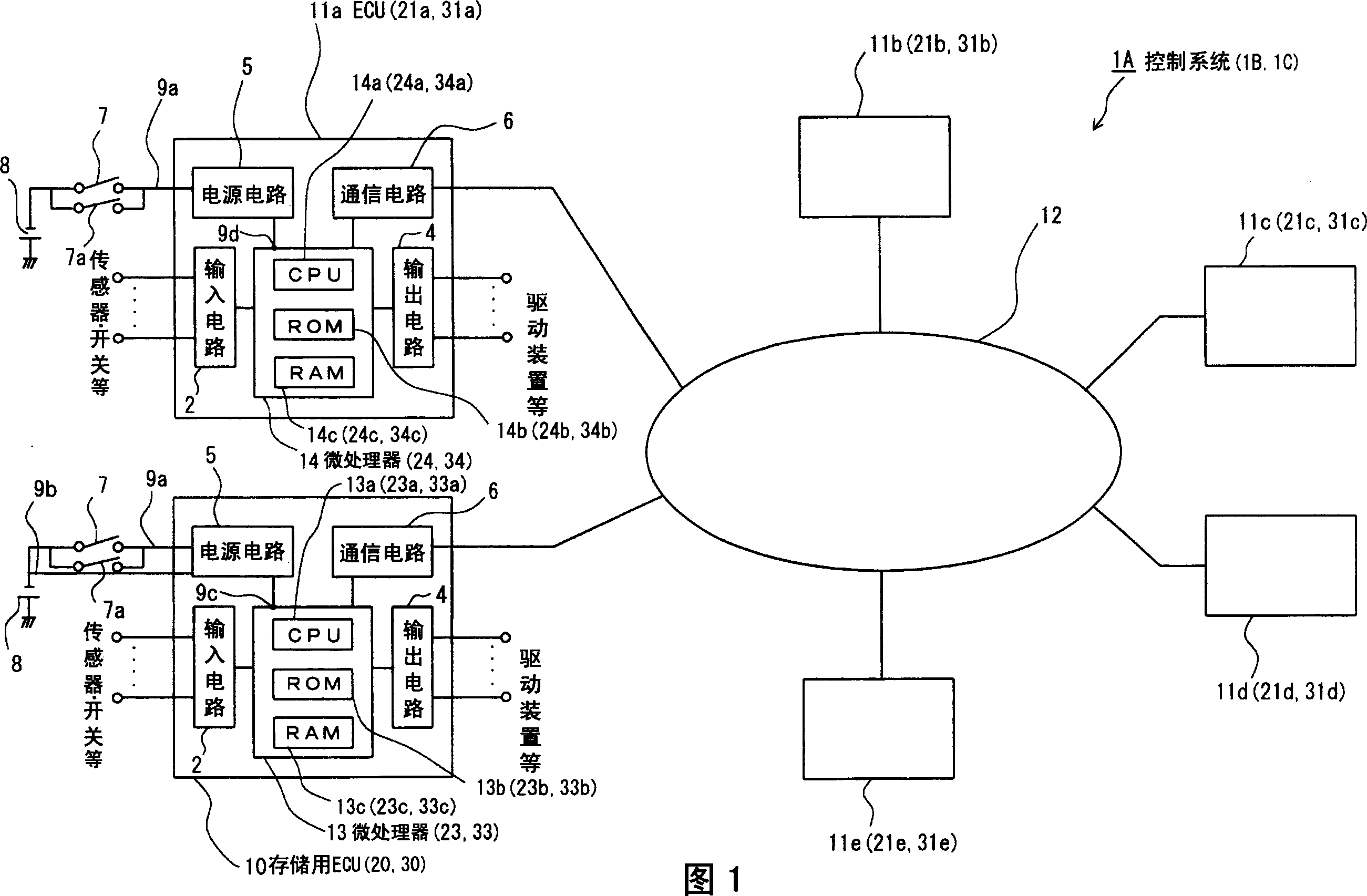

Control system

A control system and control device technology, applied in the field of control systems, can solve problems such as battery exhaustion, small EEPROM capacity, and limited data volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

