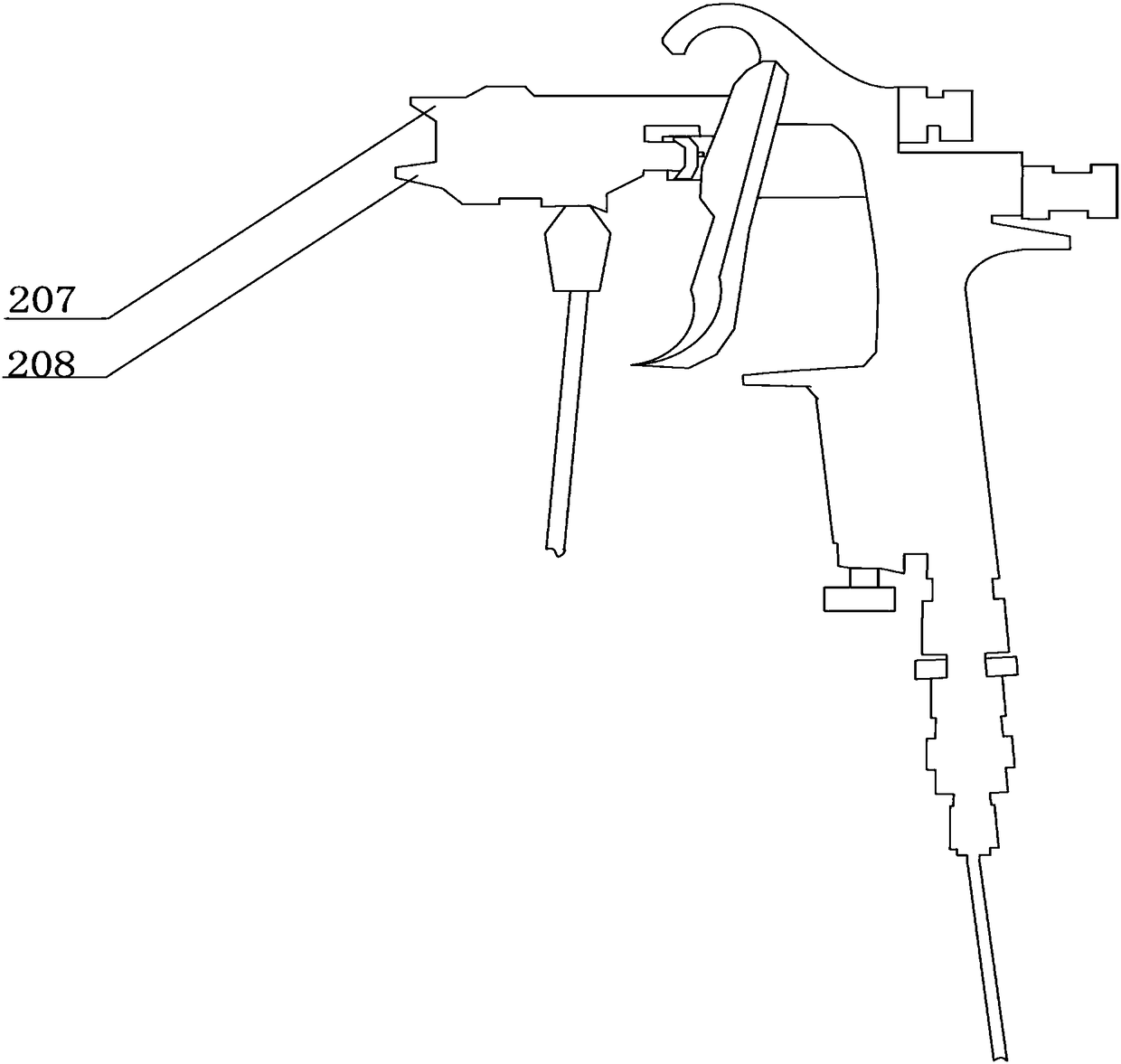

Jeans frosting apparatus and method

The invention discloses a jeans frosting apparatus, comprising a polishing device and a spraying device. The polishing device comprises a trouser-shaped soft bag, a control pedal and an electric grinder; the spraying device comprises a spray gun and another trouser-shaped soft bag; the spray gun is connected with potassium permanganate and high-pressure gas. Jeans polishing includes a grinding step and a spraying step; the grinding step includes inflating the trouser-shaped soft bag to expand jeans; primarily grinding the front and back of thighs and shanks of the jeans with the electric grinder, and holding an abrasive paper drum by hand to grind small parts so as to finish grinding; the spraying step includes placing the jeans on the trouser-shaped soft bag of the spraying device, inflating the trouser-shaped soft bag, spraying potassium permanganate to the proper parts of the front and back of the jeans with the spray gun, soaking in a soaking liquid, neutralizing the potassium permanganate, dewatering the soaked jeans, and drying to obtain jeans which are of great layering impression and have naturally changing color.

Owner:广州市创兴服装集团有限公司

Setting machine for knitwear printing and dyeing

InactiveCN110331569AGood shaping effectFast shaping efficiencyMechanical cleaningPressure cleaningEngineeringTextile dye

The invention belongs to the technical field of knitwear processing, in particular to a setting machine for knitwear printing and dyeing. Aiming at the current problems of inconvenient use, difficultyin ensuring that knitwear is always in a tensioned state, low setting efficiency, poor setting effect, inability to remove thread ends and dust on the surface of the knitwear and influence on productquality and setting operation, the following scheme is proposed and is characterized in that the setting machine comprises a dust removal box, a setting box and a base, wherein universal wheels are arranged at the bottom of the base, and the dust removal box and the setting box are arranged on the base; an output port of the dust removal box is communicated with an input port of the shaping box;the shaping box is provided with a tensioning assembly, a shaping assembly and a conveying assembly sequentially from an input port to an output port. The knitwear can always be in the tensioned state, the shaping effect is good, shaping efficiency is high, dust removal and lint removal effects are also realized, shaping operation is convenient, and quality of the knitwear can be improved.

