Novel plastic substitute material capable of being used as pesticide bottle and preparation process thereof

A technology for pesticide bottles and new materials, applied in the fields of new plastic substitute materials and their preparation processes, as well as the fields of plastic substitute new materials and their preparation processes, can solve the problem of the decline of mechanical properties of plastic products, the difficulty of degrading waste plastic products, and the poor dispersion of inorganic powders, etc. problems, to increase stability, prevent aging and yellowing, and reduce decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

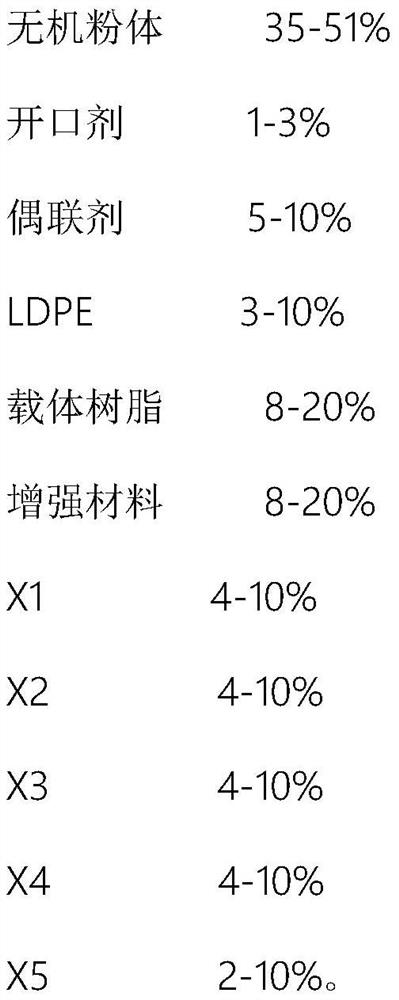

Method used

Image

Examples

Embodiment 1

[0053] The first step is to put the inorganic powder into the high-speed mixer first, and stir at a high speed of 1500r / min to raise the temperature of the powder to 100°C and keep it for 9 minutes to exhaust the water vapor of the powder and open its agglomerated particles. Form a new interface, facilitate the action of the coupling agent, and form a hydrophobic and lipophilic structure;

[0054] In the second step, add an appropriate amount of coupling agent into the high-speed mixer, and stir at a high speed of 1400r / min for 5 minutes, and the powder is activated;

[0055] The third step is to add X2, anti-blocking agent and LDPE into the high mixer at the same time, and stir for several minutes; then add X1, X3, X4, X5, carrier resin and reinforcing material, and stir for several minutes at a speed of 1400r / min;

[0056] The fourth step is to put all the materials in the high mixer into the internal mixer, and internally knead for 10 minutes through the internal mixer, she...

Embodiment 2

[0064] The first step is to put the inorganic powder into the high-speed mixer first, and stir at a high speed of 1500r / min to raise the temperature of the powder to 90°C and keep it for 10 minutes to exhaust the water vapor of the powder and open its agglomerated particles. Form a new interface, facilitate the action of the coupling agent, and form a hydrophobic and lipophilic structure;

[0065] In the second step, add an appropriate amount of coupling agent into the high-speed mixer, and stir at a high speed of 1200r / min for 5 minutes, and the powder is activated;

[0066] The third step is to add X2, anti-blocking agent and LDPE into the high mixer at the same time, and stir for several minutes; then add X1, X3, X4, X5, carrier resin and reinforcing material, and stir for several minutes at a speed of 1400r / min;

[0067] The fourth step is to put all the materials in the high mixer into the internal mixer, and internally knead for 10 minutes through the internal mixer, she...

Embodiment 3

[0075] The first step is to put the inorganic powder into the high-speed mixer first, and stir at a high speed of 1400r / min to raise the temperature of the powder to 100°C and keep it for 10 minutes to exhaust the water vapor of the powder and open its agglomerated particles. Form a new interface, facilitate the action of the coupling agent, and form a hydrophobic and lipophilic structure;

[0076] In the second step, add an appropriate amount of coupling agent into the high-speed mixer, and stir at a high speed of 1400r / min for 5 minutes, and the powder is activated;

[0077] The third step is to add X2, opening agent and LDPE into the high mixer at the same time, and stir for several minutes; then add X1, X3, X4, X5, carrier resin and reinforcing material, and stir for several minutes at a speed of 1500r / min;

[0078] The fourth step is to put all the materials in the high mixer into the internal mixer, and internally knead for 10 minutes through the internal mixer, shear an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com