Patents

Literature

51results about How to "Burn fully and completely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

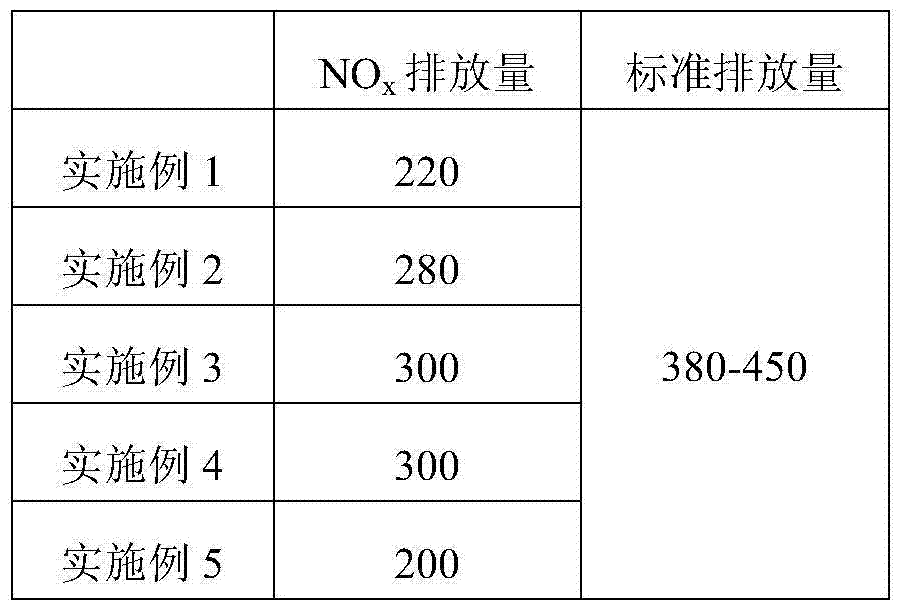

Pneumatic medical waste burning process for rotary kiln and device therefor

InactiveCN101285577AAvoid destructionAchieve turbulent combustionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberAtmospheric air

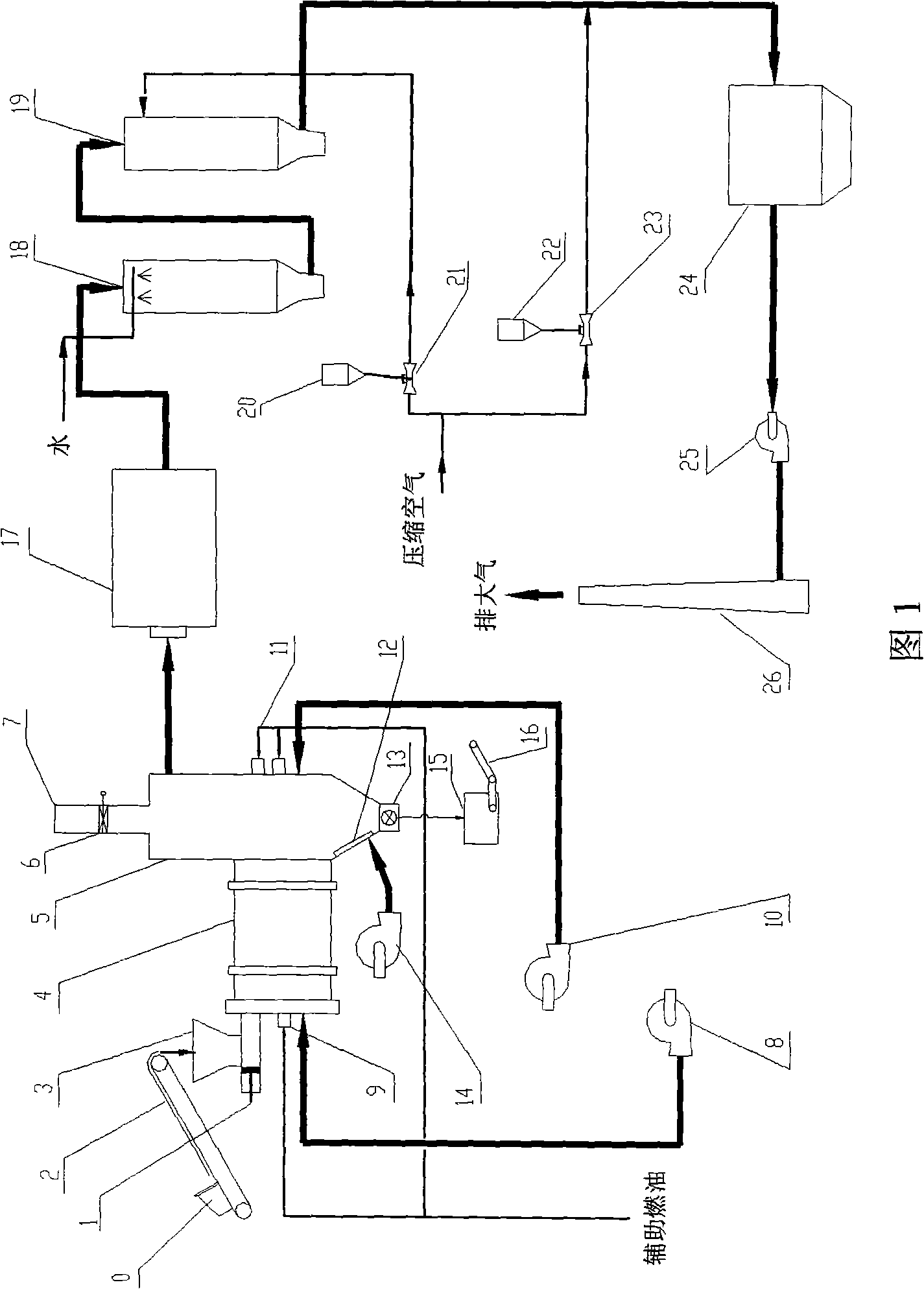

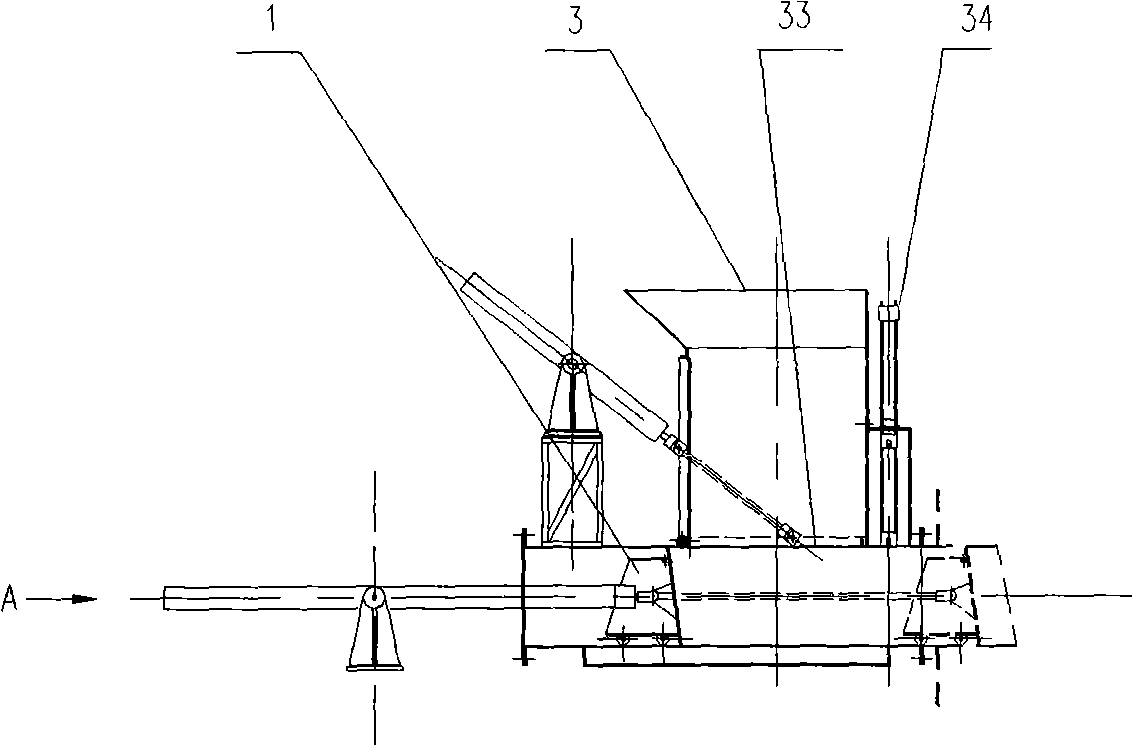

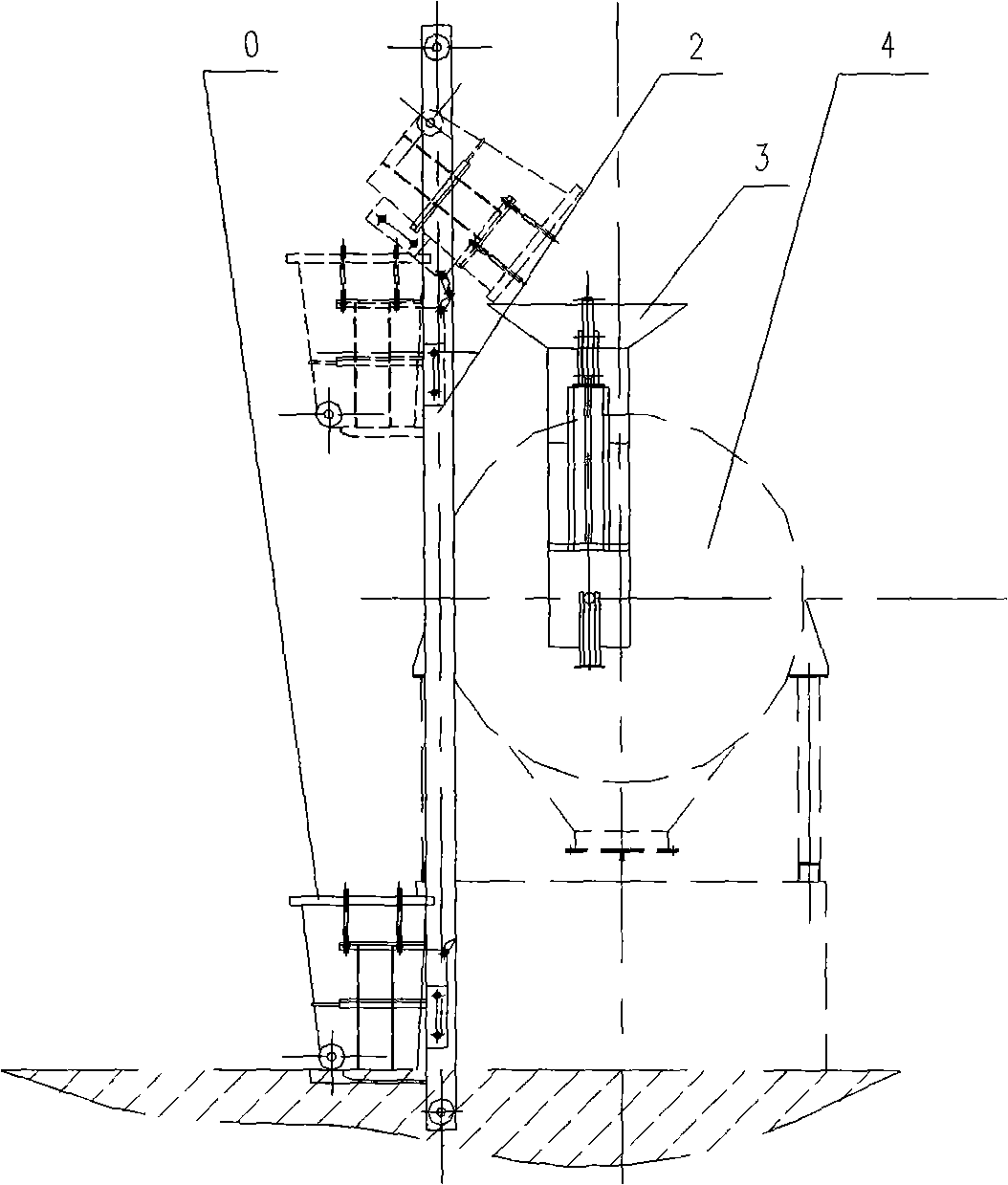

The invention discloses a process and a device for incinerating rotary kiln gas-controlled medical waste, relating to the environmental protection technical field. The process of the invention comprises the following steps of: collecting the whole packet of medical waste refuse bag and feeding into a feeding hopper, then feeding into a rotary kiln initial combustion chamber by a feeding mechanism which is closed by chain, and completing the processes of drying, pyrolyzing and air controlled anoxycausis of the medical waste. Waste gas generated by the rotary kiln initial combustion chamber enters to a secondary combustion chamber to undergo the process of air controlled oxygen-enriched complete combustion, wherein bottom ash with a little redial carbon is flamed at an inclined fire grate which is arranged in an ash well at the lower part of the secondary combustion chamber. The smoke gas at an outlet of the secondary combustion chamber is exhausted into the atmosphere by a draft fan through a chimney after surplus heat utilization of a surplus heat boiler, smoke gas sharp quenching of a quench tower, a dry-type deacidification and cloth-bag dust removal of a bag-type duster. Compared with the prior art, the process and the device for incinerating rotary kiln gas-controlled medical waste have the advantages of good operating economical efficiency, automatic safety continuous feeding, fluent slag tapping system and low index of pollution emission.

Owner:TSINGHUA UNIV +1

Method for increasing combustion efficiency of combustion engine

InactiveCN101701558ATake advantage ofIncrease the itineraryInternal combustion piston enginesCombustion-air/fuel-air treatmentJet aeroplanePlasma technology

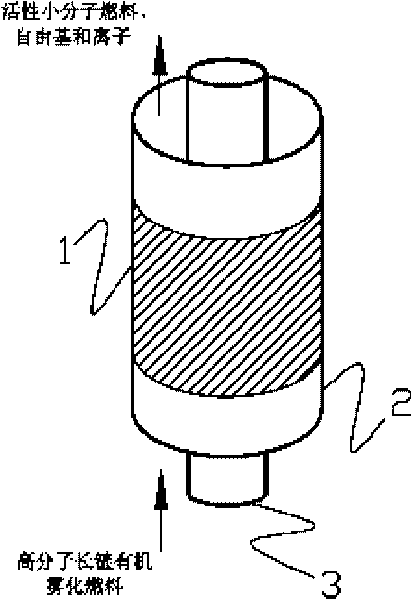

The invention provides a new method for increasing combustion efficiency of a combustion engine; based on non equilibrium plasma technology, a non equilibrium plasma generator with low power is designed and applied, has small volume, can be widely applied to such as fuel power equipment such as automobiles, airplanes and the like and really realizes the combustion efficiency increase of the fuel equipment and exhaust emission reduction. The non equilibrium plasma generator provided by the invention is applied for carrying out controllable dielectric barrier discharge so as to activate fuel or combustion-supporting fuel, thus fundamentally improving combustion situation of the fuel, causing the fuel to fully and effectively burn and simultaneously achieving the effect of energy saving and emission reduction.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

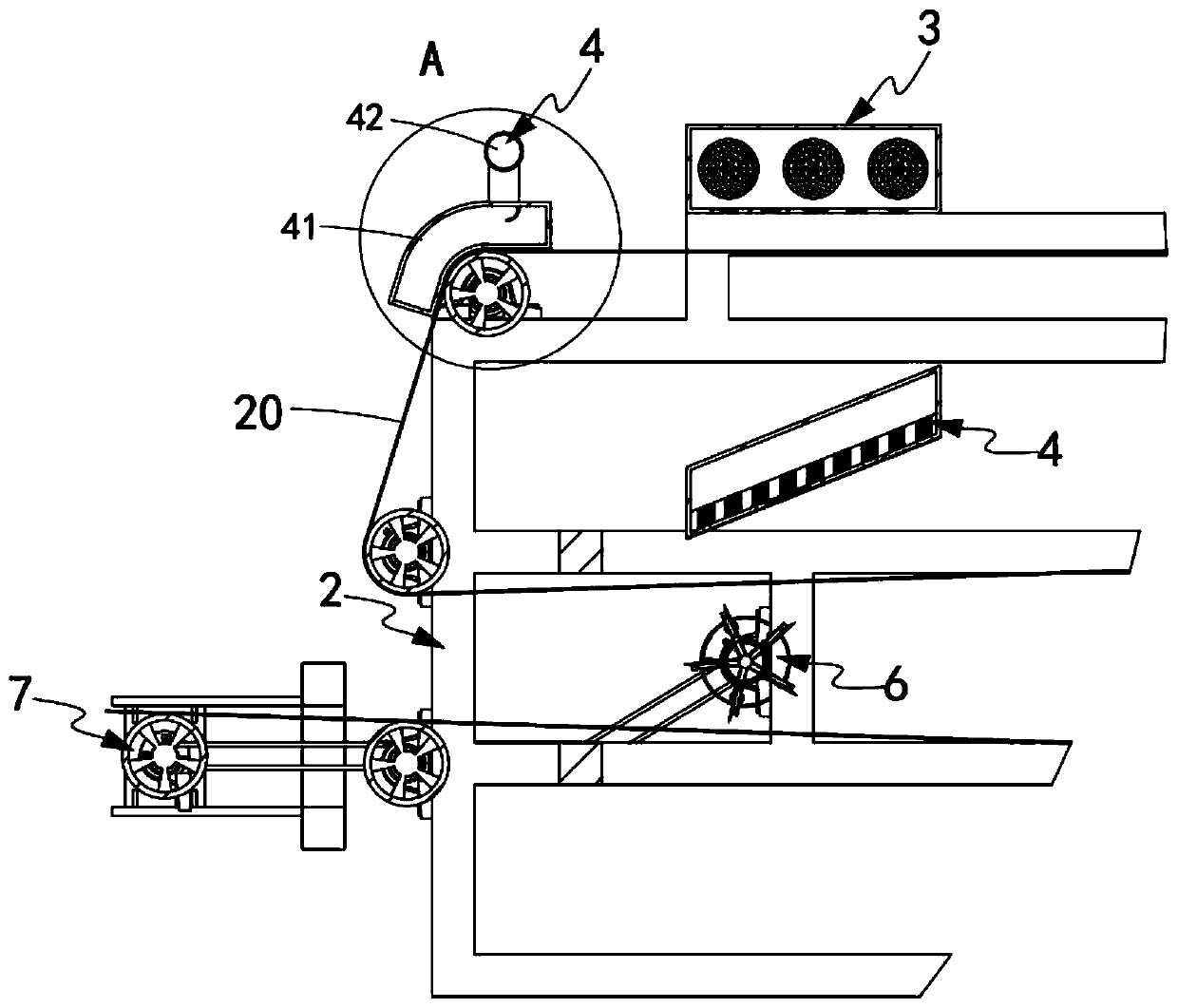

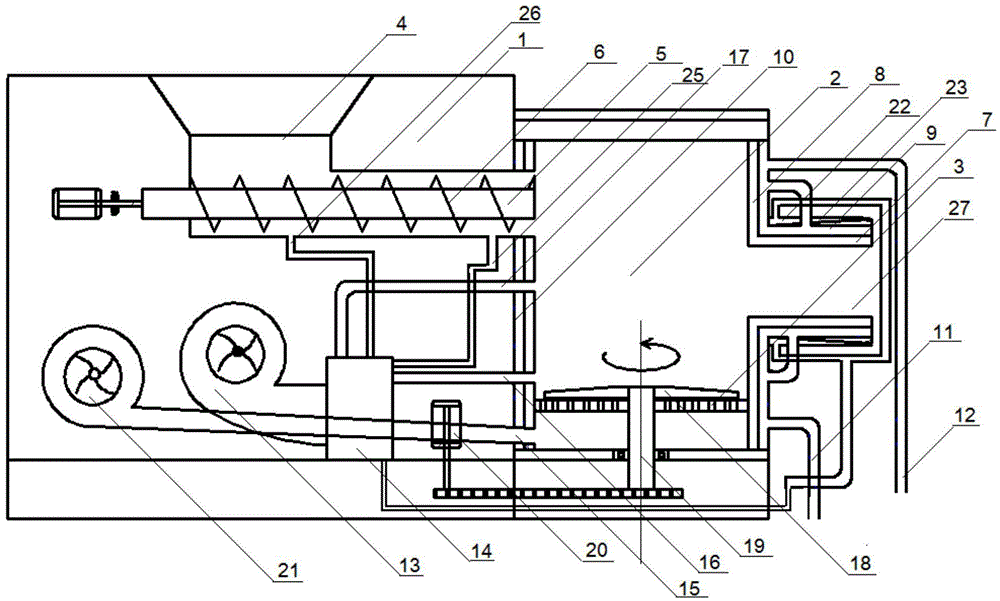

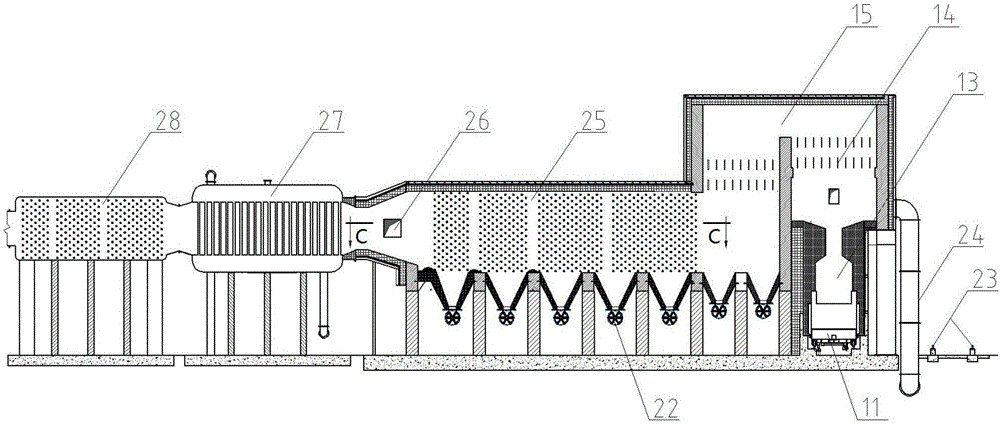

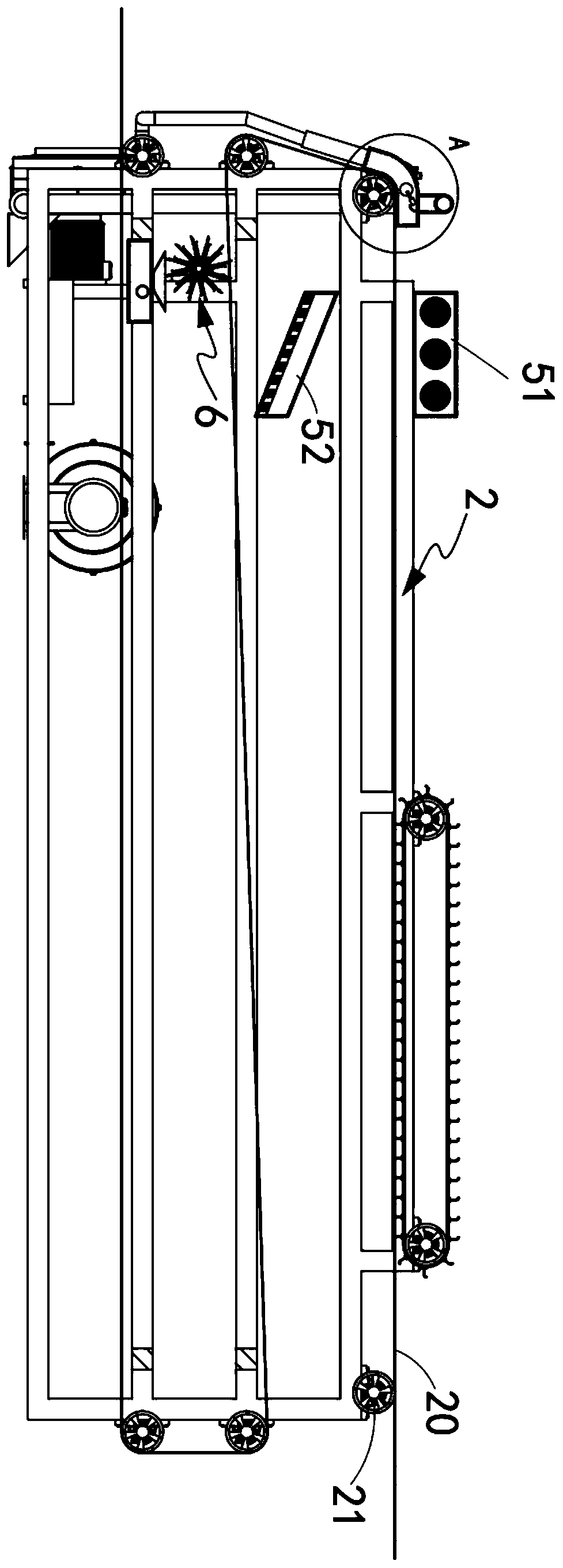

Textile fabric shaping, production and processing device

InactiveCN110067105AGuaranteed flatnessGuaranteed cleanlinessMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention provides a textile fabric shaping, production and processing device. The textile fabric shaping, production and processing device comprises a processing box, wherein a mounting frame ismounted in the processing box; and a fabric is conveyed on the mounting frame, a negative-pressure neatening mechanism, an incineration mechanism, a smoothening mechanism and a dust cleaning mechanismare separately mounted on the mounting frame in the fabric conveying direction, a rolling mechanism is installed outwards during processing, and after being subjected to singeing treatment, home textile fabrics are subjected to rotary scraping cleaning of ash incineration by using the dust cleaning mechanism before rolling; and during cleaning, rotation switching of the dust cleaning mechanism isutilized, a pressing roller is used for carrying out rolling and tensioning adjustment and smoothening treatment on the fabric to be rolled, the fabric is always smooth in a rolling process, and theproblem that the fabric has wrinkles in the rolling process after singeing is solved.

