Patents

Literature

31 results about "Run time setting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

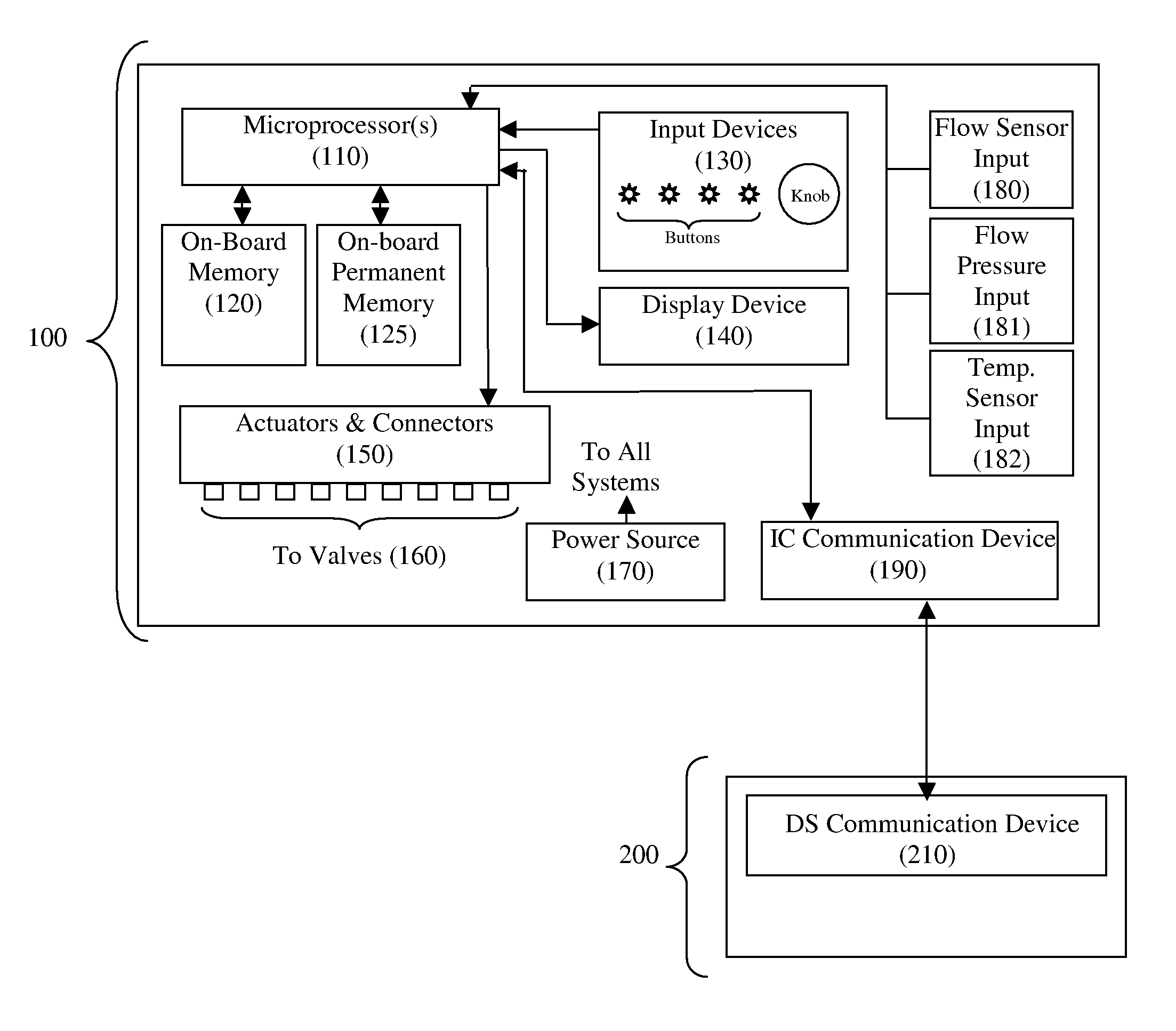

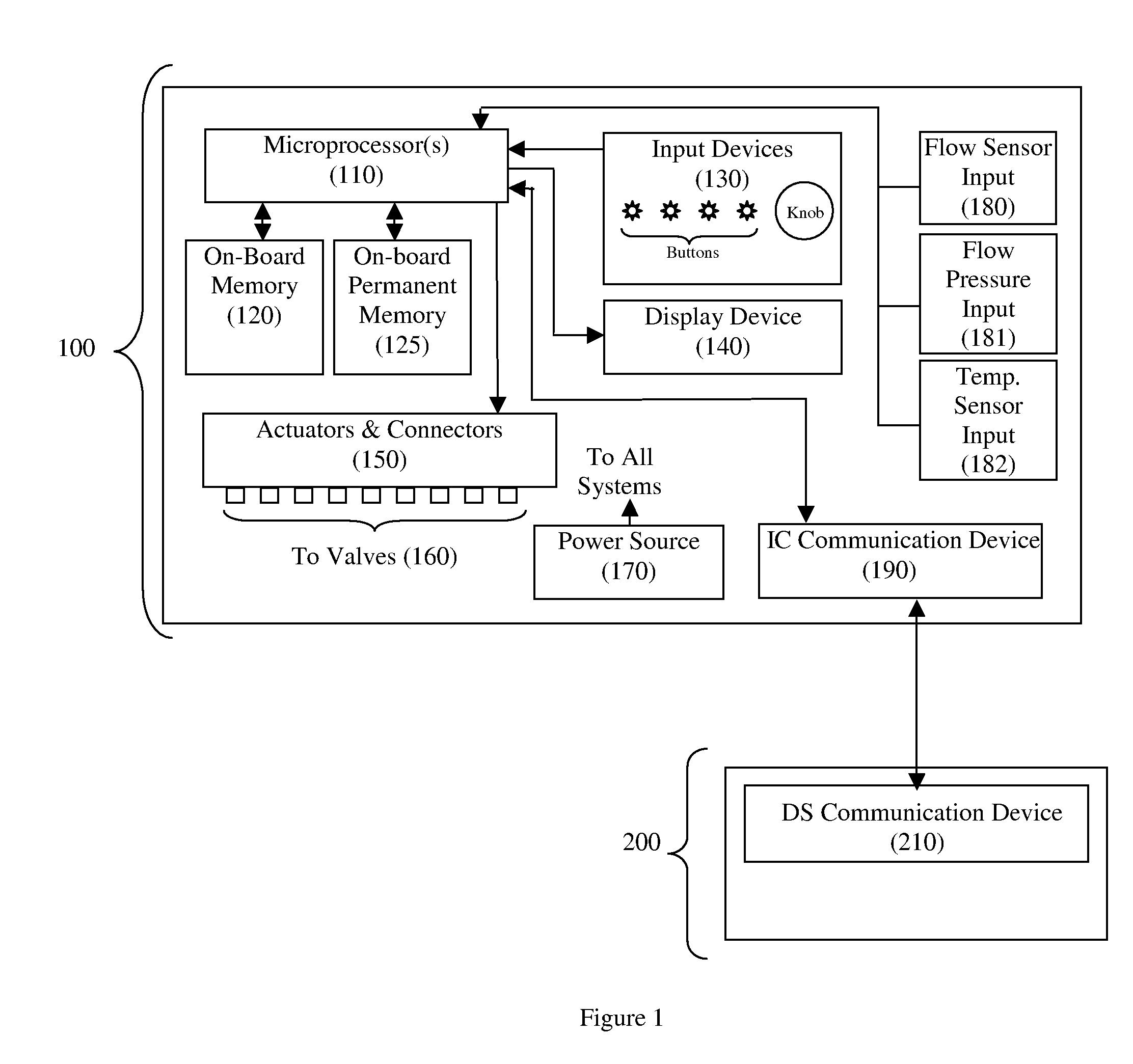

Irrigation Controller Communication System

An irrigation controller is programmed to automatically initiate communication with a data server to perform at least one of the following functions: (a) exchange irrigation data; (b) receive control data; and (c) receive synchronization data. The irrigation data can be station runtime history, evapotranspiration (ETo) data, rainfall, weather related information, irrigation faults and any other irrigation data. The control data can involve station runtime settings, cycle and soak settings, irrigation scheduling and any other irrigation control data. The synchronization data preferably includes a date and a time, originating from the data server, but can include other data that would be used to synchronize the communication between the irrigation controller and the data server. In a preferred embodiment of the present invention a microprocessor disposed in the irrigation controller is programmed to use the date and time to schedule a future contact with the data server.

Owner:AQUA CONSERVE +2

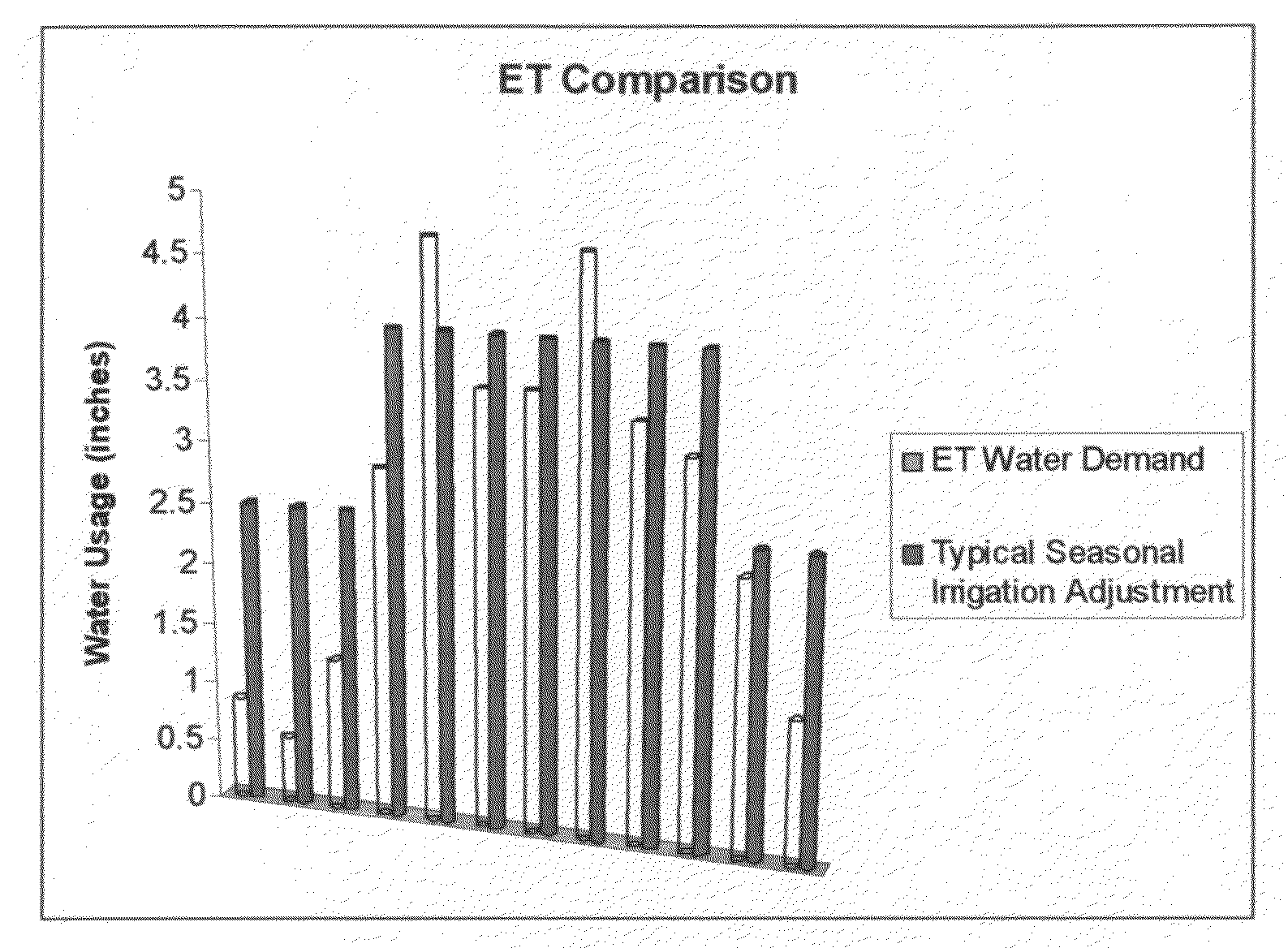

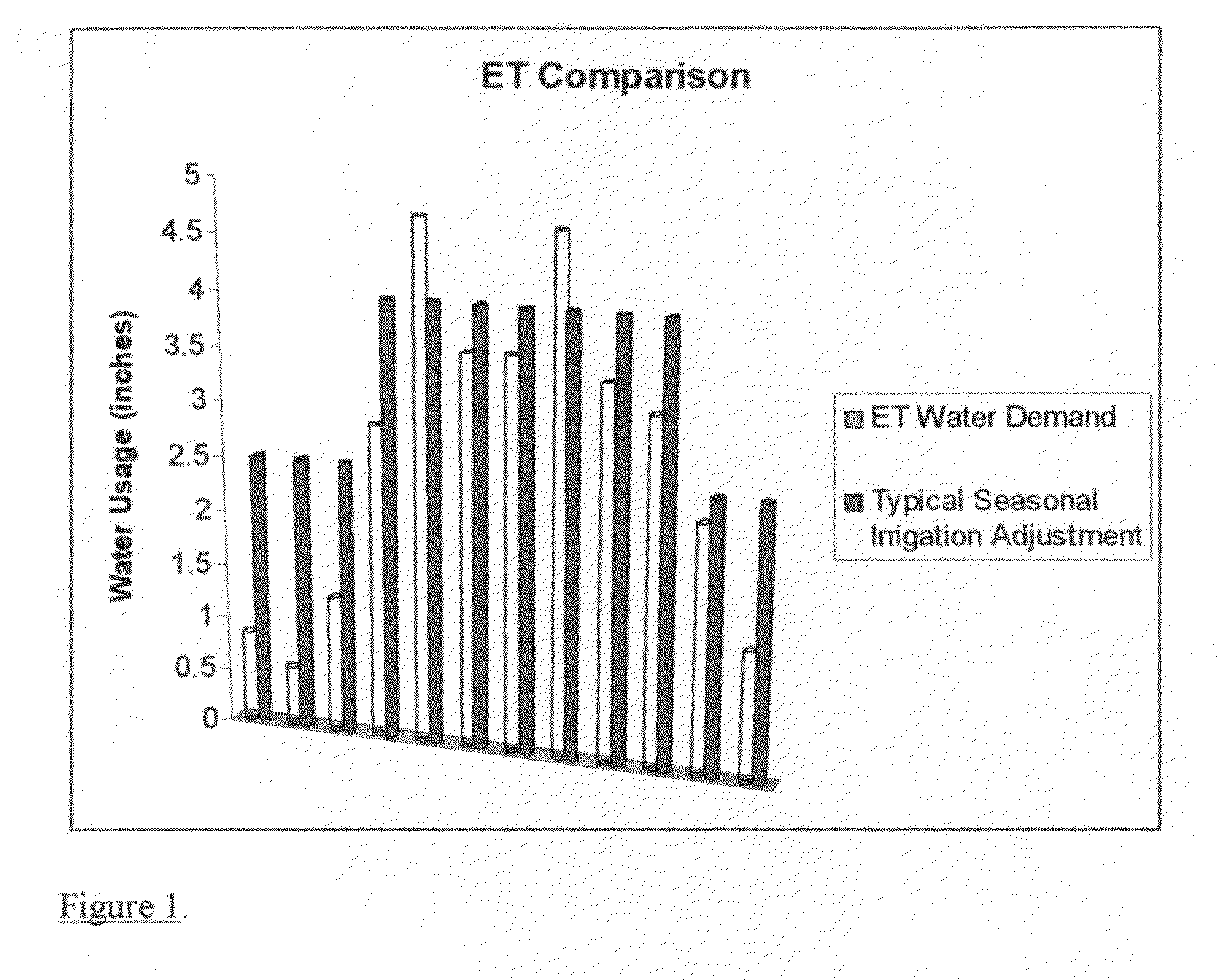

Method of controlling an irrigation system

InactiveUS20090138105A1Easy to understandEliminate excessive use of waterSafety arrangmentsClimate change adaptationRun time settingControl system

The present invention is a method of controlling an irrigation system that minimizes the amount of irrigation water applied with the use of evapotranspiration (ET) to adjust the irrigation controller. By basing the irrigation program on run times which equal a specific amount of water, ET can be used as a percentage to adjust the amount of water applied during an irrigation cycle. By setting a run time to equal 1″ of rainfall ET can be used as a multiplier against the run time to make the correct adjustment to provide required water. By setting the amount of water to be applied to 2″ or any other amount would need an additional multiplier added to make the proper adjustment. Adjustments for landscape coefficient and distribution uniformity would be placed in run time formula based on use of ET set at 1″. The adjusted run time would be the input into the control system.

Owner:CRAWFORD JEFFREY A

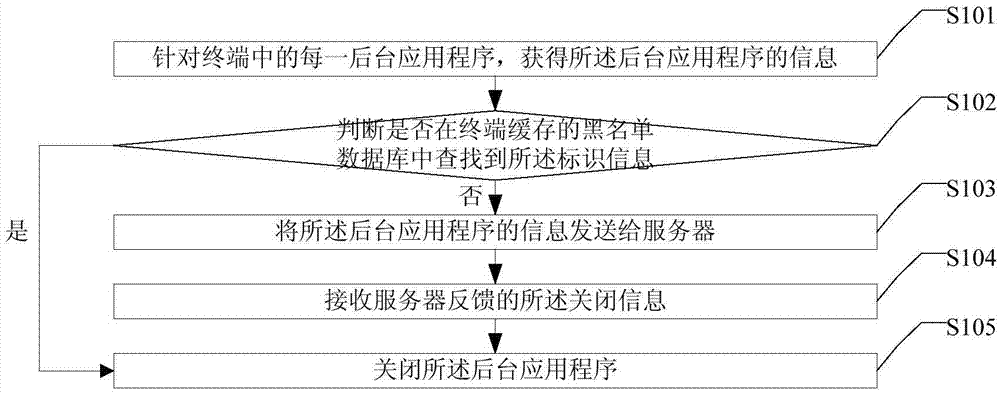

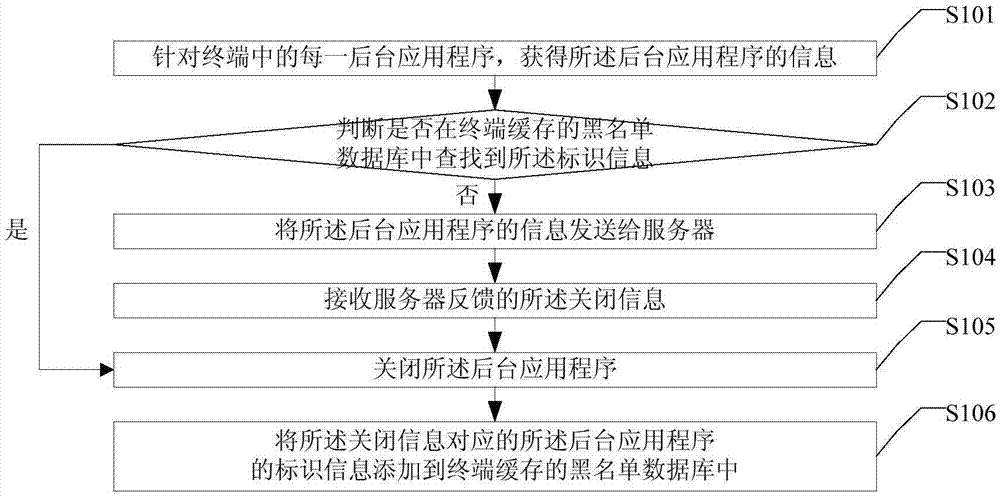

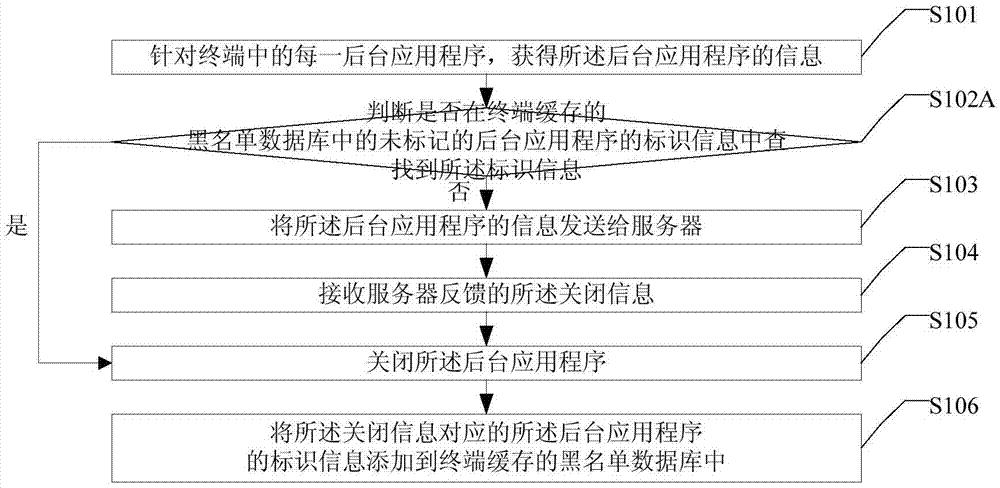

Background application closing method and device and terminal

ActiveCN106909407AOff validEasy to useDigital data processing detailsProgram loading/initiatingRun time settingSoftware engineering

The embodiment of the invention discloses a background application closing method and device and a terminal. When whether or not a background application needs to be closed is judged, identification information of the background application is looked up in a blacklist database cached in a terminal. On the condition that the identification information is found, the background application is closed; the identification information of the background application and the time that a user does not use the background application are sent to a server only when the identification information is not found, the server conducts looking up and judging in a cloud database according to the identification information of the background application and the time that the user does not use the background application, on one hand, the loading stress of the server is relieved, and on the other hand, the server sets a threshold value for the time that the user does not use the background application. Compared with the mode that in the prior art, a threshold value is set for the background operation time of the background application, the background application can be effectively closed, and normal use of the user is not influenced.

