Control Method for Reducing Yarn Breakage on Spinning Frame

A control method and technology of a spinning frame are applied to the control of the spinning process of the spinning frame, the control of reducing the yarn breakage of the spinning frame, and the field of the spinning frame, which can solve fire, control difficulties, and difficulty in the yarn breakage rate of the spinning frame, etc. problems, to achieve the effect of reducing yarn tension, reducing end breakage and shortening balloon wavelength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

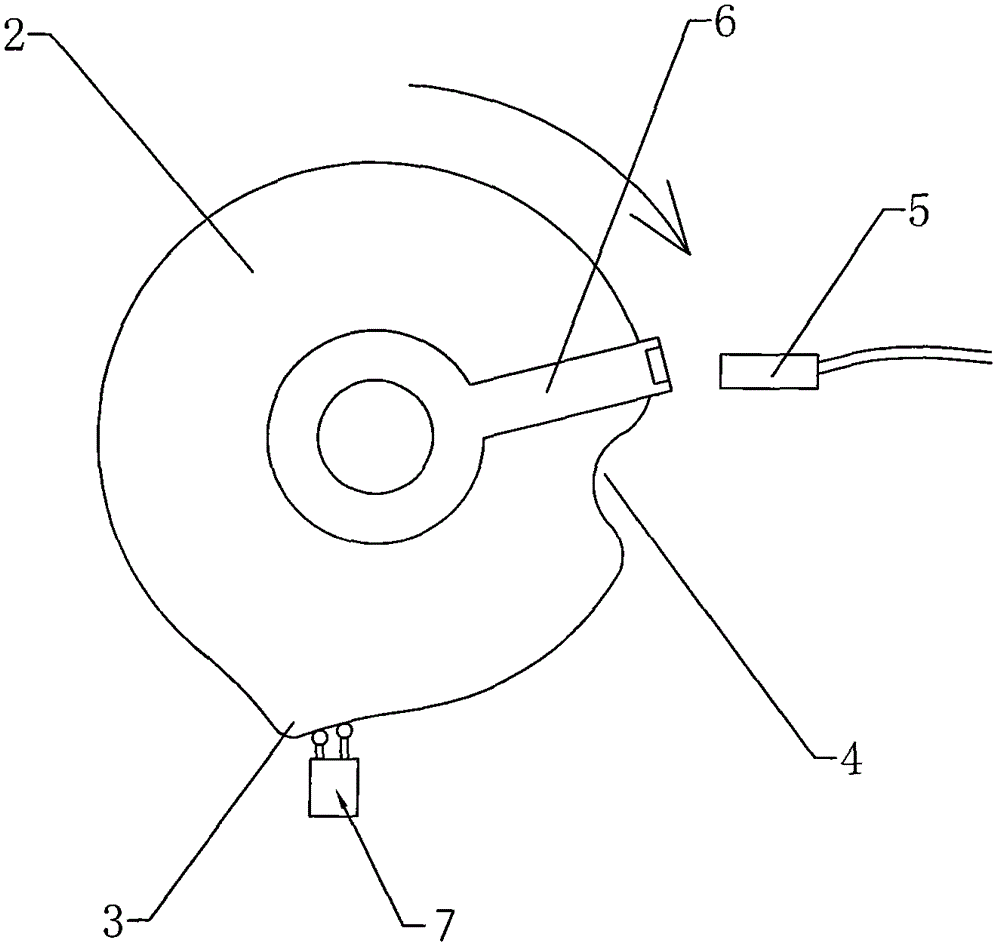

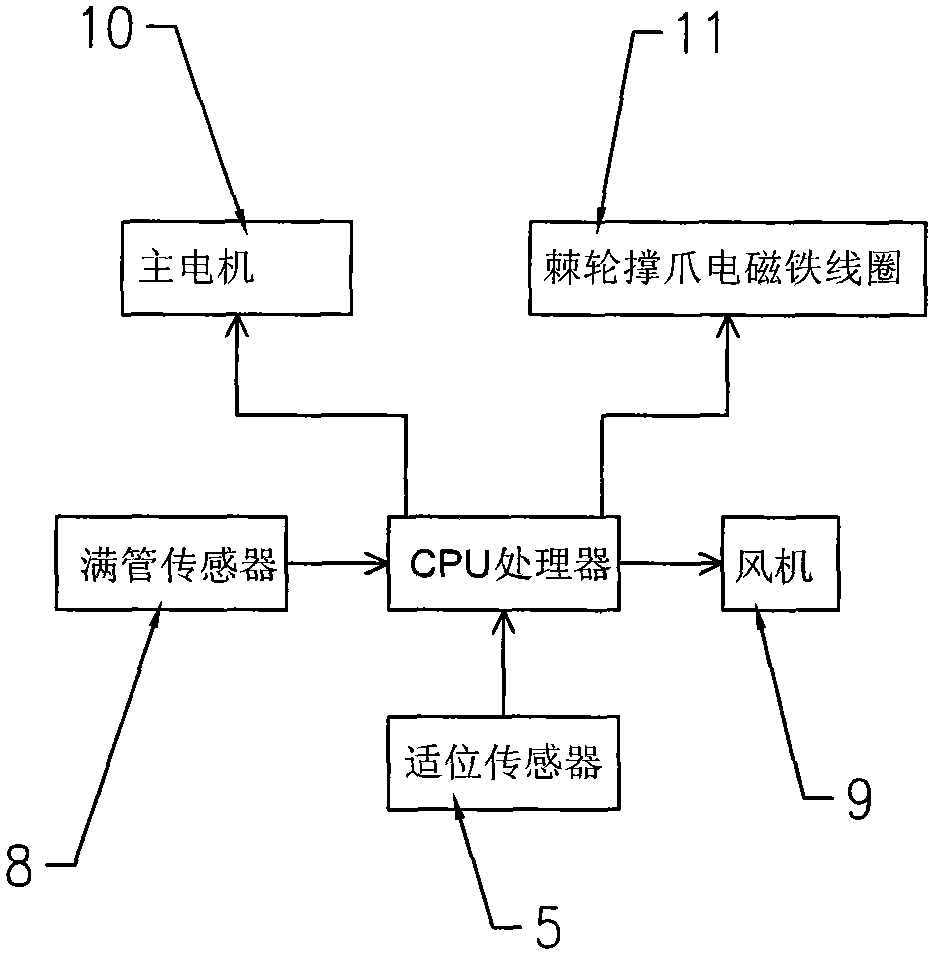

[0040] Examples such as figure 1 , figure 2 , image 3 As shown, a control method for reducing yarn breakage of a spinning frame, the device implementing the control method includes a PLC controller and a full bobbin sensor 8, a peach plate 2, a position sensor 5, and a rotor 7 arranged on the spinning frame , blower fan 9, main motor 10 and ratchet support pawl, position sensor 5 and rotor 7 are arranged on the spinning frame around peach disc 2, and full bobbin sensor 8 is arranged on the position equivalent to 90-95% of the total amount of yarn on bobbin 1. position, a signal sampler 6 is fixed on the peach plate 2,

[0041] The peach plate 2 has a peach tip 3 and the lowest end 4 of the peach plate. When the peach tip 3 contacts the rotor 7, the ring plate starts to go down. After rotating until the tip of the peach 3 contacts the rotor 7, the ring plate completes a cycle of spinning steps; when the signal sampler 6 cooperates with the position sensor 5 for induction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com