Owner:徐州嘉搏纺织股份有限公司

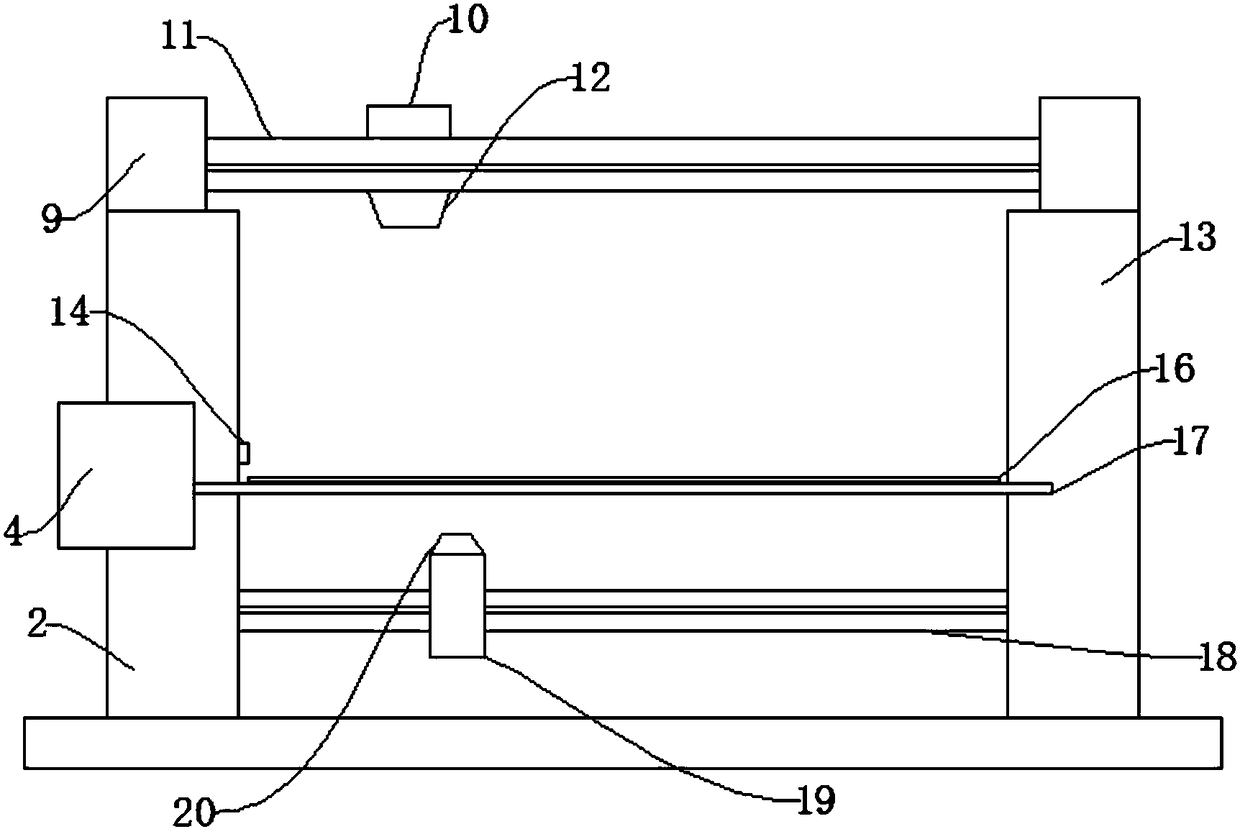

Thin clothes ironing and drying integrated machine

InactiveCN109137353AFast ironing and dryingImprove ironing effectFabric finishing guides/expandersTextiles drying apparatusProcess engineeringWater collection

The invention discloses a thin clothes ironing and drying integrated machine. The thin clothes ironing and drying integrated machine comprises an ironing equipment body, a steam ironing roller and a heating ironing roller; a water tank, a heating pipe, a joint bracket, a backflow pipe, a conveying belt, an exhaust fan, a condenser pipe, a liquefied water collection tank, the steam ironing roller,a steam conveying pipe, a steam outlet, a fan, the heating ironing roller, a heating pipe, a steam ironing box, a dry ironing box, a material inlet, an electromagnetic valve, a joint, a driving motorand a wire through hole are arranged on the ironing equipment body; as the steam ironing box and the dry ironing box are combined on the ironing equipment body, thin clothes are steam-ironed by usingthe steam ironing box first, and then are fed into the dry ironing box to be secondarily ironed; and meanwhile, the steam in the first ironing is removed. The thin clothes ironing and drying integrated machine disclosed by the invention has the advantages of reasonable design, high ironing and drying speed and good ironing effect.

Owner:NANTONG HECHENG TEXTILE CO LTD

Clothing sandblasting-pattern processing method and device

ActiveCN110106656AAvoid overheating and burningAvoid deformationPattern makingHeating/cooling textile fabricsEngineeringMechanical engineering

The invention belongs to the technical field of clothing production equipment, and particularly relates to a clothing sandblasting-pattern processing method and device. In view of the problem that cloth ironing and conveying are inconvenient to perform, fine sand left on cloth cannot be effectively removed and temperature problems exist for existing clothing sandblasting-pattern processing equipment, the clothing sandblasting-pattern processing method is provided and includes the following steps that S1, a transmission mechanism is arranged, a conveying mechanism is used for conveying cloth needing sandblasting; S2, an ironing and conveying mechanism is arranged on the conveying mechanism, the clothing sandblasting-pattern processing device includes a machine frame and a dust shield, the inner side of the machine frame is rotatably provided with a plurality of conveyor rolls, the piece of cloth is placed on the conveyor rolls, and an ironing platform is arranged between the two conveyor rolls located on the leftmost side. The design is reasonable, wrinkles on the cloth can be effectively removed, a sandblasting pattern is formed on the cloth, the cloth can be subjected to cooling sand removal treatment, cloth cleaning is facilitated, and the cloth is effectively prevented from overheating and deformation.

Owner:LIMING VOCATIONAL UNIV

Feeding equipment for dust covers

InactiveCN109722876ASmooth rotationGuaranteed persistenceSevering textilesFabric finishing guides/expandersEngineeringAir blower

The invention relates to feeding equipment for dust covers. The feeding equipment comprises a conveying mechanism, the conveying mechanism comprises a base, multiple supporting pillars A are installedon the upper portion of the base, a conveyor belt A is installed above the supporting pillars A, cutting grooves are symmetrically formed in the two sides of the outer wall of the conveyor belt A, atop plate is arranged at the top of the conveyor belt A, air cylinders are symmetrically installed on the two sides of the bottom of the top plate, blades are installed at the bottoms of the two air cylinders respectively, a pressing and ironing roll is rotatably connected between two rotating connectors, a water tank is installed at the top of the top plate, a water pump and a water pipe are communicated with the outer wall of the water tank, a bidirectional air blower is arranged at one end of a feeding port of the conveyor belt A, and an auxiliary wheel and a feeding wheel are arranged at one end of a discharging port of the conveyor belt A. The aim is to solve the problems that existing feeding equipment for dust covers does not conduct pressing and ironing treatment on the dust covers, as a result, the dust covers are wrinkled and need to be manually assisted in cutting, and production speed is low.

Owner:刘轩彤

Functionality textile cloth two-face ironing device

PendingCN108589143AGuaranteed ironing qualityAvoid damageMechanical cleaningPressure cleaningEngineeringTemperature sensing

The invention discloses a functionality textile cloth two-face ironing device which comprises a base, a first side plate and a second side plate. The first side plate is arranged at the upper side ofthe base, and the side, away from the first side plate, of the base is provided with the second side plate. The device has the advantages that by arranging a first ironing head and a second ironing head, dual-ironing can be performed on the cloth, the cloth ironing quality is ensured, by arranging a temperature sensing probe, the ironing temperature of the cloth can be kept to the certain temperature, the ironed cloth is prevented from being damaged, by arranging a dust suction head, dust and sundries on the cloth can be effectively removed, and the cloth ironing efficiency and the cloth ironing quality are improved.