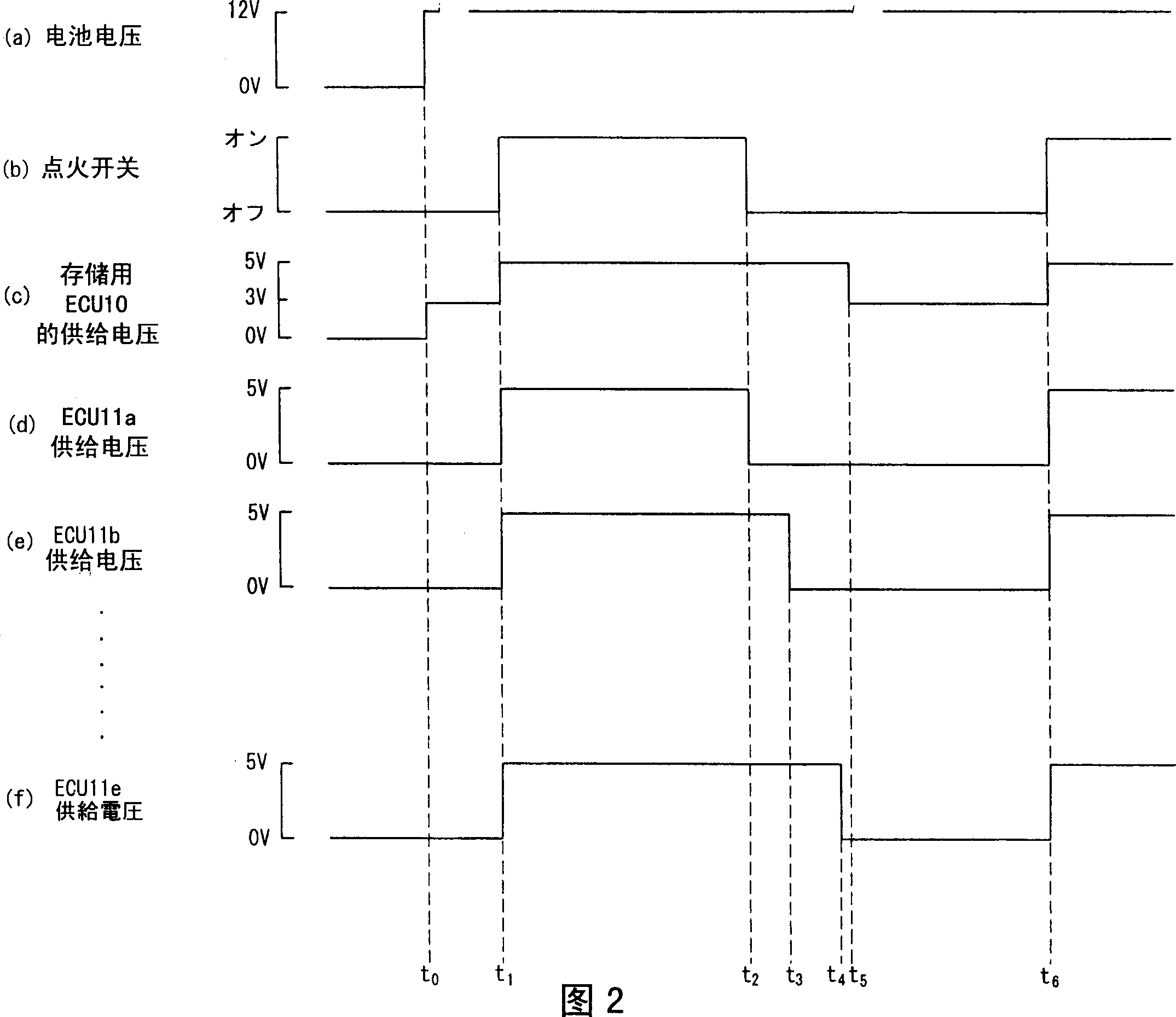

Method used

Image

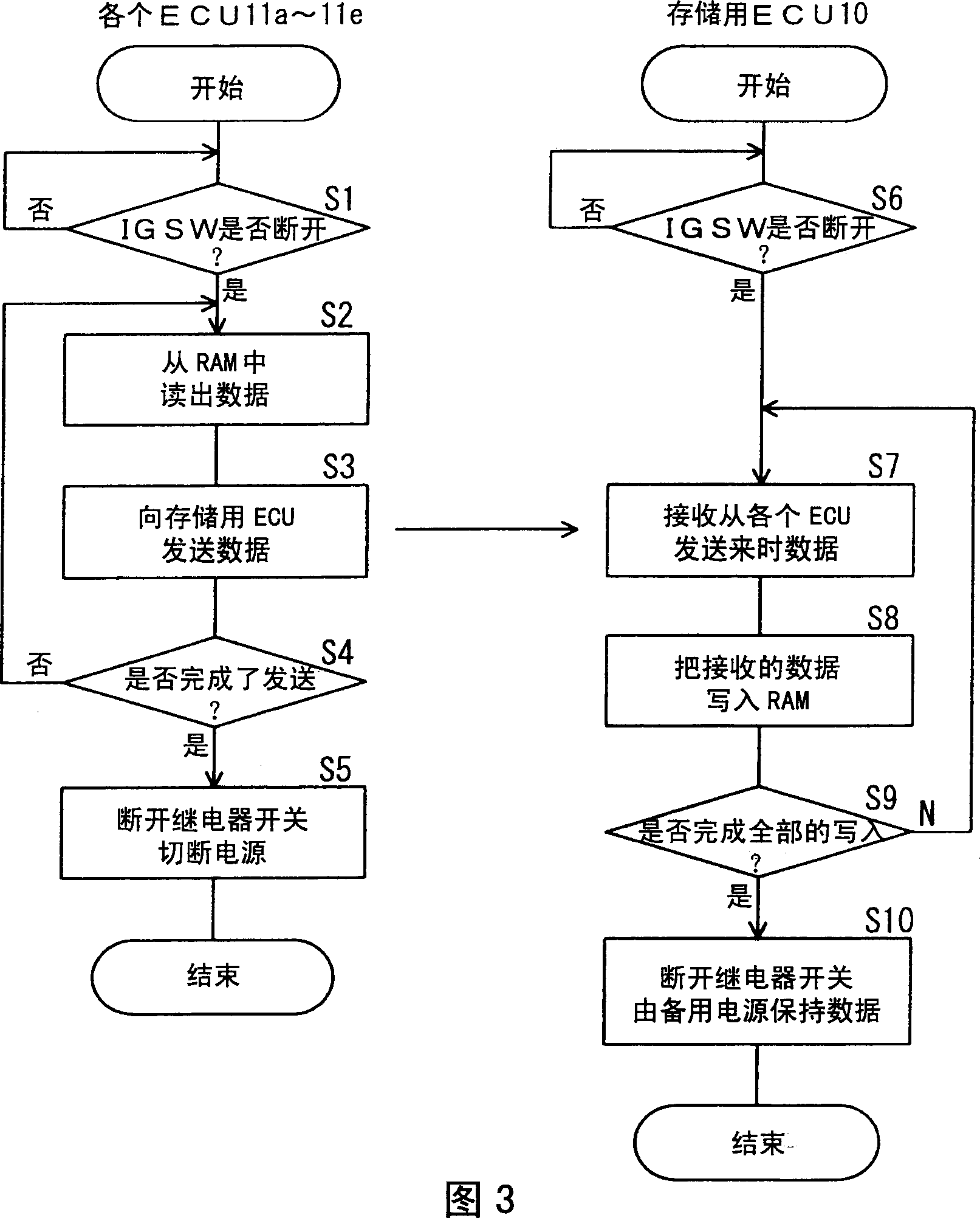

Examples

Embodiment 2

[0100] The difference between the control system of Embodiment 2 and the control system of Embodiment 1 is that each ECU 21 a to 21 e sends the data stored in RAM 24 c, ... to the storage ECU 20 multiple times when the IGSW 7 is turned off. , the ECU 20 for storage receives the data sent multiple times, judges whether they are the same, and stores them in the RAM 23c when it is judged to be the same data.

[0101] Below, combine Figure 5 The flowchart shown in the embodiment 2 is for the data transmission processing action performed by the microprocessors 24, ... of the ECUs 21a to 21e and the microprocessor 20 of the storage ECU 20 when the IGSW7 of the control system of the second embodiment is switched from on to off. The data storage processing operation performed by the processor 23 will be described. In addition, the same processes as those in the control system of the first embodiment shown in FIG. 3 are denoted by the same symbols, and their descriptions are omitted....

Embodiment 3

[0115] The difference between the control system of the third embodiment and the control system of the first embodiment is that the transmission of the data stored in the RAM 34c, ... of the ECUs 31a to 31e to the storage ECU 30 is not only when the off state of the IGSW7 is detected. , and periodically during the on-state of IGSW7.

