Patents

Literature

47results about How to "Increase fuel temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

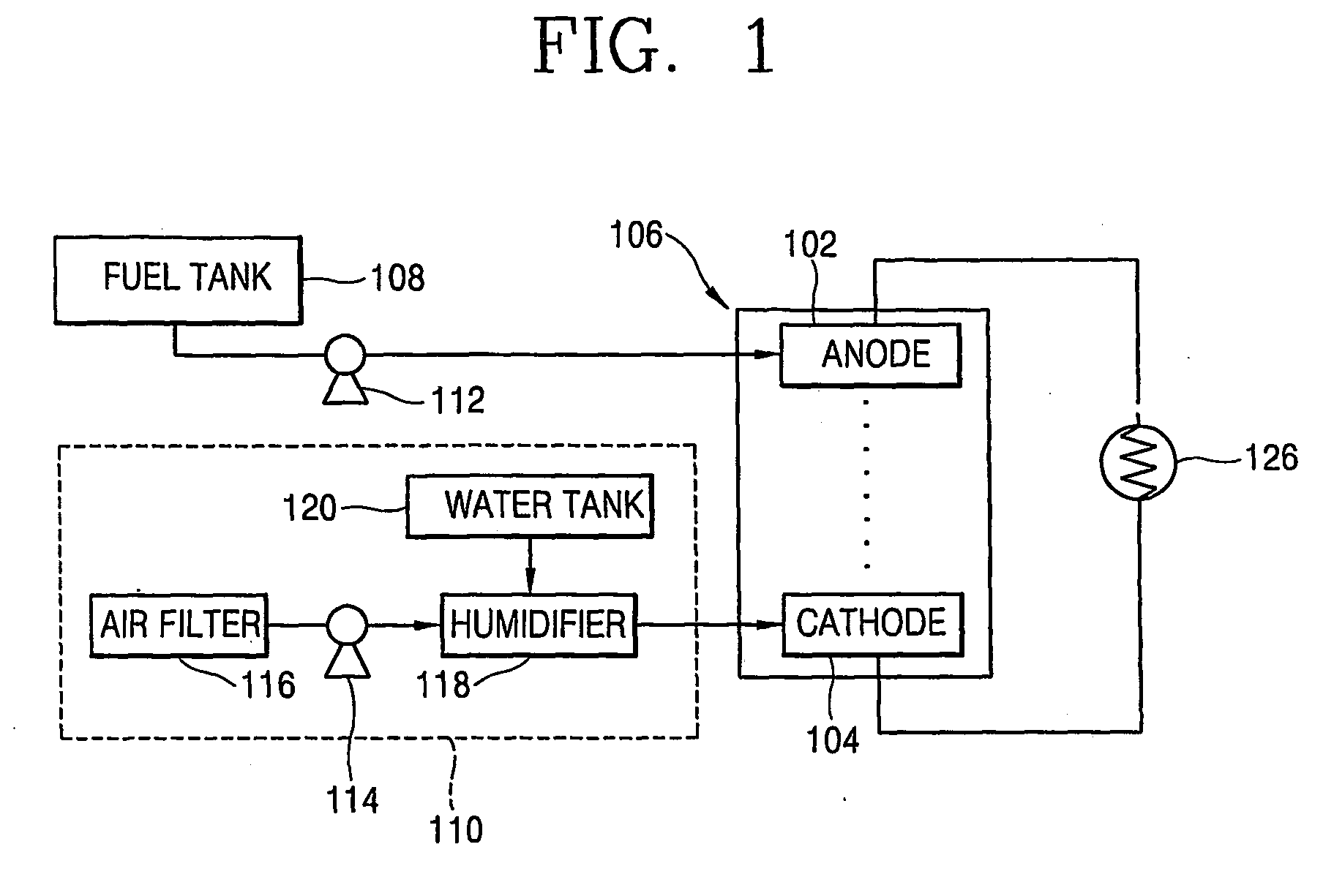

Fuel cell system

InactiveUS20060280977A1Additional heat energyGenerating efficiency is reducedFuel cell heat exchangeBattery/fuel cell control arrangementThermal energyElectrochemical response

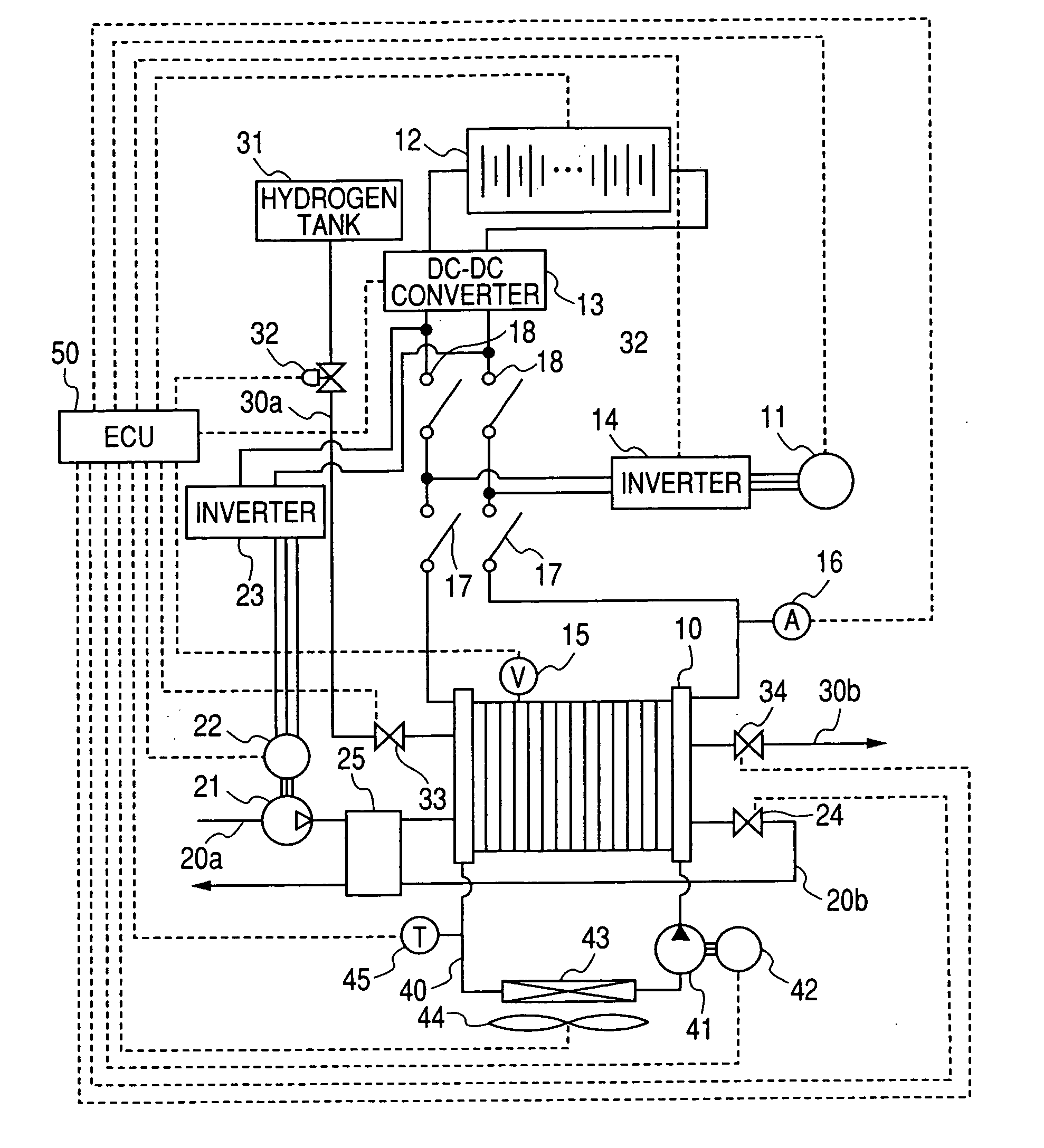

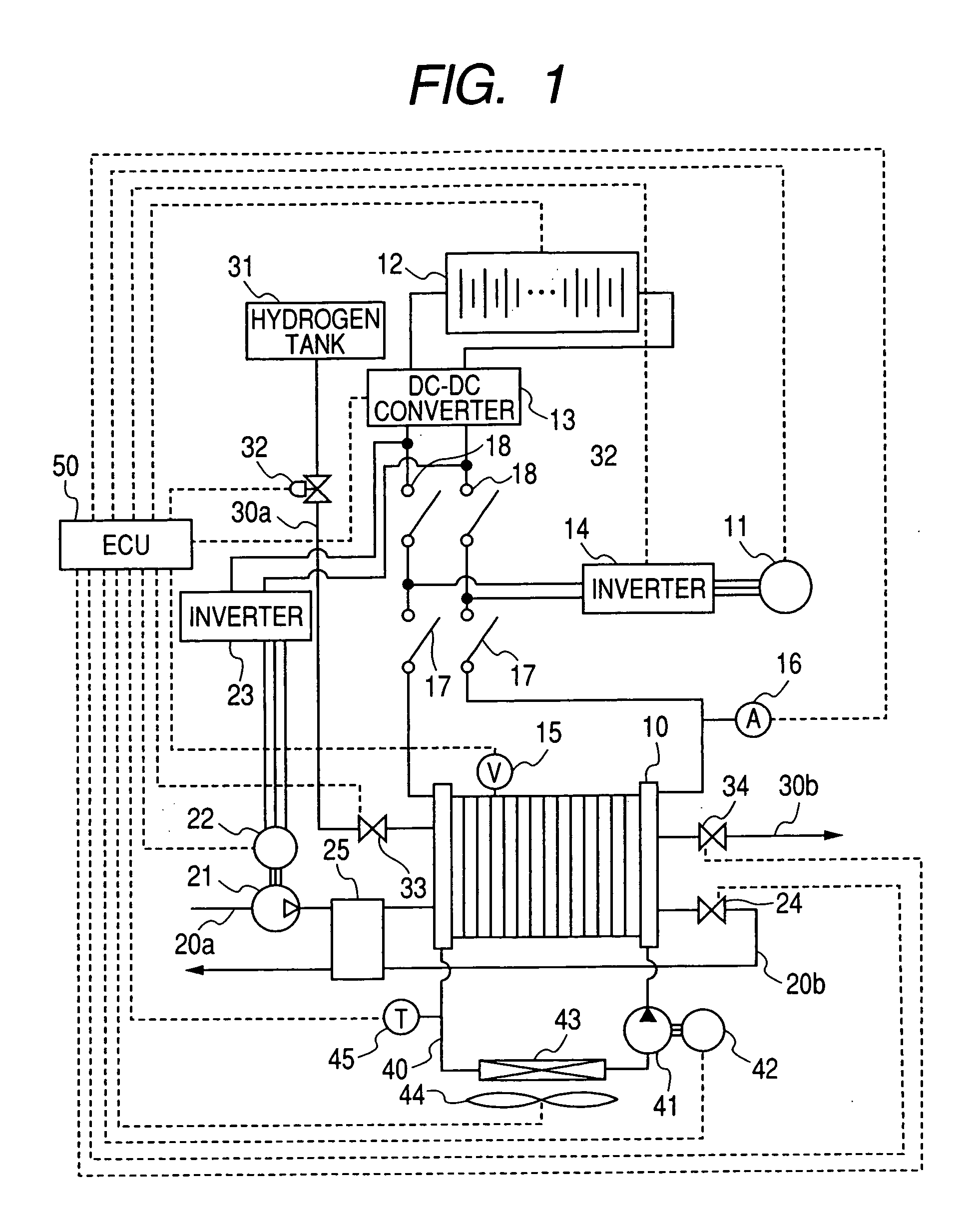

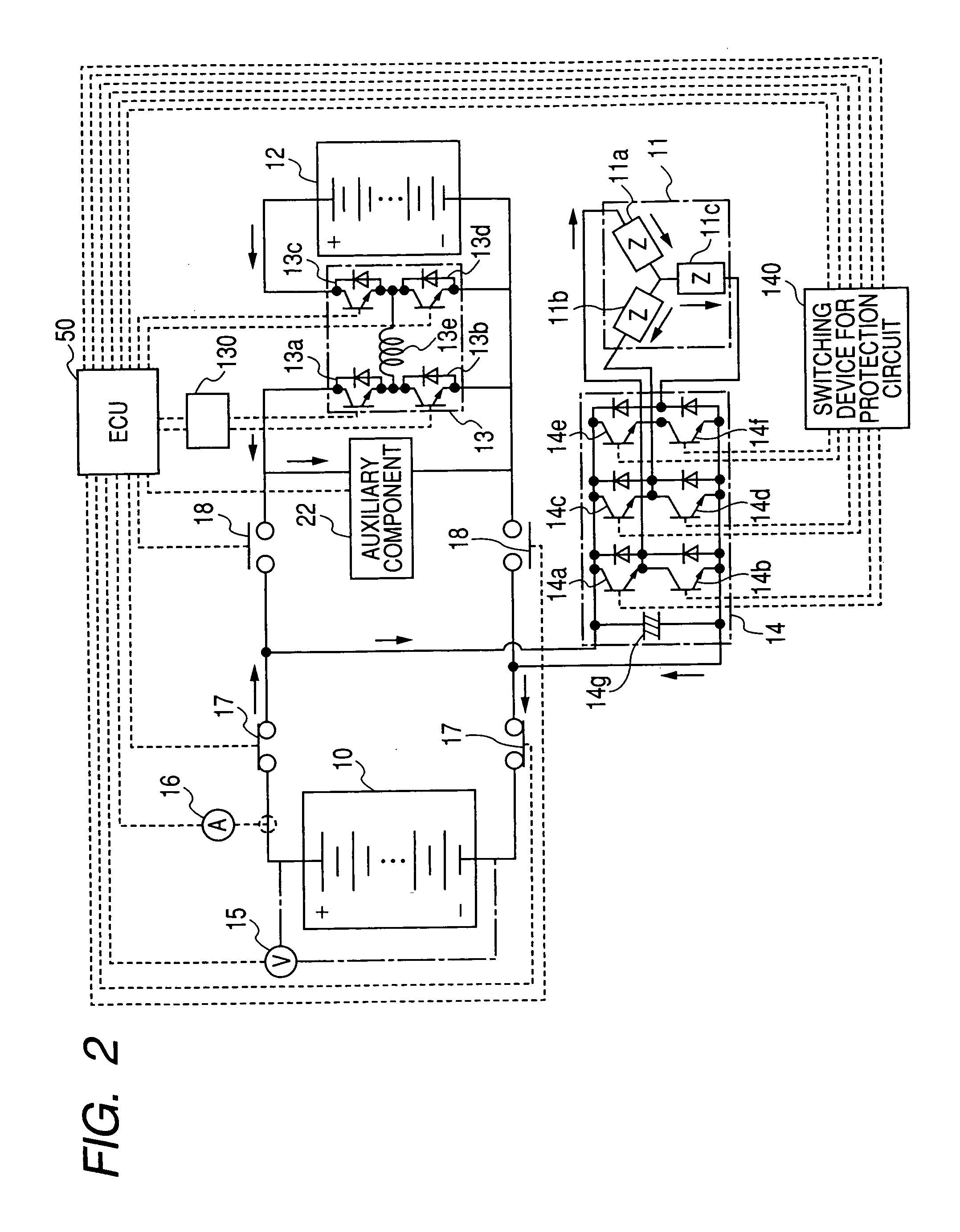

A fuel cell system equipped with a fuel cell that generates electrical power in electrochemical reaction of hydrogen and oxygen. The system has the improved cold starting capability that increases heat energy generated in the fuel cell in order to rise the temperature of the fuel cell rapidly in a cold temperature environment. The system has an inverter having plural switching elements connected in series and a control section for controlling ON / OFF operation of the plural switching elements. The control section controls the amount of current output from the fuel cell by performing the ON / OFF control of the switching elements. On commencing the cold starting process of the fuel cell, the control means changes the current path in a drive motor by performing the ON / OFF control of the switching elements, in which both the inverter and the drive motor are used as a variable resistance to the fuel cell.

Owner:DENSO CORP

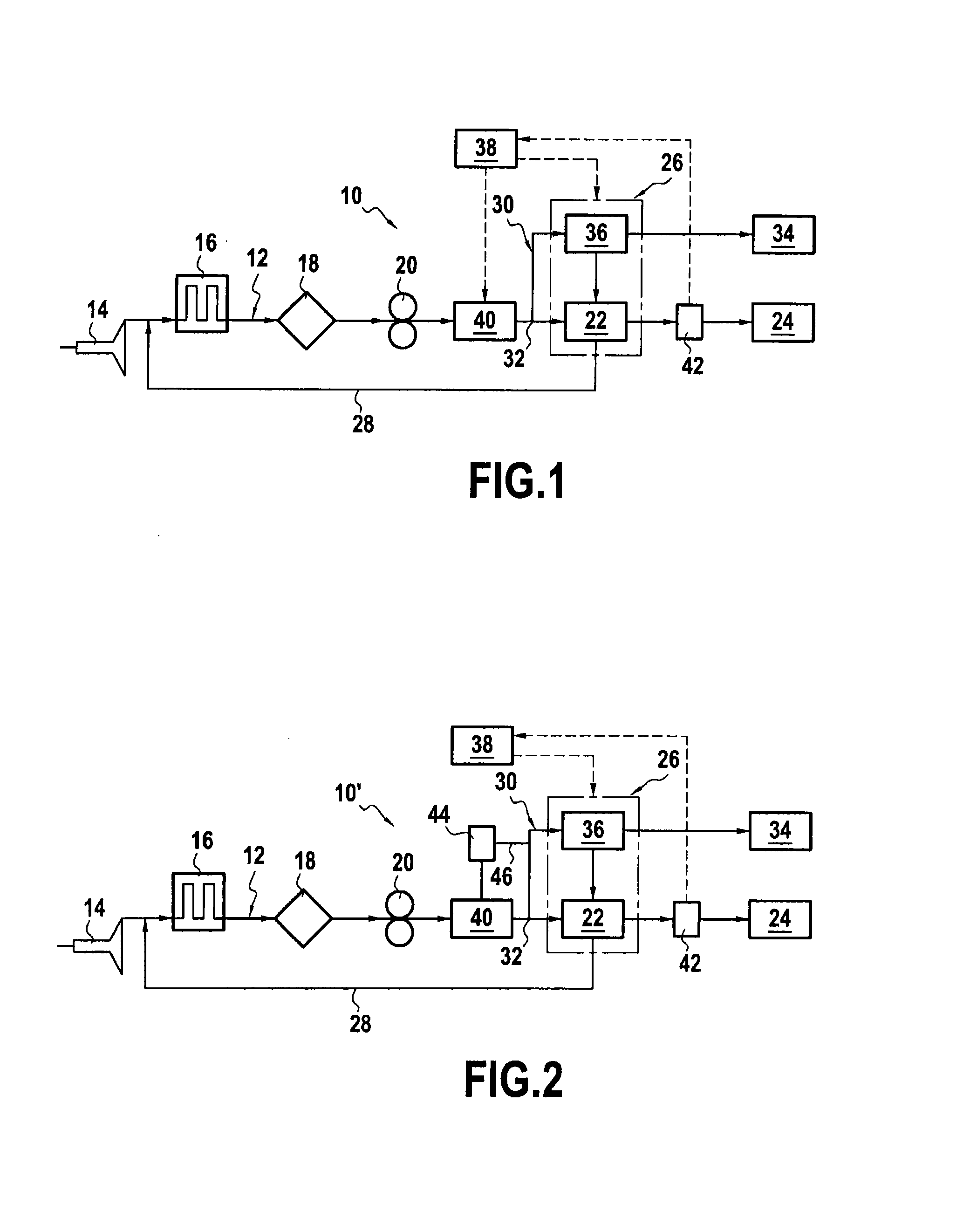

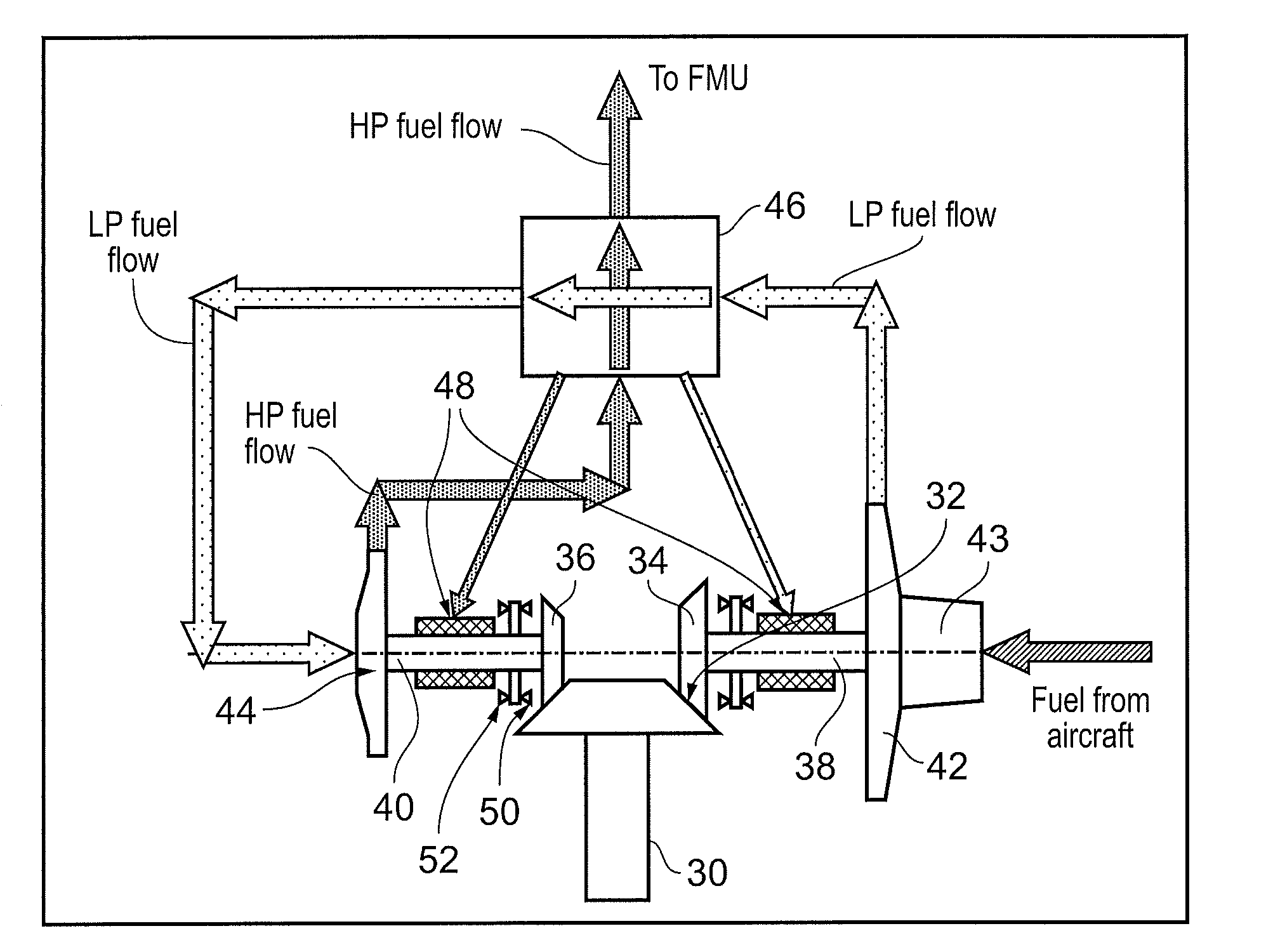

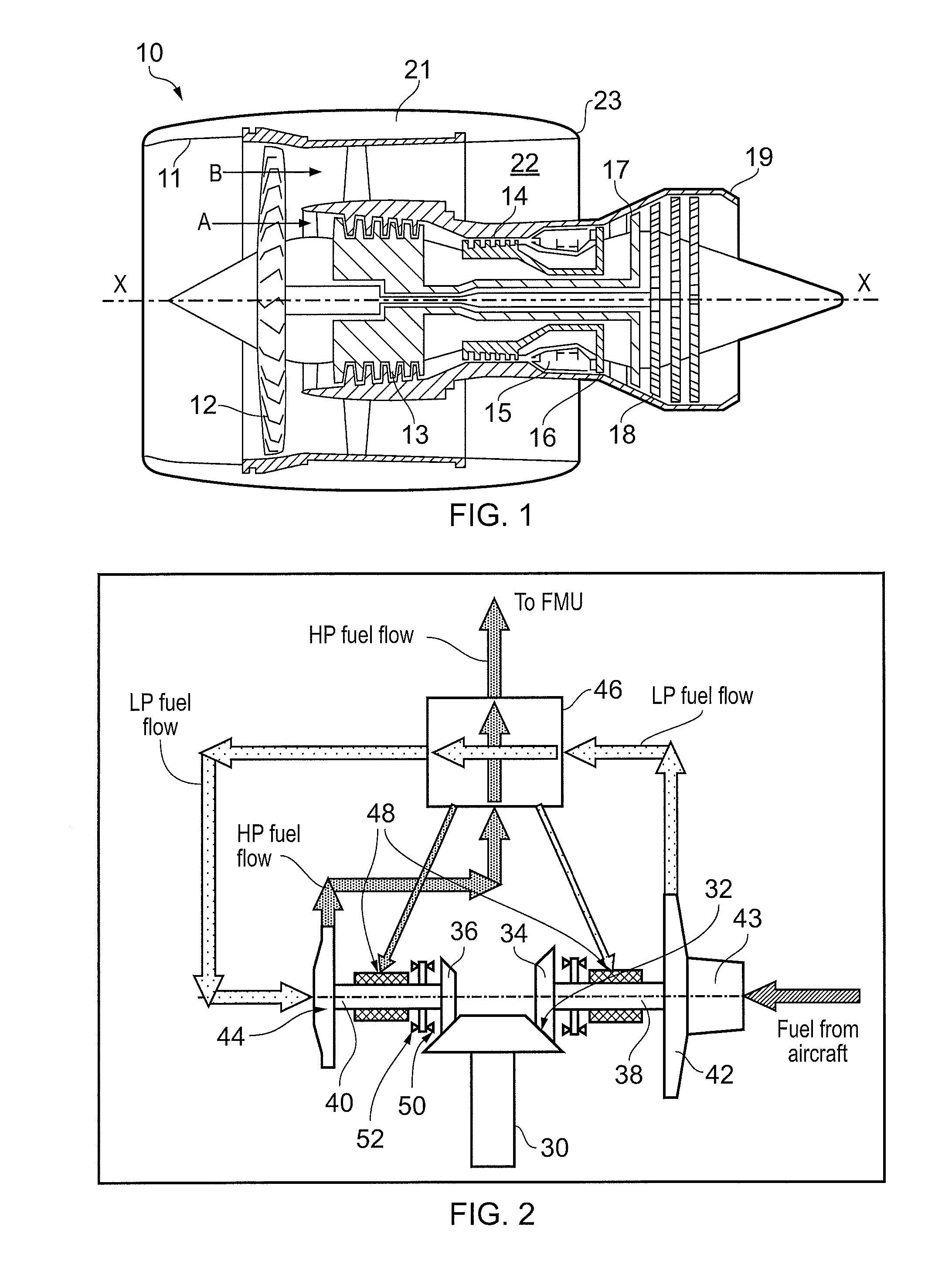

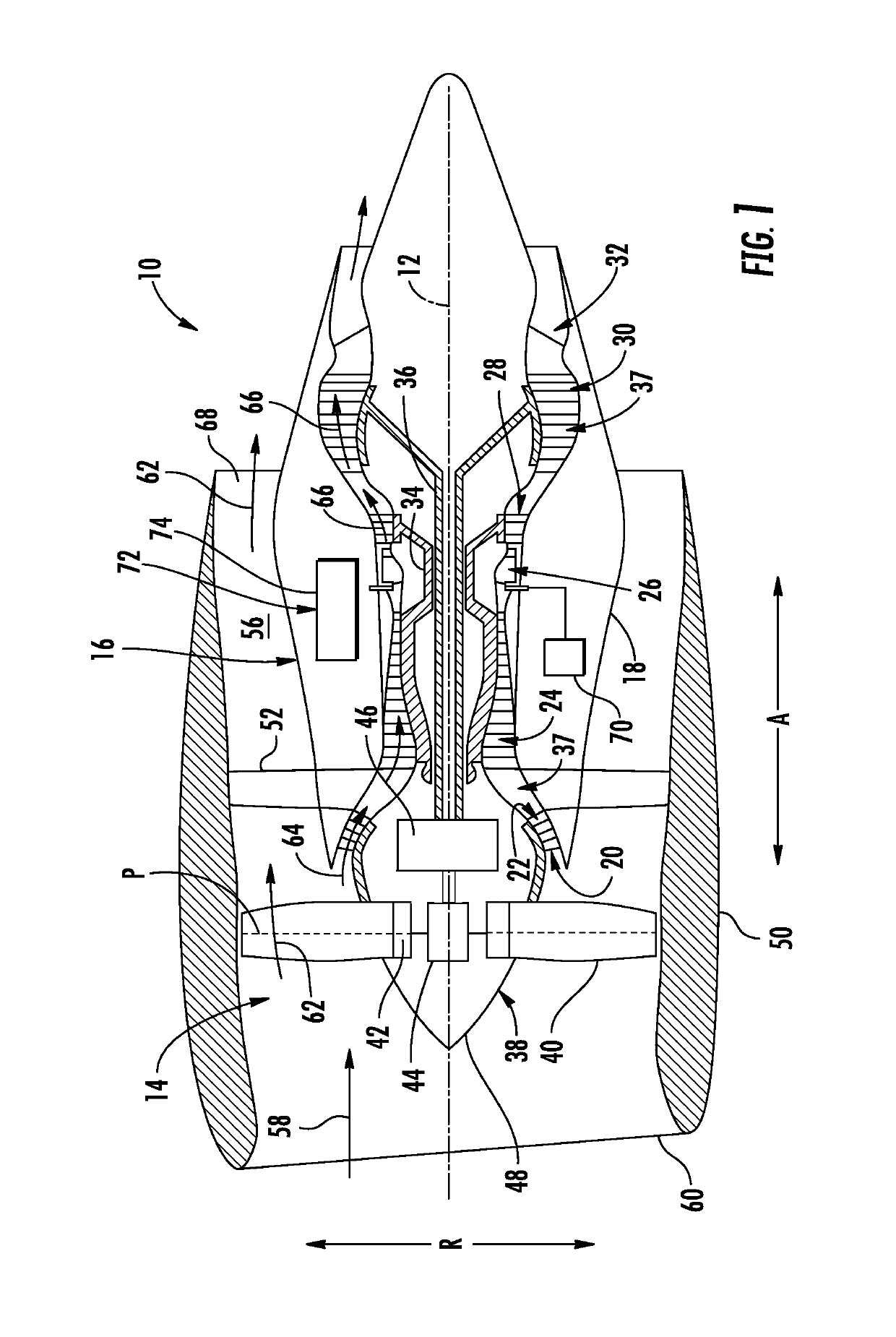

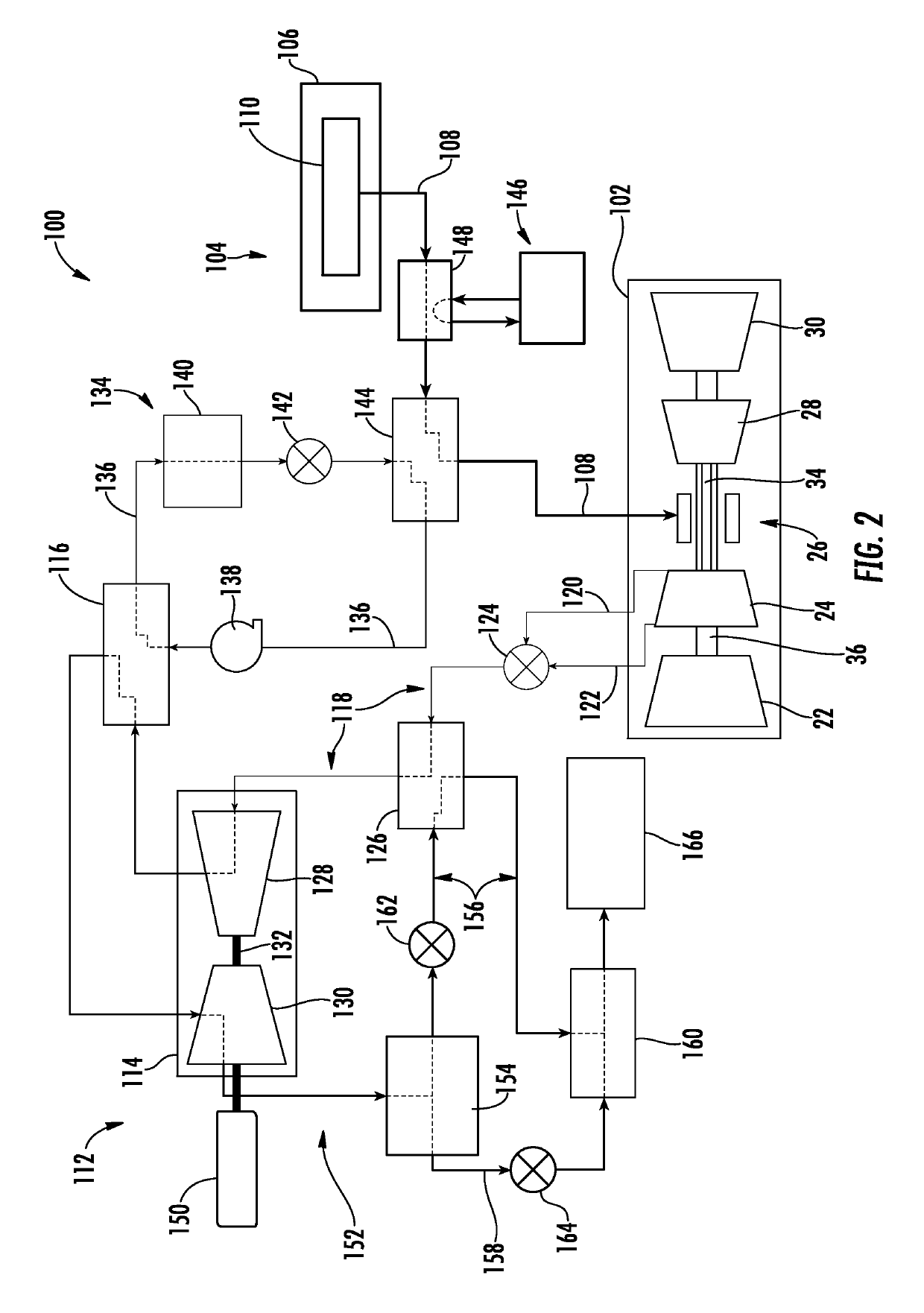

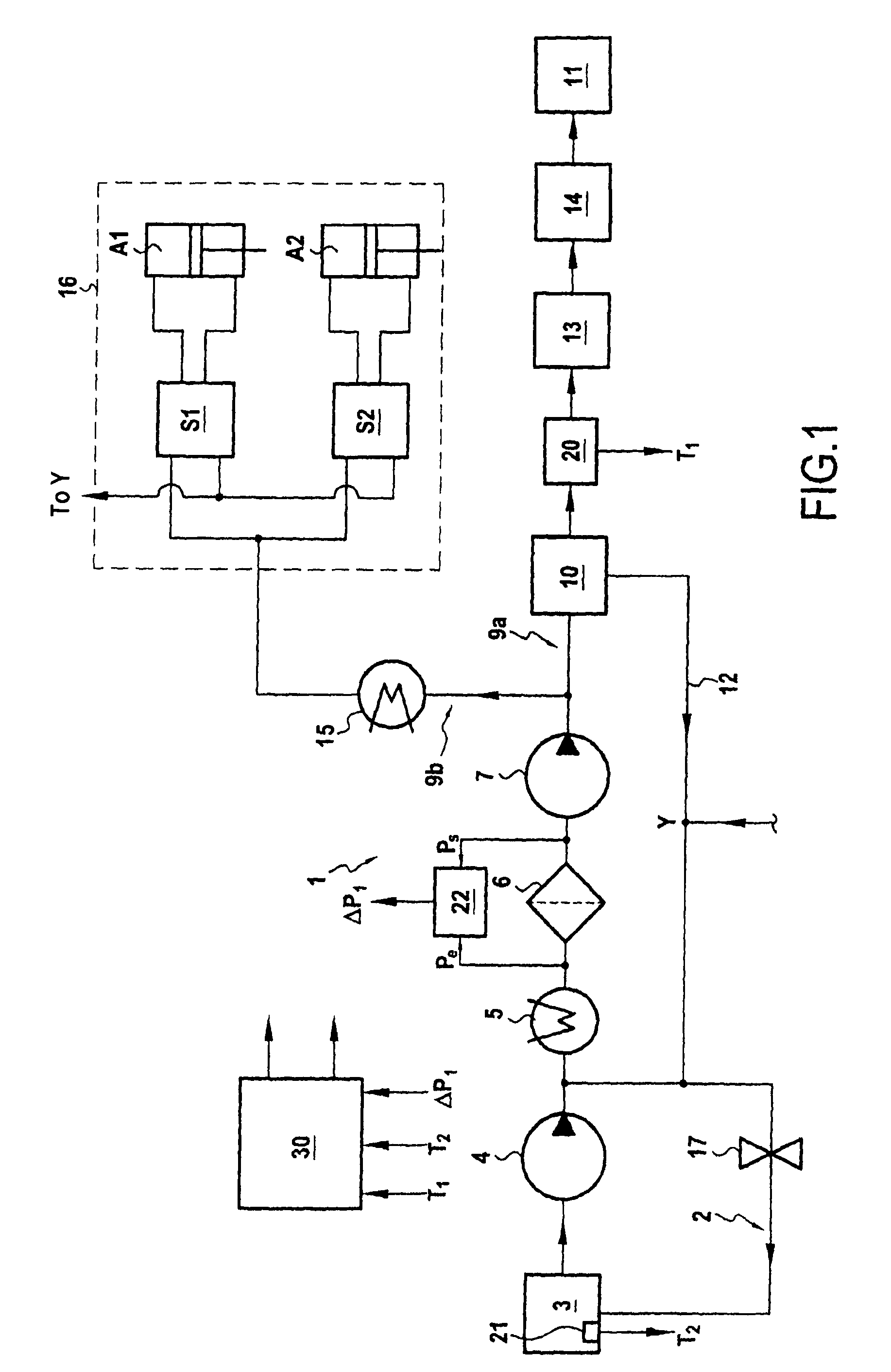

Fuel circuit for an aviation turbine engine, the circuit having a fuel pressure regulator valve