Owner:苏州七瑾年新材料科技有限公司

Sufficient and anti-wrinkling textile drying equipment

ActiveCN111380348AFully dryEnough timeDrying machines with progressive movementsFabric finishing guides/expandersStructural engineeringMechanical engineering

The invention discloses sufficient and anti-wrinkling textile drying equipment. The equipment comprises a box body, wherein a blocking door connected with the box body in a matched mode is arranged onthe front end wall of the box body, supporting blocks are fixedly connected to the rear end wall of the blocking door in a bilateral symmetry mode, the supporting blocks are rotationally connected with a spline shaft, the spline shaft is connected with a textile product containing shaft in a matched mode, textile products are arranged on the textile product containing shaft, the left textile product and the right textile product are connected through textile cloth, the textile product containing shaft is rotationally connected with the box body, an intermittent rotating mechanism is arrangedat the rear end of the textile product containing shaft, first sliding grooves with openings facing a textile product grooves are symmetrically formed in the upper end wall and the lower end wall of the textile product groove, the first sliding grooves are internally and slidably connected with first sliding blocks, flattening mechanisms are arranged in the first sliding blocks, drying mechanismsare arranged on the right sides of the first sliding grooves, repeating mechanisms are arranged at the left ends of the first sliding blocks, the two faces of the textile fabric can be fully dried atthe same time, flattening operation is conducted in time after drying, and wrinkles are reduced.

Owner:淄博玉华纺织有限公司

Fuzz ball removing equipment for textiles and using method of fuzz ball removing equipment

InactiveCN112080887AAvoid breakingAdjust the tightness in timeDirt cleaningFabric finishing guides/expandersKnife bladesForce sensor

The invention discloses fuzz ball removing equipment for textiles. The fuzz ball removing equipment comprises a bearing frame, supporting tables, a conveying mechanism, a collecting mechanism, a dustsuction mechanism and a fuzz removing mechanism, wherein the supporting tables are connected to the two sides of the bearing frame; the conveying mechanism is connected to the upper end of the bearingframe; the collecting mechanism is connected to one side of the conveying mechanism; the dust suction mechanism is connected to the collecting mechanism; the fuzz removing mechanism is connected to the lower side of the collecting mechanism; a controller is connected to the front end of the bearing frame; a transmission mechanism is connected to the rear end of the bearing frame; the fuzz removing mechanism comprises a fuzz removing box, a second electric lifting sliding block, a second supporting base and a limiting groove; the front and rear ends of the fuzz removing box are connected withthe second electric lifting sliding block by bolts; the second electric lifting sliding block is slidably connected to the second supporting base; and the limiting groove is formed between the secondelectric lifting sliding block and the second supporting base. The fuzz ball removing equipment has the beneficial effects that the tightness can be adjusted in time through a pressure sensor, so thatthe textiles are prevented from being damaged; and the cutting efficiency is improved through multiple cutting rollers and cutting blades.