Owner:浙江常鑫纺织品有限公司

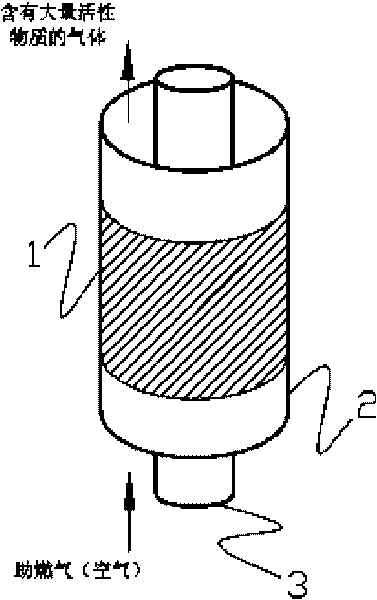

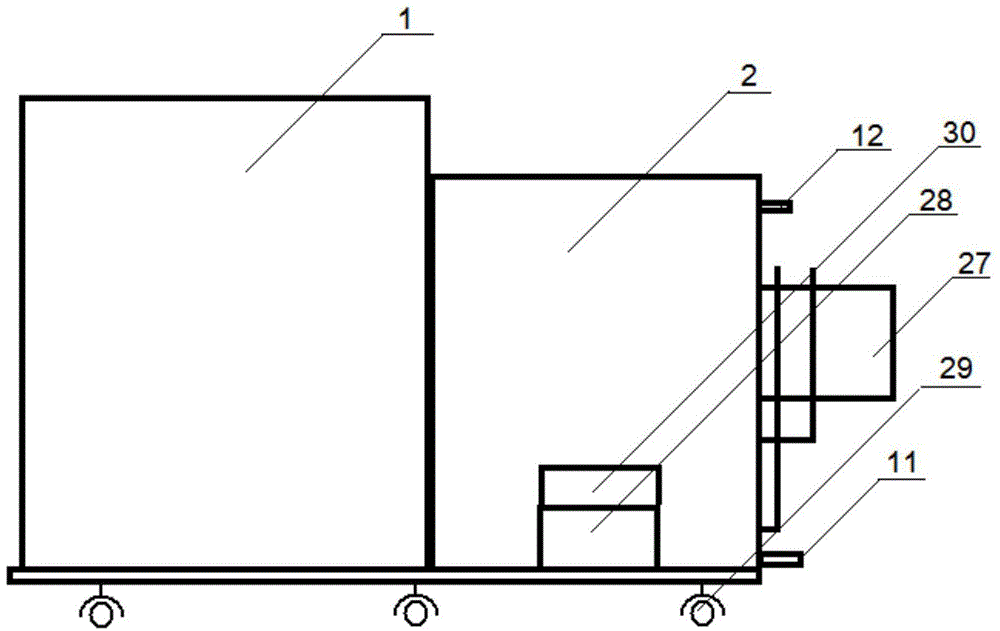

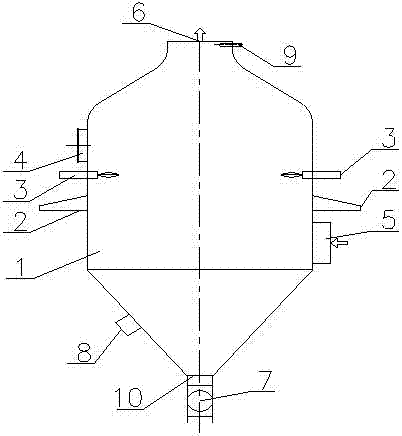

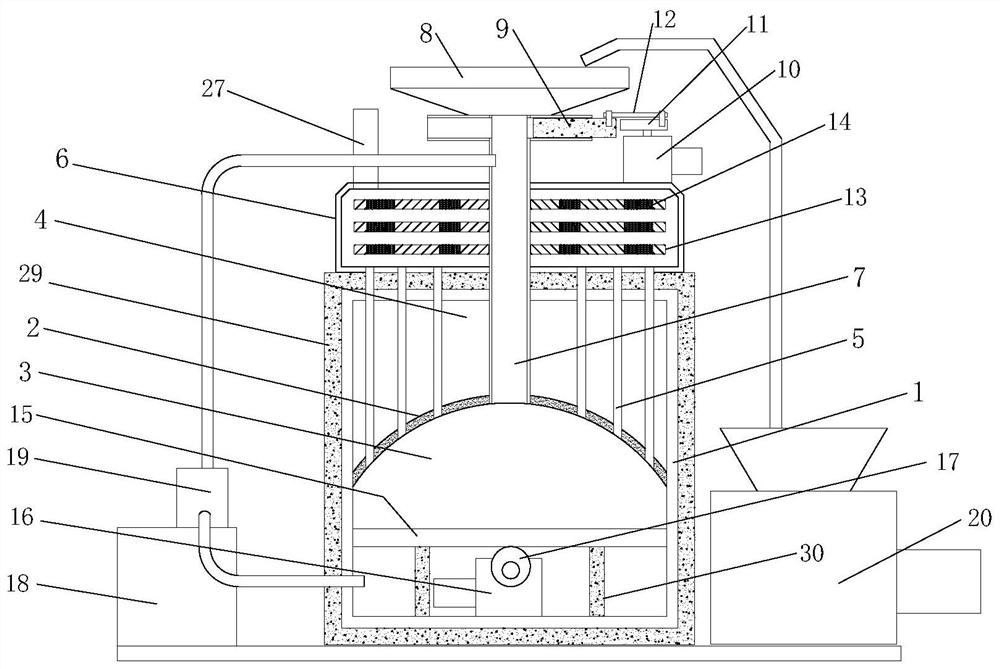

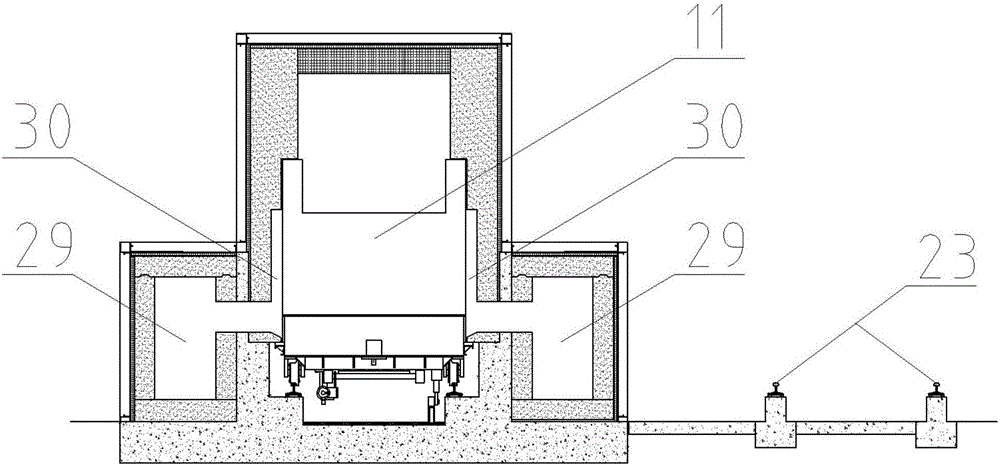

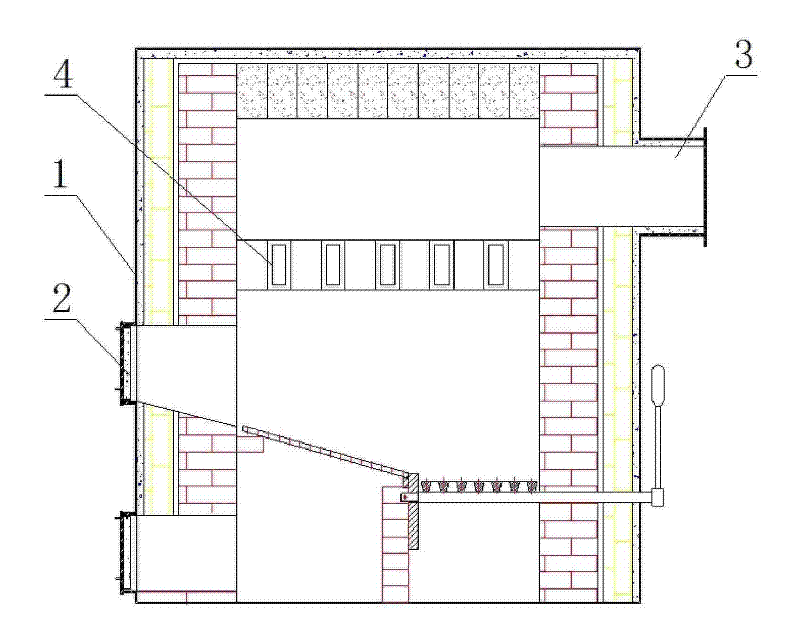

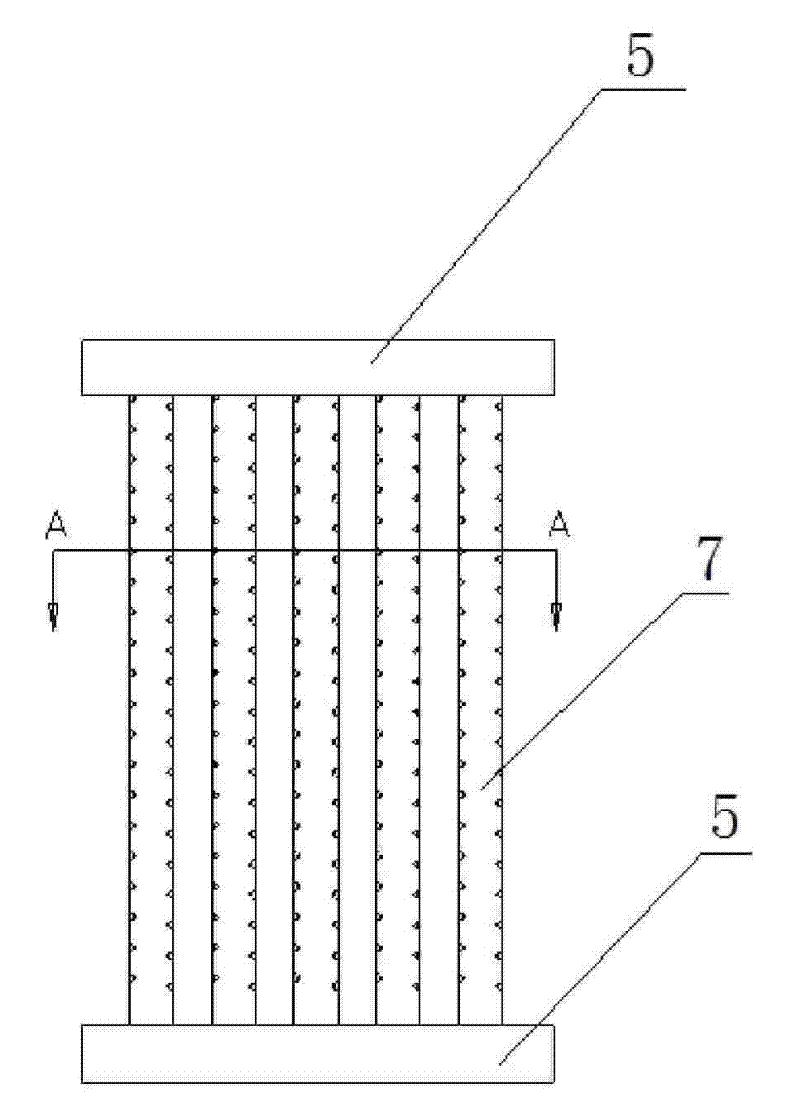

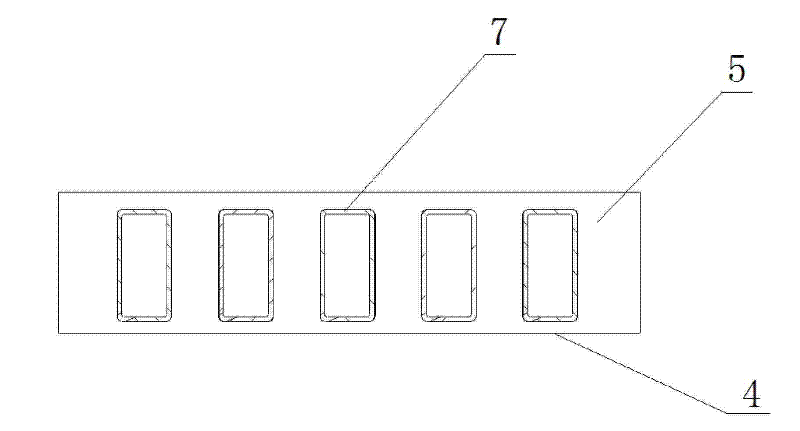

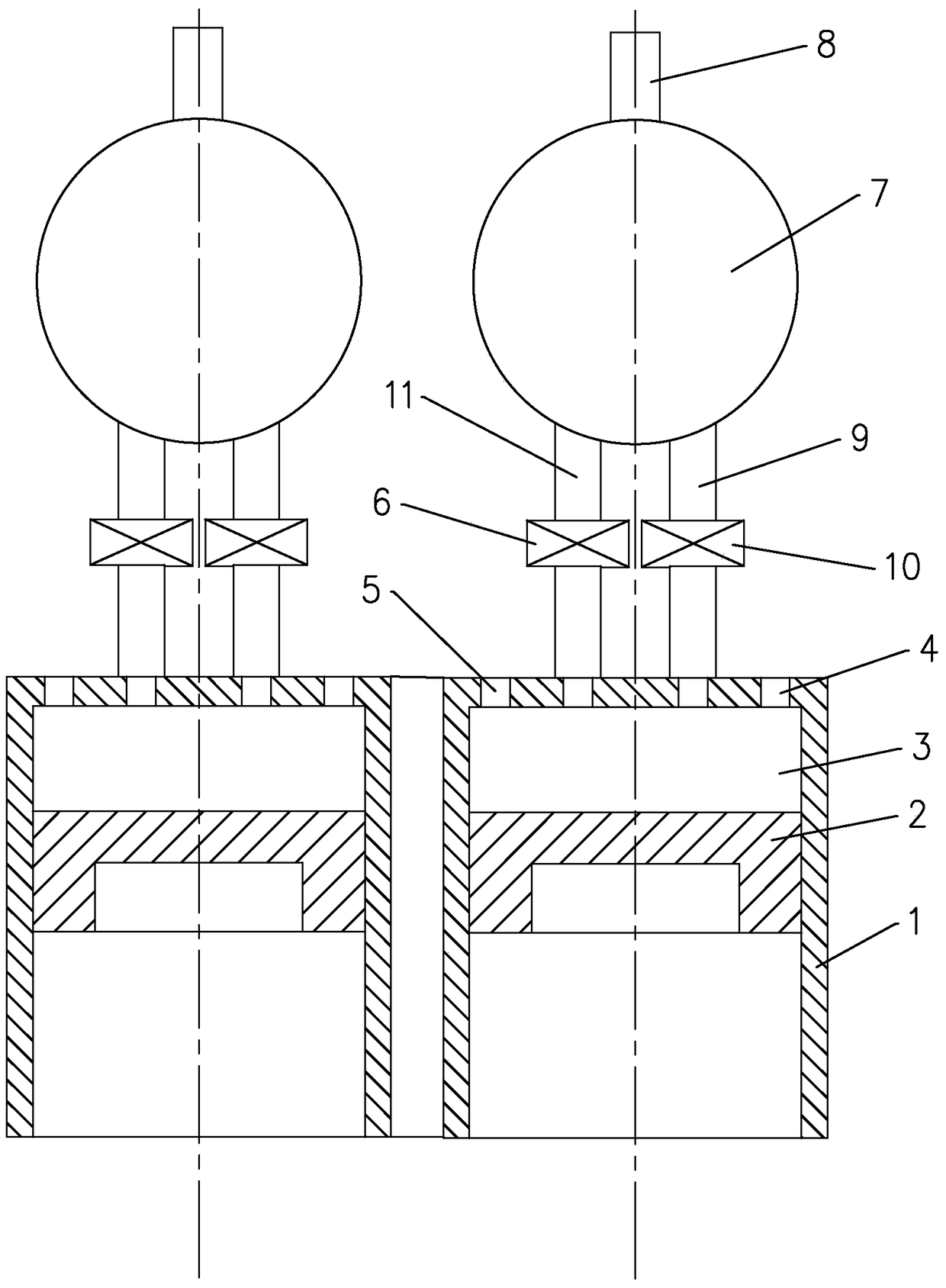

Integrated thermochemical treatment device for low-and-intermediate level radioactive wastes

PendingCN108224435AReduce volumeReduce pollutionIncinerator apparatusCombustion chamberOperational costs

The invention belongs to the technical field of low-and-intermediate level radioactive waste treatment devices, and relates to an integrated thermochemical treatment device for low-and-intermediate level radioactive wastes. The integrated thermochemical treatment device for the low-and-intermediate level radioactive wastes is used for treating organic combustible wastes containing radioactive substances produced by hospitals, scientific research institutions and nuclear power departments, solves the problems of insufficient combustion, easiness in blocking a pipeline through pyrolysis products, and higher clinker ignition loss, and realizes volume-reduction innocent treatment. A main body structure of the integrated thermochemical treatment device for the low-and-intermediate level radioactive wastes comprises a pyrolysis device and a combustion device, and is of an integrated structure; the pyrolysis products fall into a solid combustion chamber through a fire grate so as to be firedagain, so that the clinker ignition loss is reduced; a tapered feeding section realizes a sealing function; the diameter of a gas-liquid combustion chamber is larger than the diameter of the solid combustion chamber, so that the flue gas wind speed is retarded, and the fly ash quantity is reduced; and the integrated thermochemical treatment device for the low-and-intermediate level radioactive wastes is simple in overall structure, reliable in principle, compact in device, less in occupied area, high in volume reduction rate, good in curing effect, low in secondary pollution, friendly to an application environment, low in investment and operation cost, energy-saving, environmental-friendly, favorable in economic benefit and wide in market prospect.

