Cloth drying equipment with leveling function used for textile processing

A fabric drying and equipment technology, which is applied to the configuration of textile material processing equipment, fabric drying equipment, and textile material processing, can solve the problems of unfavorable processing and use, poor oven effect, and low efficiency, so as to improve processing efficiency. Reduce processing steps and improve drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

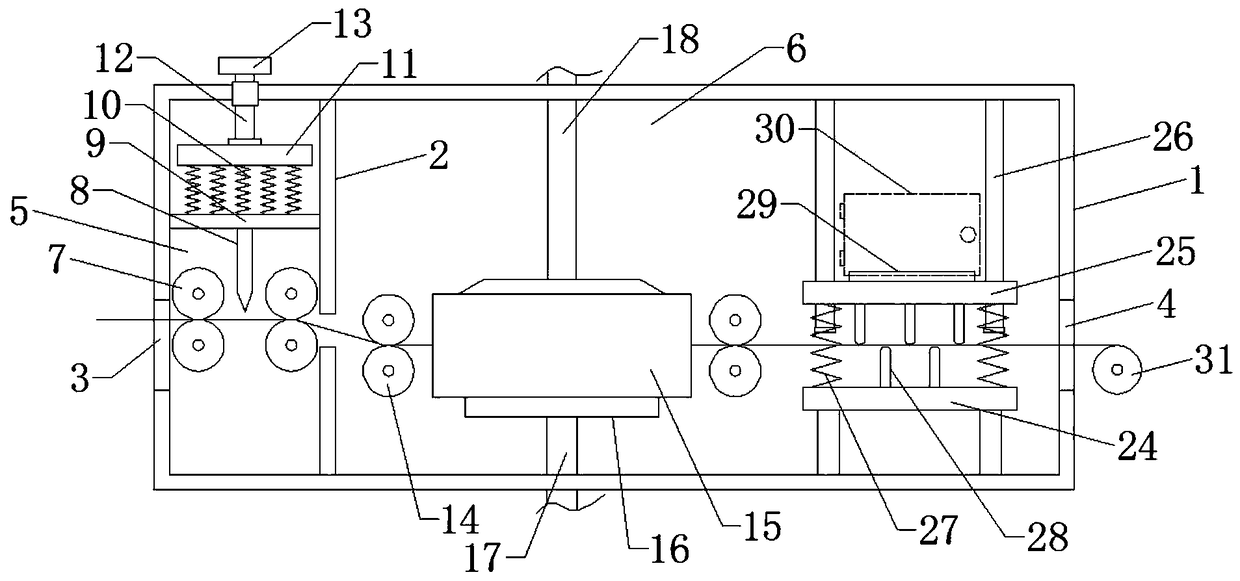

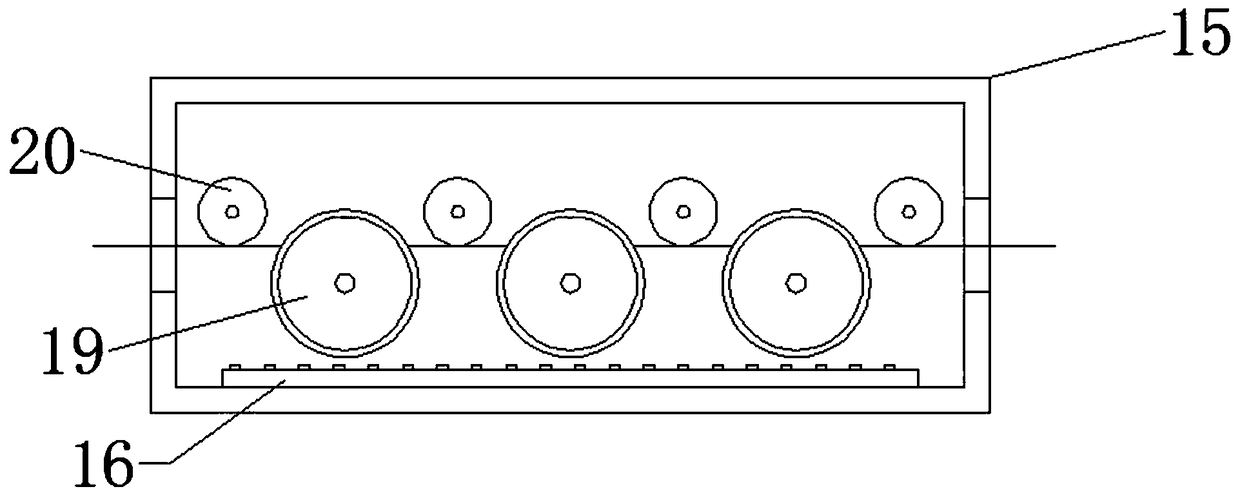

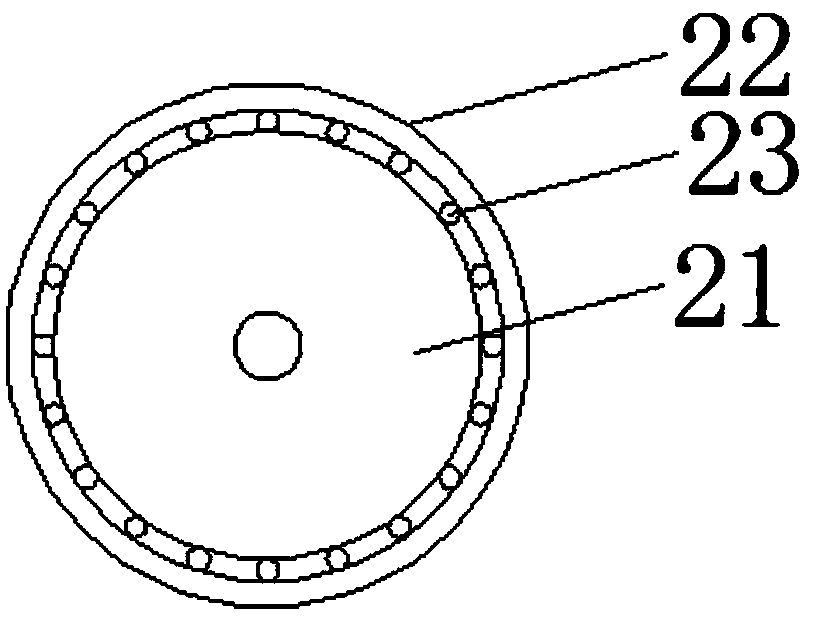

[0014] Please refer to the figure, in the embodiment of the present invention, a cloth drying equipment with leveling belt for textile processing includes a box body 1, a partition plate 2, a material inlet 3, a material outlet 4, a conveying roller group 7, a material guide Roller group 14 and take-up roller 31; Said feed port 3 and discharge port 4 are opened at the left and right ends of box body 1 respectively, and on the same horizontal plane, said dividing plate 2 is vertically positioned in box body 1, The inside of the box body 1 is divided into the wiper chamber 5 on the left and the drying chamber 6 on the right, and an opening is opened on the partition 2, so that the cloth passes through the partition 2, and in the wiper chamber 5 and the drying chamber 6 For conveying, the outside of the discharge port 4 is correspondingly equipped with a winding roller 31 with a driving click to wind up the dried and leveled cloth.

[0015] Two sets of conveying rollers 7 are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com