Feeding equipment for dust covers

A dust cover and equipment technology, applied in the cutting of textile materials, textile and paper making, fabric surface trimming, etc., can solve the problems of dust cover burrs entangled in the machine, slow production speed, low production efficiency, etc. The effect of improving convenience, ensuring durability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

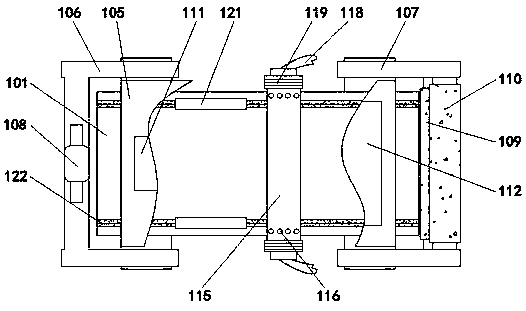

[0045] The embodiment of the present invention provides a dust cover feeding device, the purpose of which is to solve the problem that the current dust cover feeding device does not press and iron the dust cover, so that the dust cover is wrinkled, and the burr is not processed, which is easy to cause The burr of the dust cover is entangled with the machine, and the existing dust cover feeding equipment needs to manually cut the dust cover, the production speed is slow, and the production efficiency is low.

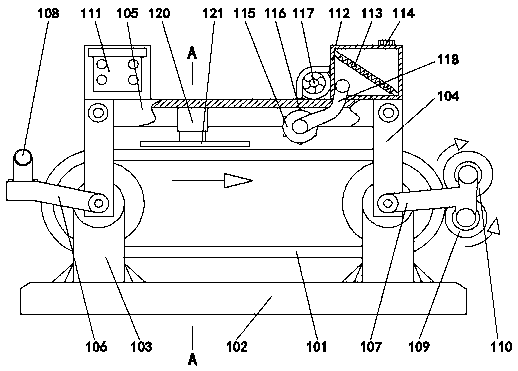

[0046] In order to better understand the technical solution of the present invention, the technical solution of the present invention is described in detail below in conjunction with the accompanying drawings and embodiments:

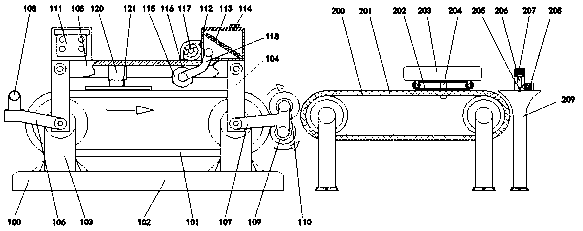

[0047] An embodiment of the present invention provides a dust cover feeding device, such as figure 1 As shown, it mainly includes a conveying mechanism 100 , and a distributing mechanism 200 is arranged on the right side of the conveying mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com