Oxy-fuel combustion furnace used in low-expansion microcrystalline glass manufacturing

A technology of glass-ceramics and oxy-fuel combustion, which is applied in glass manufacturing equipment, glass furnace equipment, glass production, etc., can solve the problems of difficult glass forming operations and the inability to guarantee the forming temperature, and achieve full and complete combustion, fuel saving, and high combustion efficiency. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

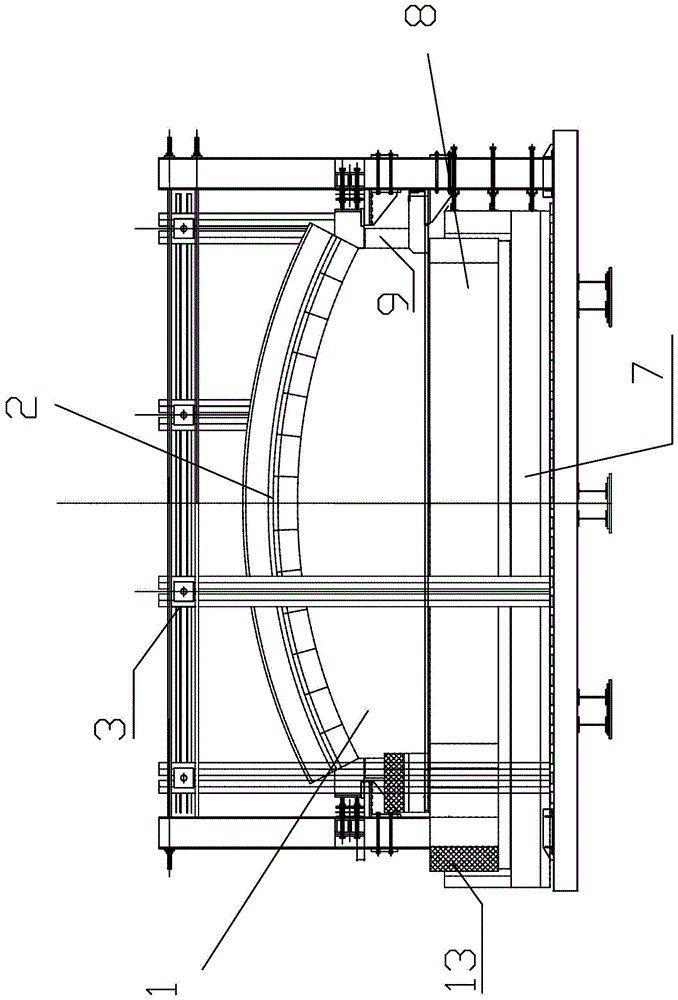

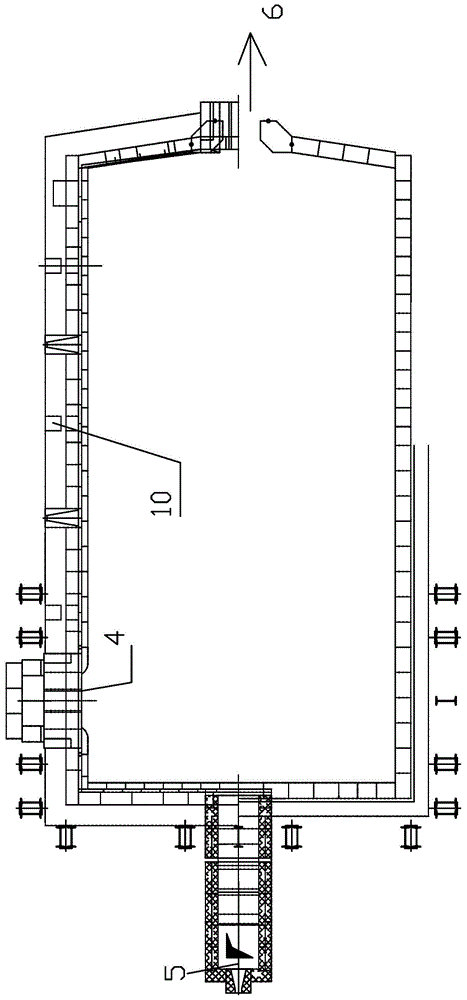

[0025] Such as figure 1 with figure 2 As shown, it includes cavity 1, furnace cover 2, steel structure fixed frame 3, bottom wall 7, glass tank kiln 8, breast wall 9 and pool wall 13, and the periphery of cavity 1 and furnace cover 2 is provided with steel structure fixed frame 3 One side of the long side of the cavity 1 is provided with a feeding port 4, one side of the two short sides of the cavity 1 is provided with a flue 5, and the other side is provided with a glass discharge port 6, the bottom of the cavity 1 is a bottom wall 7, the bottom The two sides of the wall 7 are pool walls 13, the bottom wall 7 and the pool wall 13 form a glass pool kiln 8, a parapet 9 is arranged above the pool wall 13, and more than one burner 10 is provided at a certain height on the upper part of the parapet 9, and the burner 10 is The flat external mixing graded burner include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com