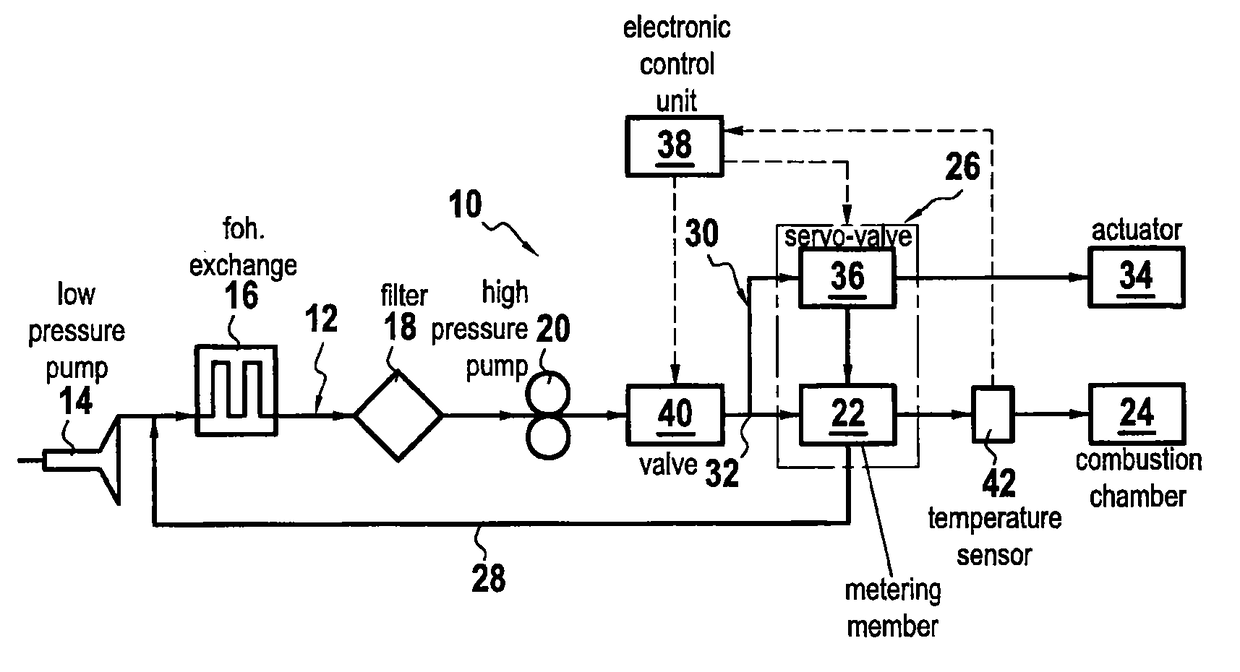

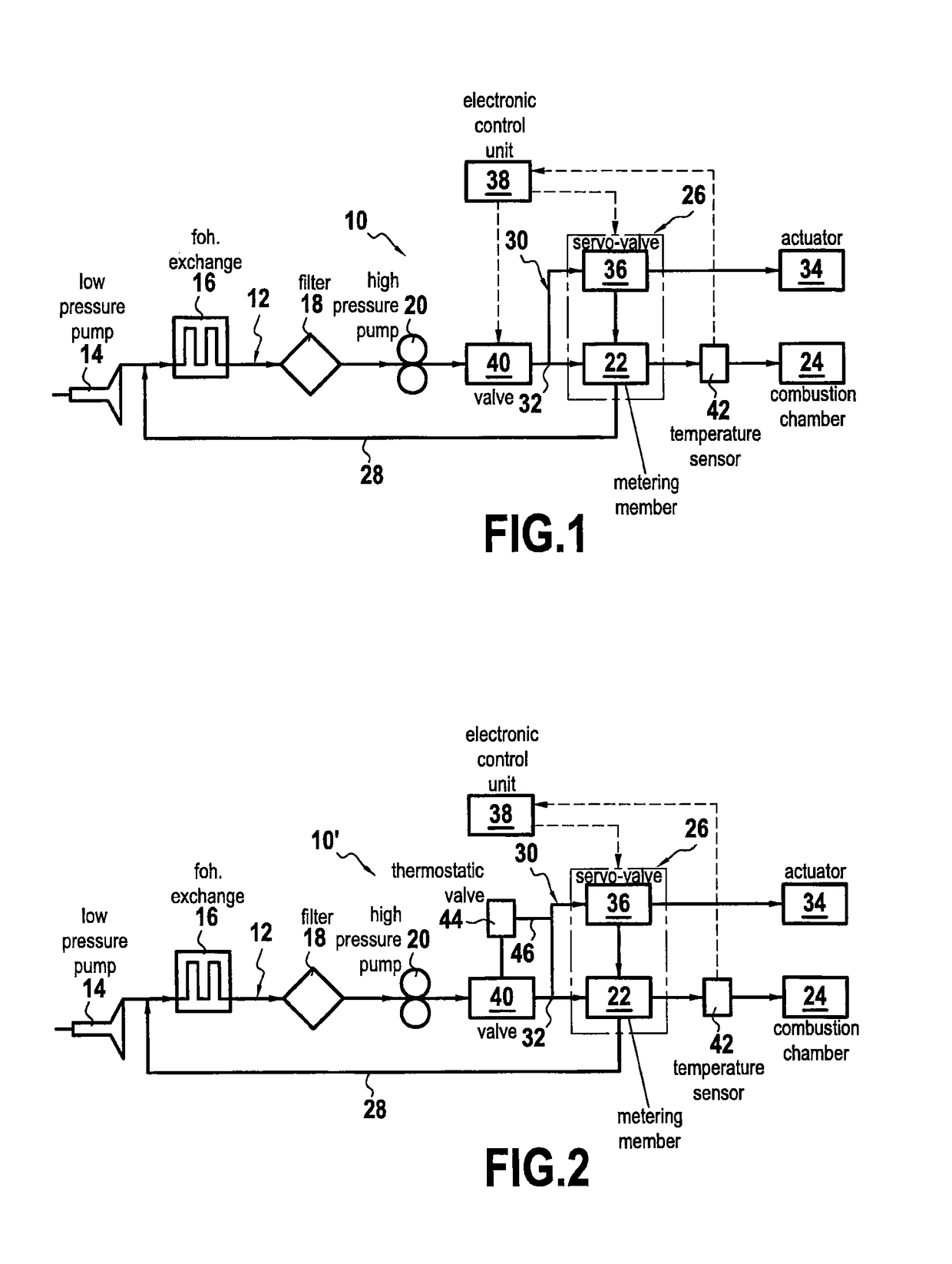

ActiveUS20130283811A1Increase fuel temperatureSimplified and effective mannerTurbine/propulsion fuel flow conduitsEngine fuctionsAviationCombustion chamber

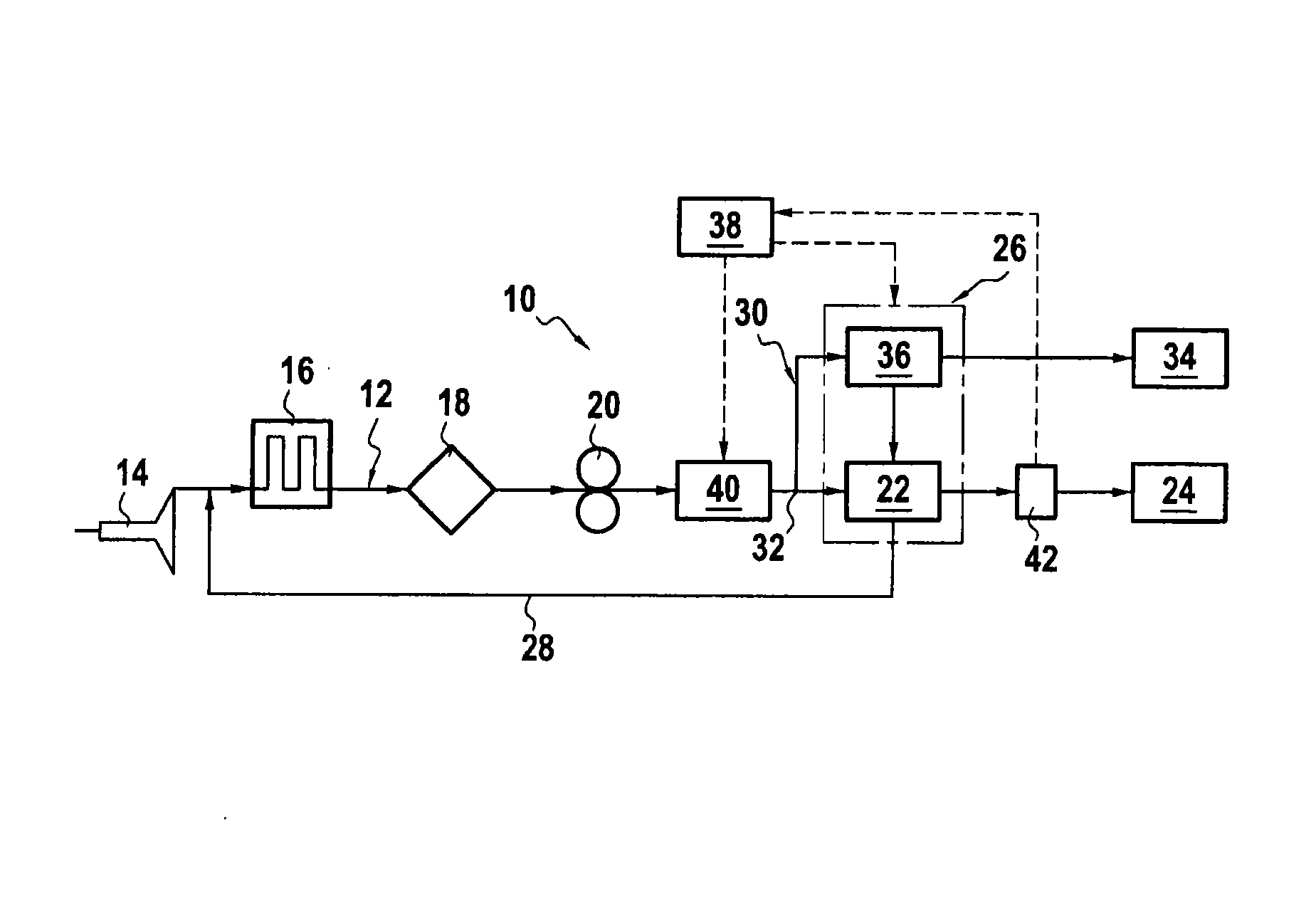

A fuel circuit for an aviation turbine engine, the fuel circuit including: a main fuel line for feeding fuel to a combustion chamber of the engine and including a positive displacement pump; an auxiliary fuel line connected to the main fuel line at a junction situated downstream from the pump and serving to feed fuel to hydraulic actuators to control variable-geometry equipment of the engine, the auxiliary fuel line including electrohydraulic servo-valves upstream from each actuator; and a fuel pressure regulator valve arranged on the main fuel line downstream from the pump.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

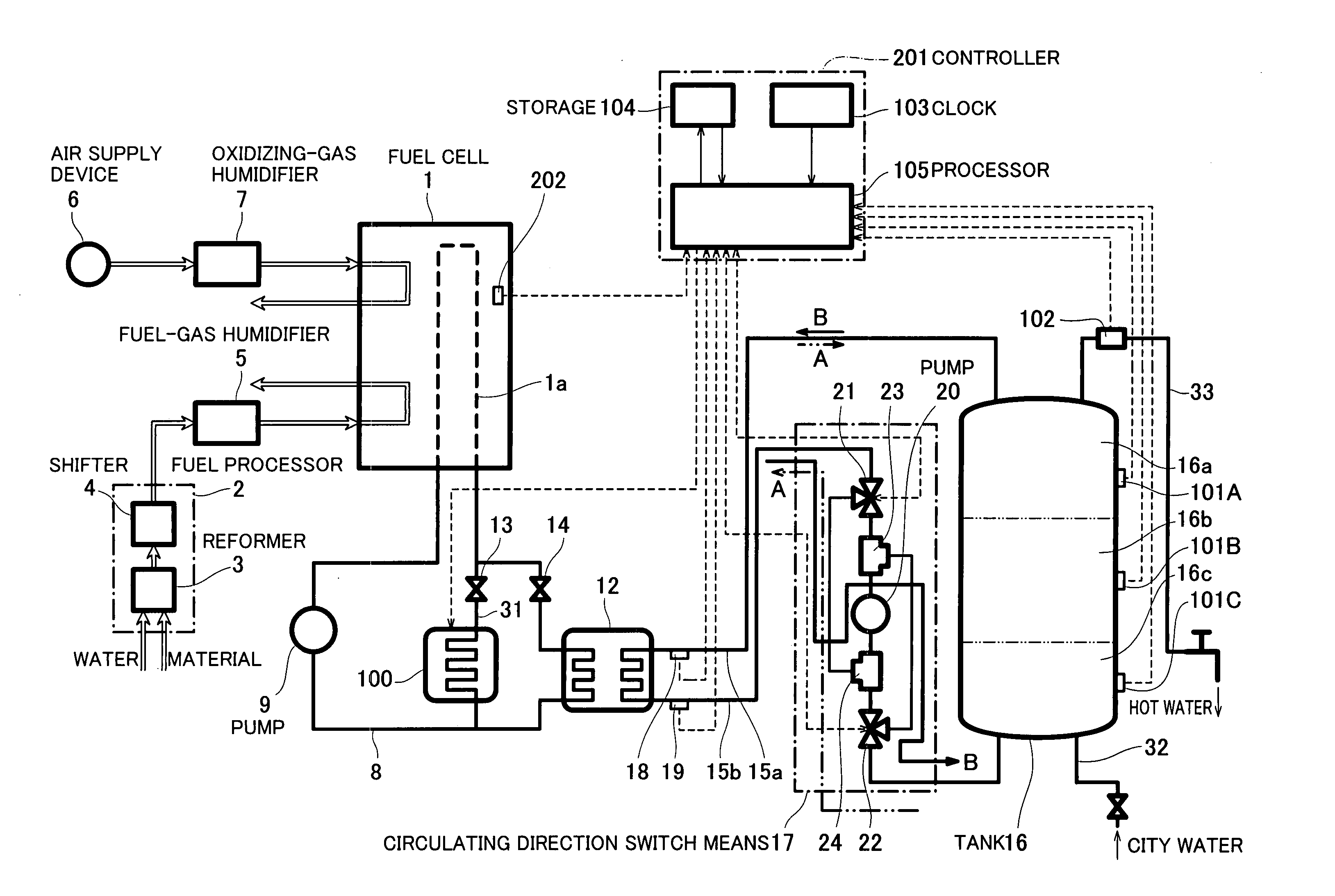

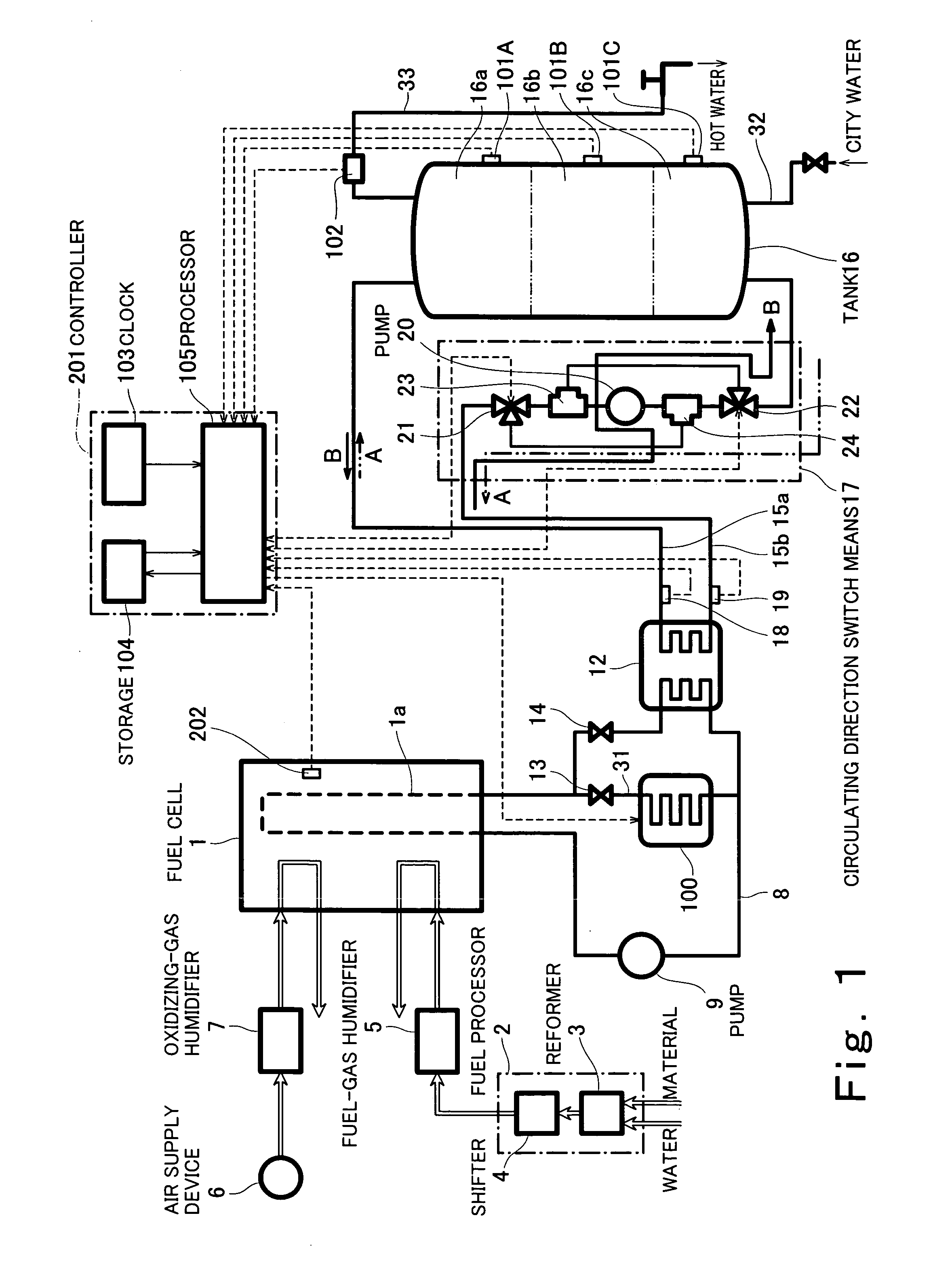

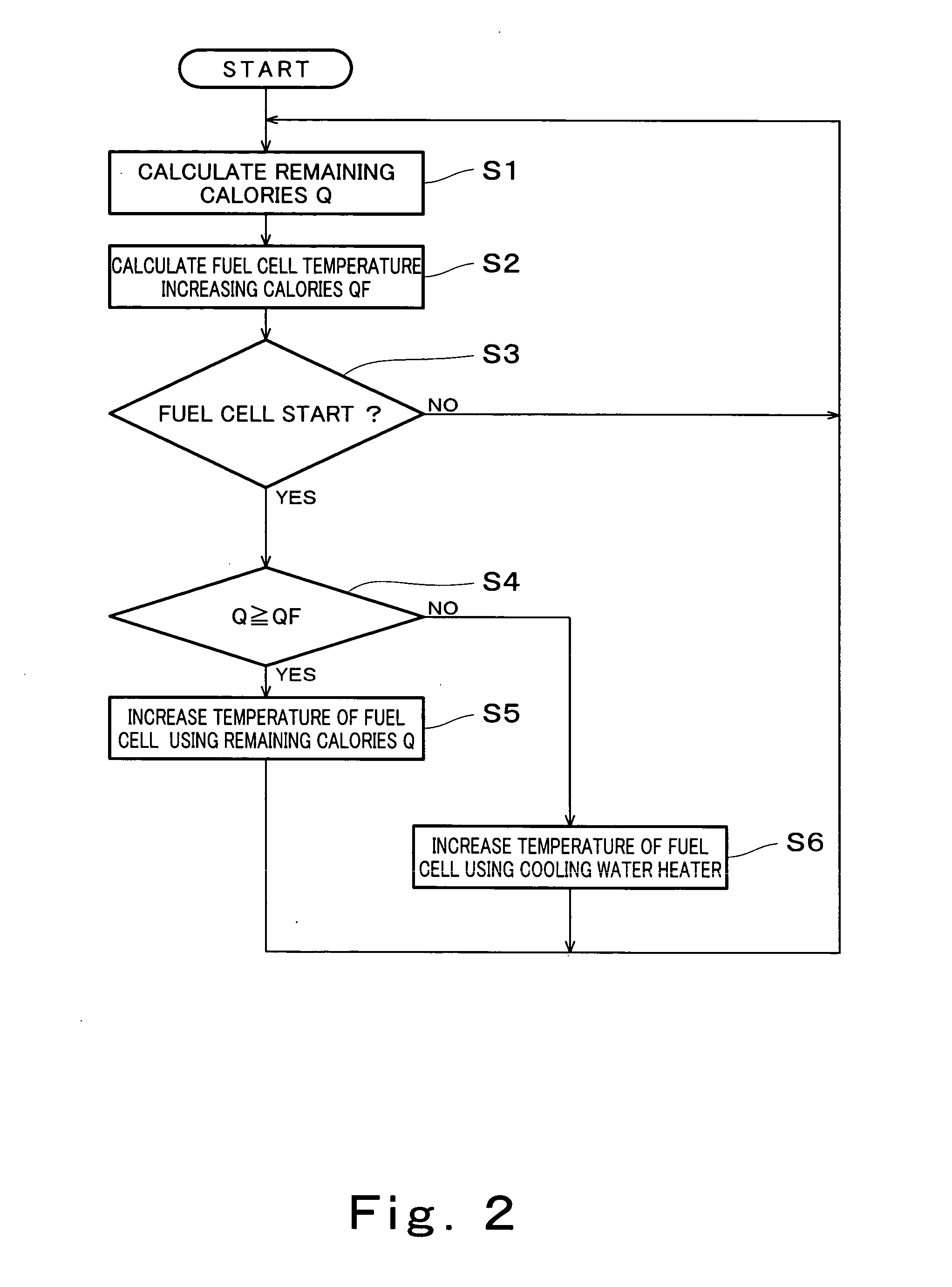

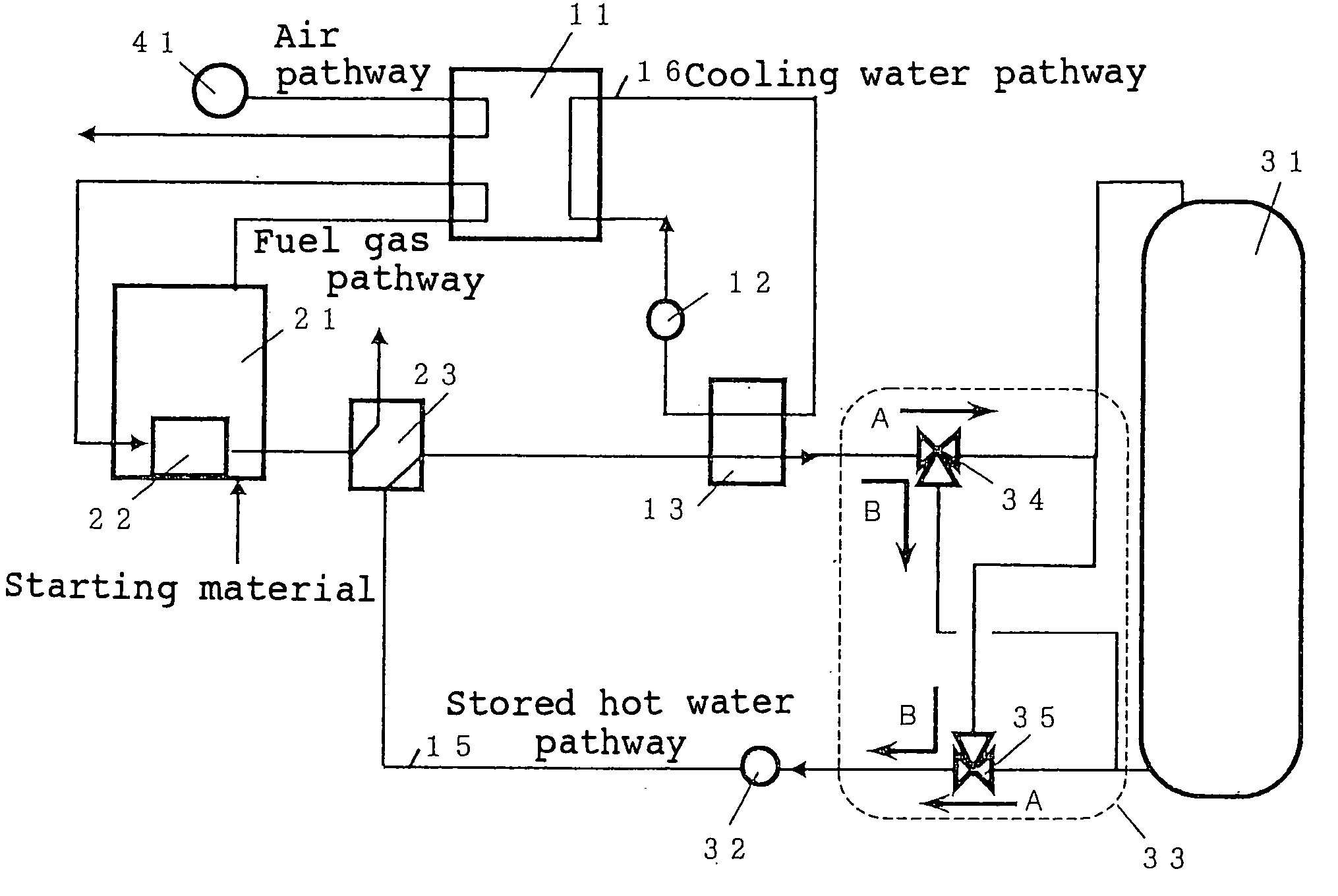

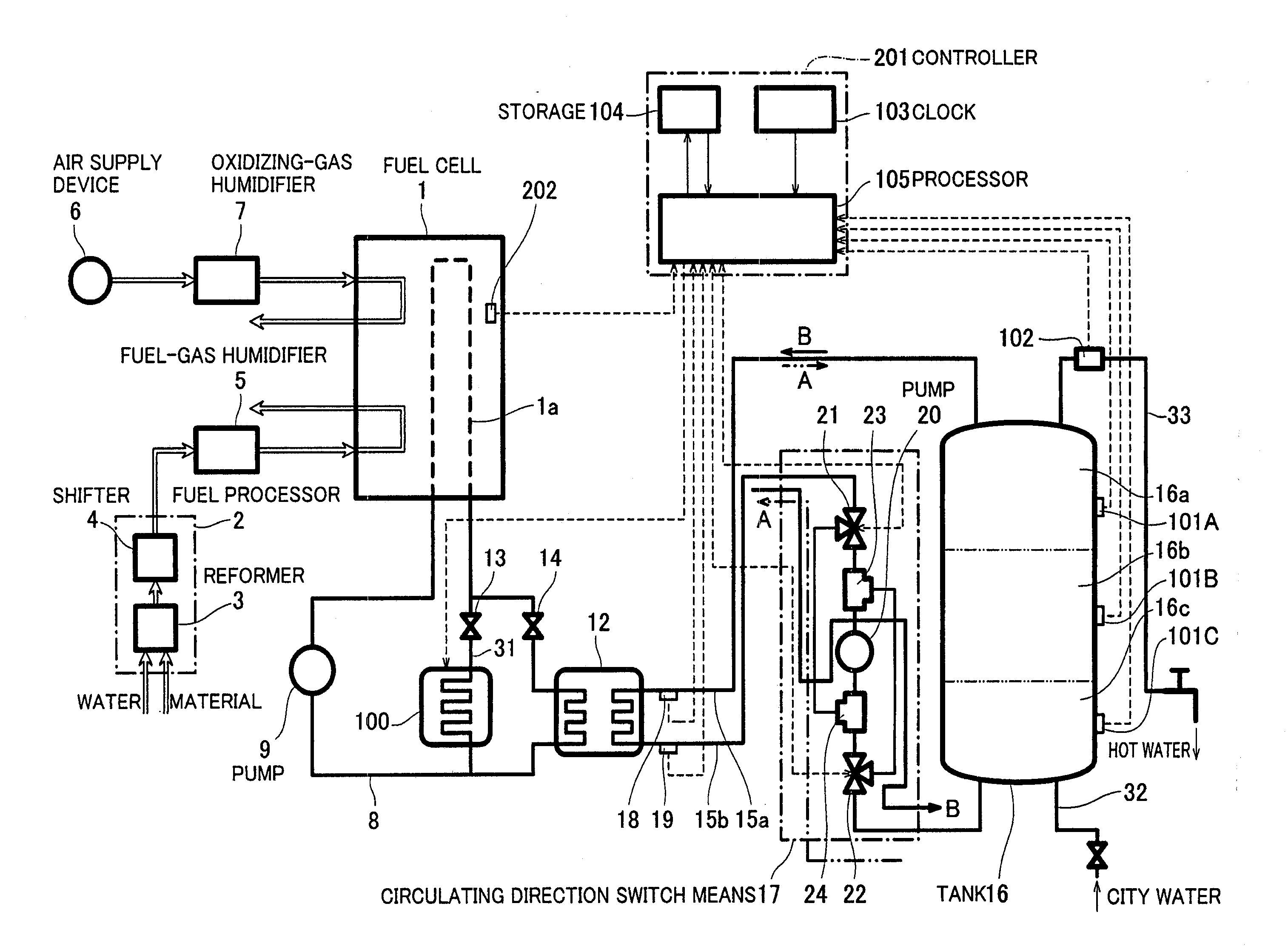

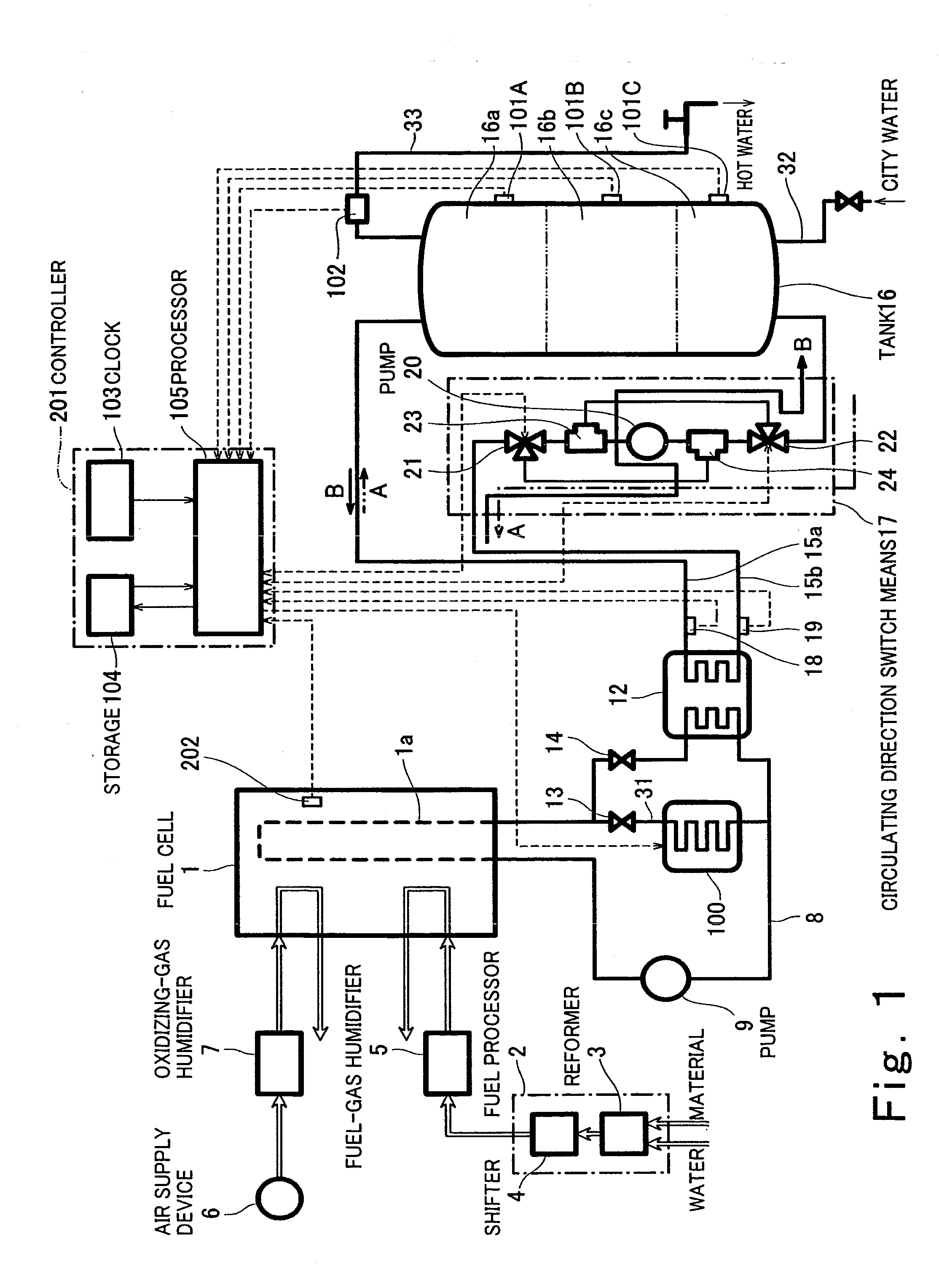

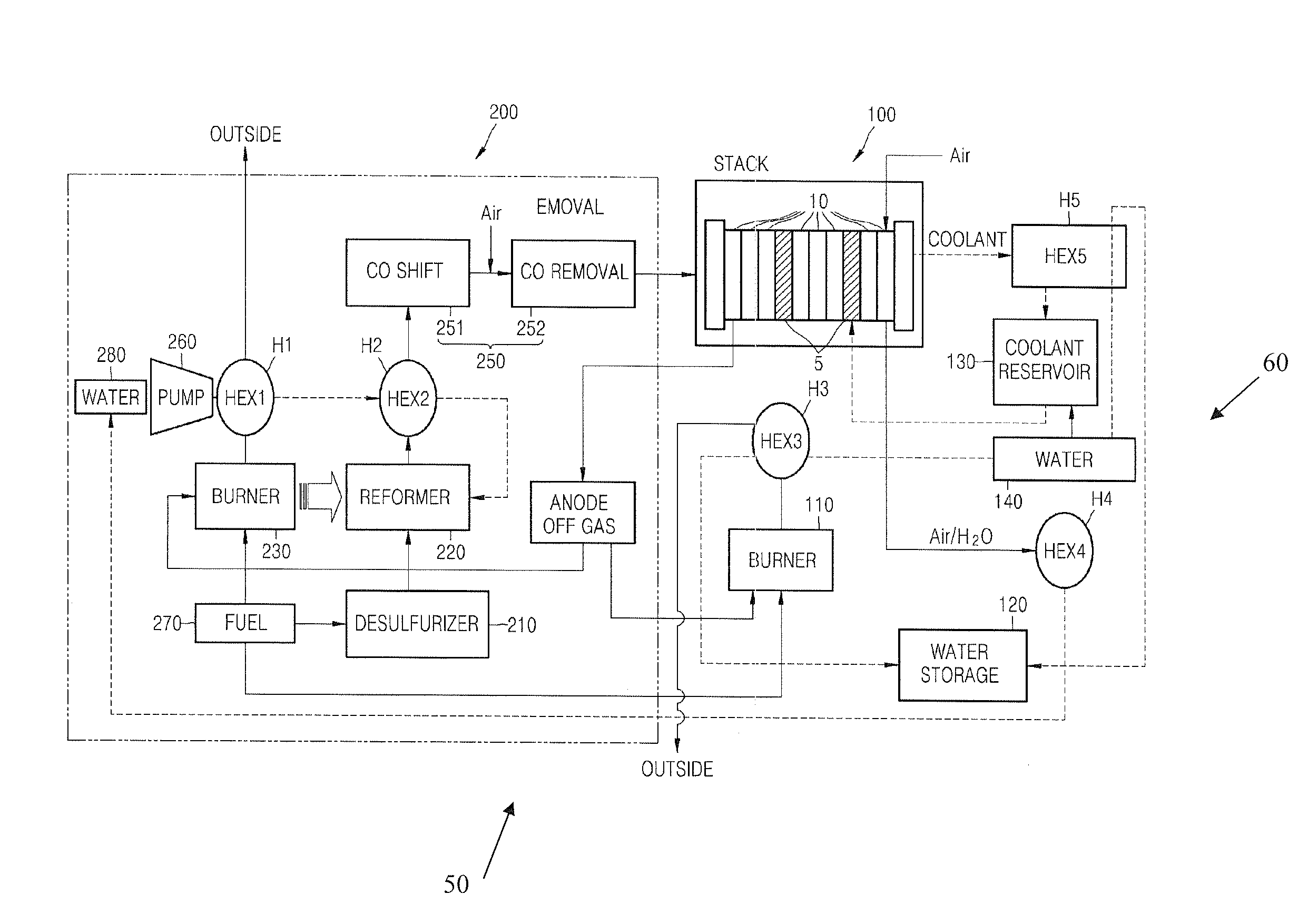

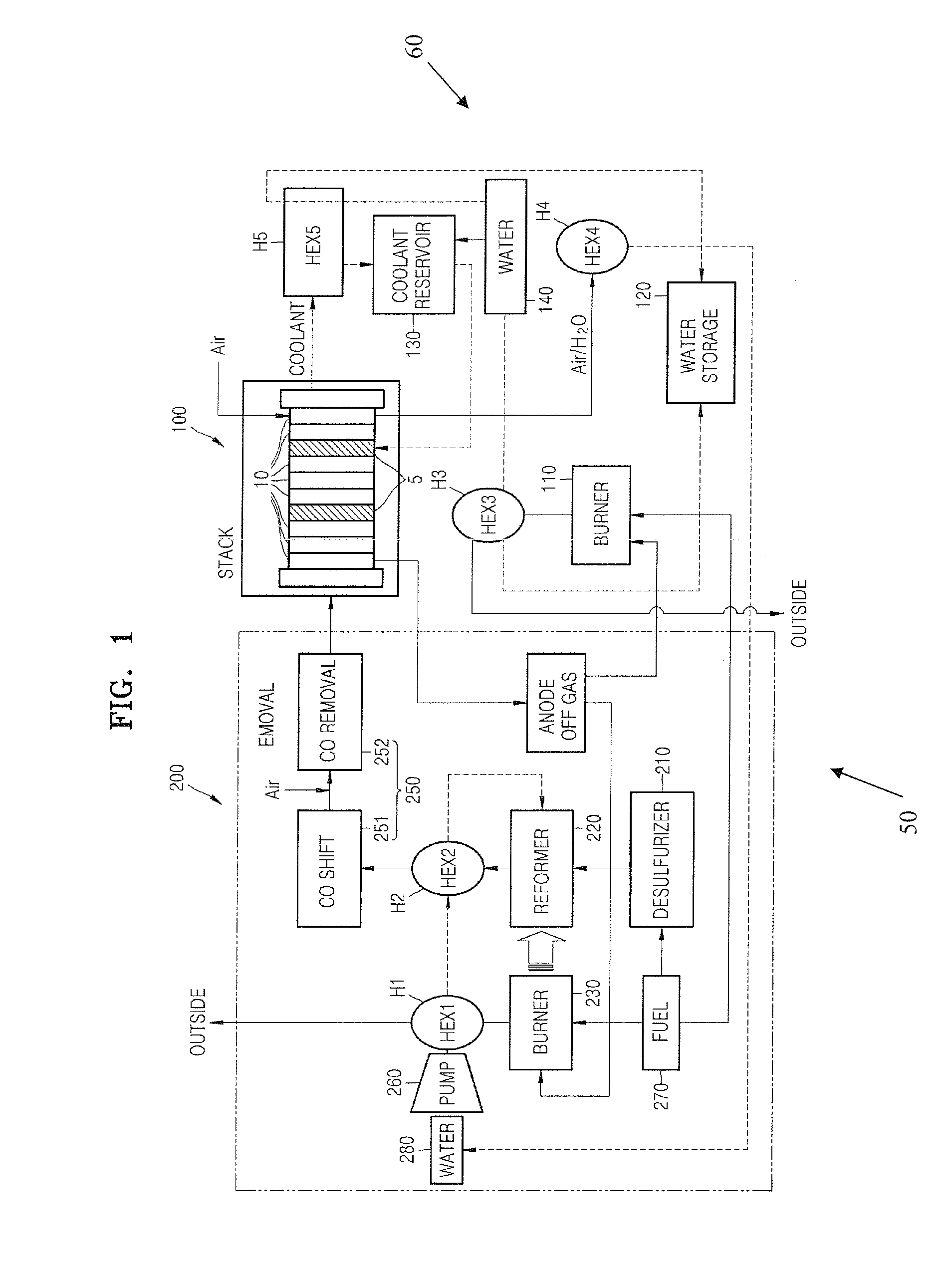

Fuel cell cogeneration system

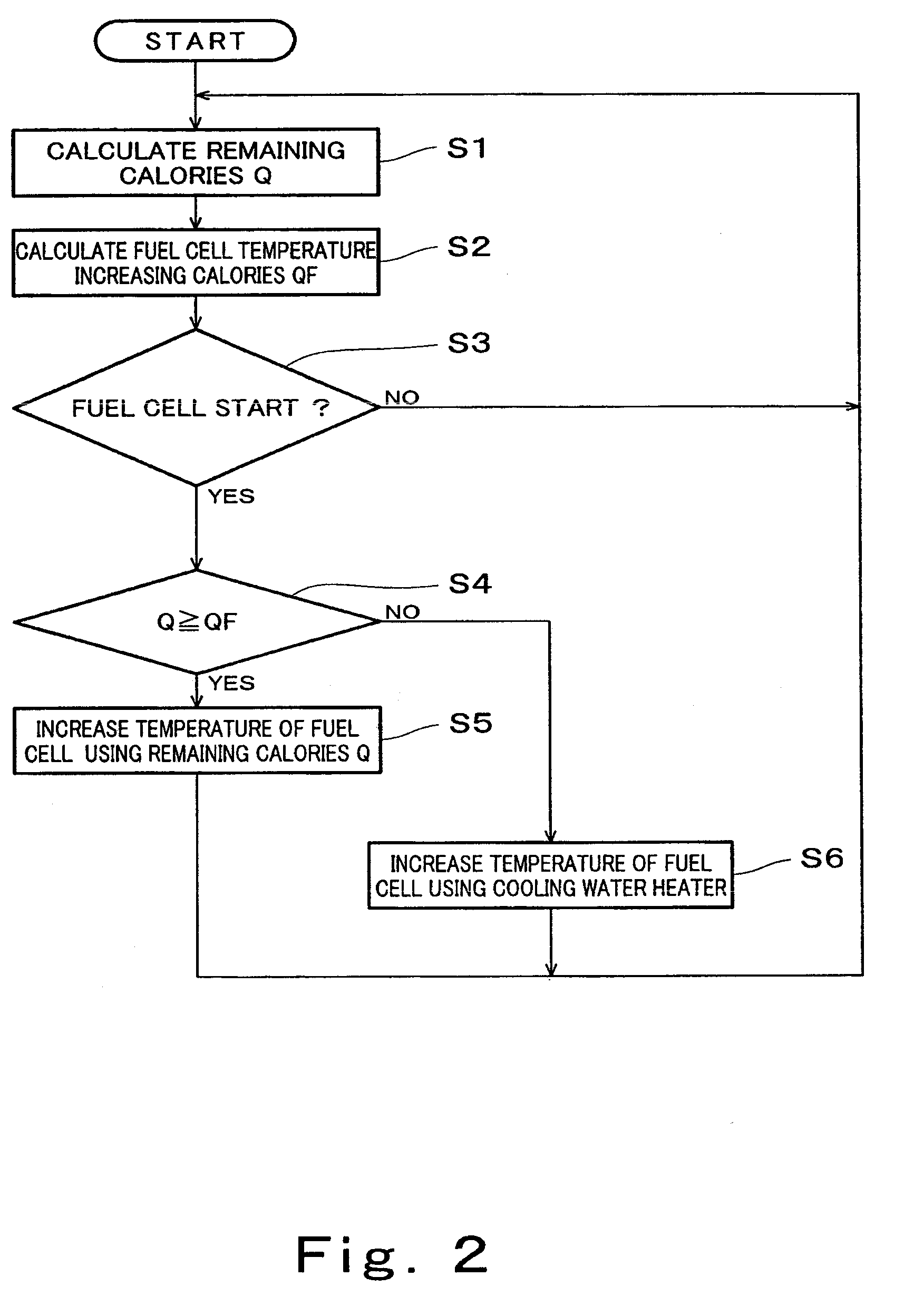

InactiveUS20050019631A1Prevent running outImprove convenienceLighting and heating apparatusEnergy efficient heating/coolingFuel cellsCogeneration

A fuel cell cogeneration system comprises a fuel cell, a cooling system for the fuel cell, a heater, a heat utilization portion configured to store heat recovered in the cooling system to allow the heat to be consumed, a detector configured to detect calories remaining in the heat utilization portion, and a controller, wherein the controller determines whether or not the calories remaining in the heat utilization portion are at least not less than the calories required to increase the temperature of the fuel cell to the operating temperature, and based on determination, increases the temperature of the fuel cell to the operating temperature by supplying the remaining calories to the fuel cell through the cooling system and / or by heating the cooling water in the cooling system by the heater.

