Continuous ironing device for textiles

A technology for ironing equipment and equipment racks, which is applied in textile and papermaking, fabric surface trimming, fabric steam/tweening treatment, etc., can solve the problems of low efficiency, trouble, poor continuity, etc., and achieve strong applicability and improve processing efficiency. , the effect of ingenious device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

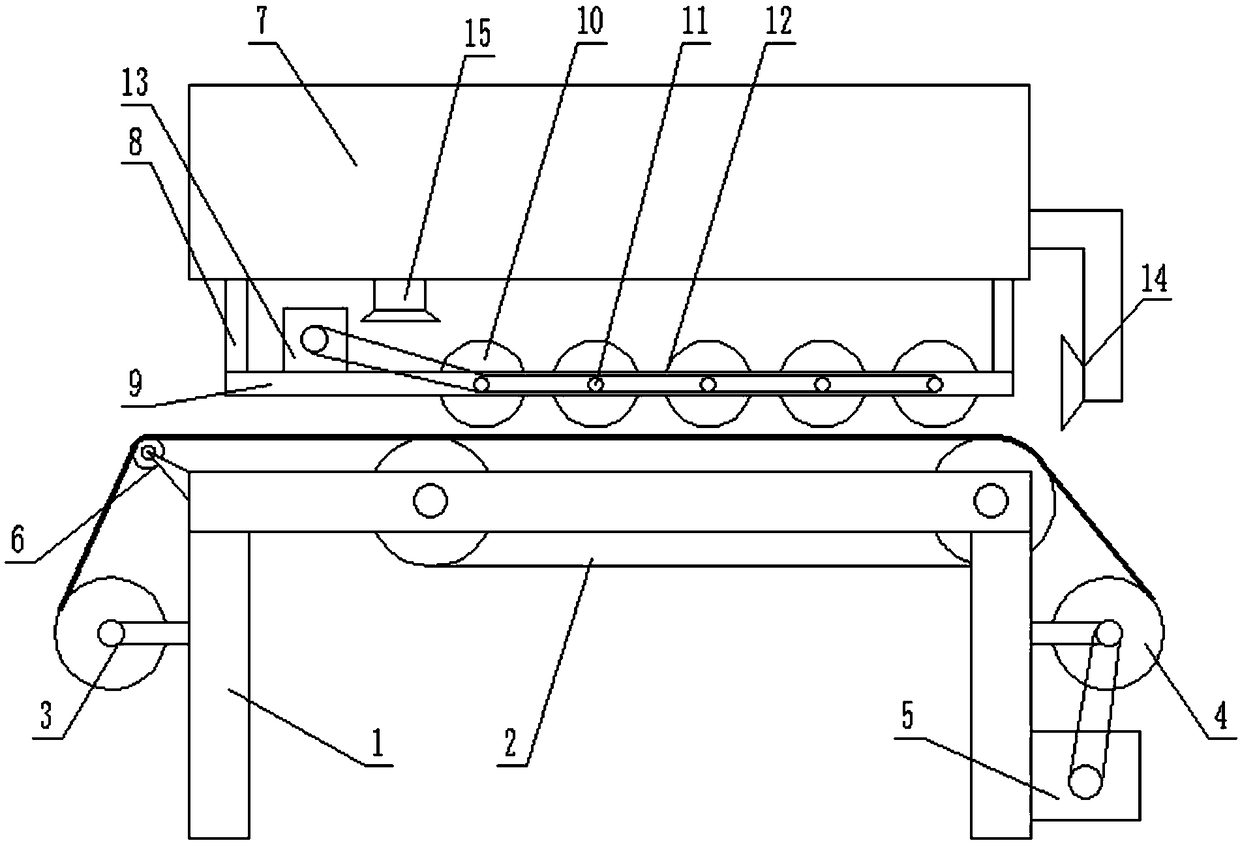

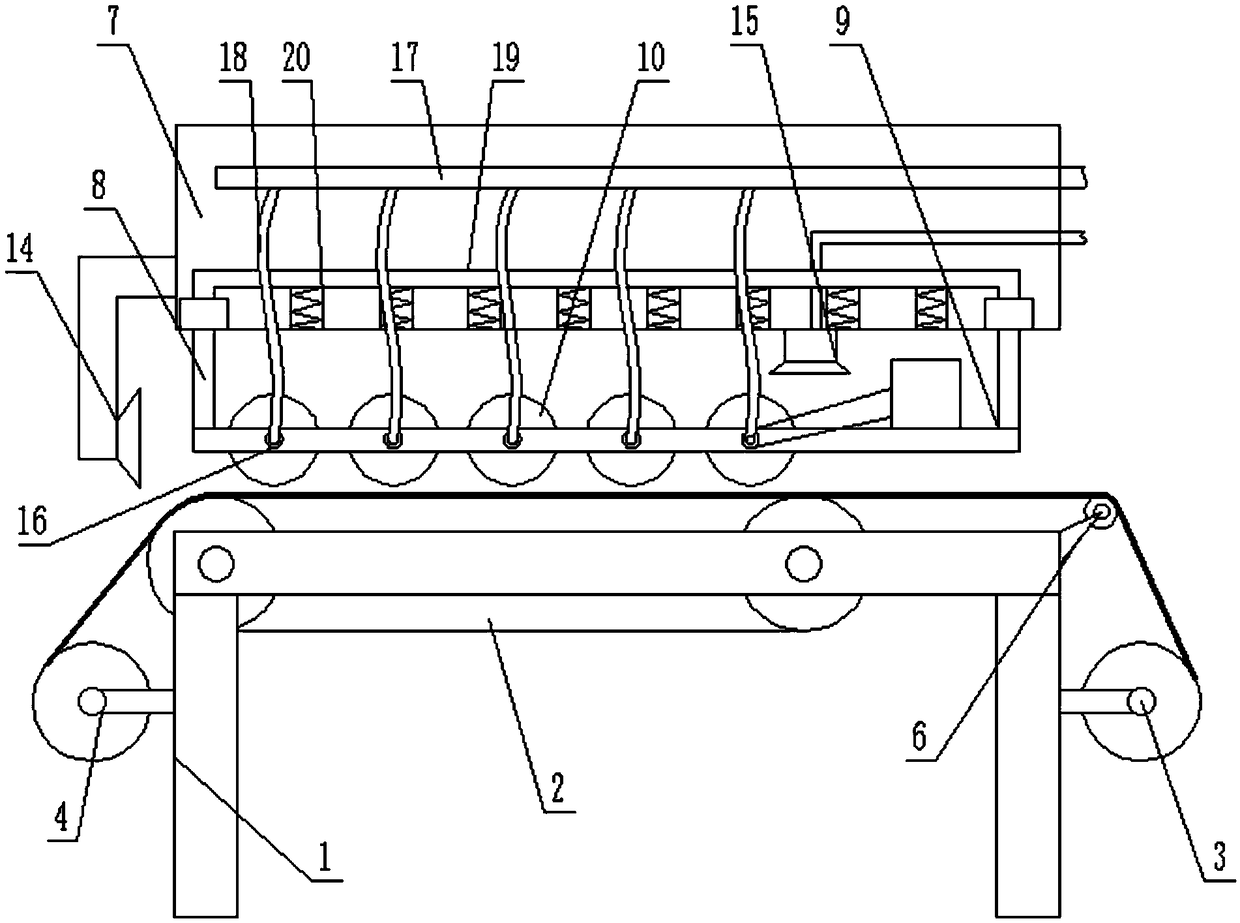

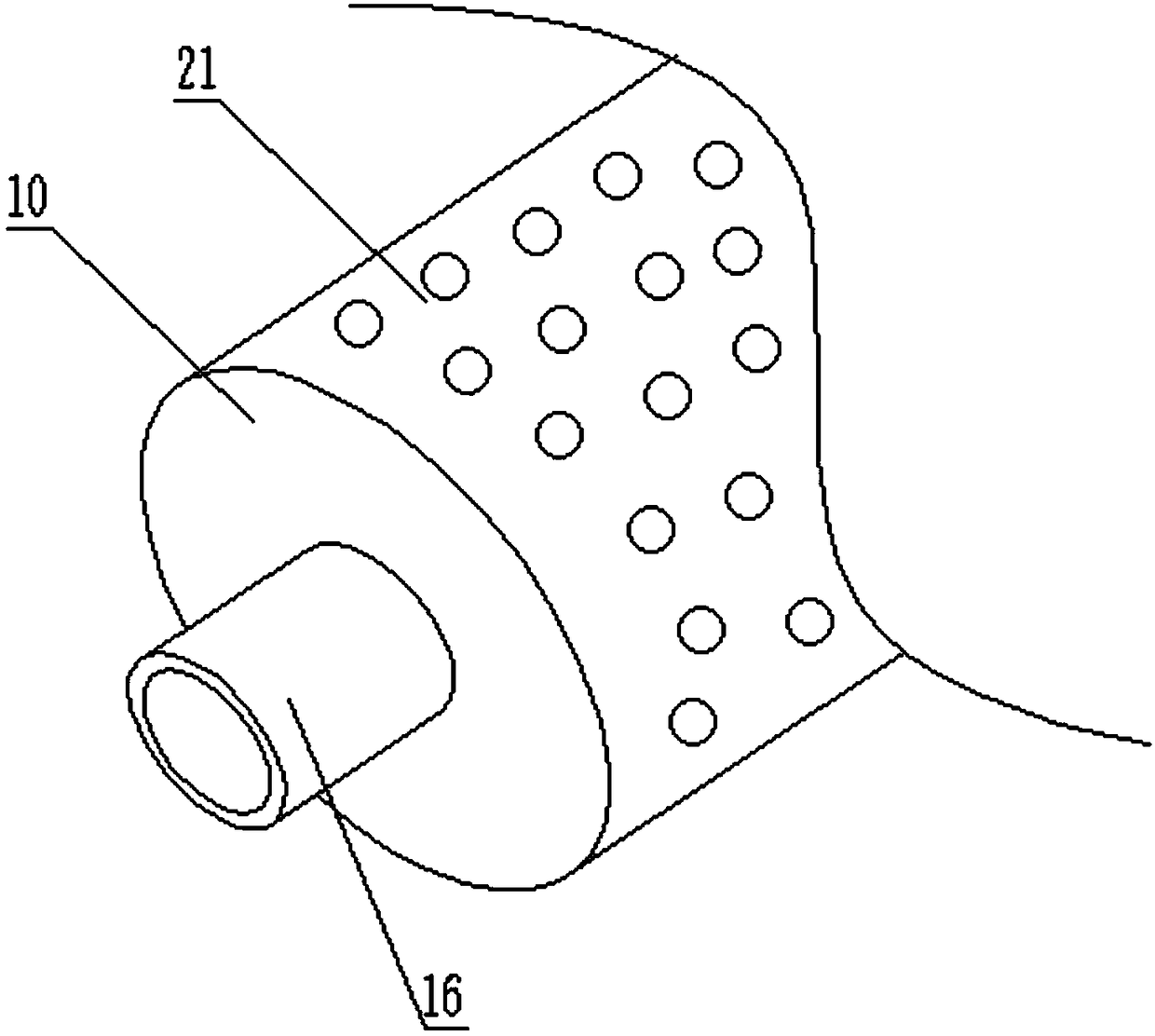

[0019] see Figure 1-3 , a continuous ironing device for textiles, comprising a frame 1 and an equipment frame 7, the frame 1 is fixed on the ground, the equipment frame 7 is suspended above the frame 1, and a conveyor belt 2 is arranged on the plane of the frame 1, An unwinding roller 3 and a winding roller 4 are respectively arranged on both sides of the frame 1, and a winding motor 5 which is connected to the winding roller 4 and controls its rotation is arranged below the winding roller 4, and a fixed motor 5 is arranged above the unwinding roller 3. The tension roller 6 at the edge of the frame 1 is provided with two support rods 9 arranged in parallel in the horizontal direction and positioned above the conveyor belt 2 below the equipment frame 7, and multiple support rods 9 are arranged between the two support rods 9 to rotate with them. The connected ironing roller 10, the two ends of the ironing roller 10 are respectively provided with a solid shaft 11 and a hollow sh...

Embodiment 2

[0023] The difference from Embodiment 1 is that the inner side of the conveyor belt 2 is provided with a plurality of support rollers that are rotatably connected to the frame 1, and the support rollers are used to provide upward support for the upper surface of the conveyor belt 2. When the ironing roller 10 is down When the pressure is applied, serious deformation of the belt surface of the upper layer of the conveyor belt 2 can be avoided, causing the cloth to separate from the ironing roller 10, thereby further ensuring the effect of ironing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com