Textile fabric shaping, production and processing device

A processing device and textile fabric technology, which is applied in the direction of textiles and papermaking, fabric surface trimming, fabric finishing guide/expander, etc., can solve the problems of home textile fabrics affecting dyeing effect, time-consuming, laborious, and impact, and achieve better singeing quality Excellent, guaranteed cleanliness, full fiber burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

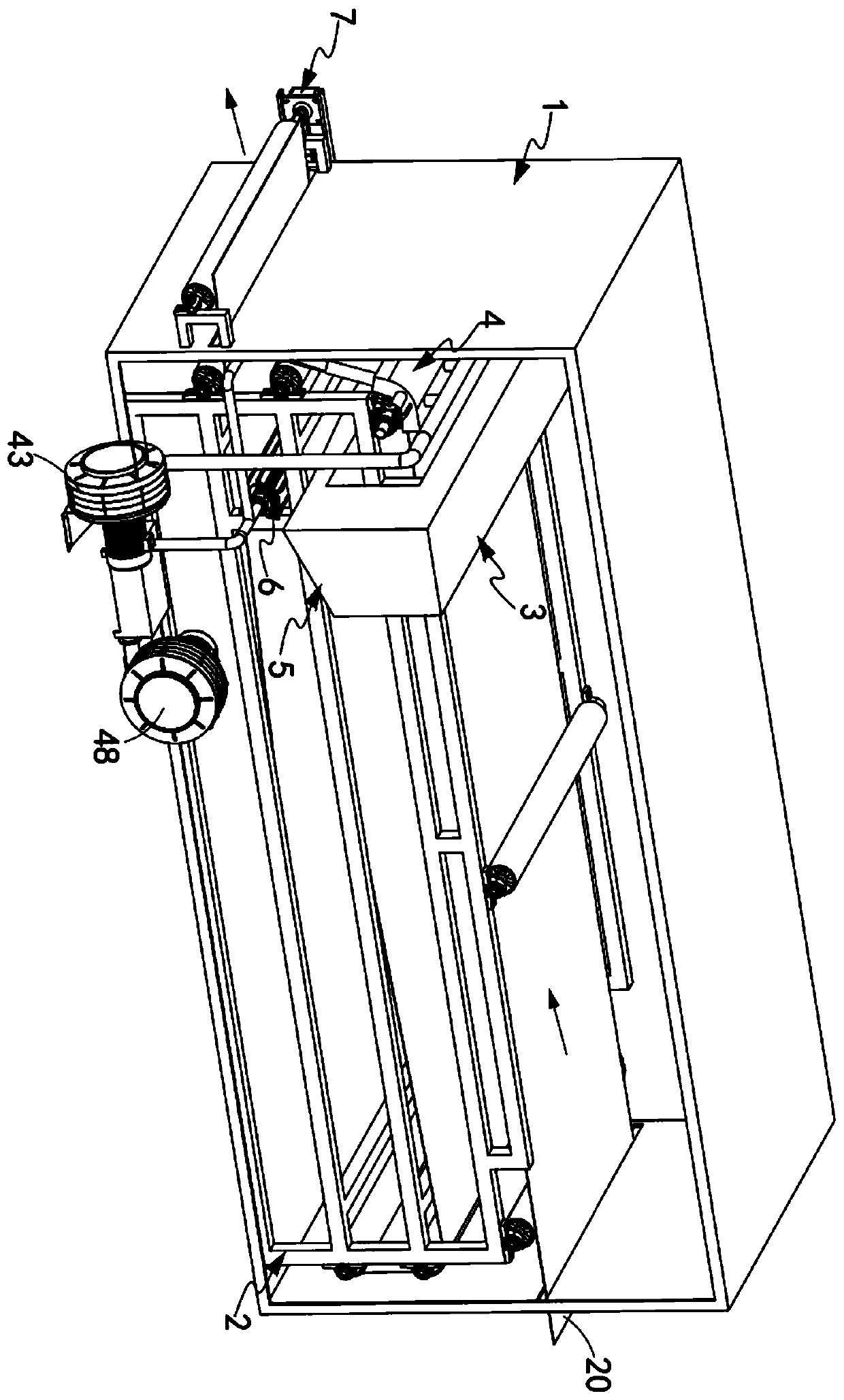

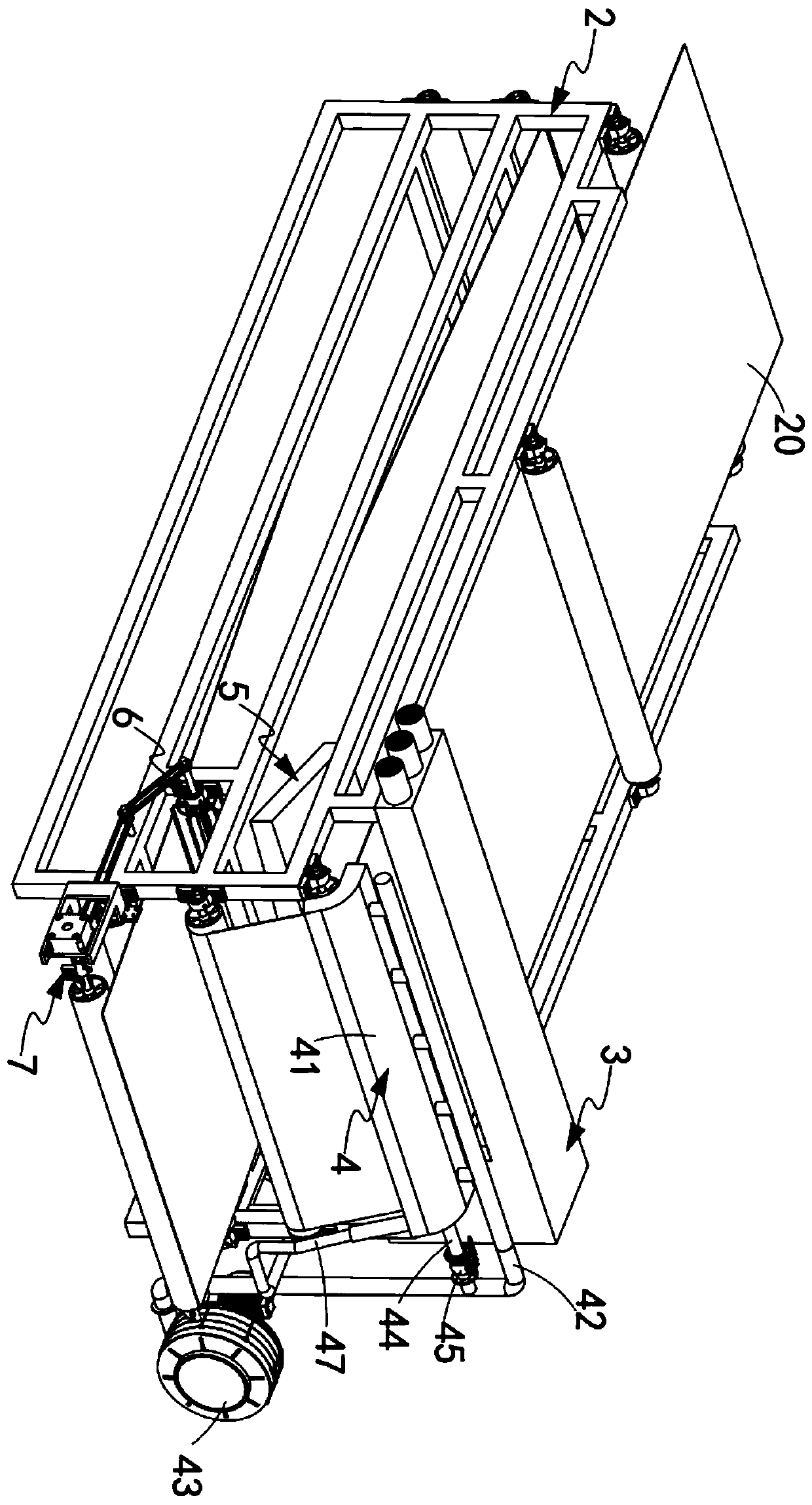

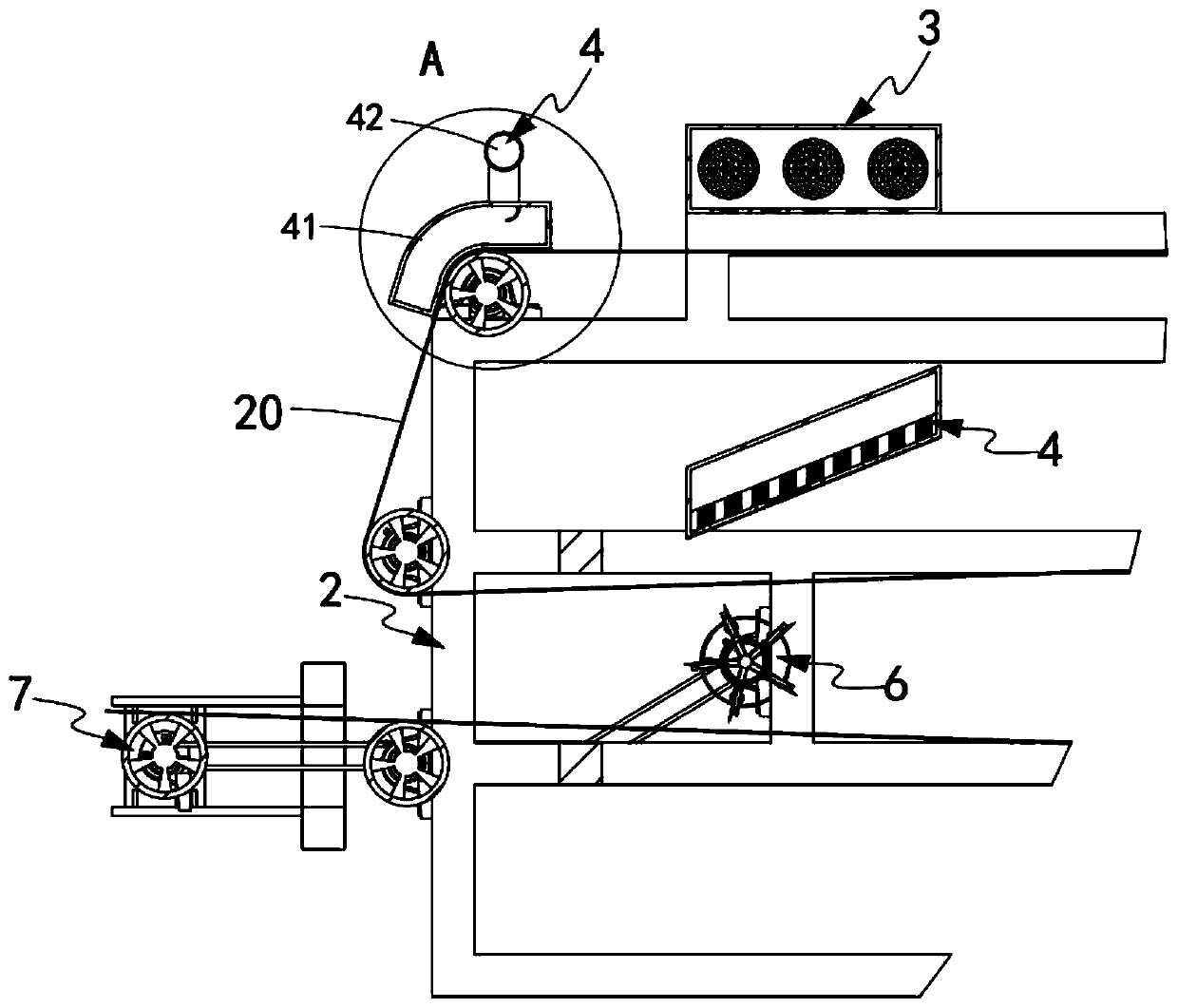

[0084] Such as figure 1 , figure 2 and image 3 Shown, a kind of textile fabric shaping production and processing device comprises:

[0085] A processing box 1, the processing box 1 is arranged in a square shape;