Owner:KINGSOFT

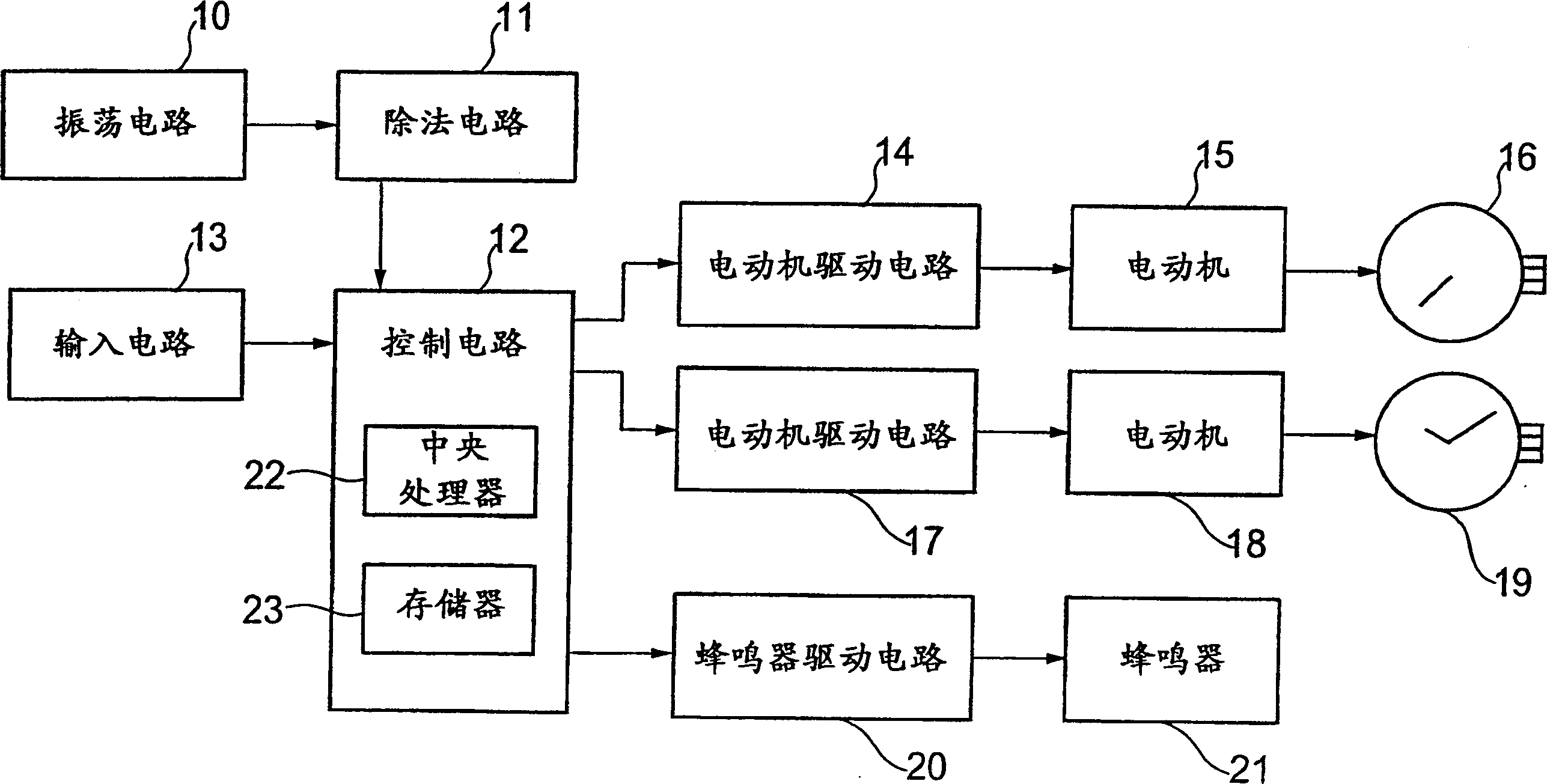

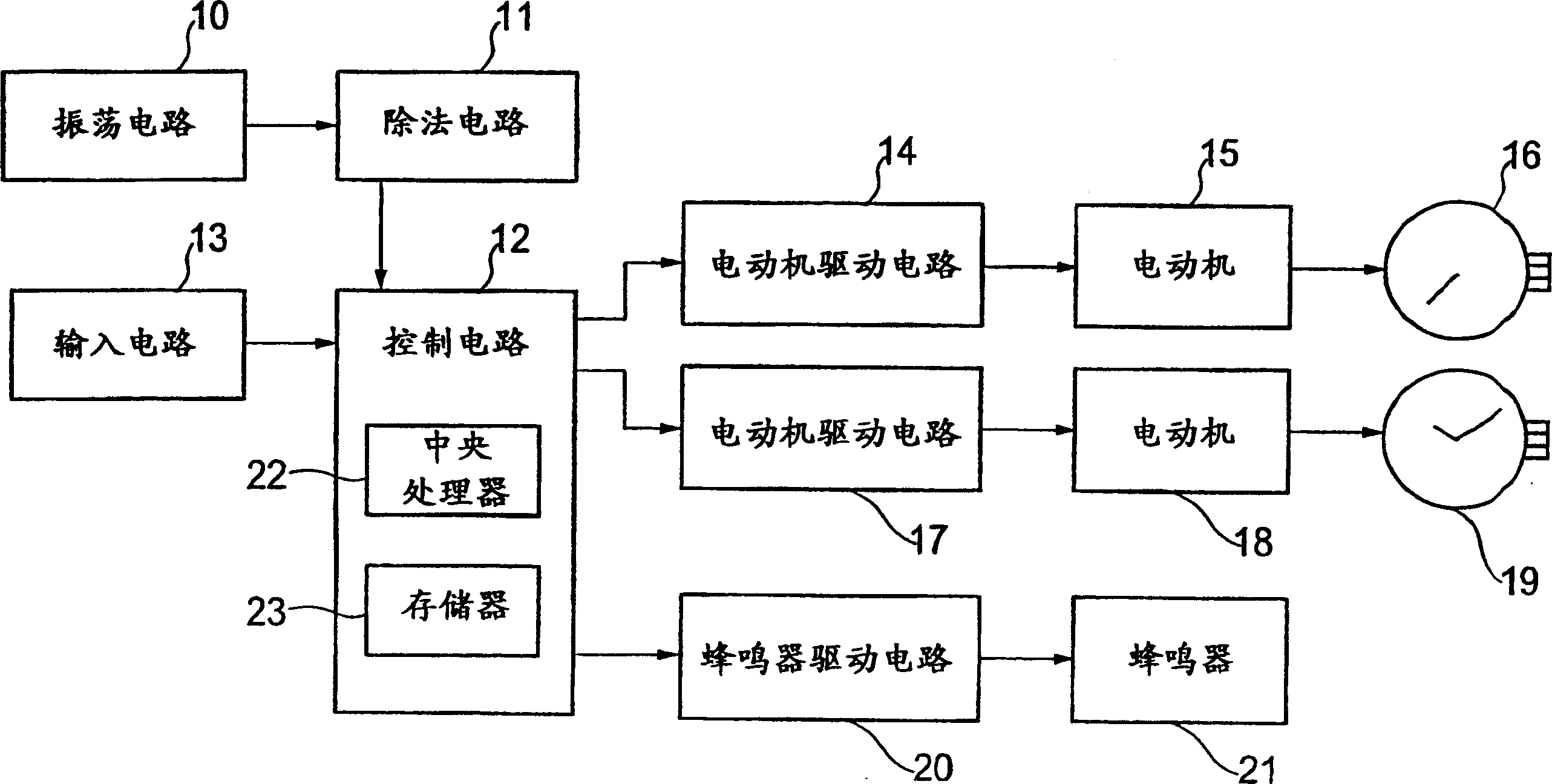

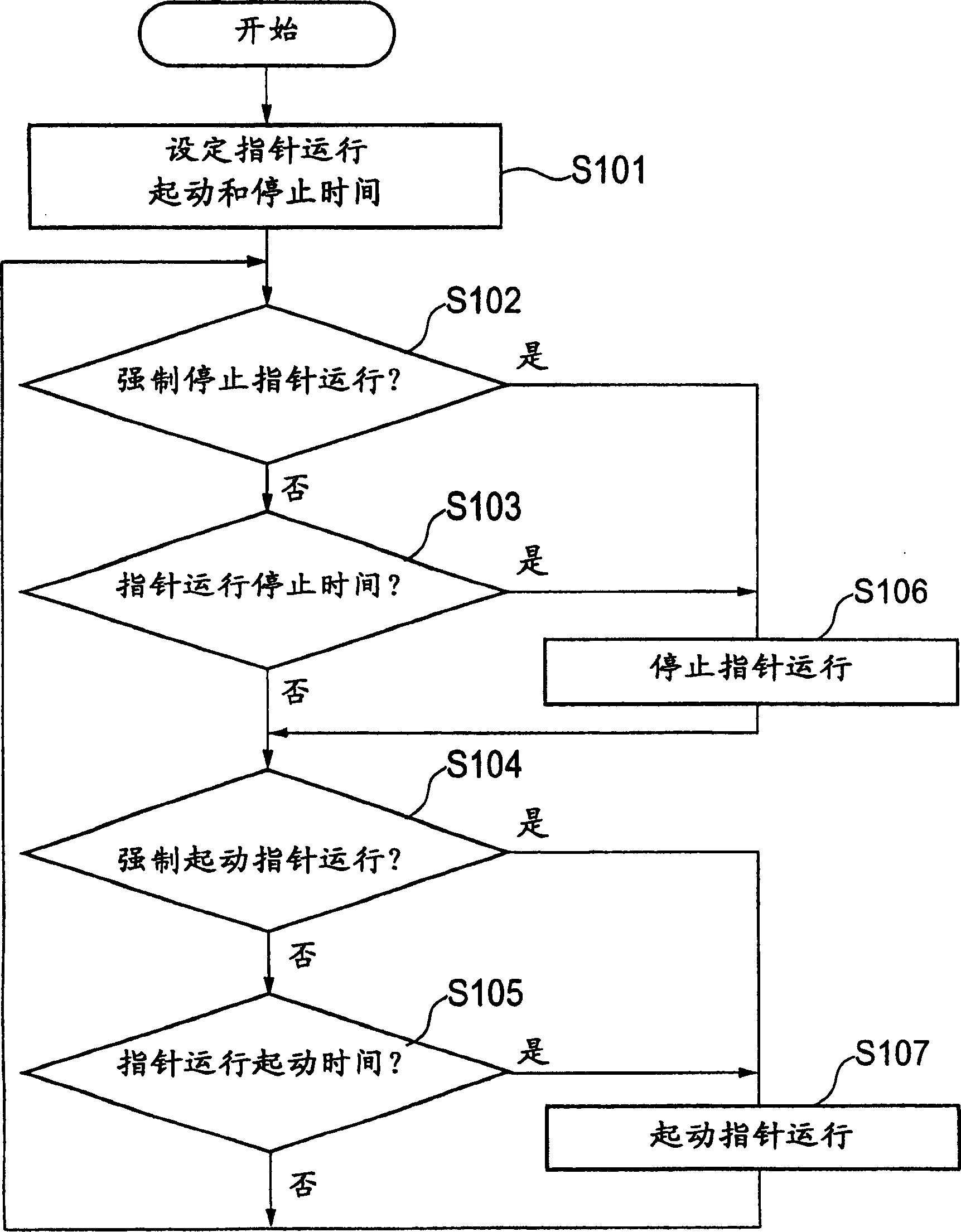

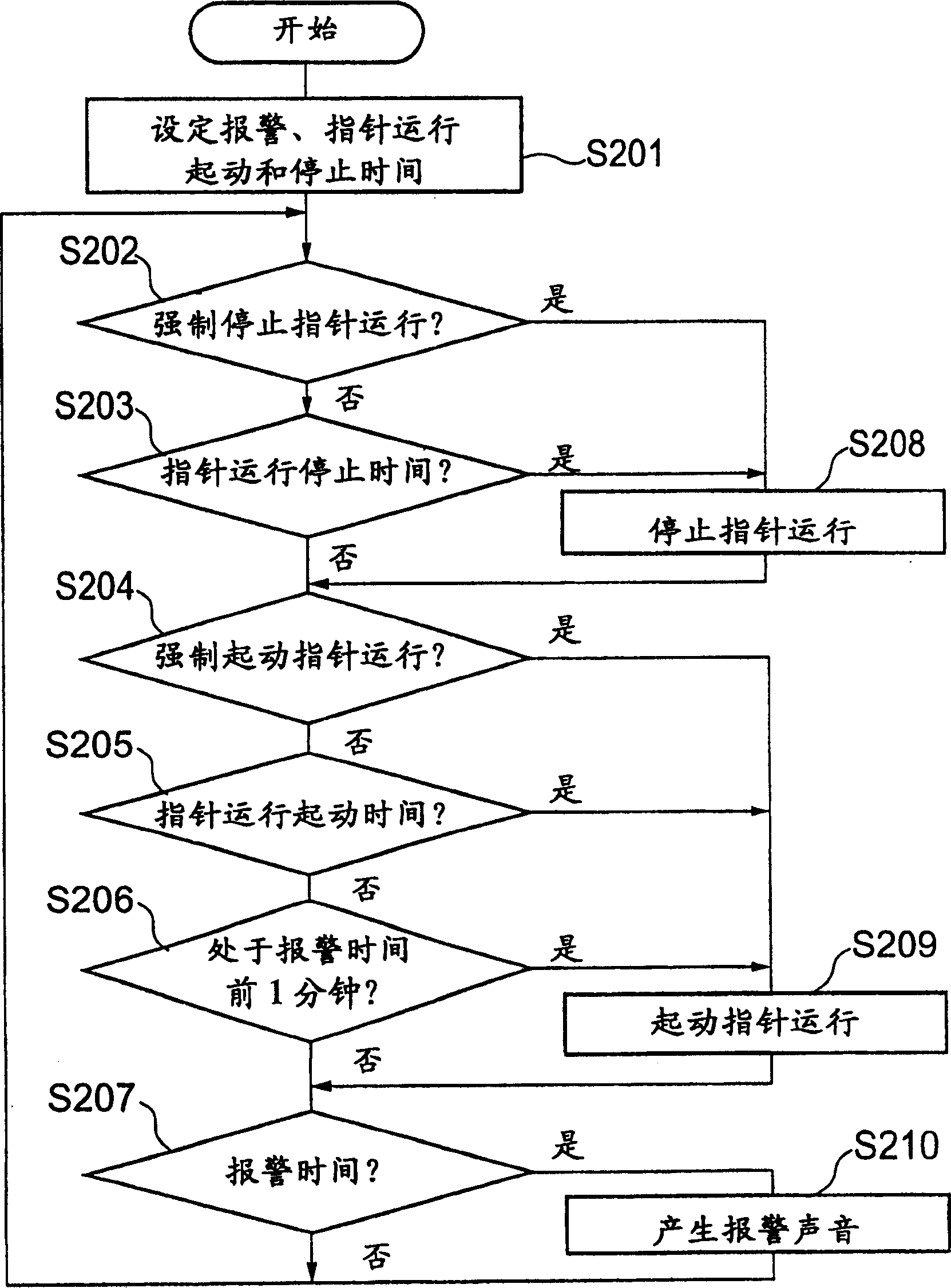

Electronic chronometer

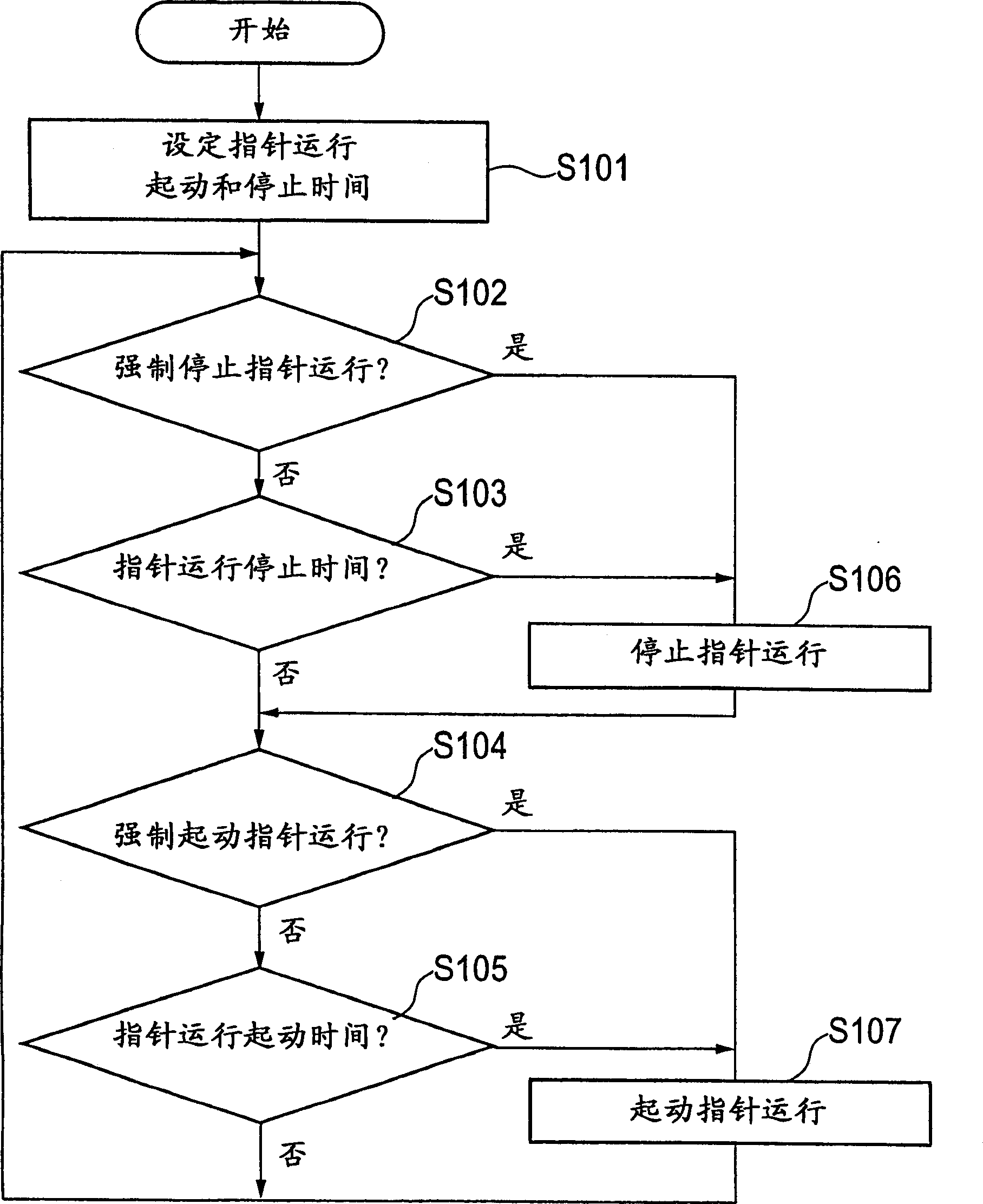

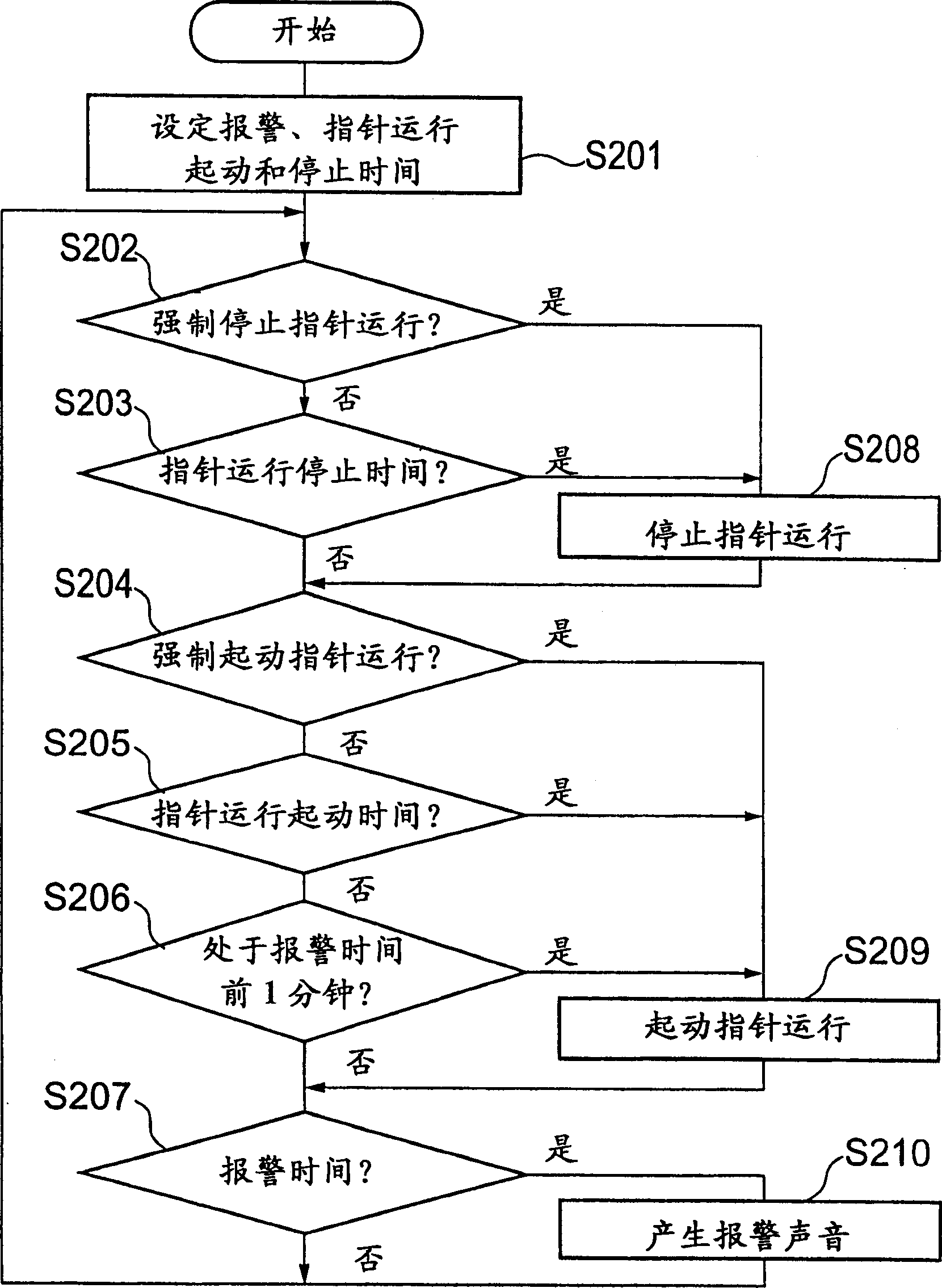

Reduces energy consumption by running hands only when needed. By pressing down the mode changeover switch, the second hand can be selectively moved to the position of the pointer running start time setting mode (wake-up), the position of the pointer running stop time setting mode (sleep) and the position of the alarm time setting mode (alarm) . When the second hand is placed in each setting mode position, the hour / minute hand is set to the required time by pressing the time setting switch, thereby setting the pointer operation stop time, pointer operation start time and alarm time. When the pointer operation stop time is reached, the operation of the pointer stops, and when the pointer operation start time is reached, the time pointer quickly advances to the normal time, and then the normal time display is performed. In the case where the operation of the pointer is stopped, within a predetermined period of time before the alarm time is reached, the pointer operates in a manner similar to the above, returning to a normal operating state, and thereafter, an alarm is generated when the alarm time is reached.

