An energy-saving and environment-friendly sludge combustion device

A technology of energy saving and environmental protection, combustion equipment, applied in the direction of combustion type, combustion equipment, combustion method, etc., can solve the problems of incomplete combustion of fuel, non-compliance of environmental protection, and reduction of thermal efficiency, so as to eliminate hidden dangers of non-compliance and reduce the water content of sludge , The effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

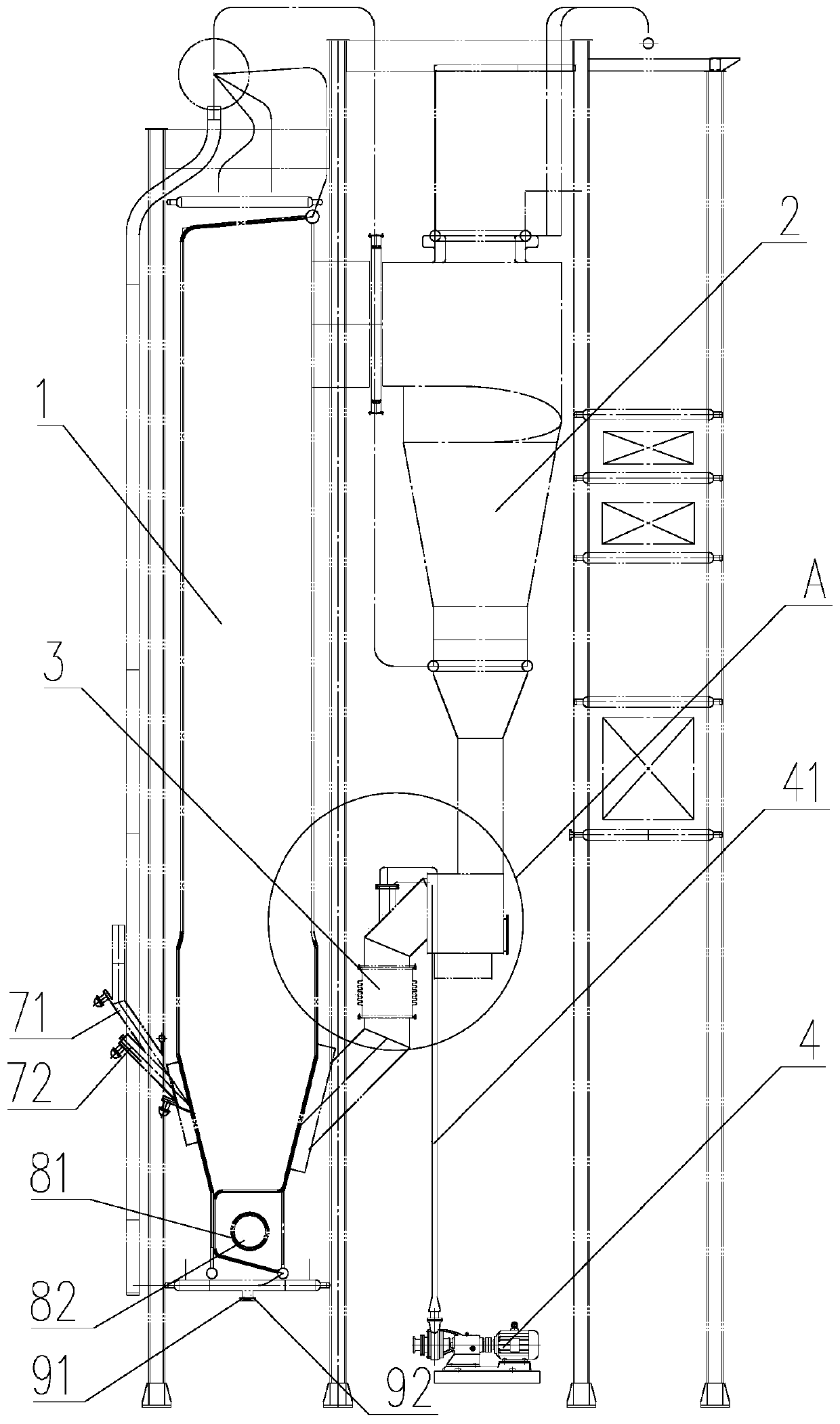

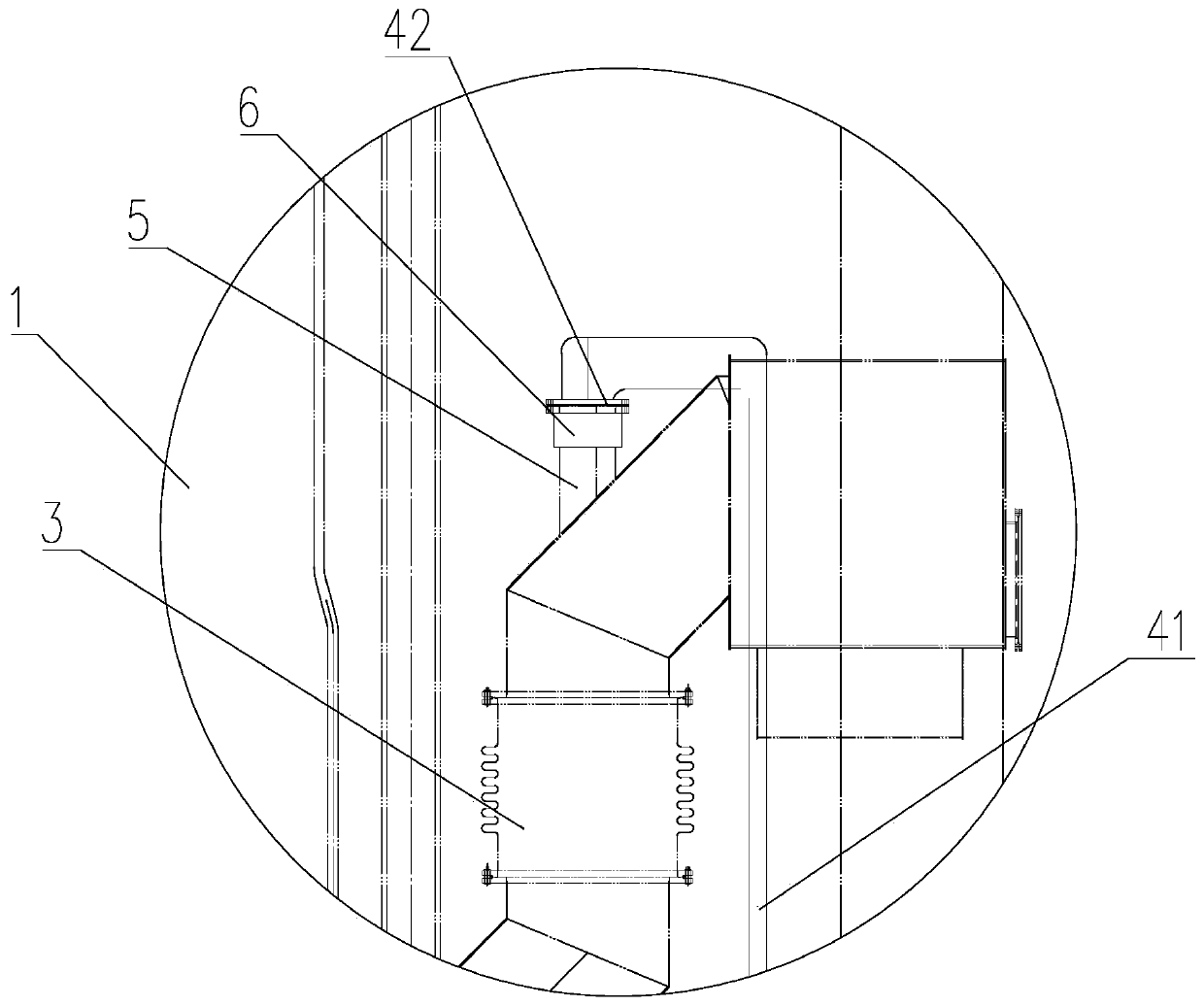

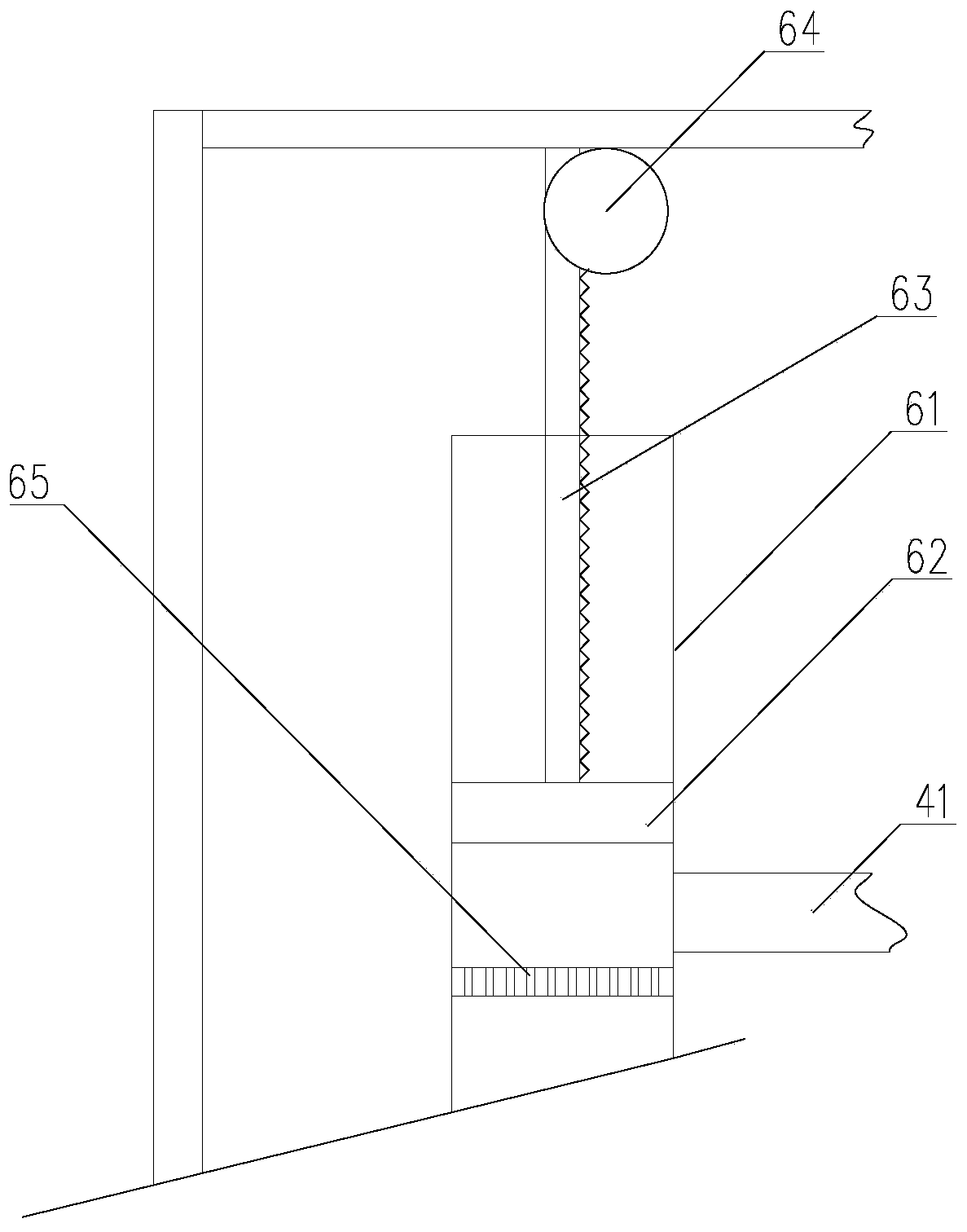

