Combustion apparatus for improving thermal efficiency of large-scale thermal power coal-fired boiler

A technology of a combustion device and a coal-fired boiler, which is applied to the fuel, combustion method, combustion type and other directions of burning in a molten state, can solve the problems of adverse environmental impact, high carbon content in ash and slag, and insufficient utilization of resources, etc. The effect of easy ignition, increased fuel temperature, and easy and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

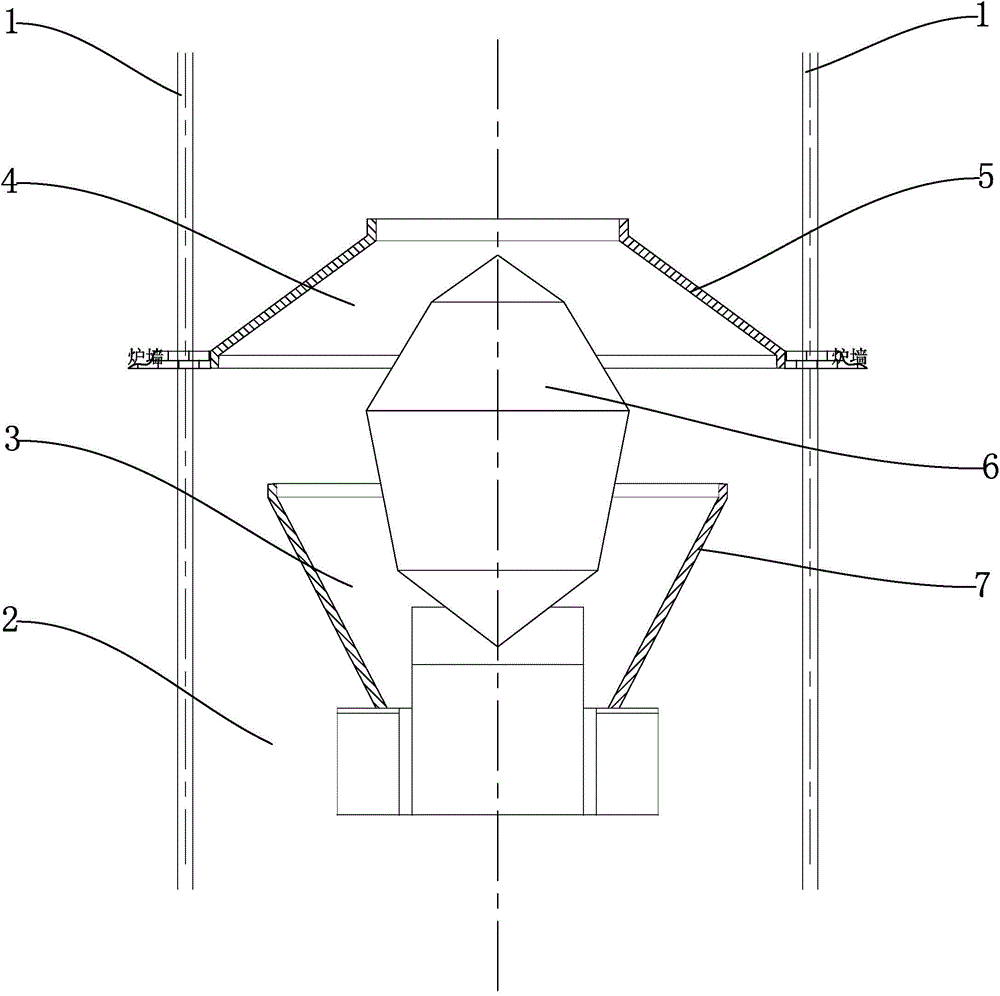

[0018] refer to figure 1 As shown, the present invention discloses a combustion device for improving the thermal efficiency of a large-scale thermal power coal-fired boiler. The combustion device includes a furnace, and water-cooled wall tubes 1 are arranged around the furnace. The above-mentioned combustion device is also provided with a rectification device, which will The furnace is divided into the first combustion chamber 2, the second combustion chamber 3 and the third combustion chamber 4, and the combustion is carried out in sections, and the combustion temperature of each section is increased to facilitate the control of the flow of combustion materials.

[0019] Further, the above-mentioned rectification device includes an upper fairing 5, a commutator 6, and a lower fairing 7, wherein the temperature of the commutator 6 is slightly higher ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com