Owner:长兴奇轩纺织科技有限公司

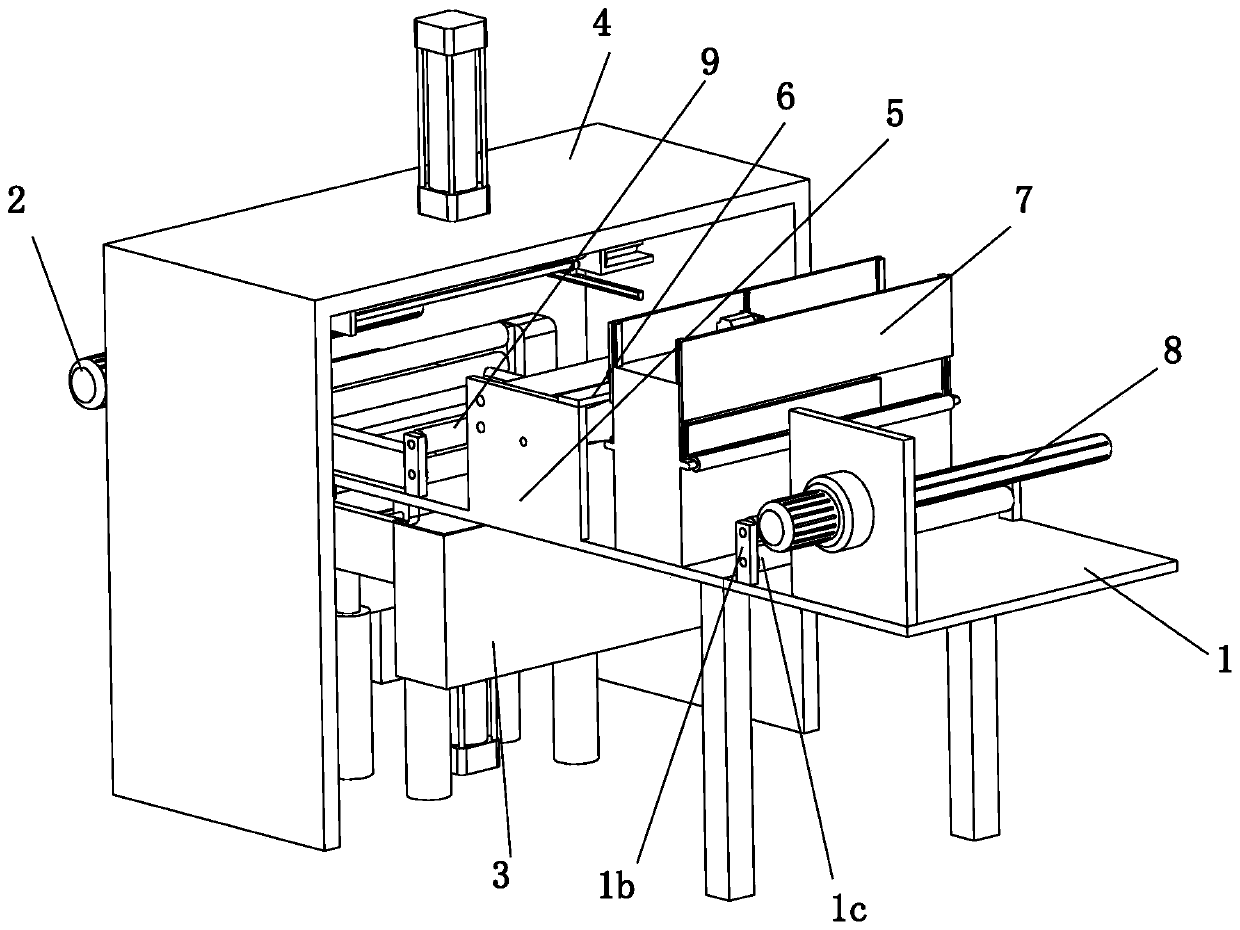

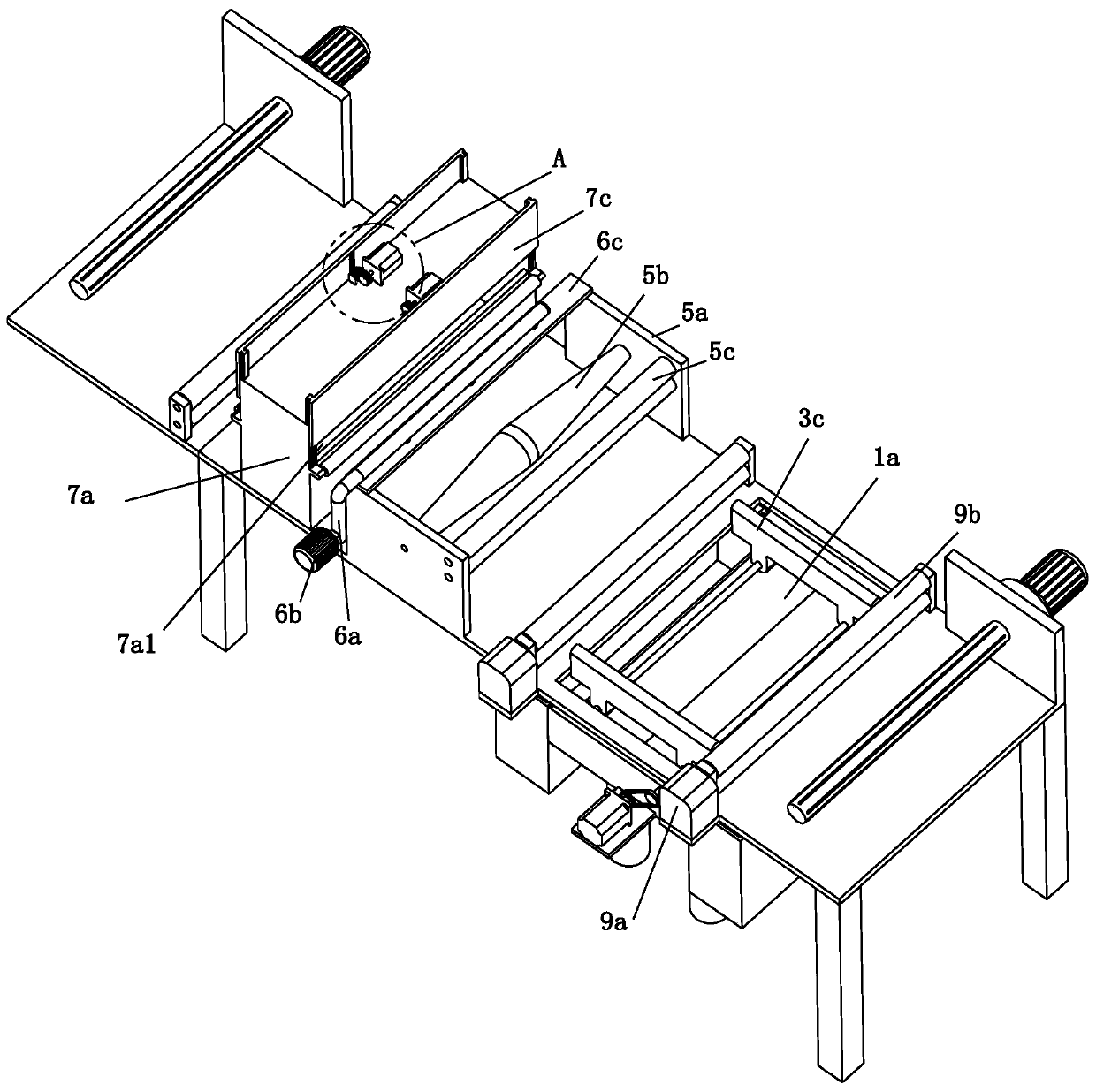

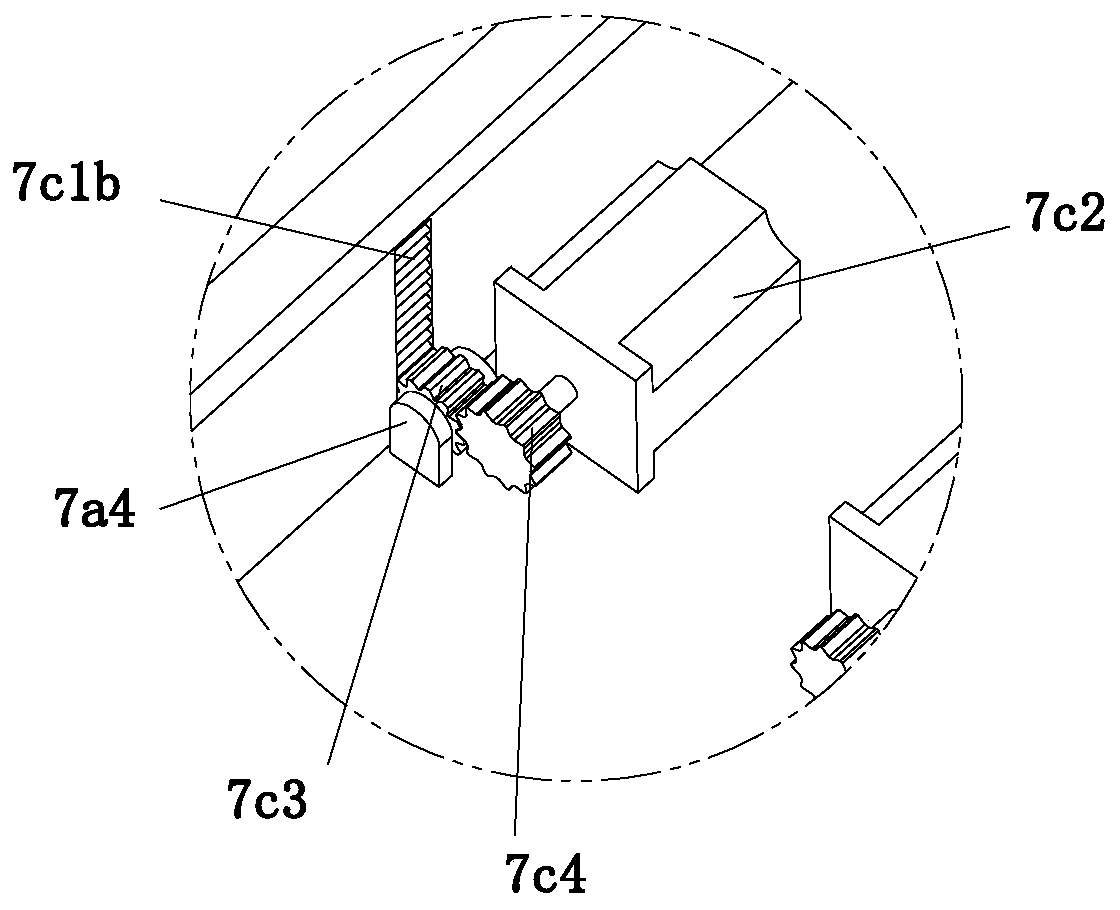

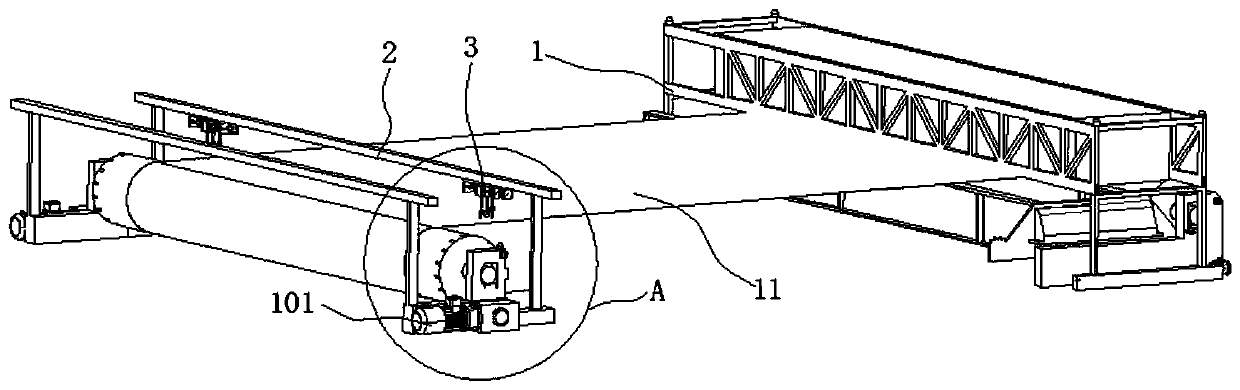

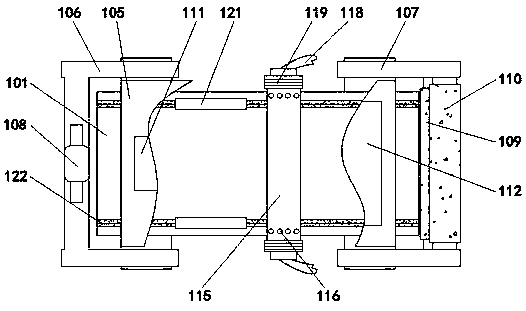