Owner:SEIKO INSTR INC

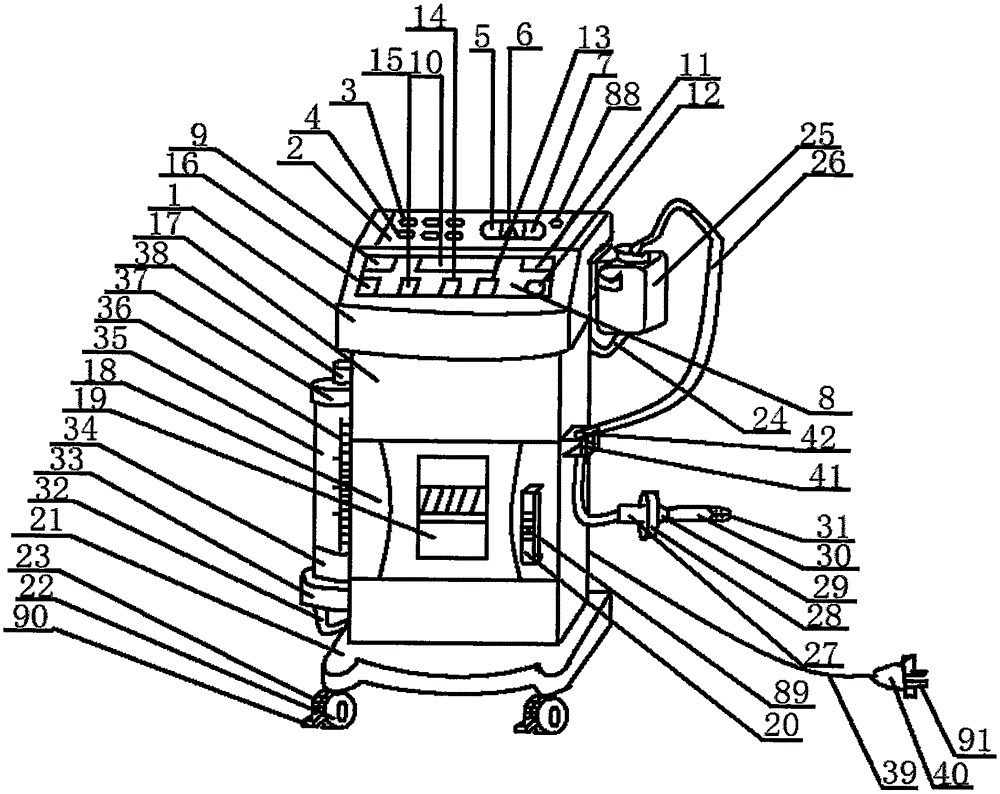

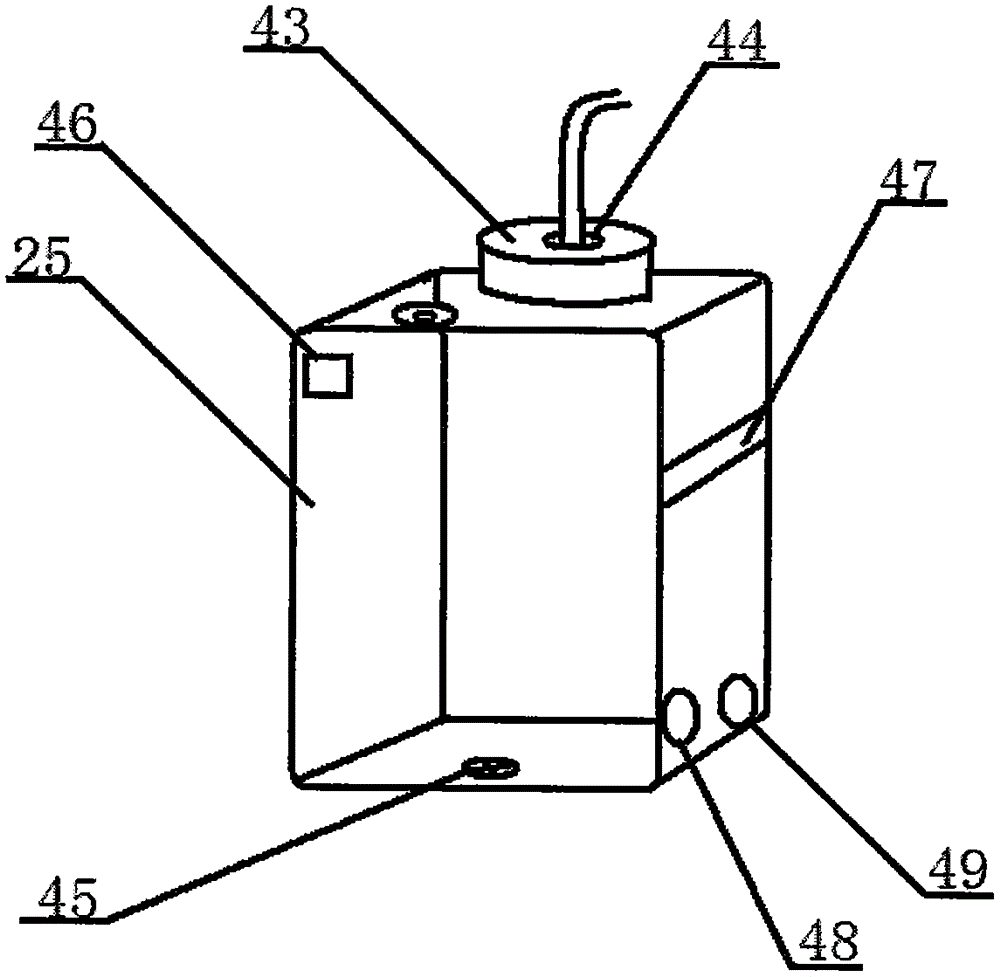

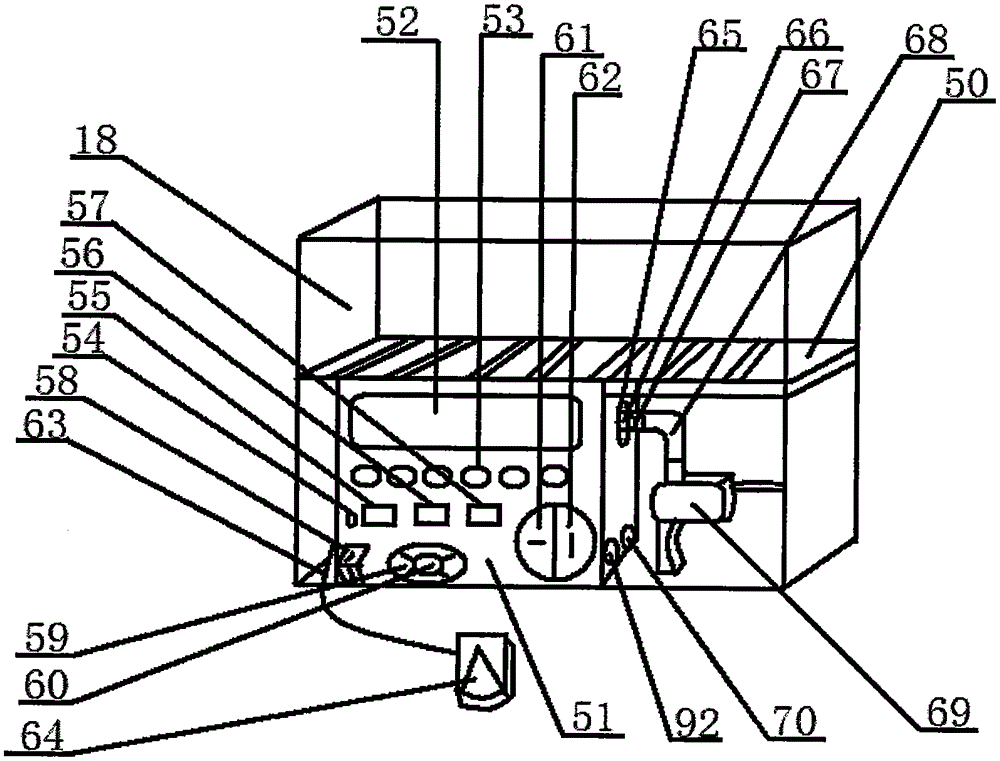

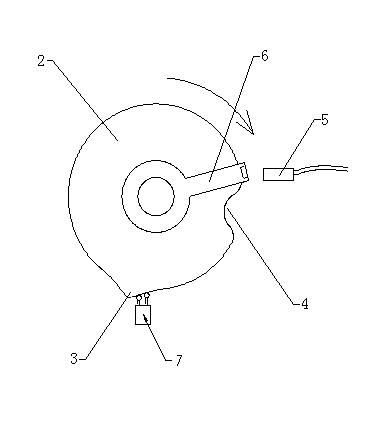

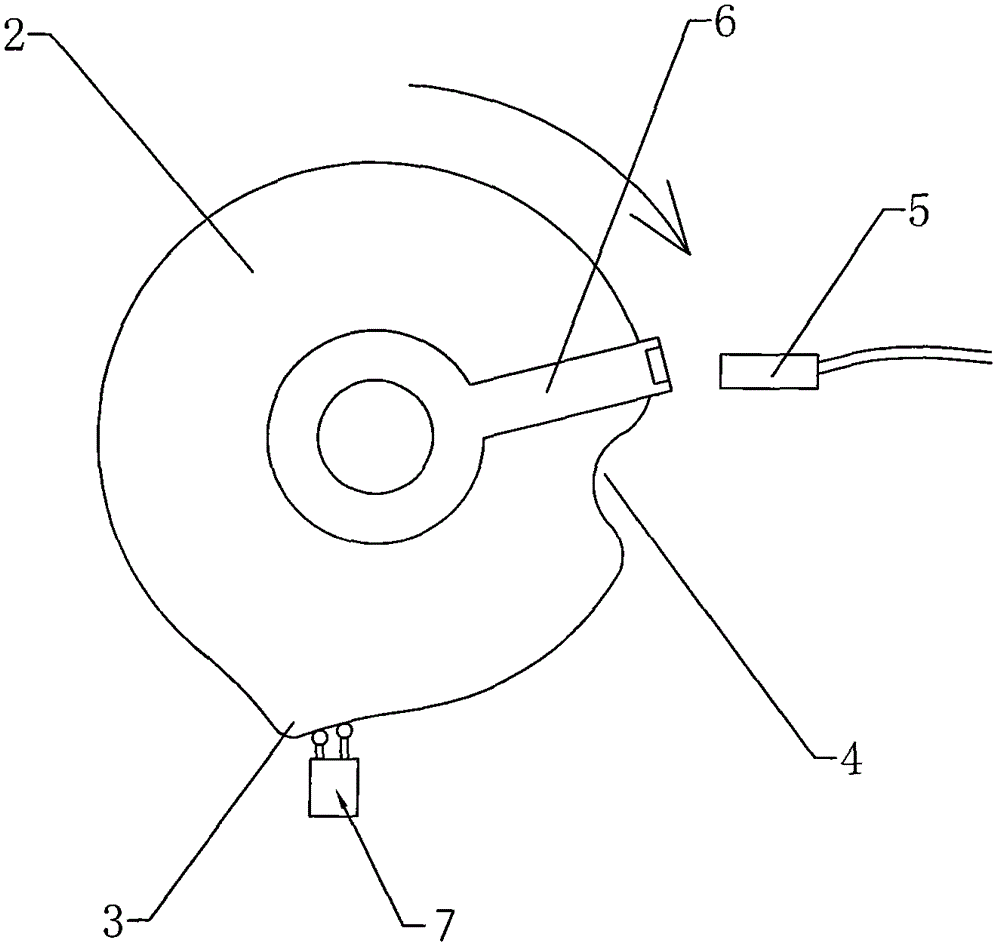

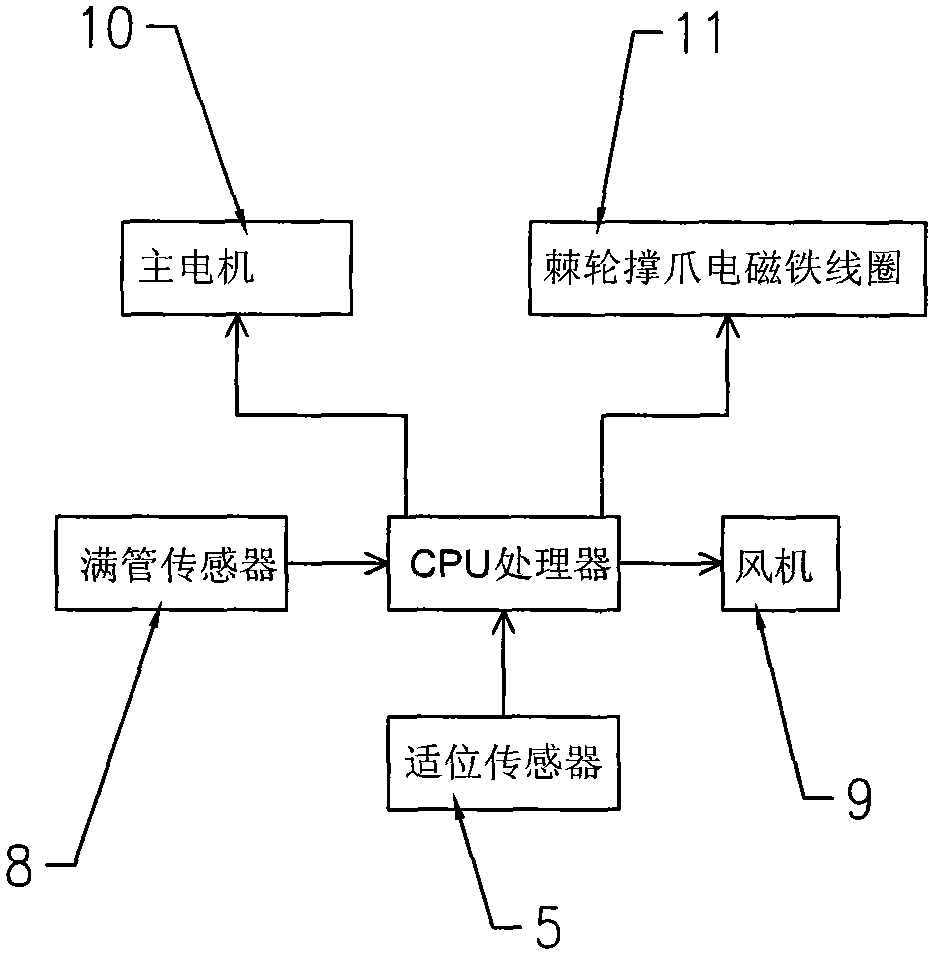

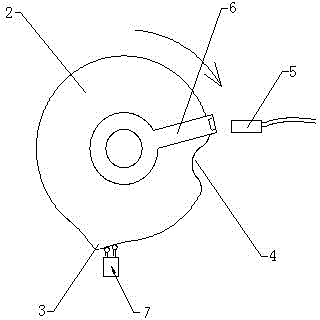

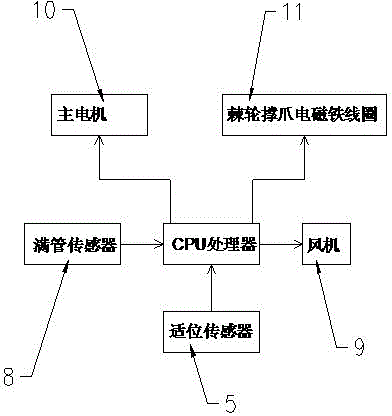

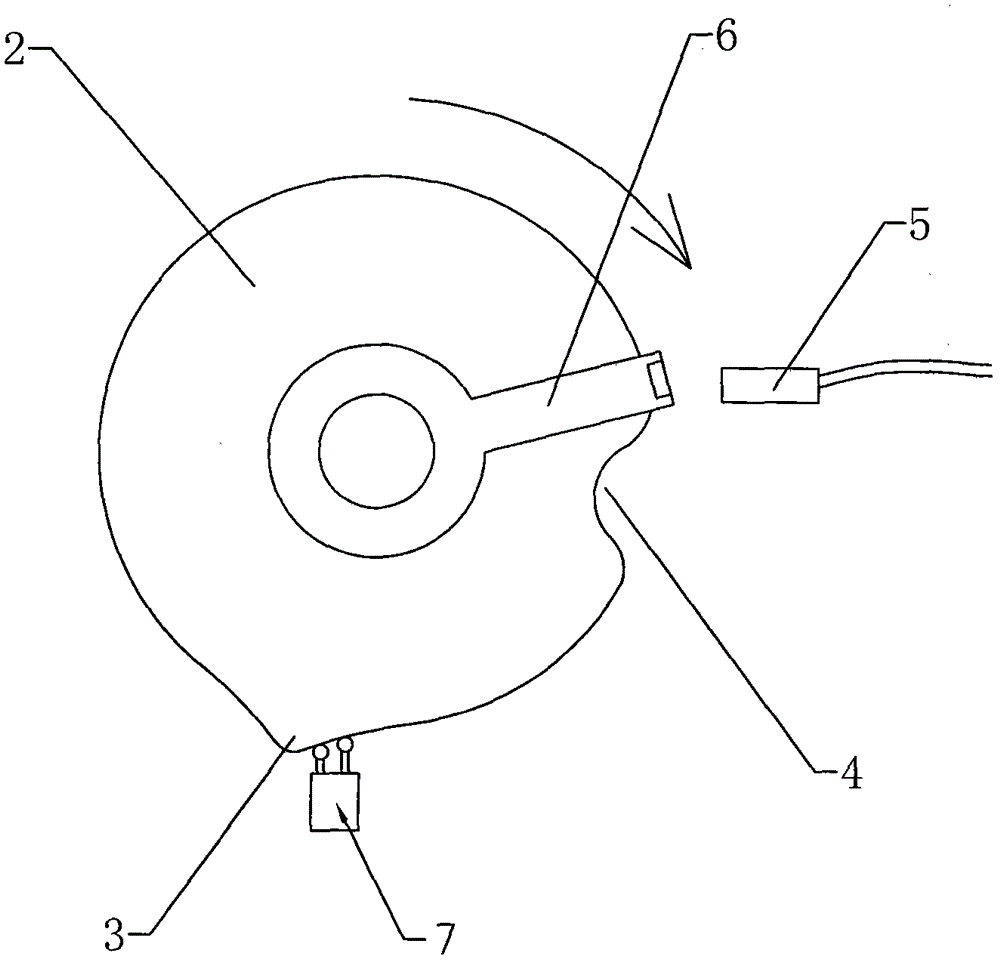

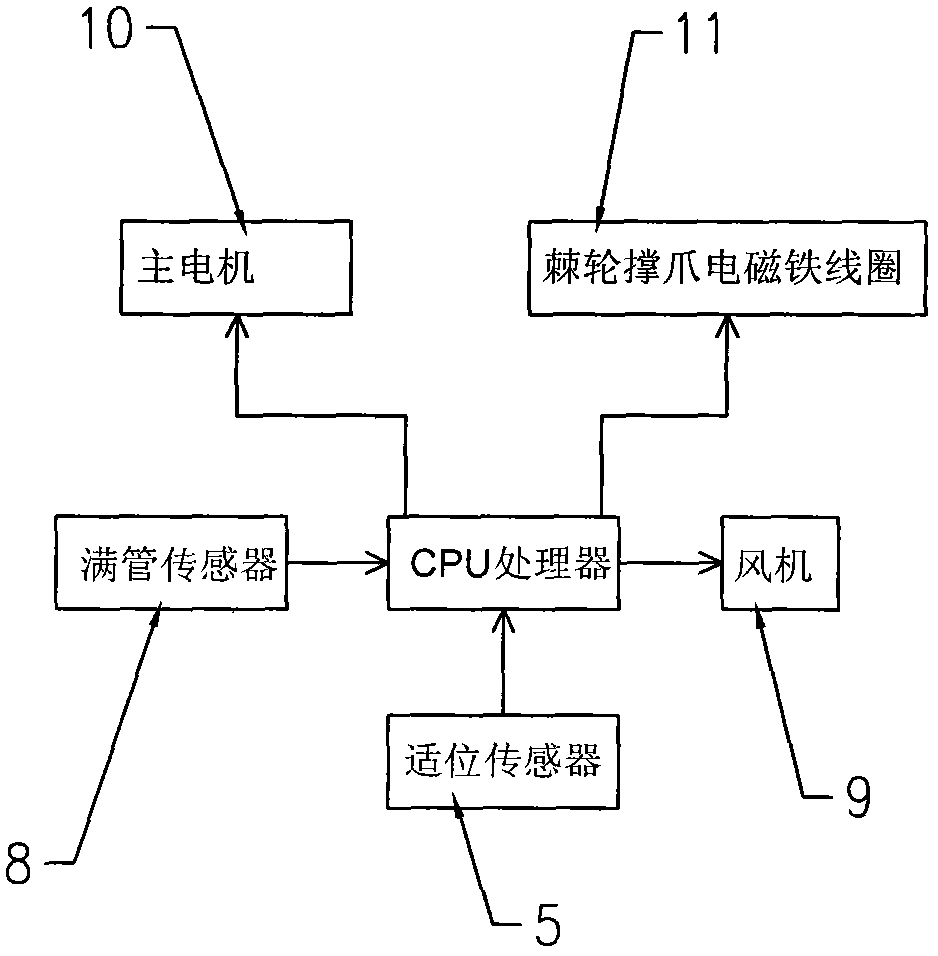

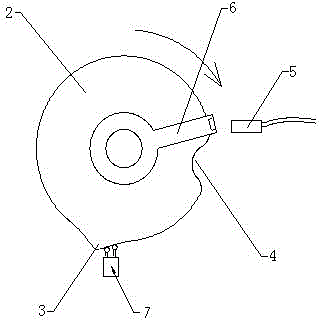

Gynecological inflammation treating and repairing device

InactiveCN105395352AEasy to moveVersatileMedical devicesBathing devicesRun time settingDisplay board

The invention relates to a gynecological inflammation treating and repairing device, and specifically belongs to the technical field of a medical apparatus. The gynecological inflammation treating and repairing device comprises a treatment control operating platform; an ozone gynecological therapeutic apparatus display board is arranged on the treatment control operating platform; a cycle time indicator lamp is arranged on the ozone gynecological therapeutic apparatus display board; a running time indicator lamp is arranged on the lower side of the cycle time indicator lamp; a running time setting key is arranged on the right side of the running time indicator lamp; an interval time setting key is arranged on the right side of the running time setting key; and a starting / stopping key is arranged on the right side of the interval time setting key. The gynecological inflammation