[0086] Mounting frame 2, said mounting frame 2 is installed in said processing box 1, and it is frame-shaped setting, and is distributed with a plurality of rotating conveying rollers 21 arranged on it, and this conveying roller 21 is wound and conveyed with fabric 20;

[0087] Negative pressure finishing mechanism 3, the negative pressure finishing mechanism 3 is installed on the top of the installation frame 1, the fabric 20 is transported through the bottom of it, and its negative pressure absorbs the textile fibers on the fabric 20 for finishing;

[0088] Incineration mechanism 4, described incineration mechanism 4 is installed on the described installation frame 2, along the conveying direction of described fabric 20, this incineration mechanism 4 is arrang...

Embodiment approach

[0122] Such as Figure 14 , Figure 15 , Figure 16 , Figure 17 and Figure 18 As shown, as a preferred embodiment, the dust removal mechanism 6 includes:

[0123] A hollow shaft 61, the hollow shaft 61 is rotatably arranged on the mounting frame 2, and the hollow pipe 611 in it is communicated with the exhaust pipe 47;

[0124] The dust removal brush 62 is arranged in a circular array along the axial direction of the hollow shaft 61, and it is rotatably connected with the hollow shaft 61. The dust removal brush 62 can be connected with the fabric 20 contact settings;

[0125] Dust collection bins 63, the dust collection bins 63 are arranged one by one on the cleaning brushes 62, which collect singeing impurities cleaned by the cleaning brushes 62 from the fabric 20;

[0126] The barrier plate 64, the barrier plate 64 is set in the shape of a hook, and it is rotated to be arranged at the opening of the dust collection bin 63, and its length is consistent with the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com