[0116] Below, combine Image 6 The flow chart shown in the control system of the third embodiment illustrates the data transmission processing action and storage performed by the microprocessors 34, ... of the ECUs 31a to 31e when the IGSW7 is switched from the on state to the off state. Data storage processing operation performed by the microprocessor 33 of the ECU 30 . In addition, the same processing as that in the control system of the first embodiment shown in FIG. 3 is denoted by the same reference numerals, and description thereof will be omitted.

[0117] In addition, since the processing operations of the respective ECUs 31a to 31e diffe...

Embodiment 5

[0156] The difference between the control system of Embodiment 5 and the control system of Embodiment 4 is that each ECU 51 a to 51 e judges whether the data read from the EEPROM 15 is consistent with the data sent from the storage ECU 50 when the IGSW 7 is turned on. If they do not match, control is performed using data read from EEPROM 15 .

[0157] Next, in conjunction with the flow chart shown in FIG. 10 , the data receiving processing actions executed by the microprocessors 54, ... of the ECUs 51a-51e when the IGSW7 is switched from off to on in the control system of the fifth embodiment are carried out. illustrate. Additionally, for Figure 9 The same processing as the processing in the control system of the illustrated fourth embodiment is denoted by the same symbols, and description thereof will be omitted.

[0158] In addition, since the processing operation of each ECU51a-51e differs only in the time of data reception and transmission, and basically performs the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com