treating and repairing device disclosed by the invention is complete in function and is safe and efficient; the comprehensive therapeutic apparatus, which integrates ozone fumigating physiotherapy technology and cervical repair technology, is simple and convenient in treatment process and is convenient to move, and treatment workload of doctors is reduced.

Owner:陈建梅

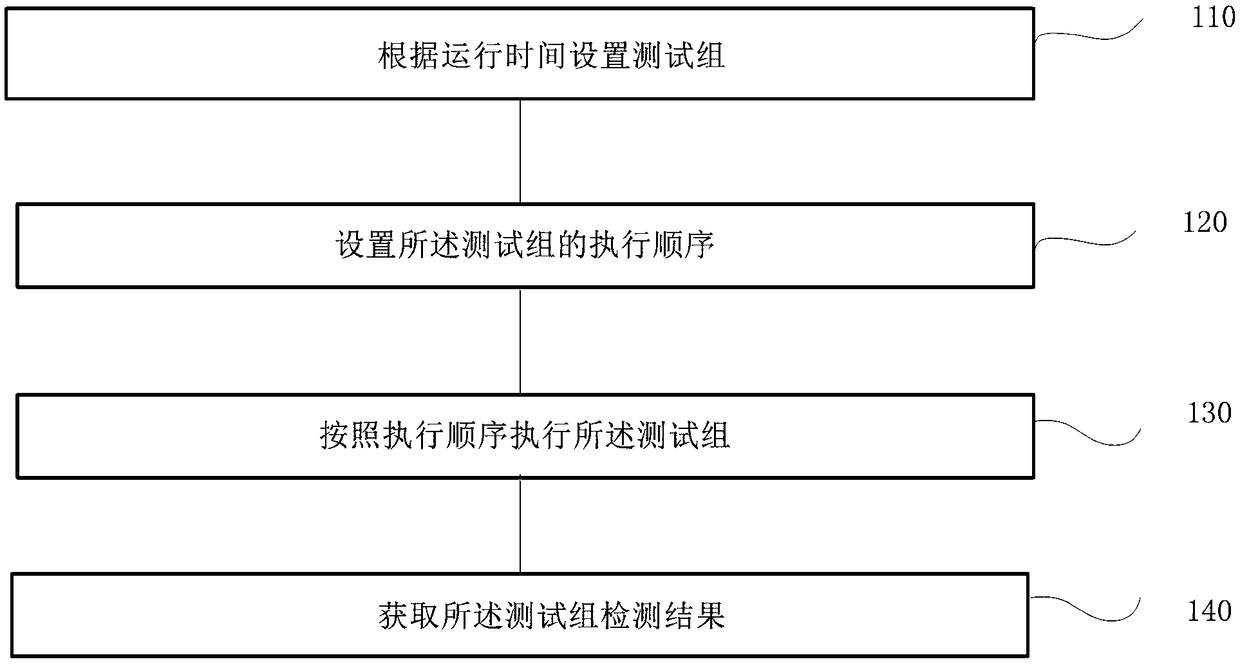

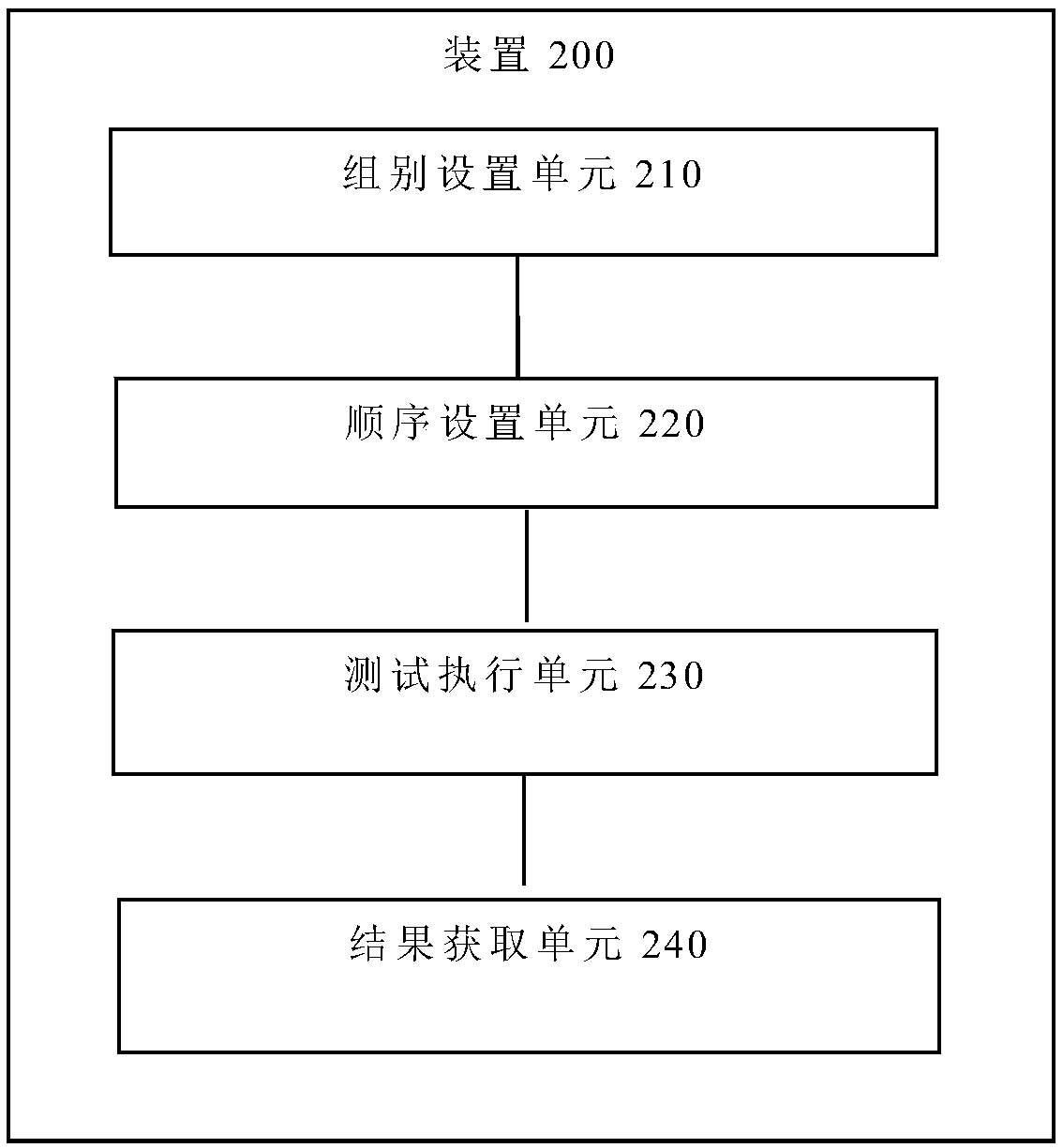

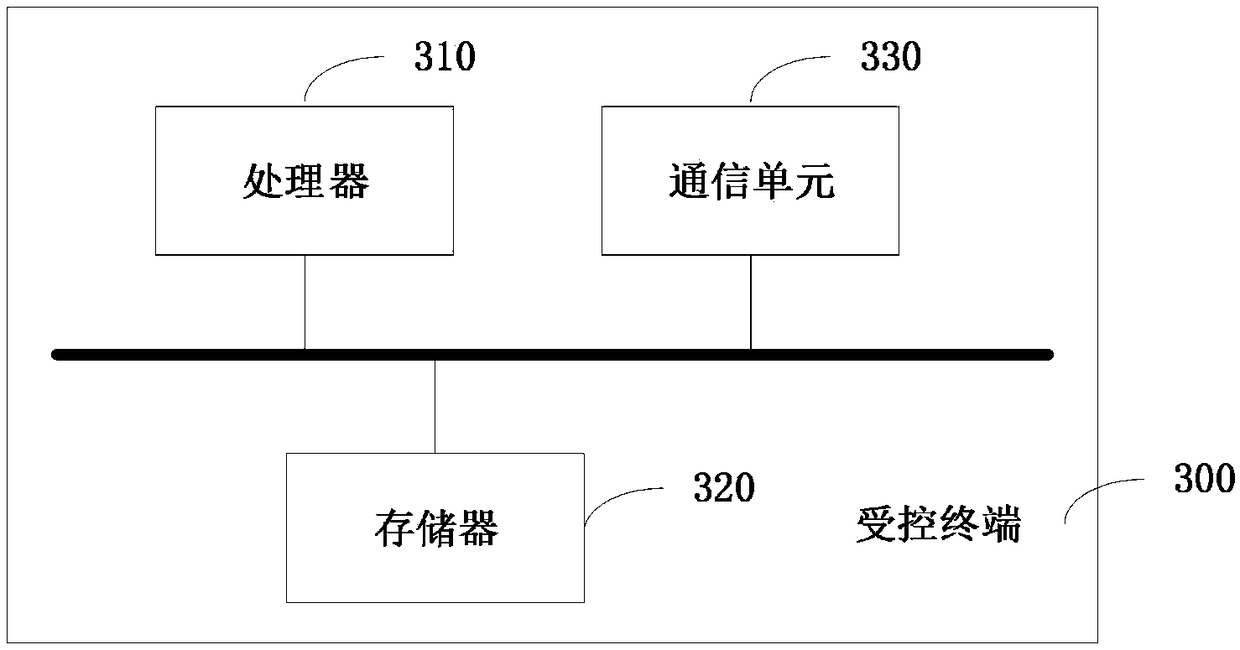

Memory pressure test method, device, terminal and storage medium

InactiveCN109032874AEfficient testingUninterrupted testingFaulty hardware testing methodsRun time settingComputer hardware

An embodiment of the present application provides a memory pressure test method, a device, a terminal and a storage medium. The method includes: setting a test group according to a running time; setting an execution order of the test group; executing the test group in an execution order; obtaining the test result of the test group. The invention divides the test groups according to the running time and sets the execution sequence of each test group. Each test group is executed in the execution order, and the corresponding test results are obtained immediately after each test group is executed.The invention can efficiently and uninterruptedly use the stressapp tool to carry out the memory pressure test. Time and human resources are saved, while test accuracy is also provided.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