Owner:PANASONIC CORP

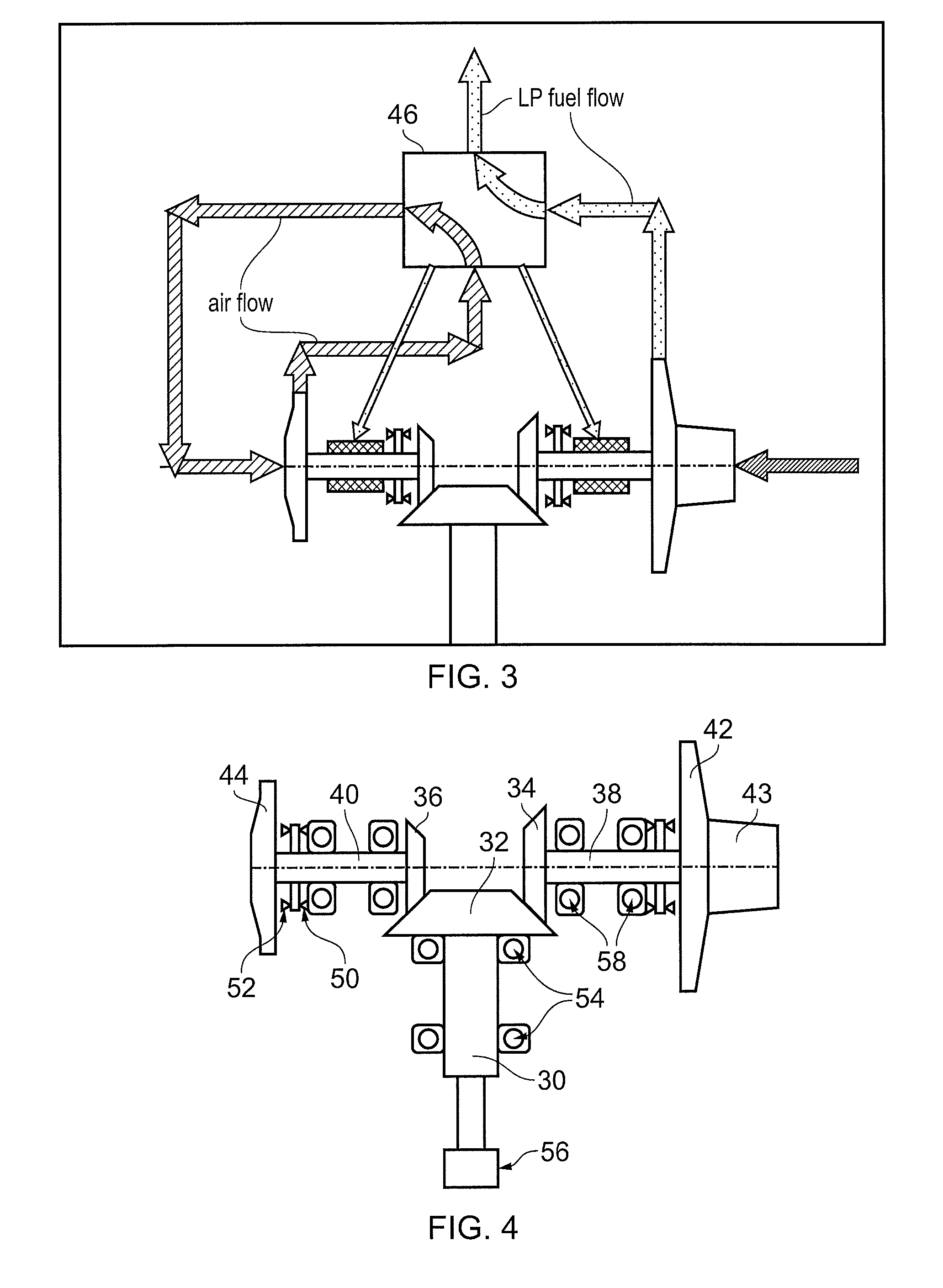

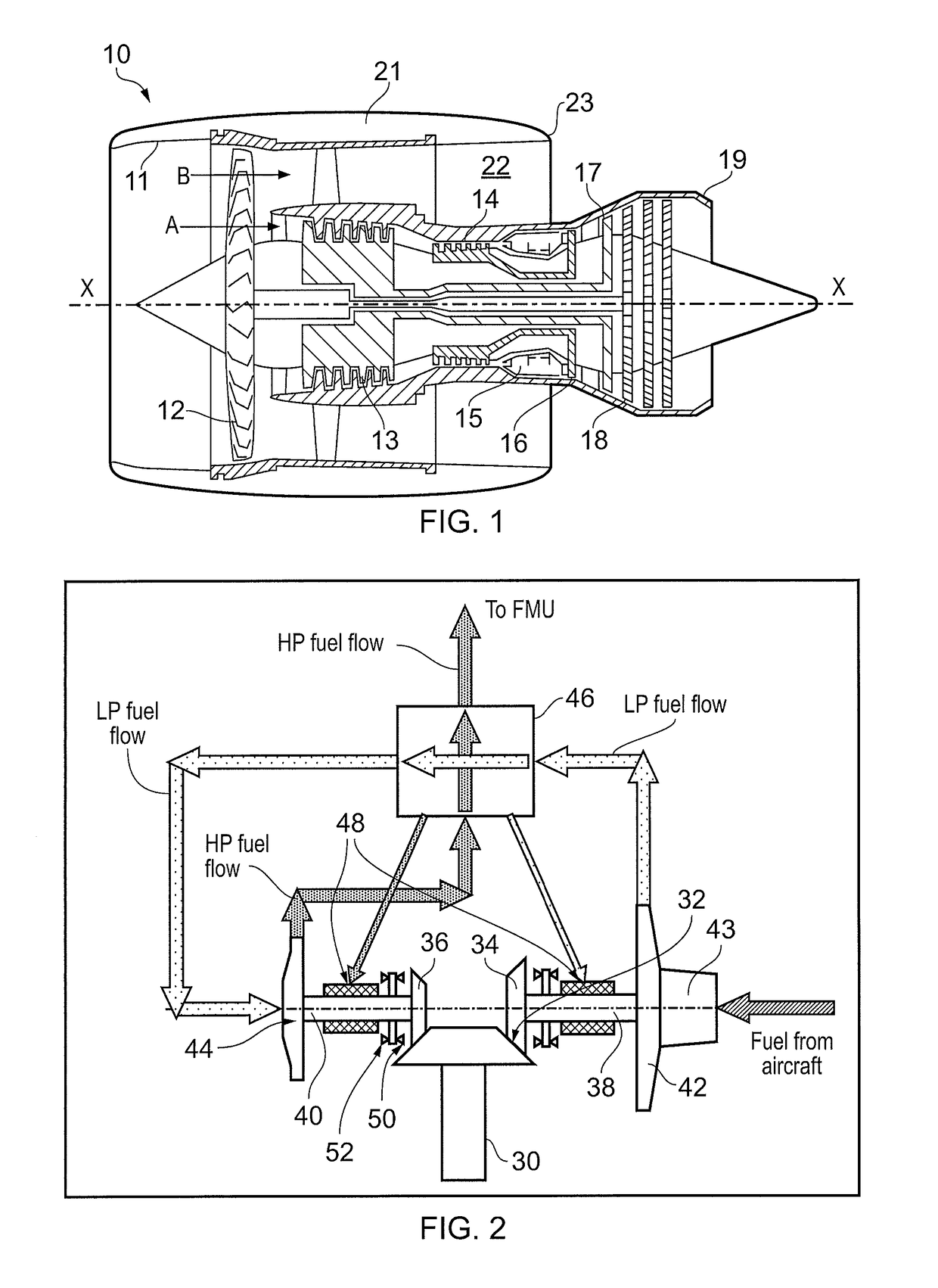

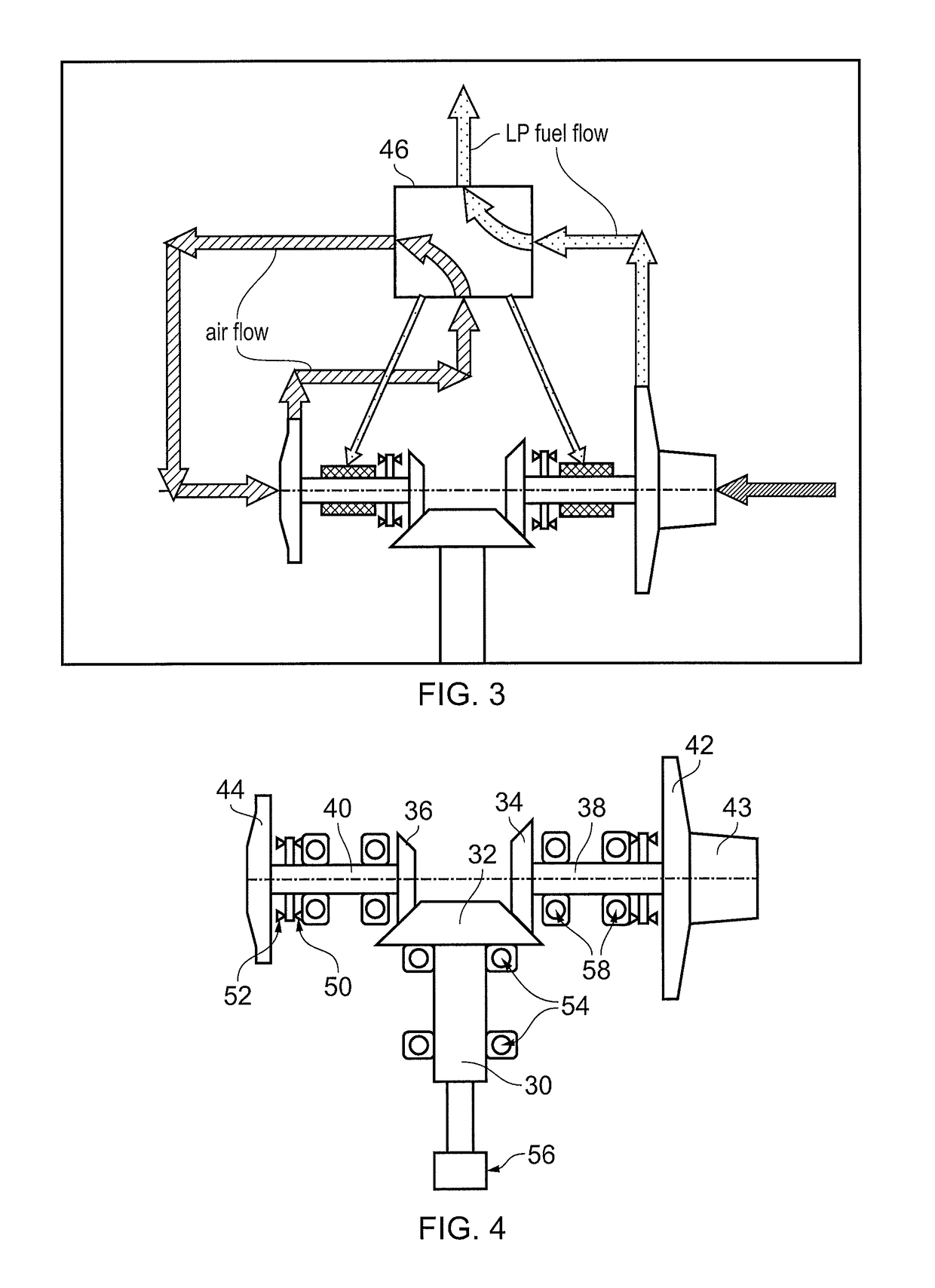

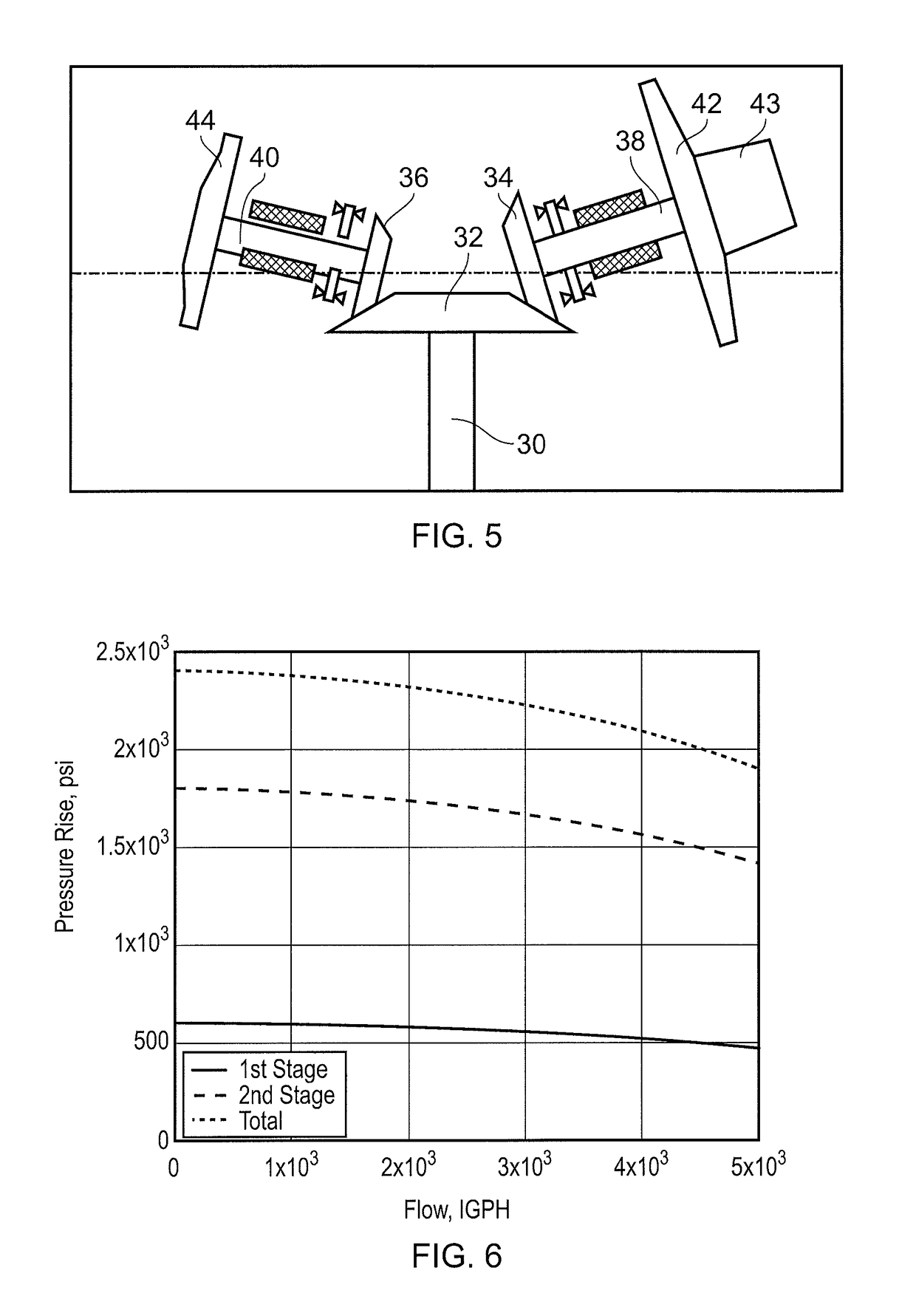

Fuel pumping unit

ActiveUS20160146108A1Reduce any fuel temperature increaseImprove pumping efficiencySpecific fluid pumpsPump componentsHigh pressureCentrifugal pump

A fuel pumping unit has a low pressure centrifugal pump and a high pressure centrifugal pump. In use, the low pressure pump supplies fuel at a boosted pressure to the high pressure pump for onward supply to a fuel metering unit. The pumping unit further has a drive input which drives the low and high pressure pumps. A gear arrangement is operatively located between the drive input and the low and high pressure pumps such that the low and high pressure pumps are driven at different speeds by the drive input.

Owner:ROLLS ROYCE PLC

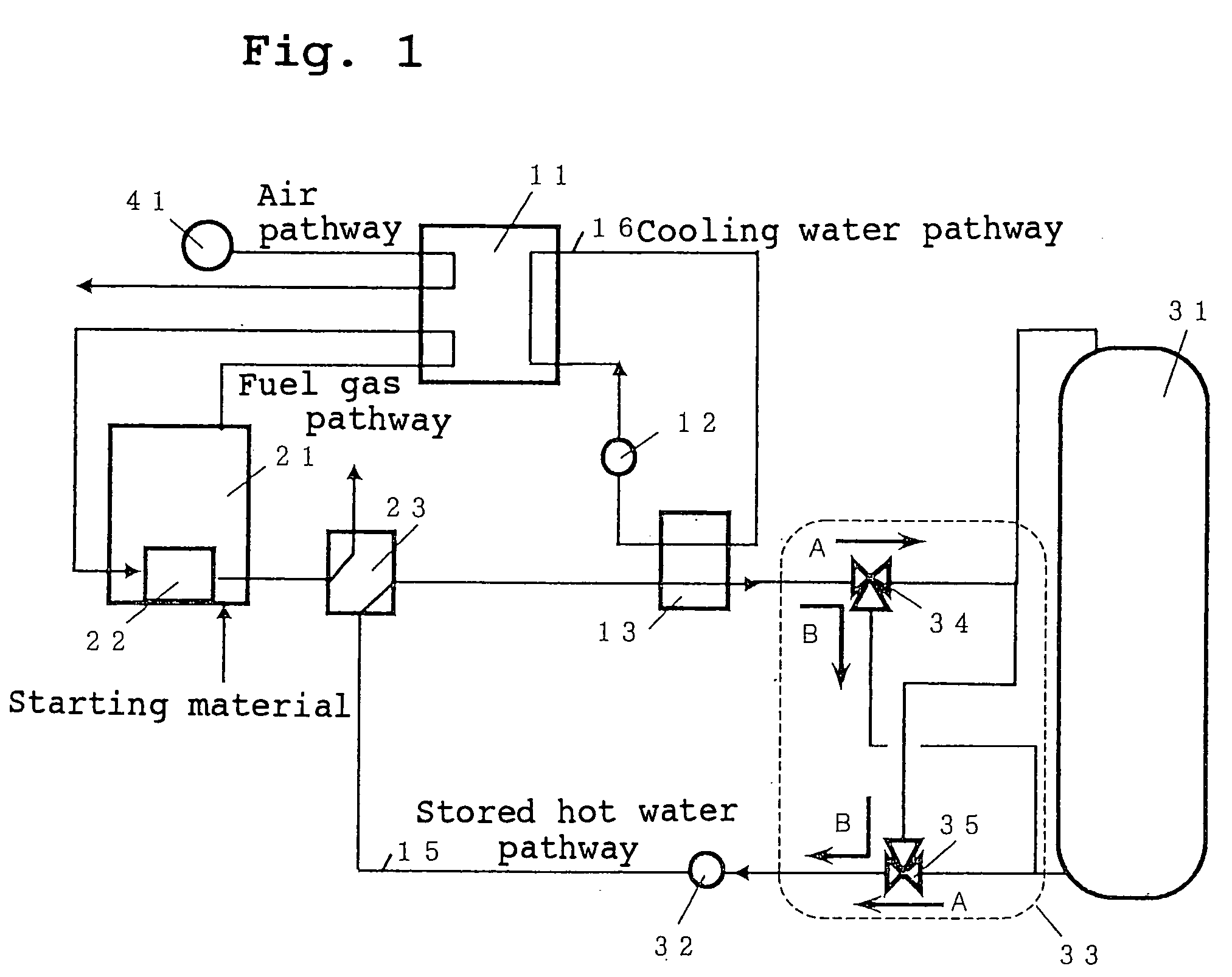

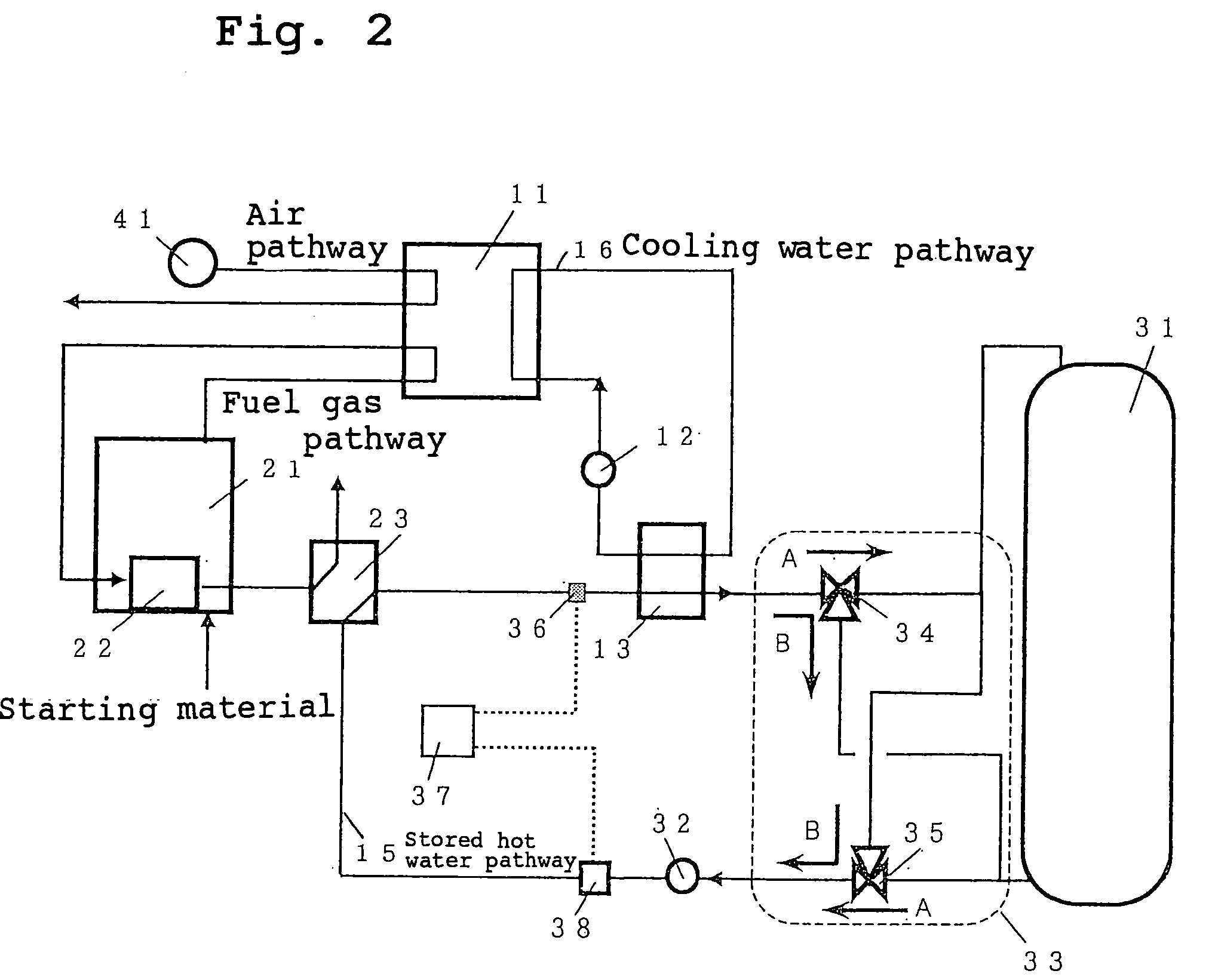

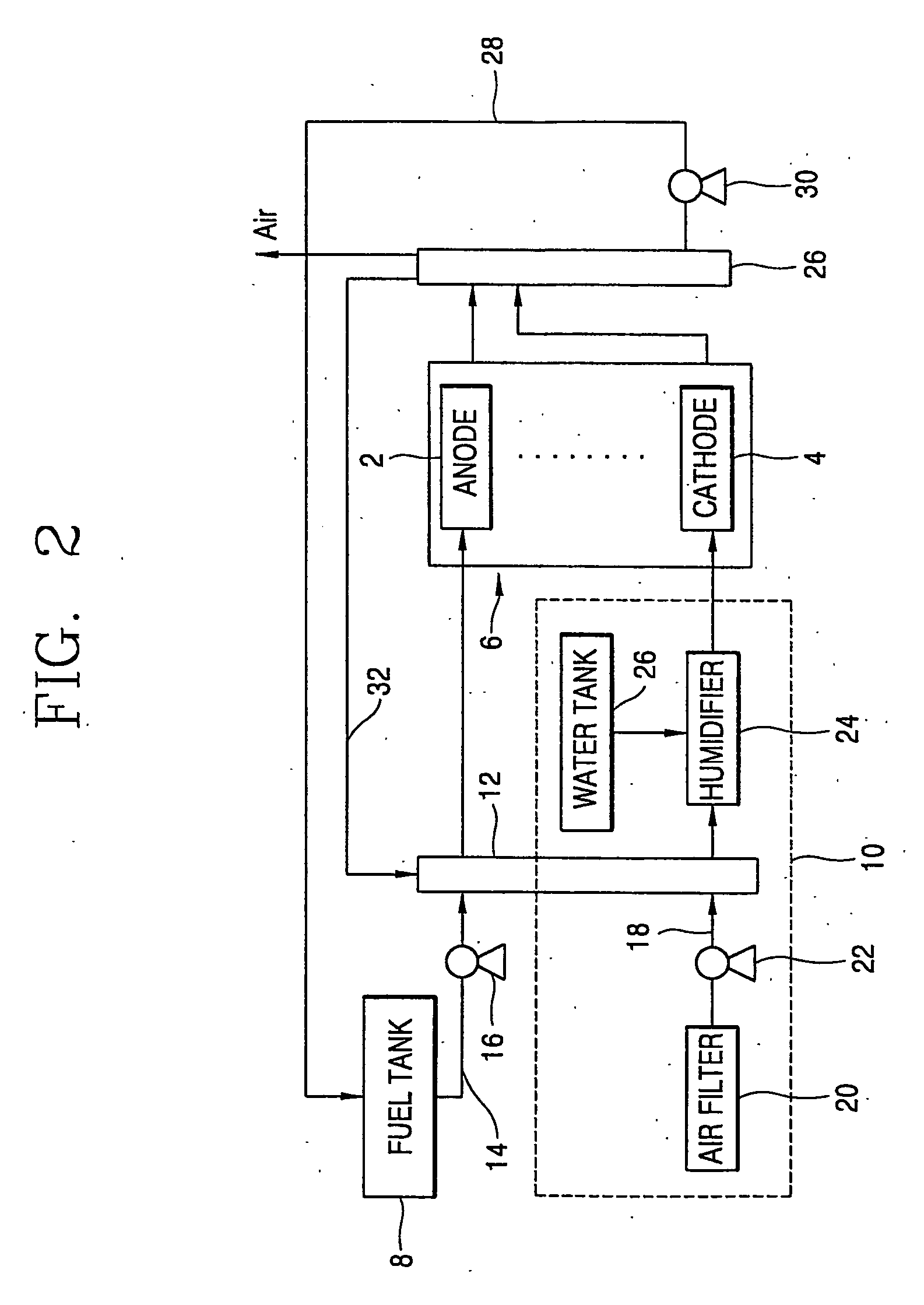

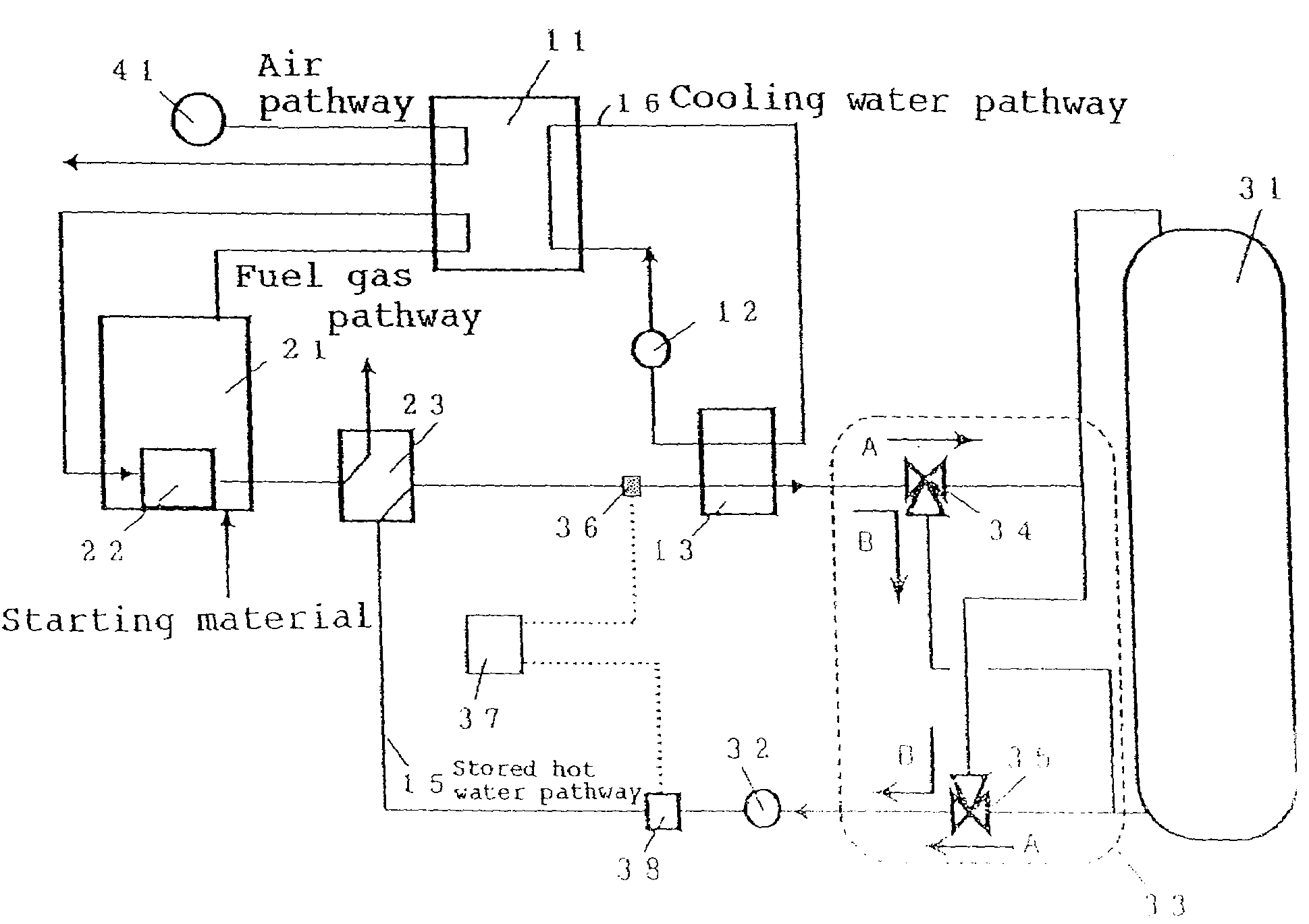

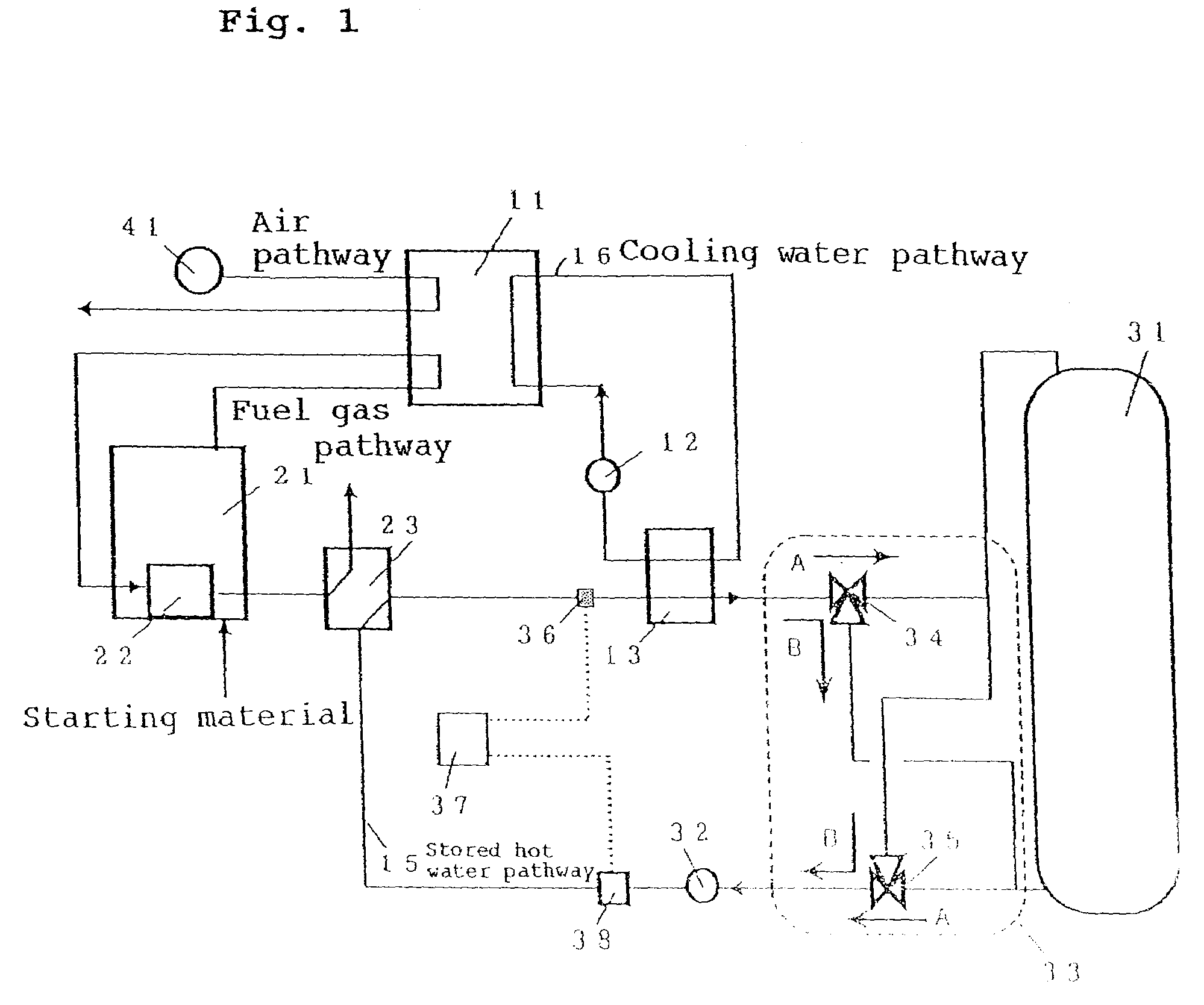

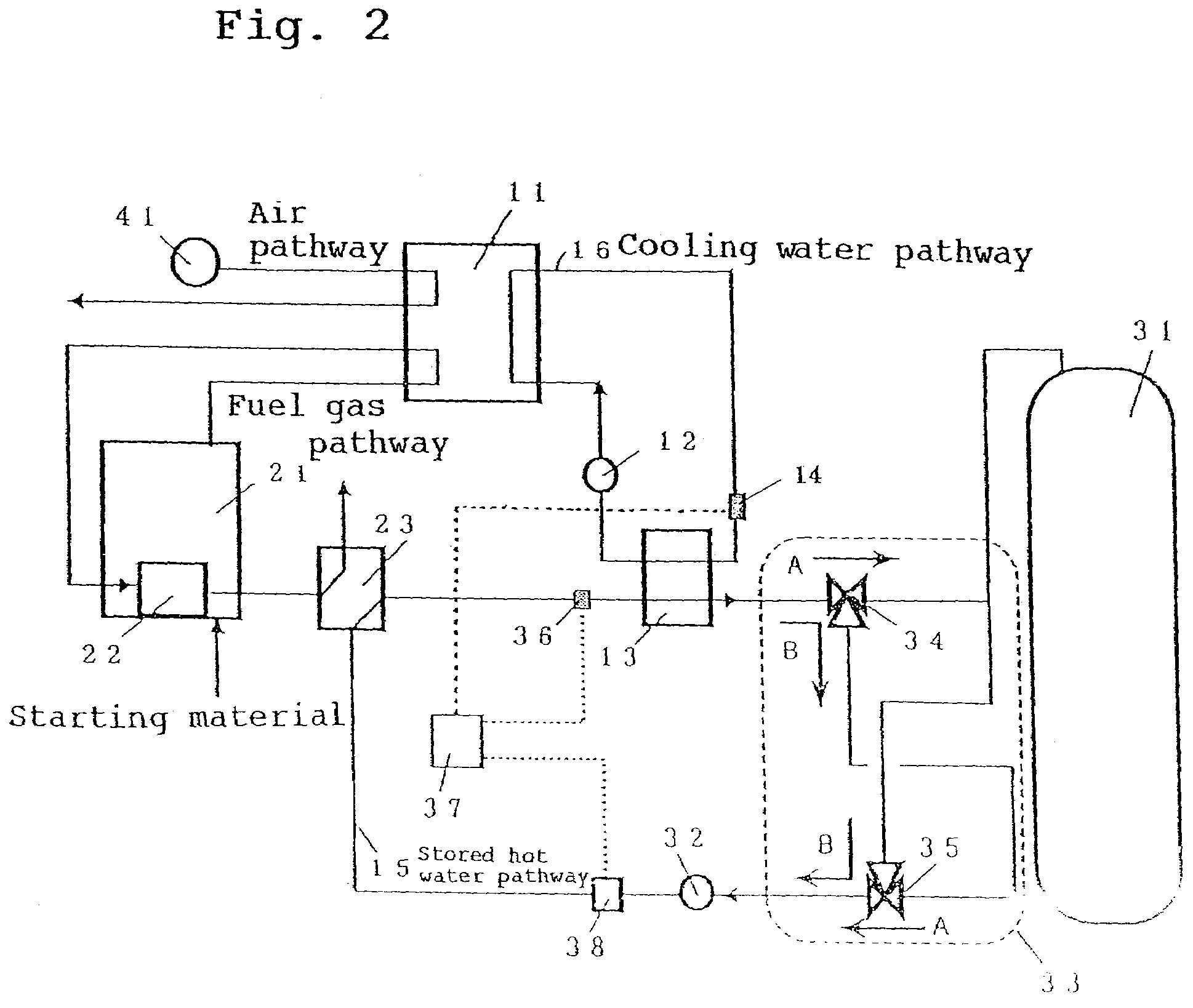

Fuel cell cogeneration system

InactiveUS20050164056A1Raise temperatureReduce timeFuel cell auxillariesFuel cell applicationsCogenerationWater tanks

A fuel cell cogeneration system includes a fuel cell, a cooling water heat exchanger provided on a cooling water pathway, a stored hot water pathway through which stored hot water that exchanges heat with cooling water flows, a stored hot water tank, a stored hot water controlling device, a stored hot water temperature measuring device, a stored hot water flow rate adjusting device, a flow rate controlling device of controlling the stored hot water flow rate adjusting device and an exhaust gas heat exchanger of exchanging heat between exhaust gas from fuel processing devices and stored hot water. The flow rate controlling device controls the stored hot water adjusting device to reduce the flow rate of stored hot water flowing through the stored hot water pathway when the temperature of stored hot water is a first predetermined temperature or less during the starting of operation of the fuel cell.

Owner:PANASONIC CORP

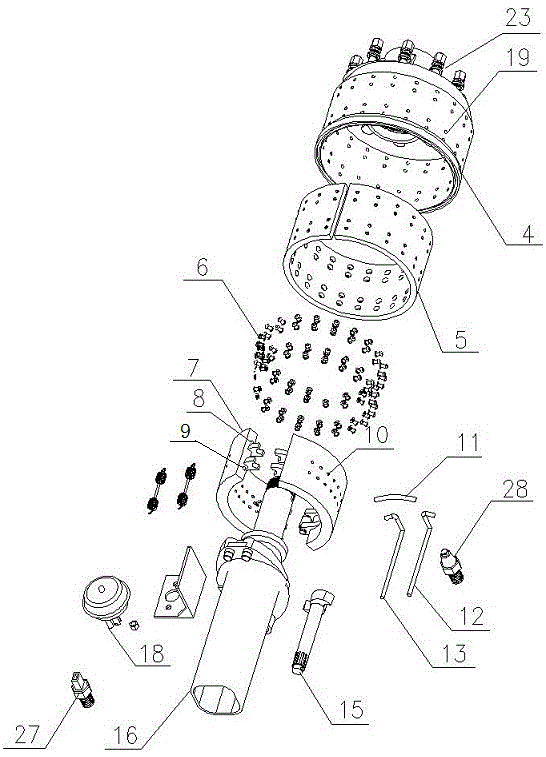

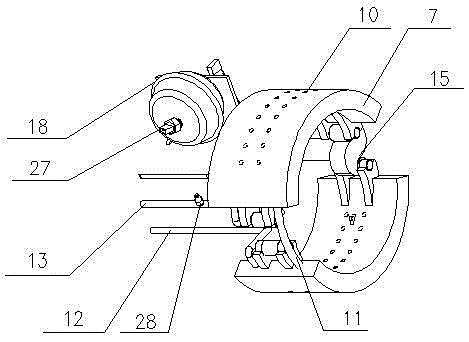

Safe low-temperature brake

ActiveCN105545984AAvoid overall overheatingReduce the temperatureBraking membersDrum brakesEngineeringCentrifugal force

The invention discloses a safe low-temperature brake which comprises a brake hub, brake pieces and a brake foot, wherein the brake hub is connected with a hub; the brake foot is connected with a shaft head; through pivot holes are formed in the brake hub wall and the brake pieces respectively; the brake pieces are fixedly connected with the inner wall of the brake hub through hollow pivots. The brake pieces of the safe low-temperature brake are fixedly connected with the inner wall of the brake hub through the hollow pivots, so that air inside and outside the brake hub can be circulated, heat dissipation is facilitated, the air can be 'thrown' out under the centrifugal force when the brake hub is rotated in an automobile running process, the air inside the brake hub can be continuously replaced, and the temperature of a brake assembly can be rapidly and effectively reduced, so as to effectively prevent the situation that the brake hub is too hot or fire is caused to a tire; the air can be replaced, at the same time particles caused by friction can be discharged out in time, the smoothness of a friction surface can be improved, the brake effect can be ensured, and furthermore the service lives of the brake pieces and the brake foot can be prolonged.