Owner:青岛天和清原科技有限公司

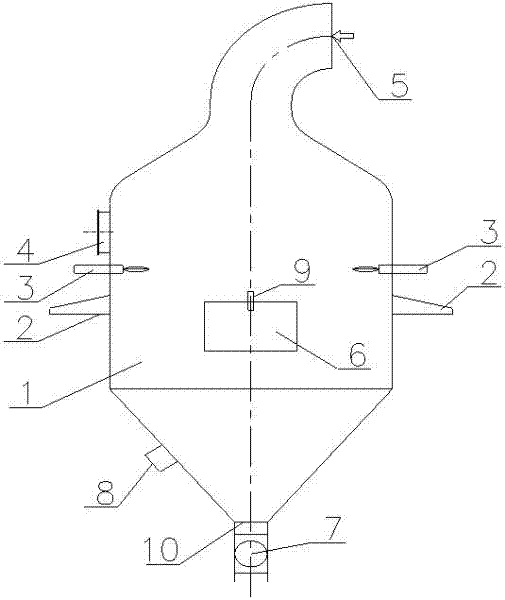

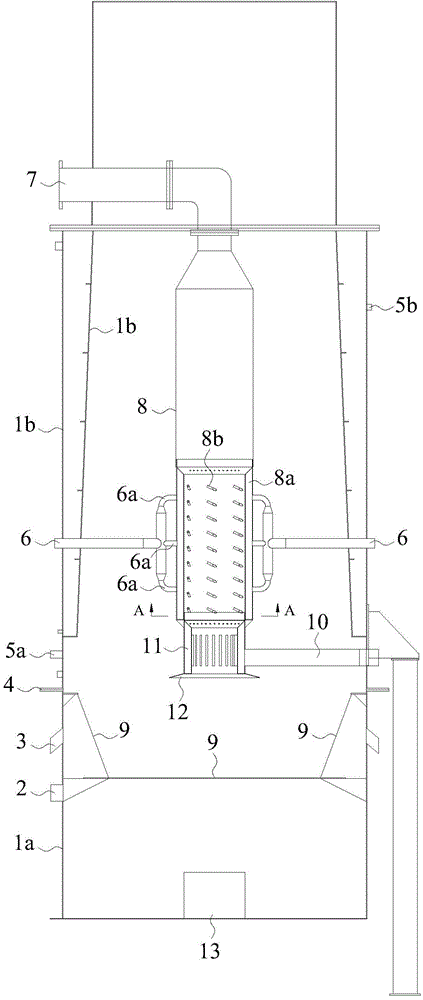

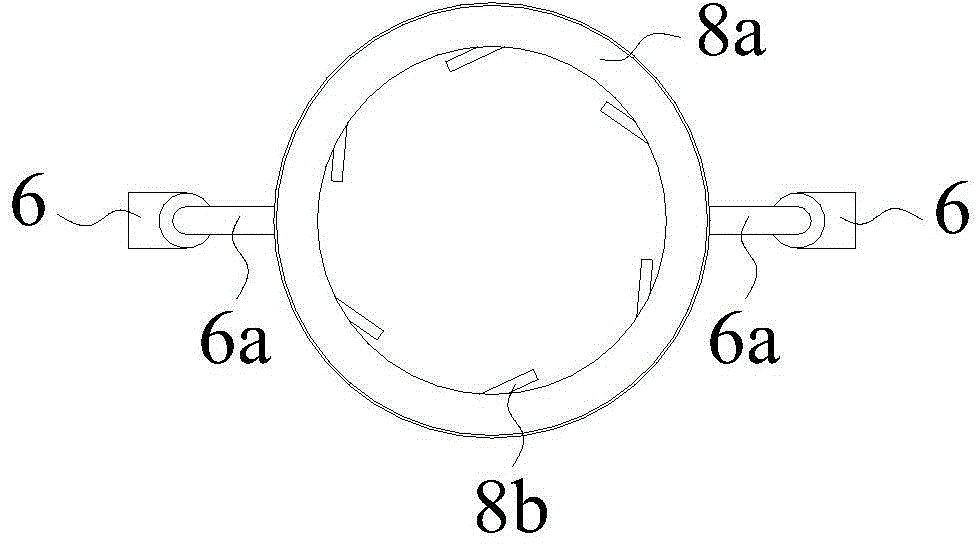

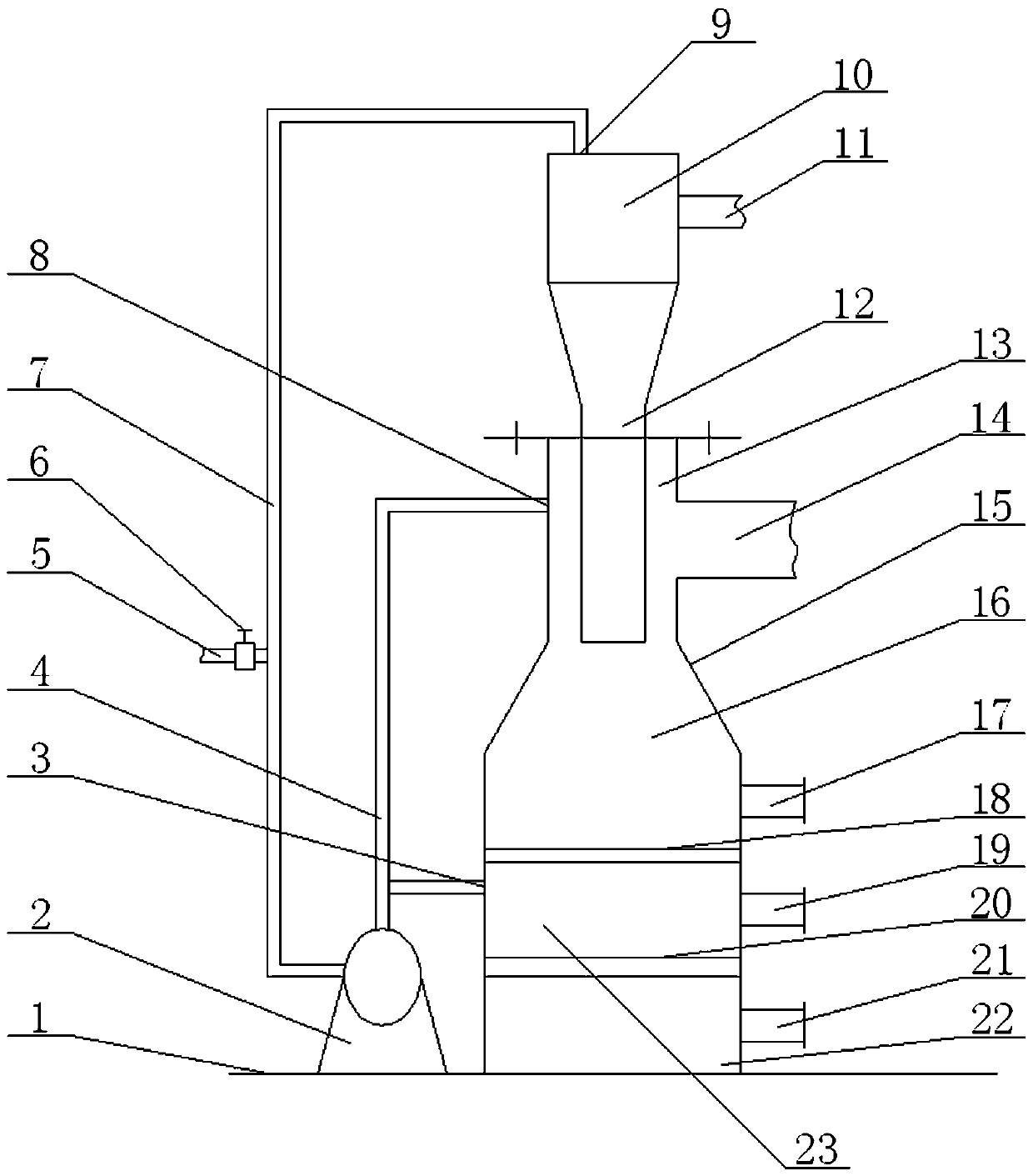

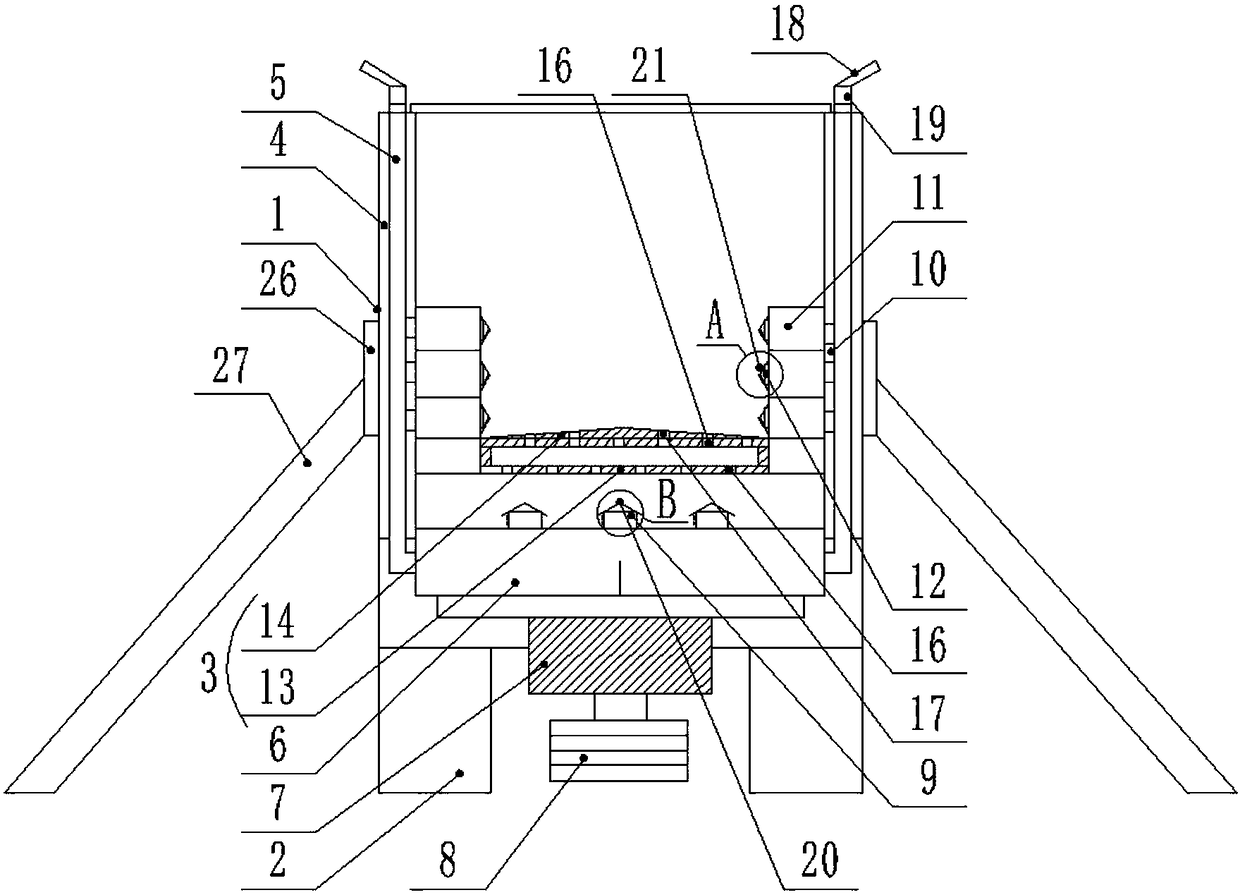

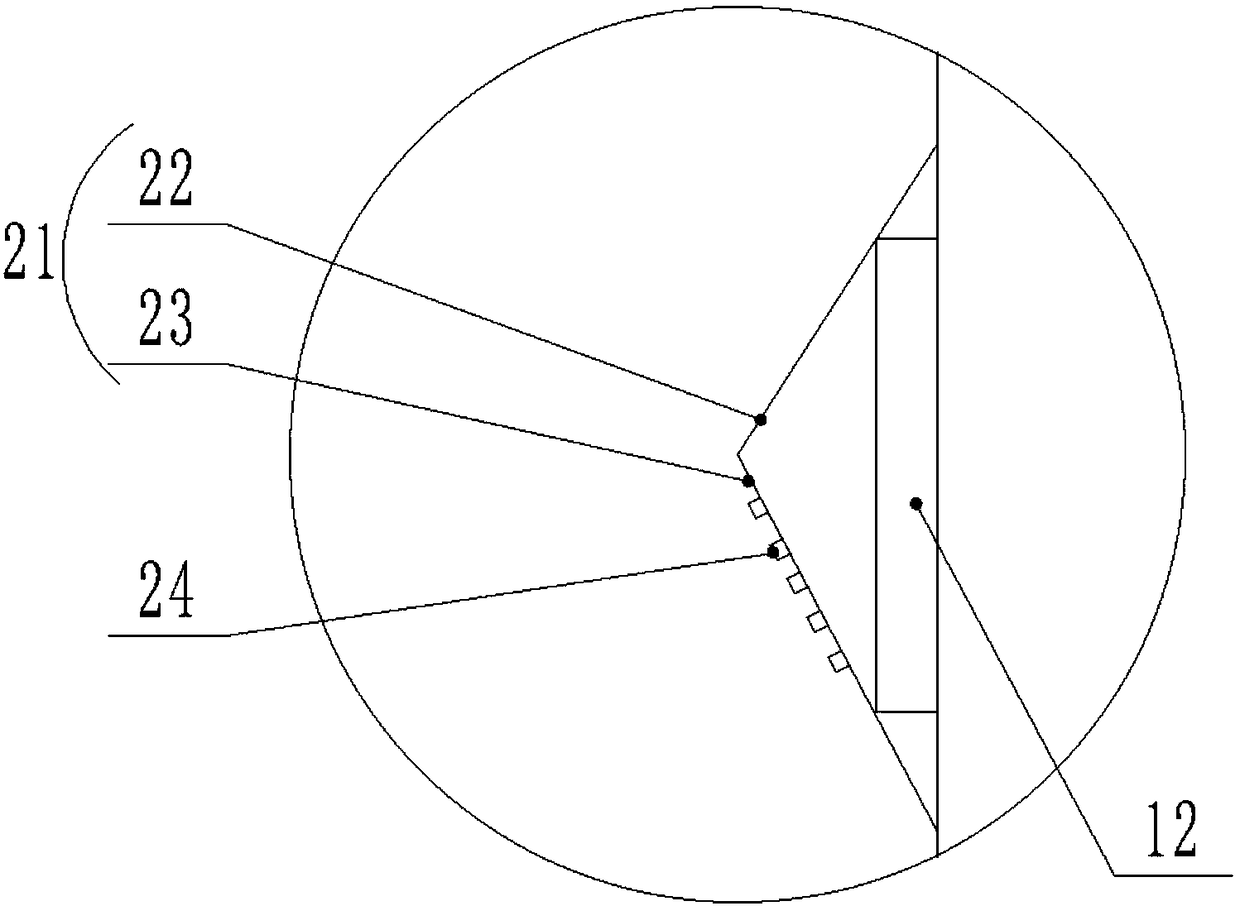

Biomass burning heating jetting furnace with fire grate

InactiveCN104819454AIncrease temperatureRaise the combustion temperatureSolid fuel combustionAir/fuel supply for combustionSpray nozzleEngineering

The invention relates to a biomass burning heating jetting furnace with a fire grate. The jetting furnace is characterized by comprising an equipment cabin (1), a hearth (2) and a nozzle (27). A feeding hopper (4) for adding fuels into a burning furnace is arranged in the equipment cabin (1). The hearth (2) is connected with the equipment cabin (1) and the nozzle (27). A grate bridge (3) is arranged on the lower portion in the hearth (2). A water inlet (11) and a water outlet (12) which are connected with a hearth clamping sleeve (10) are formed in the hearth (2). A nozzle flame retardant layer (7) is arranged on the innermost layer of the nozzle (27). A nozzle clamping sleeve (9) and a rotation air sandwich (22) are arranged in the nozzle (27). A rotation air guide sheet (23) arranged spirally is arranged in the rotation air sandwich (22). By means of the jetting furnace, the thermal efficiency is high, energy is saved by more than 30%, the furnace body temperature can reach more than 1000 DEG C, and the jetting furnace is an ideal biomass fuel furnace.

Owner:HUBEI HUANTAI BIOMASS EQUIP CO LTD

Combustion settling chamber

InactiveCN102338567AReduce concentrationEliminate dead endsIncinerator apparatusWaste heat treatmentCombustorEnvironmental engineering

The invention discloses a combustion settling chamber, which comprises a shell, a smoke inlet, a smoke outlet and an ash discharge hole, wherein the smoke inlet and the smoke outlet are arranged on the shell; the ash discharge hole is located at the bottom part of the shell; the inner wall of the shell is provided with at least combustor; and the position of the smoke outlet is provided with a carbon monoxide (CO) concentration detection device. Through arranging the combustors on the inner wall of the shell, CO contained in the smoke of an electric furnace is discharged through the smoke outlet after being fully burnt with air mixed into the smoke inlet; the CO concentration detection device arranged at the position of the smoke outlet is used for detecting the content of the CO in the discharged smoke; when the CO concentration is detected to exceed an allowed range, the amount of the air mixed into the smoke inlet is increased, and the CO contained in the smoke is fully burnt by utilizing the combustors so as to ensure the concentration of the CO of the outlet to be lower than allowed discharge concentration, thus, through full combustion and quantitative detection, the concentration of the CO contained in the smoke discharged from the combustion settling chamber disclosed by the invention meets an allowable value, thereby, potential harm cannot be caused to safety and environments any longer.

Owner:CISDI ENG CO LTD

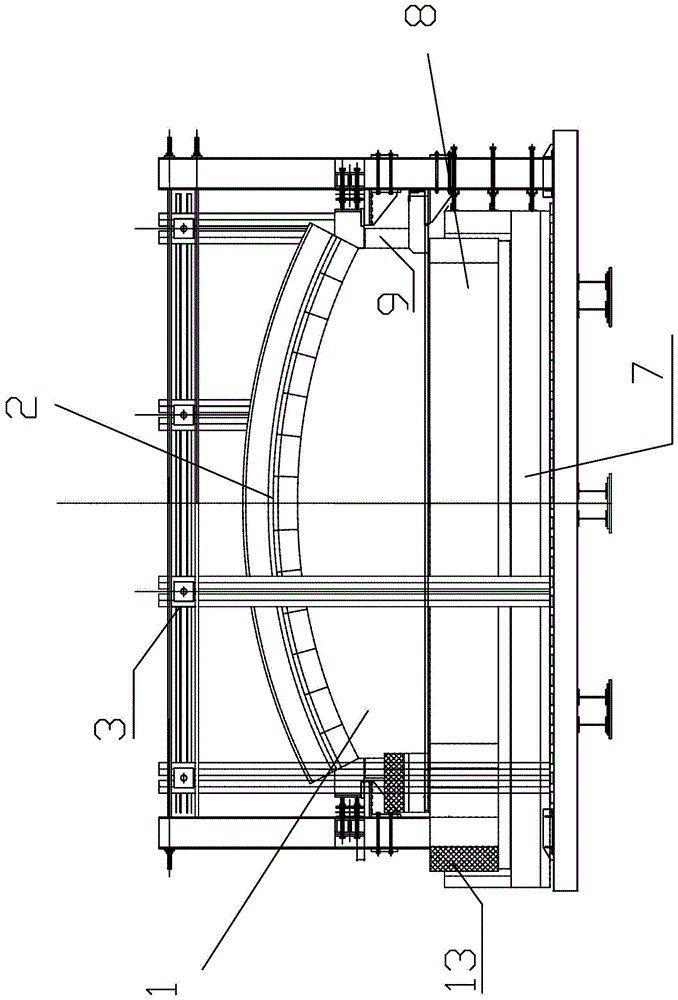

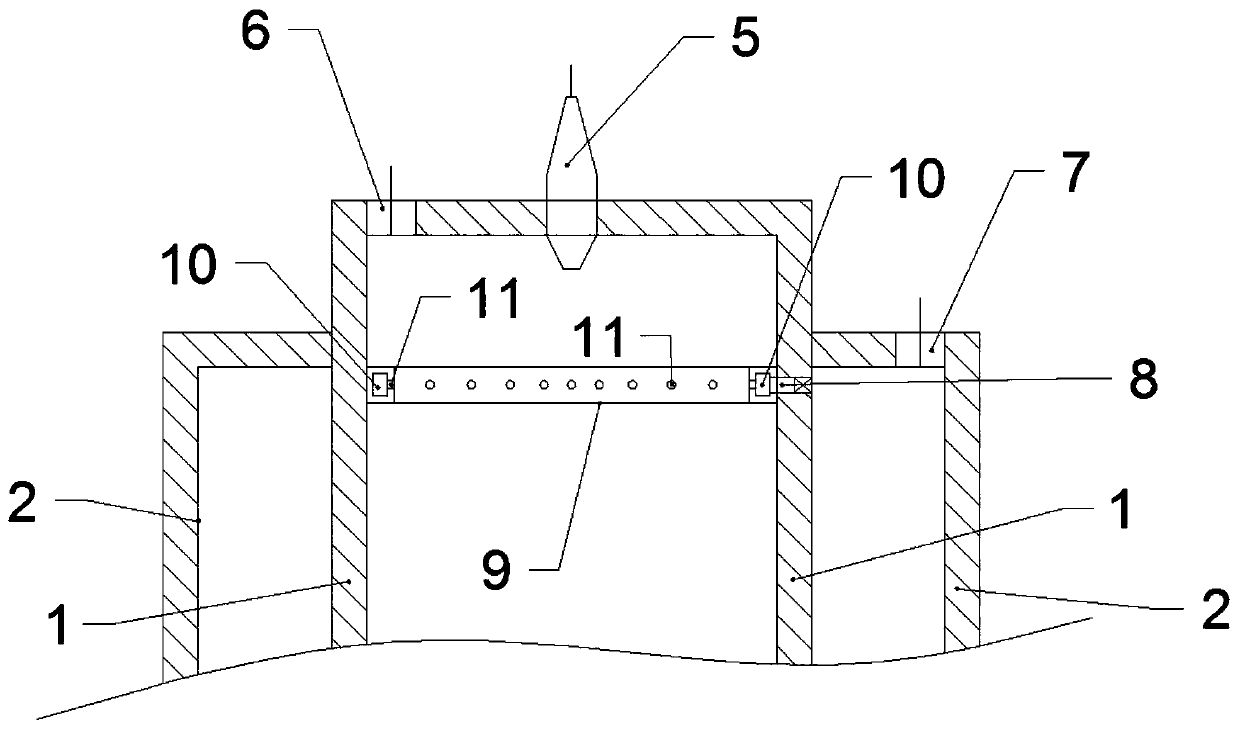

Oxy-fuel combustion furnace used in low-expansion microcrystalline glass manufacturing

InactiveCN104402194AImprove efficiencyImprove combustion conditionsGlass furnace apparatusGlass melting apparatusEngineeringGlass manufacturing

The invention provides an oxy-fuel combustion furnace used in low-expansion microcrystalline glass manufacturing. The oxy-fuel combustion furnace used in low-expansion microcrystalline glass manufacturing is characterized in comprising a cuboid-structured cavity and a furnace cover positioned on the top of the cavity. A steel-structured fixing frame is arranged on the periphery of the cavity and the furnace cover. A feeding port is arranged on a long side of the cavity. A flue is arranged on a short side of the cavity, and a glass discharge port is arranged on the other short side of the cavity. A bottom wall is arranged on the bottom of the cavity. Tank walls are arranged on two sides of the bottom wall, such that a glass tank furnace is formed. Parapets are arranged above the tank walls on the two sides. More than one burning lances are arranged at a certain height above the parapets. The burning lances comprise natural gas inlets and pure oxygen inlets.

