Semi-gasified waste incinerator

A waste incinerator and semi-gasification technology, applied in the direction of incinerator, combustion type, combustion method, etc., can solve the problems of incomplete incineration of domestic waste, achieve full and thorough combustion, avoid leakage, and burn quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

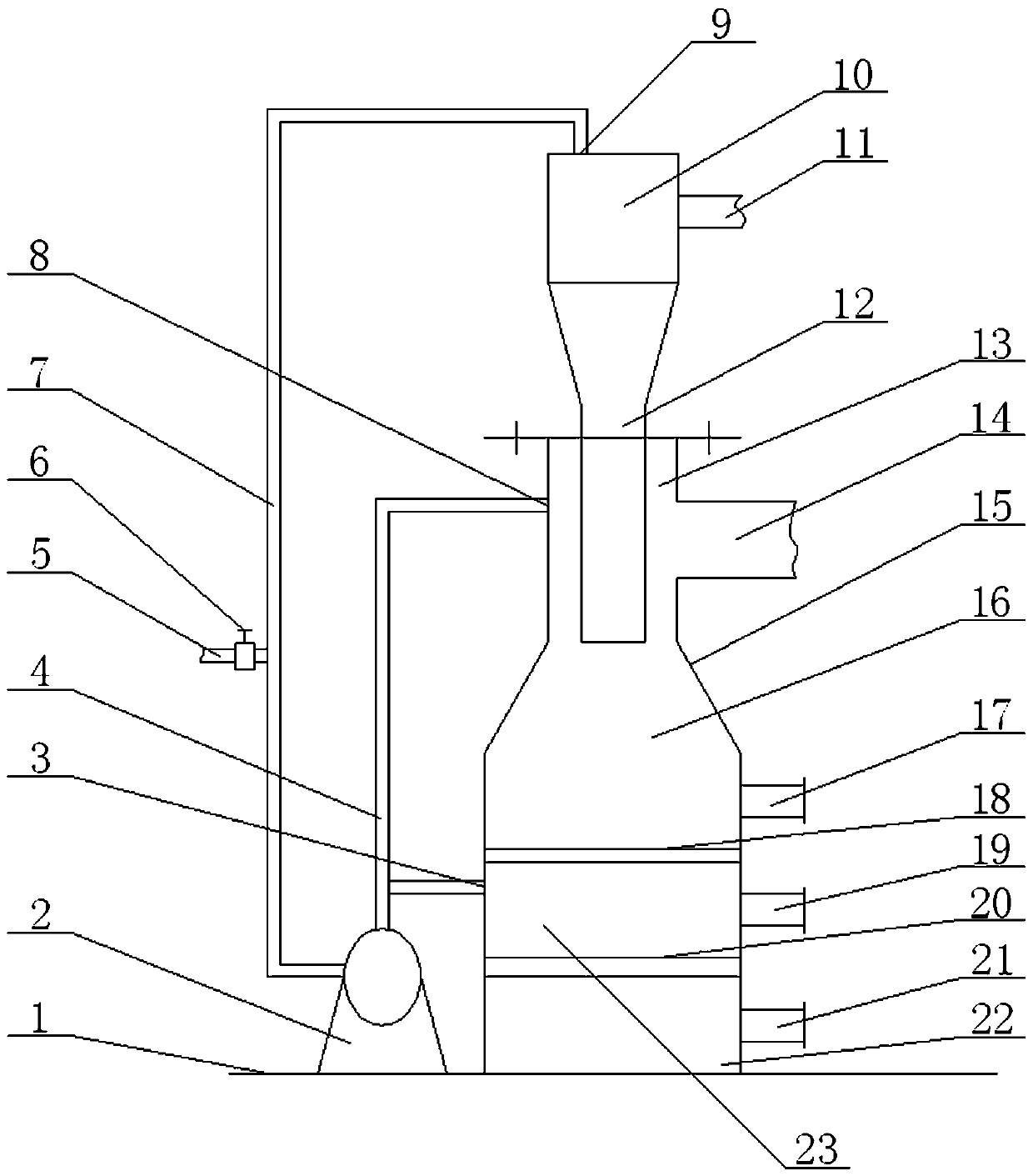

[0028] The implementation structure of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] see figure 1 As shown, the present invention is a semi-gasification incinerator, domestic waste enters the silo 10 from the feed port 11, and falls into the second combustion chamber 16 in the furnace 15 through the falling channel 12 under the weight of the domestic waste. Place a small amount of combustion-supporting raw materials in the first combustion chamber 23 and ignite it for combustion. At this time, turn on the fan 2, open the oxygen regulating valve 6, connect the oxygen pipe 5 to the exhaust pipe 7, and oxygen enters through the exhaust pipe 7 under the traction of the fan. The air supply pipe 4; then enters the third combustion chamber 13 and the second combustion chamber 16 through the first air inlet 8 and the second air inlet 3 through the air supply pipe 4; The garbage that becomes char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com