Fuel cell cogeneration system

a cogeneration system and fuel cell technology, applied in domestic hot water supply systems, heating types, sustainable manufacturing/processing, etc., can solve the problems of shortening the hot water storage means, consumers are incapable of consuming hot water, and hot water may run out with use, so as to inhibit hot water from running out and improve convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

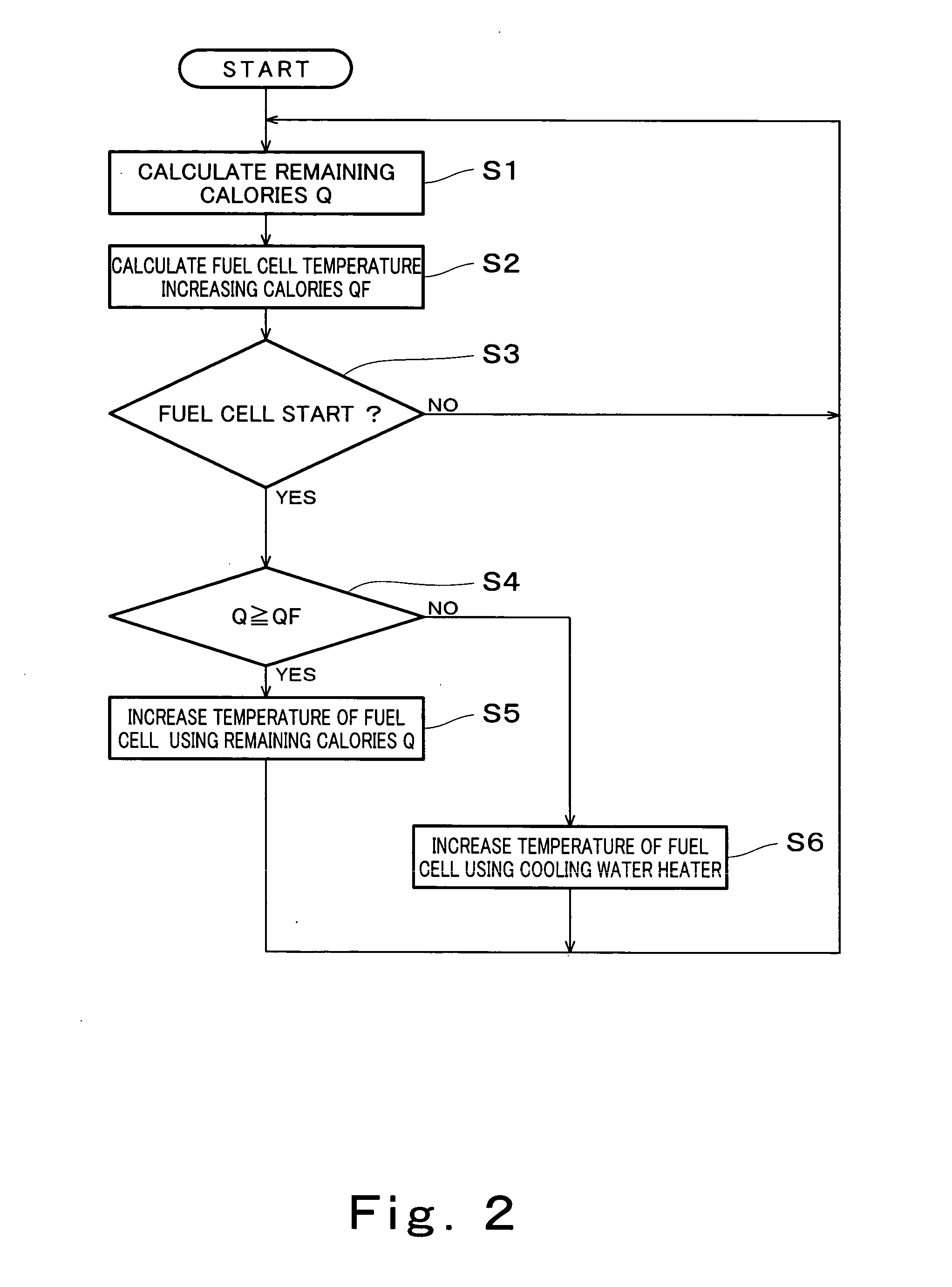

[0043] (Embodiment 1)

