Pneumatic medical waste burning process for rotary kiln and device therefor

A medical waste, rotary kiln technology, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as damage to refractory materials of rotary kilns, affecting the operation of slag systems, and achieve the effect of avoiding damage, inhibiting generation and emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

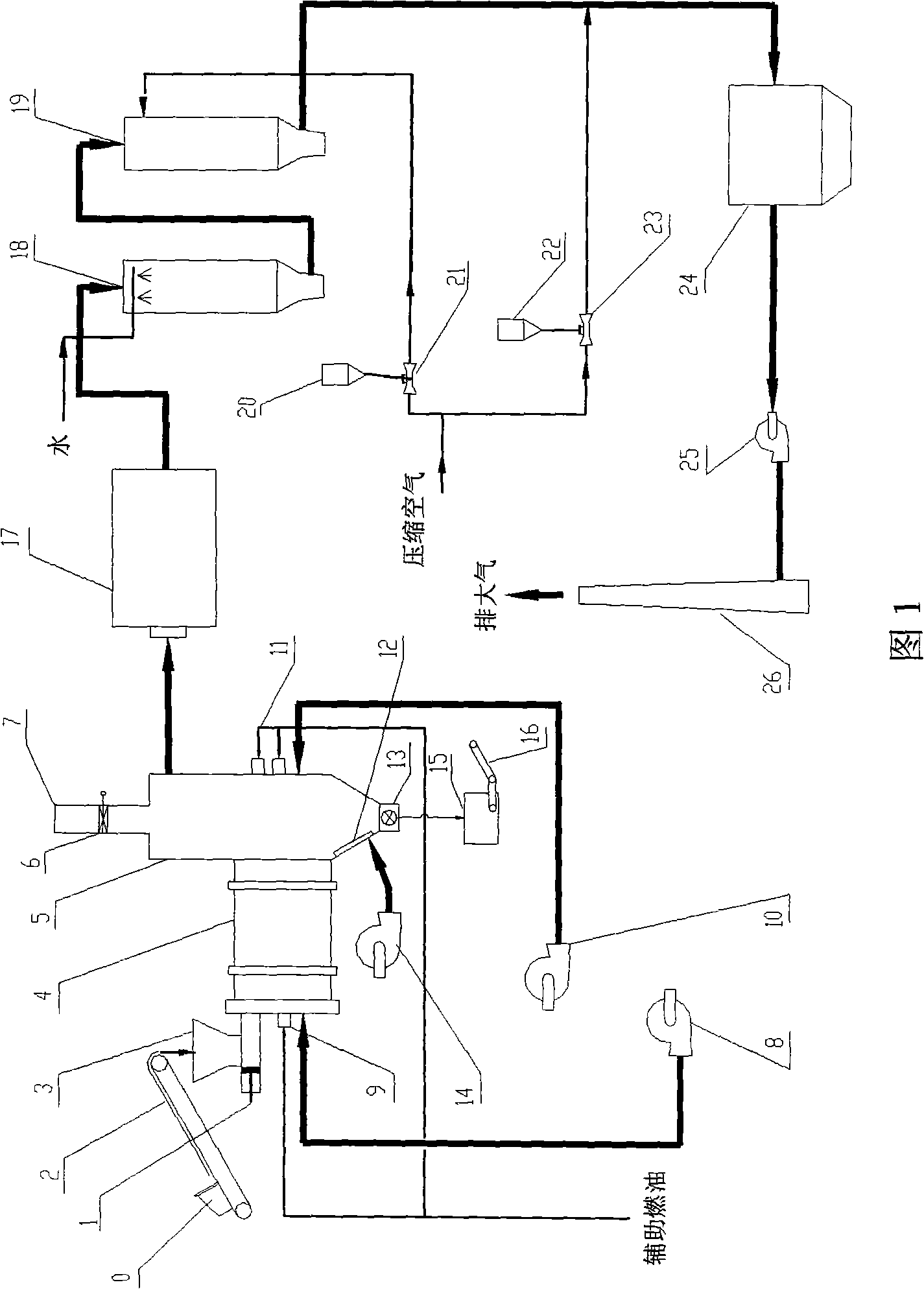

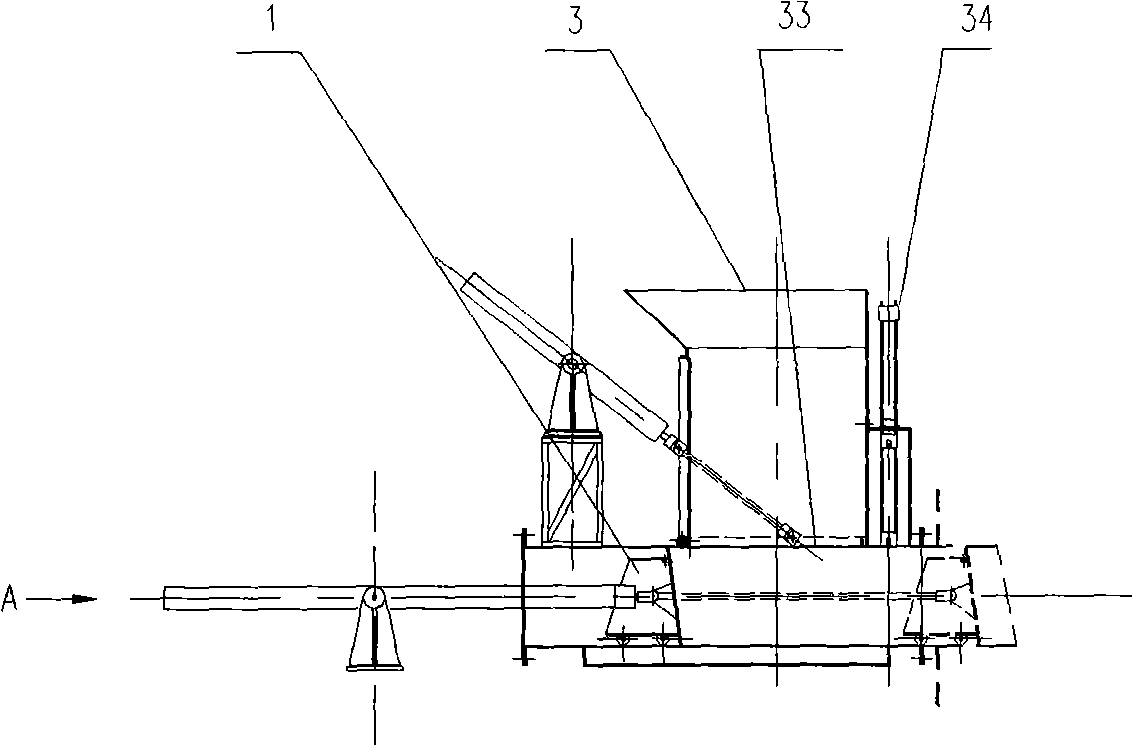

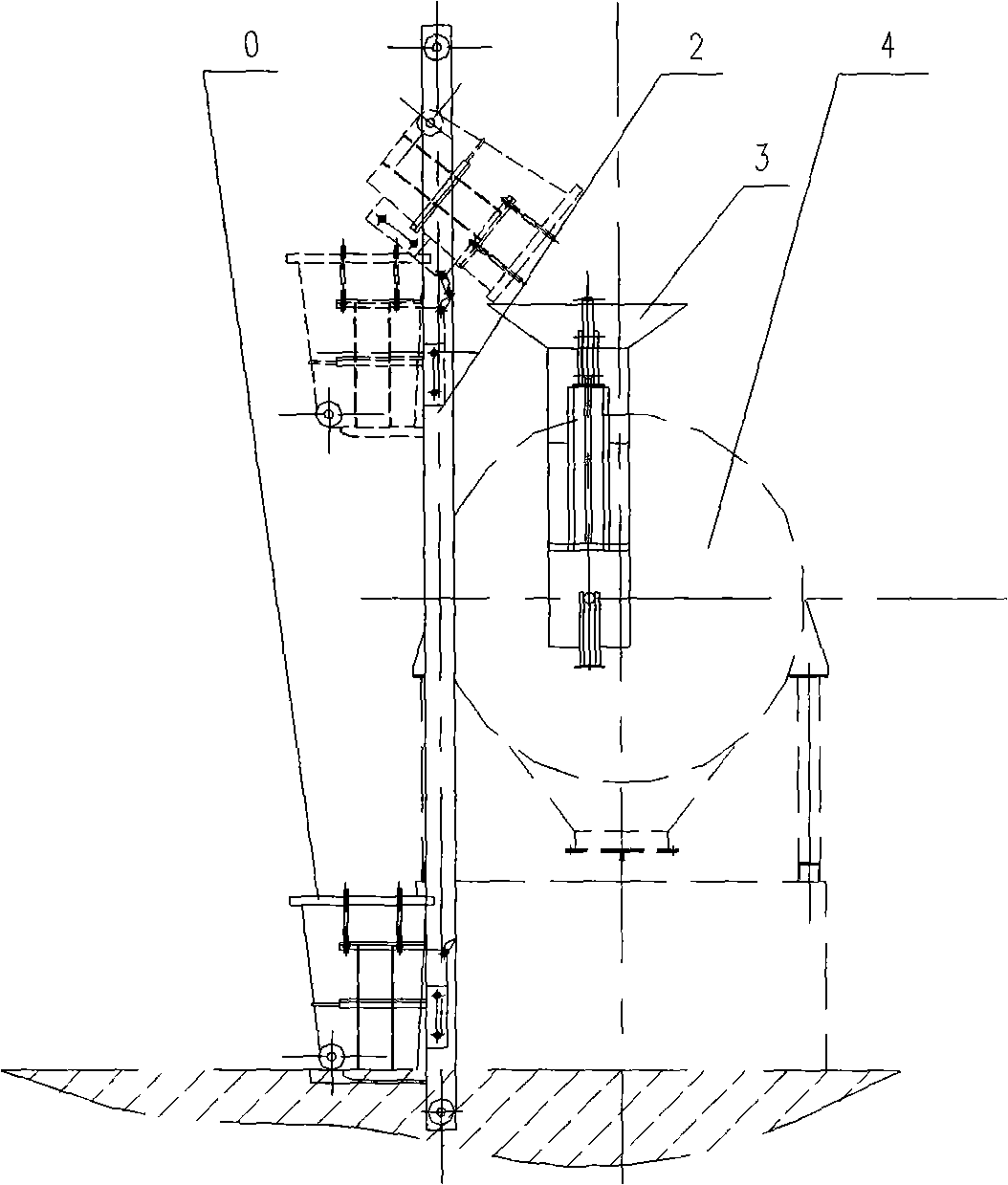

[0034] See Figure 1 to Figure 7 , the device of the present invention comprises a feeding mechanism consisting of a wheeled trash can 0 and a chain hoist 2, a hydraulic piston push rod 1 connected to the feeding hopper 3, a hydraulic pressure plate door 33, a hydraulic fire The interlocking and closed feeding mechanism composed of doors 34, the primary combustion chamber 4 of the rotary kiln connected with the feeding mechanism, the secondary combustion chamber 5 which is movable and airtightly embedded with the primary combustion chamber 4 of the rotary kiln, and the secondary combustion chamber 5 connected in turn Waste heat boiler 17, quench tower 18, absorption tower 19, bag filter 24, induced draft fan 25 and chimney 26. The primary combustion chamber 4 of the rotary kiln is provided with a primary blower 8 and an auxiliary fuel inlet 9 connected to it in the control room for air-controlled anoxic combustion. The rotating furnace wall of the primary combustion chamber 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com