Owner:江朝汽车(金湖)有限公司

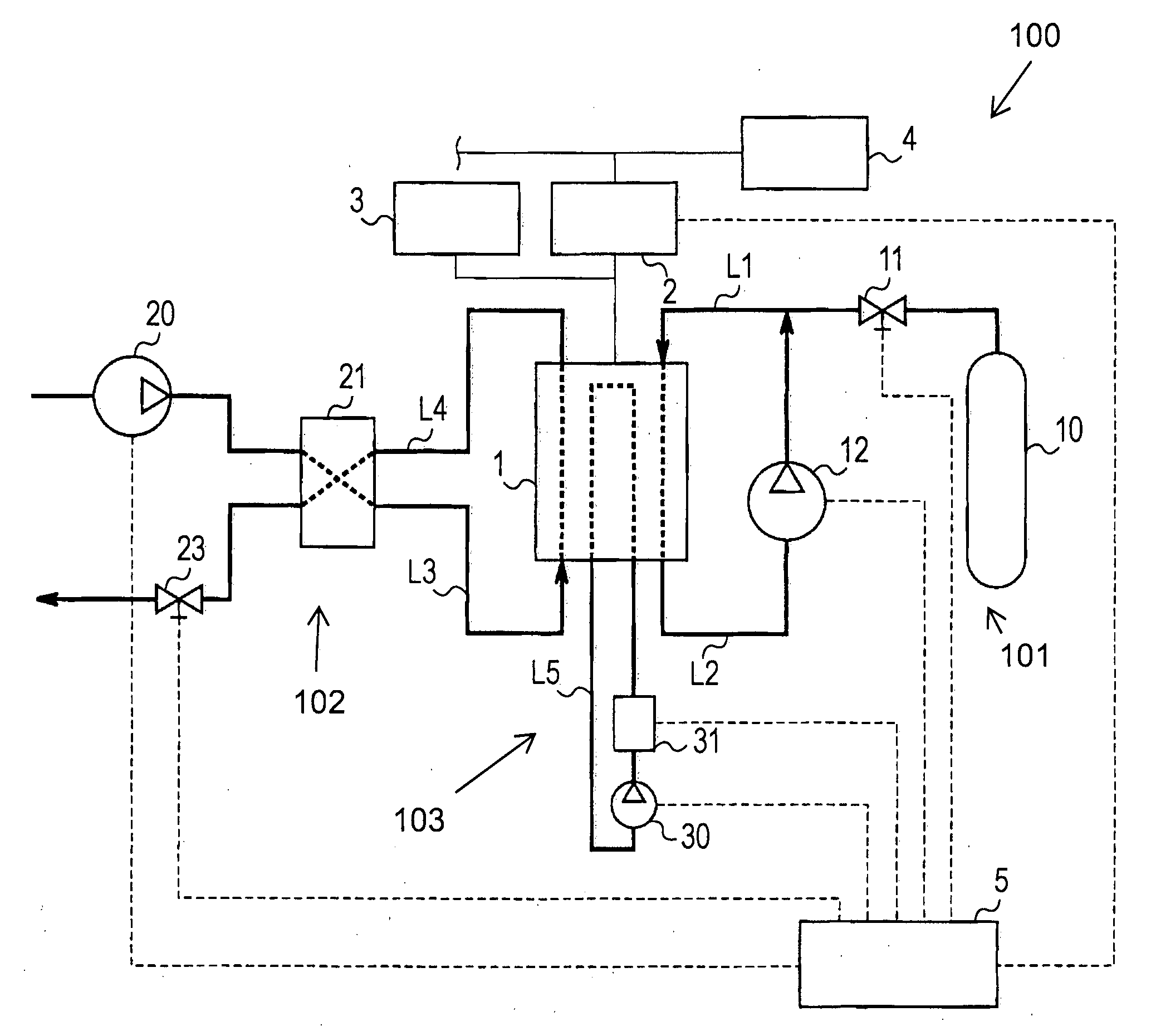

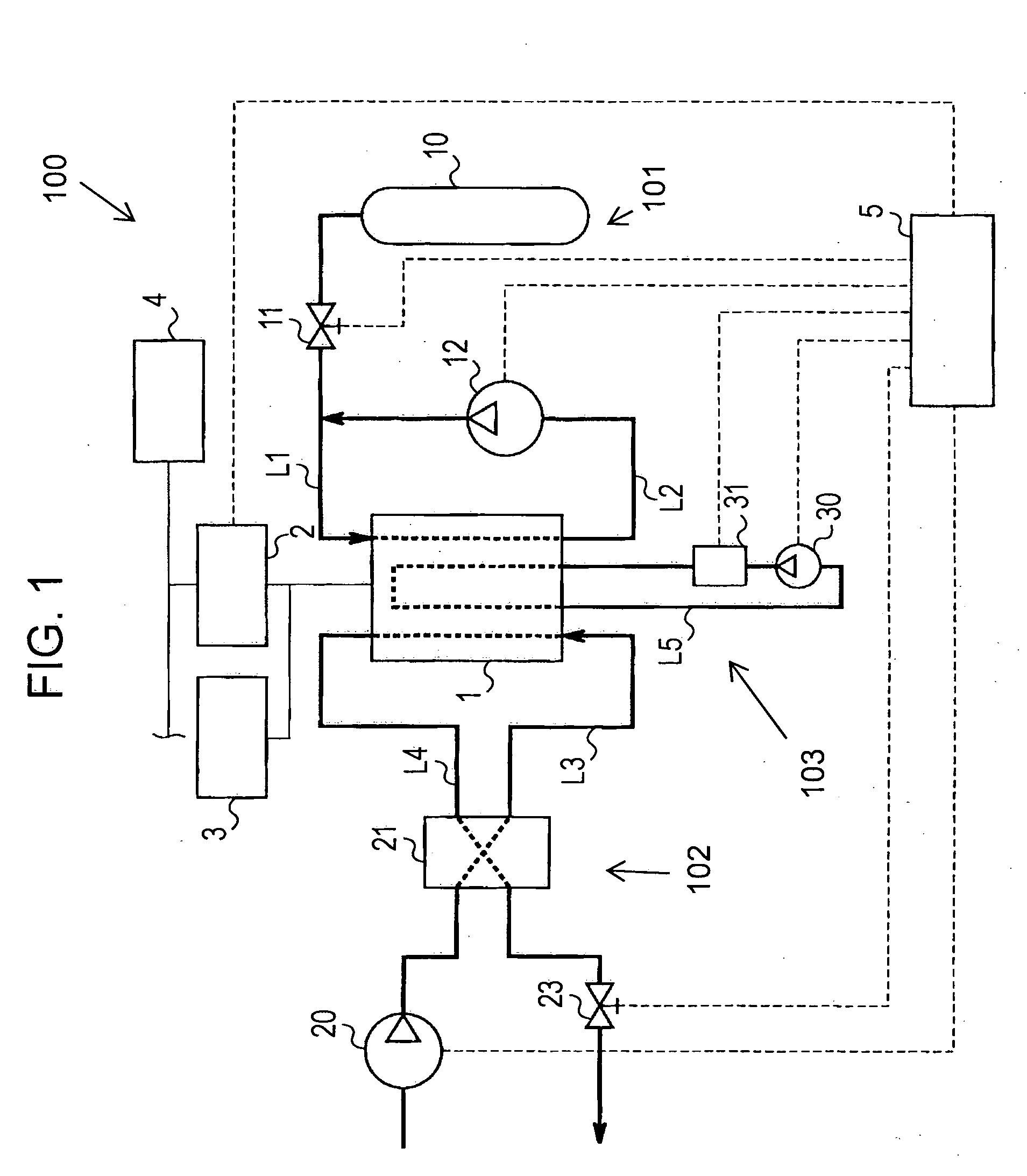

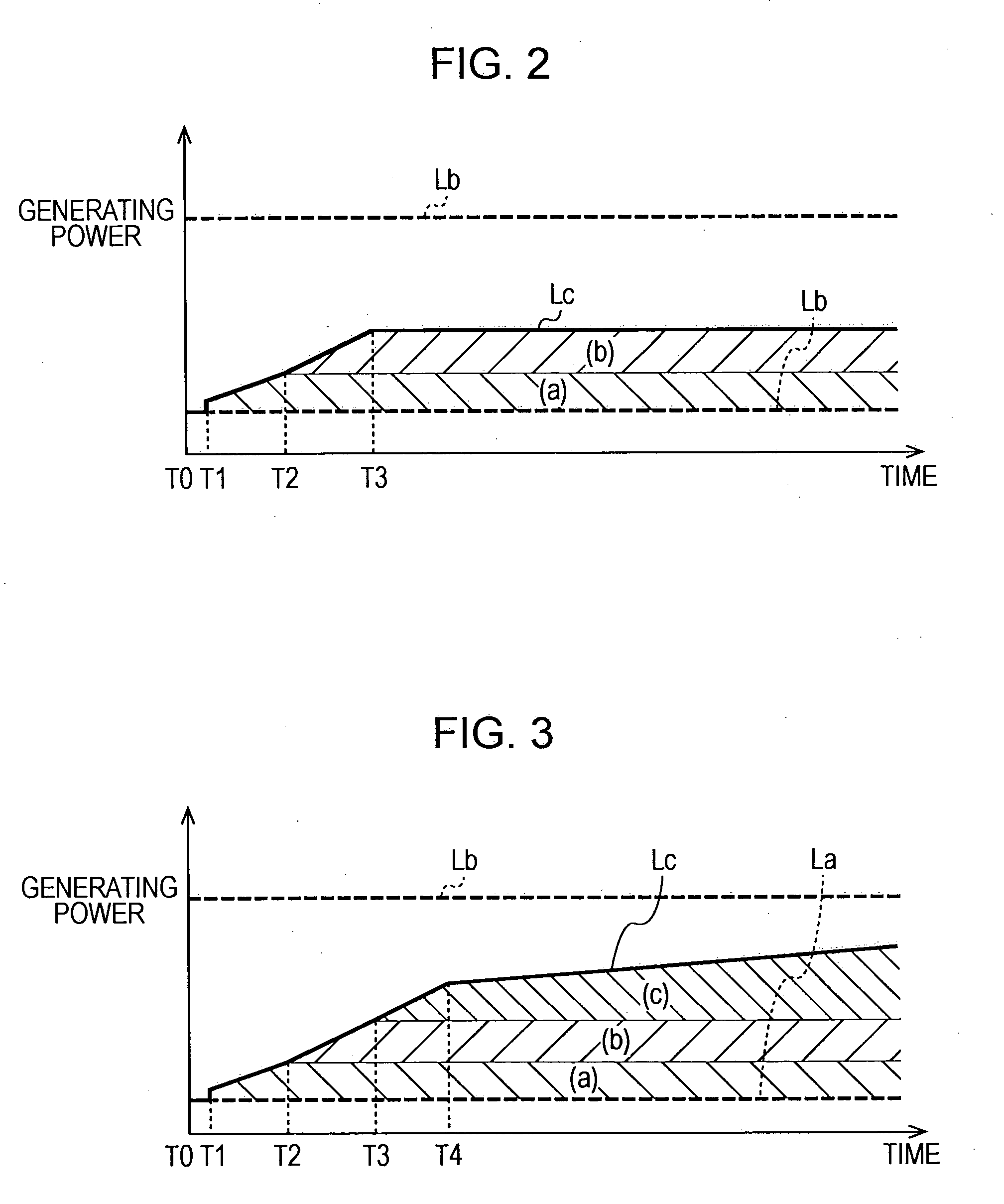

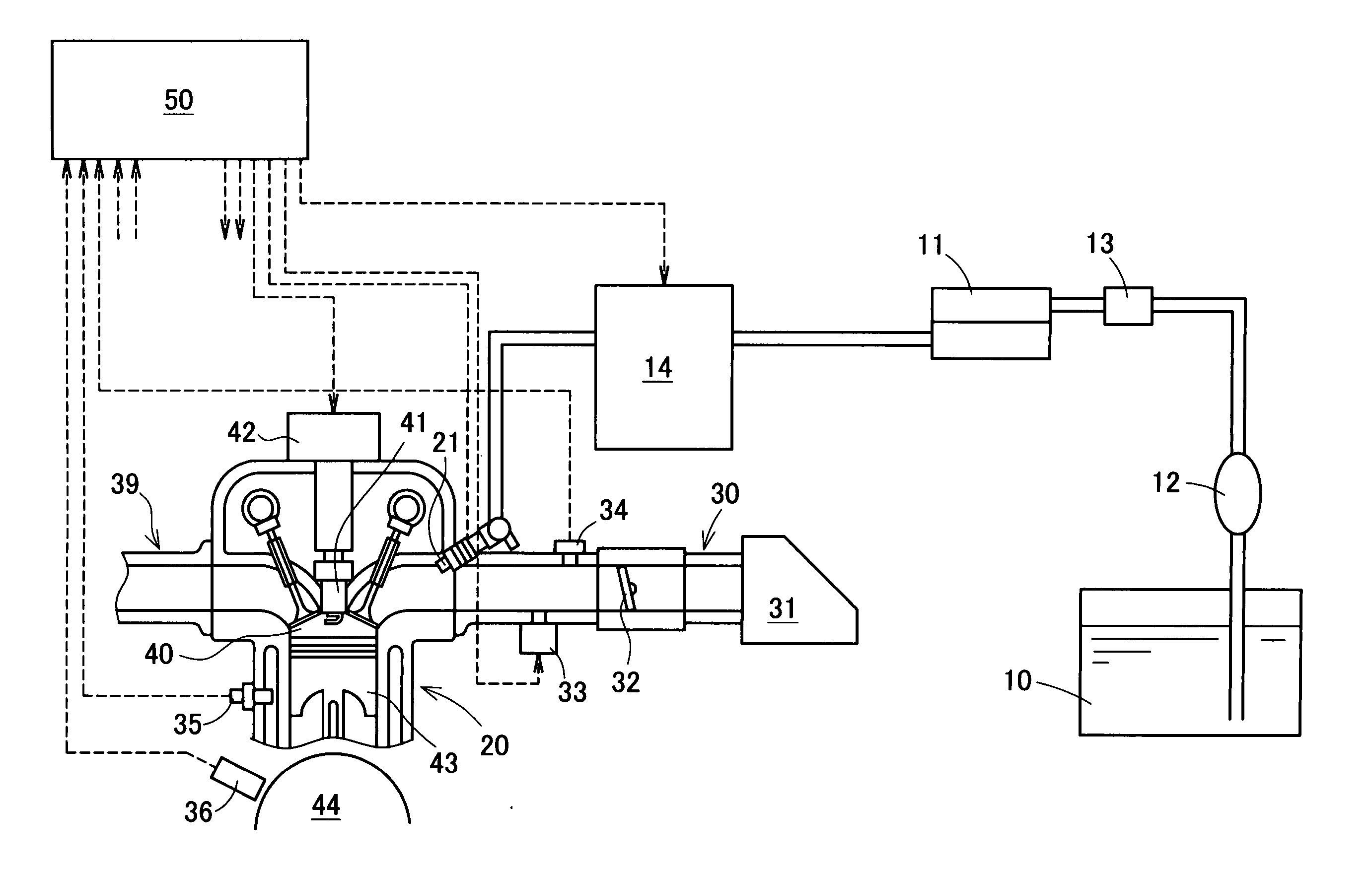

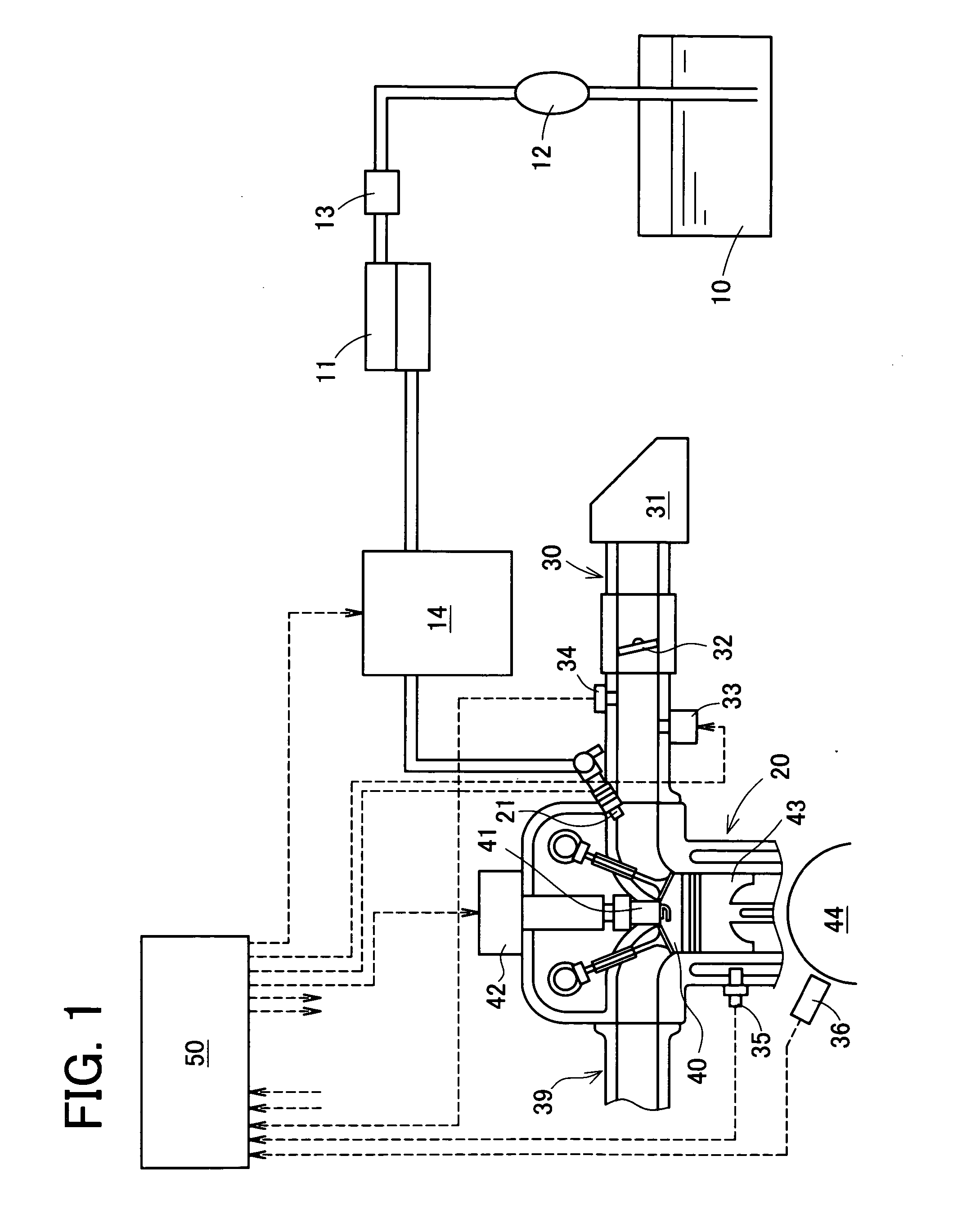

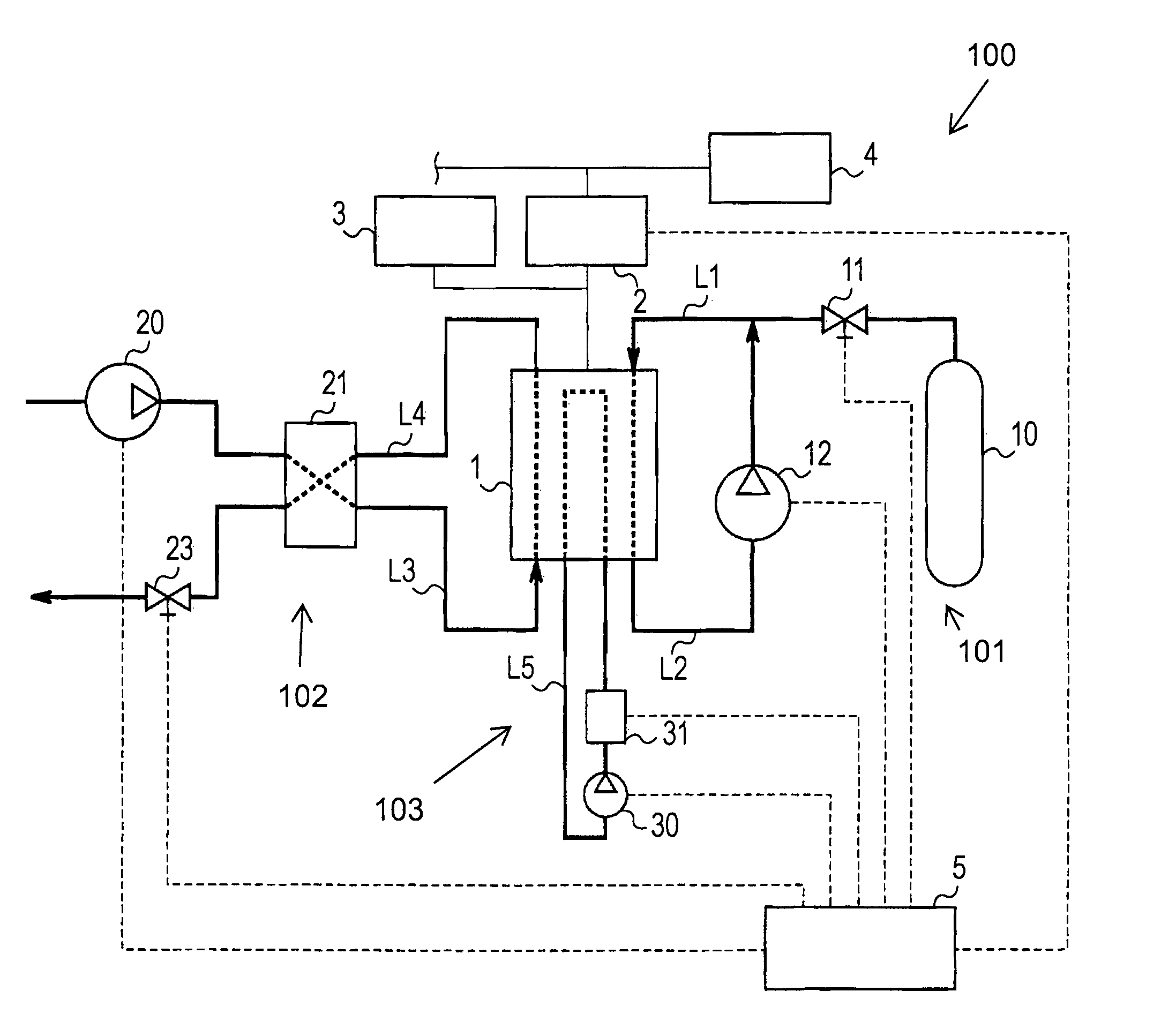

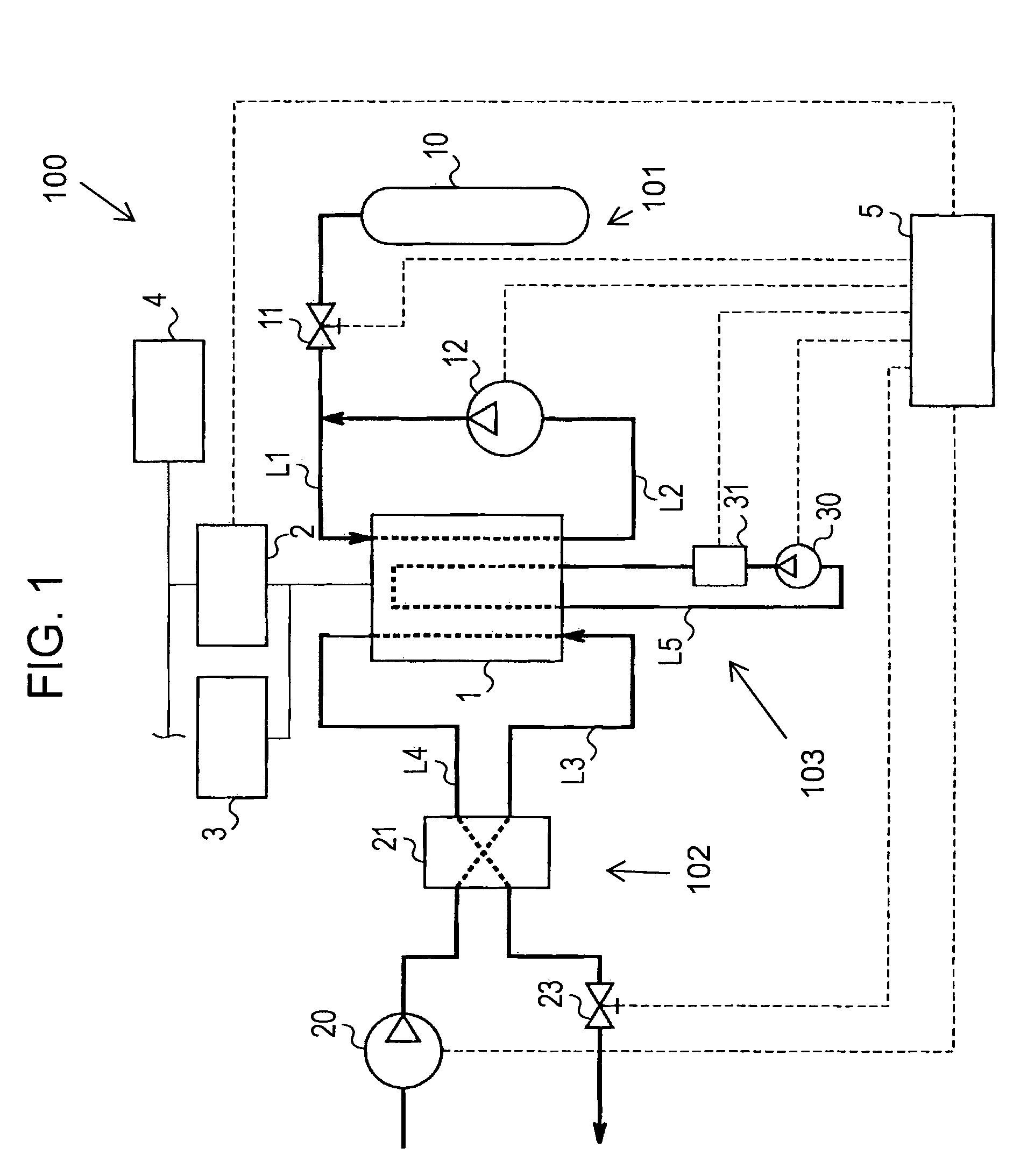

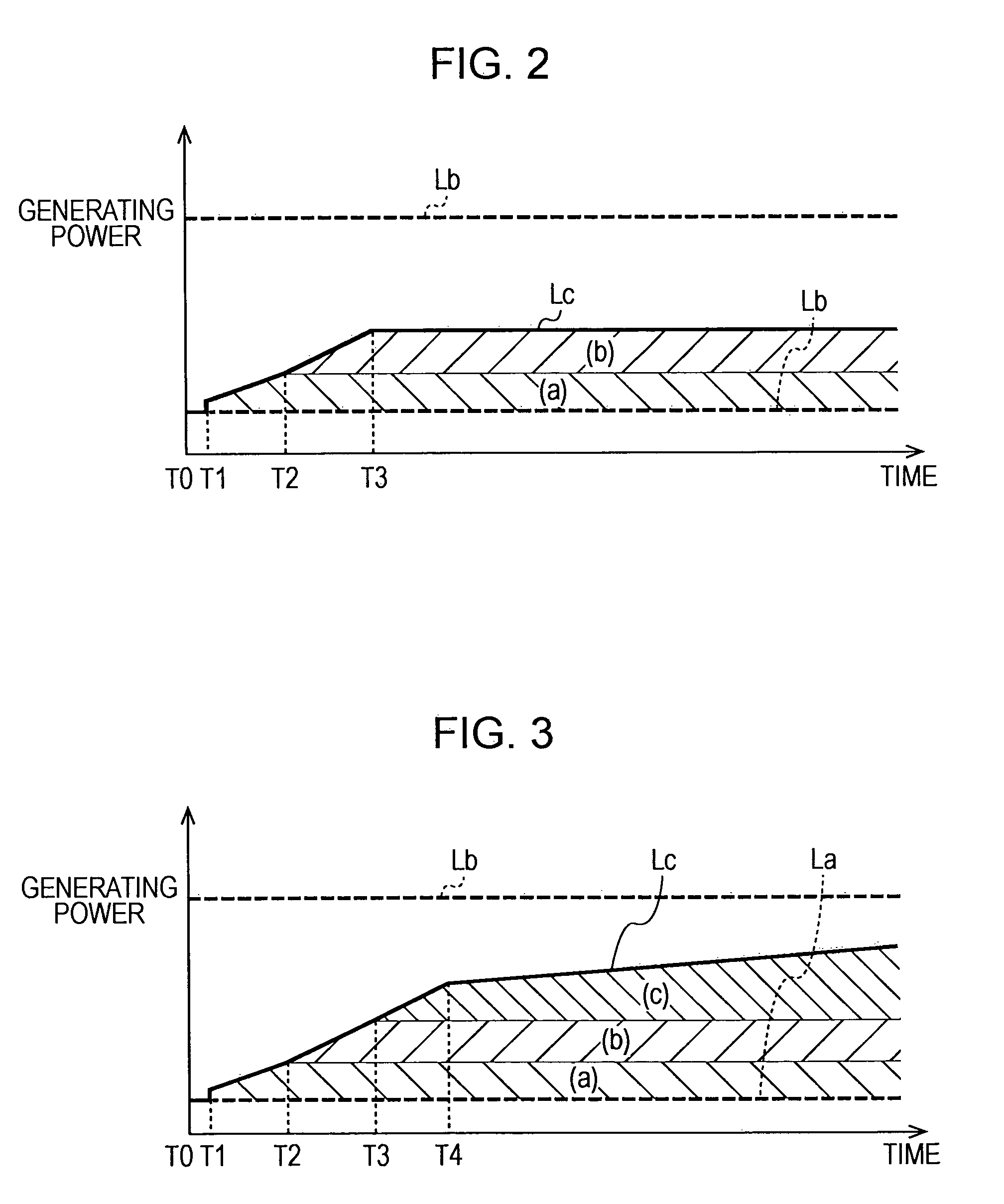

Fuel cell system and control method thereof

ActiveUS20100320960A1Increase in fuel temperaturePromote warming-upBatteries circuit arrangementsFuel cell auxillariesElectrochemical responsePower over

The present invention provides a fuel cell system including a fuel cell configured to cause reactant gas to be electrochemically reacted to generate electrical power when the reactant gas is supplied to the fuel cell, power consuming equipment such as a reactant gas supply apparatus and a heating device operable to consume electrical power generated by the fuel cell, and a controller for controlling operation of the fuel cell system. During a warm-up operation, the controller causes the reactant gas supply apparatus to start a flow of the reactant gas and to increase the flow of the reactant gas over time, such that the reactant gas supply device starts to consume power and consumes increased power over time. After starting the flow of the reactant gas, the controller causes the heating device to start heating the coolant such that the heating device consumes power.