Owner:YIXING JINYUNTONG MICROCRYSTAL TECH

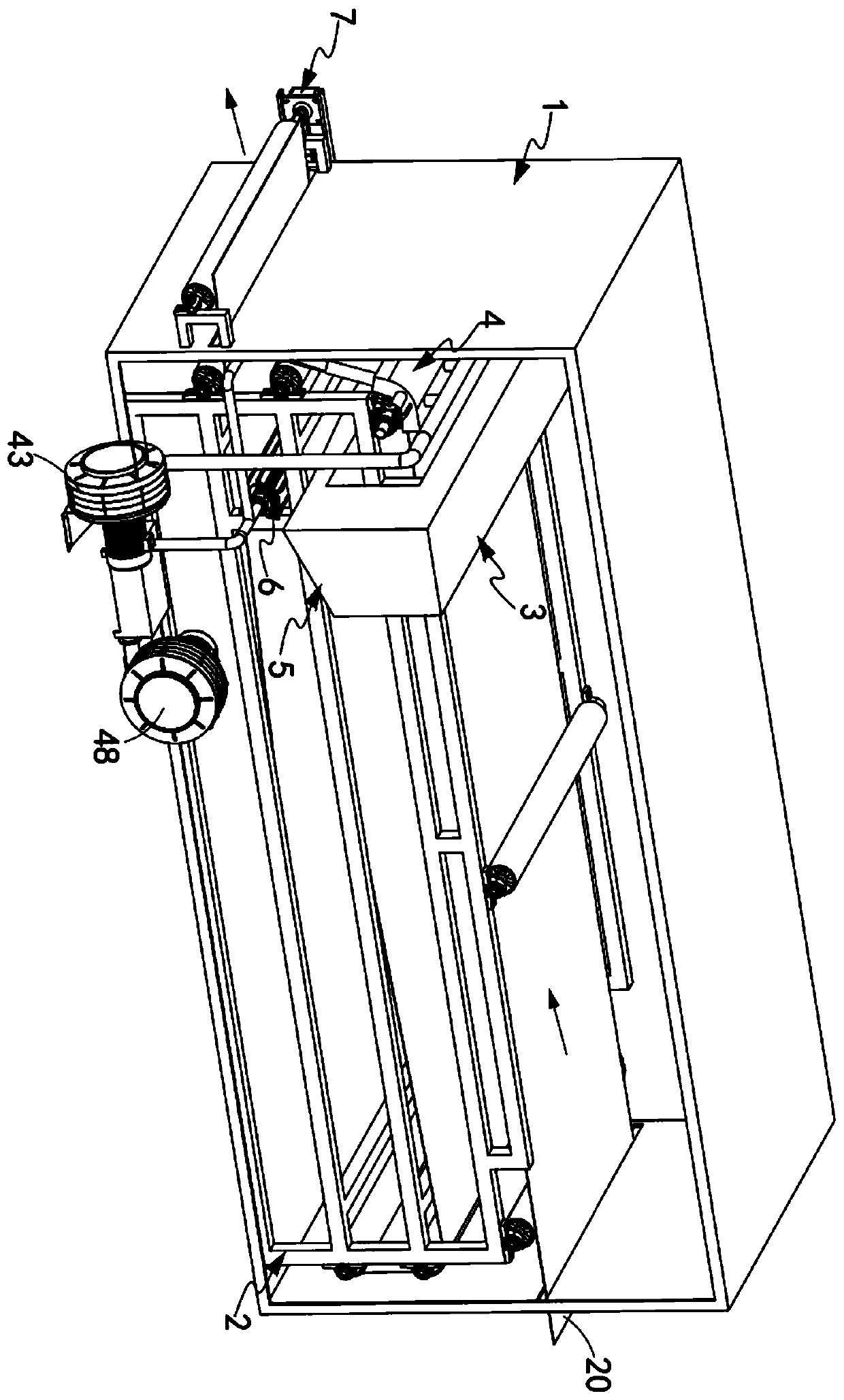

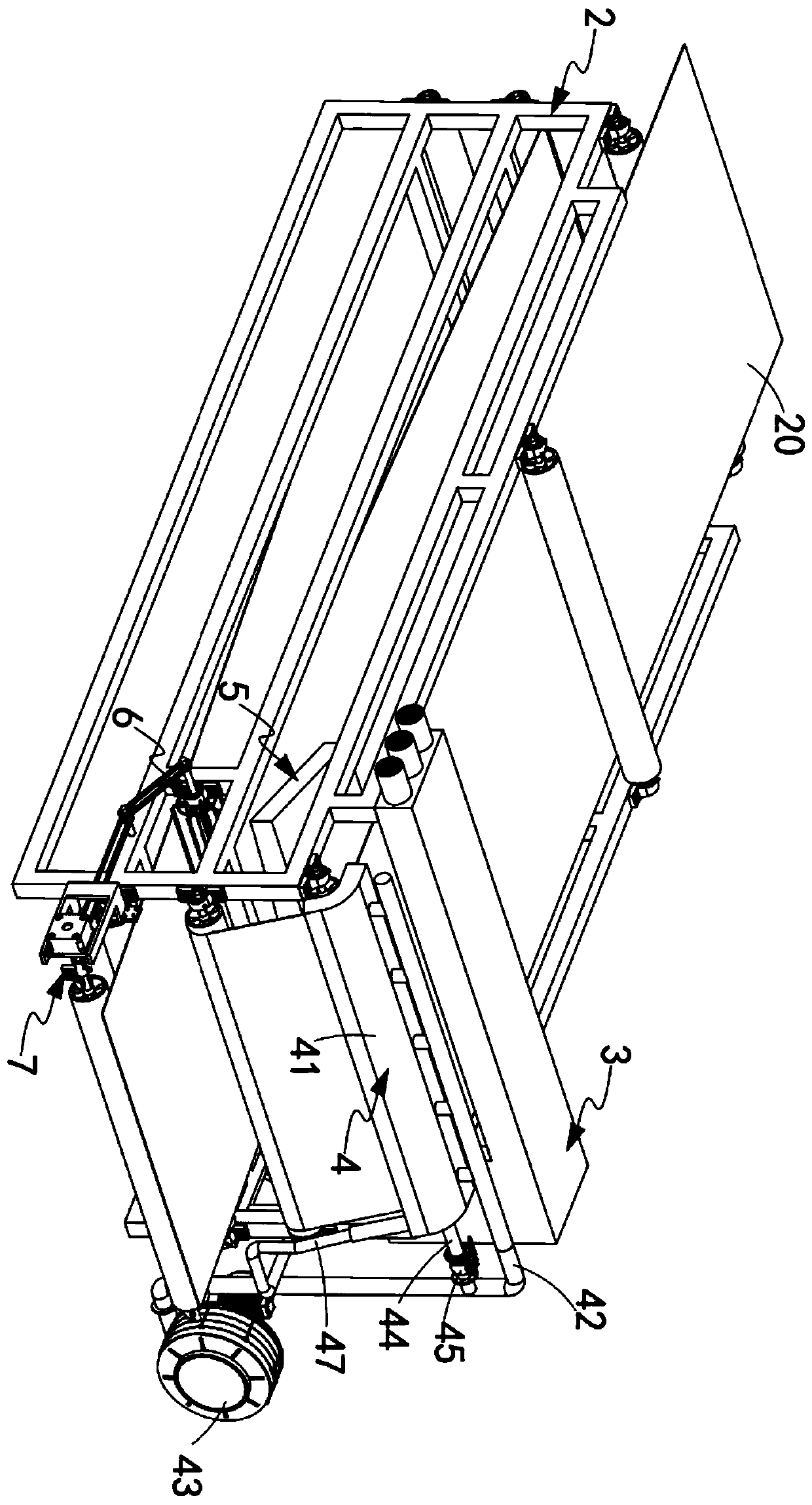

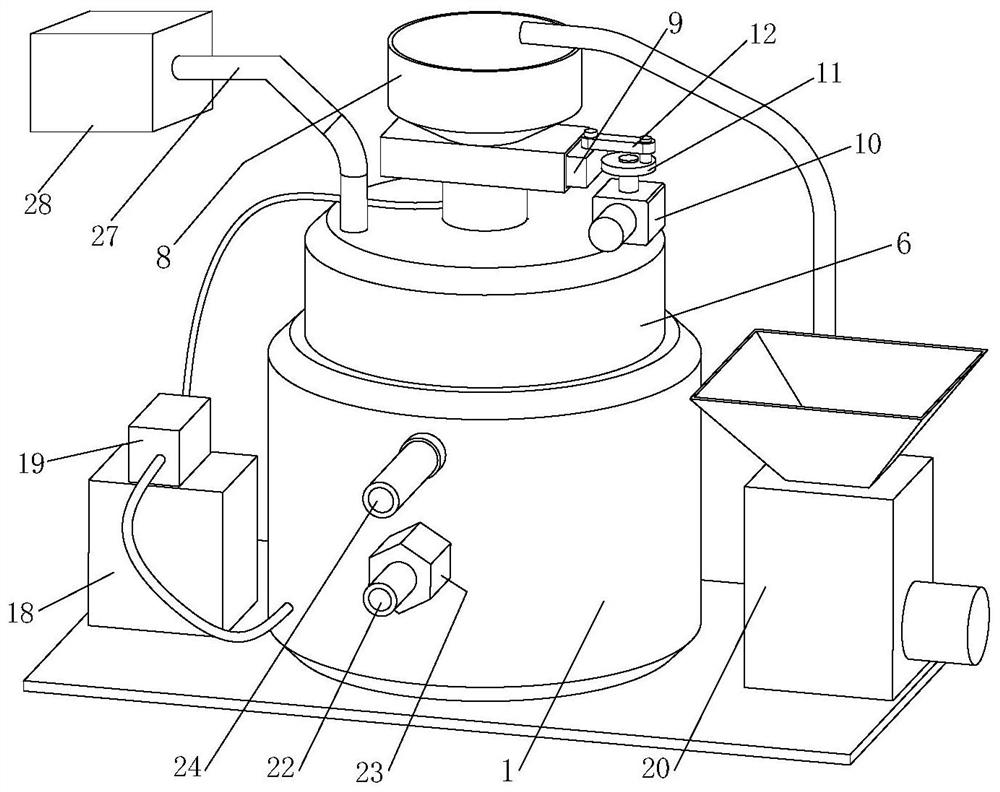

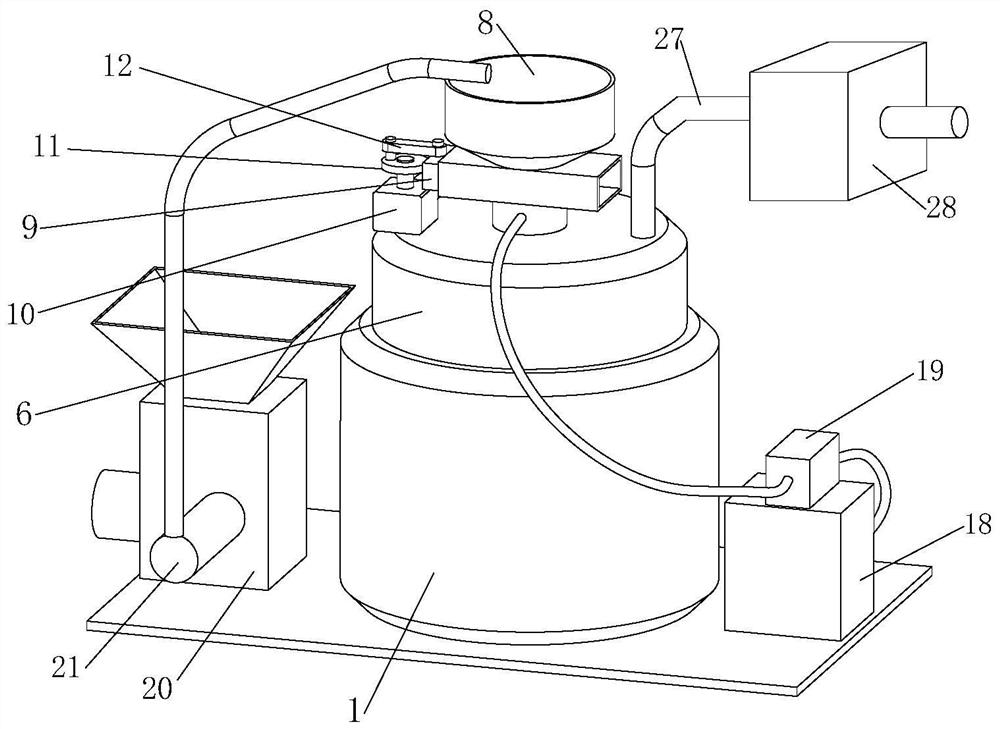

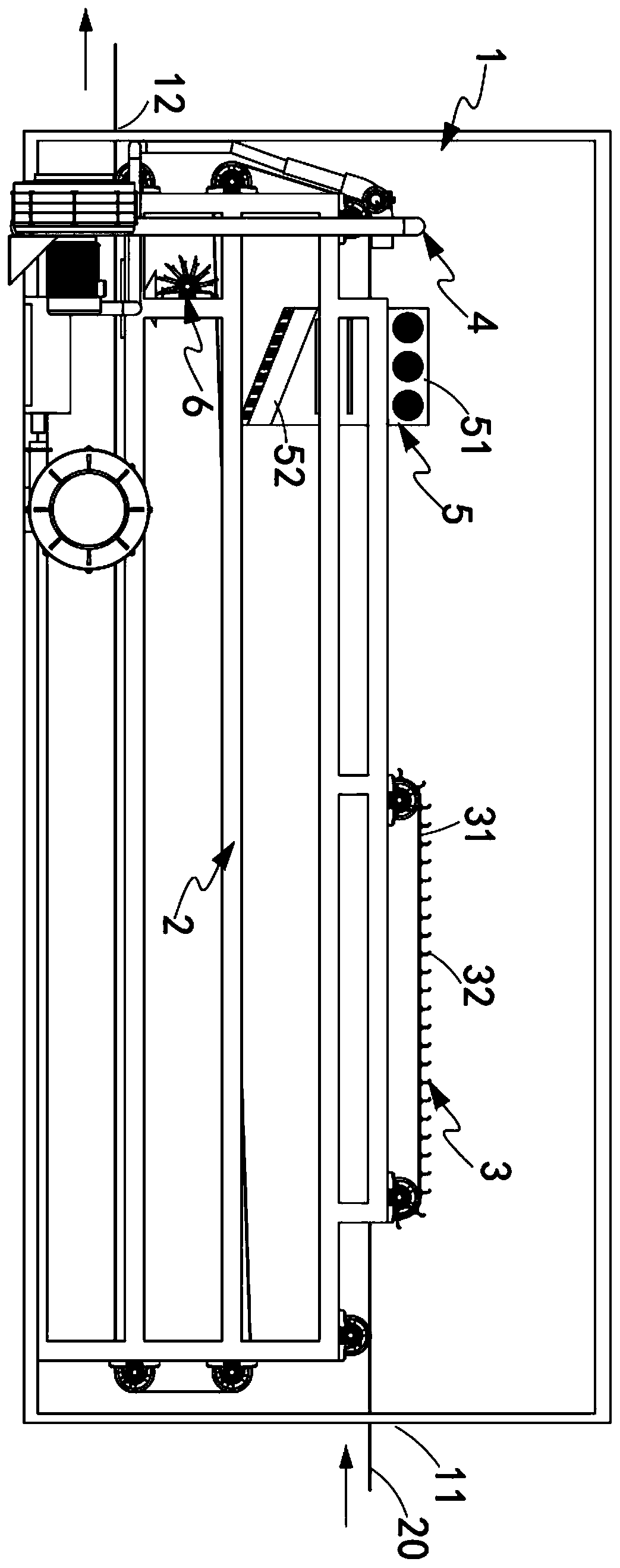

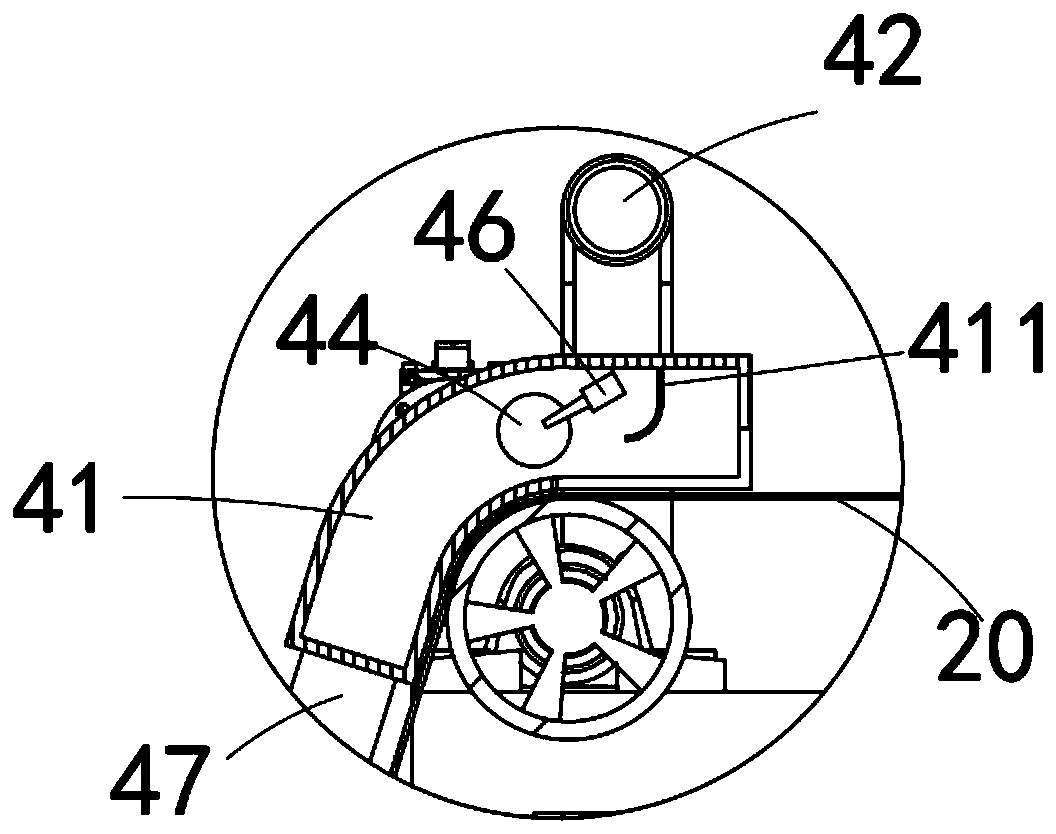

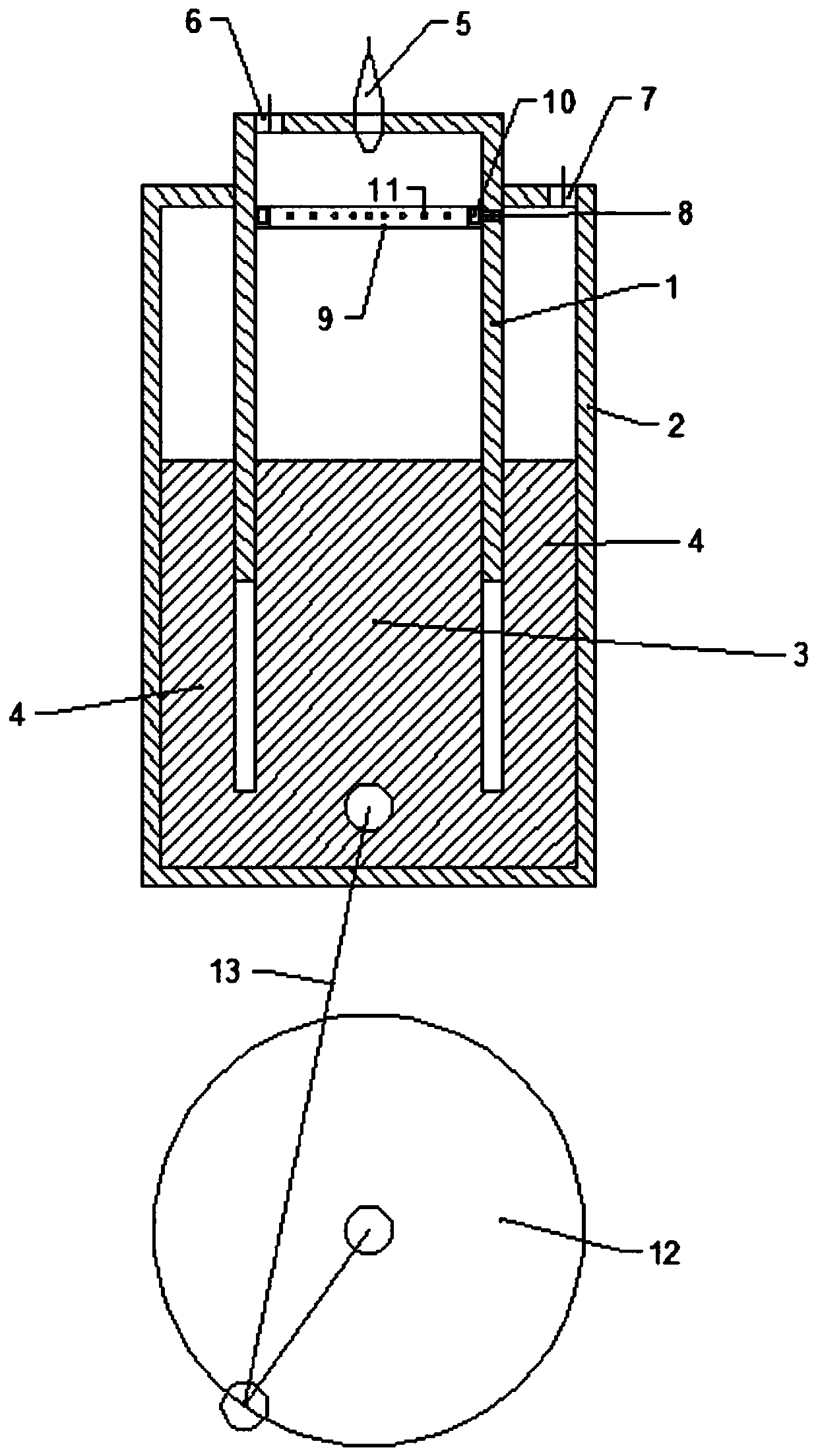

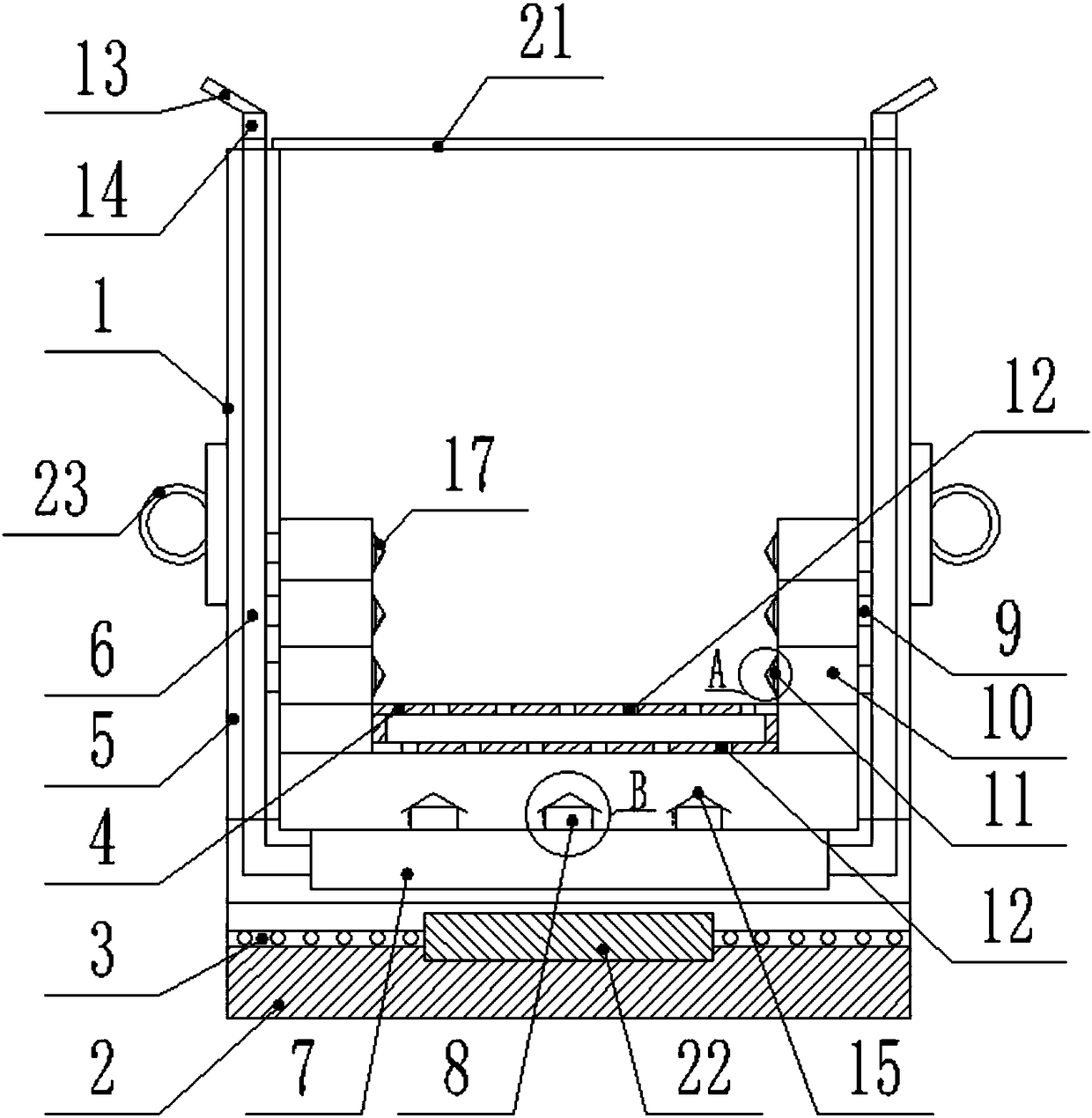

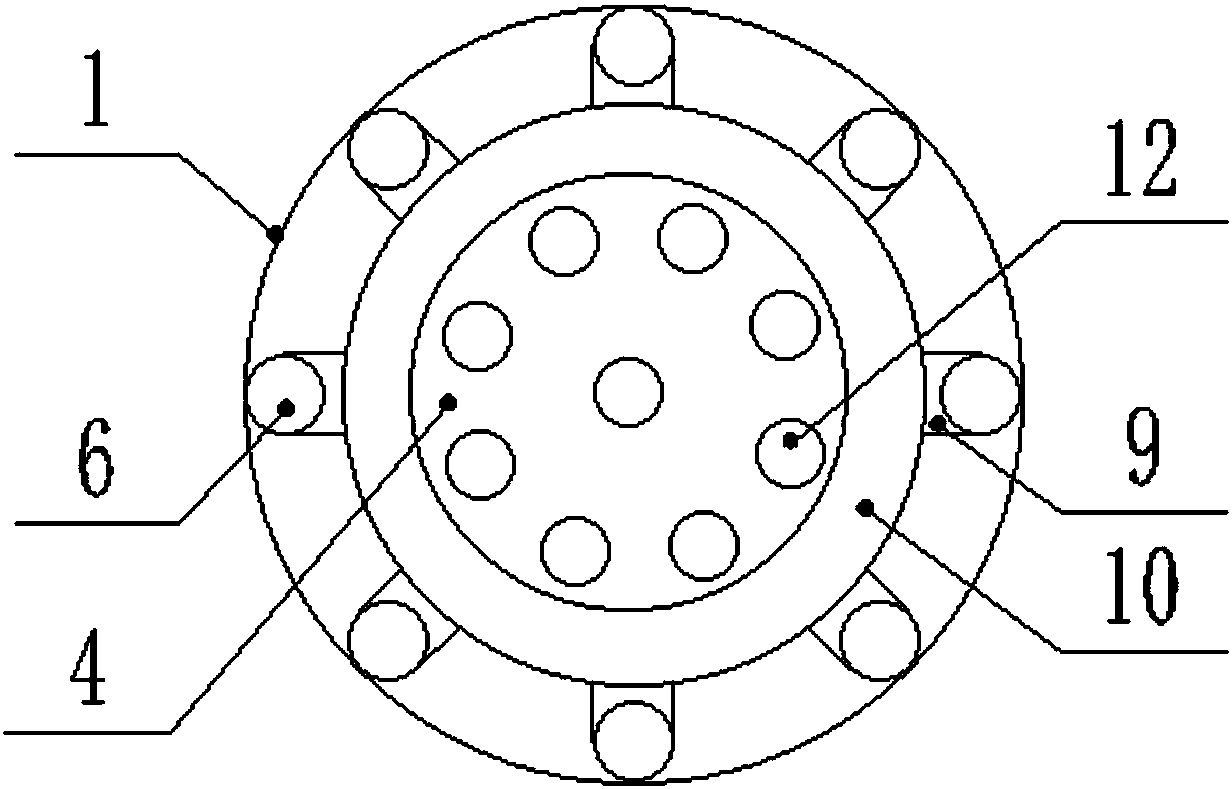

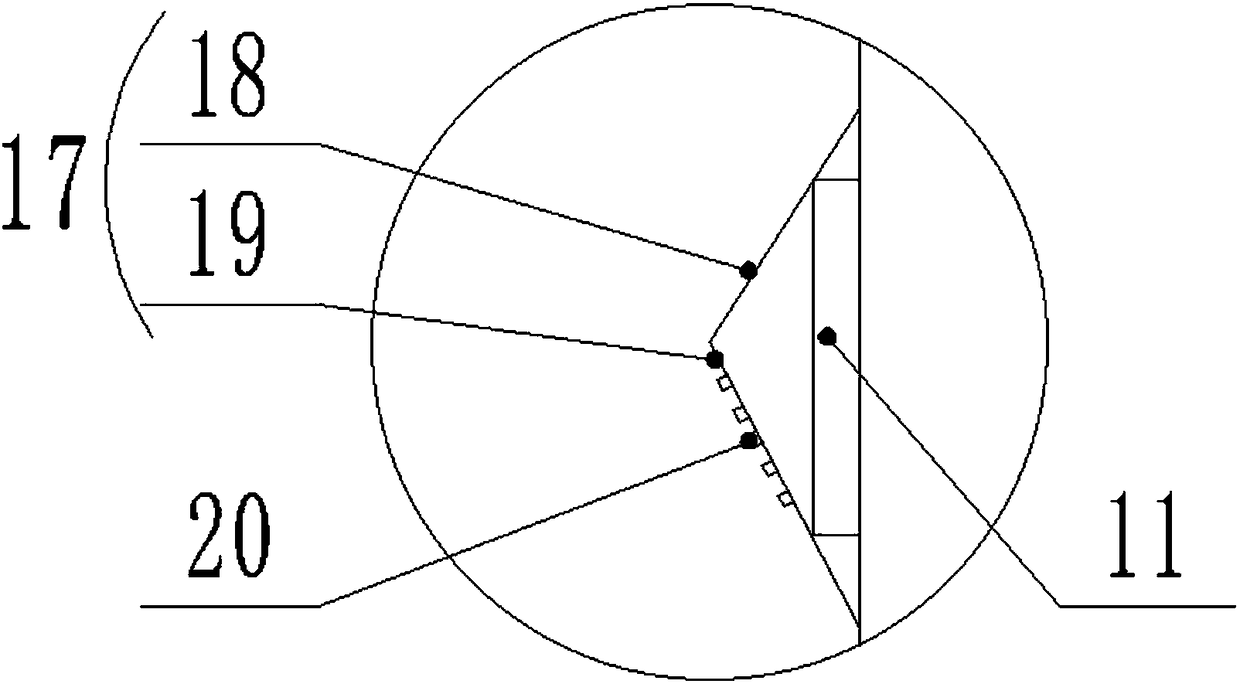

Vibrating type environment-friendly combustion equipment capable of realizing power generation on basis of biomass energy