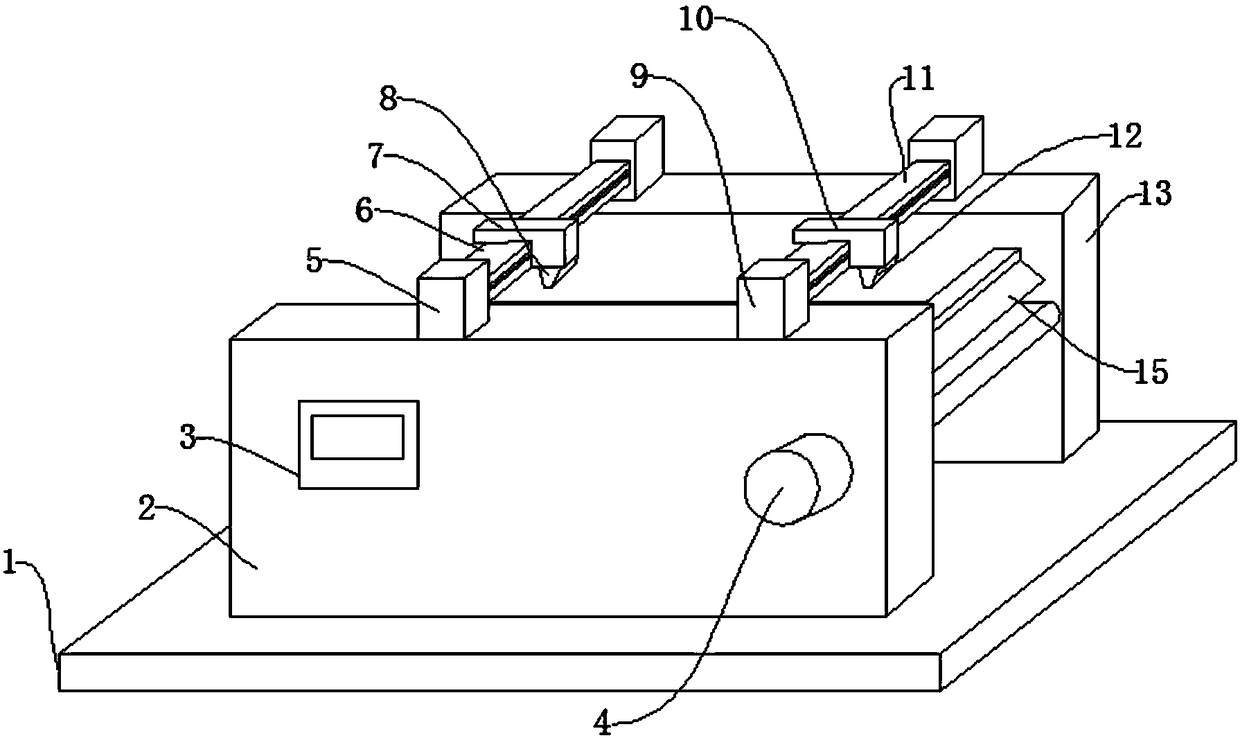

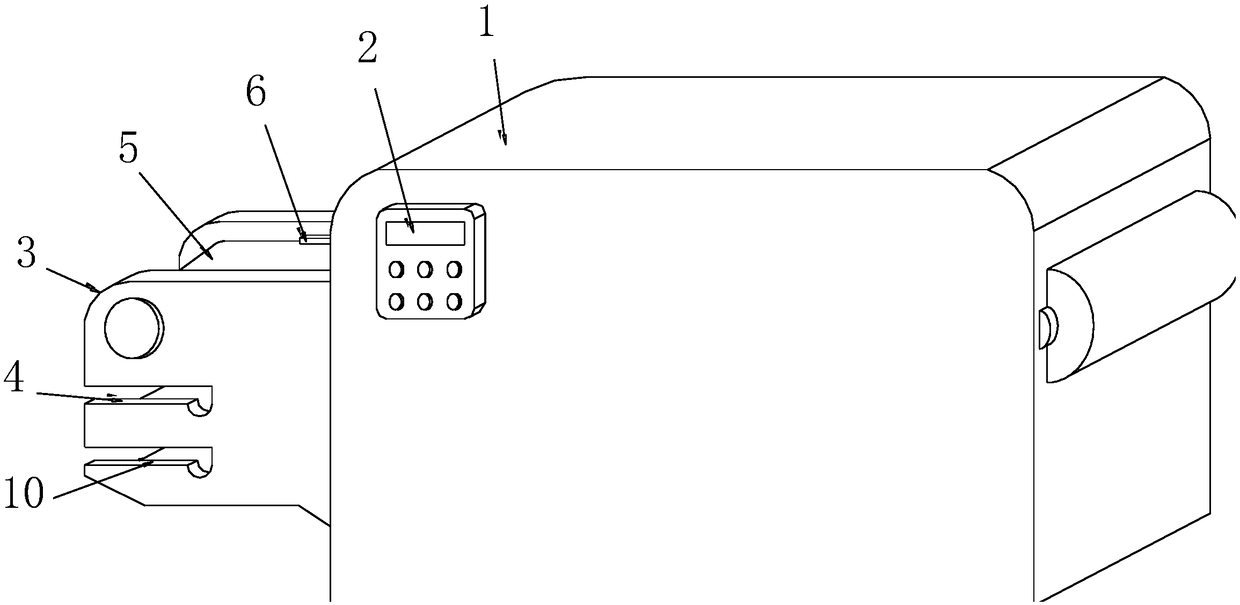

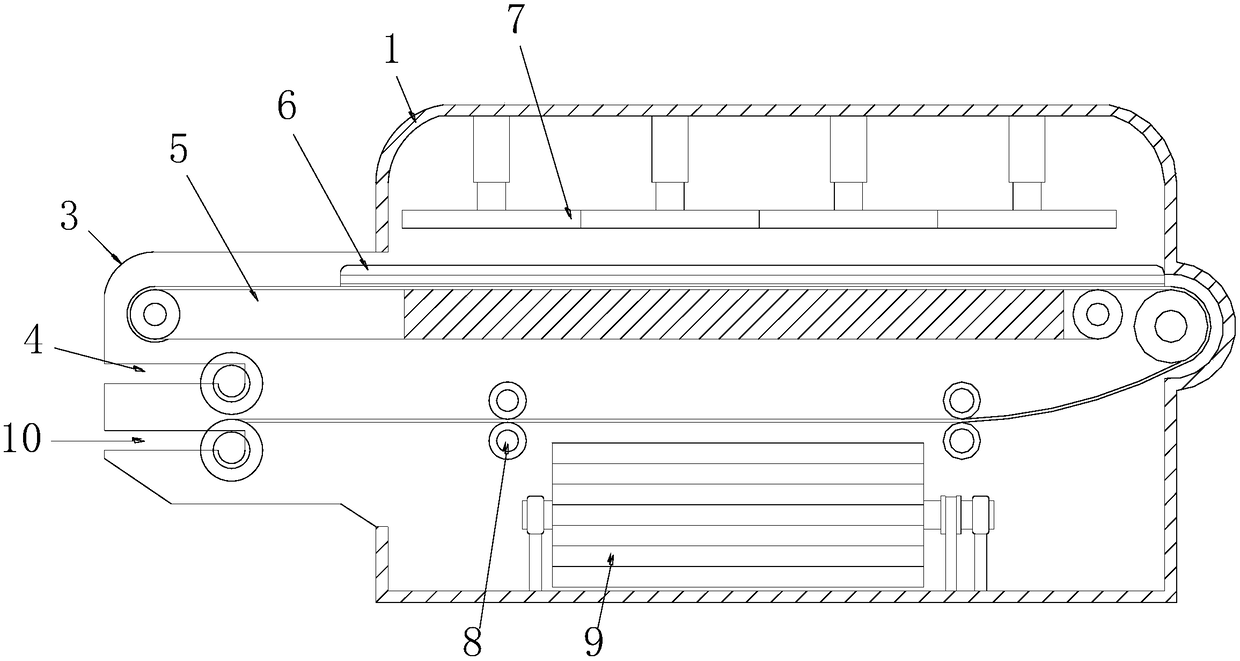

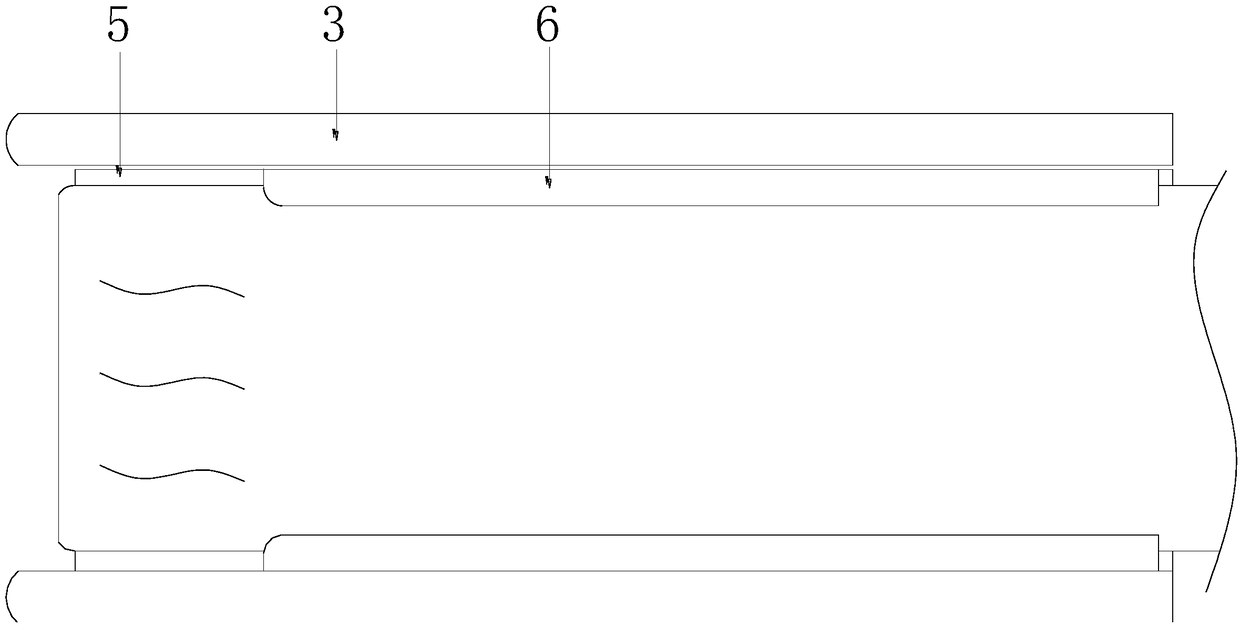

Lateral suction and pulling type fabric automatic ironing equipment