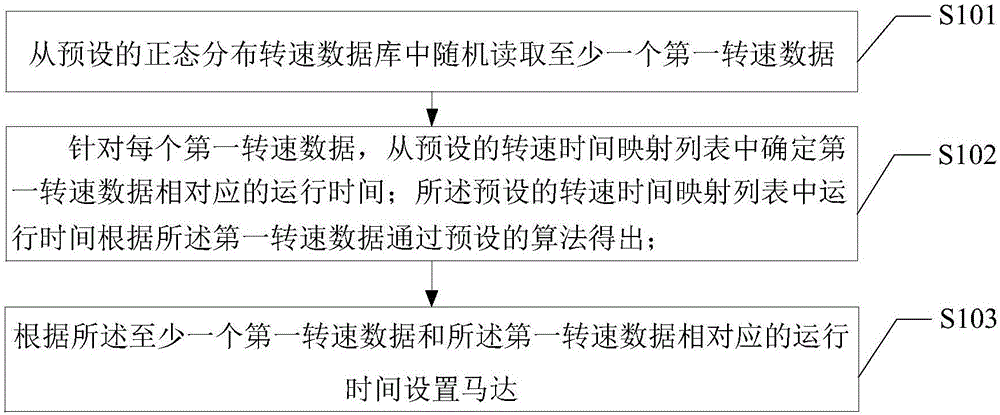

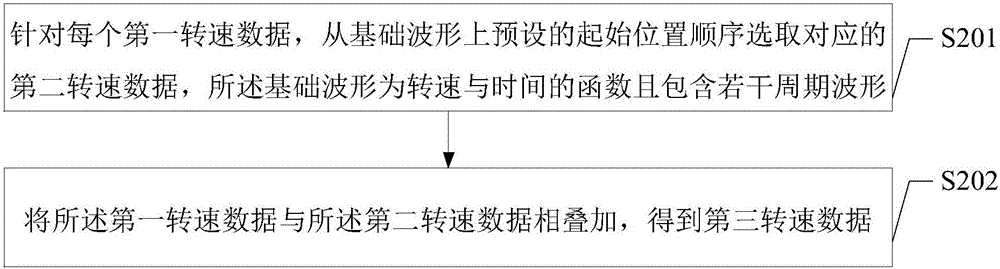

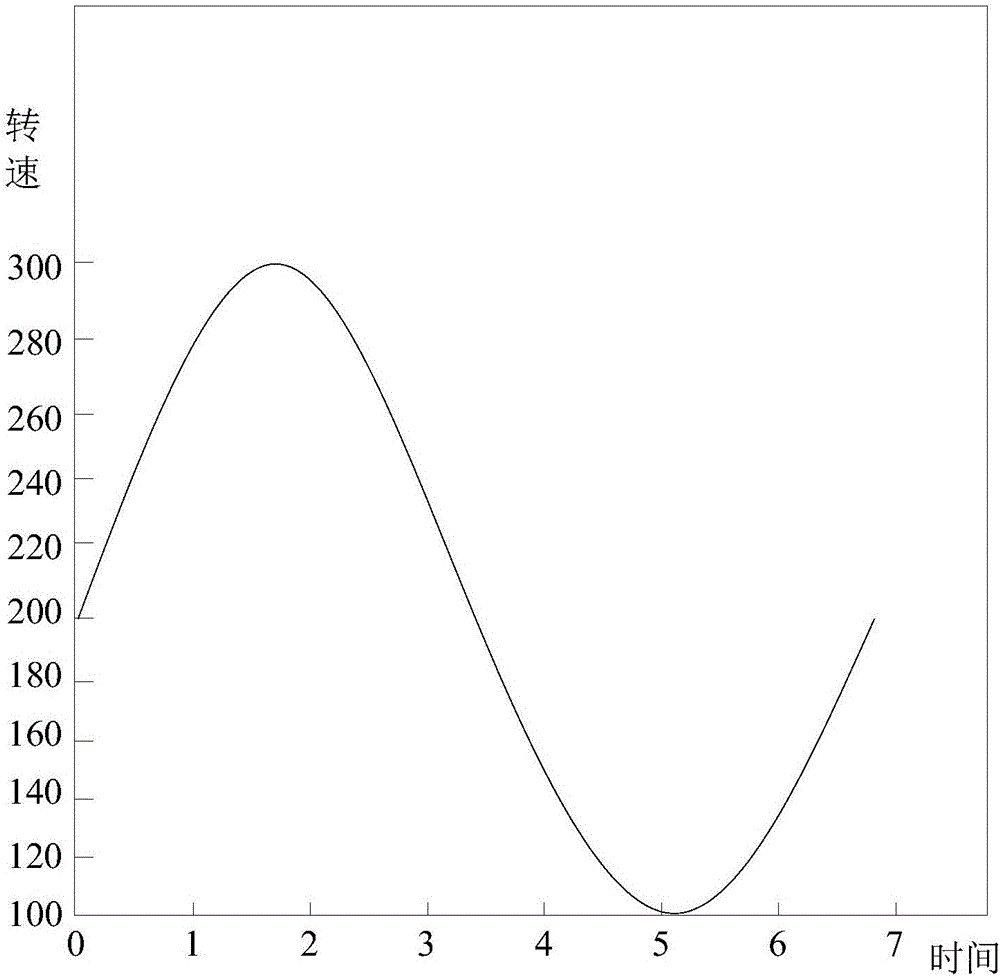

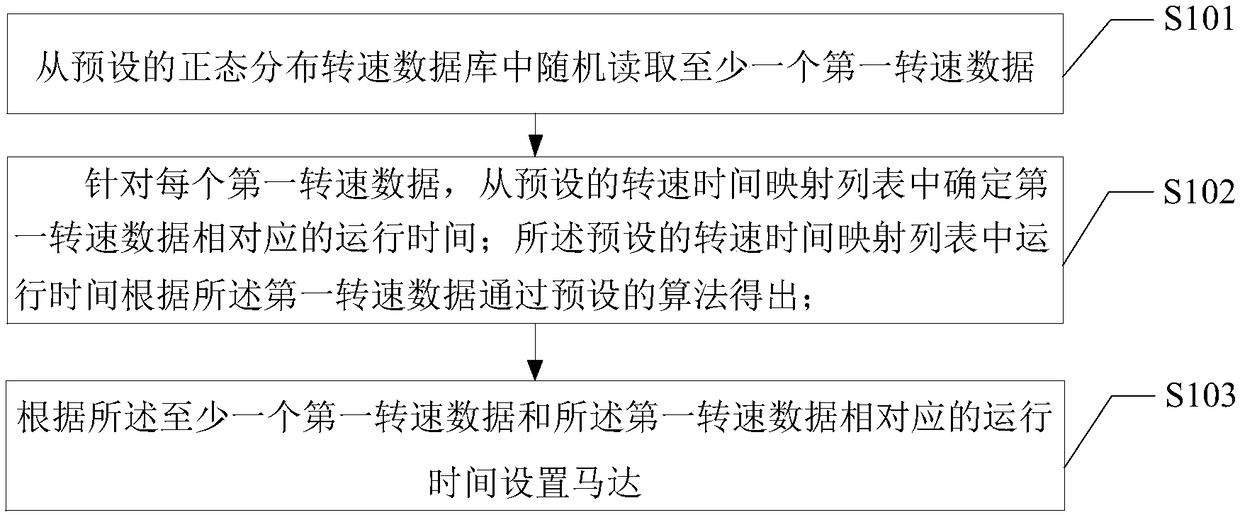

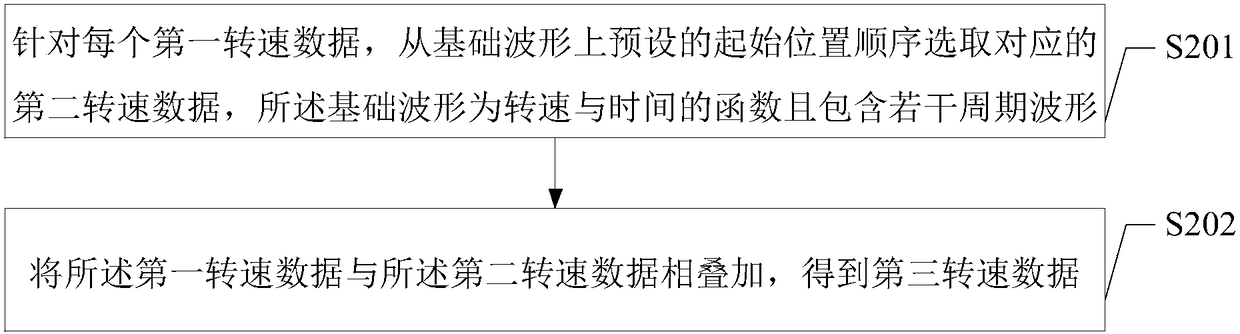

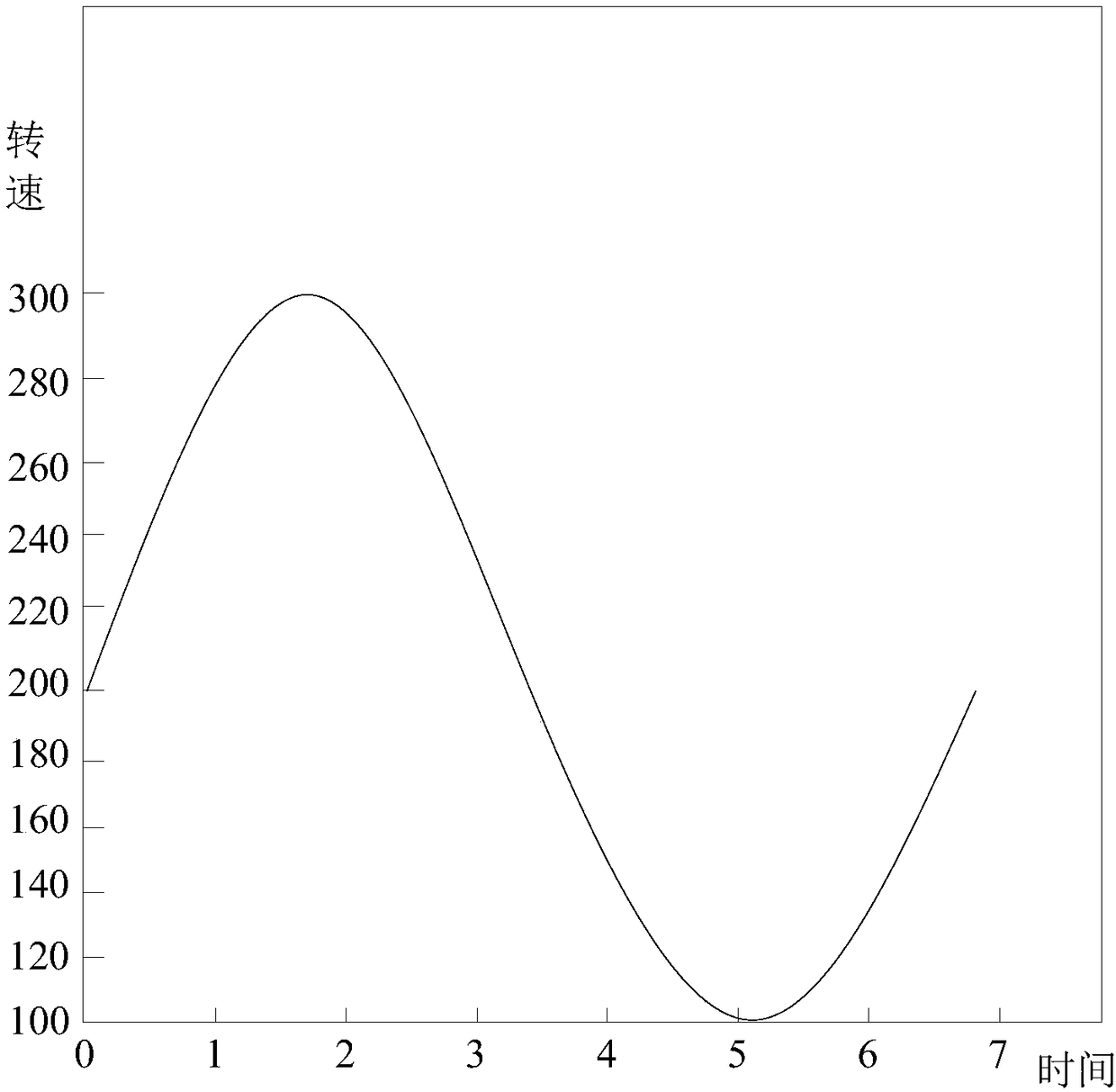

Method and device for simulating natural wind

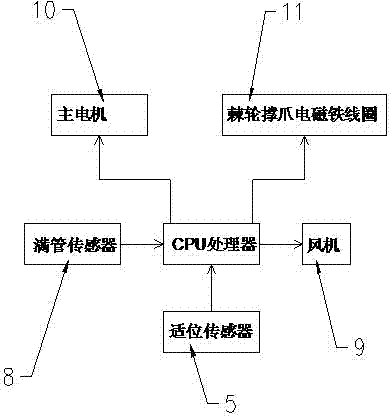

ActiveCN106481593AImprove user experiencePump controlNon-positive displacement fluid enginesRun time settingSimulation

The invention discloses a method and device for simulating natural wind. The method circularly executes the following steps: at least one first rotating speed datum is red at random from a preset normally-distributed rotating speed database, and corresponding running time of each first rotating speed datum through the preset algorithm is determined; according to the at least one first rotating speed datum and the corresponding running time of each first rotating speed datum, a motor is arranged, and the motor can run according to set rotating speed value and the running time; when the technical scheme is periodically executed, the first rotating speed data meeting normal distribution are red continuously at random, on the basis of the rotating speed value, the motor is arranged, and drives a fan to generate the wind speed meeting the normal distribution, the running time corresponding to each rotating speed is kept, and therefore the natural wind can be simulated as much as possible, and the use experience of a user is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD +1

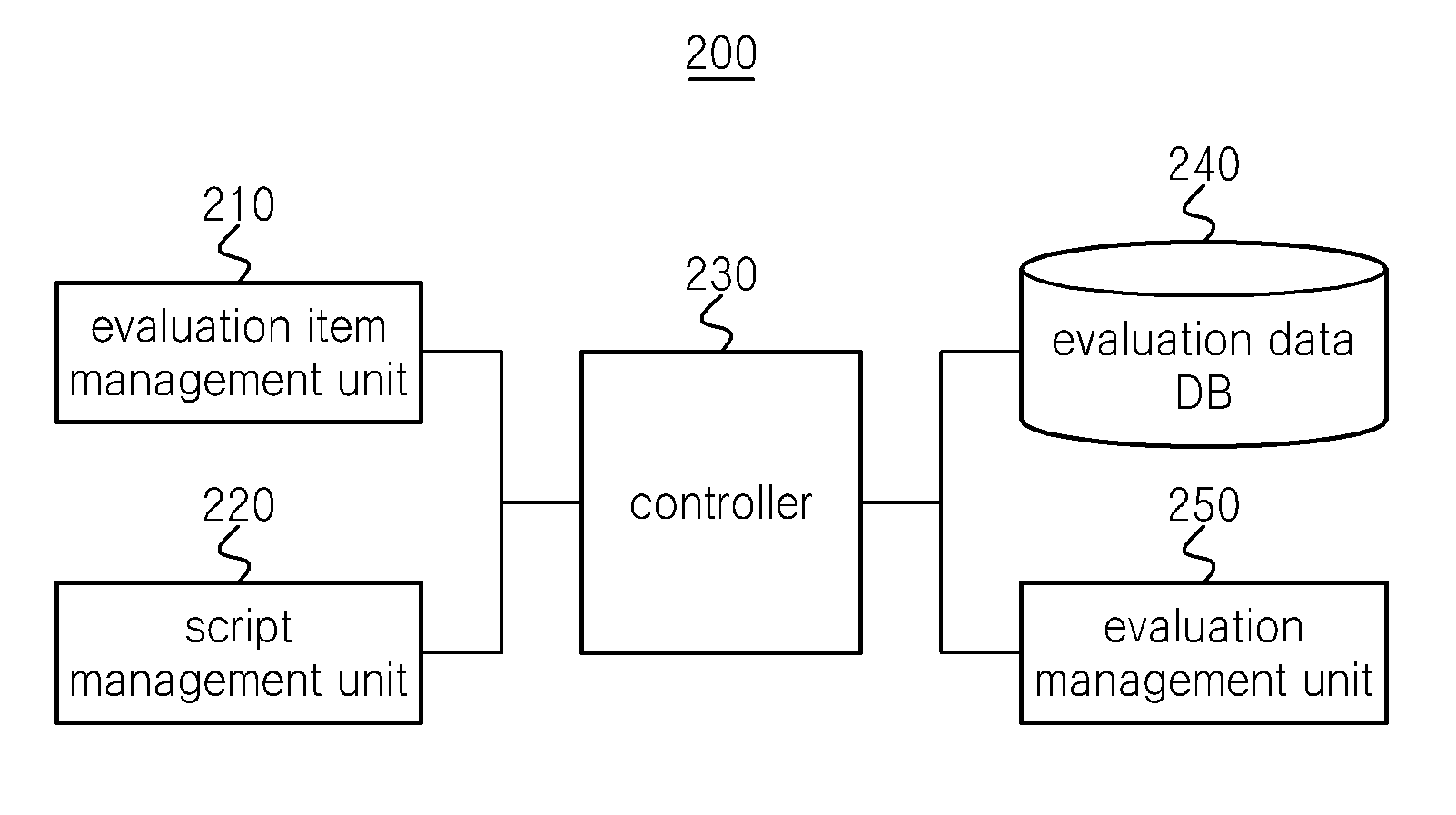

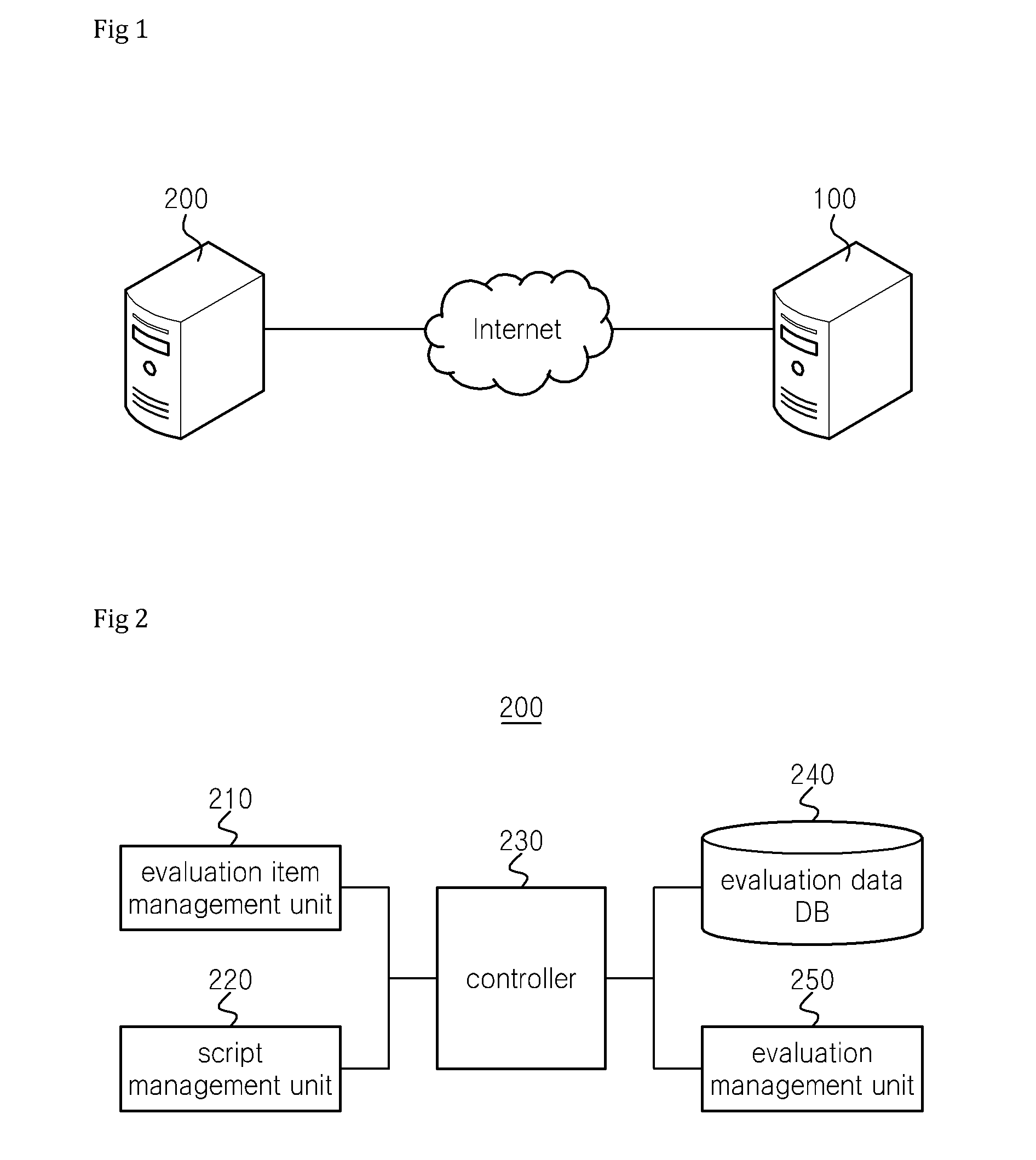

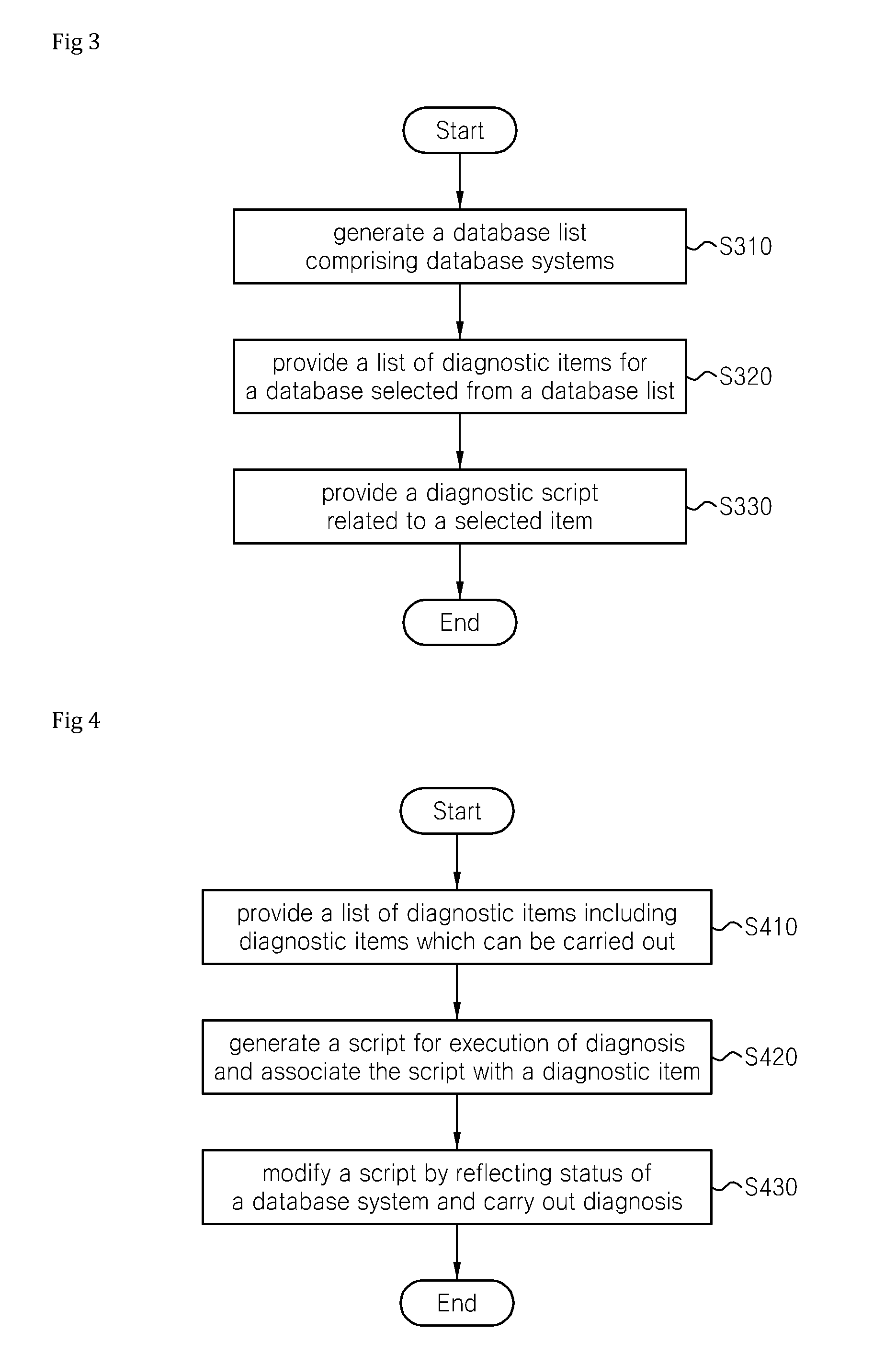

Method for providing database management and the database management server thereof

InactiveUS20130304695A1Complete and comfortable database managementManagement moreDigital data processing detailsError detection/correctionRun time settingRunning time

The present invention provides diagnosis and management of a database system. The method for database management comprises (a) generating a list of at least one database managed by the database system; (b) providing a list of diagnostic items including a plurality of diagnostic items which can be carried out against at least one database selected from the list; and (c) carrying out diagnosis by providing the database system with at least one script related to at least one diagnostic item selected from the list of diagnostic items, wherein the at least one script is configured to have a run time set up differently according to the status of the database system. Database management provides various diagnostic items through remote connection to a particular database system and providing a quantitative analysis of the corresponding diagnosis result, thereby enabling more complete and comfortable database management.

