Biomass furnace combustor and combustion method thereof

A biomass and burner technology, which is applied in the direction of combustion methods, use of multiple fuels, combustion types, etc., can solve the problems of insufficient secondary gasification combustion, etc., to save fuel costs, increase combustion efficiency, and improve heat energy The effect of conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

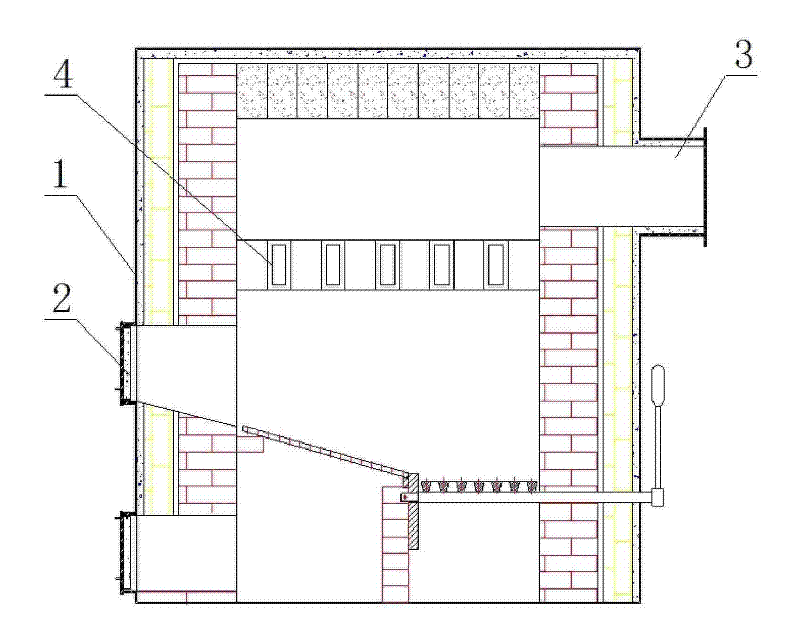

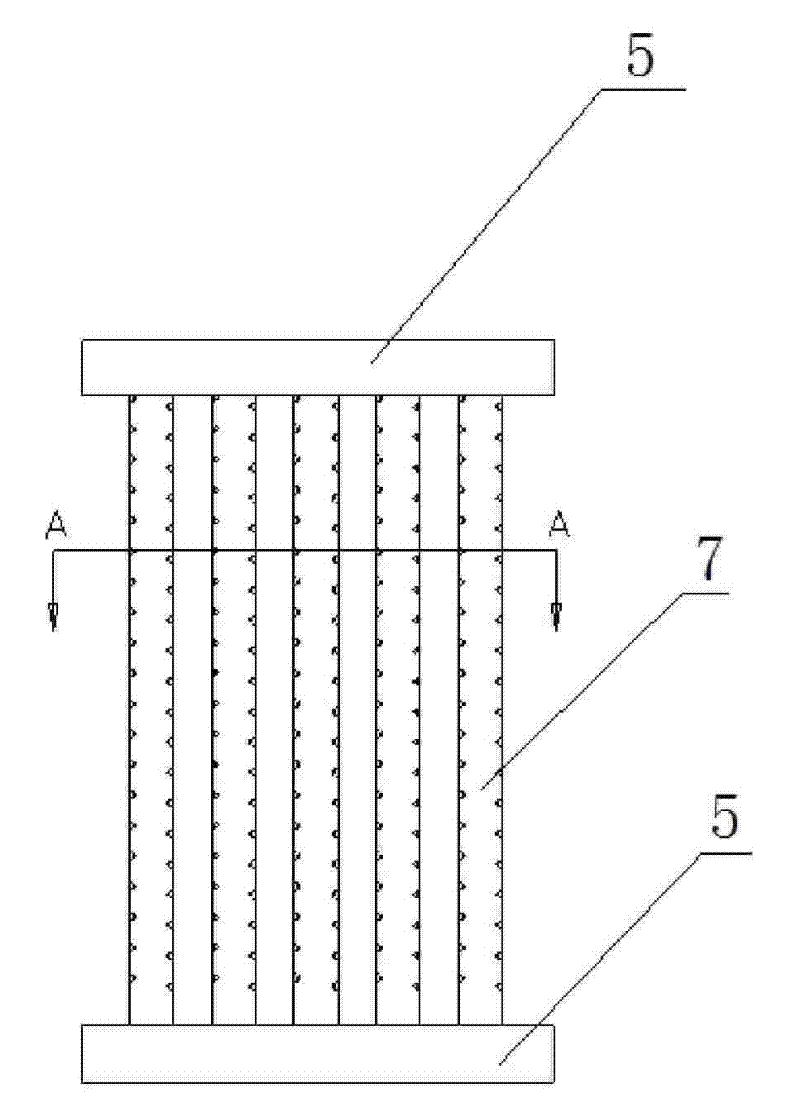

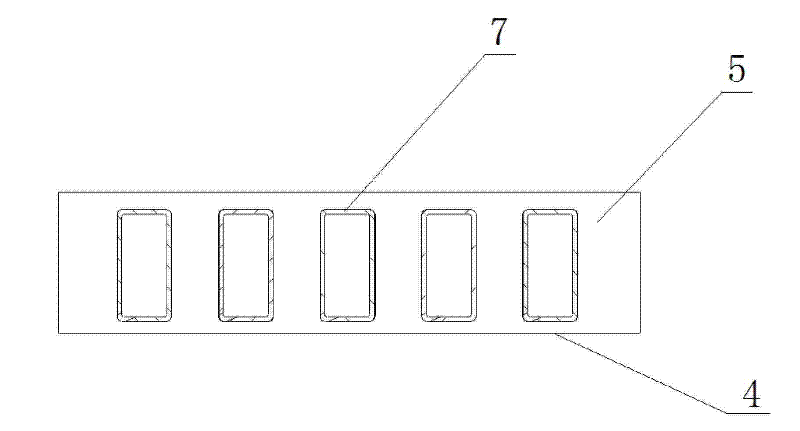

[0033] Such as Figure 1-Figure 4 As shown, a biomass stove burner includes a biomass furnace 1 and an air burner 4. The biomass furnace 1 is provided with a charging door 2 and a flue gas outlet 3. The two ends of the air burner 4 are connected to the biomass furnace 1 The inner sides of the air burner 4 are connected to each other, and the two sides of the air burner 4 are separated from the inner wall of the biomass furnace 1 . The air burner 4 is arranged between the charging door 2 and the flue gas outlet 3 . Air burner 4 is made up of support 5 and air supply pipe 7, and air support 4 is " work " shape, and its two ends are support 5, and air supply pipe 7 is vertically connected with support 5 and is evenly distributed on support 5. The air supply pipe 7 is elongated tube shape, has 5, leaves gap between two supply air pipes 7, is provided with some air supply ports on the air supply pipe 7, and the air supply ports are round holes or square holes evenly distributed. ...

Embodiment 2

[0038] In this embodiment, the cross-section of the air supply pipe 7 is a rectangle with four corners with guide angles, a secondary air supply port 71 is provided in the middle of the bottom, and a third air supply port 72 is respectively provided on the guide angles of the upper left corner and the upper right corner, as shown in FIG. Image 6 Shown, others are with embodiment 1. The section of the air supply pipe 7 in this embodiment may also be trapezoidal.

Embodiment 3

[0040] In this embodiment, the cross-section of the air supply pipe 7 is a rectangle with guide angles on the top and both sides, and two secondary air supply ports 71 are arranged on the bottom side, and the guide angles of the upper left corner and the upper right corner are respectively provided with Three air supply ports 72, such as Figure 7 Shown, others are with embodiment 1. The section of the air supply pipe 7 in this embodiment may also be trapezoidal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com