Convenient-to-adjust setter tensioning roller

A tensioning roller and machine tensioning technology, applied in the direction of fabric elongation, textile and papermaking, fabric surface trimming, etc., can solve the problems of wrinkling, easy slack of the fabric, difficult adjustment of the tensioning roller, etc., and achieves reasonable design and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

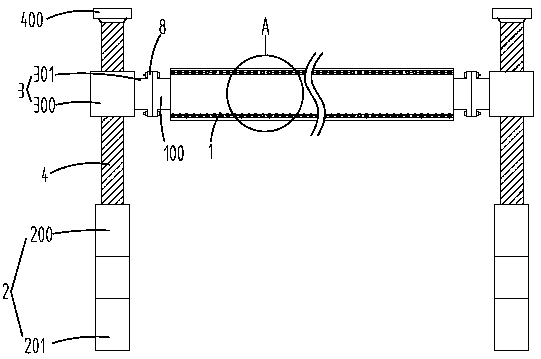

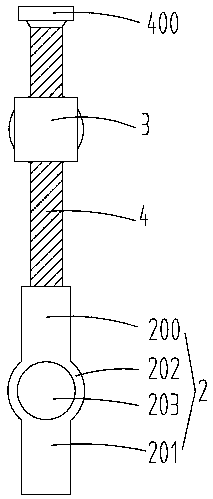

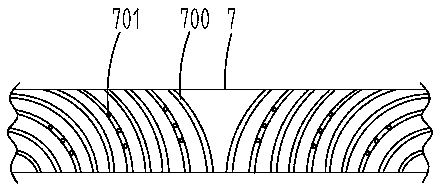

[0018] Such as figure 1 , 2 , 3, 4, and 5, a convenient adjustment of the tension roller of the sizing machine includes a tension roller body 1, a fixed threaded sleeve 3, a screw rod 4 and a tension roller bracket 2, and the outer surface of the tension roller body 1 is sleeved The cage 5, the cage 5 is covered with balls 6, the cage 5 is covered with the outer layer 7 of the tension roller, the outer surface of the tension roller 7 is provided with two guide grooves 700, and the guide grooves 700 are formed by the outer layer 7 of the tension roller. The middle position extends outwards in a spiral shape, and a group of oil inlet holes 701 are provided in the guide groove 700. The two ends of the tension roller body 1 are provided with fixed ends 100, and the guide groove 700 guides the flow of lubricating oil so that it flows all over the tension roller. The oil inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com