Owner:LG CNS

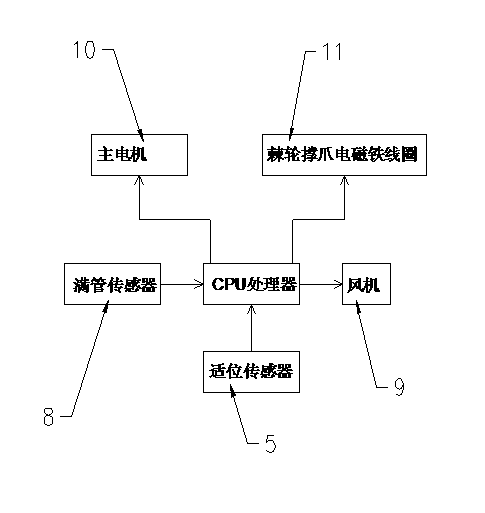

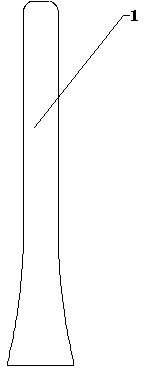

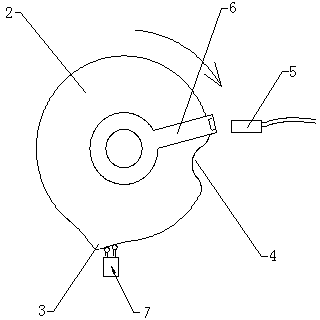

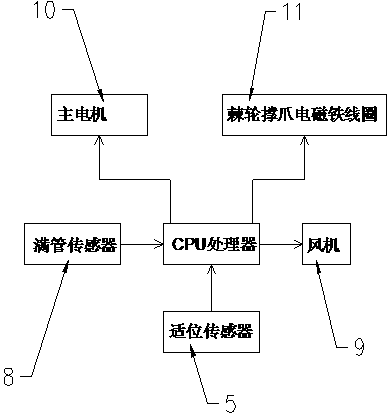

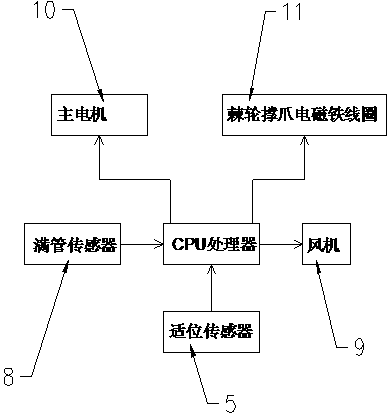

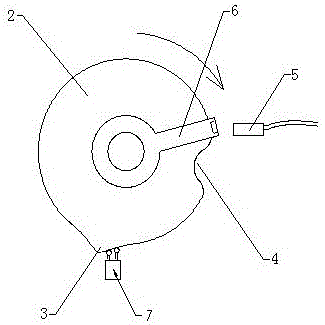

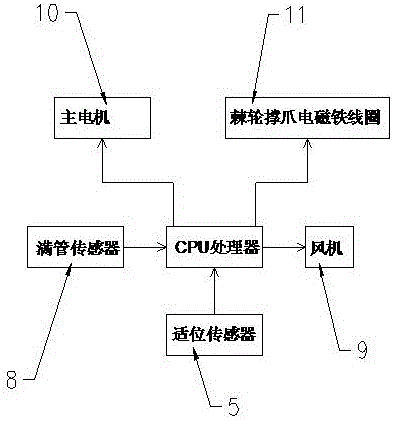

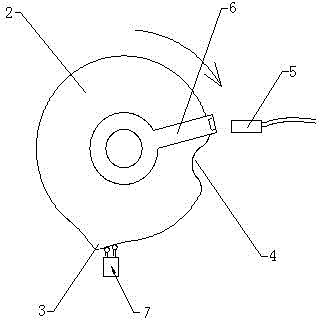

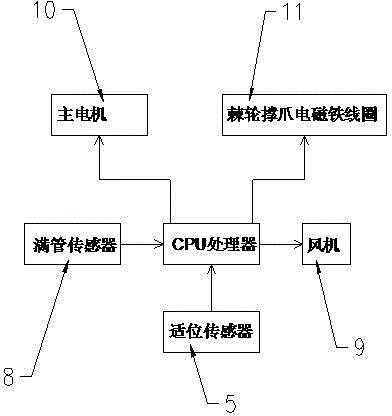

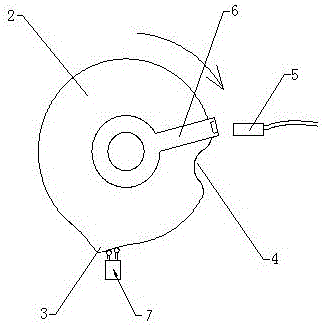

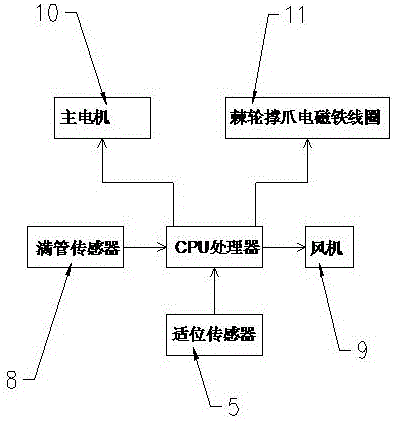

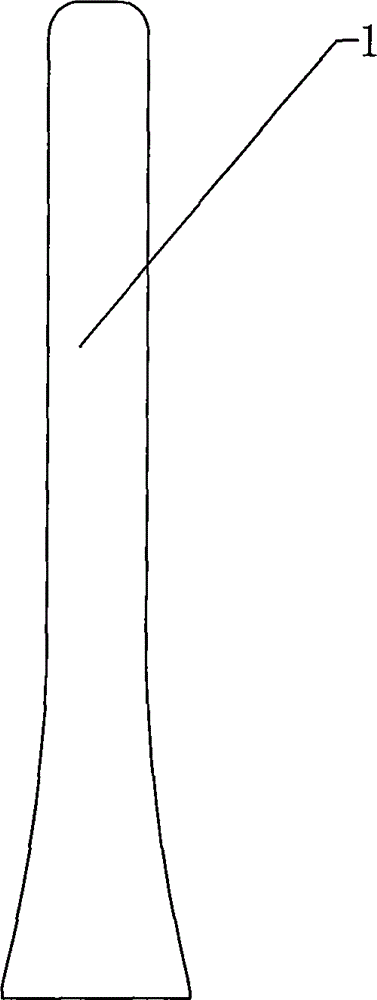

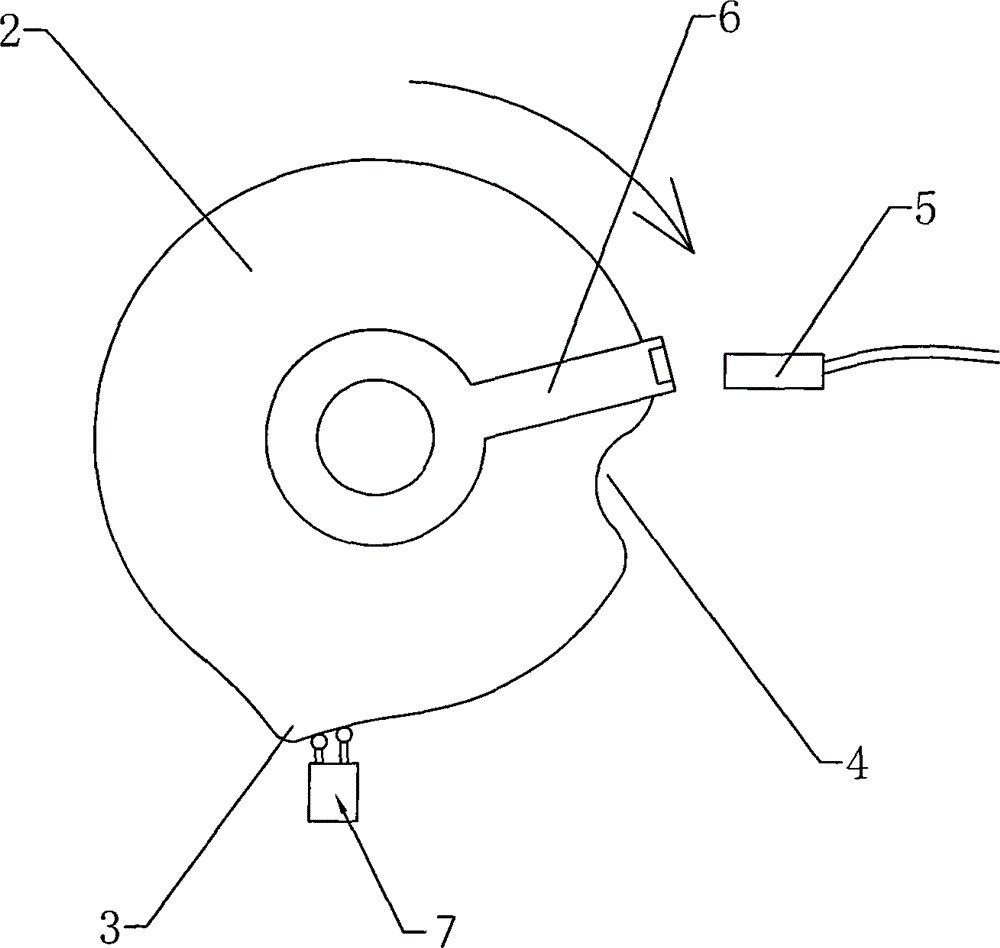

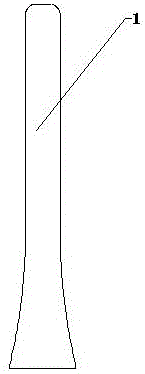

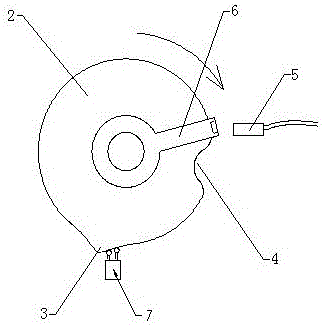

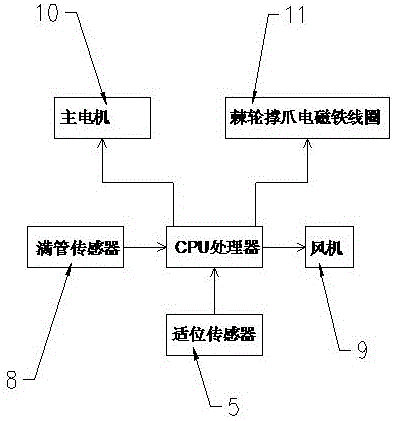

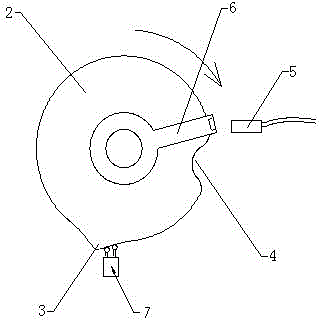

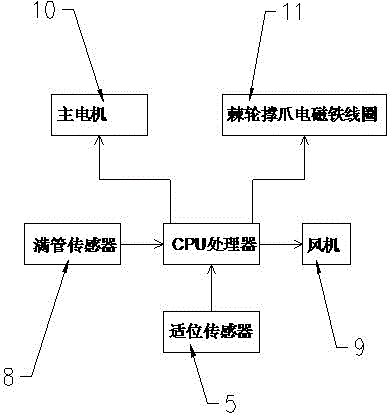

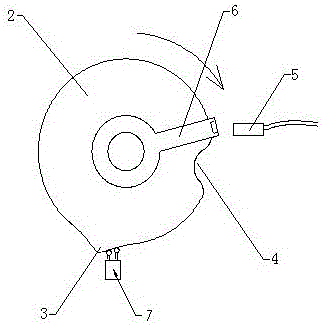

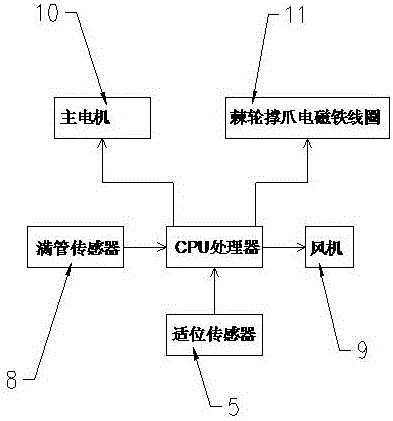

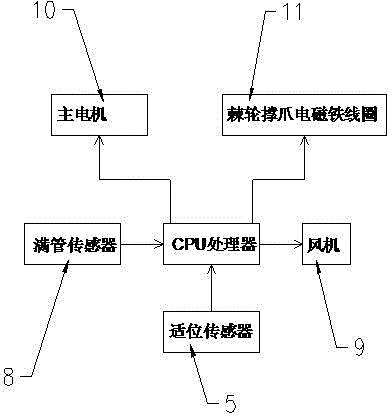

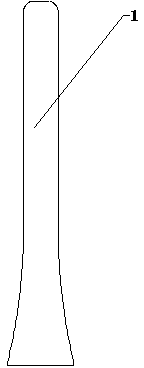

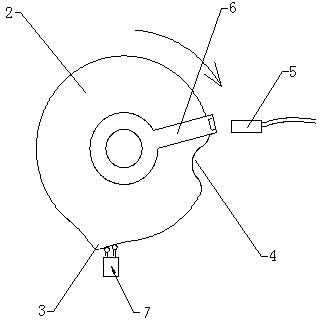

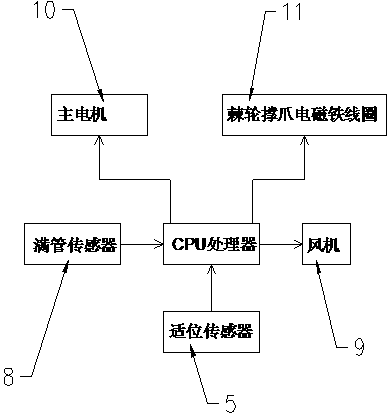

Control method and control device for reducing yarn breakage of spinning machine

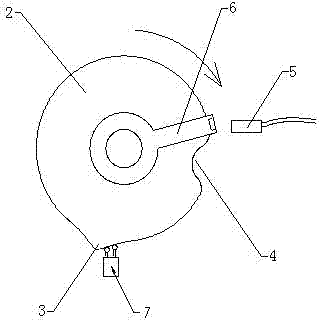

The invention discloses a control method for reducing yarn breakage of spinning machine. The control method includes: a starting procedure, a small yarn spinning procedure, a medium yarn spinning procedure, a large yarn spinning procedure and a doffing procedure. When an air blower is started, a ring plate moves upward to a start spinning position, then continue to move upward for the time of Pe; when the ring plate moves upward to an appropriate spinning position, a main motor begins to slow down the speed, the ring plate moves downward to the start spinning position for the time of Pf; then the ring plate moves upward to the appropriate spinning position, after that, moves downward to the start spinning position, and accordingly a balloon can be opened timely, the balloon wavelength is shortened, the yarn tension is reduced, and the yarn breakage rate in small yarn spinning procedure is dramatically reduced. In addition, the ring plate motor is protected, the run time of the ring plate motor can be set to 5 seconds since the start of the air blower, and if the spinning position sensor fails to work, the ring plate motor stops moving upwards in less than 5 seconds.

Owner:WEIFANG MEDICAL UNIV

Control method and device for reducing yarn break of spinning frame

The invention discloses a control method for reducing yarn break of a spinning frame. The control method comprises the following steps of starting, namely starting a fan and ensuring a ring plate goes up to an initial spinning position and then continuously goes up from the initial spinning position; when the ring plate goes up to a proper spinning position, ensuring that a main motor begins to run at a low speed and the ring plate goes down to the initial spinning position from the proper spinning position; running at a low speed for spinning, and when running time is equal to Pd, outputting a signal by using a proper position sensor and entering a medium yarn spinning step. The ring plate goes up to the proper spinning position and then goes down to the initial spinning position from the proper spinning position, so that ballooning can be timely opened, the wavelength of the ballooning is shortened, the yarn tension is reduced and the breakage of yarns in the small yarn spinning process is greatly reduced; the running time of a ring plate motor can be set to 5 seconds after the fan is started and the ring plate motor goes up for 5 second at most and stops if an initial spinning position sensor fails.