Owner:NISSAN MOTOR CO LTD

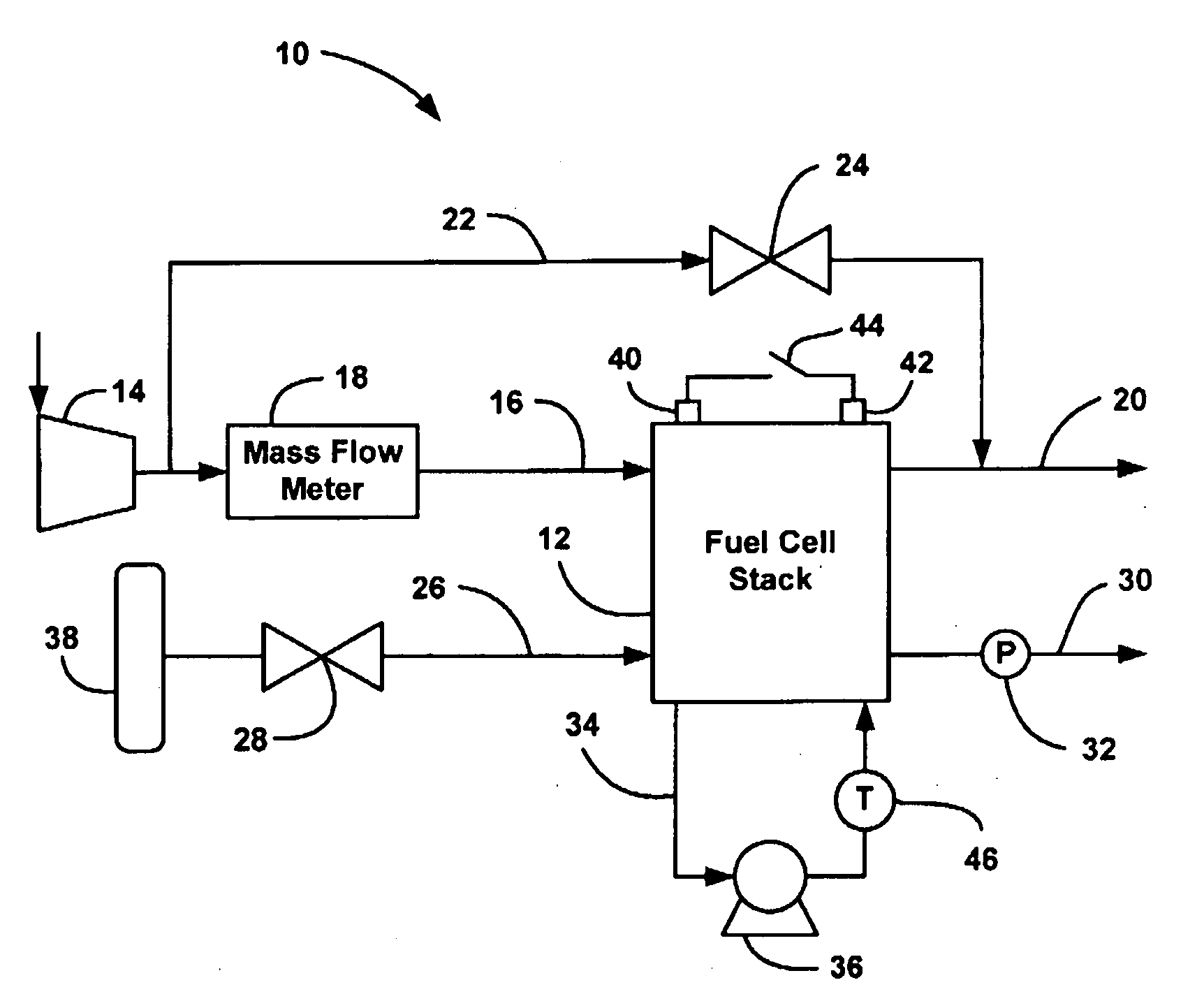

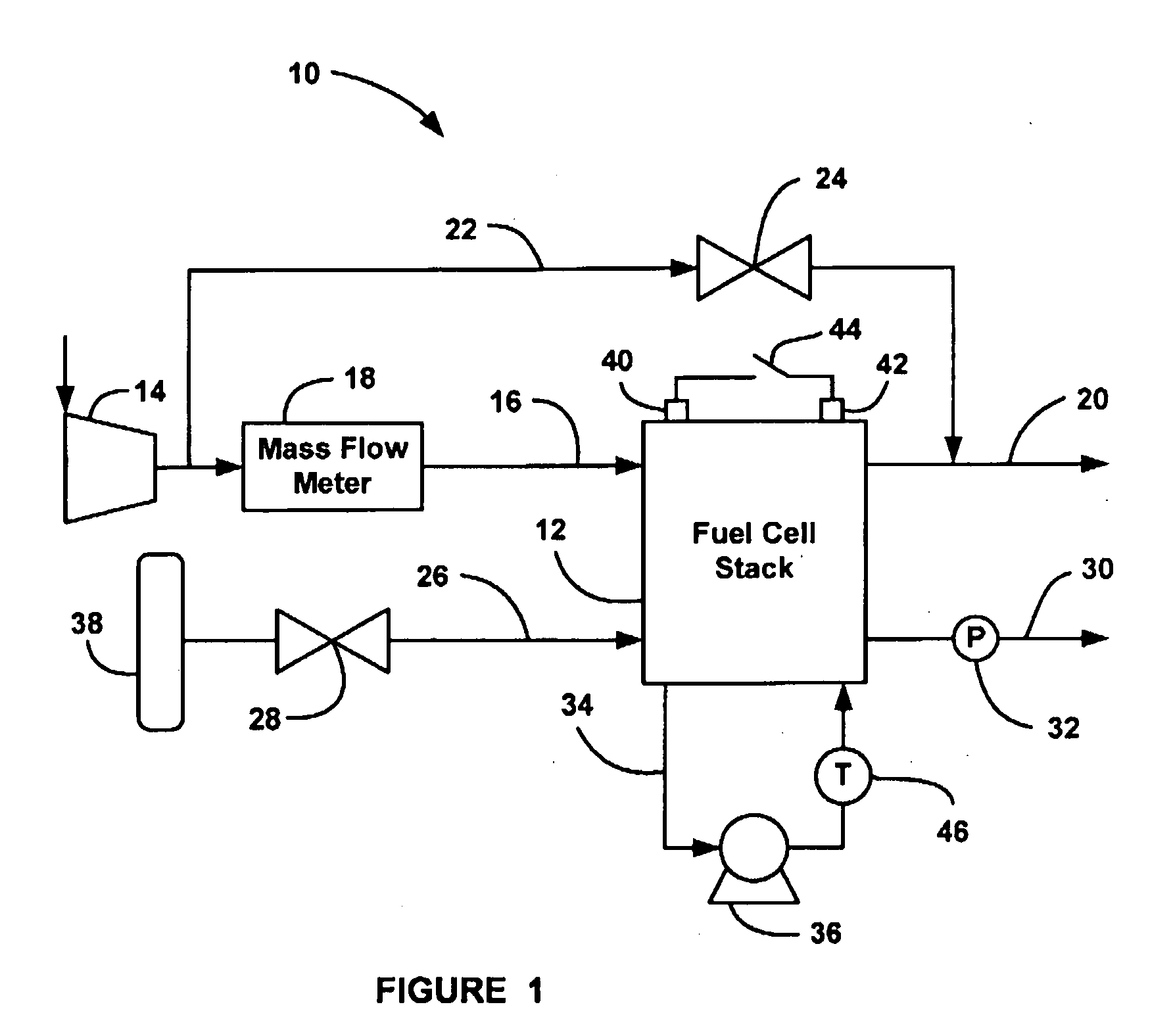

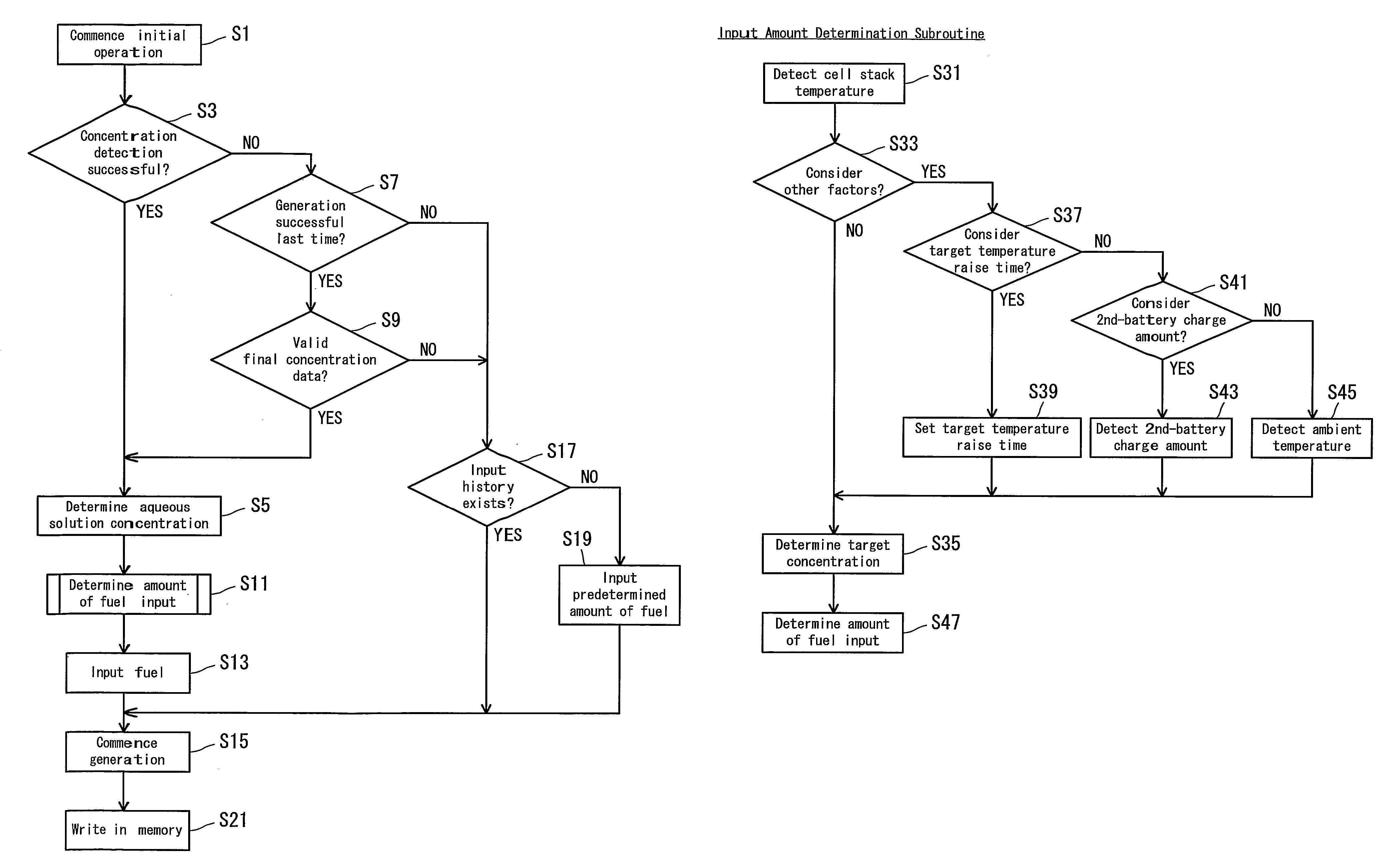

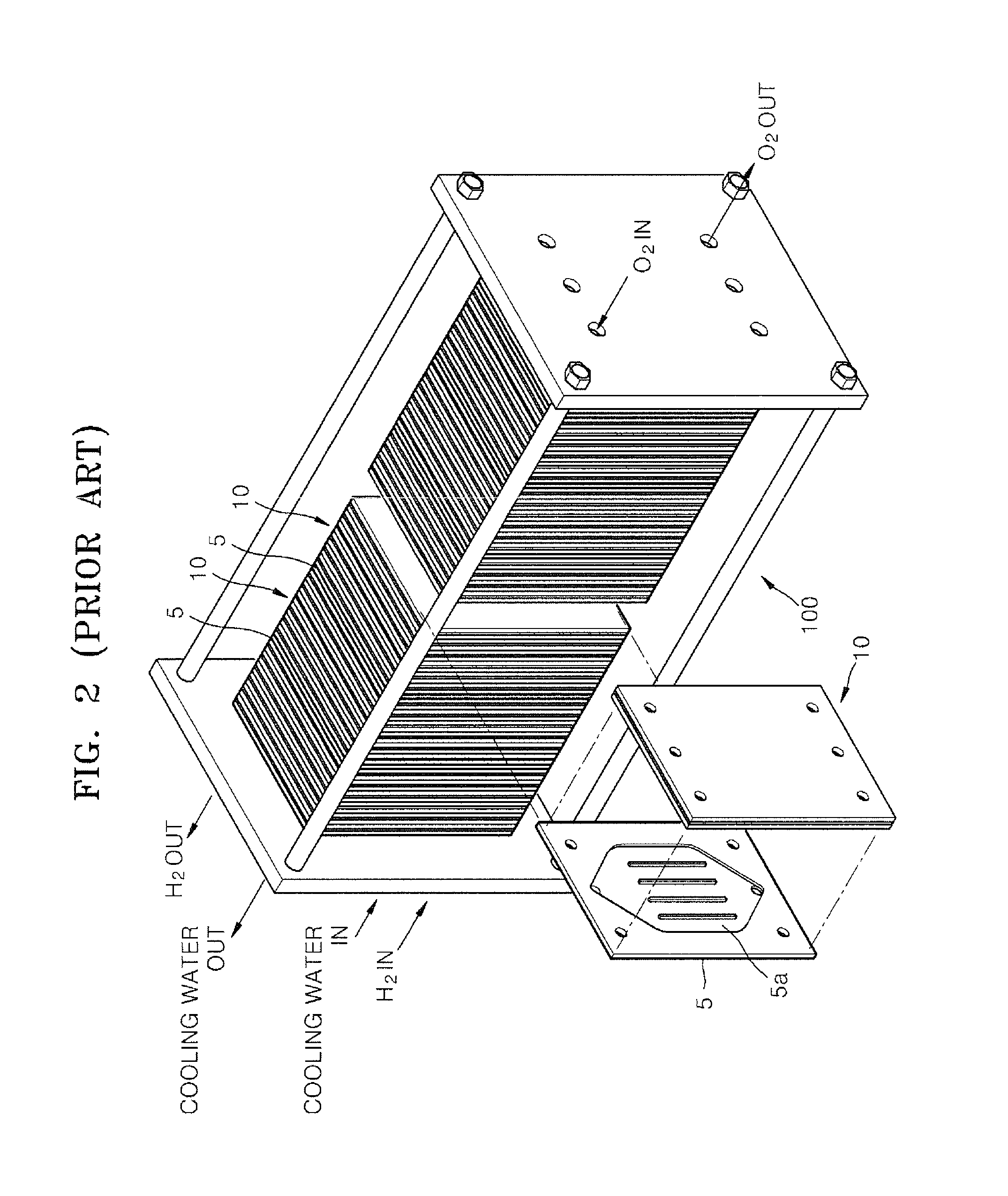

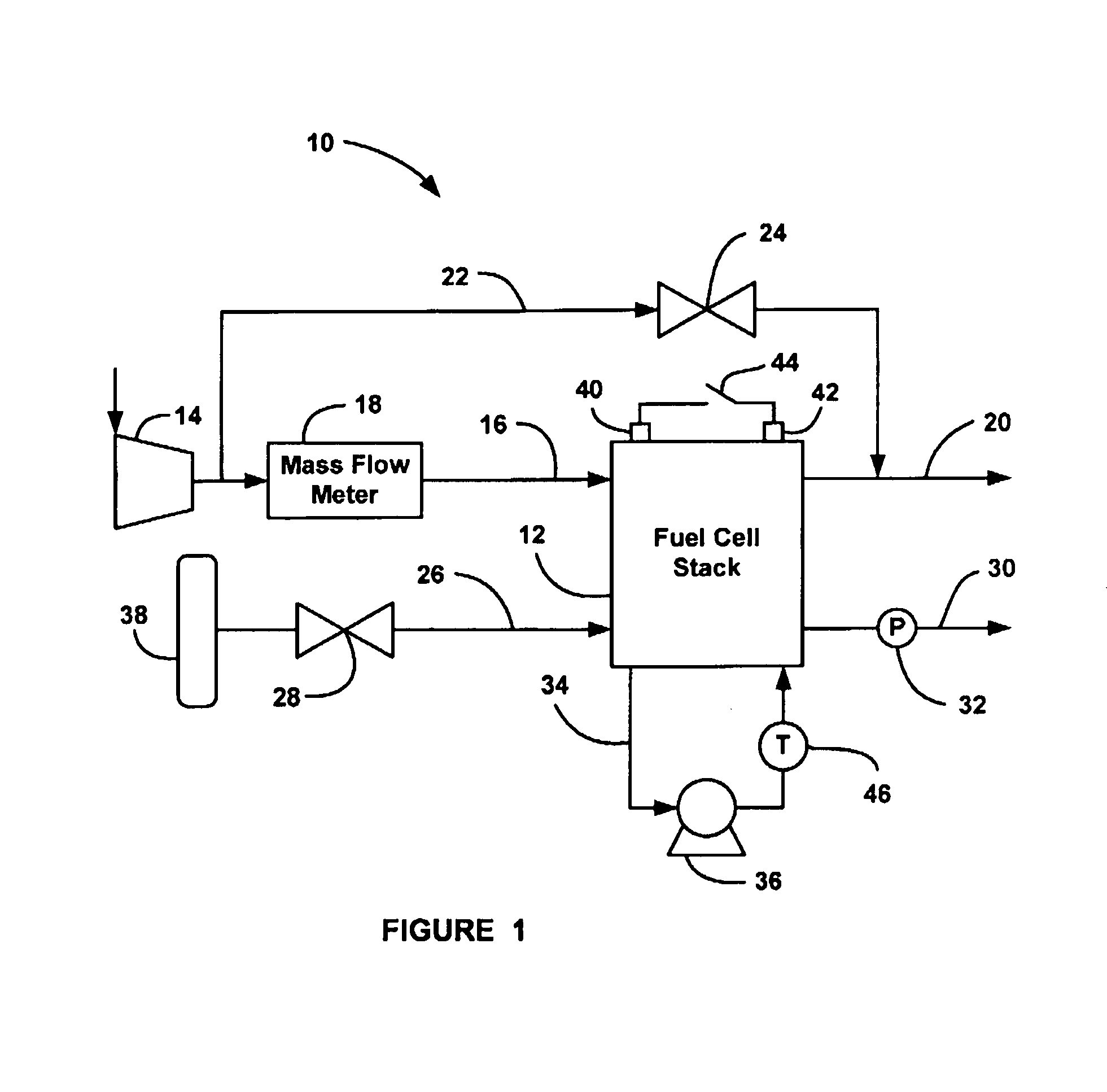

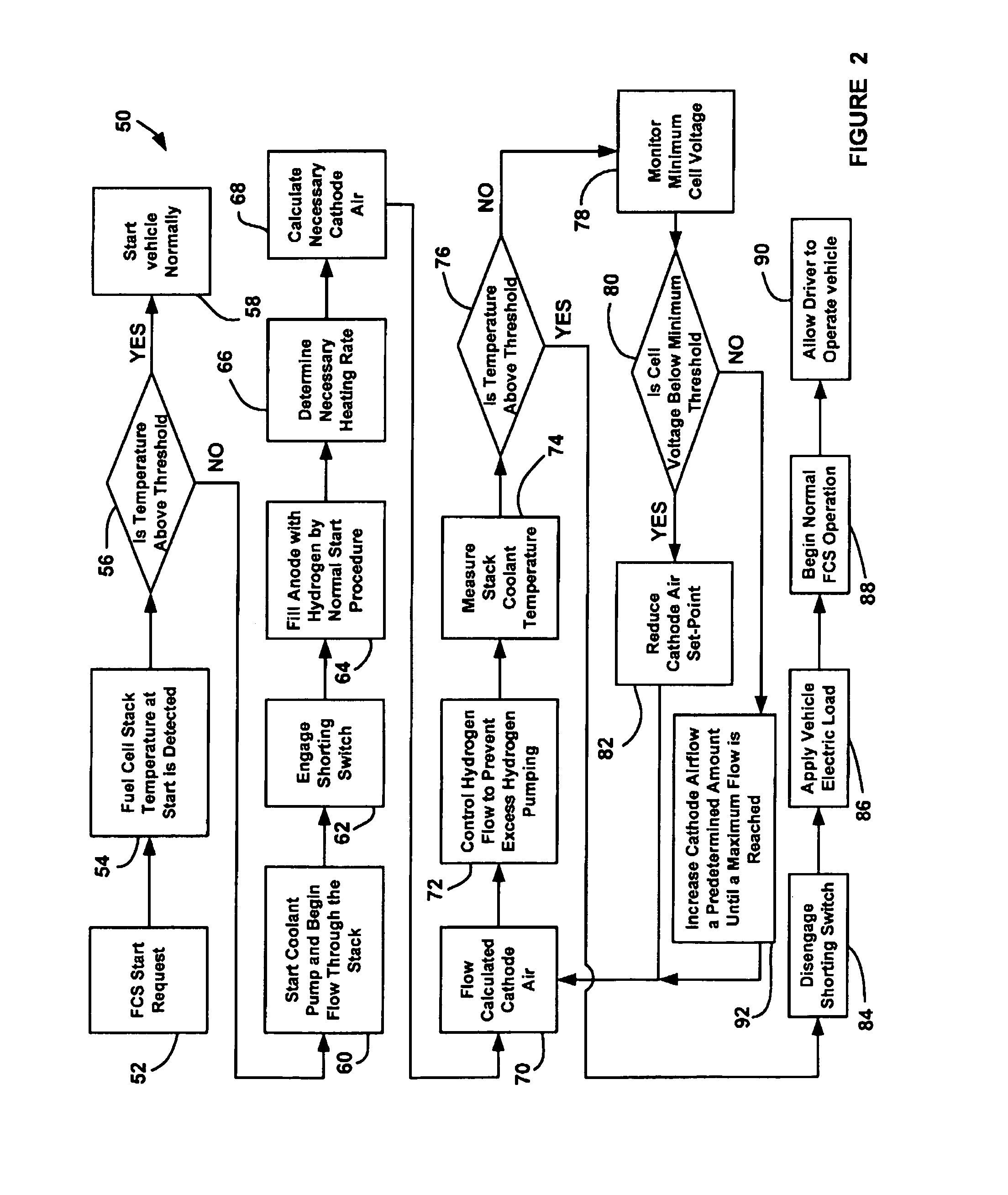

Fuel cell stack used as coolant heater

ActiveUS20100035097A1Increase fuel temperatureIncrease temperatureFuel cell auxillariesAirflowEngineering

A system and method for increasing the temperature of a fuel cell stack quickly, especially at cold stack start-up. The method includes determining whether the fuel cell stack is below a first predetermined temperature threshold, and, if so, starting a cooling fluid flow through the stack and engaging a shorting circuit across the stack to short circuit the stack and cause the stack to operate inefficiently. The method then determines a desired heating rate of the fuel cell stack and calculates a cathode airflow to the fuel cell stack based on the desired heating rate. The method reduces the flow of cathode air to the stack if a minimum cell voltage is below a predetermined minimum cell voltage threshold and disengages the shorting circuit and applies vehicle loads to the stack when the stack temperature reaches a predetermined second temperature threshold.

Owner:GM GLOBAL TECH OPERATIONS LLC

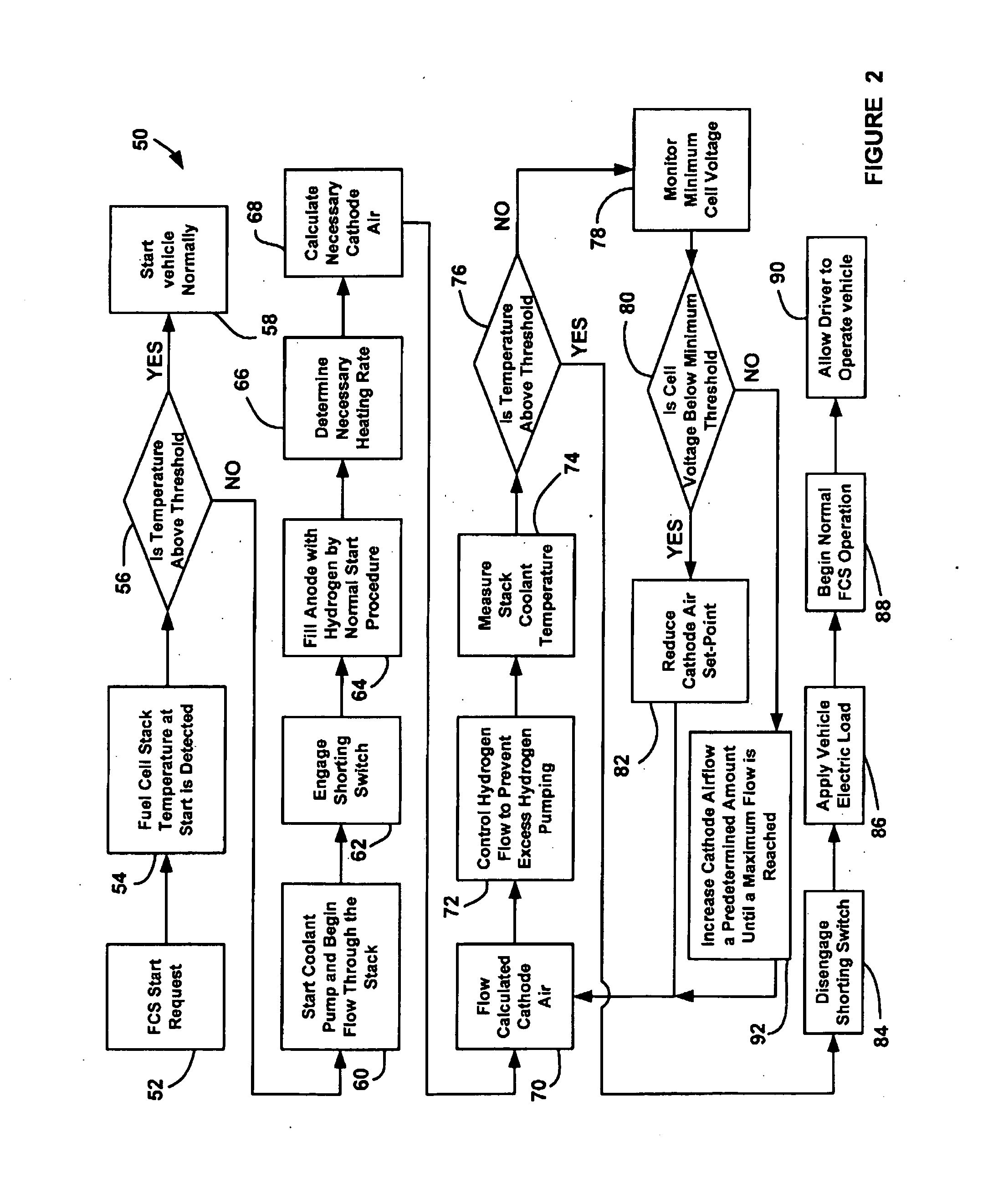

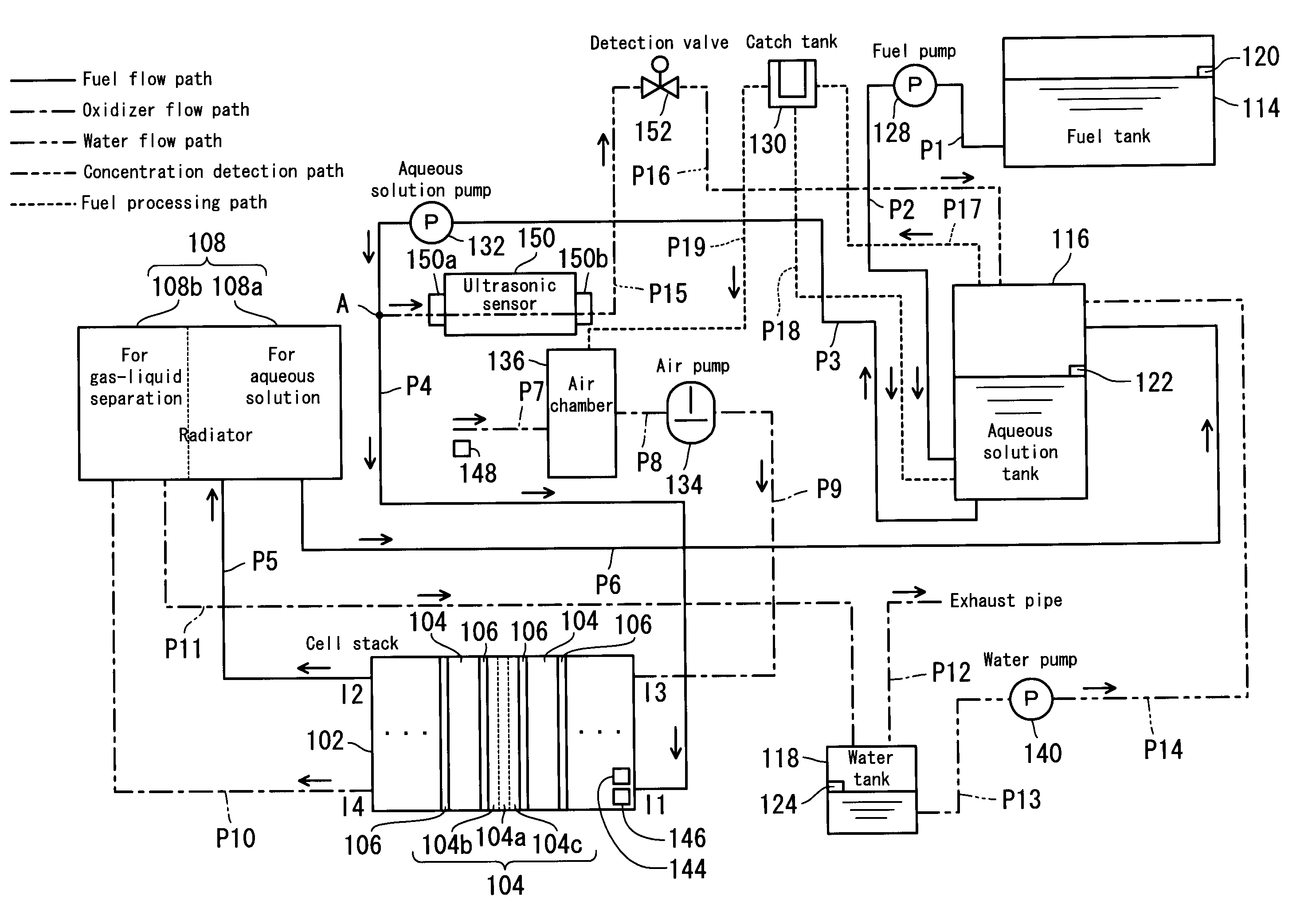

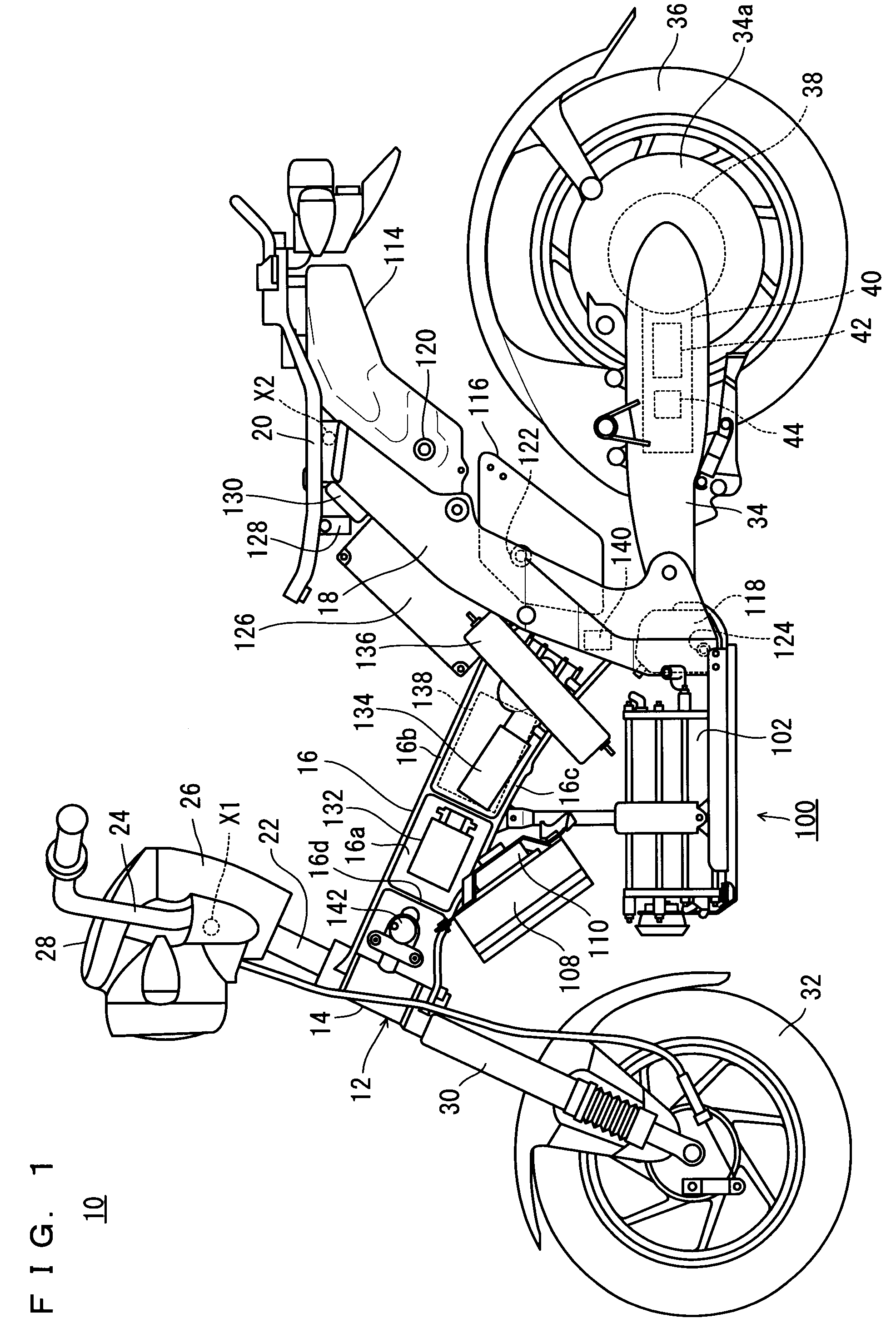

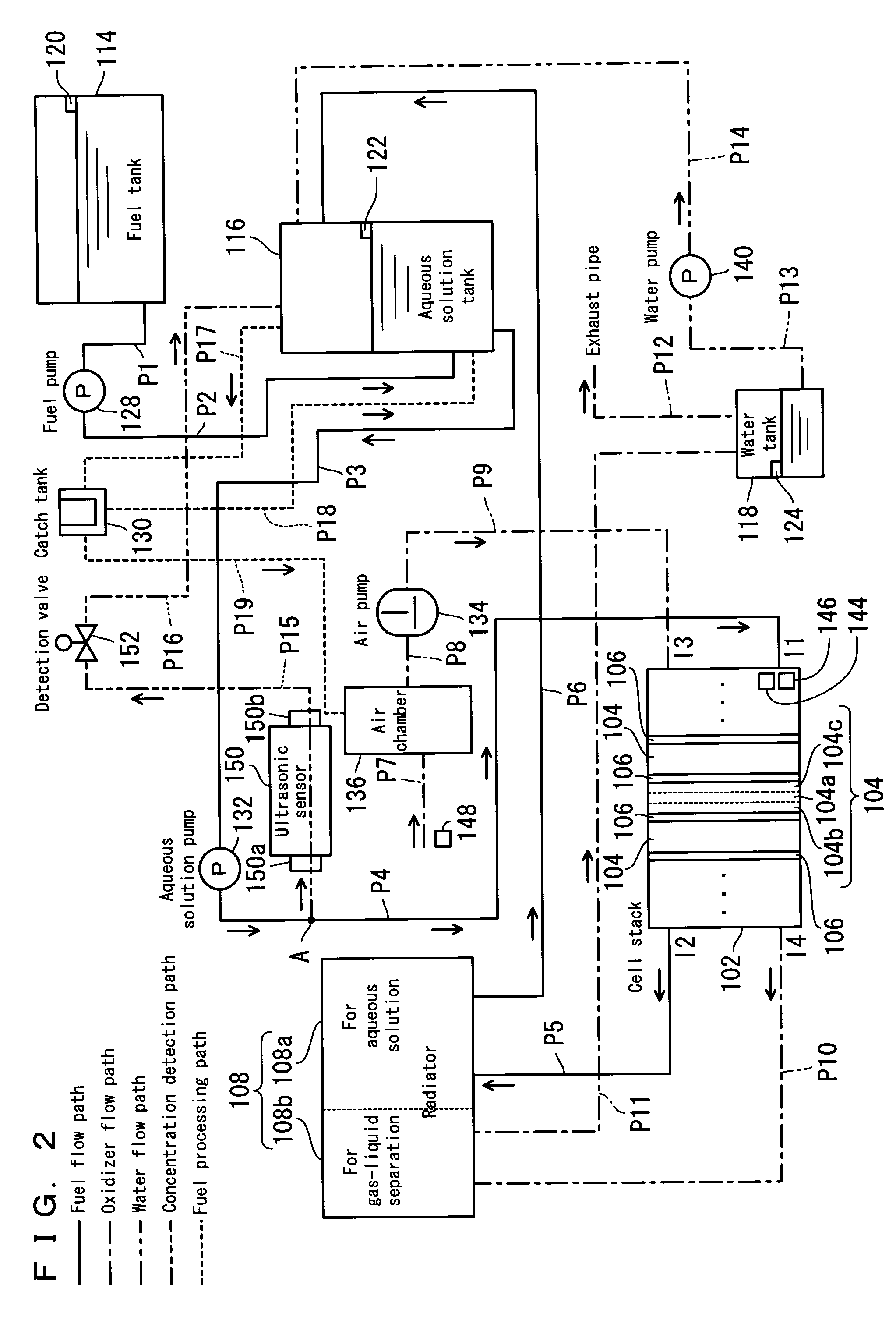

Fuel cell system and control method therefor

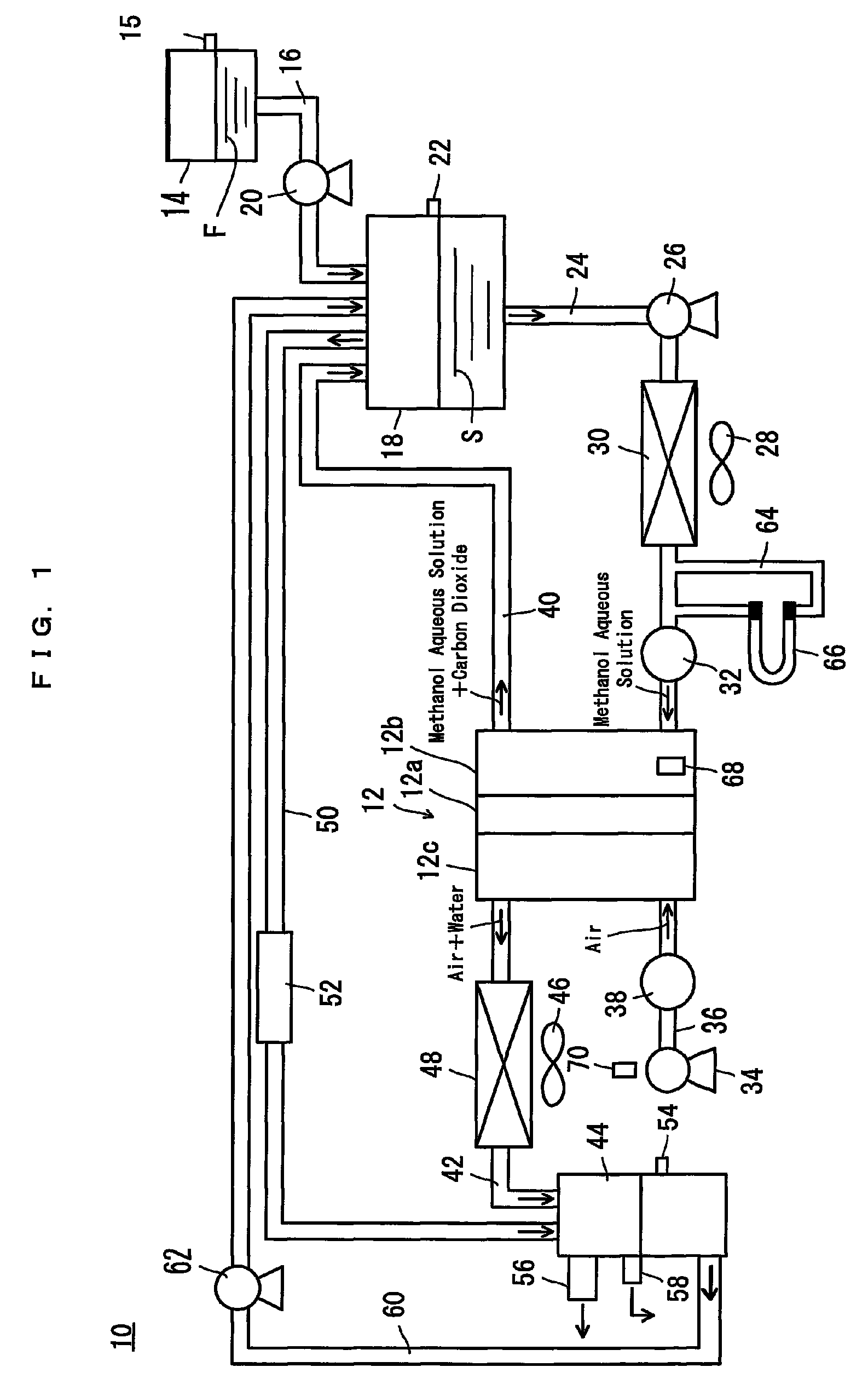

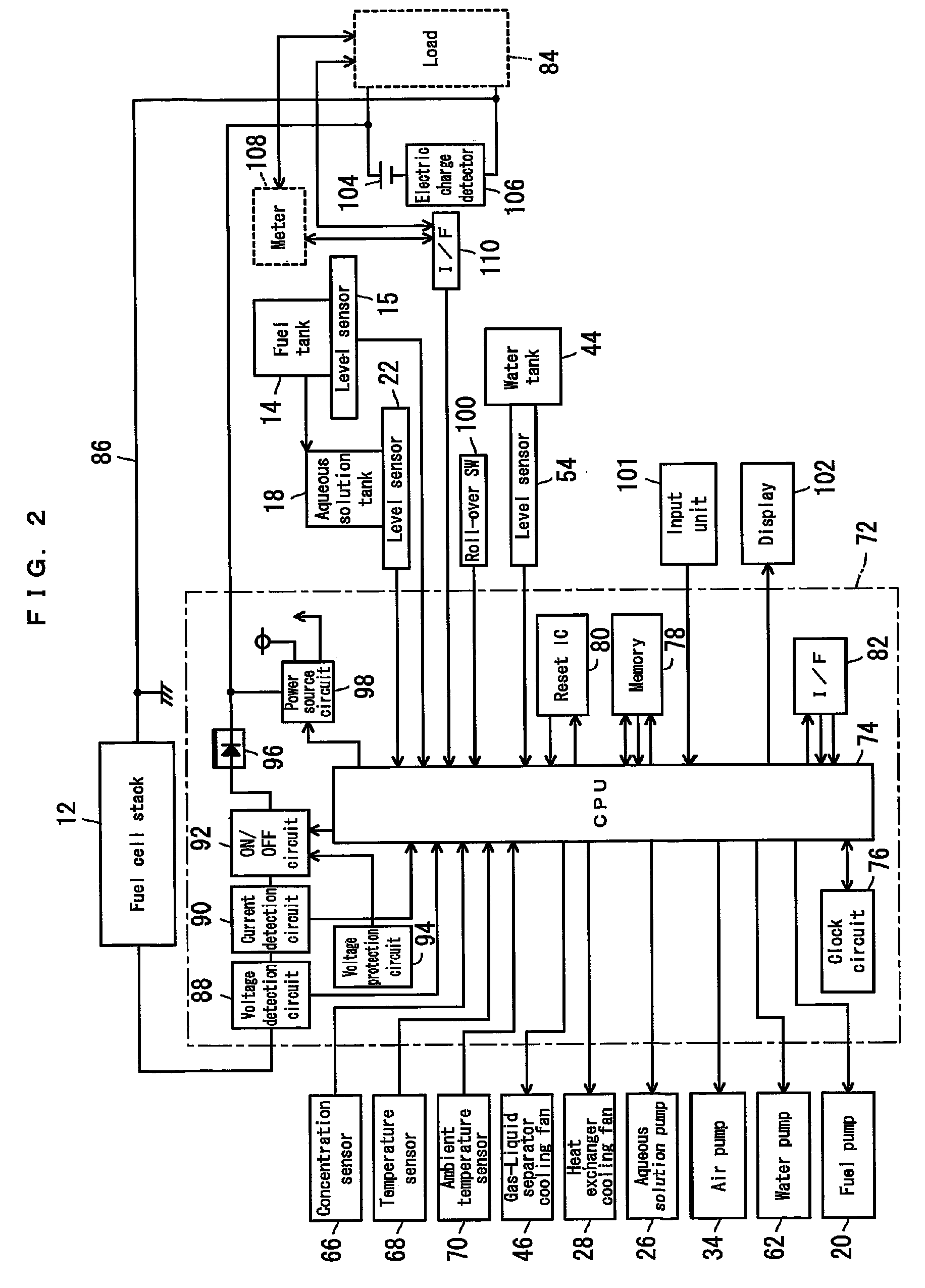

InactiveUS7816045B2Increase in fuel temperatureDecreasing fuel utilization efficiencyFuel cell heat exchangeLevel controlAqueous solutionMetal ions in aqueous solution

A fuel cell system including a fuel cell stack is capable of raising the temperature of a fuel cell stack to a predetermined temperature within a short time without decreasing methanol fuel utilization efficiency. During system startup, the concentration of methanol aqueous solution which is to be supplied to the fuel cell stack is detected by a concentration sensor, and the temperature of the fuel cell stack is detected by a temperature sensor. A target concentration of methanol aqueous solution is determined by making reference to data stored in a memory, which indicates correspondence between the temperature of the fuel cell stack and the target concentration of methanol aqueous solution, and based on the temperature of the fuel cell stack detected by the temperature sensor.

Owner:YAMAHA MOTOR CO LTD

Fuel circuit for an aviation turbine engine, the circuit having a fuel pressure regulator valve

ActiveUS9702301B2Mitigate such drawbackIncrease fuel temperatureTurbine/propulsion fuel flow conduitsEngine fuctionsAviationCombustion chamber

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Fuel supply apparatus and vapor separator in outboard engine

InactiveUS20050000495A1Low heat generationIncrease fuel temperatureMachines/enginesLiquid fuel feedersFluid levelFuel supply

With a low-pressure pump, fuel is supplied to a vapor separator comprising an air discharge port and a ball valve for closing the air discharge port in association with a rise in fluid level of the fuel supplied to the vapor separator. When the fuel is filled into the vapor separator entirely, the ball valve acts to tightly close the vapor separator, thereby pressurizing the fuel in the vapor separator.

Owner:AISAN IND CO LTD

Fuel pumping unit

ActiveUS10138816B2Improve pumping efficiencySmall sizePump componentsTurbine/propulsion fuel deliveryHigh pressureCentrifugal pump

A fuel pumping unit has a low pressure centrifugal pump and a high pressure centrifugal pump. In use, the low pressure pump supplies fuel at a boosted pressure to the high pressure pump for onward supply to a fuel metering unit. The pumping unit further has a drive input which drives the low and high pressure pumps. A gear arrangement is operatively located between the drive input and the low and high pressure pumps such that the low and high pressure pumps are driven at different speeds by the drive input.

Owner:ROLLS ROYCE PLC

Air Cycle Assembly for a Gas Turbine Engine Assembly

ActiveUS20190360401A1Reduce the temperatureIncrease fuel temperatureTurbine/propulsion engine coolingEngine fuctionsAutomotive engineeringAir cycle machine

A gas turbine engine assembly includes a turbomachine including a compressor section, a combustion section, and a turbine section in serial flow order; a fuel delivery system operable with the combustion section of the turbomachine for providing fuel to the combustion section of the turbomachine; and an air cycle assembly including an air cycle machine and a heat exchanger, the air cycle machine in airflow communication with the compressor section of the turbomachine and the heat exchanger in airflow communication with the air cycle machine. The gas turbine engine assembly also includes a thermal transfer bus thermally coupling the heat exchanger of the air cycle assembly to the fuel delivery system for transferring heat from the air cycle machine to the fuel delivery system.