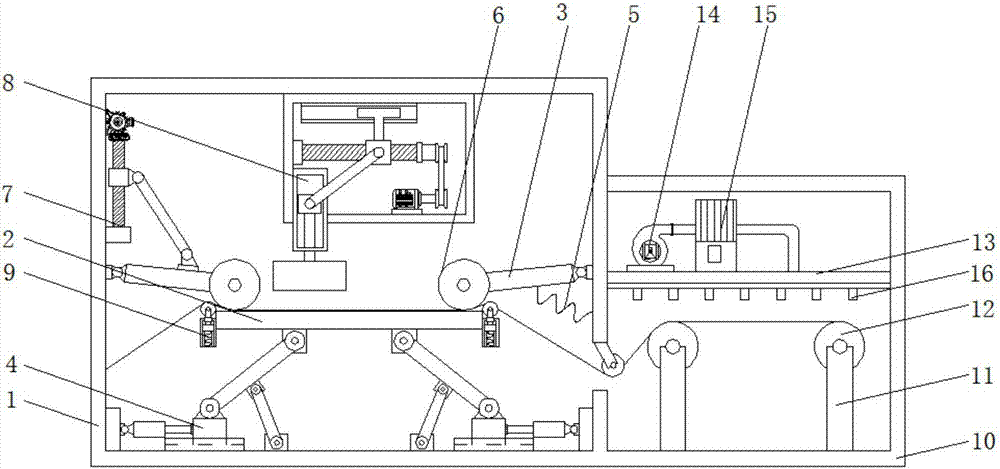

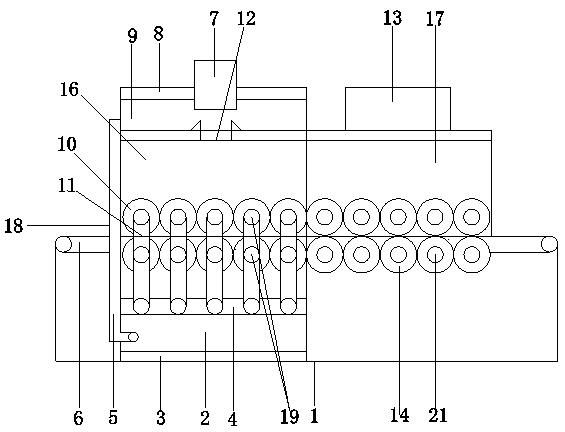

ActiveCN109457431ASolve the problem of pulling force and leaving horizontal foldsGuaranteed flatnessFabric finishing guides/expandersTextiles drying apparatusEngineeringMoisture