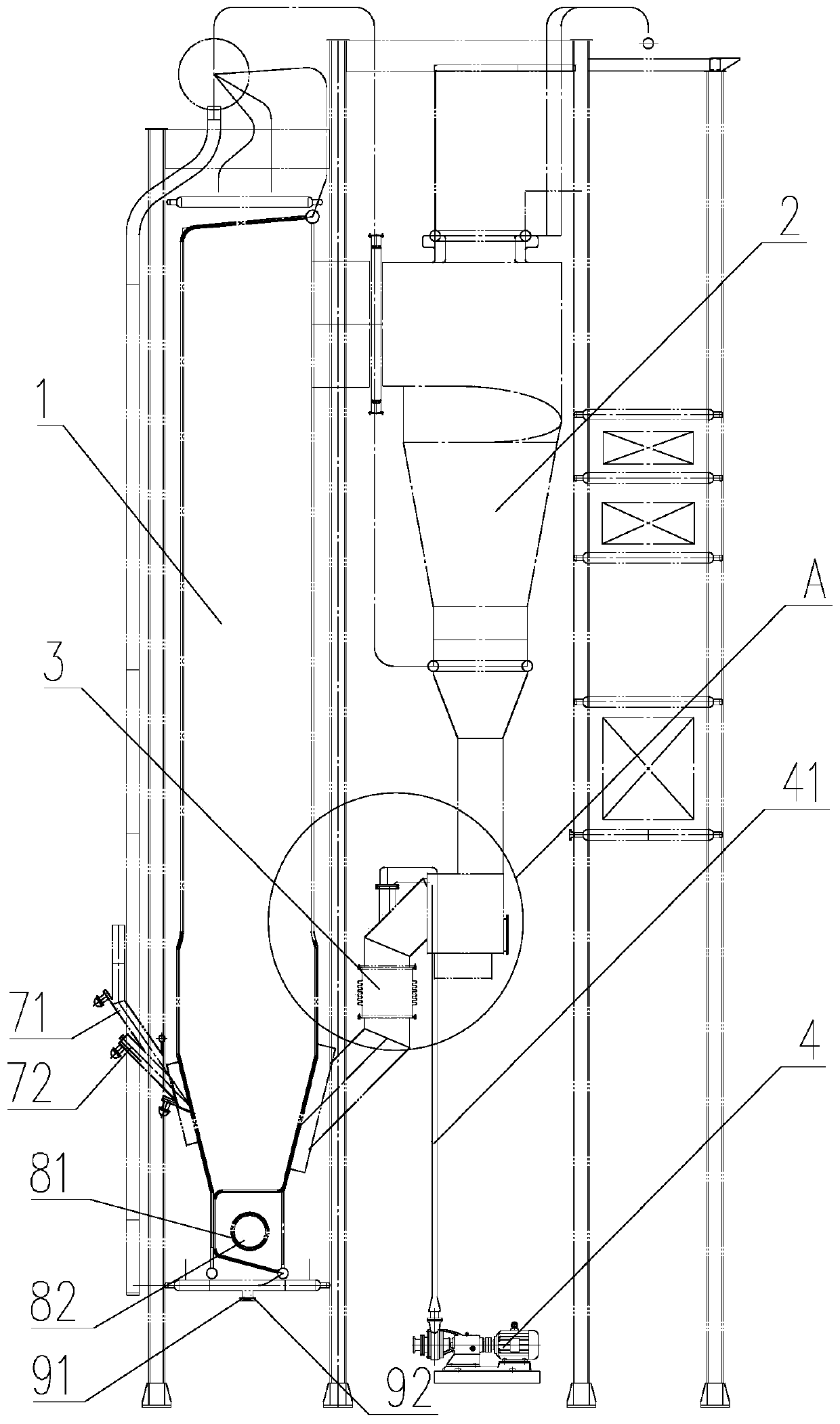

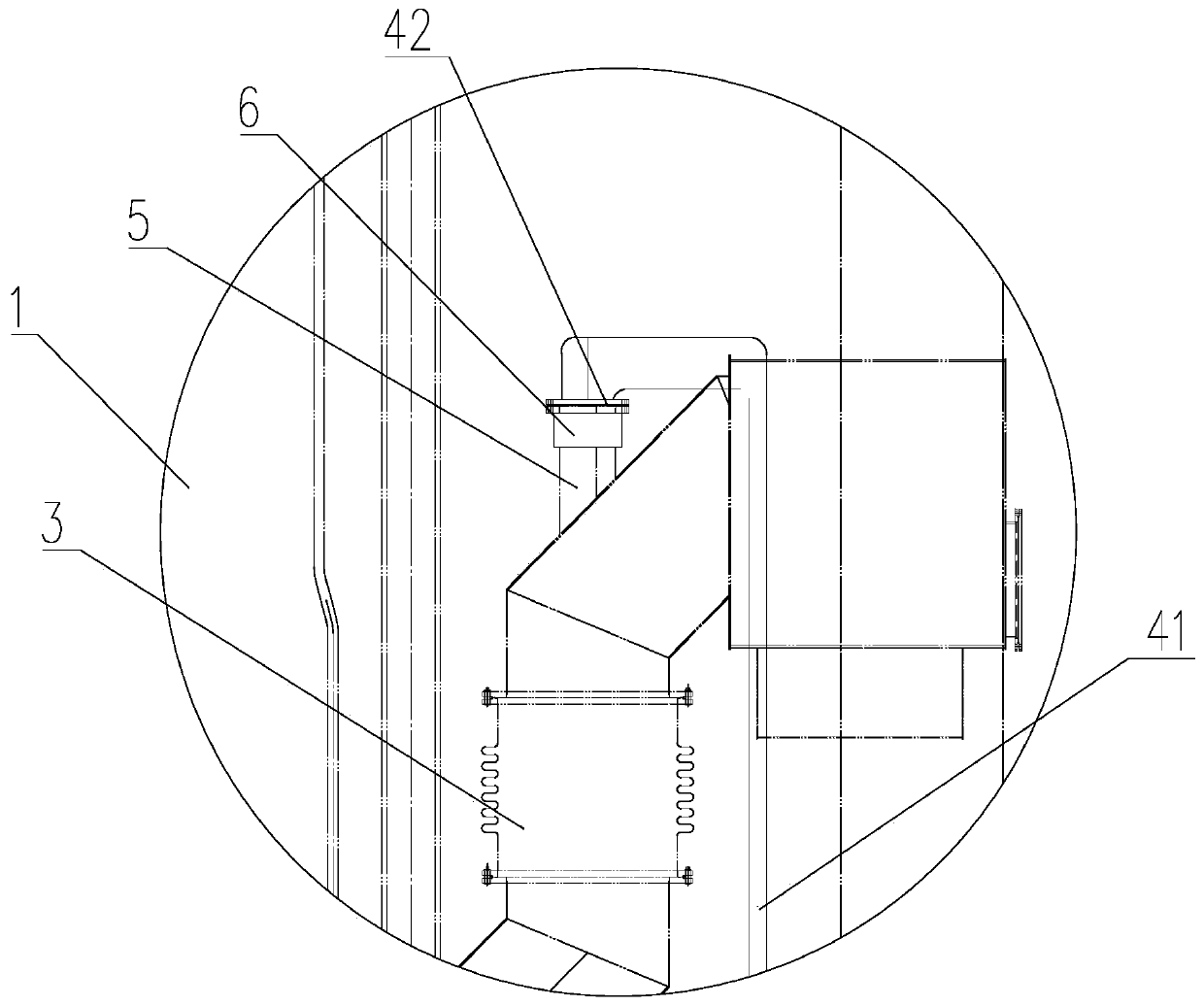

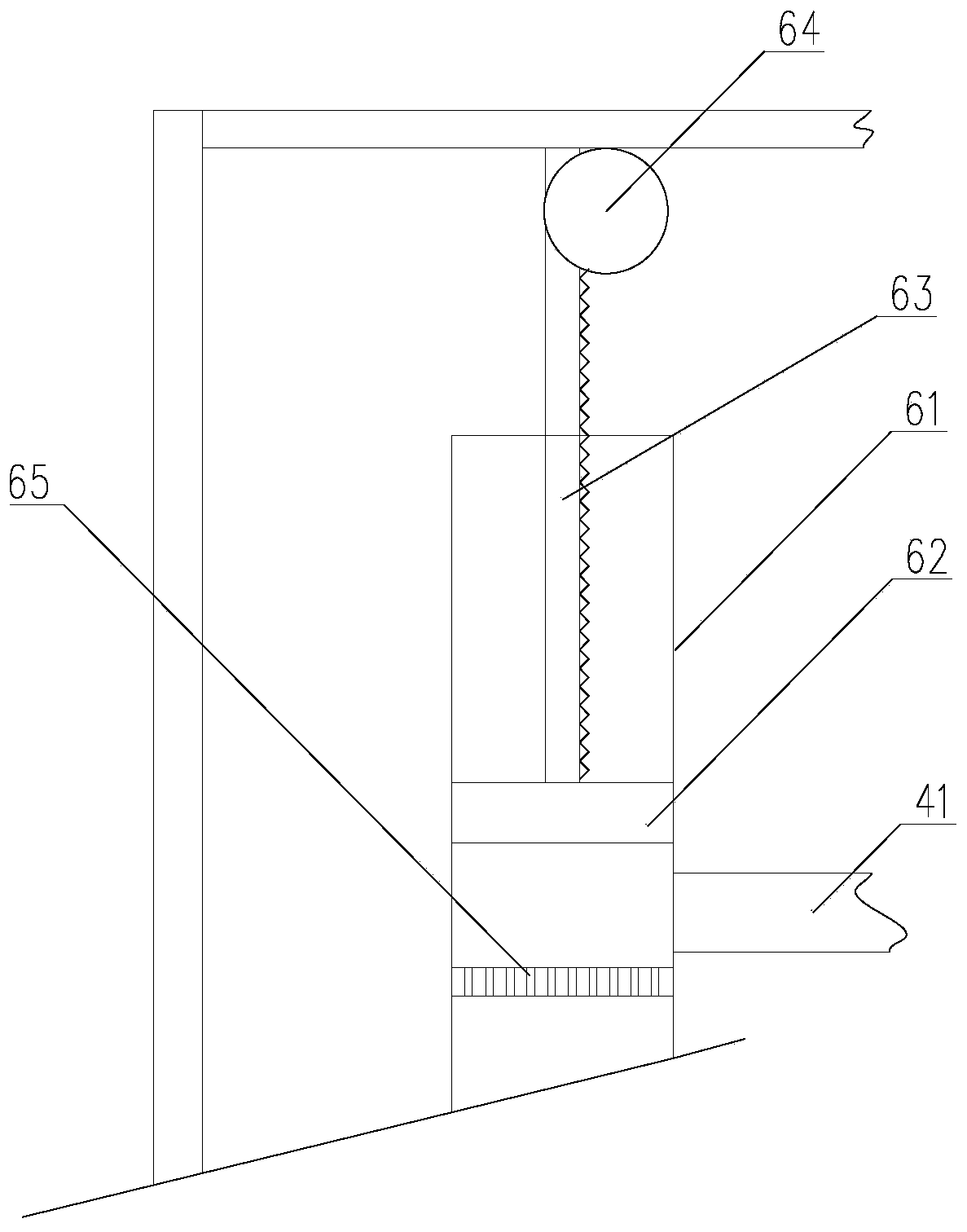

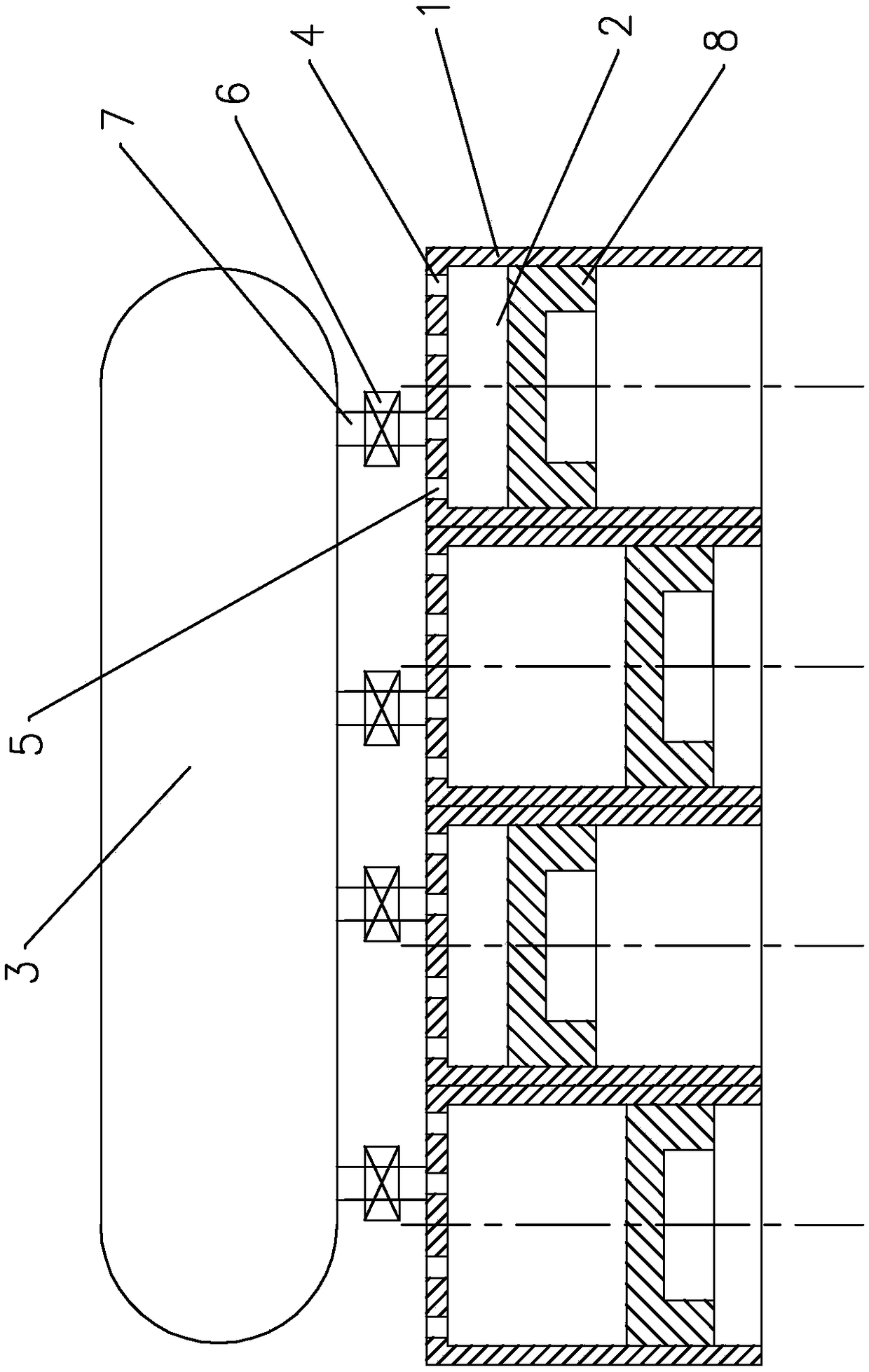

ActiveCN111765452ABurn fully and completelyEasy to igniteSolid fuel combustionCasings/liningsCombustion chamberNew energy

The invention discloses vibrating type environment-friendly combustion equipment capable of realizing power generation on basis of biomass energy, and belongs to the field of new energy. The vibratingtype environment-friendly combustion equipment capable of realizing power generation on basis of the biomass energy comprises a main combustion furnace body; the main combustion furnace body is a cylindrical cavity; a vault-shaped furnace wall is fixedly arranged in the middle of an inner cavity of the main combustion furnace body; the bottom of the vault-shaped furnace wall forms a combustion chamber; the top end of the vault-shaped furnace wall forms a water tank; a plurality of heat conduction pipes are evenly distributed on the side of the bottom surface of the water tank in a communicating manner; and a tail gas chamber is arranged at the top end of the main combustion furnace body. According to the equipment, an eccentric wheel is driven by a vibrating motor to rotate, a combustionfurnace bridge is supported under the eccentric action of the eccentric wheel to rise and fall at the bottom end of the combustion chamber and is driven to vibrate, biomass fuel which falls onto the combustion furnace bridge and is not burnt sufficiently bounces again to enter the middle of the combustion chamber for continuous combustion, and sufficient and thorough combustion is realized.

Owner:襄阳诚智电力设计有限公司 +1

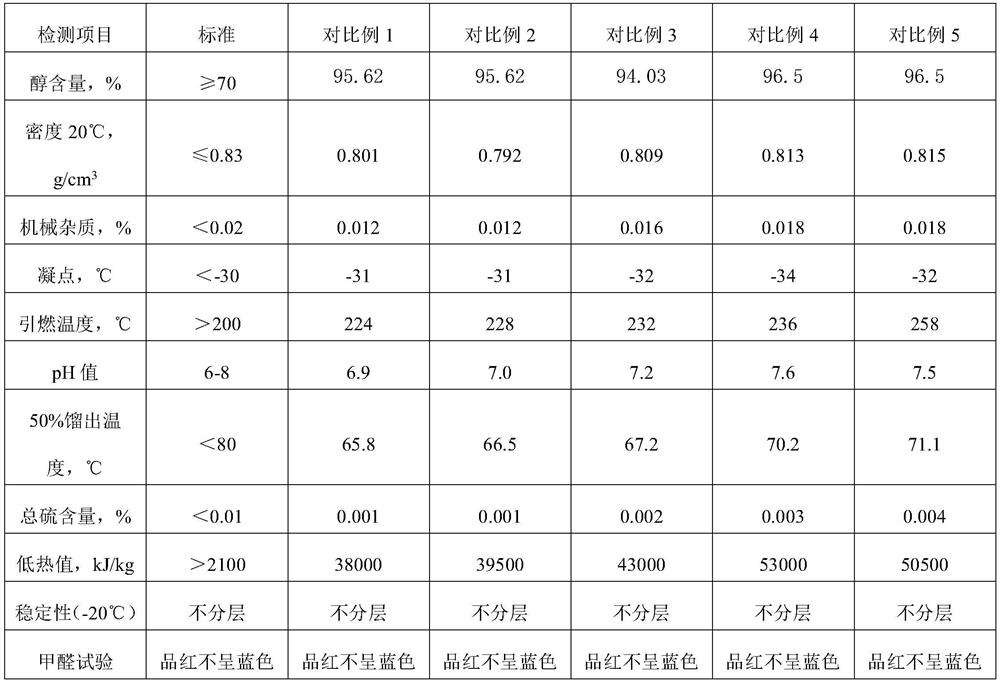

Alcohol-based fuel with high calorific value and preparation method thereof

ActiveCN107892957AHigh calorific valueEliminate odorLiquid carbonaceous fuelsFuel additivesLiquid fuelOctanol

The invention specifically relates to an alcohol-based liquid fuel with high calorific value and a preparation method thereof. The alcohol-based liquid fuel comprises the following raw materials by weight: 85 to 90 parts of methanol, 10 to 15 parts of C12 fuel oil, 5 to 10 parts of octanol, 15 to 20 parts of methylal, 1 to 4 parts of a deodorant and 10 to 15 parts of an additive. The additive comprises the following raw materials by weight: 5 to 10 parts of ethanol, 3 to 5 parts of glyceryl triacetate, 4 to 7 parts of a cationic fluorocarbon surfactant, 3 to 5 parts of ferrocene, 10 to 15 parts of a hydrocarbon compound, 10 to 15 parts of a combustion improver, 3 to 5 parts of a stabilizing agent and 3 to 5 parts of an antidetonant. According to the invention, the components of the alcohol-based liquid fuel with high calorific value cooperate with each other, so the alcohol-based liquid fuel is thorough in combustion, high in combustion heat value and free of carbon deposition, and hasgood intersolubility with gasoline, good corrosion resistance, good vaporability and good positive additivity.

Owner:临沂星火知识产权服务有限公司

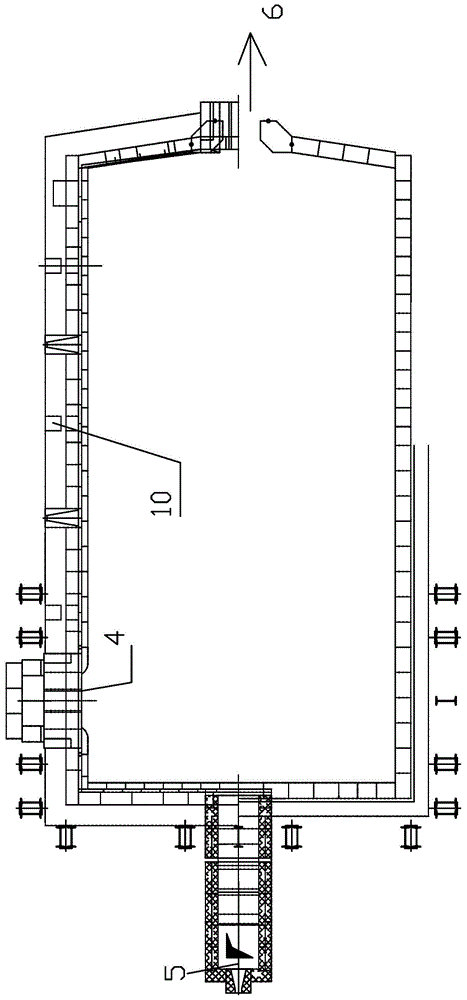

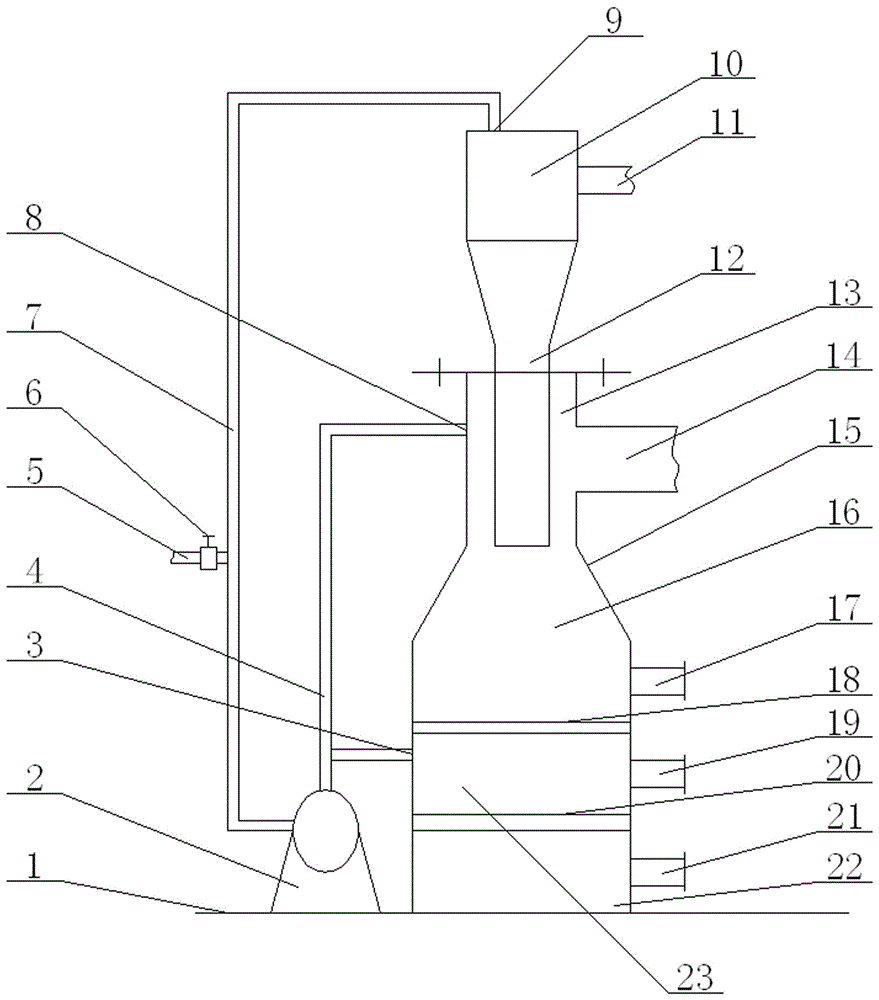

Semi-gasification garbage incinerator

InactiveCN106247341ASolve the problem of incomplete incinerationBurn fully and completelyIncinerator apparatusCombustion chamberDistribution system

The invention discloses a semi-gasification garbage incinerator which comprises a bin, a blanking channel, a hearth and an air distribution system. One end of the blanking channel is connected with the bin, and the other end of the blanking channel is arranged in the hearth. A third combustion chamber, a second combustion chamber, a first combustion chamber and an ash bucket chamber are arranged in the hearth, and the bottom of the hearth is sealed by a sealing bottom plate. One end of the air distribution system is connected with the bin, and the other end of the air distribution system is connected with the third combustion chamber and the first combustion chamber. The semi-gasification garbage incinerator solves the problem that household garbage incineration is incomplete in villages and towns, and has the beneficial effects that garbage can be completely combusted without adding auxiliary fuel, no black smoke is discharged, and the environment is protected.