[0029] Such as figure 1 , figure 2 , image 3 As shown, an energy-saving and environment-friendly sludge combustion device includes a combustion furnace 1 and a separator 2. The inlet pipe of the separator 2 is connected to the furnace cavity of the combustion furnace 1, and its bottom end is connected to the combustion chamber through a return pipe 3. The furnace cavity of the furnace 1 also includes a sludge delivery pump 4 ; a sludge inlet 5 is provided on the top of the return pipe 3 , and a discharge pipe 41 of the sludge delivery pump 4 is connected to the sludge inlet 5 . Also includes a feeding device 6, the feeding device 6 includes a barrel 61, a push head 62, a pressure rod 63, a drive motor 64 and a mesh plate 65; the discharge pipe 41 of the sludge delivery pump 4 is connected to the material Cylinder 61, the bottom end of the material cylinder 61 is connected to the sludge inlet 5, and the bottom end is provided with a mesh plate 65; the push head 62 is arrang...

Embodiment 2

[0047] Such as Figure 4 As shown, the sludge inlet can be directly opened at the top of the combustion furnace 1, and the bottom end of the feeding device 6 is connected to the sludge inlet. At the same time, the barrel 61 is in the shape of a bucket, and the pusher 62 is in the shape of an inverted cone matching it. All the other parts are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com