Owner:GENERAL ELECTRIC CO

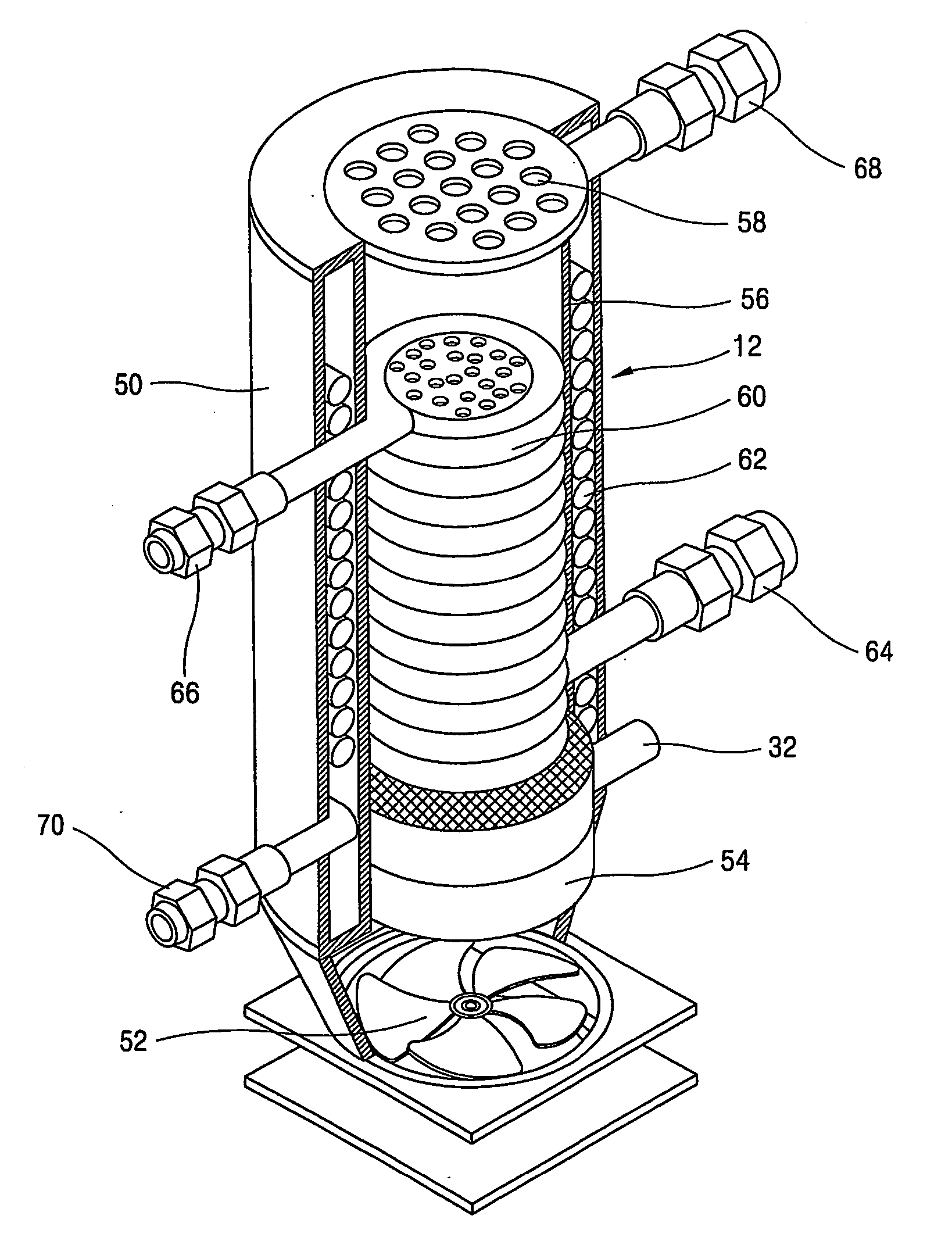

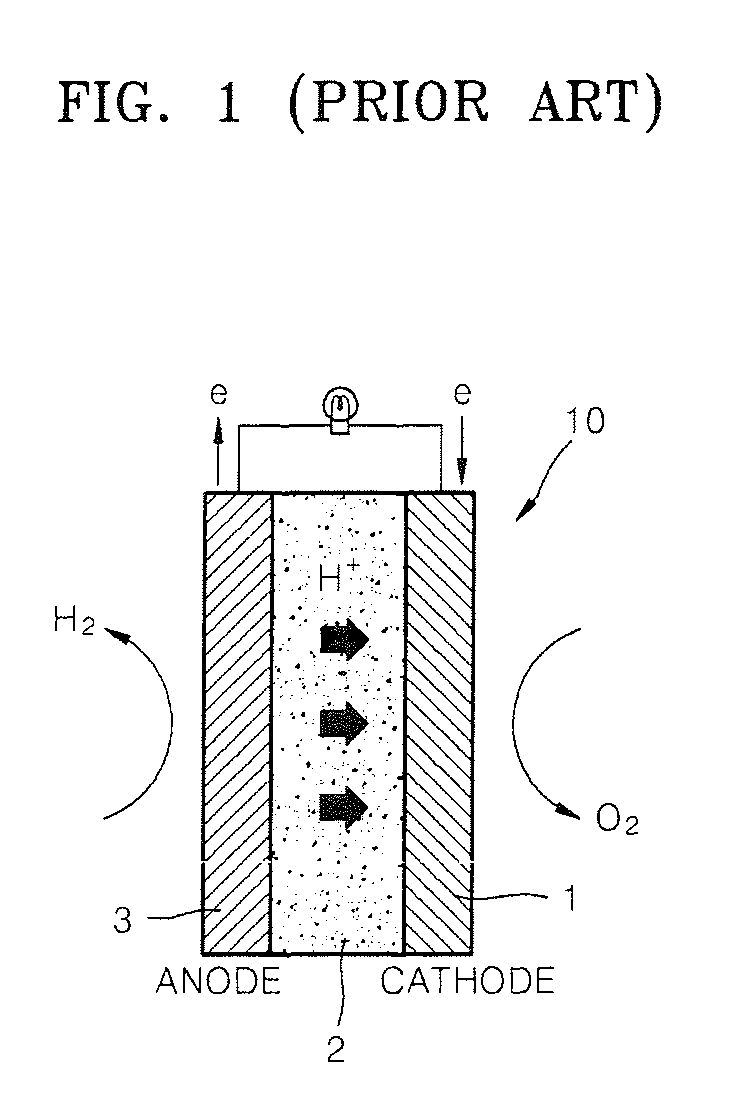

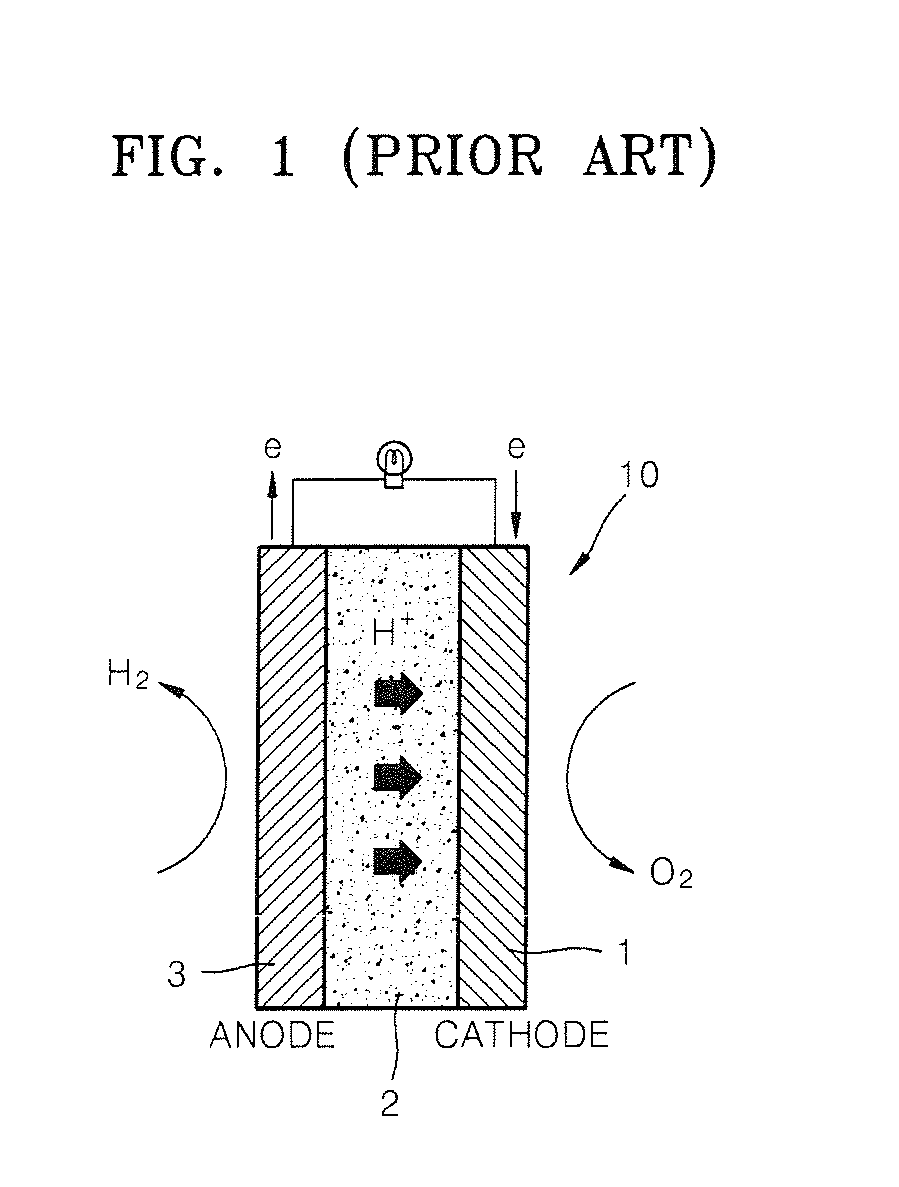

Fuel cell system

InactiveUS20060292411A1Improve fuel cell performanceIncrease fuel temperatureFuel cells groupingFuel cell auxillariesHydrogen fuelOxygen

A fuel cell system comprising: a fuel cell stack (6) including an anode (2), a cathode (4), and an electrolyte membrane disposed therebetween; a fuel supplying unit connected with the anode of the fuel cell stack (6) by a fuel supplying line (14) for supplying hydrogen-including fuel to the anode (2); an air supplying unit (10) connected with the cathode of the fuel cell stack by an air supplying line (48) for supplying oxygen-including air to the cathode of the fuel cell stack; and a heating unit (12) for heating fuel supplied to the fuel cell stack into a proper temperature. According to this, a power source for driving the heating unit (12) is not required thus to enhance a performance of a fuel cell.

Owner:LG ELECTRONICS INC

Fuel cell system and control method thereof

ActiveUS8384342B2Promote warming-upIncrease power generationBatteries circuit arrangementsFuel cell auxillariesElectrochemical responseFuel cells

The present invention provides a fuel cell system including a fuel cell configured to cause reactant gas to be electrochemically reacted to generate electrical power when the reactant gas is supplied to the fuel cell, power consuming equipment such as a reactant gas supply apparatus and a heating device operable to consume electrical power generated by the fuel cell, and a controller for controlling operation of the fuel cell system. During a warm-up operation, the controller causes the reactant gas supply apparatus to start a flow of the reactant gas and to increase the flow of the reactant gas over time, such that the reactant gas supply device starts to consume power and consumes increased power over time. After starting the flow of the reactant gas, the controller causes the heating device to start heating the coolant such that the heating device consumes power.

Owner:NISSAN MOTOR CO LTD

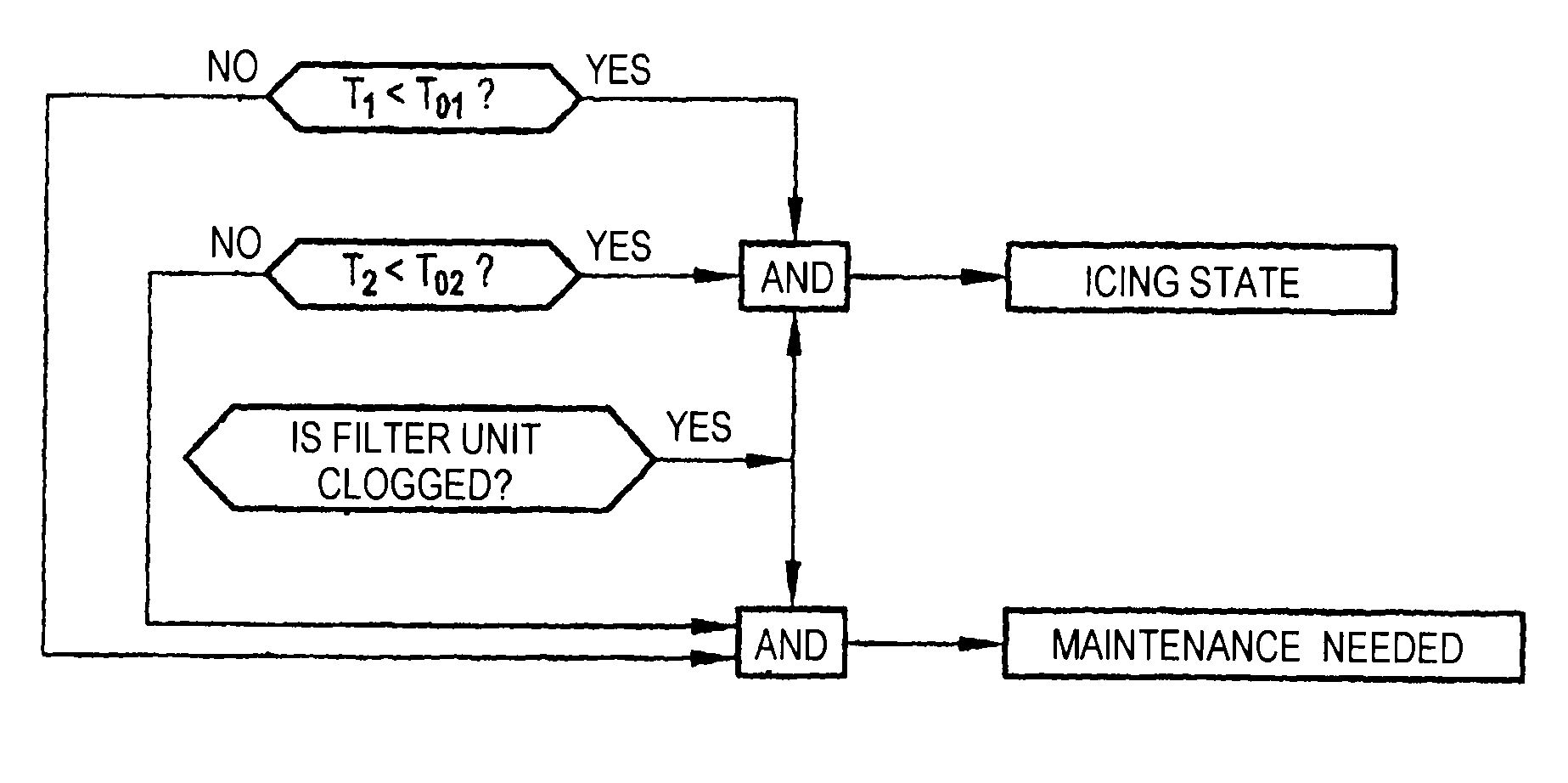

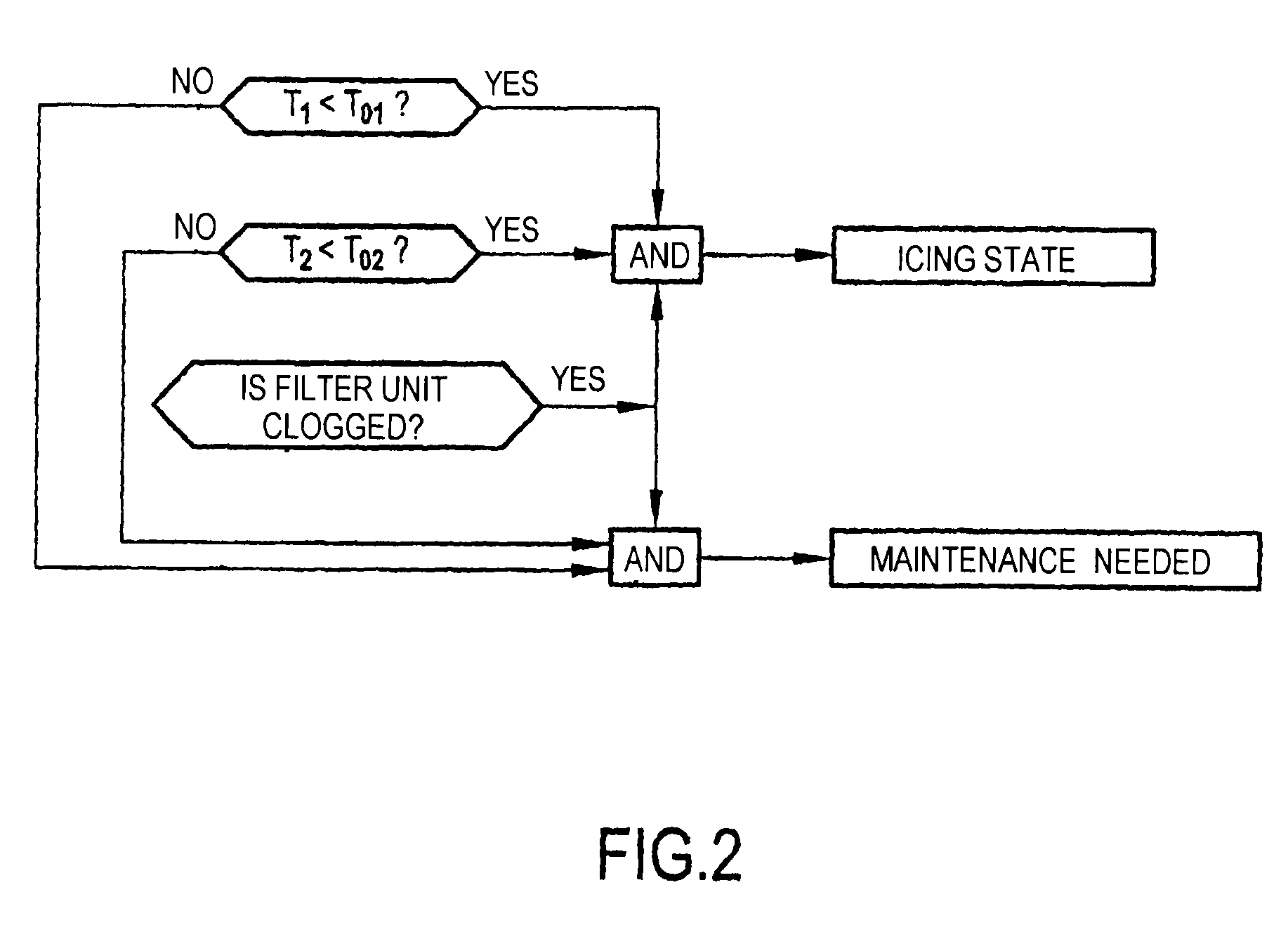

Method of detecting an icing state or a need for maintenance in a turbomachine fuel circuit

InactiveUS20120032809A1Increase fuel temperatureEliminate icingLiquid fuel feeder/distributionTurbine/propulsion fuel heatingDetection filterElectrical and Electronics engineering

Detecting a state of icing in a turbomachine fuel circuit includes reading information representative of a first temperature T1 of the fuel downstream from the metering unit, and of comparing the first temperature T1 with a first reference temperature T01. The method also includes detecting clogging of the filter unit. In the event of the temperature reading T1 being less than the first reference temperature T01 and of clogging being detected, a signal indicative of an icing state in the fuel circuit is issued. Information representative of a second fuel temperature T2 in the tank may be read and compared with a reference temperature T02 in order to confirm or contradict the icing state. A signal indicating a need for maintenance of the fuel circuit is issued when the temperature readings T1 and T2 are not less than the reference temperatures T01 and T02 and clogging has been detected.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Fuel cell cogeneration system, method of operating

InactiveUS20090239108A1Prevent running outImprove convenienceLighting and heating apparatusEnergy efficient heating/coolingFuel cellsCogeneration

A method of operating a fuel cell cogeneration system comprises the steps of cooling a fuel cell by circulating an internal heat transfer medium through the fuel cell while the fuel cell is generating electric power, storing an external heat transfer medium in a heat utilization portion, detecting remaining calories of the heat utilization portion by a first detector provided at the heat utilization portion, increasing a temperature of the fuel cell to an operating temperature by carrying out a first temperature increasing operation, and increasing the temperature of the fuel cell to the operating temperature by carrying out a second temperature increasing operation.

Owner:PANASONIC CORP

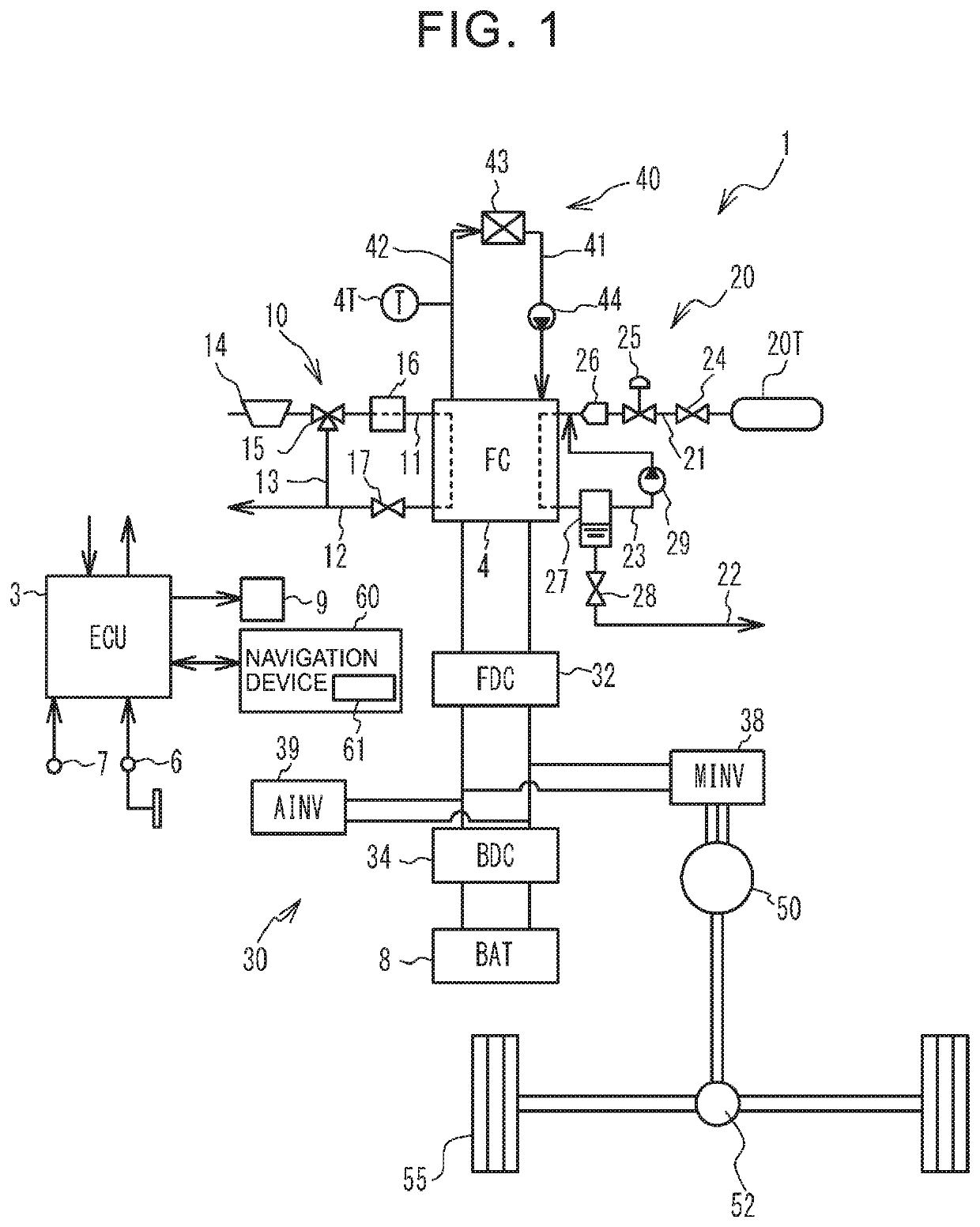

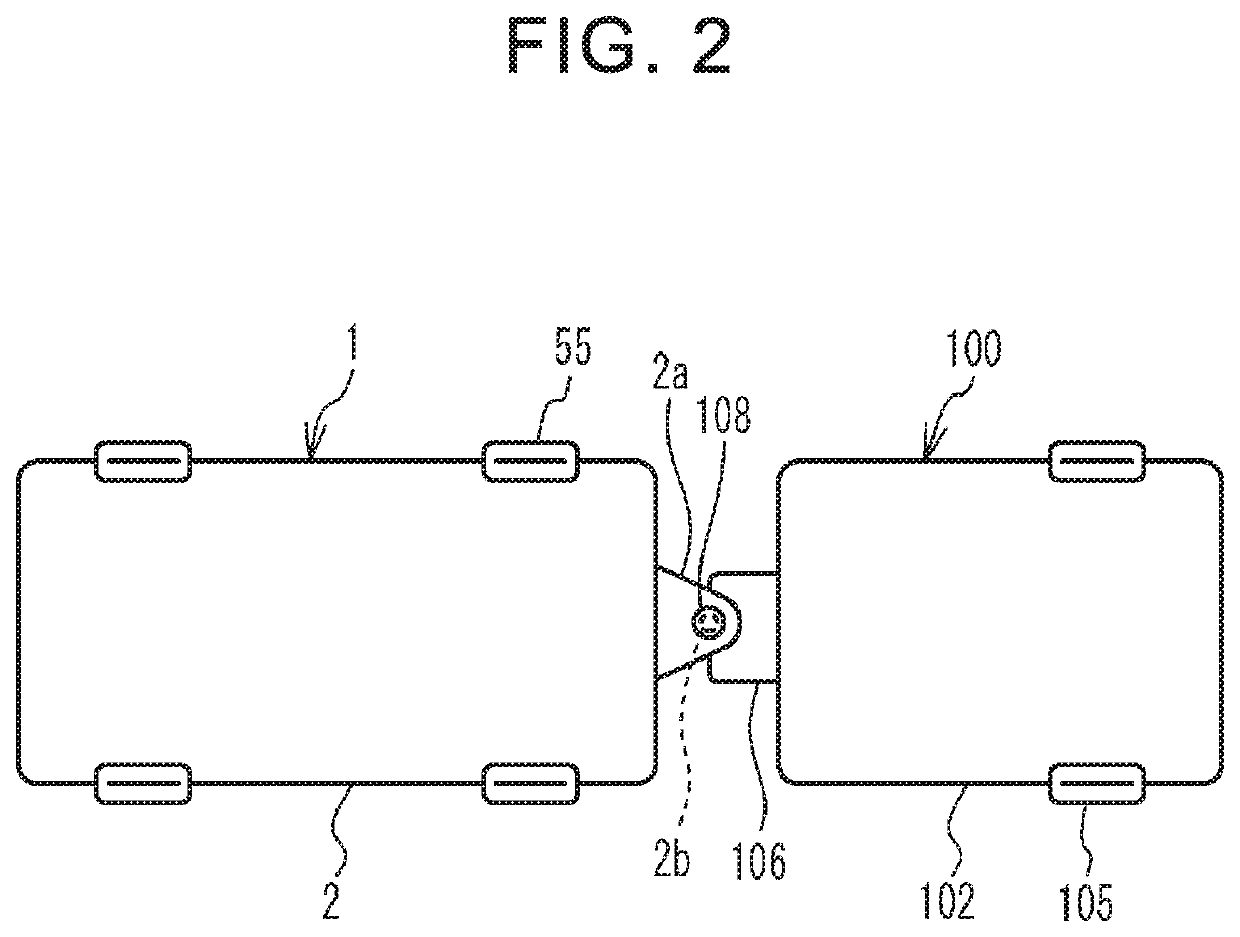

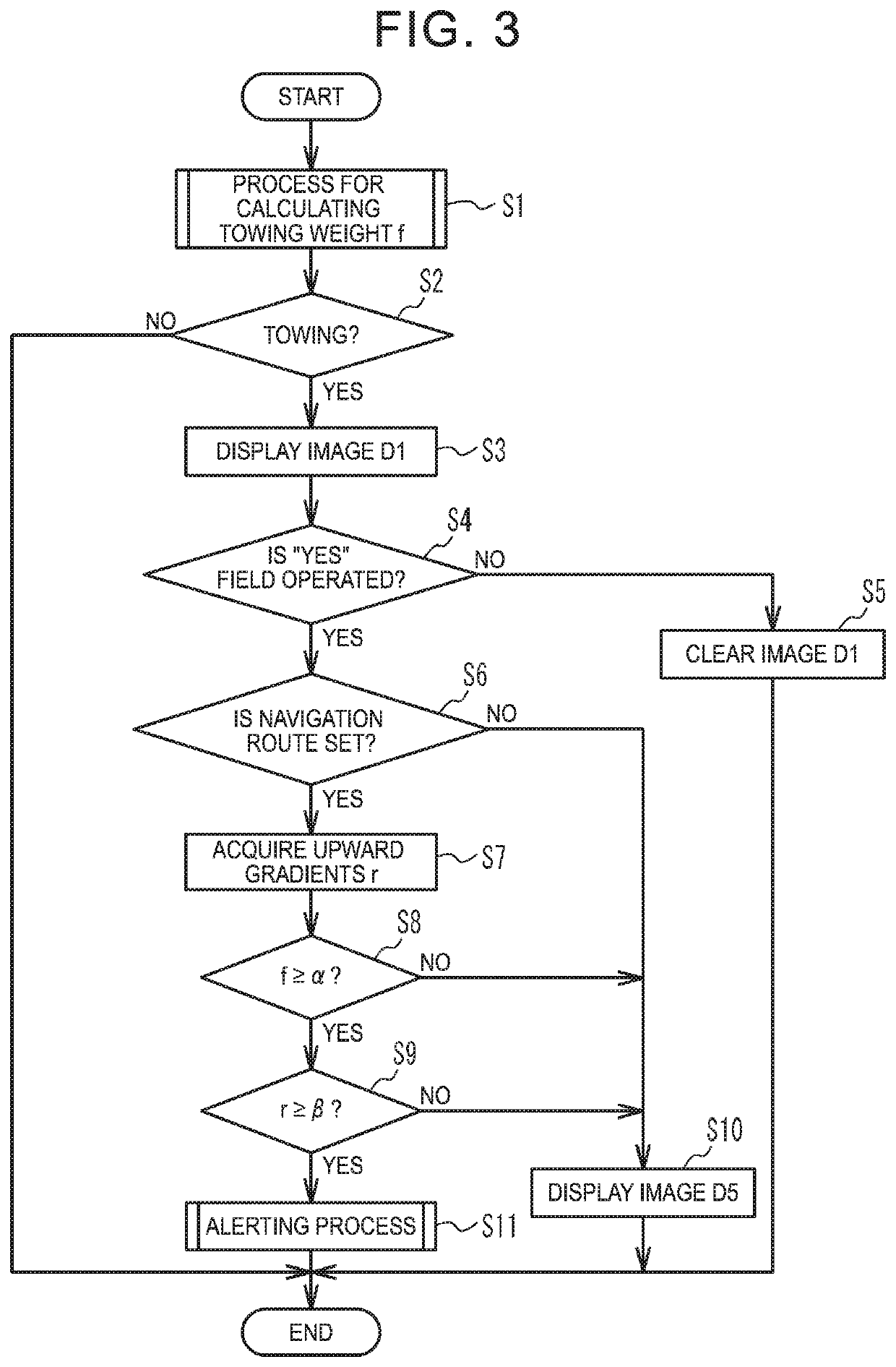

Control device for fuel cell vehicle and fuel cell vehicle

ActiveUS20210170910A1Reduce the temperatureIncrease fuel temperatureInstruments for road network navigationPropulsion by batteries/cellsFuel cellsControl theory

A control device for a fuel cell vehicle includes a power limiter limiting power of a fuel cell when a temperature correlation value correlated to a temperature of the fuel cell indicates that the temperature is equal to or higher than a temperature threshold, a calculation unit calculating a weight of a towed vehicle, a gradient acquirer acquiring upward gradients at respective points on a planned traveling route, a predictor predicting whether the power of the fuel cell is limited when the fuel cell vehicle is traveling along the planned traveling route in a towing travel state, and a controller issuing, when the predictor predicts that the power of the fuel cell is limited, an alert that a vehicle speed of the fuel cell vehicle is expected to decrease when the fuel cell vehicle is traveling along the planned traveling route in the towing travel state.

Owner:TOYOTA JIDOSHA KK

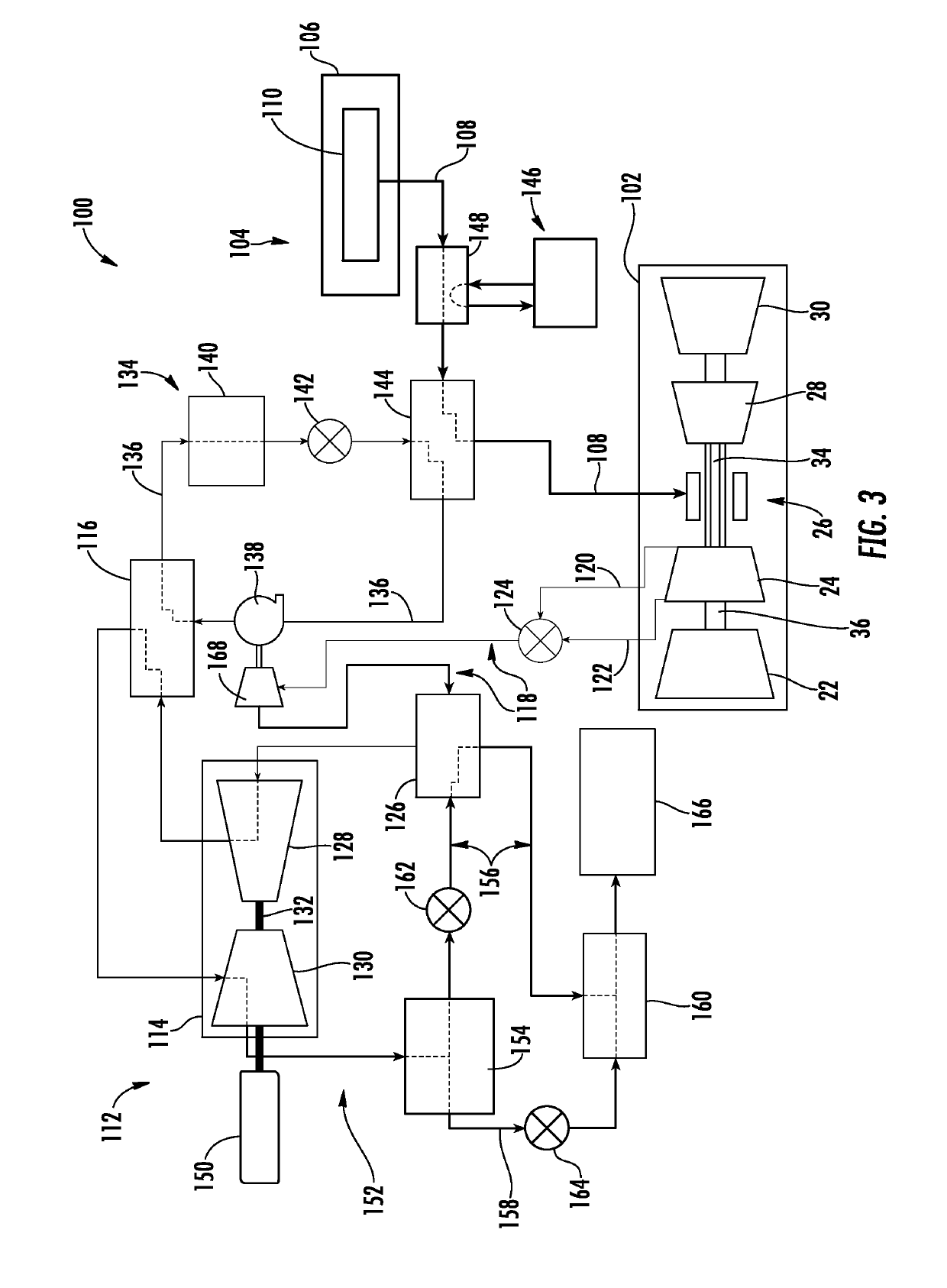

Engine and coolant system control systems and methods

ActiveUS10329995B1Reduce componentsReduce the valueLiquid coolingCoolant flow controlControl systemFuel tank

A coolant control system of a vehicle includes a coolant pump that pumps coolant to a heat exchanger. A diesel exhaust fluid (DEF) injector injects a DEF into an exhaust system and receives coolant output from the heat exchanger. A fuel heat exchanger transfers heat between coolant and fuel flowing through the fuel heat exchanger. An engine control module is configured to determine a first requested speed for DEF injector cooling, determine a second requested speed for fuel cooling, and based on at least one of the first and second requested speeds, selectively increase at least one of: opening of a valve that controls a flow rate of fuel flowing from the fuel rail to the fuel tank, a flow rate of fuel from fuel injectors of an engine to the fuel tank, and a target speed of the coolant pump.

Owner:GM GLOBAL TECH OPERATIONS LLC

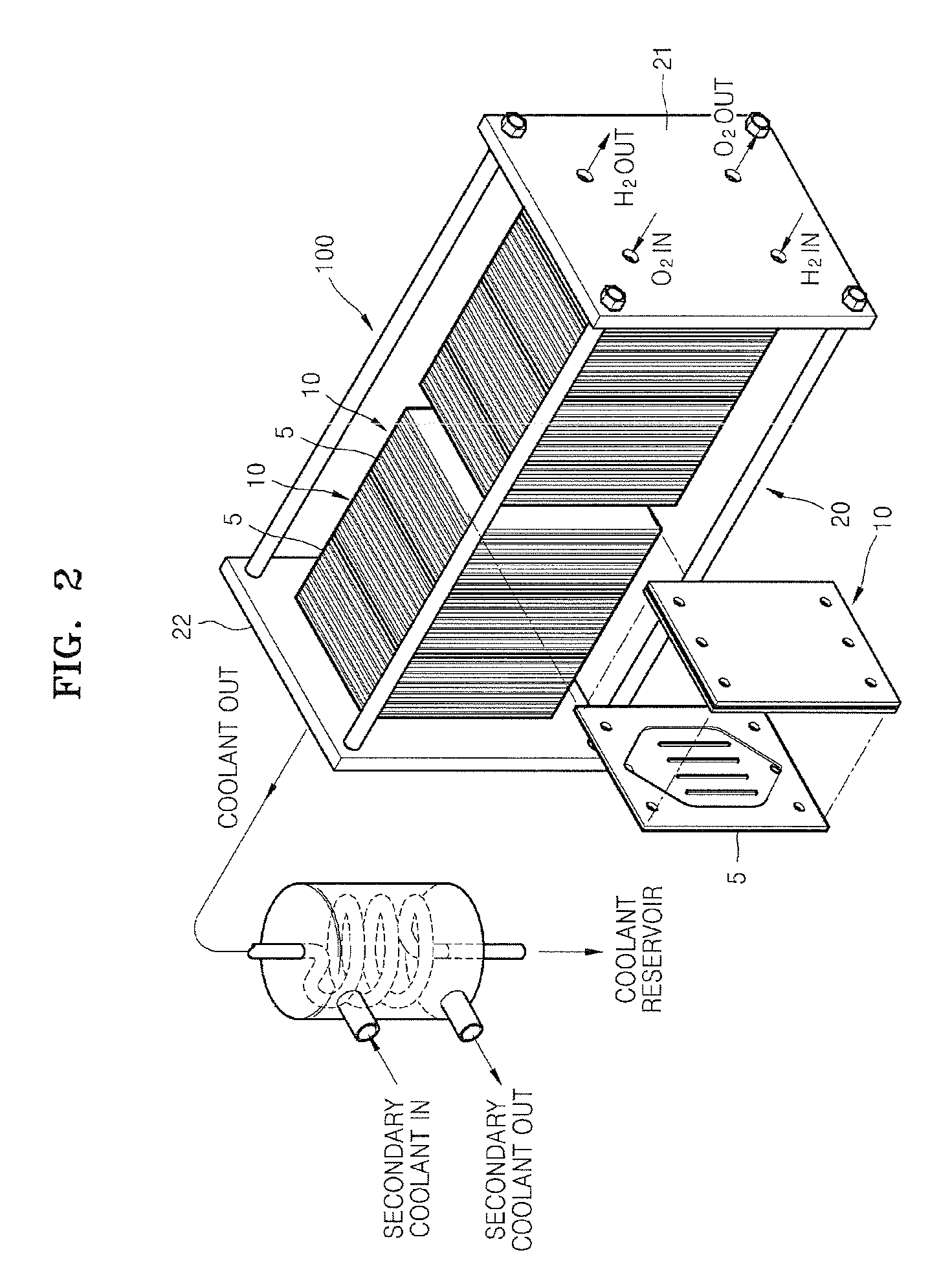

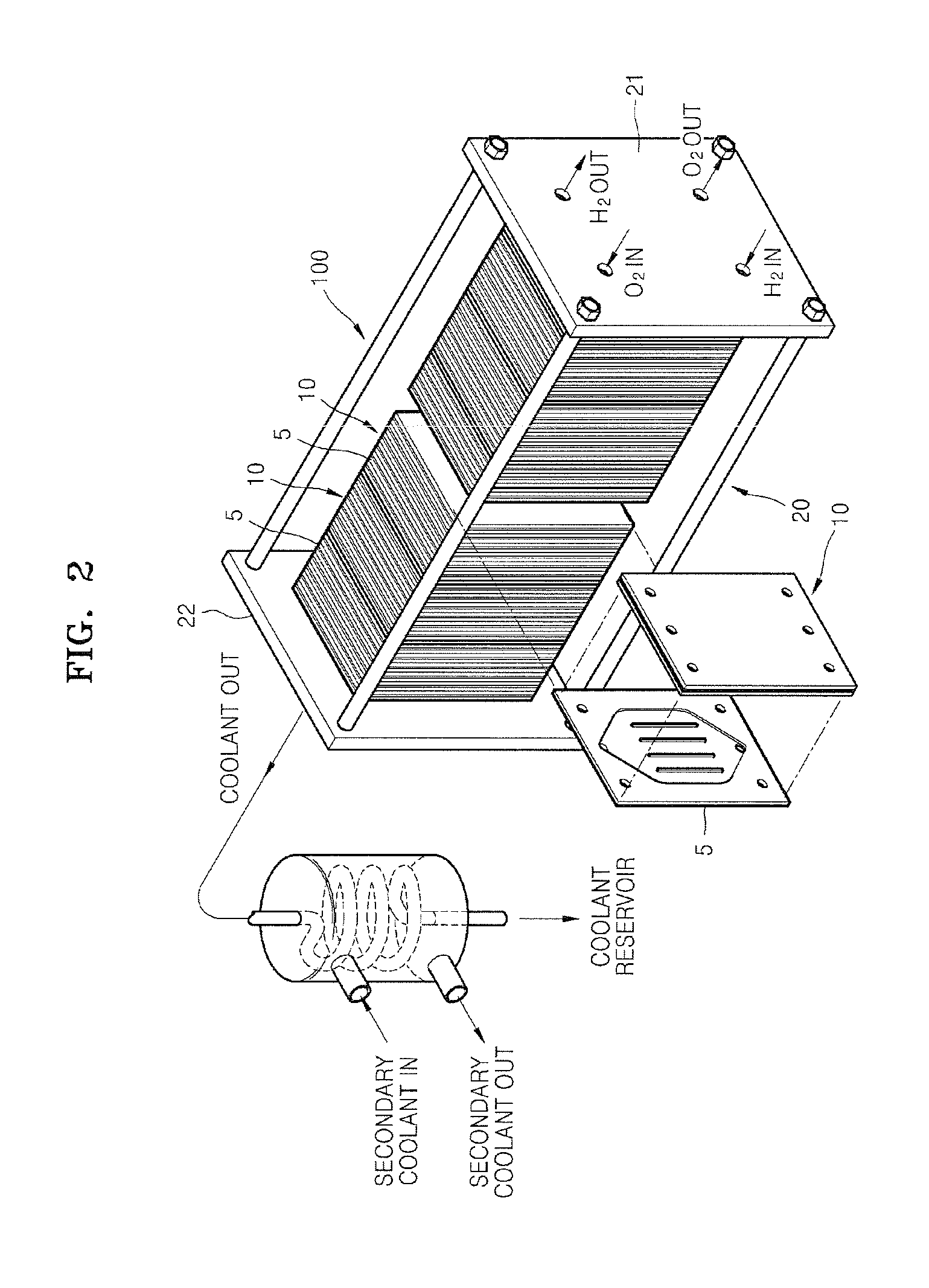

Method of rapidly increasing internal temperature of a fuel cell stack during starting of fuel cell system

ActiveUS8343677B2Increase fuel temperatureFuel cells groupingFuel cell auxillariesPolymer electrolytesFuel cells

A method of starting a polymer electrolyte membrane fuel cell (PEMFC) stack by rapidly increasing its temperature. The PEMFC stack includes: a first flow line connected to cooling plates; a second flow line connected to the cooling plates; a coolant reservoir; a heat exchanger; a by-pass line; a heating element; a first valve installed between the first flow line and the heat exchanger; and a second valve that selectively connects the coolant reservoir, the second flow line, and the by-pass line. The method of starting a PEMFC stack includes: closing the first valve and controlling the second valve so that the second flow line and the by-pass line are connected to each other, and the coolant in the coolant reservoir is not connected to the second flow line and the by-pass line; and heating the coolant in the by-pass line.