Owner:谢植笔

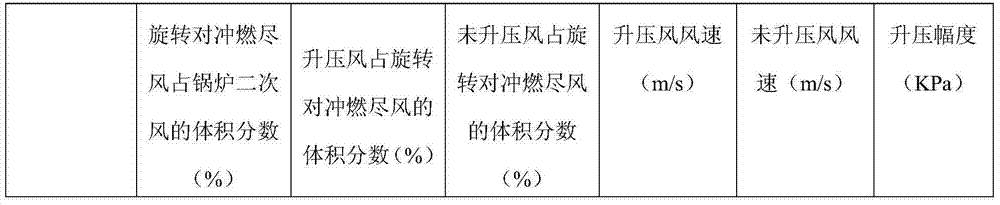

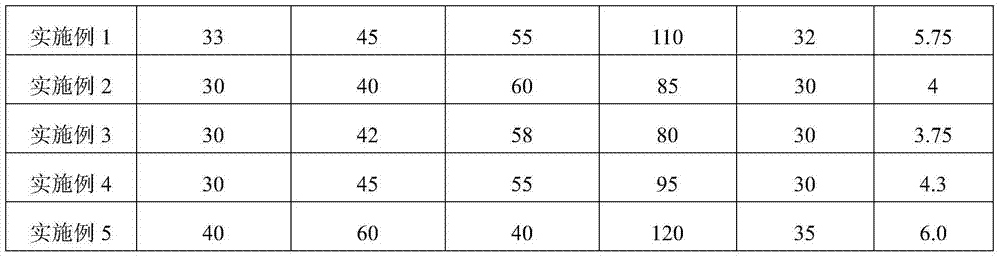

Method for reducing nitrogen oxide generated by combustion of boiler

InactiveCN103672940ABurn fullyStrong reducing atmosphereNon-combustible gases/liquids supplyCombustionHearth

The invention discloses a method for reducing nitrogen oxide generated by combustion of a boiler. The method comprises the following steps of sucking one part of secondary air of the boiler as the rotary opposed over fire air comprising two parts; directly sending the first part to the upper space of a boiler hearth at the first speed, pressurizing the remained second part, and then sending the pressurized second part to the upper space of the boiler hearth at the second speed. The method for reducing the nitrogen oxide generated by the combustion of the boiler has the advantage that in the premise of ensuring the combustion efficiency of the boiler and the stable combustion state, the total emission amount of the harmful gas of the boiler, such as NOx, is greatly reduced.

Owner:上海卫源节能环保科技有限公司

Smoke combustion chamber and environment-friendly household garbage incineration system

PendingCN106765140AReduce generationReduce synthesisIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberCarbonization

The invention discloses an environment-friendly household garbage incineration system. A carbonization zone and an incineration zone are arranged in an incineration furnace. Garbage enters the incineration zone after being carbonized. The upper space of the incineration zone is a garbage combustion chamber. A smoke outlet of the garbage combustion chamber is connected with a smoke inlet of a smoke combustion chamber at the top of the garbage combustion chamber through a pipeline. A smoke outlet of the smoke combustion chamber communicates with a first-stage heat exchanger. The upper space of the carbonization zone is connected with an air inlet of a draught fan through a pipeline. An air outlet of the draught fan is connected with the bottom of the smoke combustion chamber through a pipeline. A smoke bypass pipeline opening is formed in a main flue at the back of the first-stage heat exchanger to be connected with the carbonization zone through a pipeline. By means of the environment-friendly household garbage incineration system, dioxin emission caused by garbage incineration is effectively treated, the cost is greatly lowered, there is no need to sort garbage or add subsidized fuel before incineration, the temperature and time of drying, carbonization and combustion of garbage and smoke combustion are all controllable, garbage is combusted fully, dioxin is split thoroughly, regeneration of dioxin can be effectively prevented, and the smoke emission is superior to the national standard.

Owner:广州市澳发环保科技有限公司

Garbage dual-degradation disposal device

InactiveCN104896480AHandling is simple, quick and pollution-freeSimple structureIncinerator apparatusExhaust gasEmergency treatment

The invention belongs to the field of combustible solid garbage disposal equipment, and particularly provides a garbage dual-degradation disposal device. The garbage dual-degradation disposal device mainly comprises an outer furnace body, an inner furnace body and an oxygen supply device, wherein the inner furnace body is arranged in the outer furnace body, and the oxygen supply device is used for supplying oxygen to the inner furnace body. The garbage dual-degradation disposal device has the advantages that operation of low-temperature cracking and high-temperature combustion can be accomplished in the same device, and garbage disposal is easier, more convenient and rapider; the reduced weight of garbage disposal is large, and is greatly larger than that of the prior art; combustion energy of garbage is sufficiently utilized in the whole garbage disposal process, and more energy is saved; tail gas treatment is easy, convenient and rapid, and free of pollution; the garbage does not need to be selected, and garbage disposal is high in applicability; the device is stable in operation, and smoke combustion is thorough and sufficient; the structure is simple, and disassembly and assembly are convenient; the emergency treatment capacity is high, and automatic and auxiliary ignition operation can be achieved.

Owner:林善祖

Special briquette coal for water treatment of lime and preparation method of special briquette coal

InactiveCN111996052ABurn enoughMore complete combustionWater contaminantsBiofuelsSodium stearateFiltration

The invention discloses special briquette coal for water treatment of lime. The special briquette coal comprises bituminous coal, sawdust powder, rice hull powder, potassium permanganate, potassium perchlorate, shell powder, peanut meal, lignin, sodium stearate, aluminum powder, magnesium powder and a proper amount of water. A method for preparing the special briquette coal used for water treatment of lime comprises the following steps: (1) mixing sodium stearate with water, adding shell powder and lignin, and successively carrying out mixing, standing, suction filtration, washing, drying andgrinding to obtain modified shell powder; and (2) uniformly stirring and mixing bituminous coal, sawdust powder, rice hull powder and peanut meal, adding lignin and water, carrying out uniform mixing,adding the modified shell powder, carrying out uniform mixing, finally adding potassium permanganate, potassium perchlorate, aluminum powder and magnesium powder, carrying out uniform mixing, moldingthe formed mixture in a molding machine, and successively carrying out drying, cooling to room temperature and packaging to obtain the special briquette coal for water treatment of lime. The coal iscombusted more sufficiently and thoroughly, so a combustion heat value can be increased; and bituminous coal, sawdust powder and the like are used as main combustion raw materials, so waste utilization can be achieved, and environmental pollution is reduced.

Owner:NANNING XIAYANG CHEM TECH CO LTD

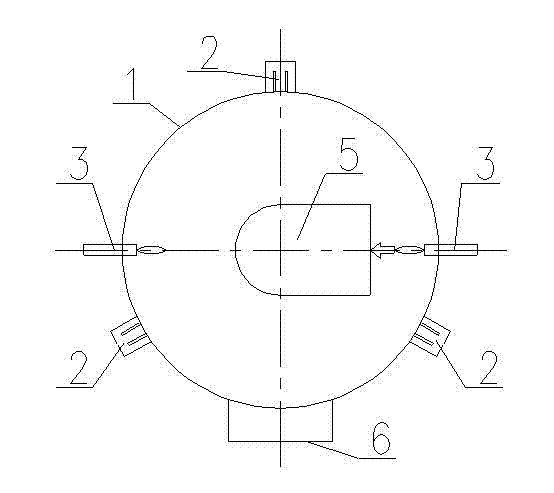

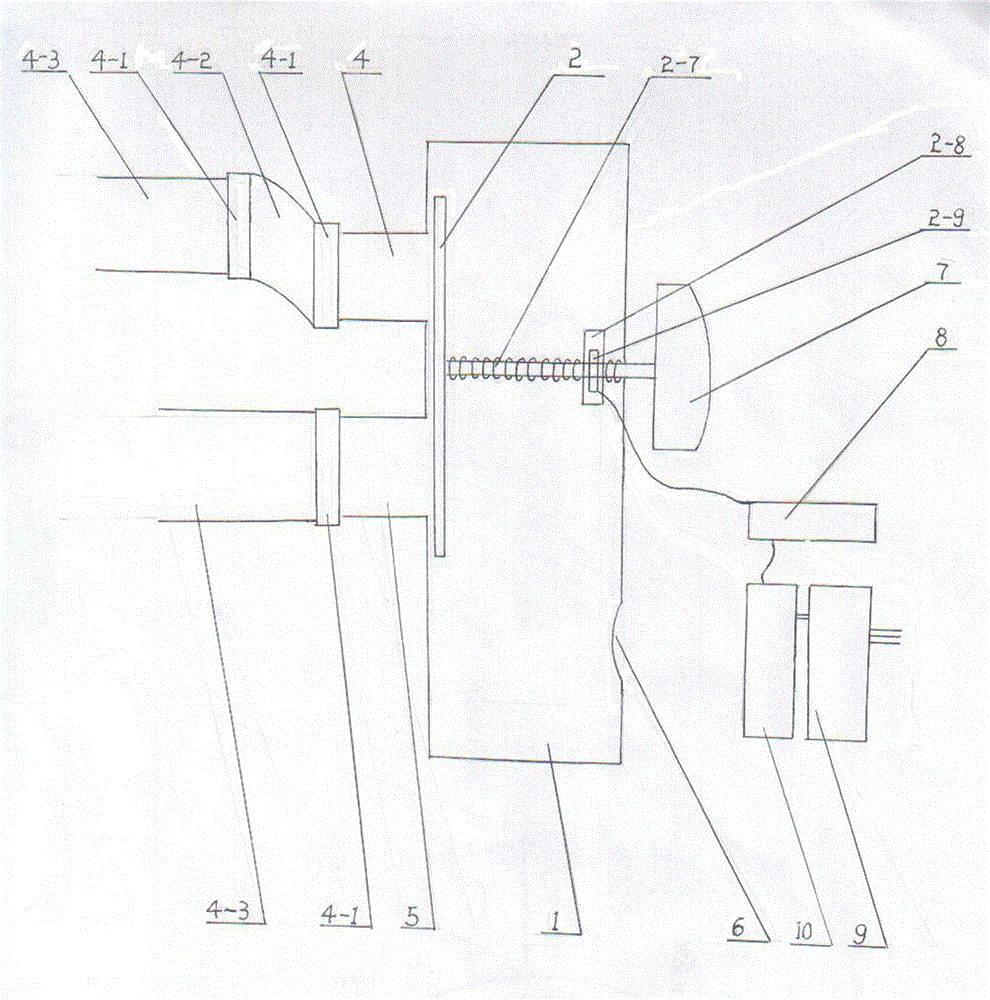

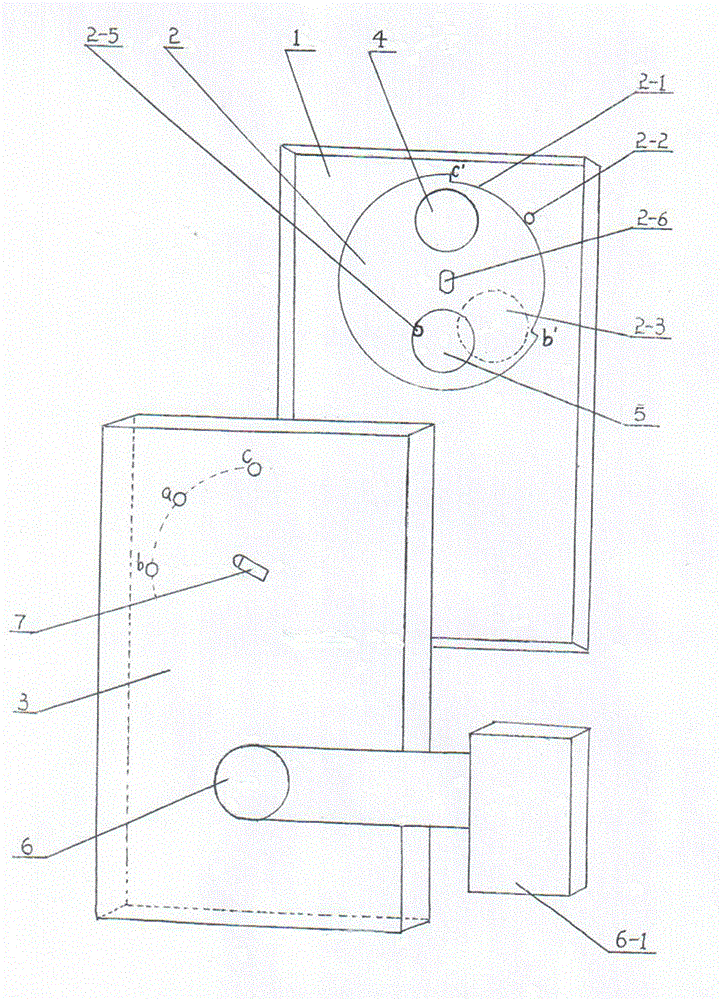

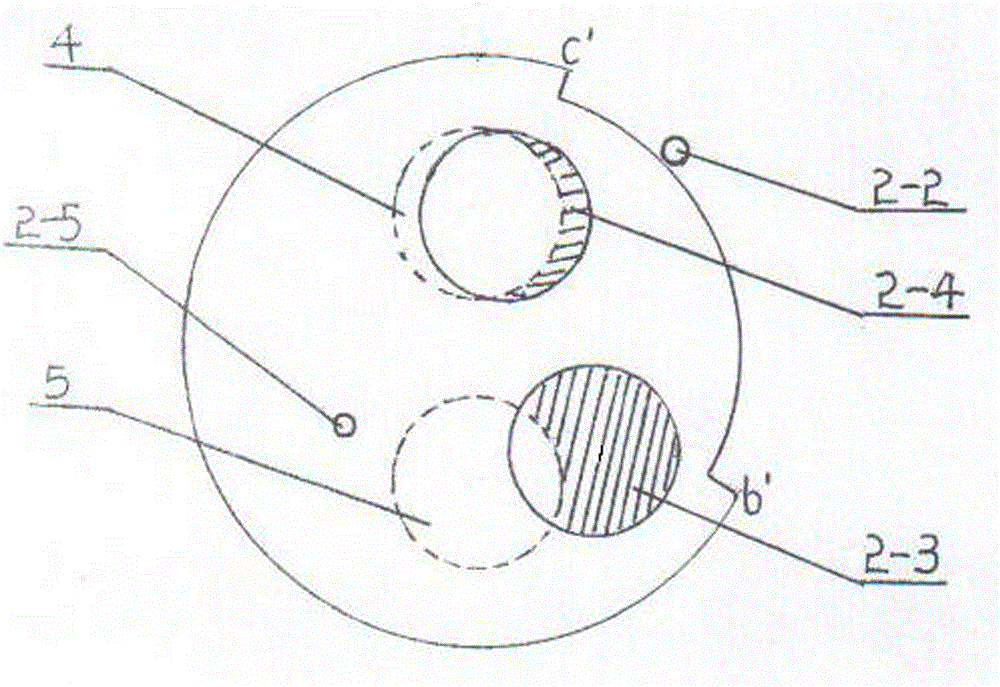

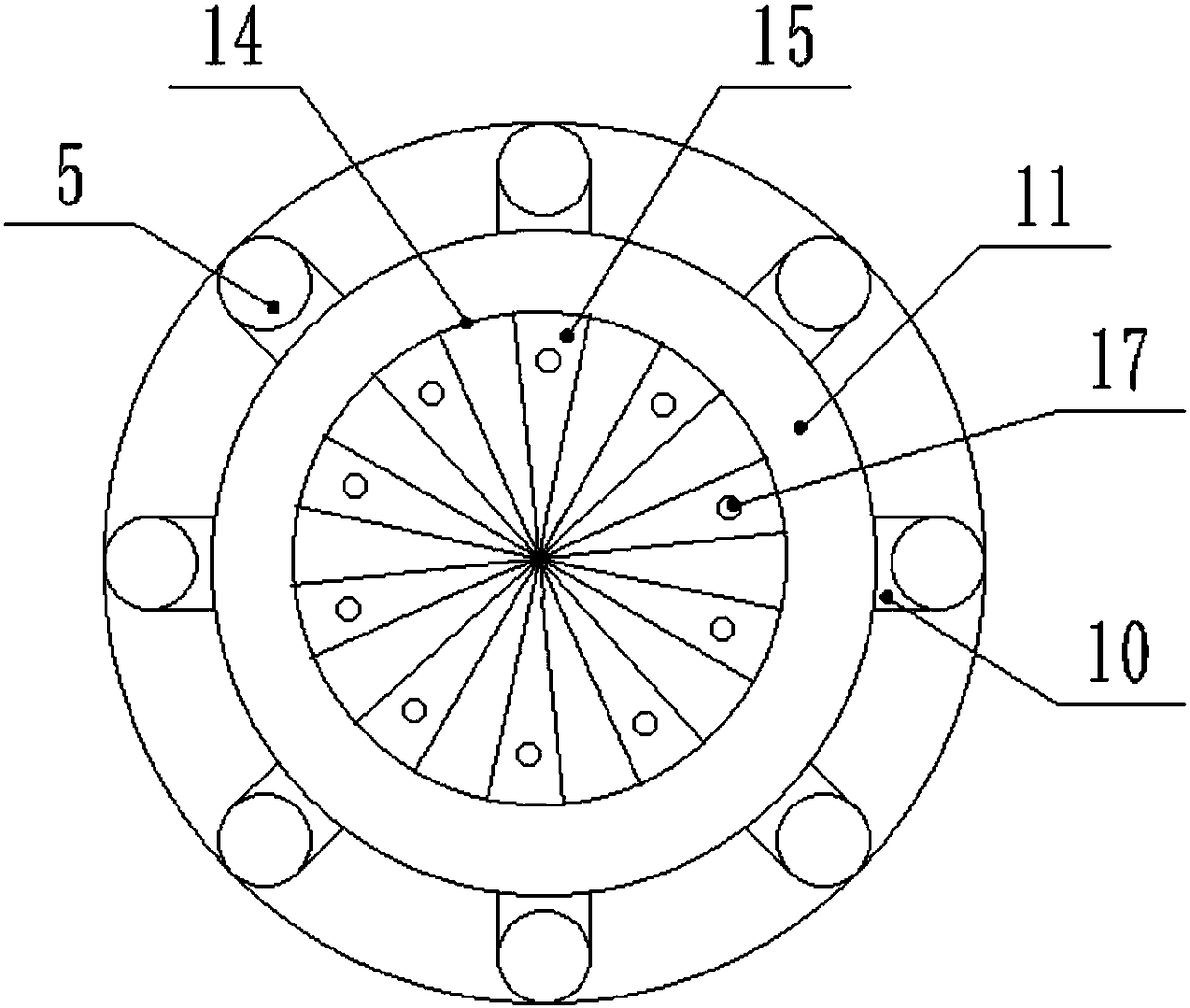

Intelligent air-distribution device for solid fuel combustion

InactiveCN104964309ABurn fully and completelyFair useAir supply regulationMicrocomputerSmoke detectors

The invention discloses an intelligent air-distribution device for solid fuel combustion. The intelligent air-distribution device comprises an air-distribution cavity, an air-distribution baffle plate, a rotary shaft, an outer cover of the air-distribution cavity, secondary and third air inlets, a primary air inlet, an air inlet, a rotary button, a driving motor, a smoke detector and a microcomputer. The air-distribution cavity is internally provided with a movable air-distribution baffle plate and a fixed limiting device. The air-distribution baffle plate is in the shape of a circular plate with an empty groove. The secondary and third air inlets are arranged in the air-distribution baffle plate. The primary air inlet has the same hole diameter as a second ventilating duct and a first ventilating duct of the back side of the air-distribution cavity. A spring, a rotary device and the rotary button are arranged on the rotary shaft of the air-distribution baffle plate. The rotary device is driven by a driving motor to perform motion for rotating the rotary shaft. The driving motor is connected with the microcomputer. The microcomputer is connected with the smoke detector. The lower portion of the outer cover of the air-distribution cavity is provided with an air inlet and the upper portion of the outer cover of the air-distribution cavity is provided with the rotary button. The intelligent air-distribution device for solid fuel combustion is uniform and reasonable in air distribution and used intelligently and manually such that combustion is performed completely.

Owner:SHANXI RONGSHENDA SCI & TECH

Pretreatment system and method for printing and dyeing of home textile fabric

InactiveCN110079962AImprove qualityGood removal effectMechanical cleaningPressure cleaningEngineeringHandling system

The invention provides a pretreatment system and method for printing and dyeing of home textile fabric. The system comprises a tank body, wherein a rack is arranged in the tank body; the home textilefabric is conveyed on the rack; the rack is provided with a carding mechanism, a singeing mechanism, a pre-cleaning mechanism and a cleaning mechanism respectively in the conveying direction of the home textile fabric. The method comprises the following steps: feeding in, carding, standing, singeing, pre-cleaning, shaping and discharging out. External air is heated by a draught fan and then is discharged to the home textile fabric after singeing, so that impurities remaining on the home textile fabric after singeing are removed; meanwhile, the hot air for removing the impurities is blown fromthe middle to two sides of the width direction of the home textile fabric, the home textile fabric is drawn to be flat by the hot air, and the technical problem that the impurity cleaning and flattingtreatment are synchronously performed on the home textile fabric after singeing is solved.