Owner:WEIFANG MEDICAL UNIV

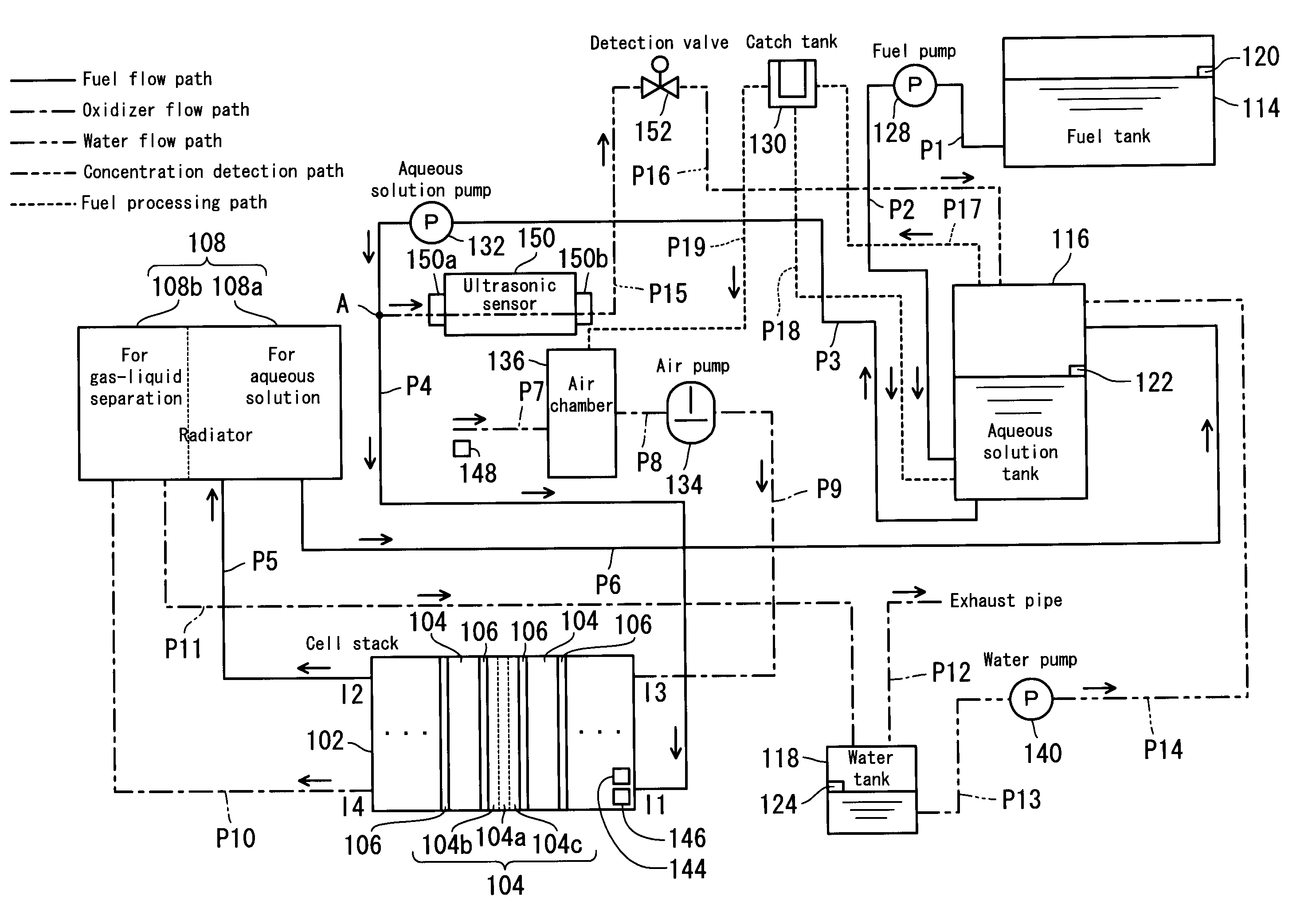

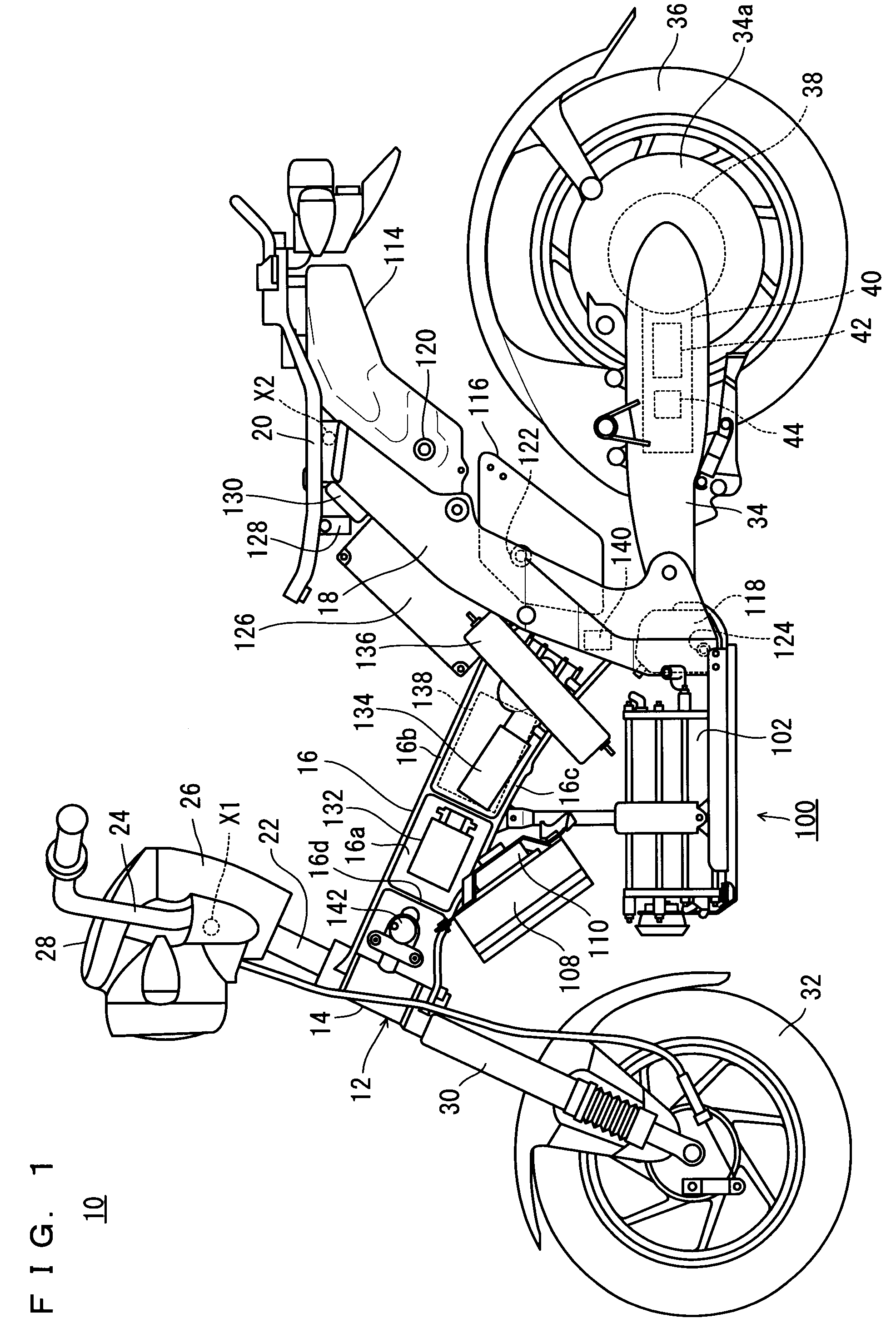

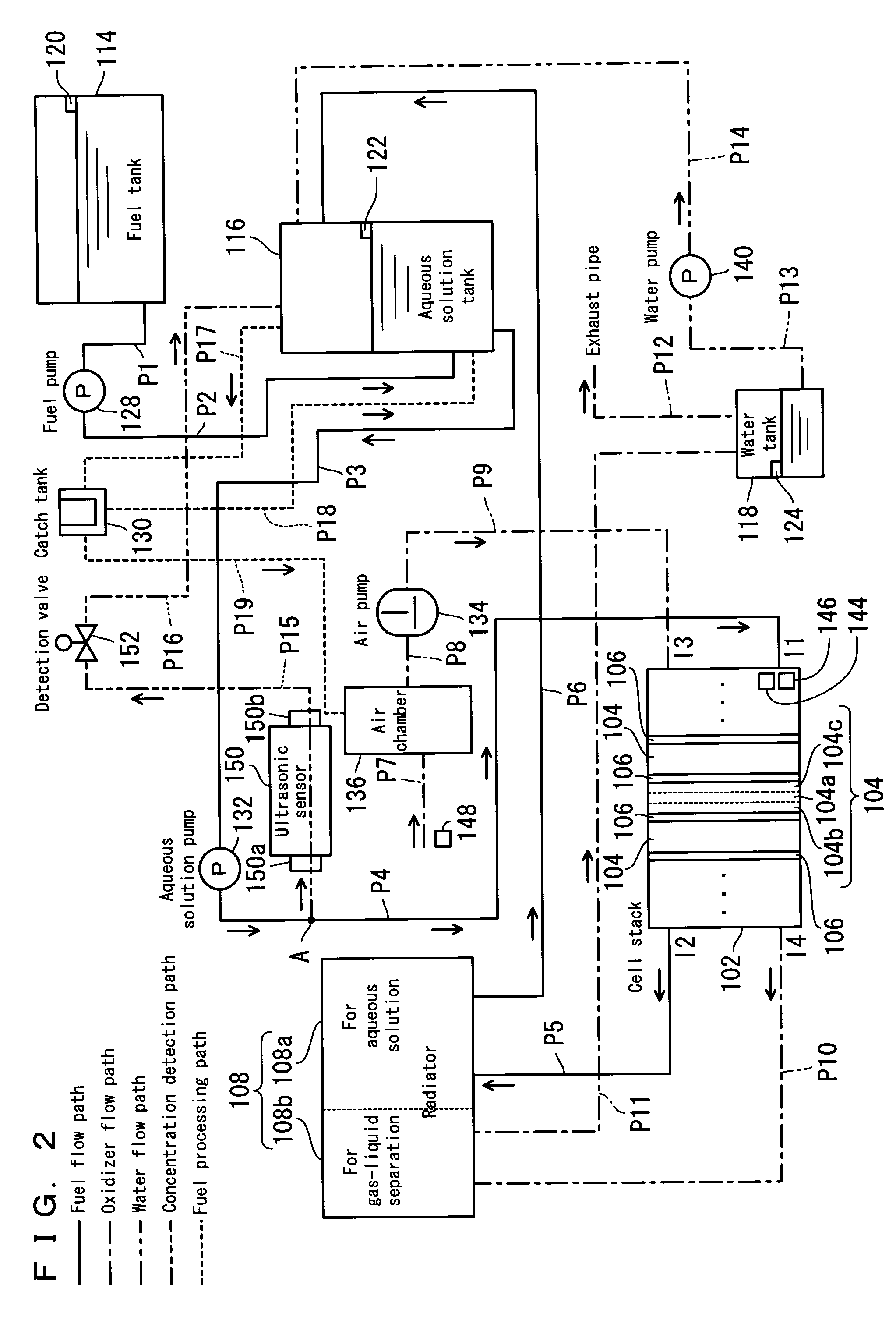

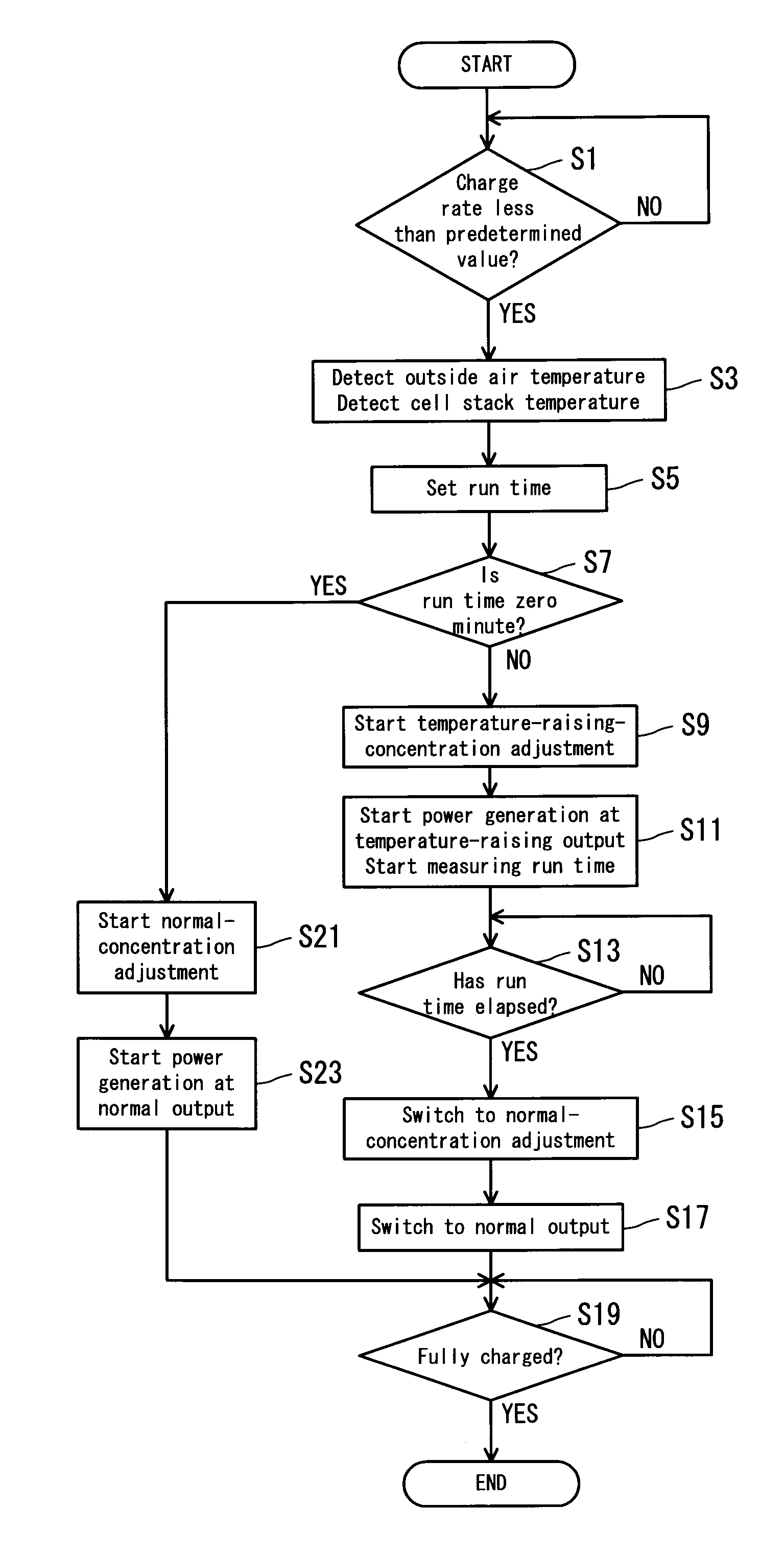

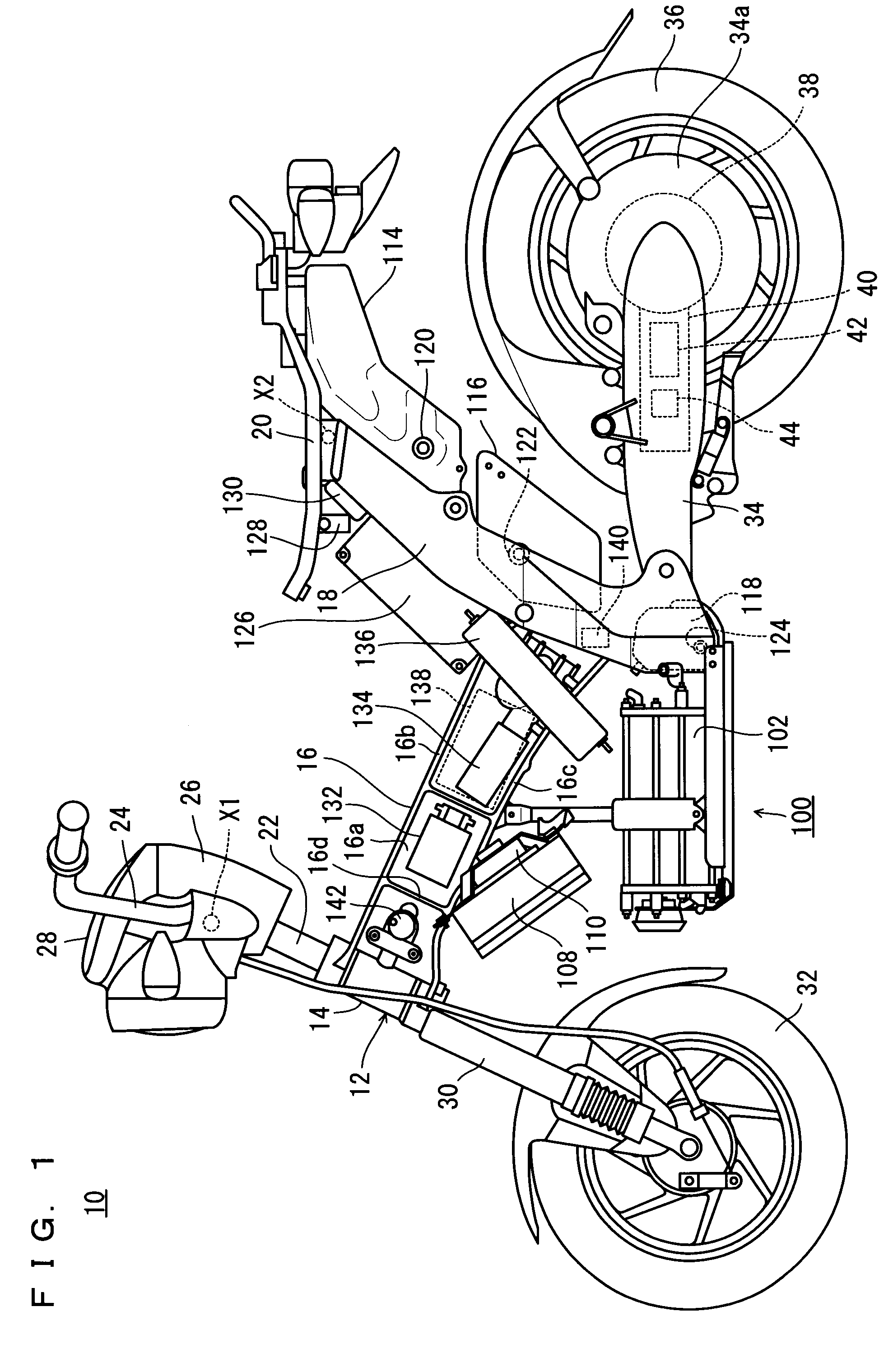

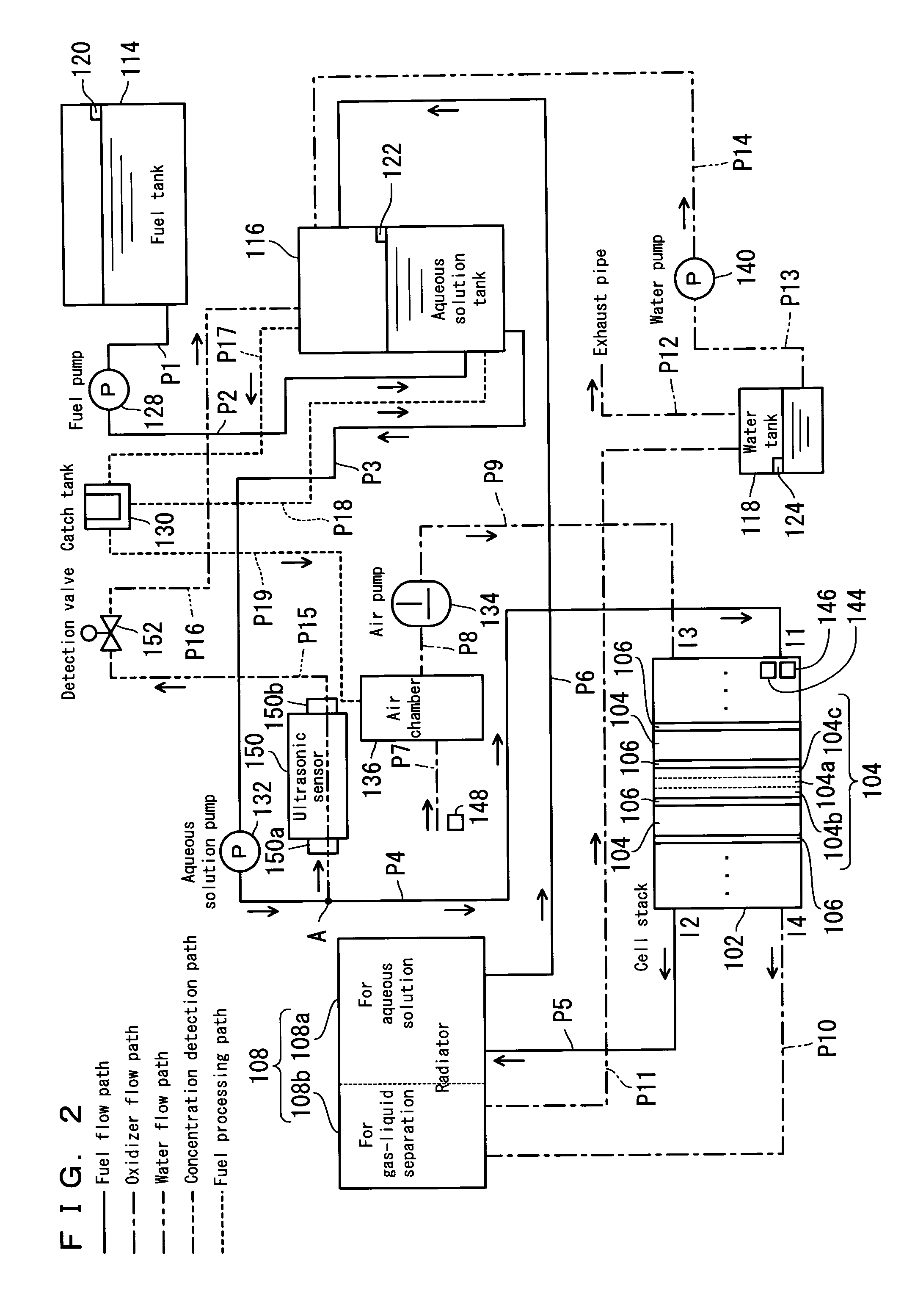

Fuel cell system

InactiveUS8071244B2Increase fuel temperatureFuel cell heat exchangeSolid electrolyte fuel cellsRun time settingFuel cells

A fuel cell system includes a cell stack, a temperature sensor which detects a temperature of the cell stack, an outside air temperature sensor which detects an outside air temperature, and a CPU which controls a process in the fuel cell system. When the temperature of the cell stack is lower than a predetermined temperature, the fuel cell system performs a temperature raising operation of the cell stack by making the concentration of aqueous methanol solution in an aqueous solution tank higher than in a normal operation and by making an output of an aqueous solution pump greater than in the normal operation. The CPU sets a run time for the temperature raising operation based on a detection result from the outside air temperature sensor, a detection result from the temperature sensor, and a run time setting table which is stored in a memory. The fuel cell system is capable of raising a temperature of the fuel cell quickly and stably to the predetermined temperature.

Owner:YAMAHA MOTOR CO LTD

Method and apparatus for controlling spinning yarn breakage

InactiveCN103060976BShort wavelengthReduce tensionContinuous wound-up machinesRun time settingLow speed

The invention discloses a method and an apparatus for controlling spinning yarn breakage. When a fan starts, a ring rail moves to the spinning starting line and continuously moves upwards; when the ring rail moves to the spinning line, the main motor starts running at a low speed, and the ring rail moves downwards from the spinning line to the starting spinning line, and then spins at the low speed. When the running time is equal to Pd, a position sensor sends signal for spinning in the middle. The ring rail moves upwards to the spinning line and then moves downwards to the starting spinning line, and then balloons are opened timely, so that the balloon wavelength is shortened, the yarn tension is reduced, and the spinning yarn breakage is dramatically reduced. The running time of the ring rail motor can also be set to 5 seconds from the beginning of the fan start, and if the starting spinning position sensor is out of order, the ring rail motor moves upwards and stops in five seconds.

Owner:WEIFANG MEDICAL UNIV

Fuel cell system

InactiveUS20080268311A1Increase fuel temperatureIncrease temperatureFuel cell heat exchangeSolid electrolyte fuel cellsRun time settingFuel cells

A fuel cell system includes a cell stack, a temperature sensor which detects a temperature of the cell stack, an outside air temperature sensor which detects an outside air temperature, and a CPU which controls a process in the fuel cell system. When the temperature of the cell stack is lower than a predetermined temperature, the fuel cell system performs a temperature raising operation of the cell stack by making the concentration of aqueous methanol solution in an aqueous solution tank higher than in a normal operation and by making an output of an aqueous solution pump greater than in the normal operation. The CPU sets a run time for the temperature raising operation based on a detection result from the outside air temperature sensor, a detection result from the temperature sensor, and a run time setting table which is stored in a memory. The fuel cell system is capable of raising a temperature of the fuel cell quickly and stably to the predetermined temperature.

Owner:YAMAHA MOTOR CO LTD

Method and apparatus for controlling spinning yarn breakage

InactiveCN103060976AShort wavelengthReduce tensionContinuous wound-up machinesRun time settingLow speed

The invention discloses a method and an apparatus for controlling spinning yarn breakage. When a fan starts, a ring rail moves to the spinning starting line and continuously moves upwards; when the ring rail moves to the spinning line, the main motor starts running at a low speed, and the ring rail moves downwards from the spinning line to the starting spinning line, and then spins at the low speed. When the running time is equal to Pd, a position sensor sends signal for spinning in the middle. The ring rail moves upwards to the spinning line and then moves downwards to the starting spinning line, and then balloons are opened timely, so that the balloon wavelength is shortened, the yarn tension is reduced, and the spinning yarn breakage is dramatically reduced. The running time of the ring rail motor can also be set to 5 seconds from the beginning of the fan start, and if the starting spinning position sensor is out of order, the ring rail motor moves upwards and stops in five seconds.