Owner:SAMSUNG ELECTRONICS CO LTD

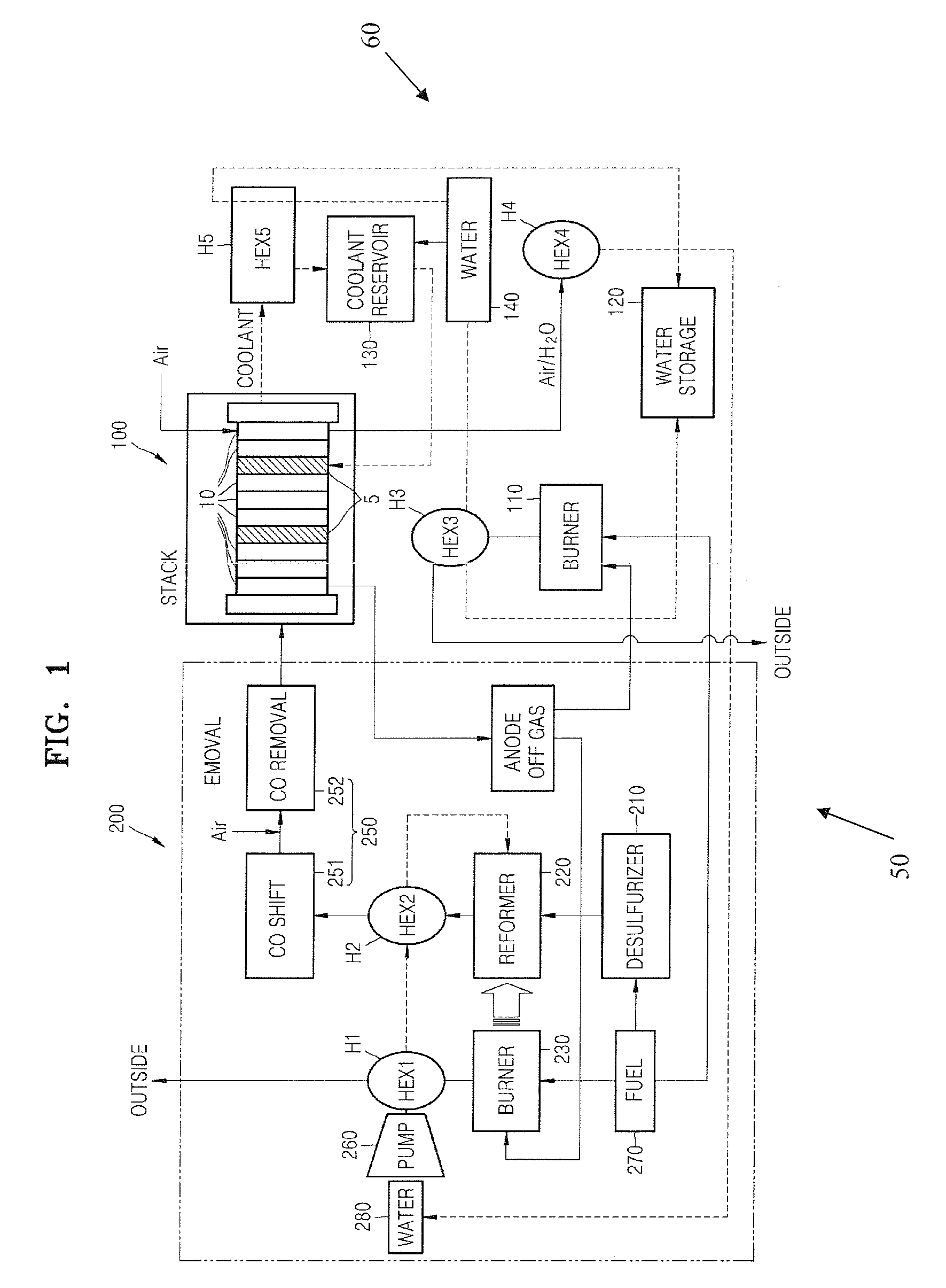

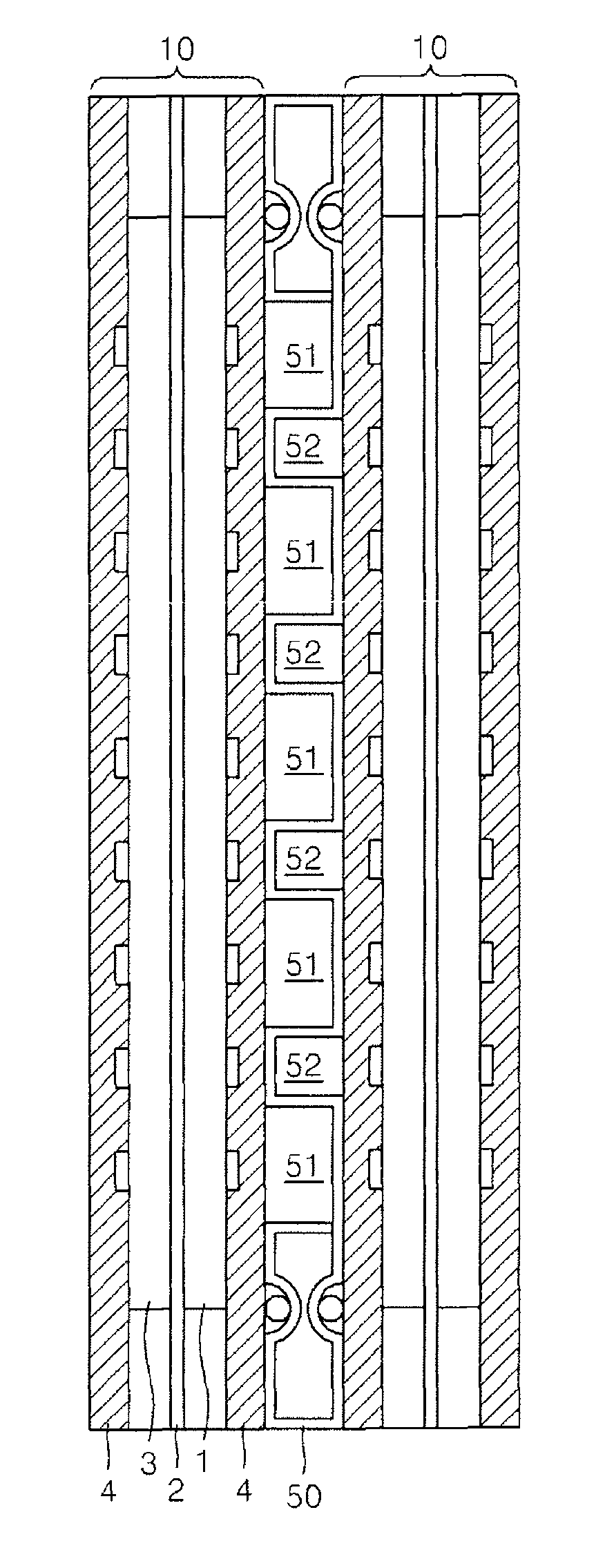

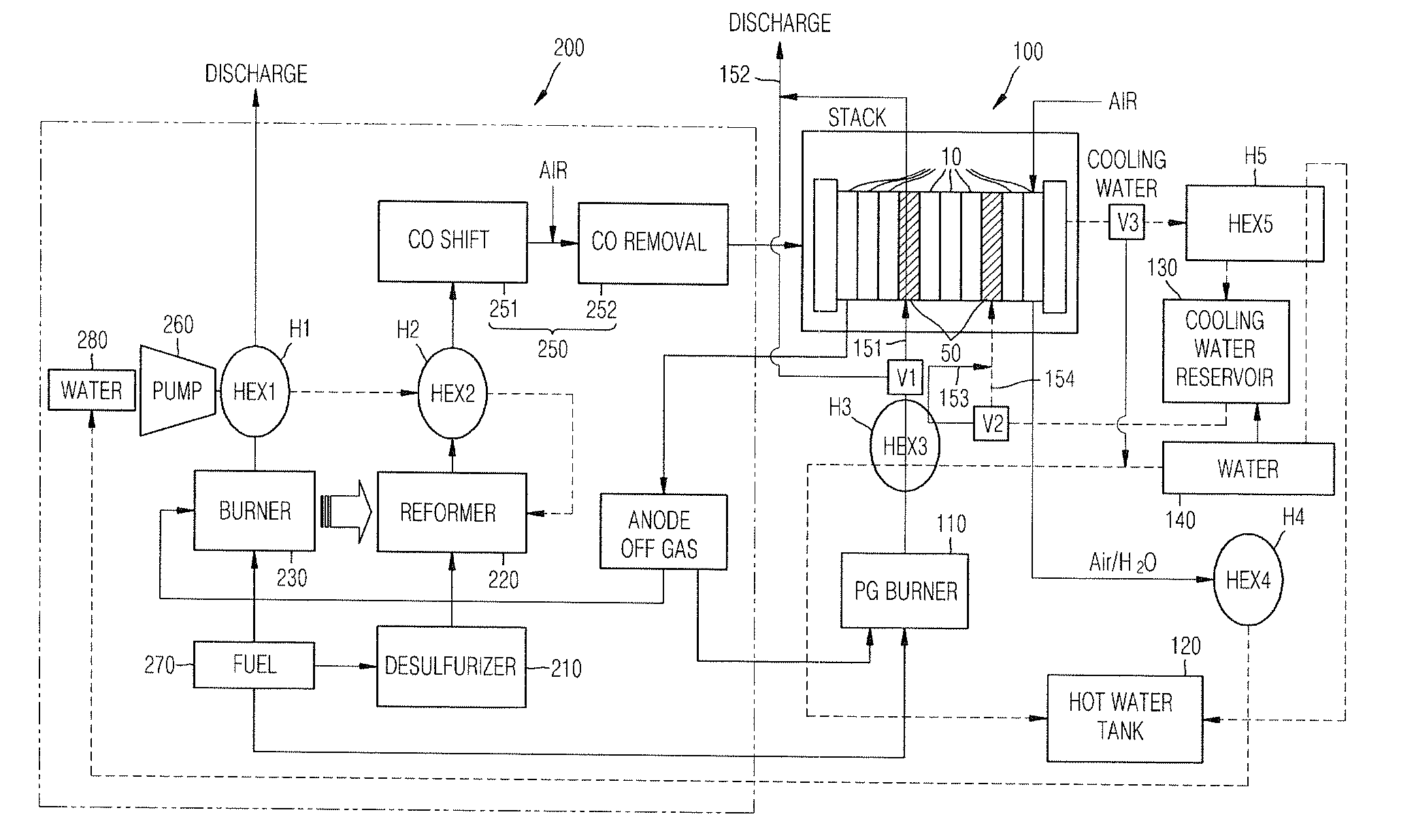

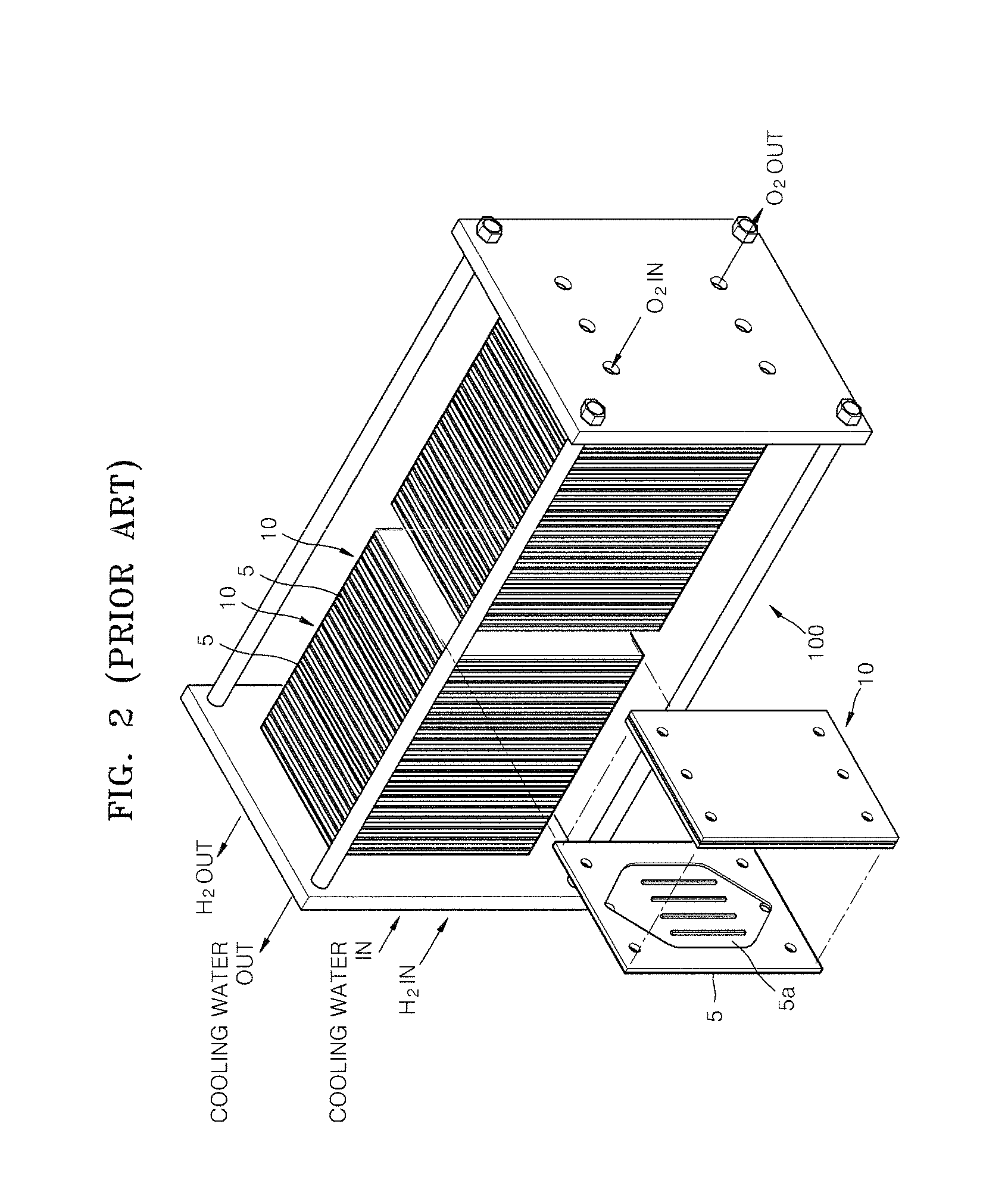

Fuel cell system for promptly increasing temperature of fuel cell stack during start up operation of the fuel cell system and method of managing the fuel cell system

InactiveUS8512904B2Increase fuel temperatureIncrease temperatureFuel cells groupingRegenerative fuel cellsFuel cellsCombustor

A fuel cell system a includes a cooling water temperature raising unit that raises the temperature of a fuel cell stack by passing discharge gas of a process burner or hydrogen gas of a fuel processing unit and cooling water that is heated by the discharge gas of the process burner through flow paths formed on opposing surfaces of cooling separators formed of a metal and installed between a plurality of cells in the stack. Thus in the fuel cell system, when the temperature of the stack needs to be rapidly raised, for example, during a start up operation of the fuel cell system, the temperature of the stack can be rapidly raised using discharge gas at a high temperature or combustion heat of hydrogen gas, and heated cooling water, and thereby, significantly reducing the time required for the fuel cell system to be in regular operation.

Owner:SAMSUNG ELECTRONICS CO LTD

Method of starting fuel cell system

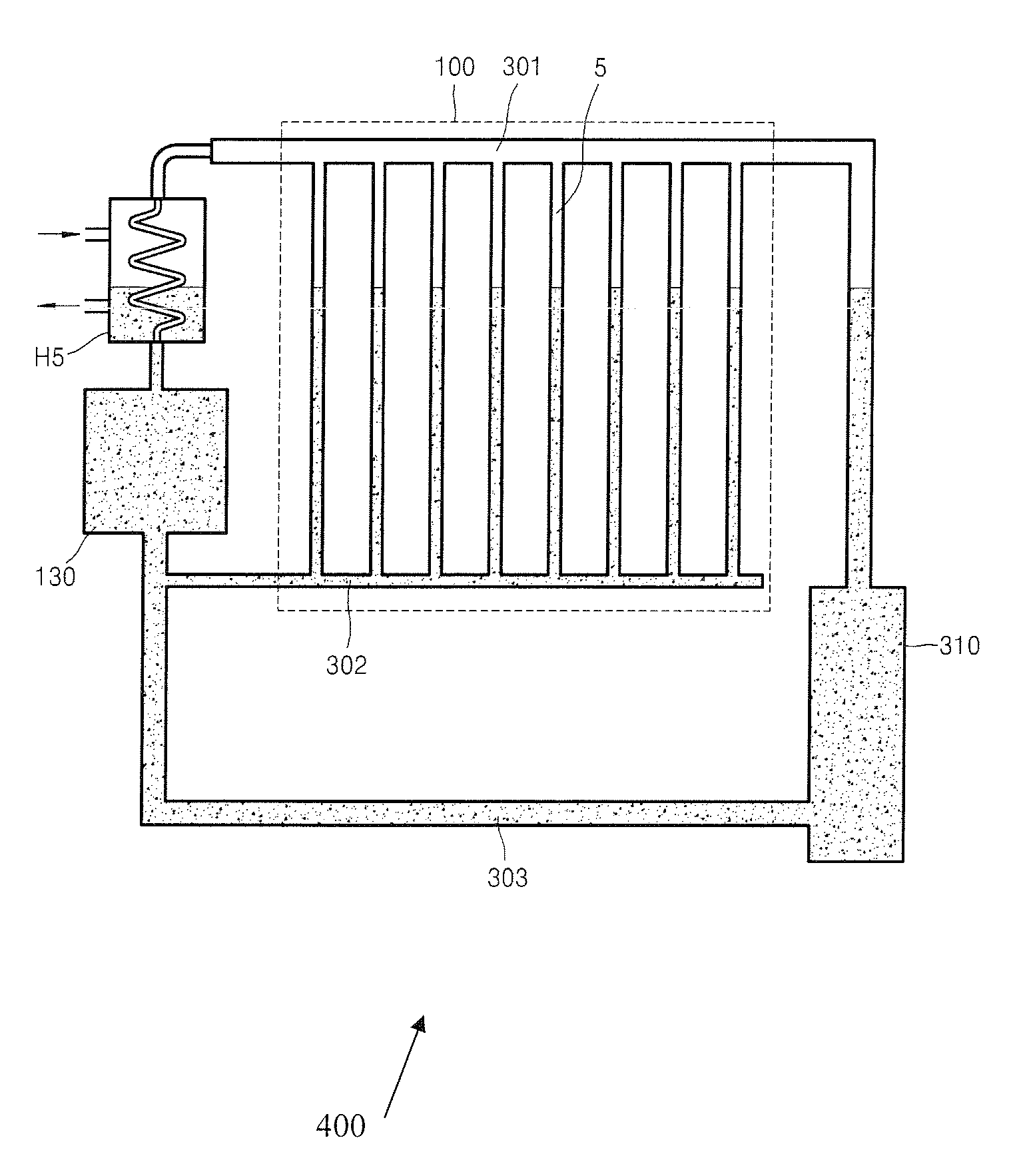

ActiveUS20090035611A1Increase internal temperatureIncrease fuel temperatureFuel cells groupingFuel cell auxillariesPolymer electrolytesFuel cells

Provided is a method of starting a polymer electrolyte membrane fuel cell (PEMFC) stack by rapidly increasing the temperature of the PEMFC stack. The PEMFC stack includes: a first flow line that is connected to upper parts of cooling plates installed in a plurality of unit cells of the PEMFC stack; a second flow line that is connected to lower parts of the cooling plates; a coolant reservoir installed between the first flow line and the second flow line; a heat exchanger installed between the first flow line and the coolant reservoir; a by-pass line that connects a point between the coolant reservoir and the second flow line, to the first flow line; a heating element that heats coolant in the by-pass line; a first valve installed between the first flow line and the heat exchanger; and a second valve that selectively connects the coolant reservoir, the second flow line, and the by-pass line. The method of starting a PEMFC stack includes: closing the first valve and controlling the second valve so that the second flow line and the by-pass line are connected to each other, and the coolant in the coolant reservoir is not connected to the second flow line and the by-pass line; and increasing the temperature of the PEMFC stack by heating the coolant in the by-pass line, using the heating element.

Owner:SAMSUNG ELECTRONICS CO LTD

Fuel cell system and managing method thereof

InactiveUS20080176114A1Increase temperatureIncrease fuel temperatureFuel cells groupingRegenerative fuel cellsFuel cellsCombustor

A fuel cell system a includes a cooling water temperature raising unit that raises the temperature of a fuel cell stack by passing discharge gas of a process burner or hydrogen gas of a fuel processing unit and cooling water that is heated by the discharge gas of the process burner through flow paths formed on opposing surfaces of cooling separators formed of a metal and installed between a plurality of cells in the stack. Thus in the fuel cell system, when the temperature of the stack needs to be rapidly raised, for example, during a start up operation of the fuel cell system, the temperature of the stack can be rapidly raised using discharge gas at a high temperature or combustion heat of hydrogen gas, and heated cooling water, and thereby, significantly reducing the time required for the fuel cell system to be in regular operation.

Owner:SAMSUNG ELECTRONICS CO LTD

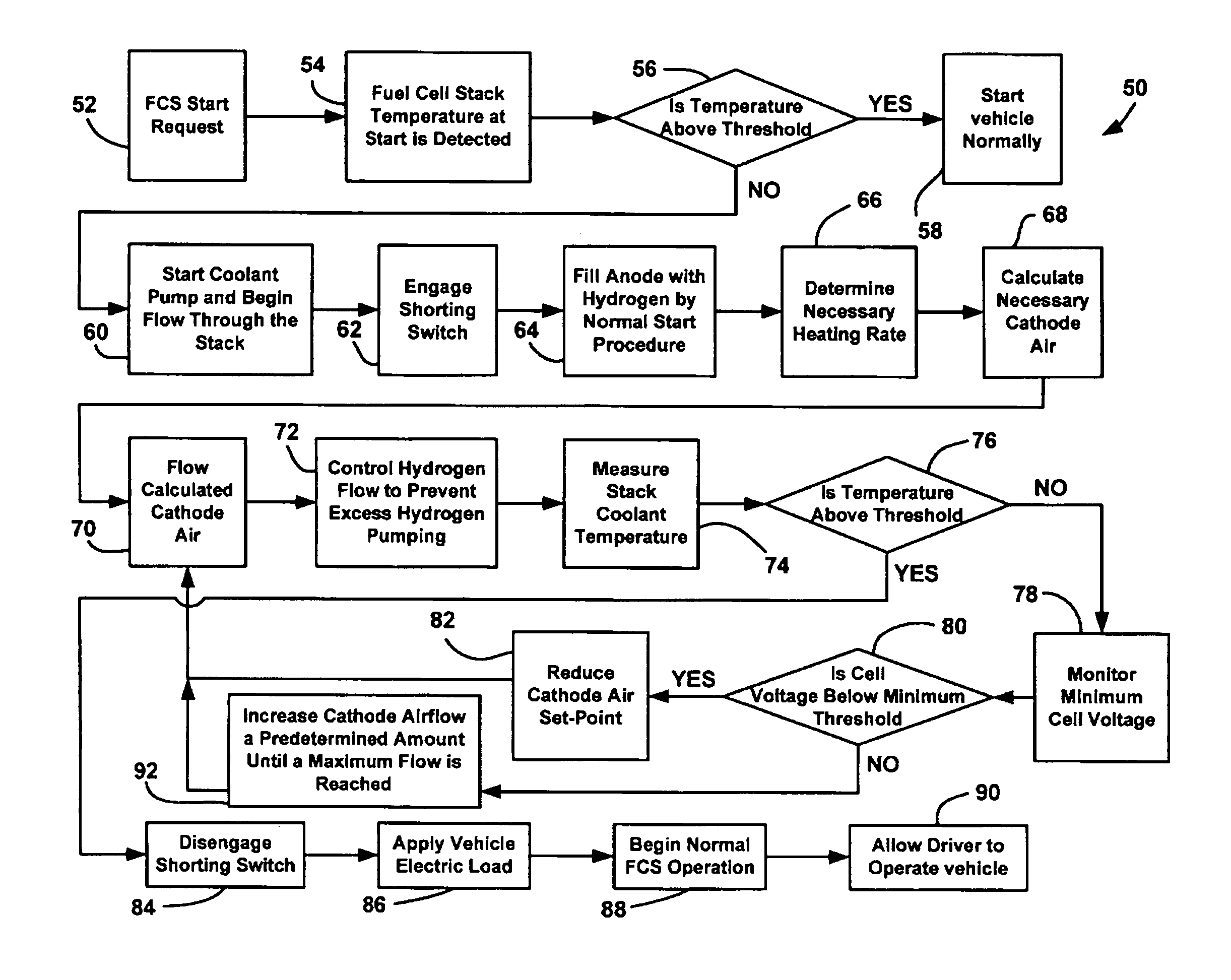

Fuel cell stack used as coolant heater

ActiveUS9034530B2Increase fuel temperatureIncrease temperatureFuel cell auxillariesFuel cellsThermal threshold

A system and method for increasing the temperature of a fuel cell stack quickly, especially at cold stack start-up. The method includes determining whether the fuel cell stack is below a first predetermined temperature threshold, and, if so, starting a cooling fluid flow through the stack and engaging a shorting circuit across the stack to short circuit the stack and cause the stack to operate inefficiently. The method then determines a desired heating rate of the fuel cell stack and calculates a cathode airflow to the fuel cell stack based on the desired heating rate. The method reduces the flow of cathode air to the stack if a minimum cell voltage is below a predetermined minimum cell voltage threshold and disengages the shorting circuit and applies vehicle loads to the stack when the stack temperature reaches a predetermined second temperature threshold.

Owner:GM GLOBAL TECH OPERATIONS LLC

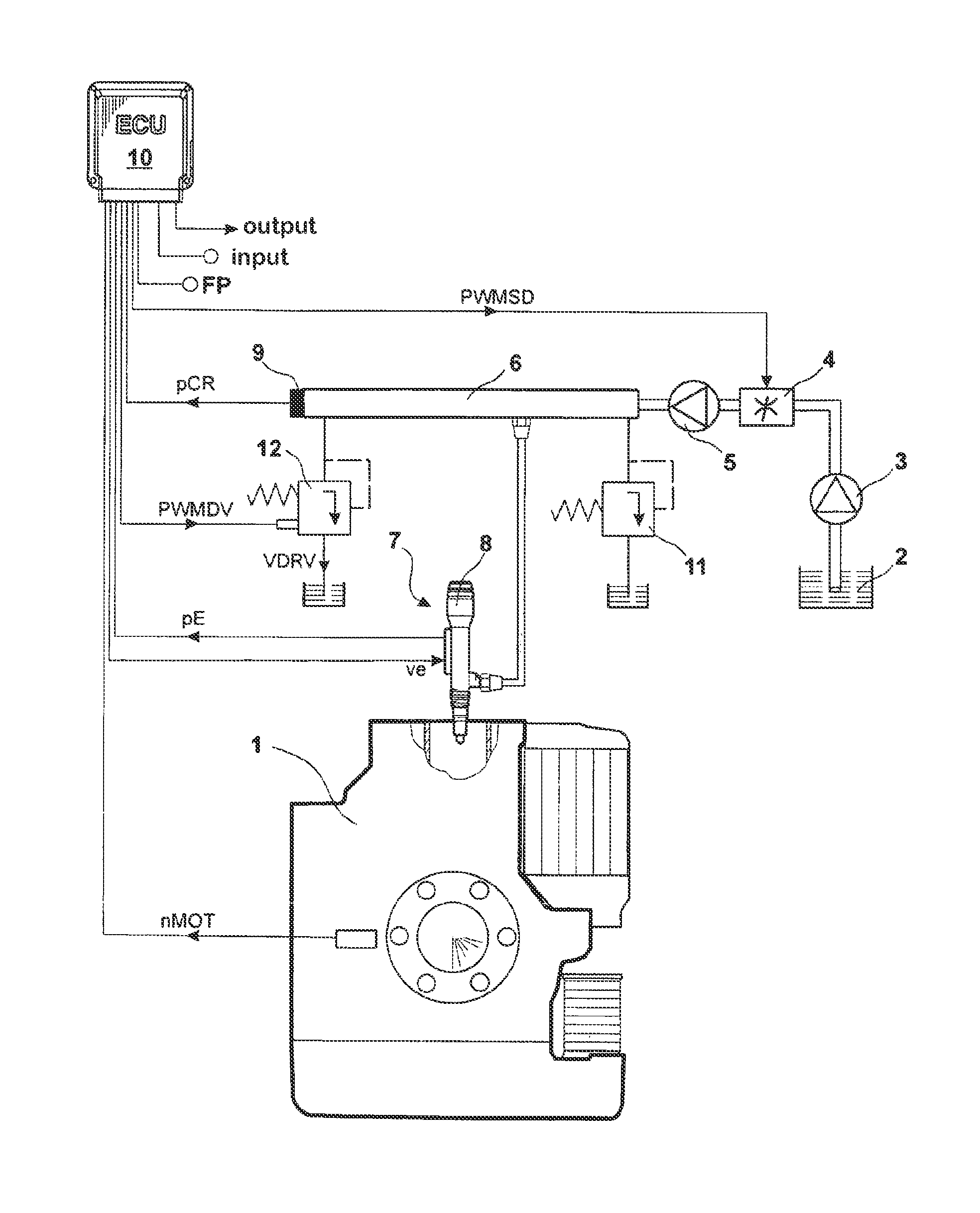

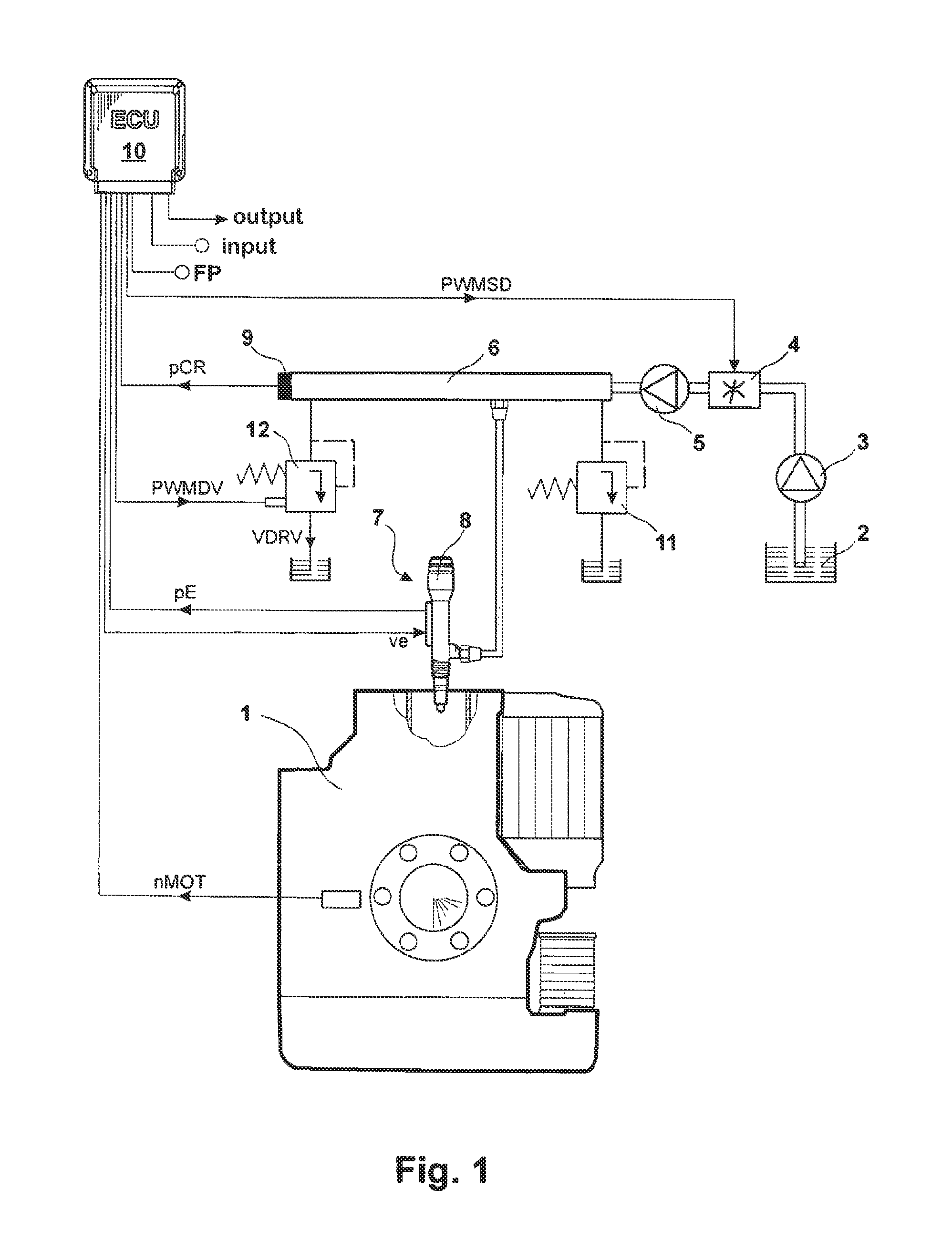

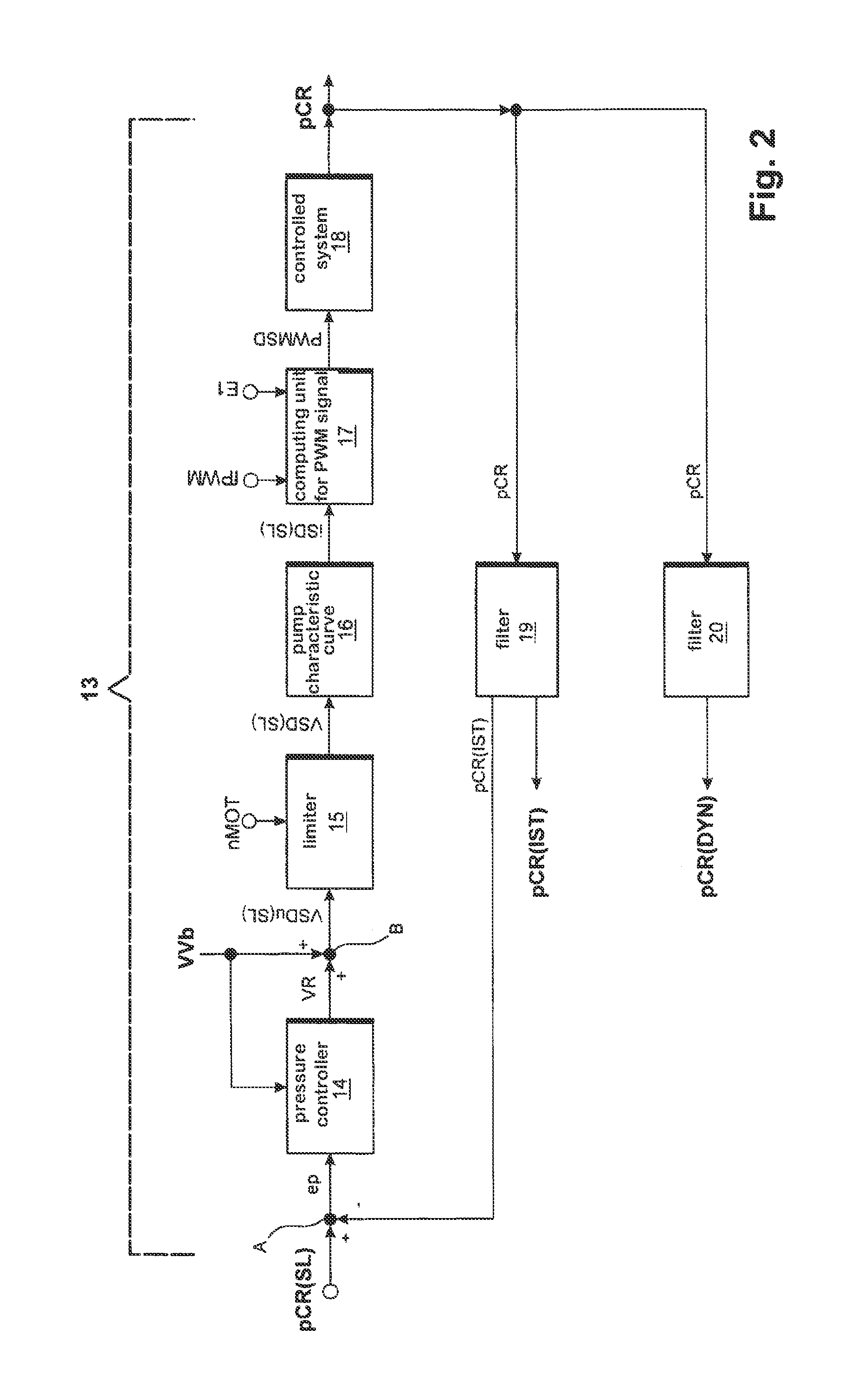

Method for regulating the rail pressure in a common rail injection system of an internal combustion engine

ActiveUS8855889B2Optimize stability behaviorOptimize correction timeAnalogue computers for vehiclesElectrical controlRail pressureExternal combustion engine

A method for open-loop and closed-loop control of an internal combustion engine (1) in which the rail pressure (pCR) is controlled via a low pressure-side suction throttle (4), as the first pressure-adjusting element in a rail pressure control loop. A rail pressure disturbance variable (VDRV) is generated to influence the rail pressure (pCR) via a high-pressure side pressure control valve (12), as the second pressure-adjusting element, by which fuel is redirected from the rail (6) into the fuel tank (2). The position of the high-pressure side pressure control valve (12) is determined by a PWM signal (PWMDV), which, when normal mode is set, is calculated as a function of the resulting target volume flow and, when protective mode is set, is temporarily set to a maximum value.