Owner:浙江常鑫纺织品有限公司

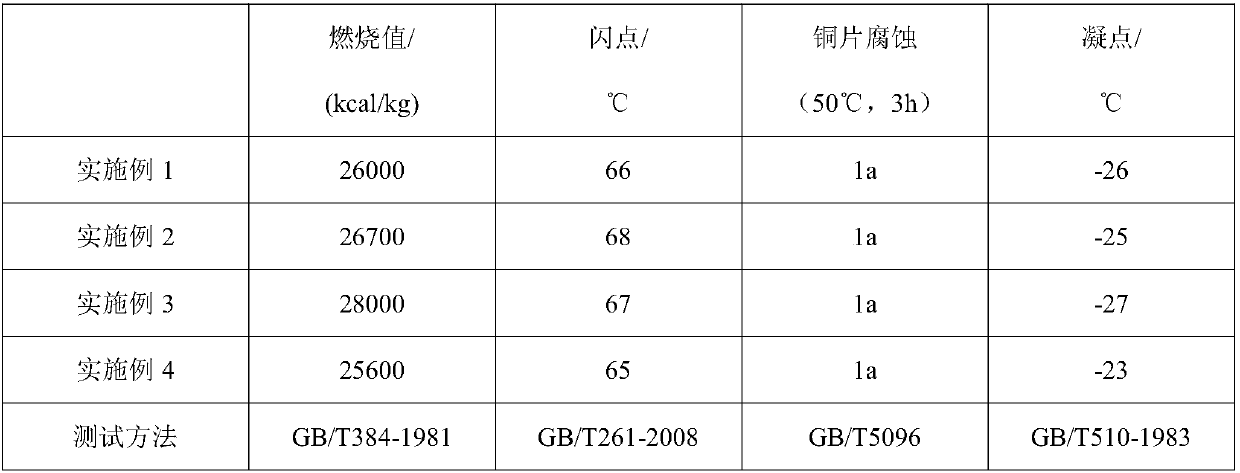

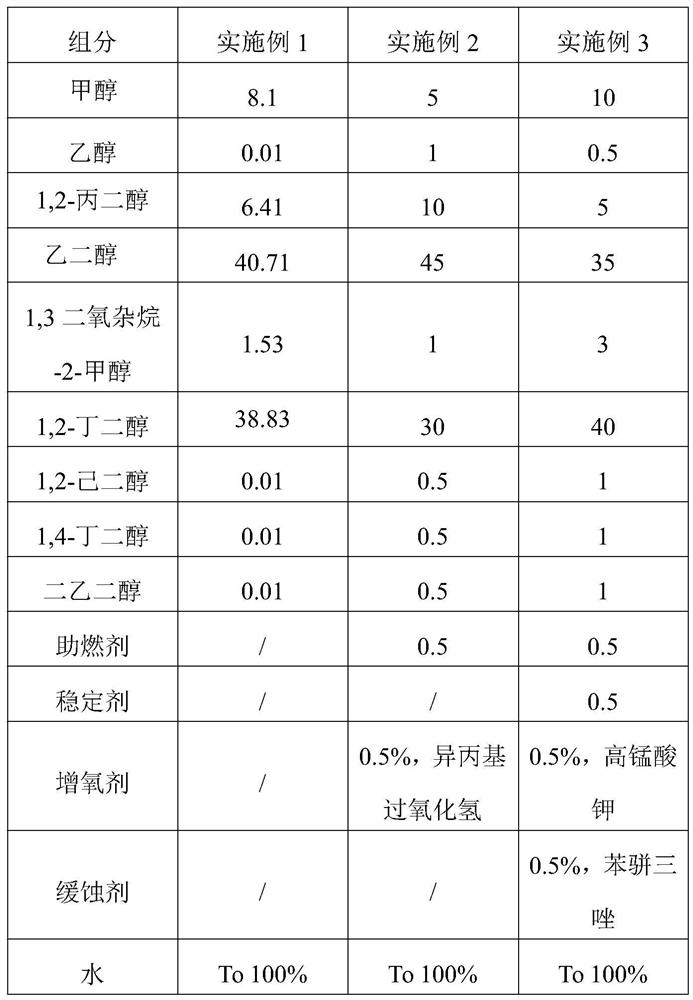

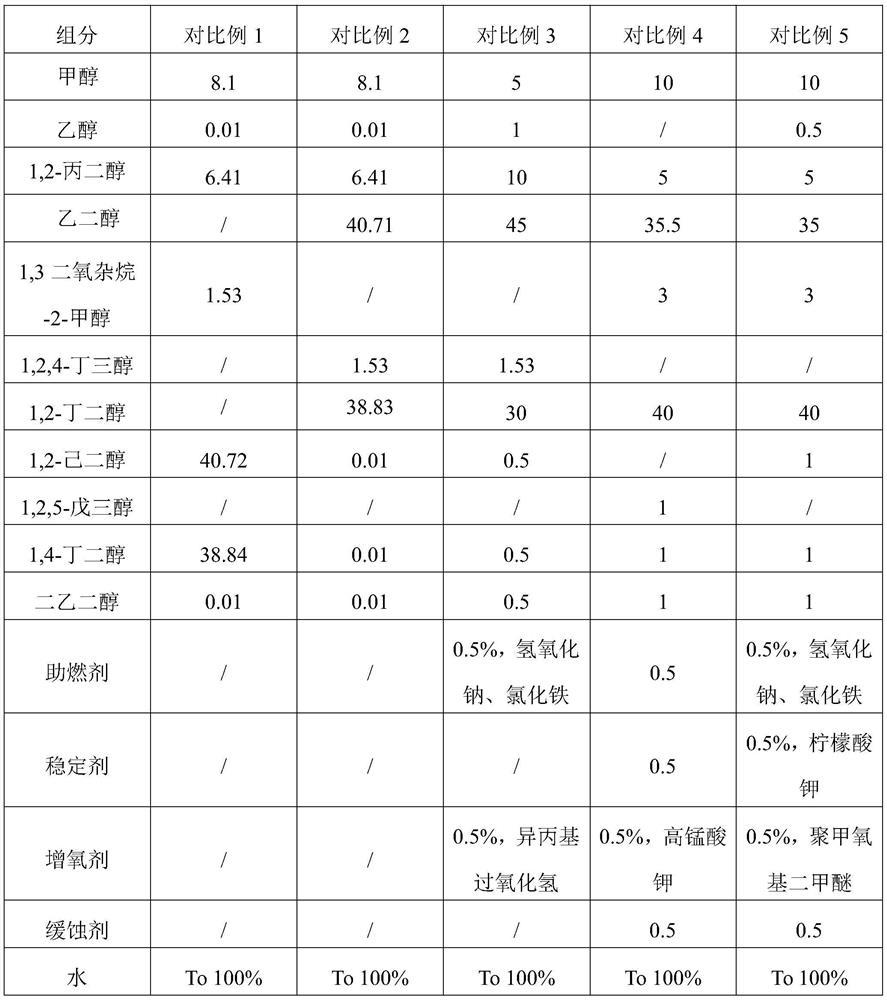

High-calorific-value environment-friendly combustion oil

ActiveCN111944567ALow kinematic viscosityLower cold filter pointLiquid carbonaceous fuelsFuel additivesGlycol synthesisEthylene glycol toxicity

The invention belongs to the technical field of fuel. High-calorific-value environment-friendly combustion oil is disclosed and comprises the following components in percentage by mass: 5-10% of methanol, 0.01-1% of ethanol, 5-10% of 1,2-propylene glycol, 35-45% of ethylene glycol, 1-3% of 1,3-dioxane-2-methanol, 30-40% of 1,2-butylene glycol, 0.01-1% of 1,2-hexanediol, 0.01-1% of 1,4-butylene glycol, and 0.01-1% of diethylene glycol, with the balance being water. The combustion oil is high in combustion heat value, sufficient and thorough in combustion, free of carbon deposition after combustion, stable in flame, high in combustion efficiency, good in safety, efficient and environmentally friendly.

Owner:汕尾市南风新能源环保科技有限公司

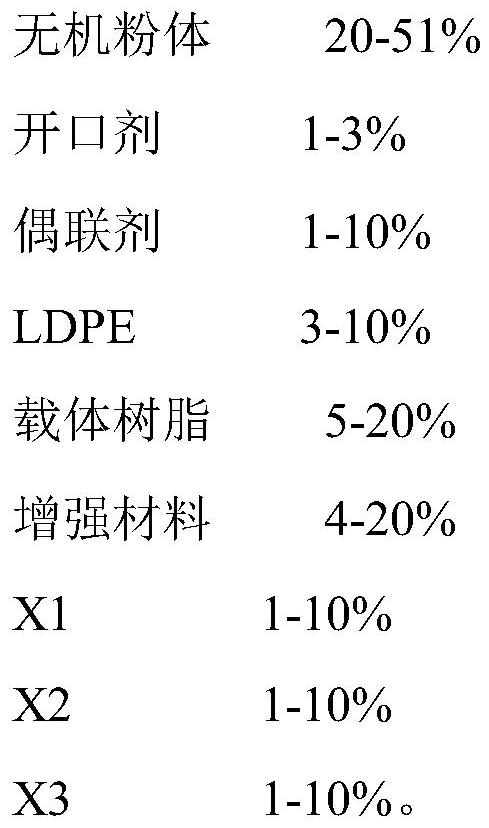

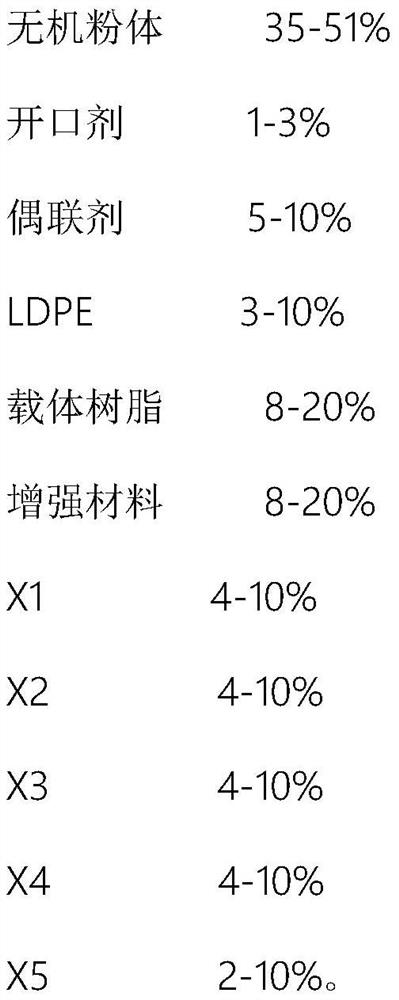

Novel plastic substitute material capable of being used as mulching film and preparation process thereof

The invention provides a novel plastic substitute material capable of being used as a mulching film. The novel plastic substitute material is composed of 20-51% of inorganic powder, 1-3% of an anti-blocking agent, 1-10% of a coupling agent, 3-10% of LDPE, 5-20% of carrier resin, 4-20% of a reinforcing material, 1-10% of X1, 1-10% of X2 and 1-10% of X3. The mulching film prepared from the materialhas the advantages of heat preservation, moisture preservation, freezing prevention, insect prevention, disease resistance, weeding, ventilation, fertilization, high efficiency, environmental protection, soil loss prevention, soil hardening improvement and the like. The prepared polyethylene blow-molded agricultural ground covering film has the thickness of 1 or 1.2 filaments, the appearance (uniform color and luster and no obvious holes or bubbles), the mechanical property (the tensile load is greater than or equal to 5.0 N and the breaking strain is greater than or equal to 400%), the weather resistance (stable chemical properties after long-time exposure), the thickness deviation (the thickness limit deviation is less than or equal to 0.005 mm), the width limit deviation (the limit deviation is less than or equal to 10 mm within the width range of 800-1500 mm), the net mass limit deviation (when the mass of each roll is less than or equal to 10 kg, the limit deviation is less than or equal to 0.10 kg) and the like meet the GB / T13735-2017 standard. Meanwhile, the biodegradable period of the plastic substitute material is short, and the plastic substitute material is environment-friendly.

Owner:深圳绿能粒子开发有限公司

Semi-gasified waste incinerator

InactiveCN106247341BSolve the problem of incomplete incinerationBurn fully and completelyIncinerator apparatusCombustion chamberDistribution system