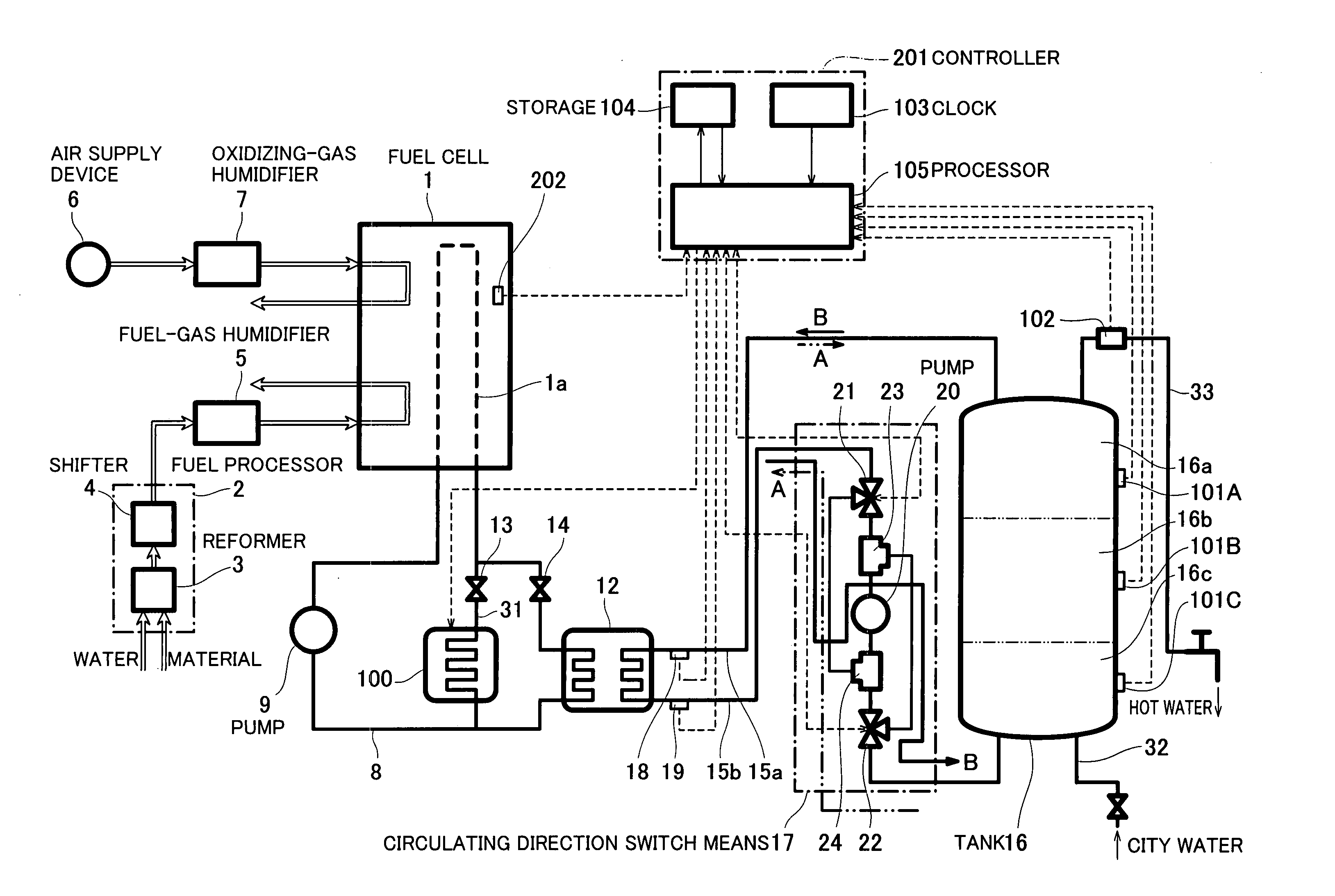

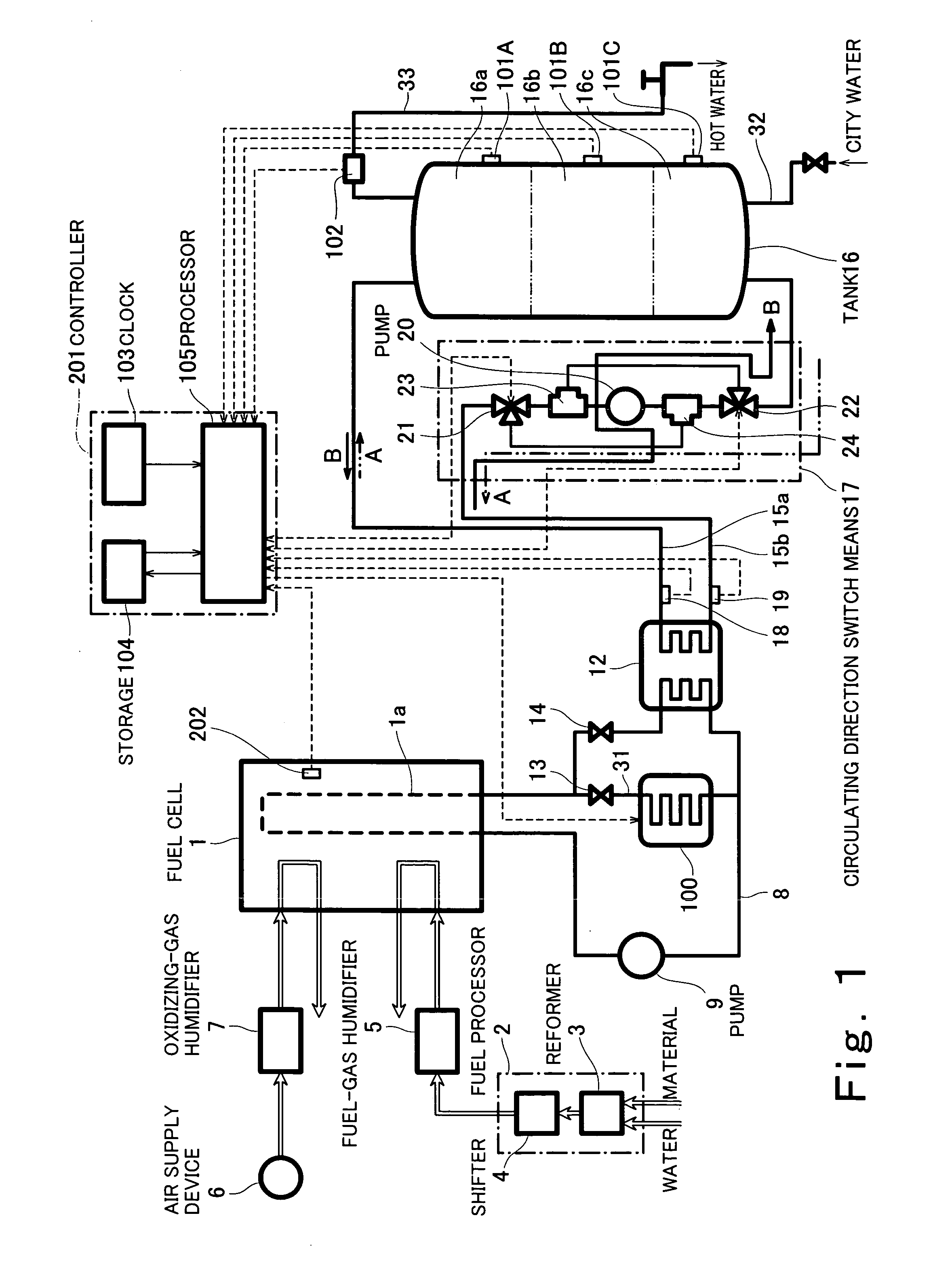

[0044]FIG. 1 is a block diagram showing a construction of a fuel cell cogeneration system according to a first embodiment of the present invention.

[0045] Turning to FIG. 1, the fuel cell cogeneration system (hereinafter simply referred to as cogeneration system) is chiefly divided into a construction of hardware and a configuration of a control system.

[0046] First of all, the construction of the hardware will be described. The cogeneration system comprises a fuel cell 1 configured to generate an electric power using a fuel gas and an oxidizing gas, a fuel processor 2 configured to generate a fuel gas from a material and water and to supply the fuel gas to the fuel cell 1, a fuel-gas humidifier 5 configured, to humidify the fuel gas being supplied to the fuel cell 1 at a position in a flow path extending to the fuel cell 1, an air supply device 6 configured to supply air as an oxidizing gas to the fuel cell 1, and an oxidizing-gas humidifier 7 configured to hum...

embodiment 2

[0103] (Embodiment 2)

[0104] Although the temperature increasing means select threshold QLT is set considering the life pattern of consumers in the alternative examples 2 and 3 of the first embodiment, the life pattern of the consumers varies depending on seasonal change. In general, the calories used for hot water supply or air conditioning in the morning tend to increase as ambient air temperature decreases. In the second embodiment, the threshold OLT is set considering the variation in the consumed calories during the start time period due to such seasonal change.

[0105]FIG. 8 is a block diagram showing a construction of a fuel cell cogeneration system according to the second embodiment of the present invention. In FIG. 8, the same reference numerals as those in FIG. 1 denote the same or corresponding parts which will not be further described.

[0106] In the second embodiment, an ambient air temperature sensor 106 is attached at a proper position to detect ambient air temperature. ...

example 1

[0119] [Alternative Example 1 of the Embodiment 2]

[0120] An alternative example 1 of the second embodiment will now be described.

[0121] In the alternative example 1, the ambient air temperature sensor 106 configured to detect the ambient air temperature, which is shown in FIG. 8, is omitted. And, the processor 105 calculates monthly average start time period consumed calories and selects temperature increasing means based on the monthly average start time period consumed calories. This follows that the temperature increasing means is selected considering the ambient air temperature. The other construction is identical to that in FIGS. 8 and 9.

[0122] Hereinafter, the difference between the construction of the alternative example 1 and the construction in FIGS. 8 and 9 will be described.

[0123]FIG. 11 is a flowchart showing an operation to select a temperature increasing means of a fuel cell cogeneration system according to the alternative example 1 of the second embodiment. FIG. 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

| heat utilization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com