Owner:ROLLS ROYCE SOLUTIONS GMBH

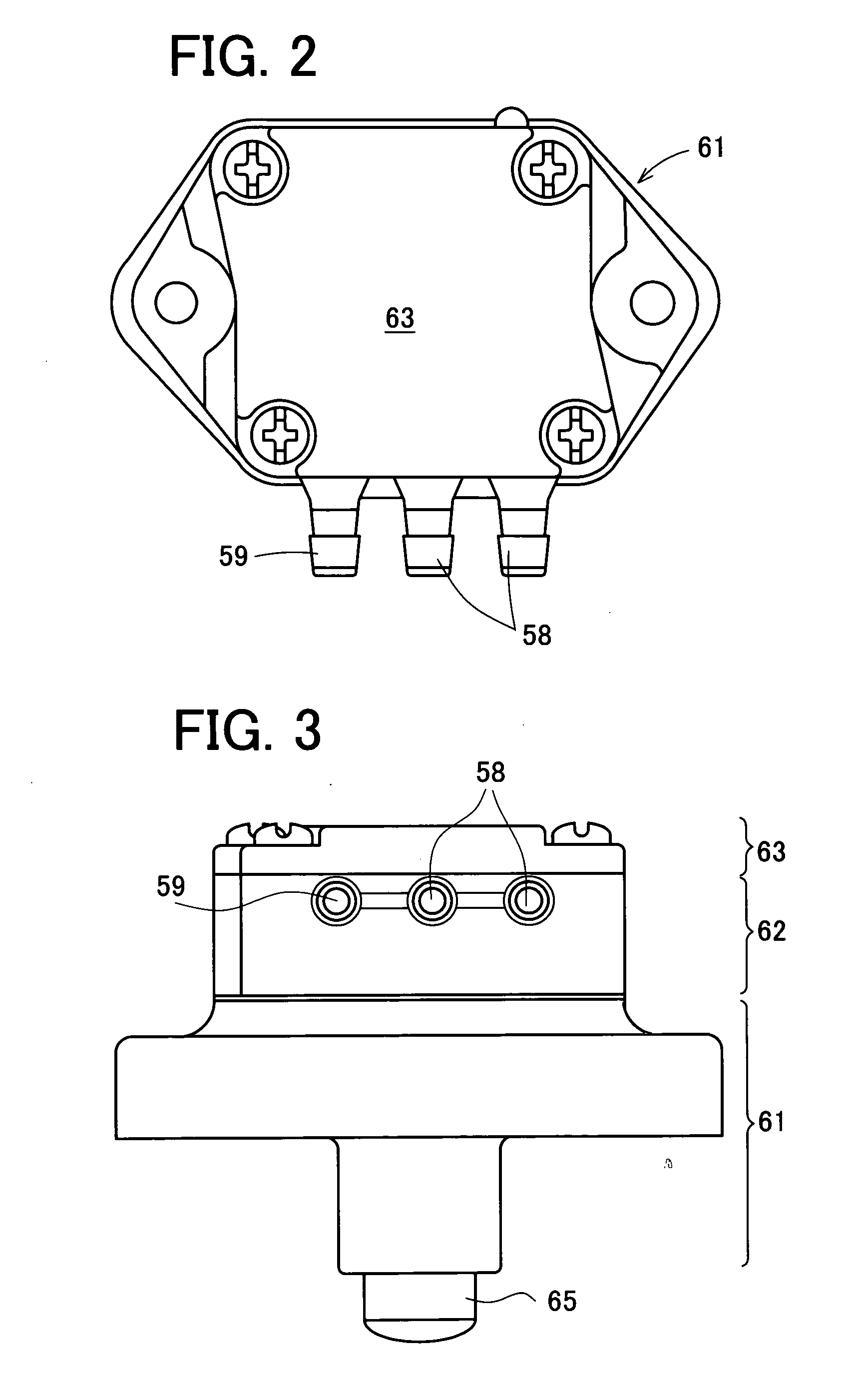

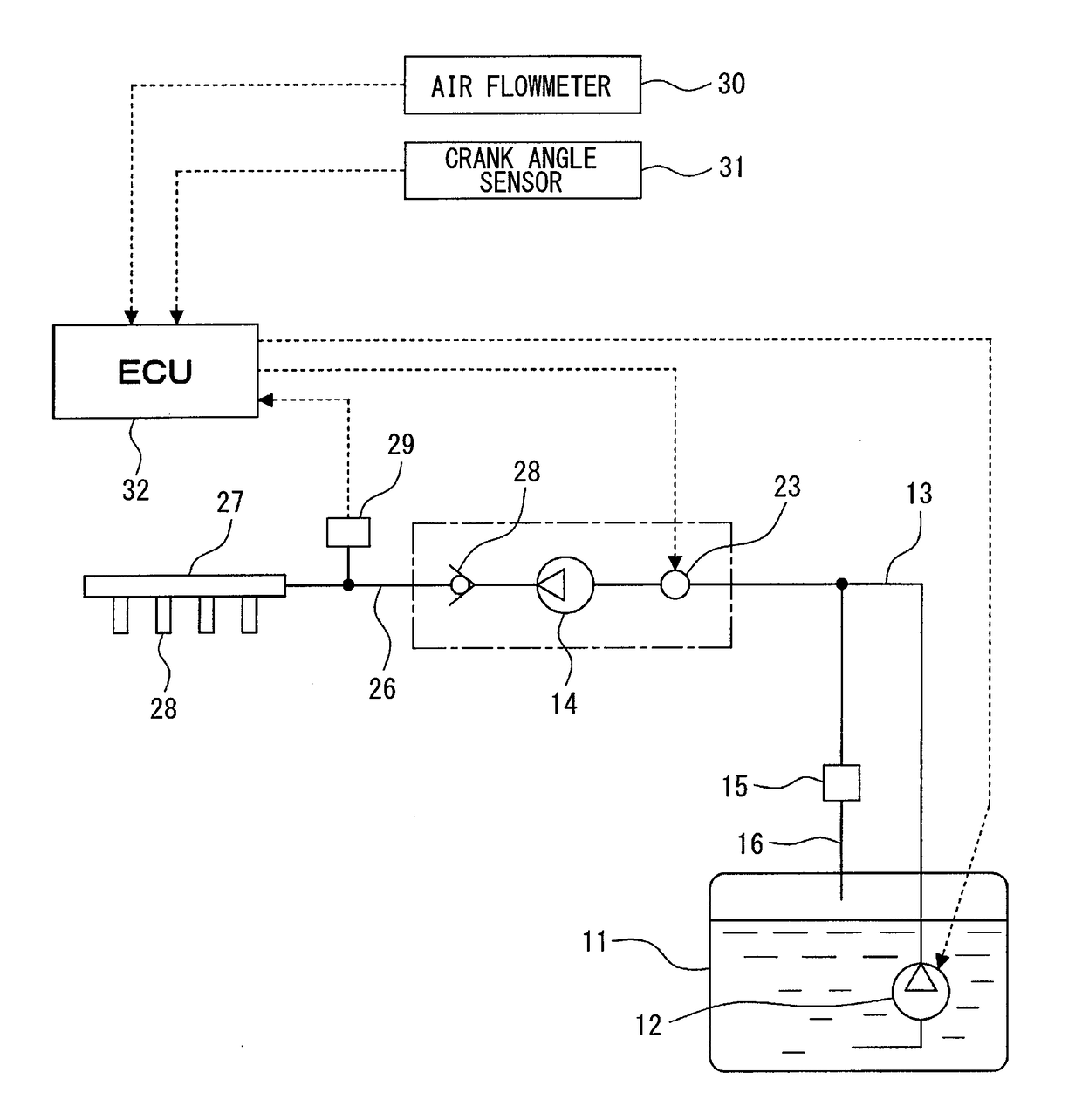

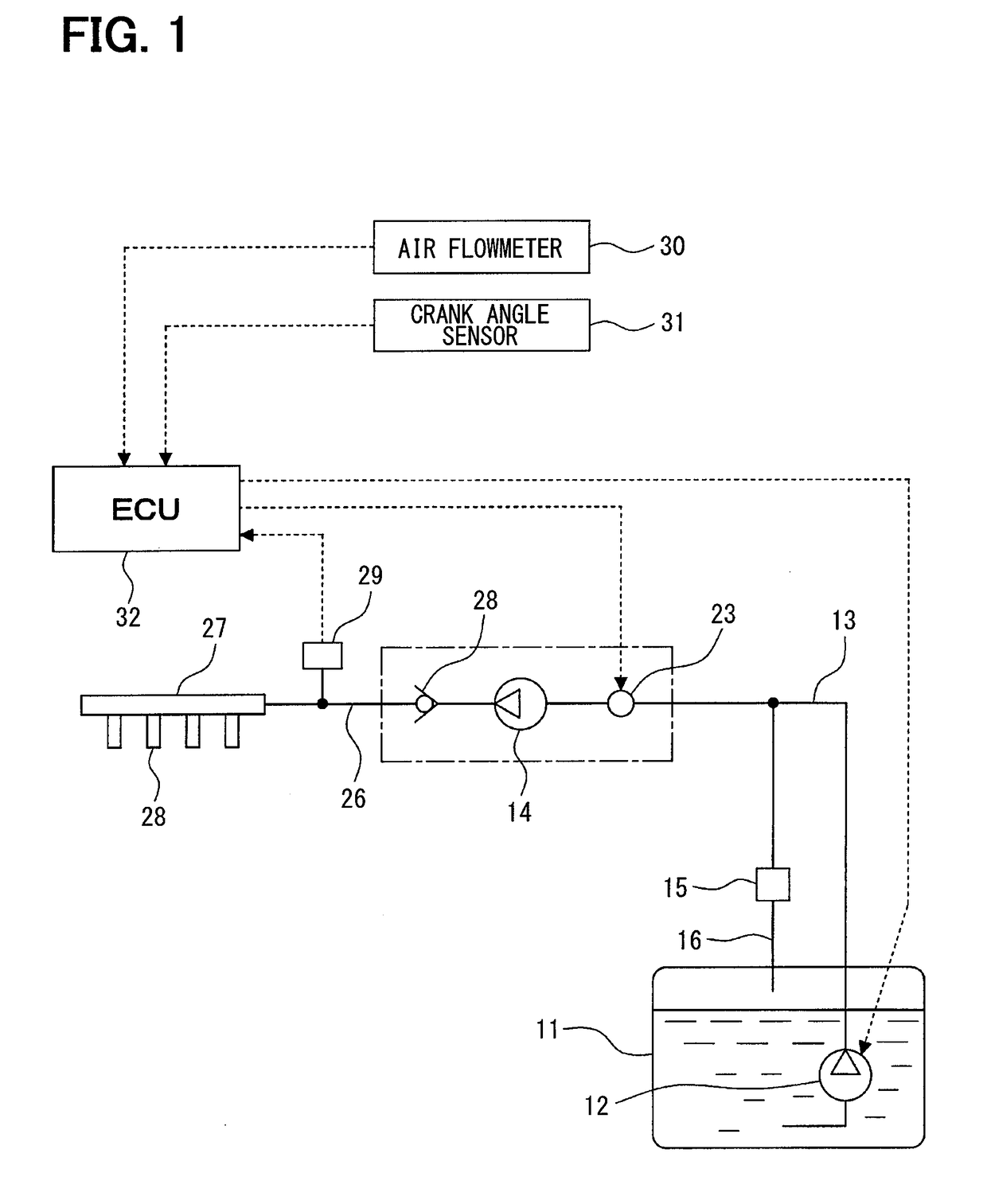

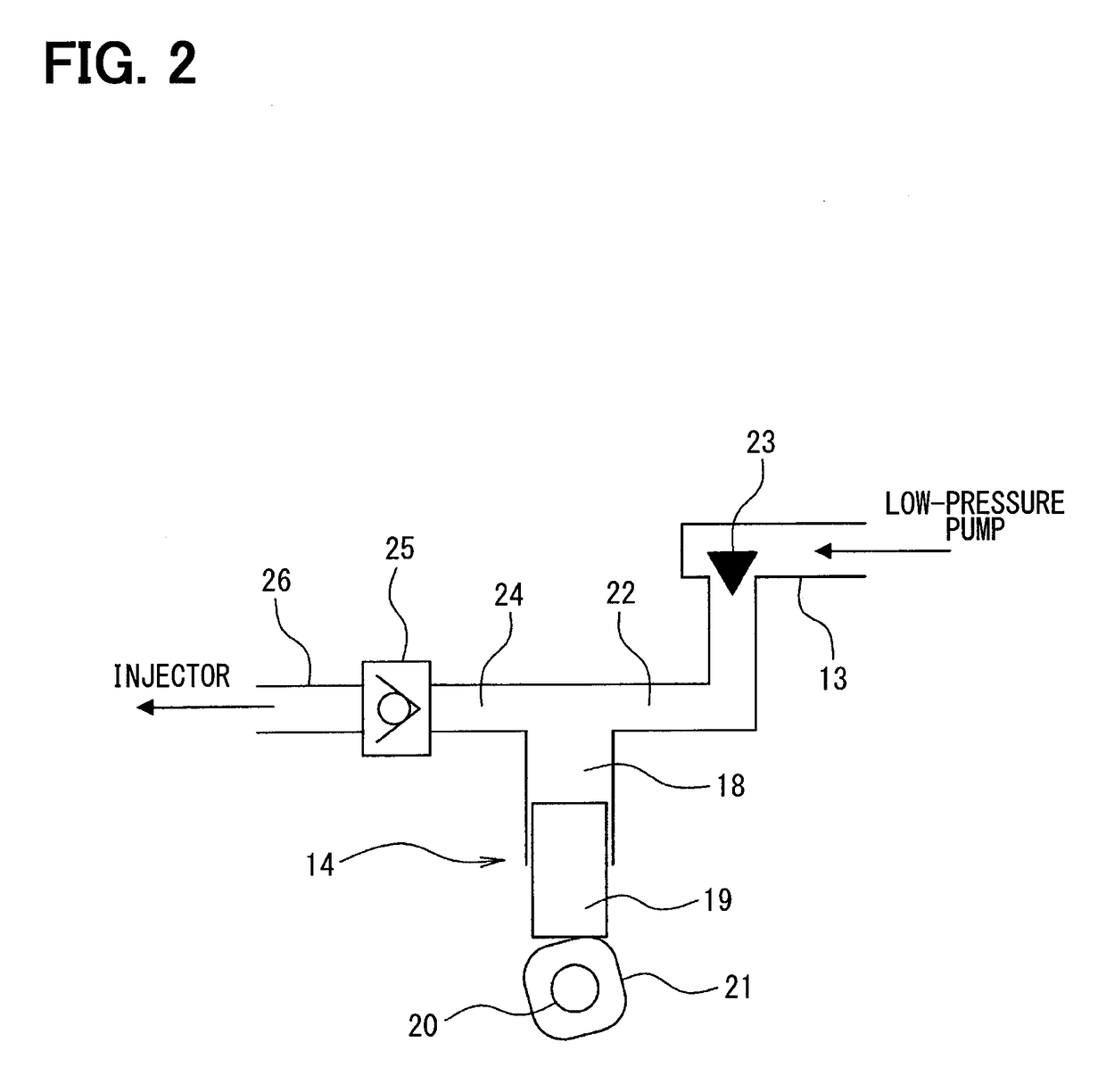

High-pressure pump control device for internal combustion engine

ActiveUS20180128188A1Prolong lifeImprove dynamic rangeElectrical controlFuel-injection pumpsEngineeringInternal combustion engine

A high-pressure pump control device is applied to an internal combustion engine including a high-pressure pump supplied with fuel discharged from a low-pressure pump and an injector supplied with fuel discharged from the high-pressure pump. The high-pressure pump control device includes a prediction unit predicting whether a discharge quantity of the high-pressure pump exceeds a discharge quantity of the low-pressure pump and a restricting unit executing a discharge quantity restriction control to restrict a discharge quantity of the high-pressure pump not to exceed a predetermined value when the prediction unit predicts that a discharge quantity of the high-pressure pump exceeds a discharge quantity of the low-pressure pump.

Owner:DENSO CORP

Fuel cell system

InactiveUS8071244B2Increase fuel temperatureFuel cell heat exchangeSolid electrolyte fuel cellsRun time settingFuel cells

A fuel cell system includes a cell stack, a temperature sensor which detects a temperature of the cell stack, an outside air temperature sensor which detects an outside air temperature, and a CPU which controls a process in the fuel cell system. When the temperature of the cell stack is lower than a predetermined temperature, the fuel cell system performs a temperature raising operation of the cell stack by making the concentration of aqueous methanol solution in an aqueous solution tank higher than in a normal operation and by making an output of an aqueous solution pump greater than in the normal operation. The CPU sets a run time for the temperature raising operation based on a detection result from the outside air temperature sensor, a detection result from the temperature sensor, and a run time setting table which is stored in a memory. The fuel cell system is capable of raising a temperature of the fuel cell quickly and stably to the predetermined temperature.

Owner:YAMAHA MOTOR CO LTD

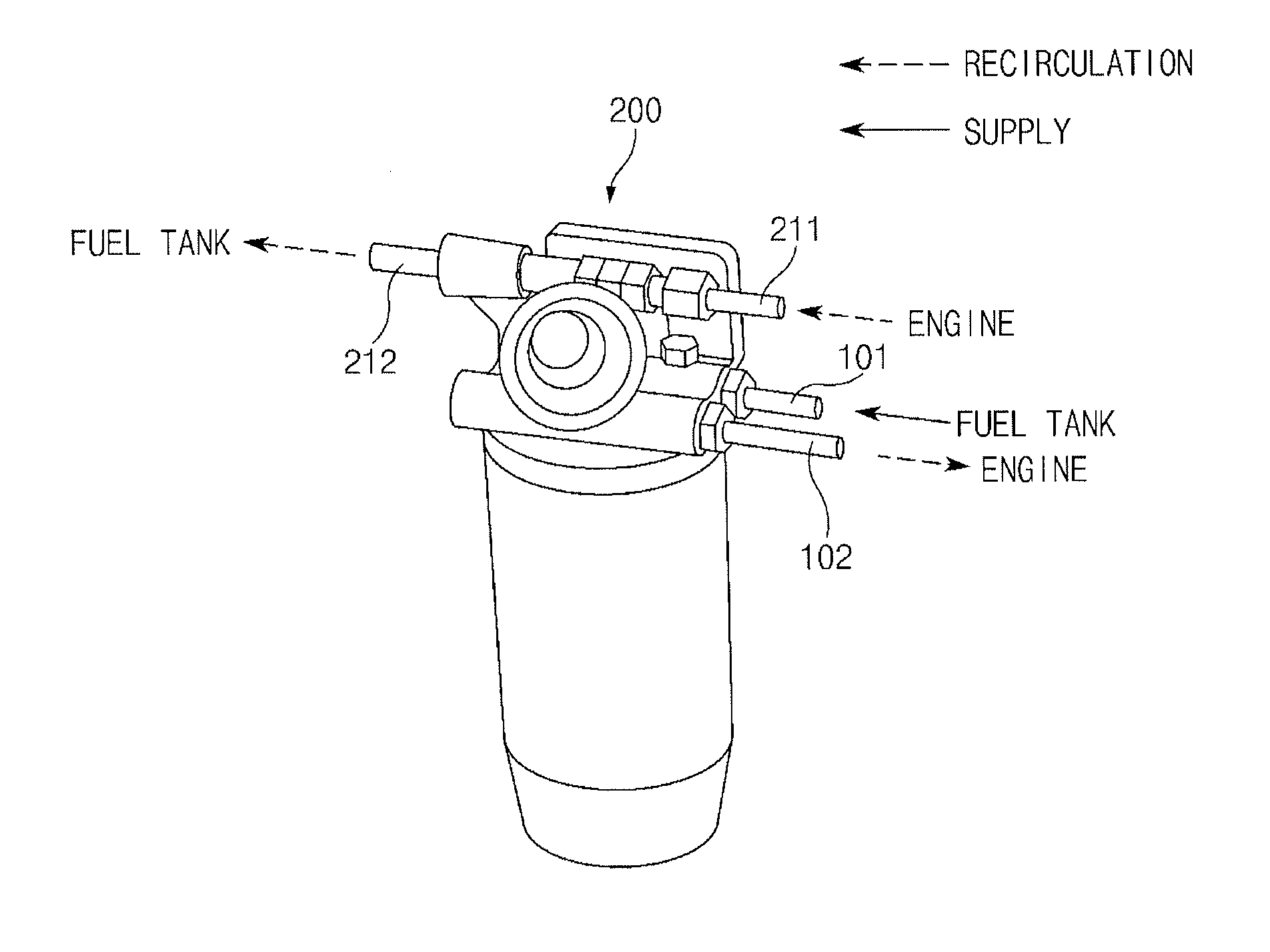

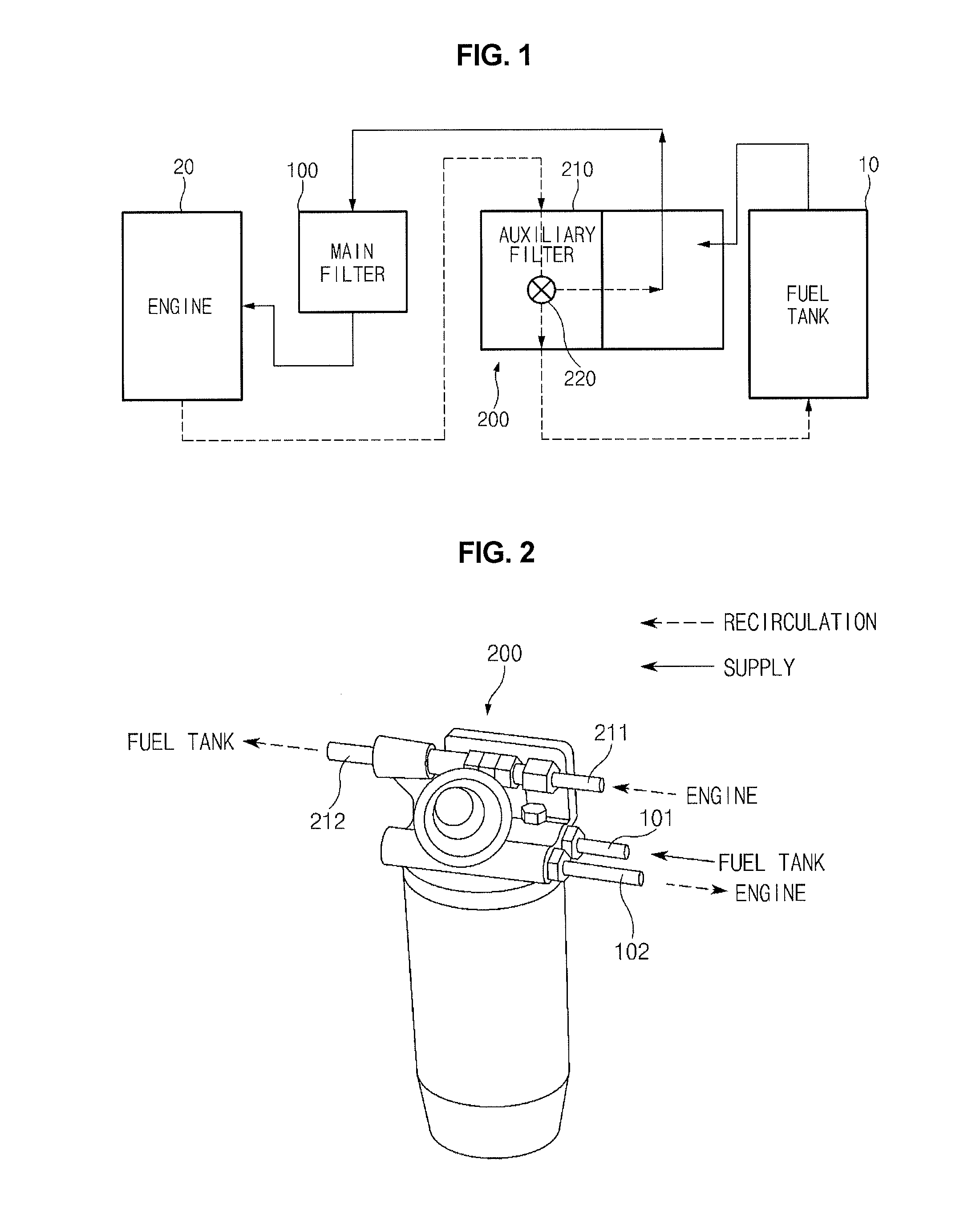

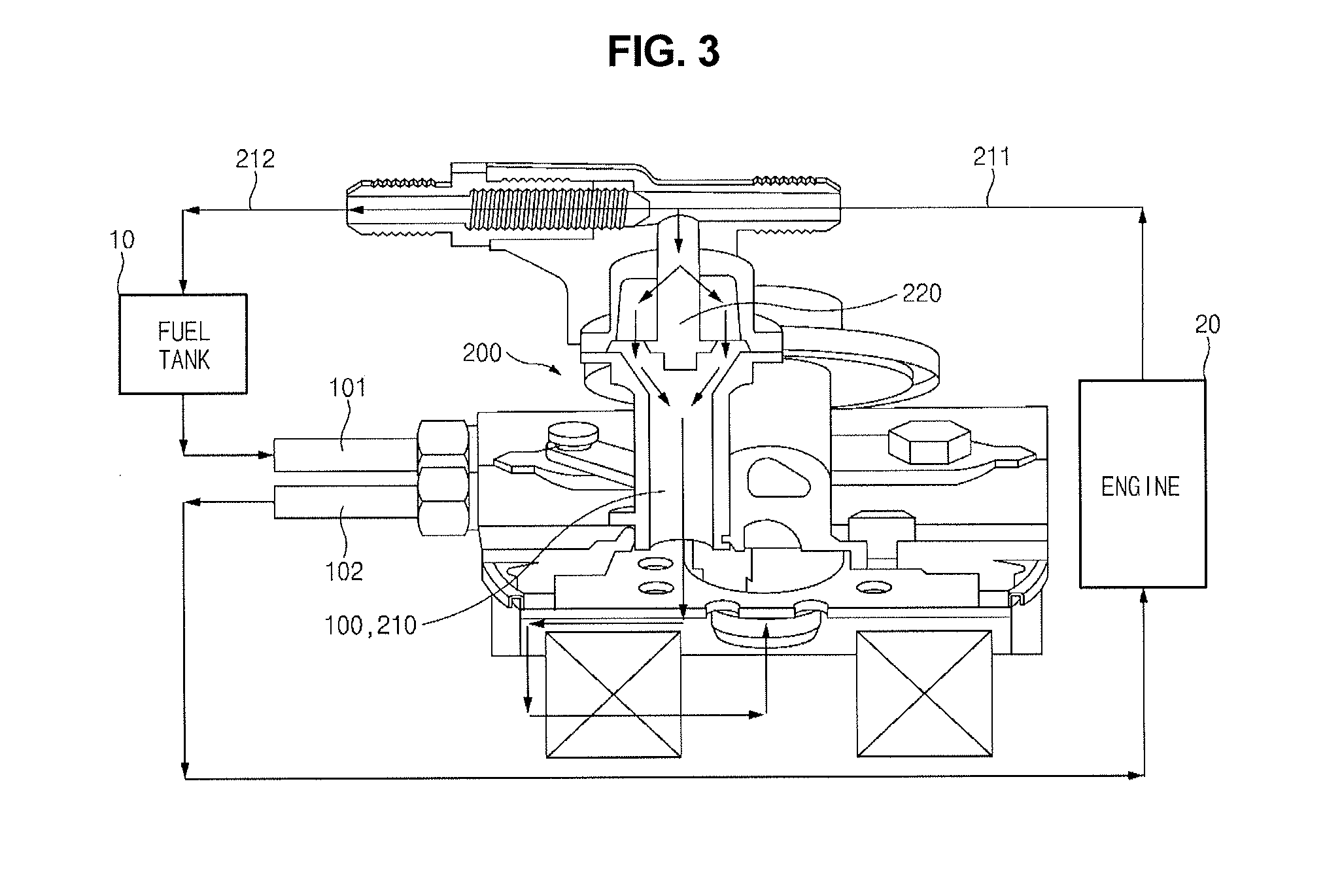

Diesel fuel recirculation device

ActiveUS20160138536A1Improve starting performanceIncrease fuel temperatureMachines/enginesLiquid fuel feedersStart timeFuel tank

A diesel fuel recirculation device may include a fuel tank configured to store and supply diesel fuel, a main filter connected to the fuel tank and filter diesel fuel to supply the filtered diesel fuel to an engine, and a recirculation member provided in the main filter and be resupplied with high temperature fuel from the engine to supply the resupplied high temperature fuel to the fuel tank or the main filter, such that marketability and usage convenience may be improved by increasing a temperature of the fuel using the high temperature fuel resupplied from the engine to shorten a starting time under low temperature conditions.

Owner:HYUNDAI MOTOR CO LTD

Fuel cell cogeneration system

InactiveUS7452618B2Increase fuel temperatureShorten the timeFuel cell auxillariesFuel cell applicationsCogenerationEngineering

A fuel cell cogeneration system includes a fuel cell, a cooling water heat exchanger provided on a cooling water pathway, a stored hot water pathway through which stored hot water that exchanges heat with cooling water flows, a stored hot water tank, a stored hot water controlling device, a stored hot water temperature measuring device, a stored hot water flow rate adjusting device, a flow rate controlling device of controlling the stored hot water flow rate adjusting device and an exhaust gas heat exchanger of exchanging heat between exhaust gas from fuel processing devices and stored hot water. The flow rate controlling device controls the stored hot water adjusting device to reduce the flow rate of stored hot water flowing through the stored hot water pathway when the temperature of stored hot water is a first predetermined temperature or less during the starting of operation of the fuel cell.

Owner:PANASONIC CORP

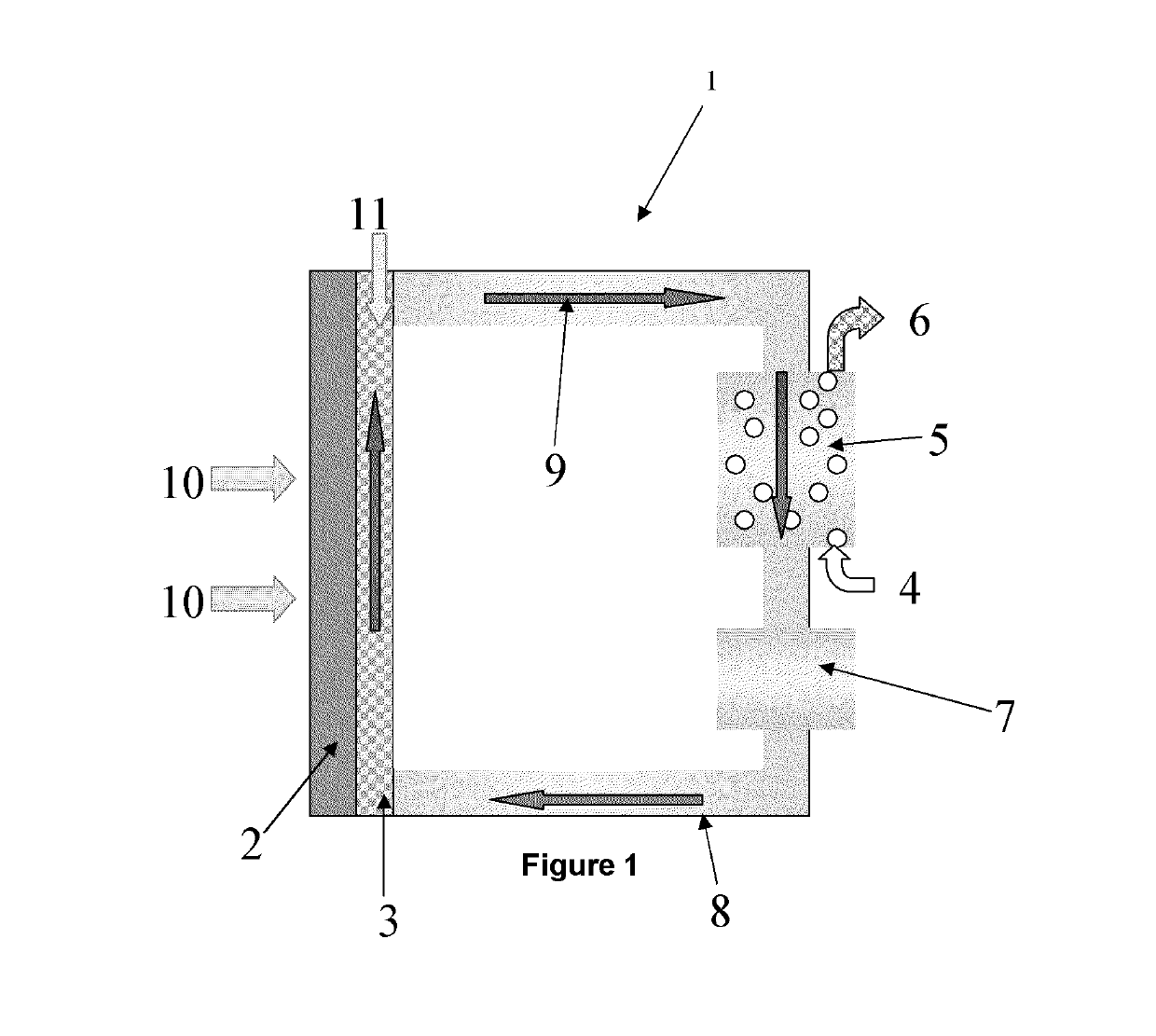

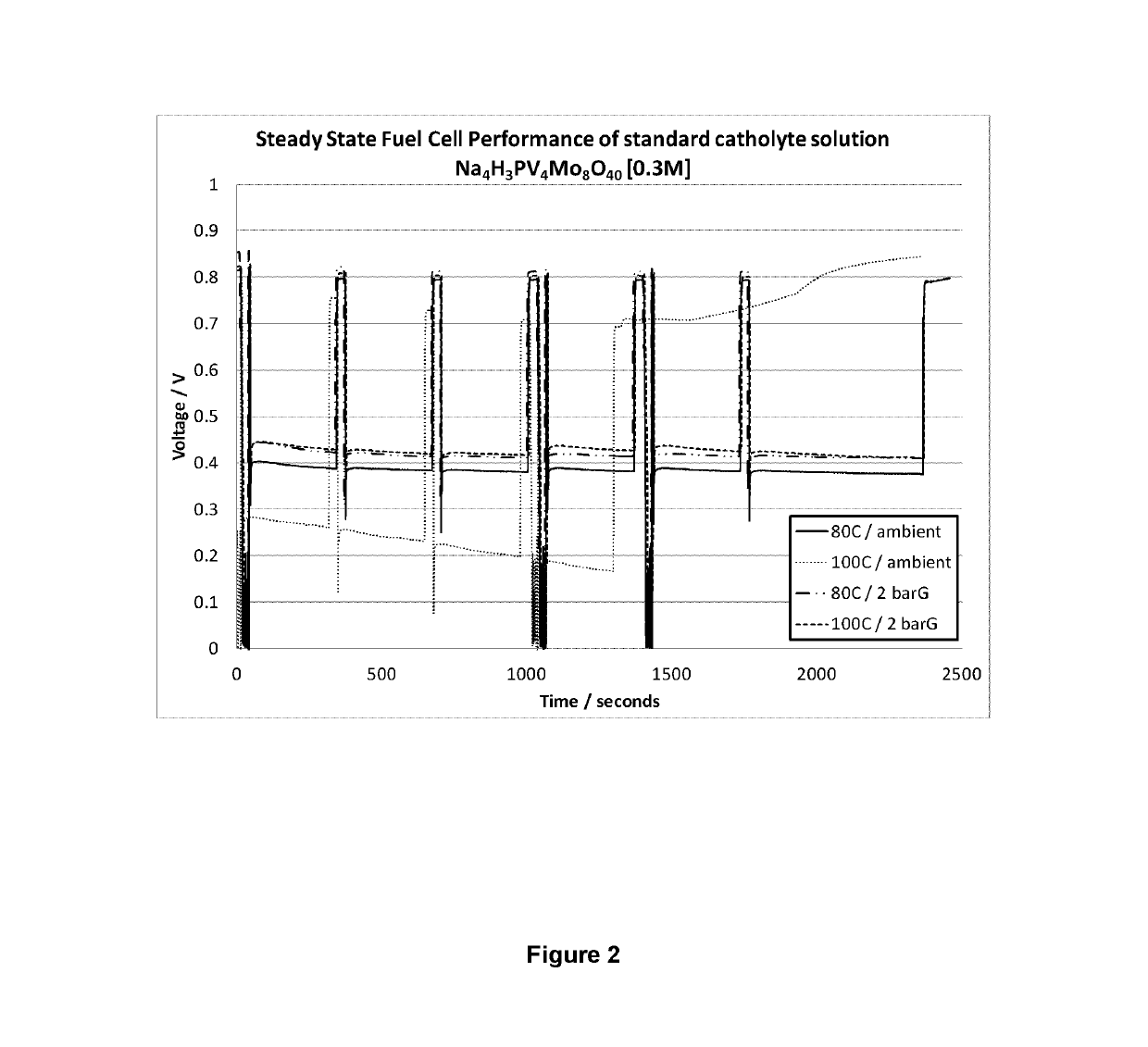

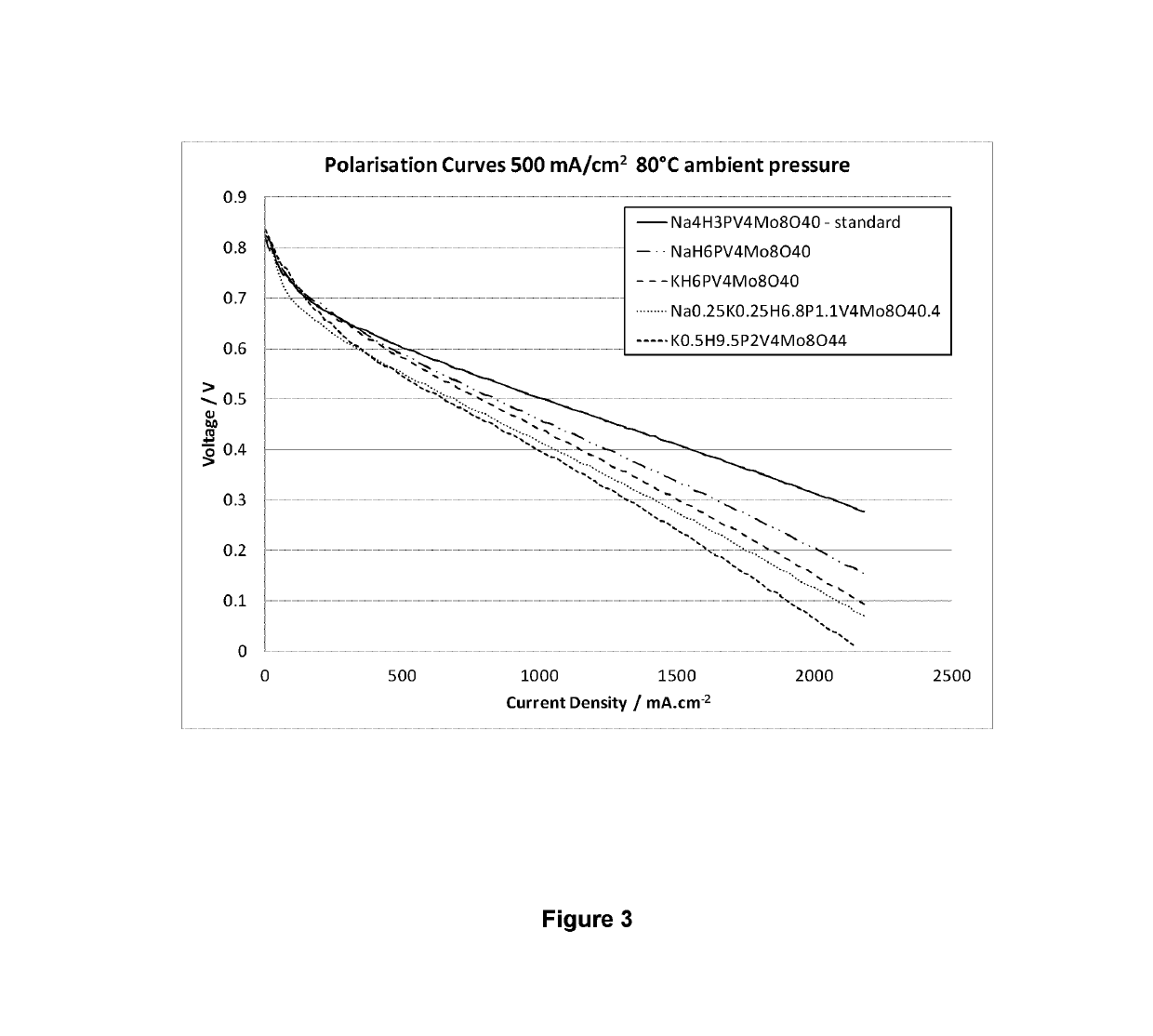

Polyozometallates for use at elevated temperatures and pressures

ActiveUS10468703B2High regeneration rateImprove steady state performanceCell electrodesRegenerative fuel cellsAlkaline earth metalLanthanide

The present invention relates to a redox fuel cell comprising an anode and a cathode separated by an ion selective polymer electrolyte membrane; means for supplying a fuel to the anode region of the cell; means for supplying an oxidant to the cathode region of the cell; means for providing an electrical circuit between the anode and the cathode; a non-volatile catholyte solution flowing in fluid communication with the cathode, the catholyte solution comprising a polyoxometallate redox couple being at least partially reduced at the cathode in operation of the cell, and at least partially re-generated by reaction with the oxidant in a regeneration zone after such reduction at the cathode, the catholyte solution further comprising one or more vanadium species that result from the speciation of the polyoxometallate at an elevated temperature and / or pressure, wherein the polyoxometallate is represented by the formula:Xa[ZbMcOd]wherein X is selected from hydrogen, alkali metals, alkaline earth metals, ammonium, transition metal ions and combinations of two or more thereof; Z is selected from B, P, S, As, Si, Ge, Ni, Rh, Sn, Al, Cu, I, Br, F, Fe, Co, Cr, Zn, H2, Te, Mn and Se and combinations of two or more thereof; M comprises vanadium and optionally one or more of Mo, W, Nb, Ta, Mn, Fe, Co, Cr, Ni, Zn Rh, Ru, TI, Al, Ga, In and other metals selected from the 1st, 2nd and 3rd transition metal series and the lanthanide series and combinations of two or more thereof; a is a number of X necessary to charge balance the [ZbMcOd] anion; b is from 0 to 20; c is from 1 to 40; d is from 1 to 180; X includes an amount of a non-hydrogen cation and the molar ratio of the non-hydrogen cation to vanadium is more than 0 and less than 1.

Owner:UNIVERSITY OF CHESTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com