Owner:WEIFANG MEDICAL UNIV

Method and device for simulating natural wind

ActiveCN106481593BImprove user experiencePump controlNon-positive displacement fluid enginesRun time settingSimulation

The invention discloses a method and device for simulating natural wind. The method circularly executes the following steps: at least one first rotating speed datum is red at random from a preset normally-distributed rotating speed database, and corresponding running time of each first rotating speed datum through the preset algorithm is determined; according to the at least one first rotating speed datum and the corresponding running time of each first rotating speed datum, a motor is arranged, and the motor can run according to set rotating speed value and the running time; when the technical scheme is periodically executed, the first rotating speed data meeting normal distribution are red continuously at random, on the basis of the rotating speed value, the motor is arranged, and drives a fan to generate the wind speed meeting the normal distribution, the running time corresponding to each rotating speed is kept, and therefore the natural wind can be simulated as much as possible, and the use experience of a user is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD +1

Control Method for Reducing Yarn Breakage on Spinning Frame

InactiveCN104562329BShort wavelengthReduce tensionTextiles and paperProgramme control in sequence/logic controllersYarnRun time setting

The invention discloses a control method for reducing broken ends of yarns of a spinning frame. The control method is characterized by comprising a starting step, a step for spinning small yarns, a step for spinning medium yarns, a step for spinning large yarns, a yarn feeding step and a high-speed halfway stopping step. When a fan is started, a ring plate moves upwards to an initial spinning position and moves upwards continuously; the ring plate moves upwards to an appropriate spinning position; a main motor is operated at a low speed; the ring plate moves downwards to the initial spinning position from the appropriate spinning position; the spinning is carried out at a low speed; if the operating time is equal to Pd, the step for spinning the medium yarns is started; the ring plate moves upwards to the appropriate spinning position first and then moves downwards to the initial spinning position; an air ring can be opened in time; the wavelength of the air ring is shortened; the tension of the yarn is reduced, and the broken end rate of yarns when the small yarns are spun can be greatly reduced; in order to protect the ring plate motor, the operating time of the ring plate motor can be set to start five seconds later after the fan is started, and if an initial spinning position sensor is in malfunction, the ring plate motor can be stopped when moving upwards for five seconds at most.

Owner:WEIFANG MEDICAL UNIV

Electronic chronometer

Reduces energy consumption by running hands only when needed. By pressing down the mode changeover switch, the second hand can be selectively moved to the position of the pointer running start time setting mode (wake-up), the position of the pointer running stop time setting mode (sleep) and the position of the alarm time setting mode (alarm) . With the second hand at each setting mode position, set the hour / minute hand to the desired time by pressing the time setting switch, thereby setting the hand stop time, hand start time, and alarm time. When the pointer operation stop time is reached, the operation of the pointer is stopped, and when the pointer operation start time is reached, the time pointer is rapidly advanced to the normal time, and then the normal time display is performed. In the case that the pointer operation stops, within a predetermined period of time before the alarm time is reached, the pointer operates in a manner similar to the above, returning to a normal operating state, and then an alarm is generated when the alarm time is reached.

Owner:SEIKO INSTR INC

Control Method for Reducing Yarn Breaks on Spinning Frame

ActiveCN104562315BShort wavelengthReduce tensionContinuous wound-up machinesRun time settingYarn tension

The invention discloses a control method for reducing yarn broken heads of a spinning frame. The control method comprises a starting step, a small-yarn spinning step, a middle-yarn spinning step, a big-yarn spinning step and a doffing step; in the starting step, a fan is started while a steel collar plate moves up to an initial spinning position, and then the steel collar plate moves up from the initial spinning position till reaching a proper spinning position, and then a primary motor starts to run at low speed, the steel collar plate moves down from the proper spinning position to the initial spinning position and then runs at the low speed and spins, and if the running time is equal to Pd, the middle-yarn spinning step is started; the steel collar plate firstly moves up to the proper spinning position and then moves down to the initial spinning position from the proper spinning position; an air ring is timely opened, the wavelength of the air ring is shortened, the yarn tension is reduced, and the breaking rate of yarns during the small-yarn spinning process is greatly reduced; the steel collar plate motor can be protected; the running time of the steel collar plate motor can be set as 5 seconds after the fan is started; if a sensor is in fault at the initial spinning position, the steel collar plate motor moves up for at most 5 seconds and then stops.

Owner:苏州能事达针纺织造有限公司

Control method and device for reducing yarn breakage of spinning frame

InactiveCN103149872BShort wavelengthReduce tensionProgramme control in sequence/logic controllersRun time settingLow speed

The invention discloses a control method used for reducing broken yarn ends of a spinning machine. The control method comprises a starting step, a small yarn spinning step, a middle yarn spinning step, a large yarn spinning step and a yarn discharge step. The starting step is that a fan is started, a steel collar plate simultaneously moves upwards to the initial spinning position when the fan is started, then the steel collar plate can continue moving upwards from the initial spinning position, the steel collar plate moves upwards to the appropriate place spinning position, then a main motor begins to run at low speed, and the steel collar plate can move downwards from the appropriate place spinning position to the initial spinning position to run at low speed to spin. If running time is equal to Pd, the middle yarn spinning step begins, the steel collar plate can move upwards to the appropriate place spinning position and then moves downwards from the appropriate place spinning position to the initial spinning position, an air ring is opened timely, wavelength of the air ring is shortened, yarn tension is reduced, and broken yarn end rate in spinning small yarns is remarkably reduced. A steel collar plate motor can be protected, and running time of the steel collar plate motor can be arranged 5 seconds after the fan is started. If an initial spinning position sensor is in fault, the steel collar plate motor moves upwards 5 seconds at most to be stopped.

Owner:WEIFANG MEDICAL UNIV

Control method and device for reducing yarn breakage of spinning frame

ActiveCN104570906BShort wavelengthReduce tensionProgramme control in sequence/logic controllersNumerical controlRun time settingLow speed

Owner:青纺联(枣庄)纤维科技有限公司

Control method for reducing broken ends of yarns of spinning frame

InactiveCN104562329AShort wavelengthReduce tensionTextiles and paperProgramme control in sequence/logic controllersRun time settingYarn

The invention discloses a control method for reducing broken ends of yarns of a spinning frame. The control method is characterized by comprising a starting step, a step for spinning small yarns, a step for spinning medium yarns, a step for spinning large yarns, a yarn feeding step and a high-speed halfway stopping step. When a fan is started, a ring plate moves upwards to an initial spinning position and moves upwards continuously; the ring plate moves upwards to an appropriate spinning position; a main motor is operated at a low speed; the ring plate moves downwards to the initial spinning position from the appropriate spinning position; the spinning is carried out at a low speed; if the operating time is equal to Pd, the step for spinning the medium yarns is started; the ring plate moves upwards to the appropriate spinning position first and then moves downwards to the initial spinning position; an air ring can be opened in time; the wavelength of the air ring is shortened; the tension of the yarn is reduced, and the broken end rate of yarns when the small yarns are spun can be greatly reduced; in order to protect the ring plate motor, the operating time of the ring plate motor can be set to start five seconds later after the fan is started, and if an initial spinning position sensor is in malfunction, the ring plate motor can be stopped when moving upwards for five seconds at most.

Owner:WEIFANG MEDICAL UNIV

A control method and device for reducing yarn breakage of spinning frame

InactiveCN104480578BShort wavelengthReduce tensionContinuous wound-up machinesRun time settingLow speed

The invention discloses a control method for reducing yarn breakage of a spinning frame. The control method comprises the starting step, the step of spinning the small yarn, the step of spinning the medium yarn, the step of spinning the large yarn and the step of doffing. A blower is started, a steel collar plate is upwards moved to the initial spinning position while the blower is started, and continuously moved upwards from the initial spinning position. The upward time is Pe. The steel collar plate is upwards moved to the suitable spinning position, and then a main motor is operated in the low speed, the steel collar plate is downwards moved from the suitable spinning position to the initial spinning position. The downward time is Pf. The steel collar plate is upwards moved to the suitable spinning position first, and downwards moved from the suitable spinning position to the initial spinning position. An air ring is opened in time, the wave length of the air ring is shortened, the yarn tension is reduced and the breakage rate of the yarn is greatly reduced during the moment of spinning the small yarn. In addition, the motor of the steel collar plate can be protected, and the operation time of the motor of the steel collar plate is set as 5 seconds from the blower start. If a sensor on the initial spinning position does not work, the motor of the steel collar plate is stopped after at most 5 seconds of upward movement.

Owner:WEIFANG MEDICAL UNIV

Control method for reducing yarn breakage of spinning machine

The invention discloses a control method for reducing yarn breakage of a spinning machine. When a fan starts, a ring rail moves to the spinning starting line and continuously moves upwards; when the ring rail moves to the spinning line, a main motor starts running at a low speed, and the ring rail moves downwards from the spinning line to the starting spinning line, and then spins at the low speed. When the running time is equal to Pd, a position sensor sends signal for spinning in the middle. The ring rail moves upwards to the spinning line and then moves downwards to the starting spinning line, and then balloons are opened timely, so that the balloon wavelength is shortened, the yarn tension is reduced, and the spinning yarn breakage is dramatically reduced. The running time of the ring rail motor can also be set to 5 seconds from the beginning of the fan start, and if the starting spinning position sensor is out of order, the ring rail motor moves upwards and stops in five seconds.

Owner:赵清滨

Control method and control machine used for reducing broken yarn ends of spinning machine

InactiveCN103149872AShort wavelengthReduce tensionProgramme control in sequence/logic controllersRun time settingLow speed

The invention discloses a control method used for reducing broken yarn ends of a spinning machine. The control method comprises a starting step, a small yarn spinning step, a middle yarn spinning step, a large yarn spinning step and a yarn discharge step. The starting step is that a fan is started, a steel collar plate simultaneously moves upwards to the initial spinning position when the fan is started, then the steel collar plate can continue moving upwards from the initial spinning position, the steel collar plate moves upwards to the appropriate place spinning position, then a main motor begins to run at low speed, and the steel collar plate can move downwards from the appropriate place spinning position to the initial spinning position to run at low speed to spin. If running time is equal to Pd, the middle yarn spinning step begins, the steel collar plate can move upwards to the appropriate place spinning position and then moves downwards from the appropriate place spinning position to the initial spinning position, an air ring is opened timely, wavelength of the air ring is shortened, yarn tension is reduced, and broken yarn end rate in spinning small yarns is remarkably reduced. A steel collar plate motor can be protected, and running time of the steel collar plate motor can be arranged 5 seconds after the fan is started. If an initial spinning position sensor is in fault, the steel collar plate motor moves upwards 5 seconds at most to be stopped.

Owner:WEIFANG MEDICAL UNIV

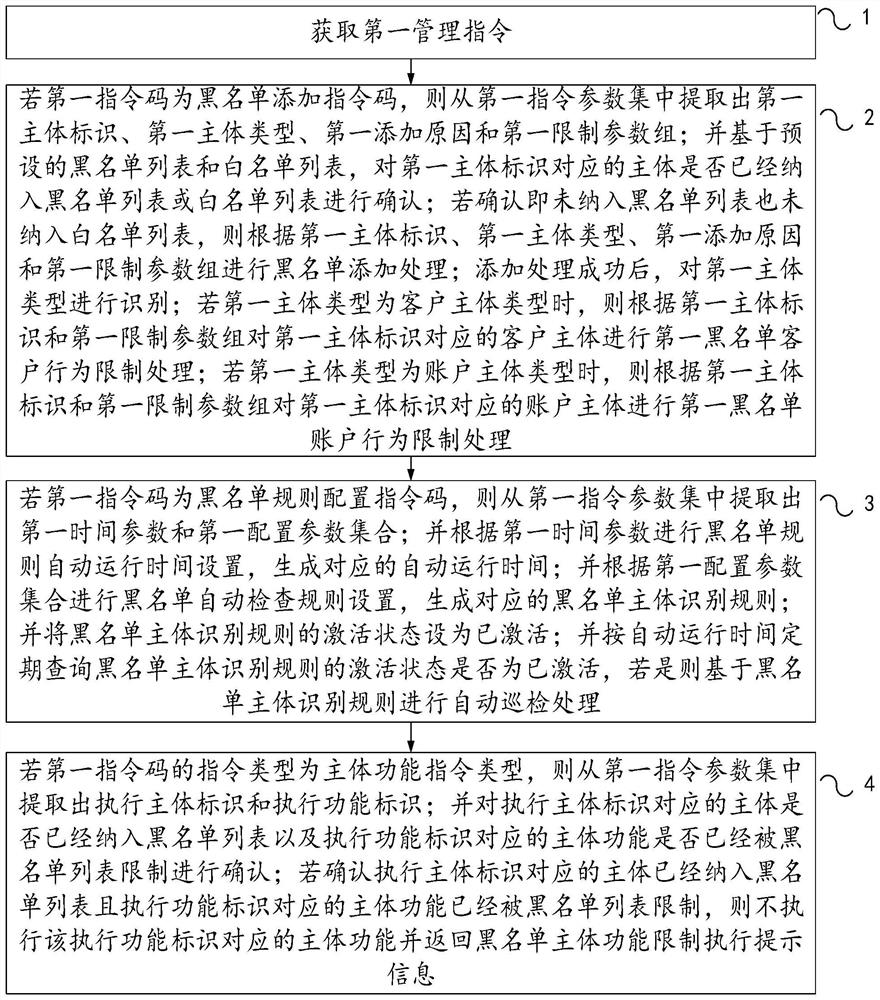

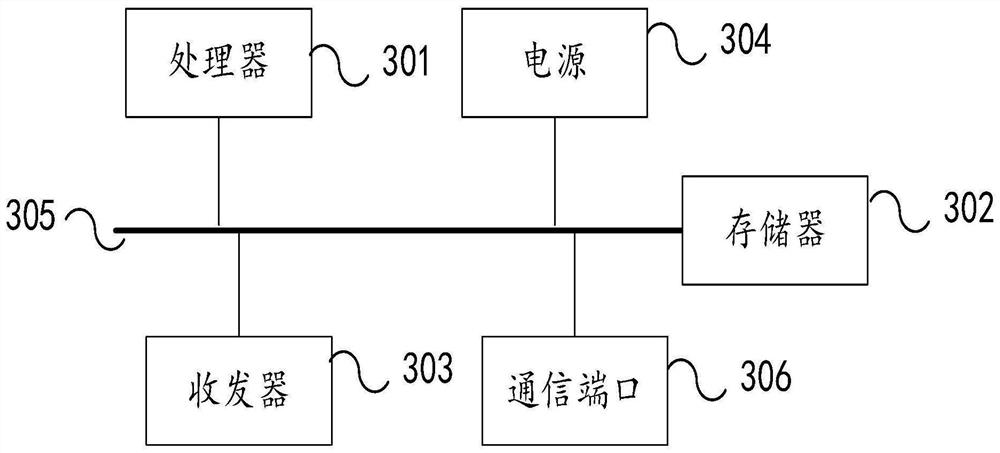

Blacklist processing method

PendingCN114240491AImprove convenienceImprove real-time performanceFinanceResourcesRun time settingBody identification

The embodiment of the invention relates to a blacklist processing method. The method comprises the following steps: acquiring a first management instruction; if the instruction code is a blacklist adding instruction code, whether the main body is included in a blacklist or a white list or not is confirmed; if so, adding the blacklist; if the type is the client main body type, carrying out first blacklist client behavior restriction processing; if the account type is the account main body type, carrying out first blacklist account behavior restriction processing; if the instruction code is a blacklist rule configuration instruction code, carrying out automatic running time setting and blacklist automatic checking rule setting; activating a blacklist main body identification rule; automatic inspection processing is carried out; and if the instruction type is a main body function instruction type, determining that the main body is included in the blacklist and the main body function corresponding to the execution function identifier is limited by the blacklist, not executing the function and returning prompt information. According to the invention, the risk clients can be found and limited in time, and the platform operation and maintenance risk is reduced.

Owner:北京维卓网络科技有限公司

Handheld automatic flag raising and lowering device

The invention relates to a handheld automatic flag raising and lowering device. The handheld automatic flag raising and lowering device comprises an improved flag raising and lowering crank and is characterized in that the tail end of a rolling sleeve joint is manufactured into a prism with at least 3 sides, and the prism is concentric to a rolling sleeve and can be mounted a handheld electric rolling device; the handheld electric rolling device achieves the functions of forward and backward rotation, speed regulation, starting and stopping, and operating time setting. The handheld automatic flag raising and lowering device is powered by dry batteries or lithium batteries to save an external alternate current power supply; the rolling sleeve joint can be transformed from an original manualflag raising and lowering crank. A user can hold the handheld automatic flag raising and lowering device by hands to stably control the time and speed of flag raising and lowering and meanwhile to reduce the labor intensity.

Owner:杨相宜

A control method and device for reducing yarn breakage of spinning frame

The invention discloses a control method for reducing yarn break of a spinning frame. The control method comprises the following steps of starting, namely starting a fan and ensuring a ring plate goes up to an initial spinning position and then continuously goes up from the initial spinning position; when the ring plate goes up to a proper spinning position, ensuring that a main motor begins to run at a low speed and the ring plate goes down to the initial spinning position from the proper spinning position; running at a low speed for spinning, and when running time is equal to Pd, outputting a signal by using a proper position sensor and entering a medium yarn spinning step. The ring plate goes up to the proper spinning position and then goes down to the initial spinning position from the proper spinning position, so that ballooning can be timely opened, the wavelength of the ballooning is shortened, the yarn tension is reduced and the breakage of yarns in the small yarn spinning process is greatly reduced; the running time of a ring plate motor can be set to 5 seconds after the fan is started and the ring plate motor goes up for 5 second at most and stops if an initial spinning position sensor fails.

Owner:WEIFANG MEDICAL UNIV

A control method for reducing yarn breakage in a spinning frame

InactiveCN104532417BShort wavelengthReduce tensionContinuous wound-up machinesRun time settingLow speed

The invention discloses a control method for reducing breakage of yarn of a spinning machine. The starting step begins with starting of a fan, a ring plate ascends to the spinning beginning position while the fan is started, then continues ascending from the spinning beginning position and ascends to the suitable-station spinning position, a main motor begins operating at a low speed, the ring plate descends to the spinning beginning position from the suitable-station spinning position and then operates at a lower speed to carry out spinning, when operating time is equal to Pd, a suitable-station sensor outputs signals, the middle yarn spinning step is executed, the ring plate ascends to the suitable-station spinning position at first and then descends to the spinning beginning position from the suitable-station spinning position, an air ring can be opened in time, the wave length of the air ring is shortened, yarn tension is reduced, and therefore the breakage rate of the yarn in the small yarn spinning process is greatly reduced; the operating time of the motor of the ring plate can be set to be five seconds from starting of the fan, and if a spinning beginning position sensor is out of order, the ring plate stops after ascending for at most five seconds.

Owner:WEIFANG MEDICAL UNIV

Control method for reducing yarn broken heads of spinning frame

ActiveCN104562315AShort wavelengthReduce tensionContinuous wound-up machinesRun time settingLow speed

The invention discloses a control method for reducing yarn broken heads of a spinning frame. The control method comprises a starting step, a small-yarn spinning step, a middle-yarn spinning step, a big-yarn spinning step and a doffing step; in the starting step, a fan is started while a steel collar plate moves up to an initial spinning position, and then the steel collar plate moves up from the initial spinning position till reaching a proper spinning position, and then a primary motor starts to run at low speed, the steel collar plate moves down from the proper spinning position to the initial spinning position and then runs at the low speed and spins, and if the running time is equal to Pd, the middle-yarn spinning step is started; the steel collar plate firstly moves up to the proper spinning position and then moves down to the initial spinning position from the proper spinning position; an air ring is timely opened, the wavelength of the air ring is shortened, the yarn tension is reduced, and the breaking rate of yarns during the small-yarn spinning process is greatly reduced; the steel collar plate motor can be protected; the running time of the steel collar plate motor can be set as 5 seconds after the fan is started; if a sensor is in fault at the initial spinning position, the steel collar plate motor moves up for at most 5 seconds and then stops.

Owner:苏州能事达针纺织造有限公司

Control method and control device for reducing yarn breakage of spinning machine

The invention discloses a control method for reducing yarn breakage of spinning machine. The control method includes: a starting procedure, a small yarn spinning procedure, a medium yarn spinning procedure, a large yarn spinning procedure and a doffing procedure. When an air blower is started, a ring plate moves upward to a start spinning position, then continue to move upward for the time of Pe; when the ring plate moves upward to an appropriate spinning position, a main motor begins to slow down the speed, the ring plate moves downward to the start spinning position for the time of Pf; then the ring plate moves upward to the appropriate spinning position, after that, moves downward to the start spinning position, and accordingly a balloon can be opened timely, the balloon wavelength is shortened, the yarn tension is reduced, and the yarn breakage rate in small yarn spinning procedure is dramatically reduced. In addition, the ring plate motor is protected, the run time of the ring plate motor can be set to 5 seconds since the start of the air blower, and if the spinning position sensor fails to work, the ring plate motor stops moving upwards in less than 5 seconds.

Owner:WEIFANG MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com