The invention discloses lateral suction and pulling type fabric automatic ironing equipment. The lateral suction and pulling type fabric automatic ironing equipment structurally comprises a main machine box, a control panel, a worktable, a fabric release roll clamping groove, a conveying mechanism, a lateral suction and pulling device, an ironing device, a leading-out mechanism, a hot moisture removal mechanism, and a fabric uncoiling roll clamping groove. The lateral suction and pulling type fabric automatic ironing equipment has the advantages that by arranging the lateral suction and pulling equipment, a mode of negative-pressure suction and pulling type and the crawler pressing and pulling type is adopted, the edges of the front part and back part of the fabric are pulled, and the pulling forces at the starting end and finishing end of the automatic ironing equipment are utilized to pull the surrounding edges of the fabric, so that the fabric can be more flatly ironed in the ironing process; by arranging the hot moisture removal mechanism, the remaining hot moisture in the ironing process can be absorbed by lime, the hot moisture removal mechanism is arranged in a spiral way and is in short-distance contact with the fabric to quickly absorb and remove the hot moisture, then the moisture is prevented, and the dampness and mildewing of the directly coiled fabric due to coiling of the hot moisture into the fabric can be prevented.

Owner:四会市永利布匹定型有限公司

A fabric setting machine

ActiveCN107938233BImprove stylingWrinkles disappearHeating/cooling textile fabricsFabric finishing guides/expandersEngineeringMechanical engineering

Owner:ZHEJIANG TEXWELL TEXTILE

Printed fabric hair brushing and sucking machine

PendingCN109295647AFast realization of surface preparationHigh surface finishMechanical cleaningPressure cleaningSurface finishTreatment effect

The invention discloses a printed fabric hair brushing and sucking machine which comprises a grey fabric supporting seat, a machine body, a movable swing arm, a hair polishing mechanism and a hair brushing mechanism. The grey fabric supporting seat is positioned on one side of the machine body, a supporting roller is horizontally mounted on the grey fabric supporting seat and set up on the same and rotates relative to the same, the movable swing arm is mounted at one end of the machine body and hinged to the machine body, a driving cylinder is arranged on the machine body and connected with the movable swing arm and drives the movable swing arm to rotate, and a driving roller, an electrostatic eliminating roller and a heating roller are mounted on the movable swing arm at least. The printed fabric hair brushing and sucking machine is simple and reasonable in structure, convenient to use, high in flexibility and working efficiency, capable of quickly realizing surface treatment of printed grey fabric to improve surface smoothness of the printed grey fabric and good in treatment effect.

Owner:苏州高研纺织科技有限公司

Preheating drying anti-fold device for textile

ActiveCN107513839ASpeed up the flowImprove drying and preheating efficiencyFabric finishing guides/expandersTextiles drying apparatusWork in processEngineering

The invention discloses a preheating drying anti-fold device for textile. The device comprises a support control table and is characterized in that the two sides of the top end of the outer of the support control table are fixedly connected with a first gear transmission group and a second gear transmission group through a support frame, and both ends of the first gear transmission group are rotatably connected with the second gear transmission group through a rotation shaft, the top end of the support control table is provided with an air flow acceleration drying box which is at a position directly below a part between the first gear transmission group and the second gear transmission group, and the bottom of the support control table board is fixedly connected with a power box. The invention relates to the technical field of textile industry equipment. The preheating drying anti-fold device for the textile solves a series of problems of the existing textile products caused by incomplete preheating drying processes and the semi-finished products being easily damaged by different degrees due to unfixed reasons, meanwhile, also improves the preheating drying efficiency of the device, and achieves the purpose of reducing energy consumption.

Owner:天津市六福针织有限公司

Cotton kneading machine used for processing cotton yarn

ActiveCN107938241AImprove work efficiencyIncrease the level of automationFabric breaking/softeningLap forming devicesYarnPulp and paper industry

The invention discloses a cotton kneading machine used for processing cotton yarn. The cotton kneading machine comprises a damping pedestal, a first rubbing mechanism is arranged at top of the dampingpedestal, a lower kneading plate is fixed at the top of the first rubbing mechanism, the damping pedestal is connected with a top seat through a bracing frame, an elevating system is arranged at thebottom of the top seat, a second rubbing mechanism is arranged at the bottom of the elevating system, an upper kneading plate is fixed at the bottom of the second rubbing mechanism, an mounting rack is arranged at a side surface of the top seat, and a U-shaped groove is arranged on the mounting rack. The cotton kneading machine is characterized in that the second rubbing mechanism and the first rubbing mechanism drives the rubbing plate for mutual rubbing, rubbing capability is strong, work efficiency of the cotton kneading machine is greatly increased, operating positions of a fabric-spreading apparatus, a pressing apparatus and a cutting apparatus are positioned through a positioner, an intelligentization degree is high, positioning is accurate, and the automation level of the cotton kneading machine is greatly increased.