Owner:谢植笔

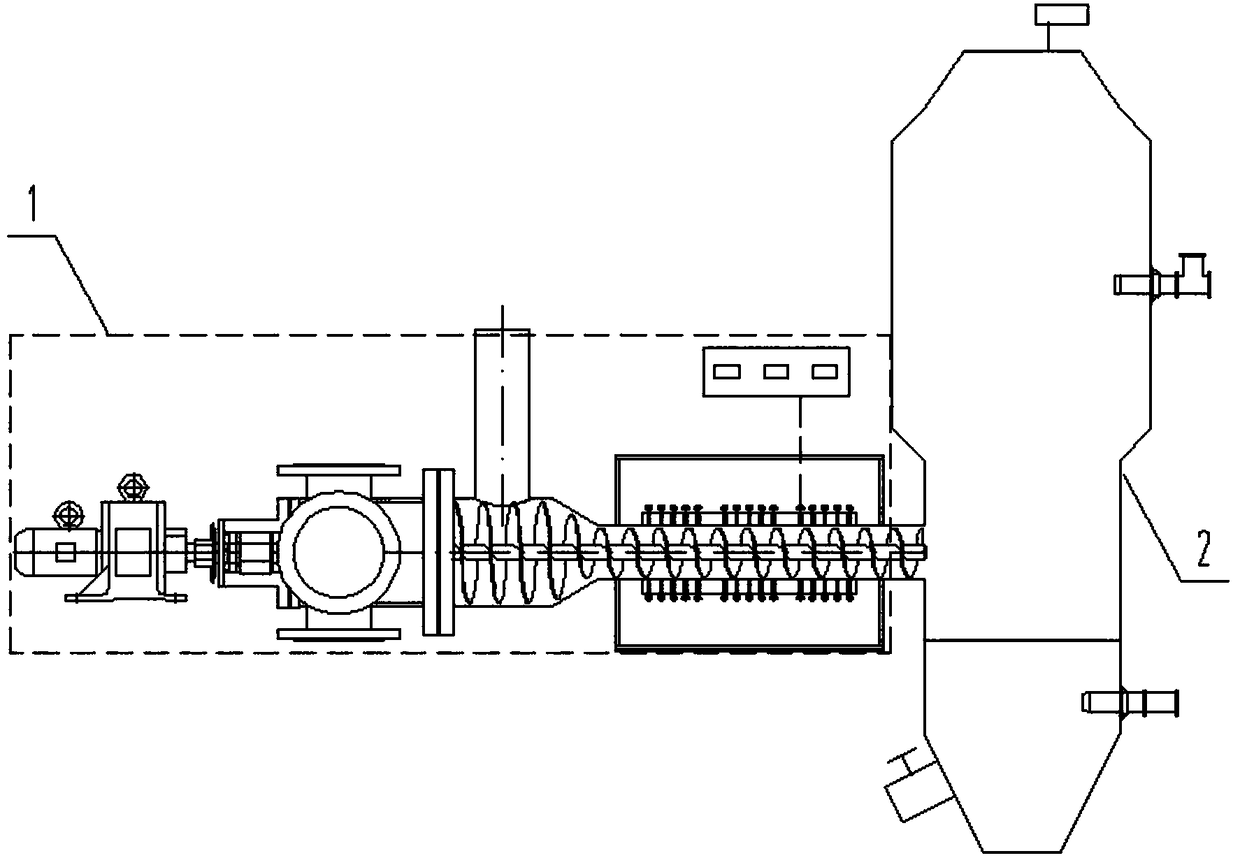

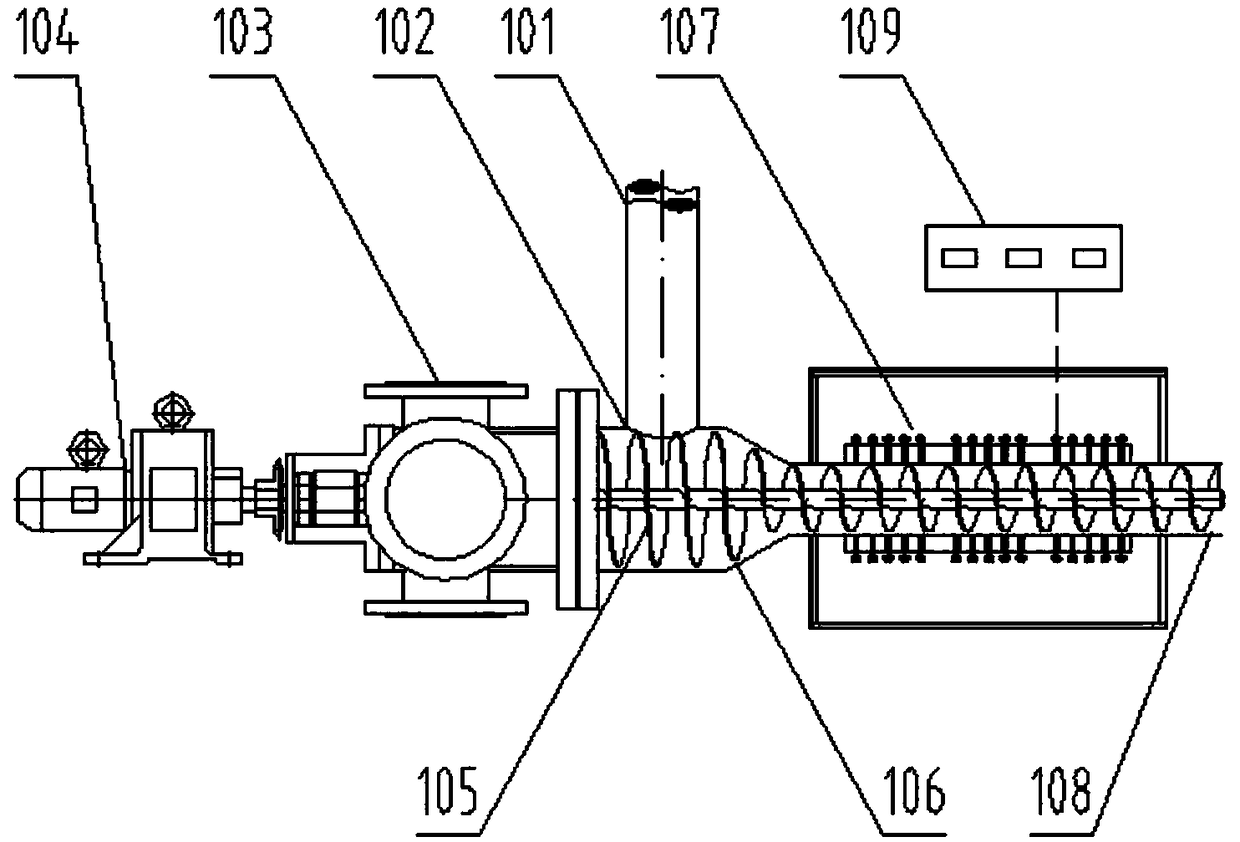

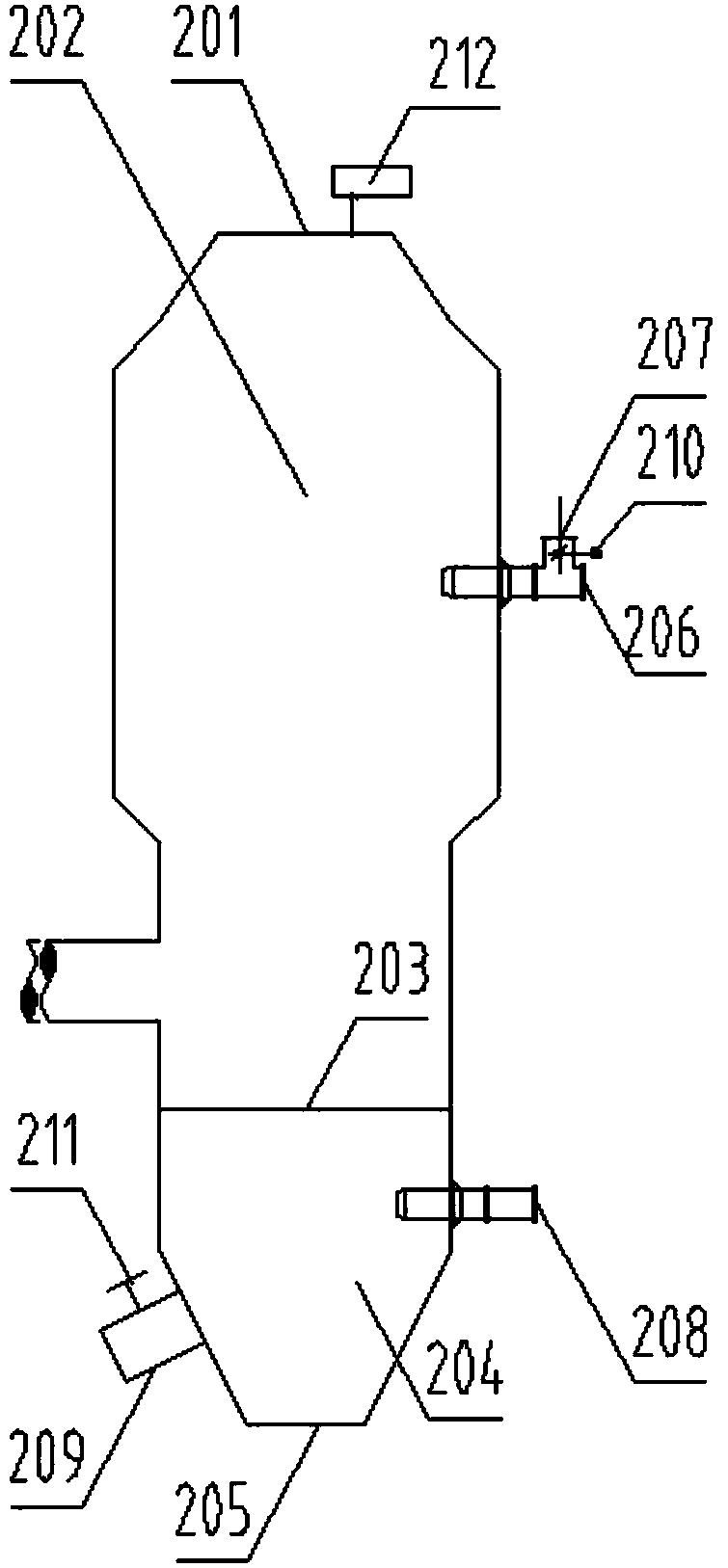

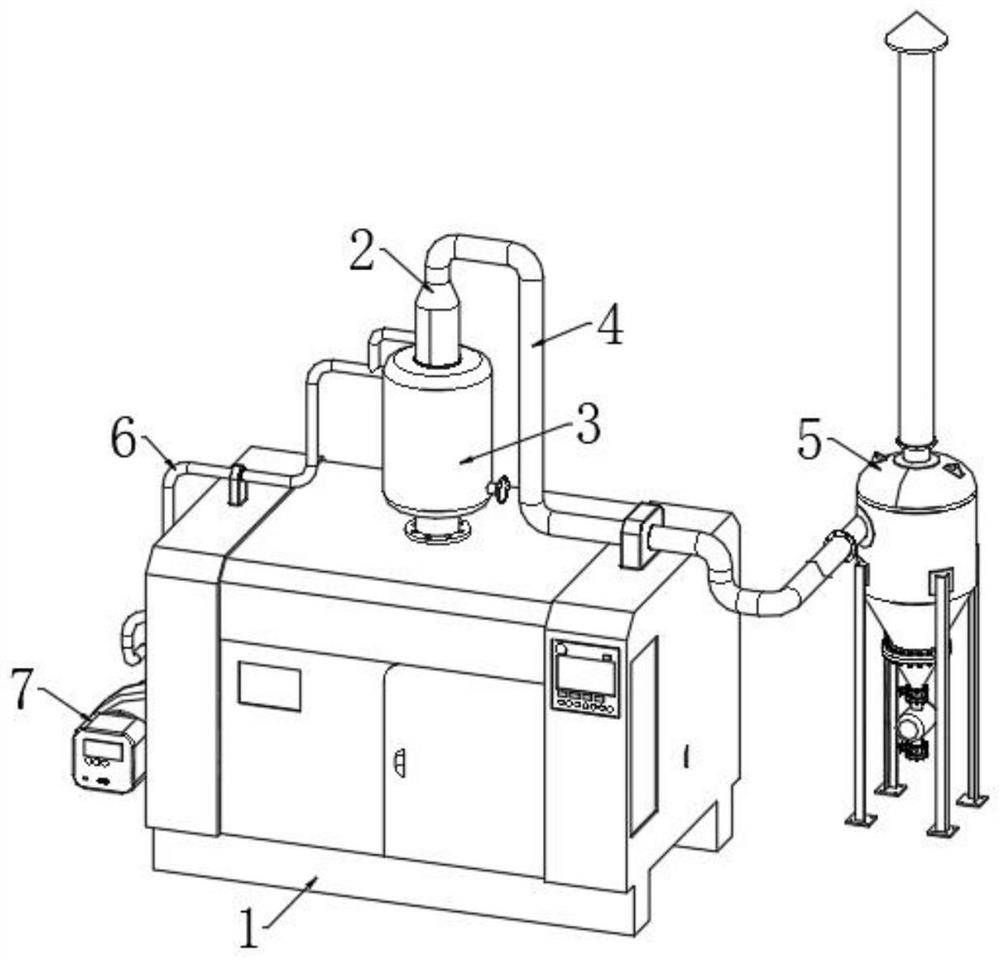

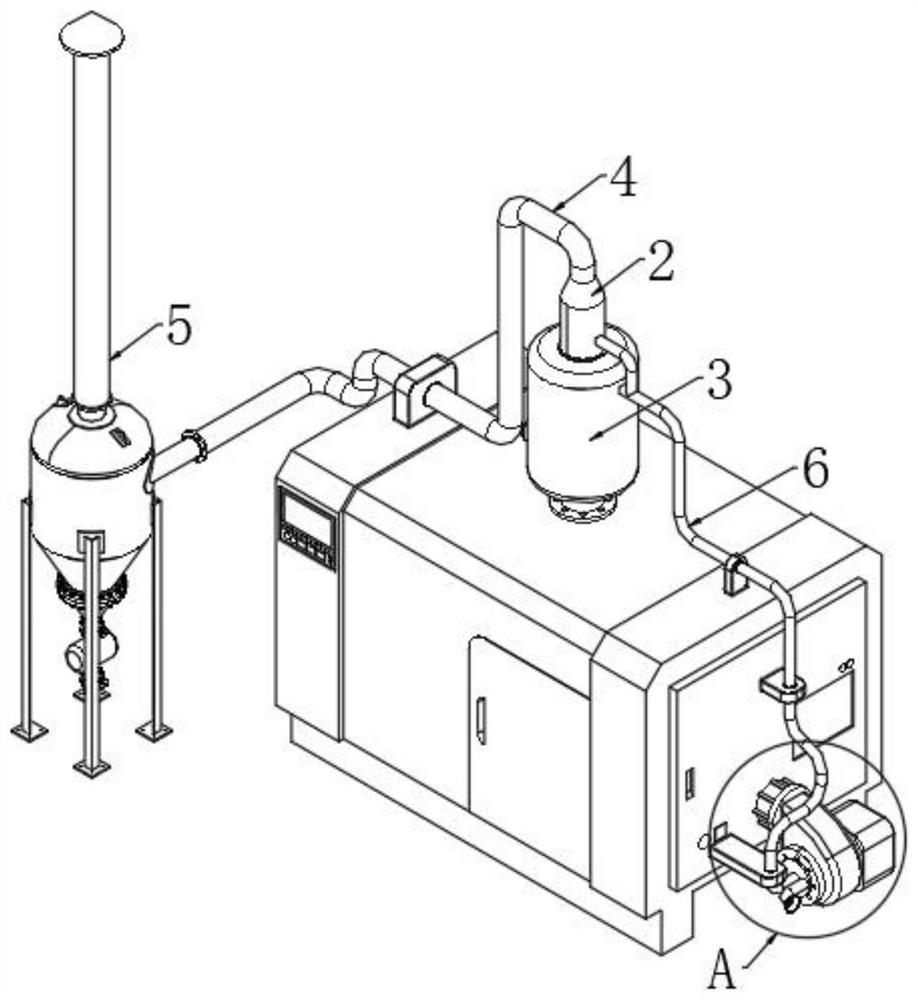

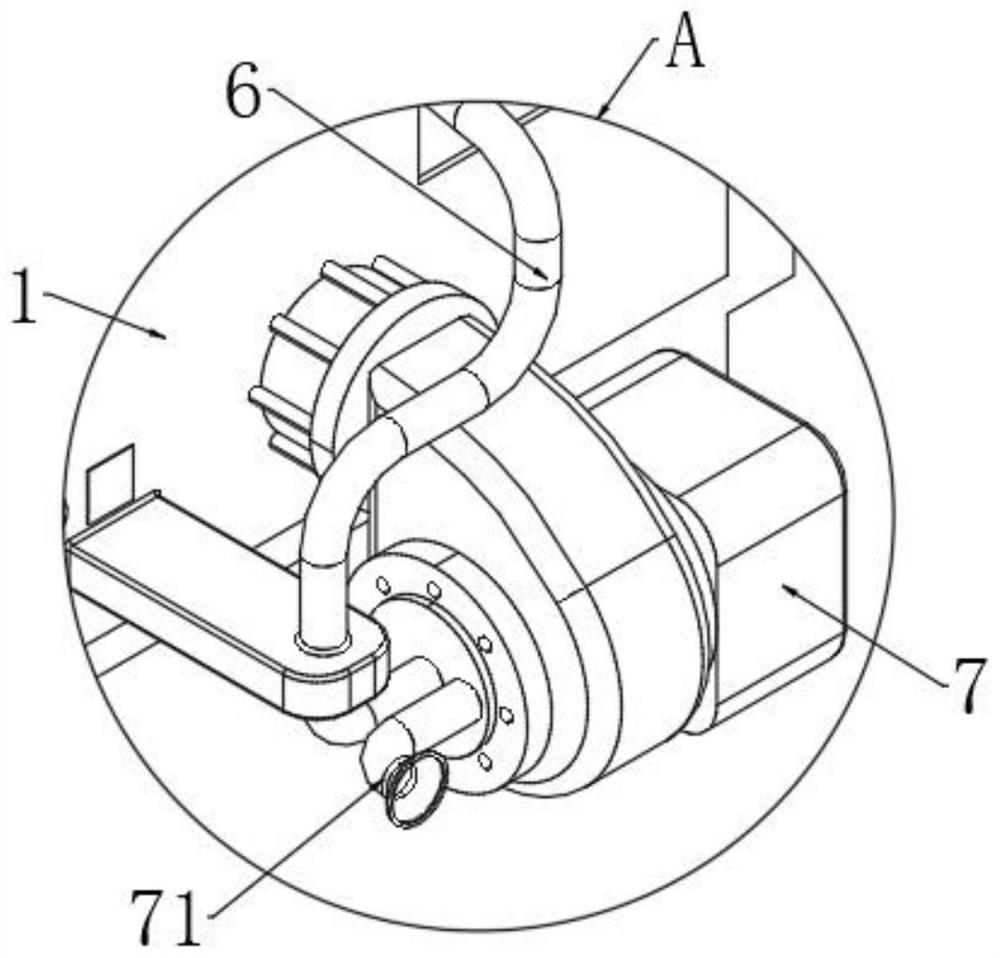

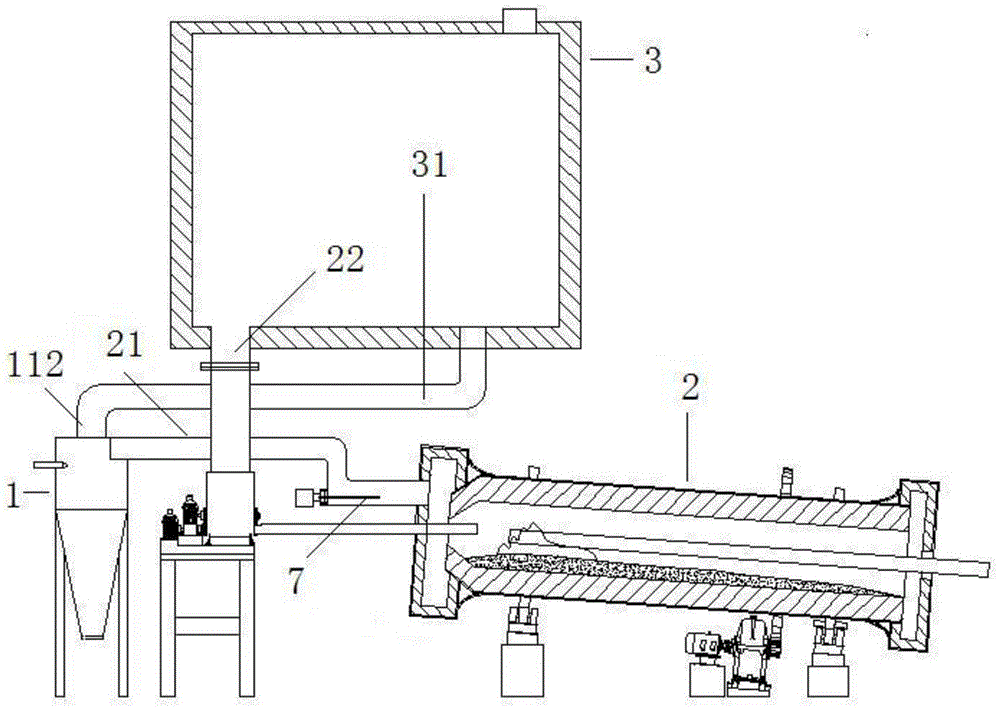

An energy-saving and environment-friendly sludge combustion device

ActiveCN107166408BEasy to burn fullyBurns easily and completelyFluidized bed combustionIncinerator apparatusSludgeThermal efficiency

The invention discloses an energy-conservation and environmental-protection sludge combustion device. The sludge combustion device comprises a combustion furnace and a separator; and an intake pipe of the separator communicates to a furnace cavity of the combustion furnace, and the bottom end of the separator communicates to the furnace cavity of the combustion furnace through a return pipe. The device further comprises a sludge conveying pump; a sludge inlet is formed in the top of the return pipe; and a discharge pipe of the sludge conveying pump communicates to the sludge inlet. The combustion device adopts the top feeding, so that sludge is fully and thoroughly combusted in the combustion process. In addition, in the process of the sludge falling by the return pipe, the return pipe achieves a heating and drying effect on the sludge, so that the water content of the sludge is reduced, the dried sludge is fully combusted more easily, the hidden trouble of unqualified environmental protection emission is eliminated, the wind cap blockage problem is solved, and the heat efficiency is effectively improved.

Owner:DONGGUAN UNIV OF TECH +1

Method for improving fuel utilization efficiency of internal combustion engine and air exhausting type internal combustion engine

PendingCN108612582AImprove utilization efficiencyReduce consumptionCombustion enginesExternal combustion engineControlled combustion engine

The invention discloses a method for improving the fuel utilization efficiency of an internal combustion engine and an air exhausting type internal combustion engine. The method comprises the following steps: when certain air cylinder of the internal combustion engine is in the work doing stroke, a part of combustion hot gas in the combustion chamber of the air cylinder is conveyed into the air cylinder, wherein the air cylinder is in the later period of the compression stroke of the internal combustion engine, the combustion hot gas of the air cylinder is inputted to ignite the fuel in the air cylinder in the later period of the compression stroke, the air cylinder is enabled to enter the work doing stroke with higher initial pressure and initial combustion temperature, during the workingdoing stroke entering process of the air cylinder, a part of combustion hot gas in the combustion chamber of the air cylinder is conveyed into the air cylinder, and the air cylinder is in the later period of other compression strokes of the internal combustion engine. The invention aims to provide the method for improving the fuel utilization efficiency of the internal combustion engine and the air exhausting type internal combustion engine, and the method and the air exhausting type internal combustion engine have the following benefits: the fuel utilization efficiency can be greatly improved, the energy consumption is reduced, combustion is enabled to be more homogeneous and is adapted to higher air-fuel ratio, the selective range of the air-fuel ratio is larger, and the emission load of various pollutants harmful to the environment is greatly reduced.

Owner:孟金来

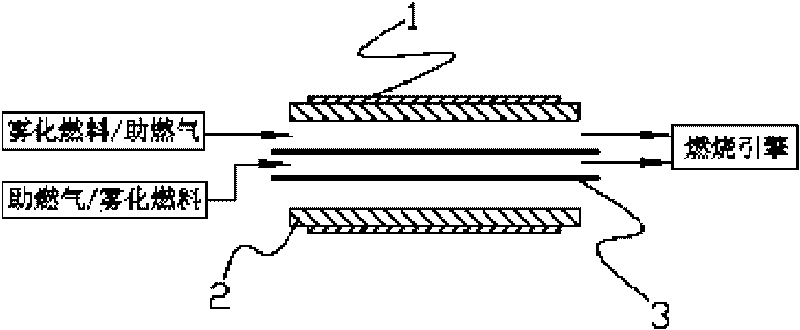

Biomass furnace combustor and combustion method thereof

InactiveCN101644429BHigh heat conversion rateLow costCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermal energyCombustor

The invention relates to a biomass furnace combustor and a combustion method thereof. The biomass furnace combustor comprises a biomass furnace and an air combustion supporting device, wherein the biomass furnace is provided with a charging door and a smoke outlet, both ends of the air combustion supporting device are connected with the inner side of the biomass furnace, and the two lateral facesof the air combustion supporting device are separated from the inner wall of the biomass furnace; and the air combustion supporting device mainly comprises a bracket and at least two air replenishingpipes, both ends of each of the air replenishing pipe are connected with the bracket, a gap is kept between the air replenishing pipes, a plurality of air replenishing openings are arranged on the air replenishing pipes, at least one air inlet is arranged on the bracket, and air passages connected with the mouths of the air replenishing pipes are arranged in the bracket. The biomass furnace combustor is installed above an industrial biomass semi-gasification stove, and enables coal or biomass solid fuel to be directly combusted to generate a great amount of combustible gas and particle black carbon; and when passing through the air combustion supporting device, the combustible gas and the particle black carbon can be thoroughly and completely combusted, black smoke can be eliminated, and the thermal energy conversion rate of the fuel can be increased. The invention saves the fuel cost, protects the environment, etc.

Owner:宁波双翼能源科技有限公司

High-performance two-stroke internal combustion engine

InactiveCN110805491AUniform and fully ignited combustionFully ignite combustionMachines/enginesEngineeringInternal combustion engine

The invention provides a high-performance two-stroke internal combustion engine which includes an acting cylinder block, an air pressing cylinder block, an acting piston, an air pressing piston, a power output structure and a spark plug. The acting cylinder block is sleeved and fixedly installed in the air pressing cylinder block and is provided with an air outlet hole, the air pressing cylinder block is provided with an air inlet, the acting cylinder block is provided with a communication hole for communicating the inside of the acting cylinder block and the inside of the air pressing cylinder block, the air inlet hole, the air outlet hole and the communication hole are provided with valves, a circular air applying ring is arranged in the acting cylinder body, the air applying ring is internally provided with air applying channels, the air applying channels are connected with the communication hole, the air applying ring is provided with a plurality of air applying holes for communicating the multiple air applying channels, and the air applying holes are evenly arranged in the circumferential direction of the air applying ring; the acting piston is arranged in the acting cylinderblock in a matched manner, the air pressing piston is arranged in the air pressing cylinder body in a matched manner, and the acting piston and the air pressing piston are linked and combined to forman output piston; and the power output structure is connected to the output piston and externally outputs power, and the spark plug is arranged on the acting cylinder block.

Owner:郭博颖

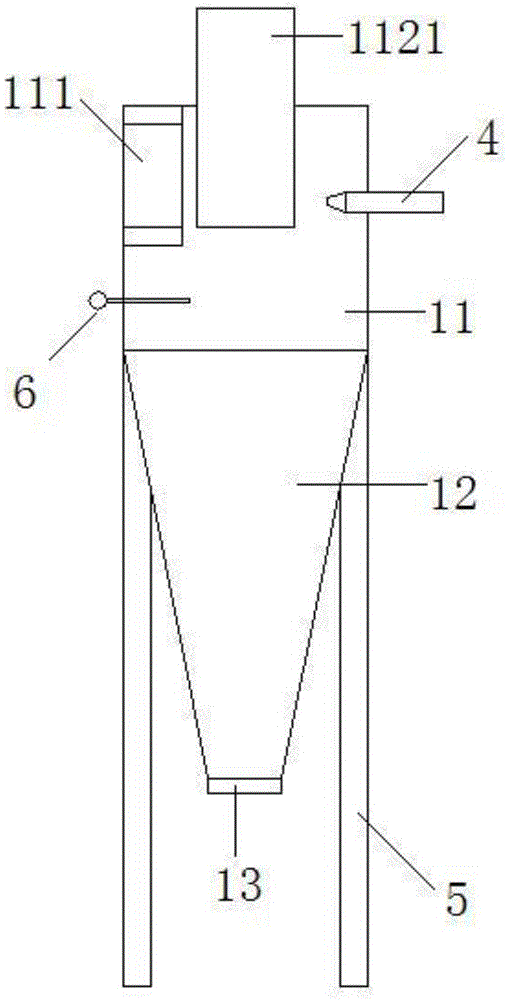

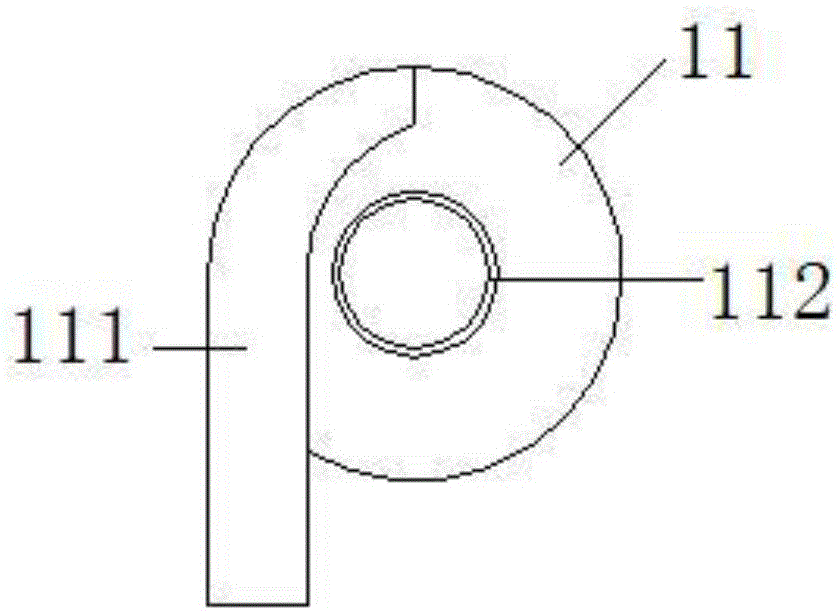

Harmless secondary recycling system for waste incineration fly ash

PendingCN114777131AEffect of filtration and purification effectReduce the temperatureIncinerator apparatusRotary device cleaningCombustionFlue gas

The invention belongs to the technical field of waste incineration, and particularly relates to a harmless secondary recycling system for waste incineration fly ash, which comprises an incinerator and a smoke exhaust assembly, a preheating assembly is arranged on the smoke exhaust assembly, one side of the preheating assembly is connected with an air blower, and the air blower and the incinerator are connected together and communicated with each other. High-temperature flue gas discharged by an incinerator can be cooled, it is ensured that the temperature is low when the high-temperature flue gas enters the cyclone filter to be filtered and purified, and the filtering and purifying effect of the cyclone filter cannot be affected or damaged due to the high temperature; flying-back particles in the flue gas can be recycled, gathered and secondarily utilized through the cyclone filter; air which enters the incinerator and is mixed with garbage for combustion is heated through high-temperature flue gas, the combustion speed of the garbage in the incinerator can be higher when the air enters the incinerator, and the garbage can be combusted more sufficiently in the incinerator.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

new internal combustion engine

ActiveCN105275608BPromote combustionBurn fully and completelyExhaust gas recirculationMachines/enginesExternal combustion engineFuel gasification

A new type of internal combustion engine, comprising more than one cylinder (1), each cylinder (1) is respectively provided with a piston (2), the piston (2) and the cylinder (1) form a combustion chamber (3), each cylinder The wall of (1) is respectively provided with the intake port (4) and exhaust gas outlet (5) that can communicate with the combustion chamber (3) in the cylinder, and the combustion chamber (3) of each cylinder (1) passes through a The gas path (11) with the valve (6) for cutting off or connecting the medium flow in series is connected with a fuel gasification chamber (7), and each fuel gasification chamber (7) is respectively connected with a fuel injection gas path (8 ) is connected to the outlet. Its purpose is to provide a new type of internal combustion engine that can greatly improve fuel utilization efficiency, reduce energy consumption, and greatly reduce the discharge of various pollutants harmful to the environment.

Owner:孟金来

A secondary combustion system

ActiveCN104235858BPromote recoveryIncrease the burning areaIncinerator apparatusCombustion systemCombustion chamber

Owner:ZHEJIANG SANLIAN ENVIRONMENT MACHINERY EQUIP

Environment-friendly combustion oil and production process

InactiveCN112646618ALow kinematic viscosityHigh calorific valueLiquid carbonaceous fuelsFuel oilButanediol

The invention discloses environment-friendly combustion oil, which relates to the technical field of fuel oil production and processing and comprises the following components in percentage by mass: 5 to 10 percent of methanol, 0.01 to 1 percent of ethanol, 5 to 10 percent of 1, 2-propylene glycol, 35 to 45 percent of ethylene glycol, 1 to 3 percent of 1, 3-dioxane-2-methanol, 30 to 40 percent of 1, 2-butanediol, 0.01 to 1 percent of 1, 2-hexanediol, 0.01 to 1 percent of 1, 4-butanediol, 0.01 to 1 percent of diethylene glycol and the balance of water. The production process comprises the following steps: adding the emulsifier and the surfactant into the combustion oil and mixing in proportion to obtain mixed combustion oil; stirring the mixed combustion oil at a high speed; carrying out offset mixing and stirring on the mixed combustion oil; and mixing the mixed combustion oil with water in proportion to obtain emulsified combustion oil. According to the invention, methanol and various alcohols are mixed, so that the combustion oil can better in sufficient and thorough low-temperature combustion, and is efficient and environment-friendly; the energy-saving and environment-friendly emulsified combustion oil prepared from the combustion oil, the emulsifier and the water in proportion can be produced, an oil-water-oil triple structure is formed, and the production efficiency is high.

Owner:江西瑞府环保石化有限公司

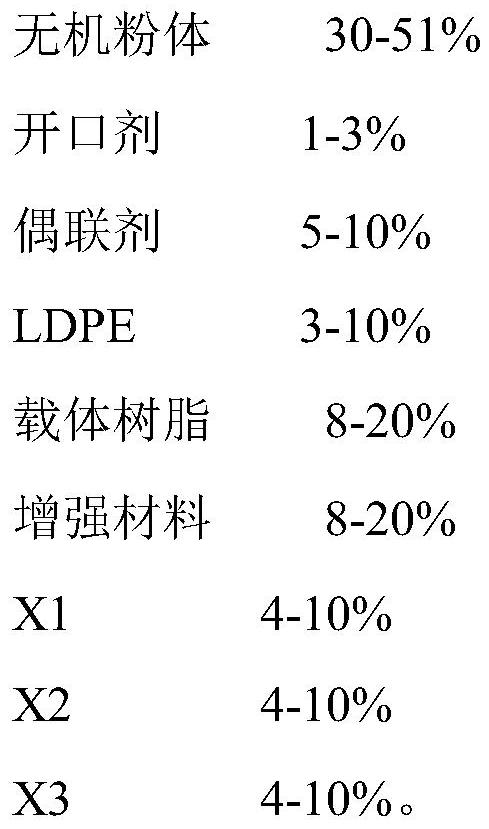

Novel plastic substitute material capable of being used as pesticide bottle and preparation process thereof

The invention provides a novel plastic substitute material capable of being used as a pesticide bottle and a preparation process thereof. The novel plastic substitute material comprises 30-51% of inorganic powder, 1-3% of an anti-blocking agent, 3-10% of a coupling agent, 3-10% of LDPE, 4-20% of carrier resin, 5-20% of a reinforcing material, 1-10% of X1, 1-10% of X2, 1-10% of X3, 1-10% of X4 and1-10% of X5. The pesticide bottle prepared from the novel plastic substitute material can meet the requirements of using functions, appearance inspection, measurement of bottleneck and height deviation, measurement of perpendicularity deviation, measurement of full capacity, measurement of the wall thickness ratio of the minimum wall thickness to symmetrical parts, measurement of mass deviation, measurement of physical and mechanical properties (including axial pressure bearing capacity, air tightness, internal pressure resistance, drop performance, heat storage weightlessness and loading resistance) can meet the requirements of the industry standard BB / T 0044-2007.

Owner:深圳绿能粒子开发有限公司

Converter high in fuel utilization rate

InactiveCN108396098ARaise the combustion temperatureFast heatingManufacturing convertersCombustionEngineering

The invention discloses a converter high in fuel utilization rate, belongs to the technical field of metal smelting, and aims at solving the problems that according to an existing converter, air inflow is insufficient, and ventilation holes are prone to being blocked by residues. The converter comprises a converter body and a converter base. The converter body is internally provided with a ventilation assembly and a combustion frame for containing fuel. A cavity is formed in the side wall of the converter body. An air guiding assembly comprises air guiding pipes, an air collecting chamber, a ventilation assembly, a rotation shaft and a motor, wherein the ventilation assembly comprises a ventilation pipe and a ventilation chamber. A plurality of ventilation through holes are formed in the combustion frame, and the combustion frame is located above a first air outlet pipe and arranged between inner rings of the ventilation chamber. The rotation shaft penetrates the bottom of the converter body, the top of the rotation shaft is connected with the bottom of the air collecting chamber, and the bottom of the rotation shaft is connected with the output end of the motor. The combustion frame comprises a supporting frame and a supporting disc with the section being a conical face. The supporting frame is of a hollow structure, ventilation through holes are formed in the top end and thebottom end of the supporting frame correspondingly, and the ventilation holes in the top end of the supporting frame and the ventilation holes in the bottom end of the supporting frame are arranged ina staggered manner.

Owner:CHENGDU JUNSHUO RUIZHI INFORMATION TECH CO LTD

Novel converter for metal smelting

InactiveCN108518976ARaise the combustion temperatureFast heatingRotary drum furnacesCombustionEngineering

The invention discloses a novel converter for metal smelting, and belongs to the technical field of metal smelting. The novel converter is used for solving the problems that air introduction for an existing converter is insufficient and residue is likely to block vent holes. The novel converter comprises a converter body and a converter base, the converter body and the converter base are connectedthrough a bearing, a ventilation assembly and a combustion frame where fuel is placed are arranged in the converter body, the side wall of the converter body is provided with a plurality of cavities,an air guide assembly comprises an air guide pipe, an air collection chamber and the ventilation assembly, the air guide pipe penetrates through the cavity to be distributed inside the converter bodyin a circumference shape, the top end of the air guide pipe is arranged outside the converter body, the bottom end of the air guide pipe communicates with the air collection chamber, the air collection chamber is arranged at the bottom of the converter body, the top of the air collection chamber is provided with a plurality of first air outlet pipes, the ventilation assembly comprises a ventilation pipe and a ventilation chamber, the ventilation pipe is distributed between the air guide pipe and the ventilation chamber in a circumference shape, one end of the ventilation pipe communicates with the air guide pipe, the other end of the ventilation pipe communicates with the ventilation chamber, and the end, close to the axis center, of the ventilation chamber is provided with a second air outlet pipe.

Owner:CHENGDU JUNSHUO RUIZHI INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com