Owner:阜阳市发明协会

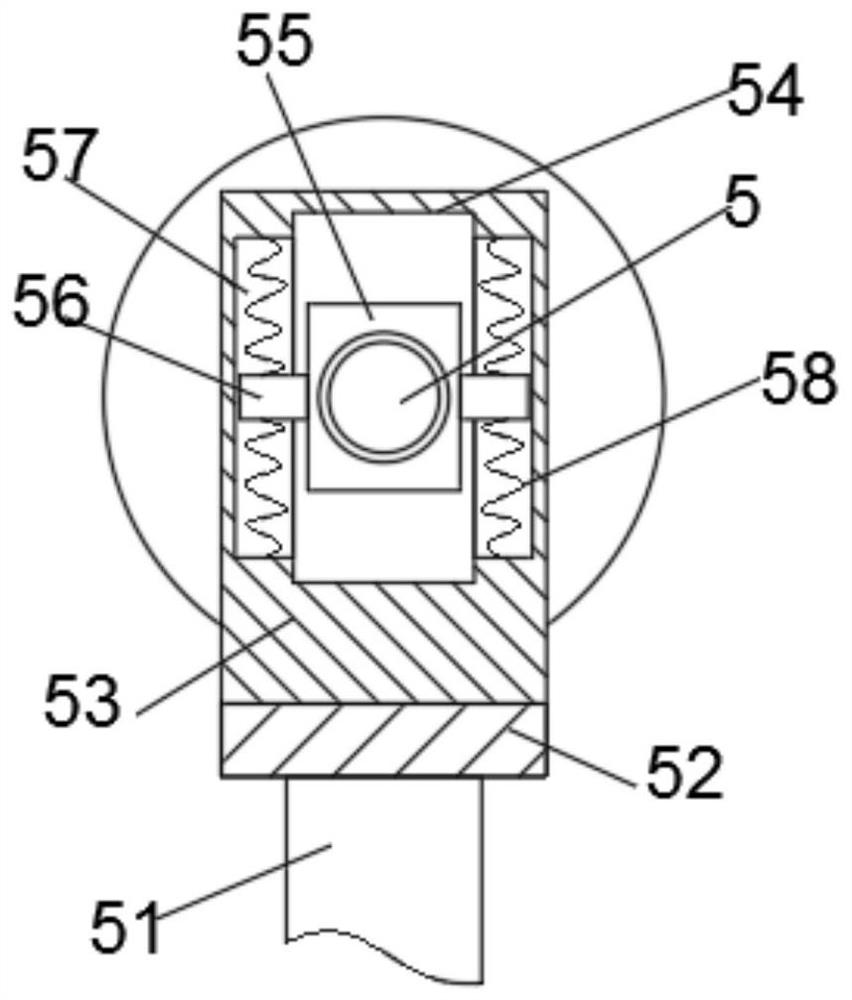

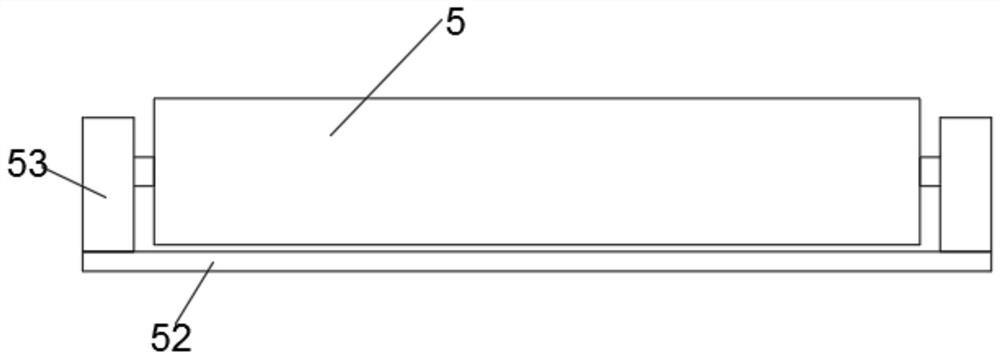

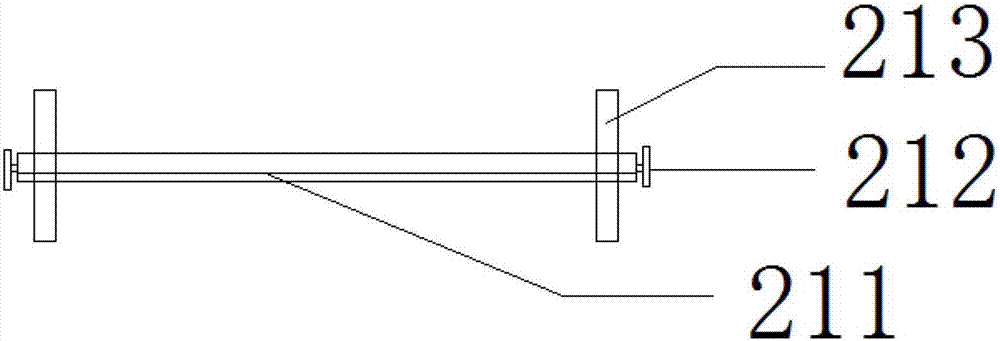

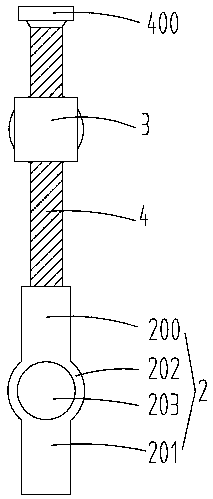

Convenient-to-adjust setter tensioning roller

InactiveCN107829251ANo need to worry about slackNo need to worry about wrinklingFabric finishing guides/expandersStretchingSetterRoller screw

The invention discloses a conveniently adjustable tension roller for a sizing machine, which comprises a tension roller body, a fixed thread sleeve, a screw rod and a tension roller bracket. The outer layer of the tension roller is arranged outside the frame, and the two ends of the tension roller body are provided with fixed ends; the fixed threaded sleeve includes a fixedly connected threaded sleeve body and a connecting seat, and the fixed end and the connecting seat are fixedly connected by a flange, and the threaded sleeve The main body is screwed with the screw rod; the tension roller bracket includes a bracket connecting part and a lower fixing part which are threadedly matched with the lower end of the screw rod, and the bracket connecting part and the lower fixing part are hinged. The invention is reasonable in design and simple in structure. The height of the tension roller body can be adjusted through the fixed threaded sleeve, and the angle can also be adjusted through the tension roller bracket. There is no need to worry about the loosening and wrinkling of the cloth, and it is very practical.

Owner:浙江仁信印染机械有限公司

Fabric corner treatment device

InactiveCN109505087AWith limit fixed functionEasy to cutFabrics trimmingFabric finishing guides/expandersEngineeringSlide plate

The invention discloses a fabric corner treatment device which comprises a support column, wherein a working table is fixedly mounted at the top end of the support column; a concave surface groove isformed in the middle of the top end of the working table; sliding grooves are formed in the left side and the right side of the bottom end of the working table; concave grooves are formed in the surfaces of the bottom ends of the sliding grooves; sliding blocks are moveably mounted inside the sliding grooves; connecting rods are mounted at bottom ends of the sliding blocks; bottom ends of oppositesides of the two connecting rods penetrate through the two concave grooves and extend into the sliding grooves. Due to cooperation of the sliding grooves, the concave grooves, the connecting rods, the working table, a soft rubber pad, a limiting plate, a rotating shaft, a handle, the concave surface groove, the sliding blocks, a cavity, a limiting bolt, a sliding plate, a threaded hole and a connecting block, the fabric corner treatment device has a function of limiting and fixing a fabric, and thus convenience can be brought to operators to cut corners of the fabric.

Owner:嘉兴富宏纺织有限公司

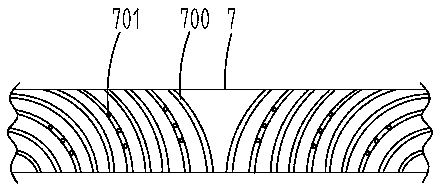

Production equipment for knurling and forming double sides of non-woven fabrics

InactiveCN108842357AMeet structural requirementsStable deliveryMechanical cleaningPressure cleaningTransmission beltElectric machinery

The invention discloses production equipment for knurling and forming double sides of non-woven fabrics. The production equipment comprises a base and a wind diffusing plate. A transmission motor is mounted on the right side above the base, and a transmission belt is arranged above the transmission motor, chutes are formed in the left and right sides of the surface of the wind diffusing plate, andthe wind diffusing plate is located above the transmission belt. By arranging a supporting plate, a knurling base plate structure by means of a hydraulic lifting and descending theory is arranged onthe equipment. A replaceable pattern plate on the supporting plate and the supporting plate are in fit connection, and the replaceable pattern plate can slide horizontally based on the supporting plate, so that the replaceable pattern plate can be replaced, and the changeability of bottom grains is ensured. By arranging a knurling sleeve, the equipment can knurl the upper surface of a non-woven fabric synchronously. The knurling sleeve is fixedly connected to a rotating shaft by means of a buffer cushion and rotates along with the rotating shaft so as to achieve circumferential and tortuous repeated knurling work.

Owner:陈雪莲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com